Environment-friendly treatment process for papermaking wastewater

A technology for papermaking wastewater and environmental protection treatment, which is applied in processing wastewater treatment, multi-stage water treatment, flotation water/sewage treatment, etc. The effect of avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

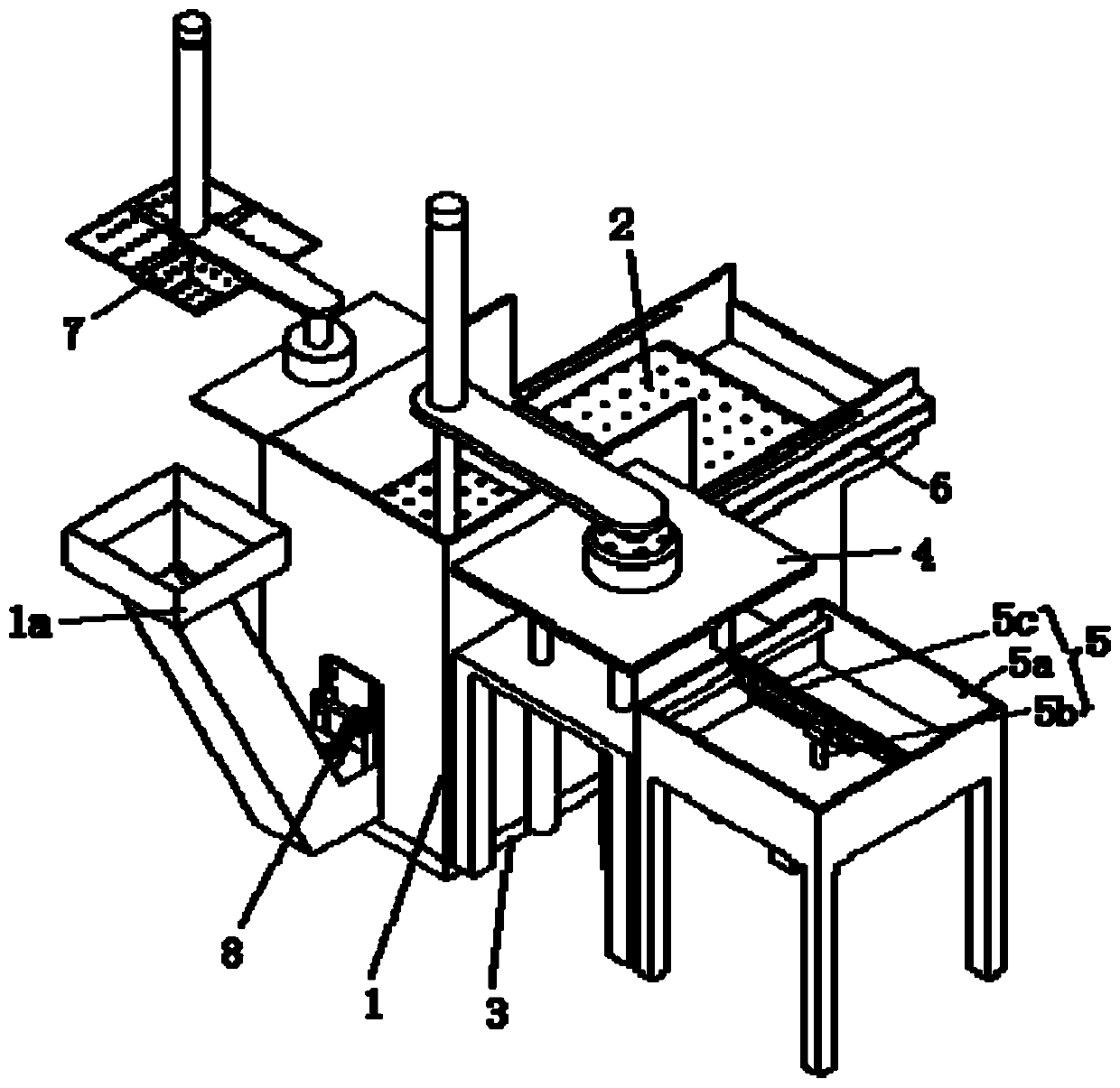

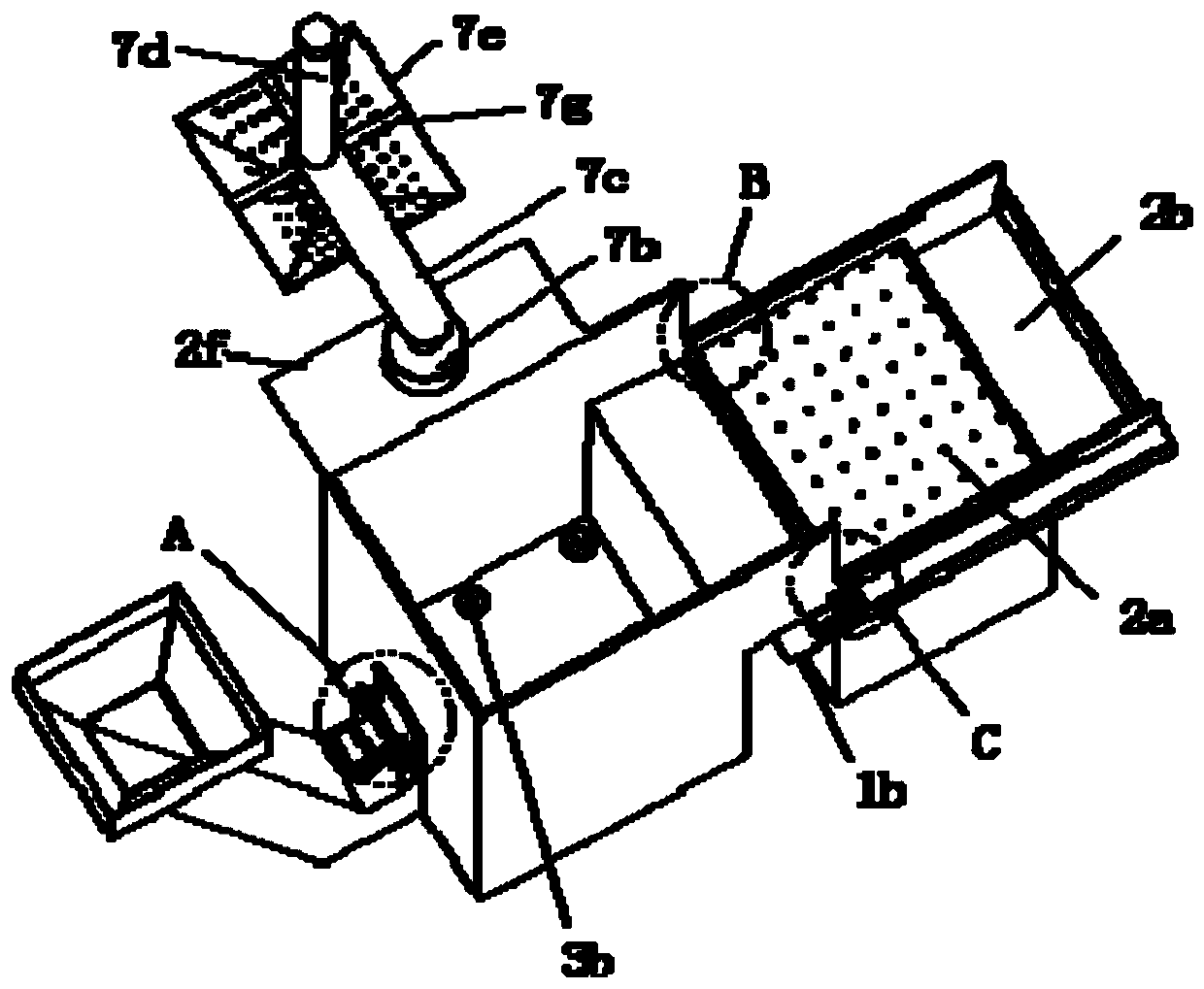

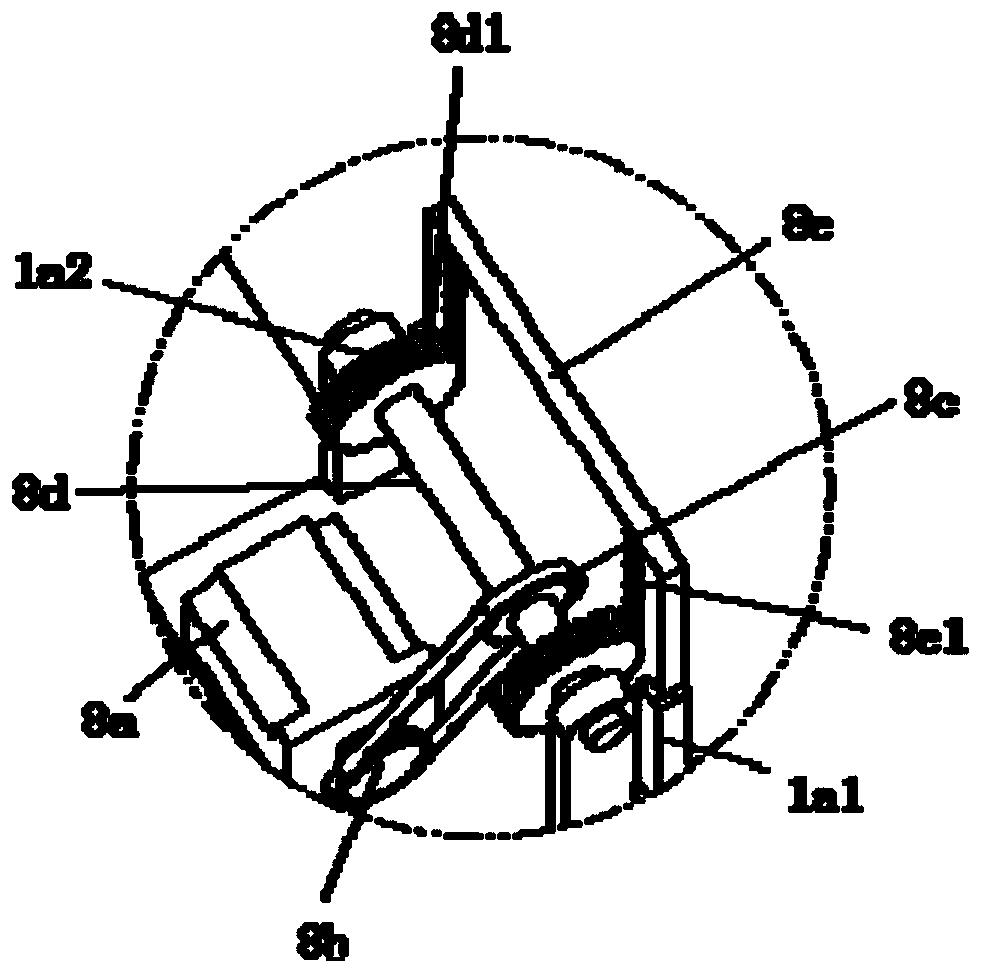

[0040] Below, combined with Figure 1 to Figure 10 And specific embodiment, the present invention is described further:

[0041] The papermaking wastewater environmental protection treatment process includes the following steps:

[0042] Step 1. Papermaking wastewater enters the first filter tank: first filter tank 1, second filter tank 2, air injection device 3, filter device 4, first scraper device 5, second scraper device 6 and salvage device 7 are set, One end of the first filter tank 1 is provided with a feed pipeline 1a communicating with the inside thereof, and a feed adjustment device 8 is provided on the feed pipeline 1a, and the second filter tank 2 is connected with the first filter tank 1 as a In one piece, the air injection device 3 is installed at the bottom of the first filter tank 1, the filter device 4 and the fishing device 7 are respectively located on both sides of the first filter tank 1, and the first scraper device 5 is located at the bottom of the filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com