Patents

Literature

186results about How to "Ingenious process design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for synchronously extracting iron and niobium from Bayan Obo low-grade ores

InactiveCN105154659AReduce consumptionReduce constructionFluidised-bed furnacesRare-earth elementMetal chloride

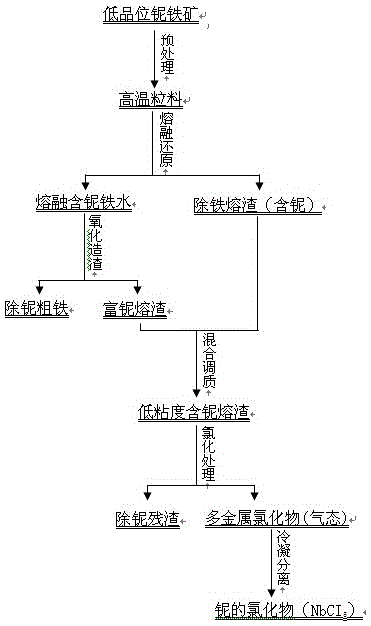

The invention provides a method for synchronously extracting iron and niobium from Bayan Obo low-grade ores. The method comprises the following process steps: 1) pretreating low-grade niobate to obtain high-temperature aggregates; 2) carrying out smelting reduction on the high-temperature aggregates to obtain niobium-containing molten iron and niobium-containing iron removed slag; 3) carrying out oxidative slagging on the niobium-containing molten iron to obtain niobium removed crude iron and niobium-rich slag; 4) carrying out mixed hardening and tempering on the iron removed slag in the step 2) and the niobium-rich slag in the step 3) to obtain low-viscosity niobium-containing slag; 5) carrying out chlorination on the low-viscosity niobium-containing slag to obtain niobium removed slag and a gaseous multi-metal chloride; and 6) carrying out condensation separation on the gaseous multi-metal chloride to obtain a chloride of niobium. Rare earth elements in the ores, such as niobium, are separated while iron is extracted from the low-grade ores by adopting the method, thus achieving short-process stepped extraction separation of multiple metal resources in a same thermal process.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Graphene organic size and preparation method thereof

The invention discloses a preparation method of graphene organic size. The preparation method includes: utilizing a graphene oxide water solution as a raw material; subjecting the raw material and an organic solvent with a dispersant dissolved in to liquid-liquid mixing and homogenizing; removing water in the solvent while performing reduction to obtain the graphene organic size. Conventional ideas are broken through, high dispersity of GO (graphene oxide) in water is utilized to bring a non-stacked state of GO in water into an organic phase, reduction of graphene oxide is realized synchronously in the process of solvent replacement, and finally the graphene organic size which is high in concentration and dispersity can be obtained; process design is ingenious, and production cost can be lowered effectively. In addition, content of graphene in the graphene organic size obtained by the preparation method can reach higher than 0.05wt%, and the graphene organic size does not settle after being placed at normal temperature for 30 days. Graphene oxide is reduced in the process of heating, distilling and dewatering, in this case, graphene is heated uniformly, and reductive effect is better at same temperature; under a heating condition of 150 DEG C, reductive degree can reach below 20wt% in oxygen content.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

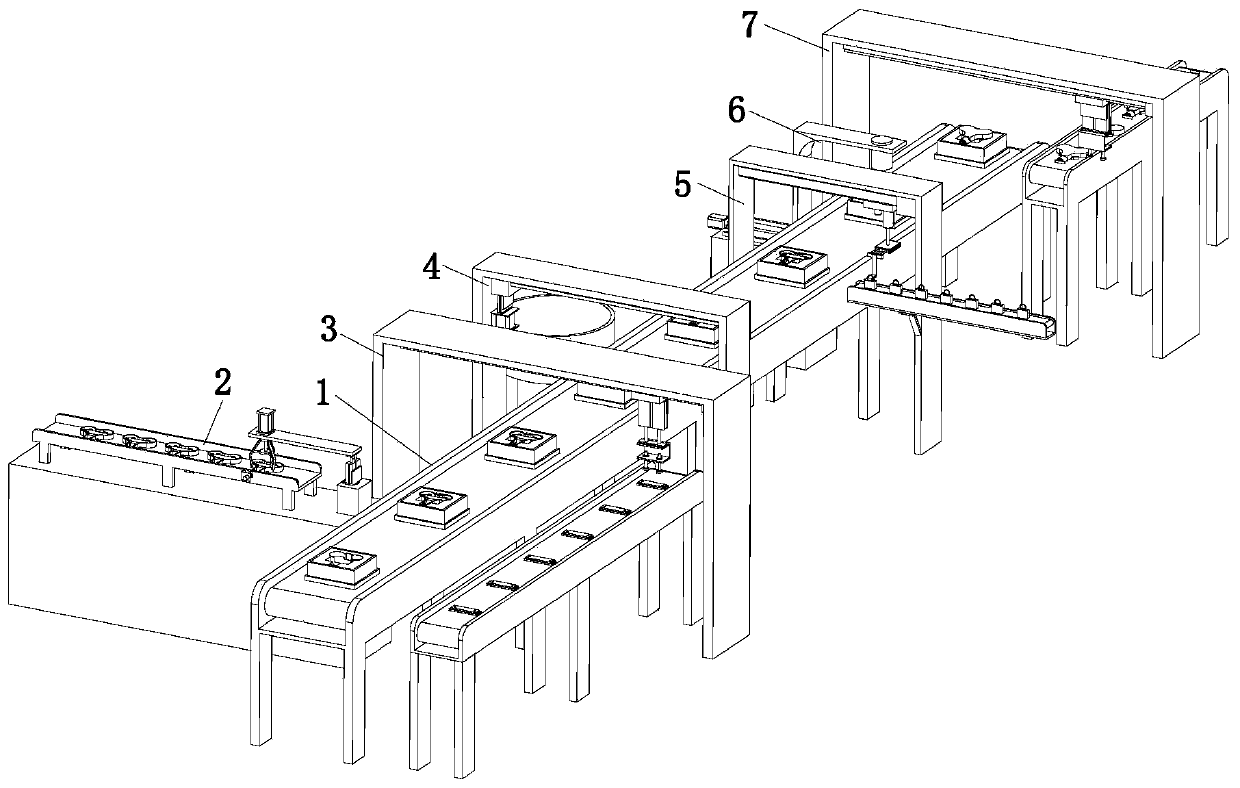

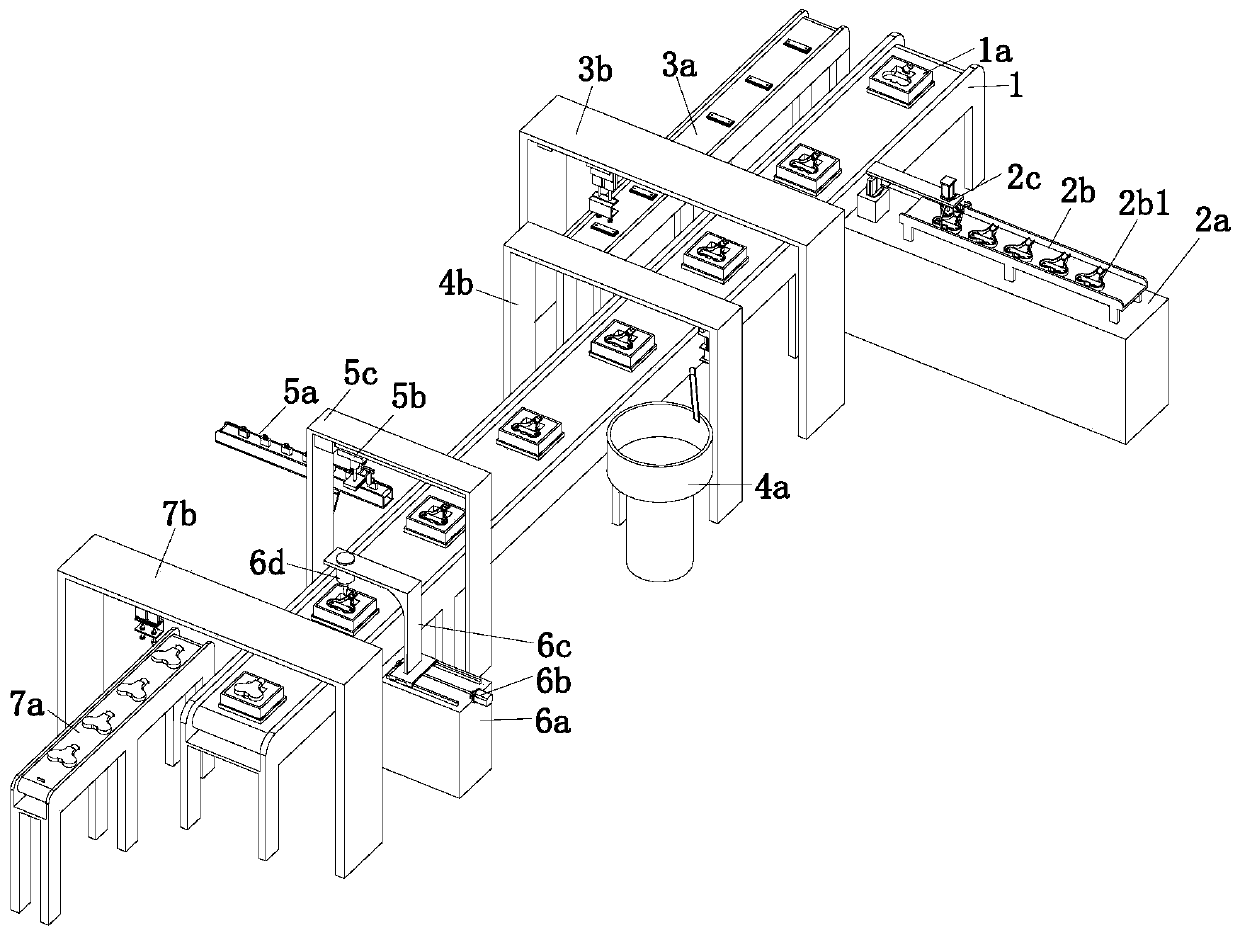

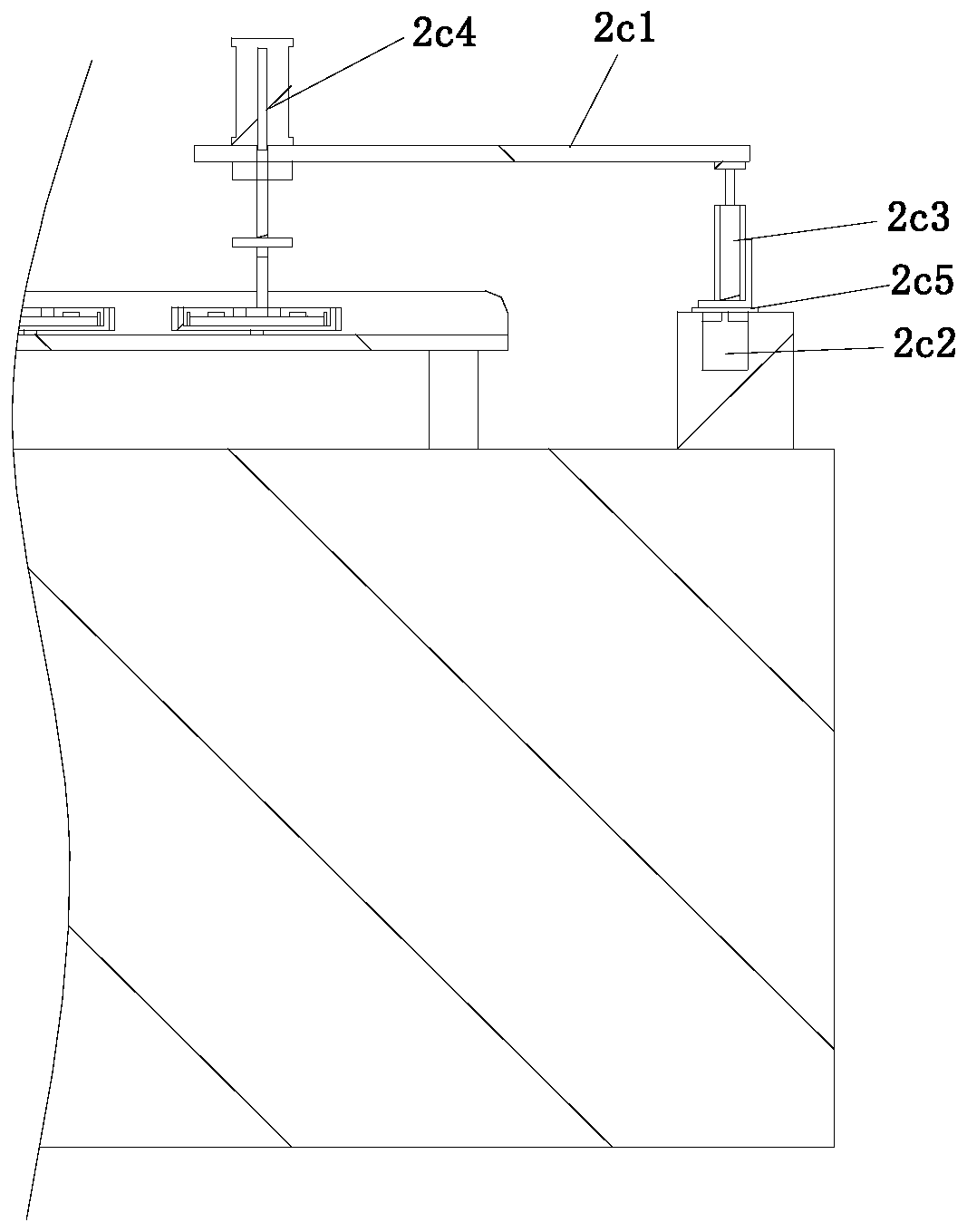

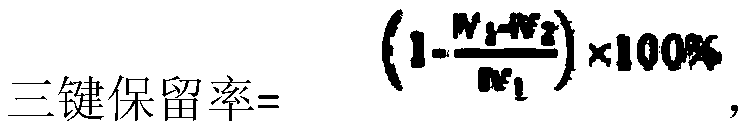

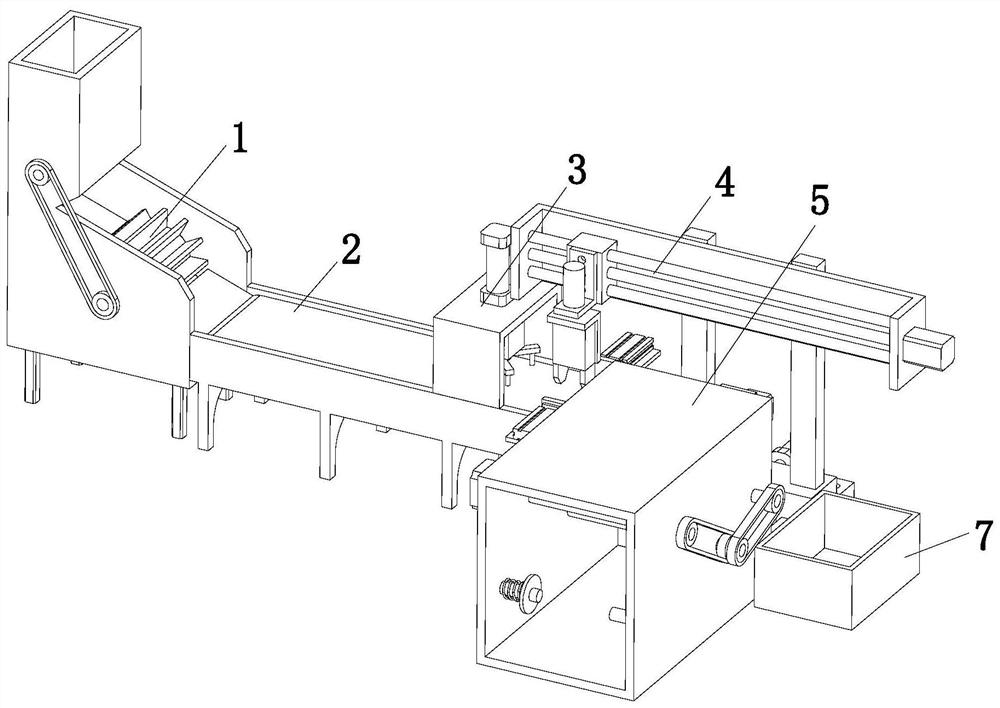

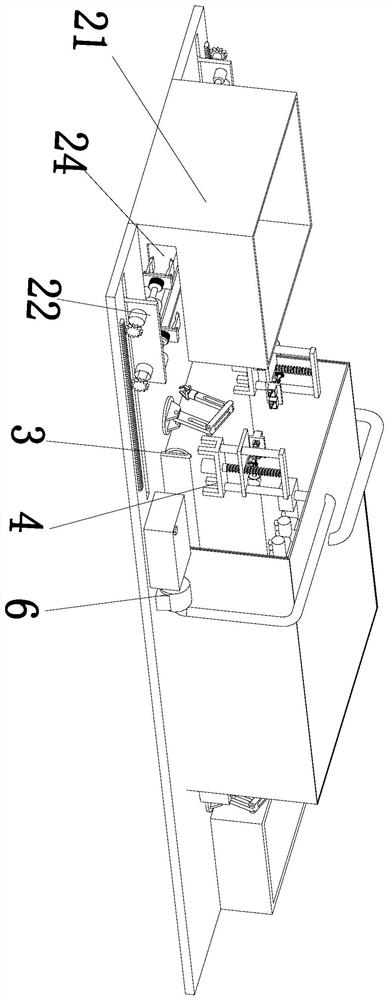

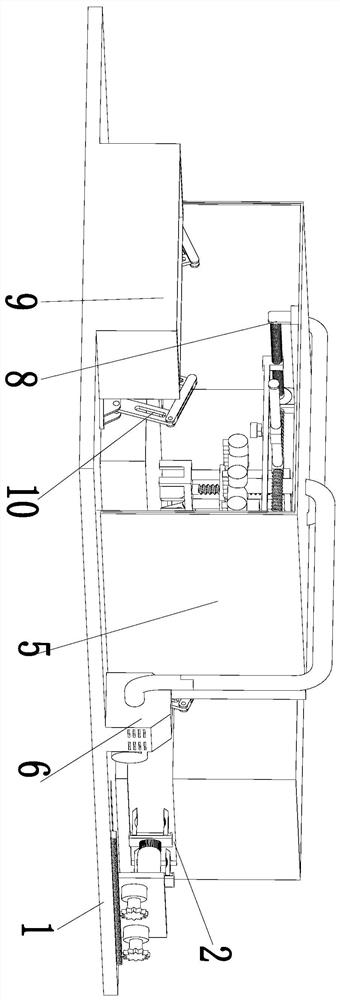

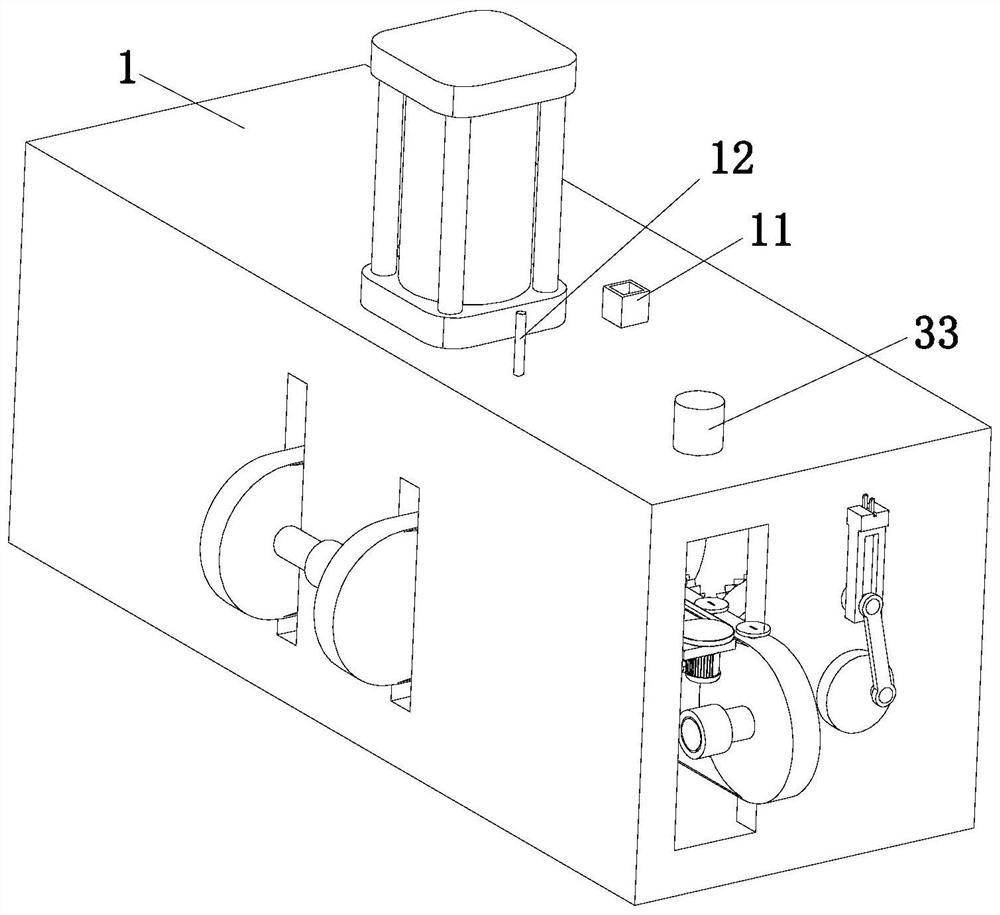

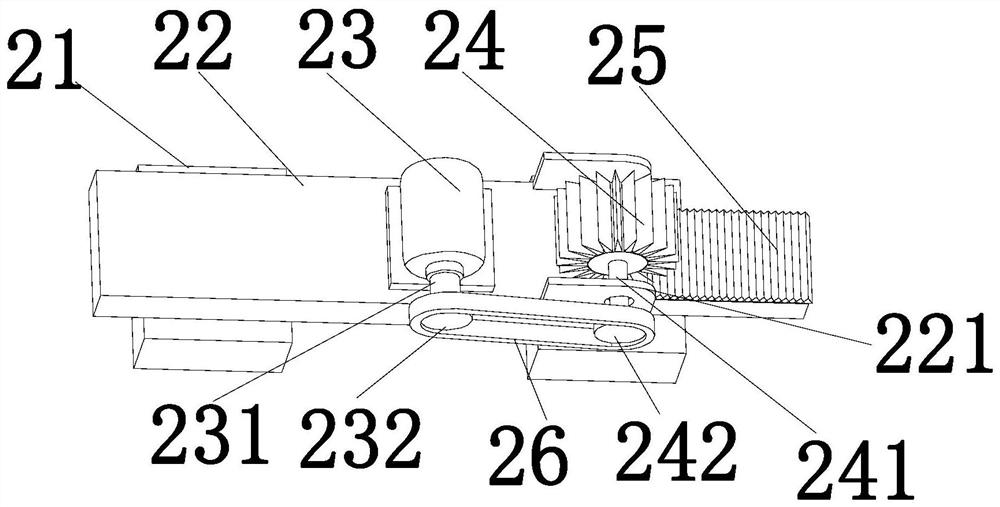

Automatic production process of built-in tire pressure sensor

ActiveCN111266847AIncrease productivityImprove production yieldAssembly machinesProcess engineeringConveyor belt

The invention relates to the field of tire monitoring, in particular to an automatic production process of a built-in tire pressure sensor. The automatic production process comprises the following steps of Step 1, feeding a bottom shell; Step 2, feeding a circuit board and fixing the circuit board to the bottom shell; Step 3, feeding a seal ring and sealing; and Step 4, assembling a cover shell and the bottom shell. The bottom shell, the circuit board, the seal ring and the cover shell are sequentially moved to a conveyor belt by a bottom shell feeding device, a circuit board feeding device, afastening device, a seal ring feeding device, a sealing device and a cover shell mounting device to be assembled to complete the automatic assembly, and such a production method not only improves production efficiency but also reduces labor costs; and the process is cleverly designed, working procedures are smoothly connected, and the production efficiency and the yield of the built-in tire pressure sensor are greatly improved.

Owner:深圳市马力德科技有限公司

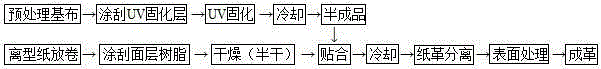

UV curing technology based solvent-free synthetic leather manufacturing method

The invention discloses a UV curing technology based solvent-free synthetic leather manufacturing method. The method is characterized by: firstly coating a pre-treated base cloth with a photosensitive group containing solvent-free polyurethane slurry, and performing ultraviolet curing to obtain a semi-finished product; and then taking waterborne polyurethane as the surface layer resin, and conducting dry (i.e. transfer coating) overlaying to obtain the environment friendly polyurethane synthetic leather product. The method provided by the invention adopts the UV curing technology to coat the base cloth with the polyurethane free of any organic solvent and performs UV curing to obtain the synthetic leather product. The method has the characteristics of high curing efficiency, environmental friendliness, low energy consumption and the like. By adopting solvent-free UV curable resin and waterborne polyurethane to substitute the traditional solvent type polyurethane, organic solvent pollution is eliminated from the source, the organic solvent source is saved, the product does not contain VOC, and the ecological level and international market competitiveness of synthetic leather are enhanced.

Owner:SICHUAN UNIV

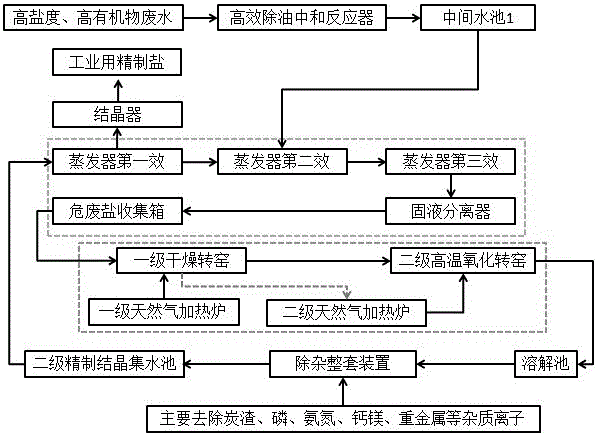

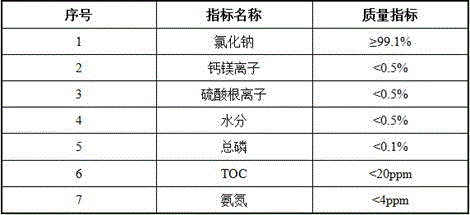

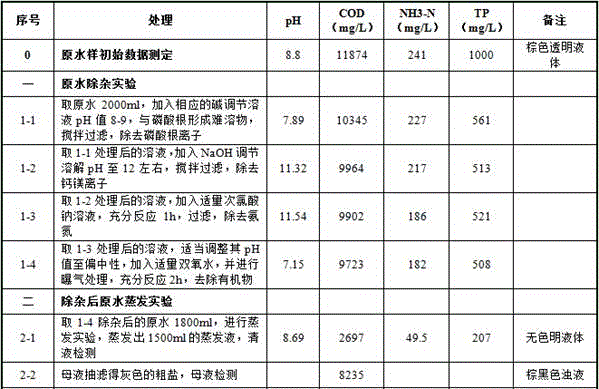

Technology for using organic contaminated high salinity wastewater to produce industrial refined salt

ActiveCN106495384AComplete workmanshipRealize resource utilizationWater contaminantsMultistage water/sewage treatmentResource utilizationEvaporation

The invention discloses a technology for using organic contaminated high salinity wastewater to produce industrial refined salt. The technology comprises the steps of conducting pretreatment and oil removal on the organic contaminated high salinity wastewater, afterwards, leading the pretreated organic contaminated high salinity wastewater into a secondary evaporation crystallizer in a multiple-effect evaporative crystallization system to be subjected to multiple-effect evaporation, obtaining risky waste salt particles after multiple-effect evaporation dewatering, leading the risky waste salt particles into a multi-stage ring kiln to be subjected to thermal desorption treatment, removing organic matter in the risky waste salt and obtaining solid particles, conducting dissolution and impurity removal on the solid particles, removing carbon dregs, phosphorous, ammonia nitrogen and calcium and magnesium in the solid particles to obtain a saline solution, leading the saline solution again into a primary evaporation crystallize in the multiple-effect evaporative crystallization system, and obtaining the industrial refined salt after evaporative crystallization. According to the technology for using the organic contaminated high salinity wastewater to produce the industrial refined salt, the technology is intact, resource utilization of the organic contaminated high salinity wastewater can be directly achieved, a set of evaporative crystallization device is saved, the problem of waste gas treatment in thermal desorption of the risky waste salt is effectively solved; meanwhile, the whole technological process is simple and automation of an operation can be achieved.

Owner:NANJING GW ENVIRONMENT ENG

Preparation method of tert-alkynol polyether

ActiveCN109970964ASmooth responseMild conditionsEther preparation by compound dehydrationReaction temperatureFine chemical

The invention relates to a preparation method of tert-alkynol polyether, and belongs to the field of fine chemical engineering. The preparation method comprises following steps: (1) adding a catalystand tert-alkynol into a reactor, carrying out degassing for 1 hour at a certain temperature under a certain pressure, controlling the reaction temperature and reaction pressure, slowly and evenly adding part of olefin oxide into the reactor within a certain period, and after addition, maintaining the temperature until the pressure becomes stable; and (2) keeping on adding olefin oxide at a certaintemperature until the reactions are finished, maintaining the temperature until the pressure becomes stable, cooling to remove a little of unreacted olefin oxide, adding an acid to carry out neutralization, and discharging obtained tert-alkynol polyether. The invention provides a preparation method of tert-alkynol polyether, which has the advantages of light color, high unsaturation degree, narrow distribution, low residual raw materials, and low PEG / PPG content.

Owner:ZHEJIANG HUANGMA TECH +3

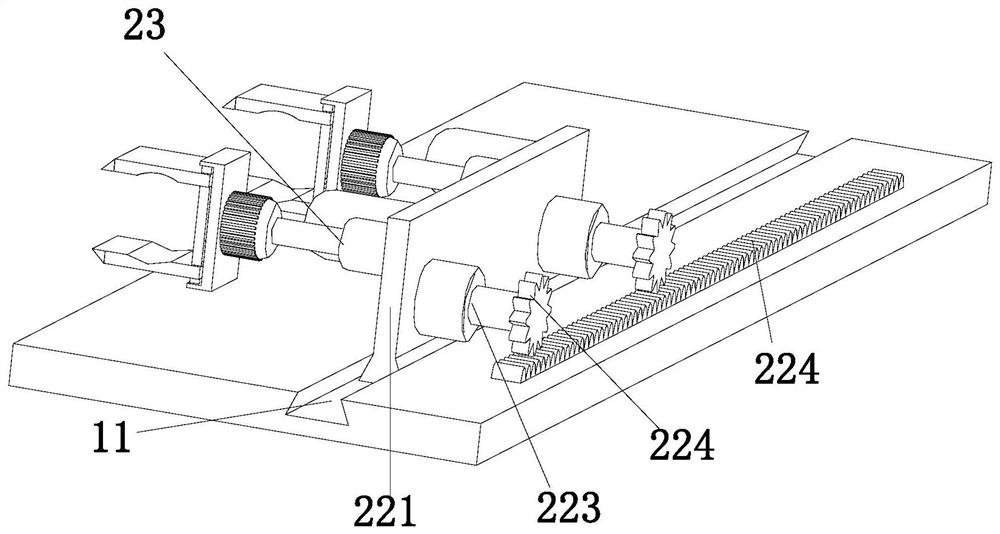

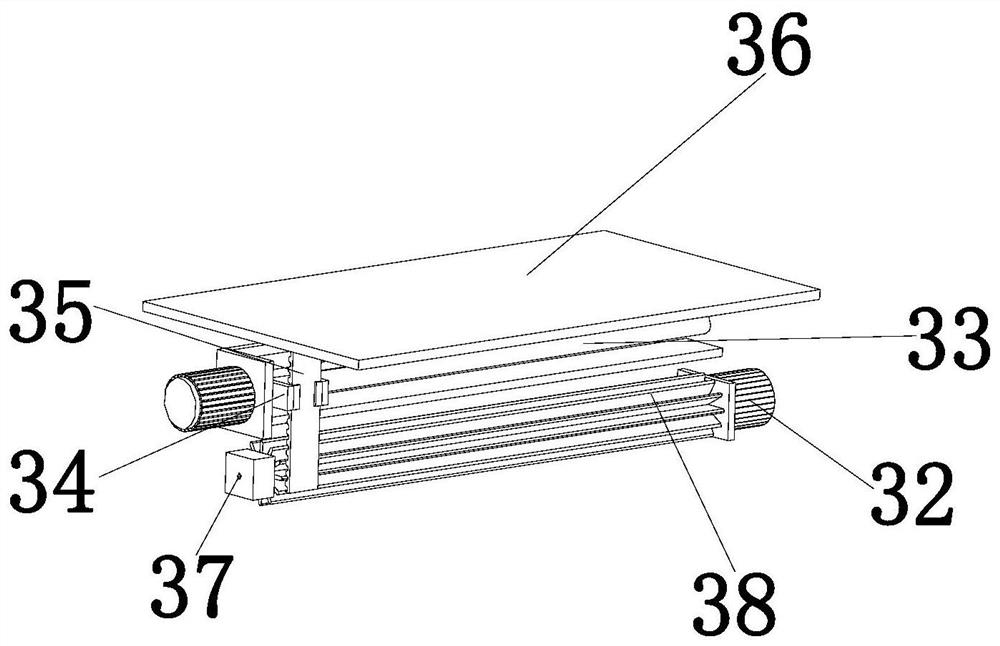

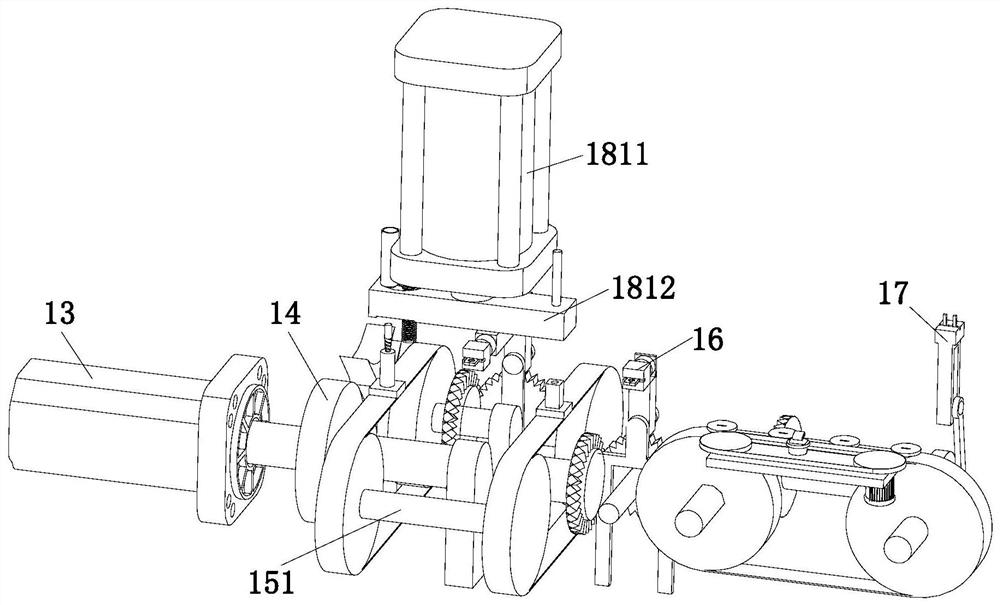

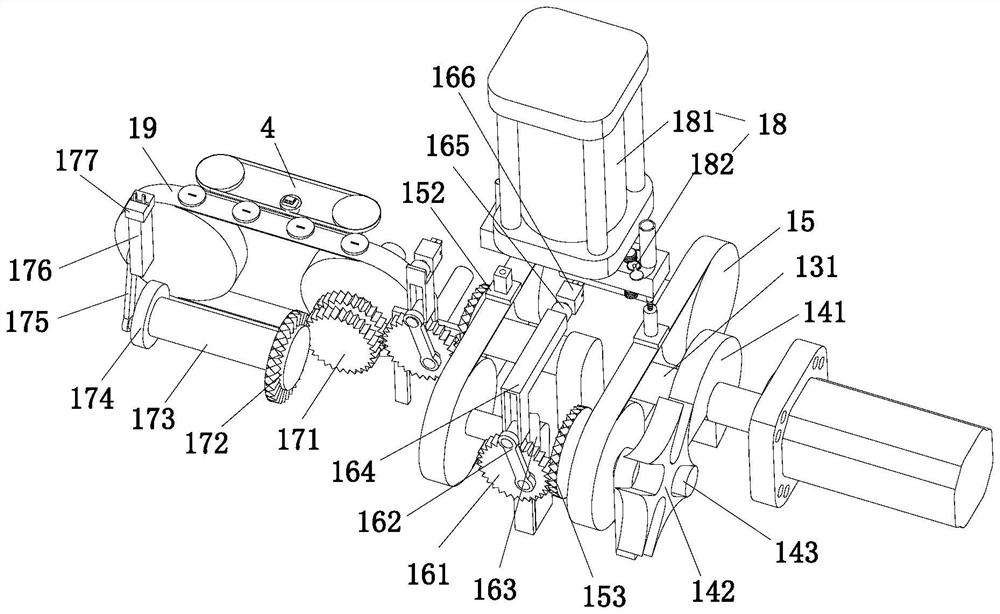

Grinding wheel automatic dismounting machine containing Teflon sheet and dismounting technology thereof

ActiveCN108333010AAutomatically and efficiently splitEffective splitGrinding drivesPreparing sample for investigationEngineeringConveyor belt

The invention relates to the field of dismounting of a group of grinding wheels, and especially relates to a grinding wheel automatic dismounting machine containing Teflon sheets. The grinding wheel automatic dismounting machine comprises a stepping conveyor belt, an automatic removing mechanism and a two-stage separation mechanism, the automatic removing mechanism comprises a friction part and aremoving part, the friction part comprises several friction rods, and a charging end of the friction rod close to the stepping conveyor belt, the removing part comprises several removing thin plates,and a middle position of the removing thin plate close to the stepping conveyor belt, a first cylinder is arranged besides the removing thin plate, several positioning tools arranged at intervals along a conveying direction are arranged at a conveying plane of the stepping conveyor belt, a placing groove with an upward opening is arranged at the positioning tool, the positioning tool is in a cuboid structure, first semicircle grooves are respectively arranged at two sides of a width direction of the positioning tool, a third inclined surface is arranged at top of two sides of the placing groove, the Teflon sheet in an entire tool can be automatically and effectively dismounted, so that the integral efficiency is increased, and the technology is simple and reliable.

Owner:金华市国泰砂轮研磨有限公司

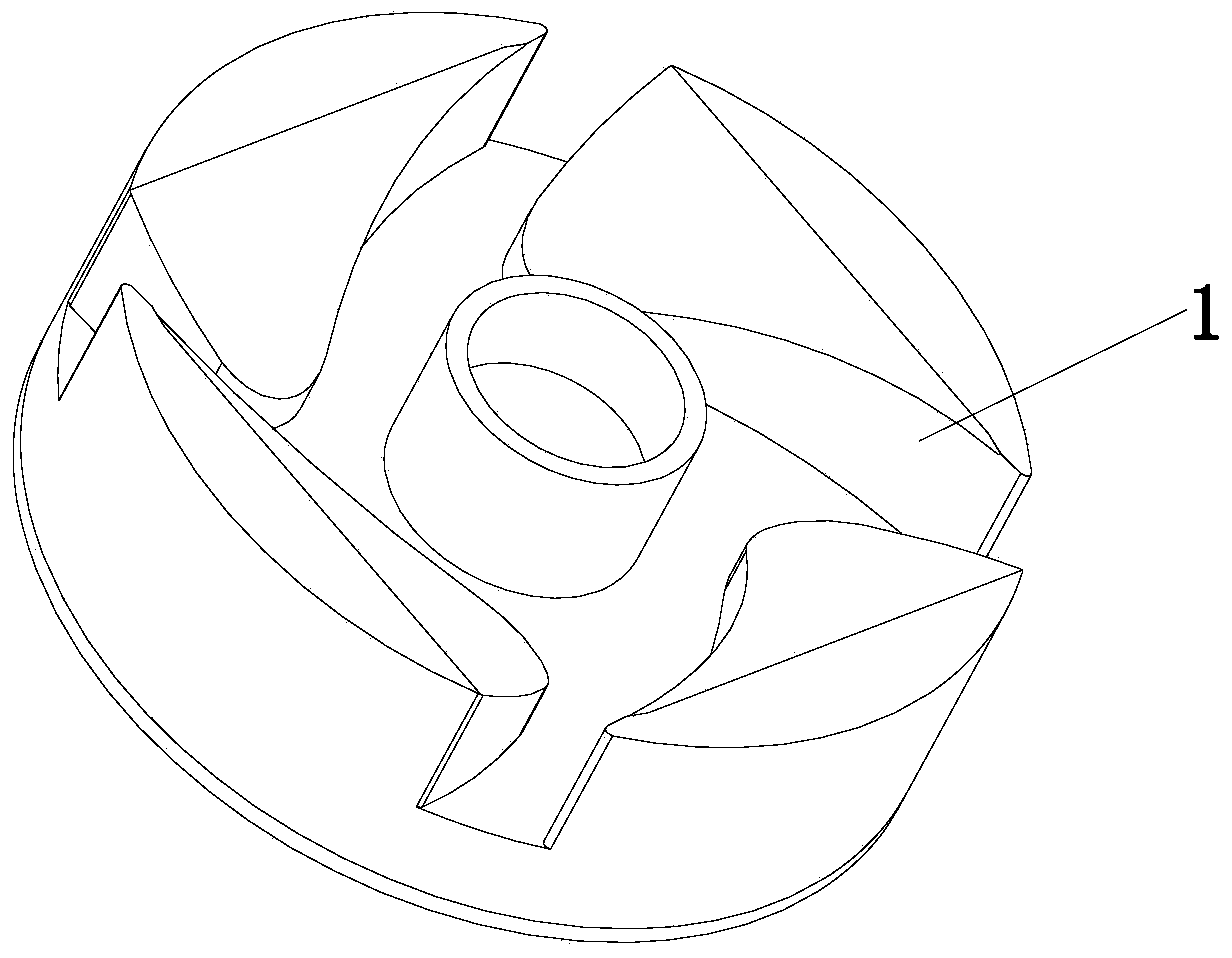

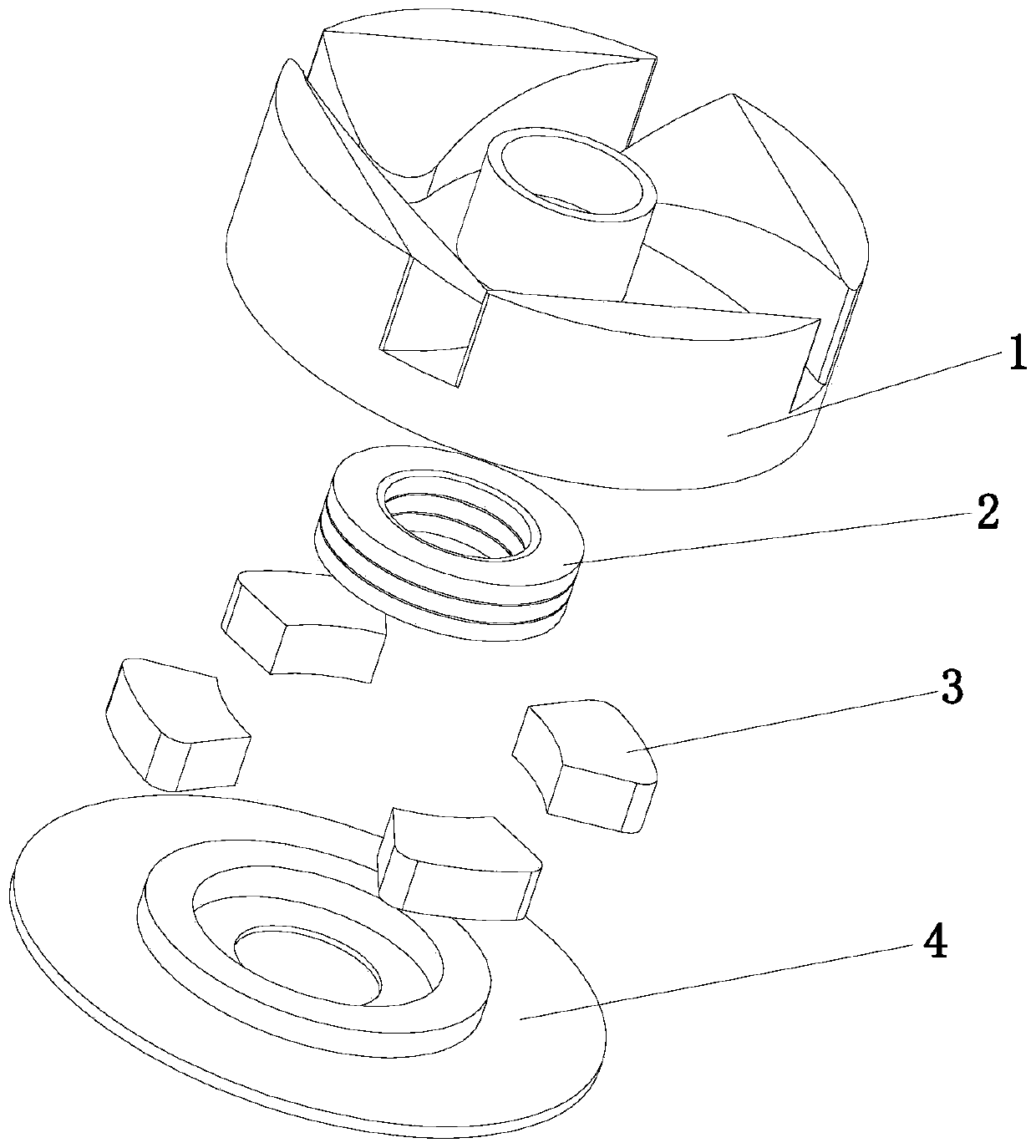

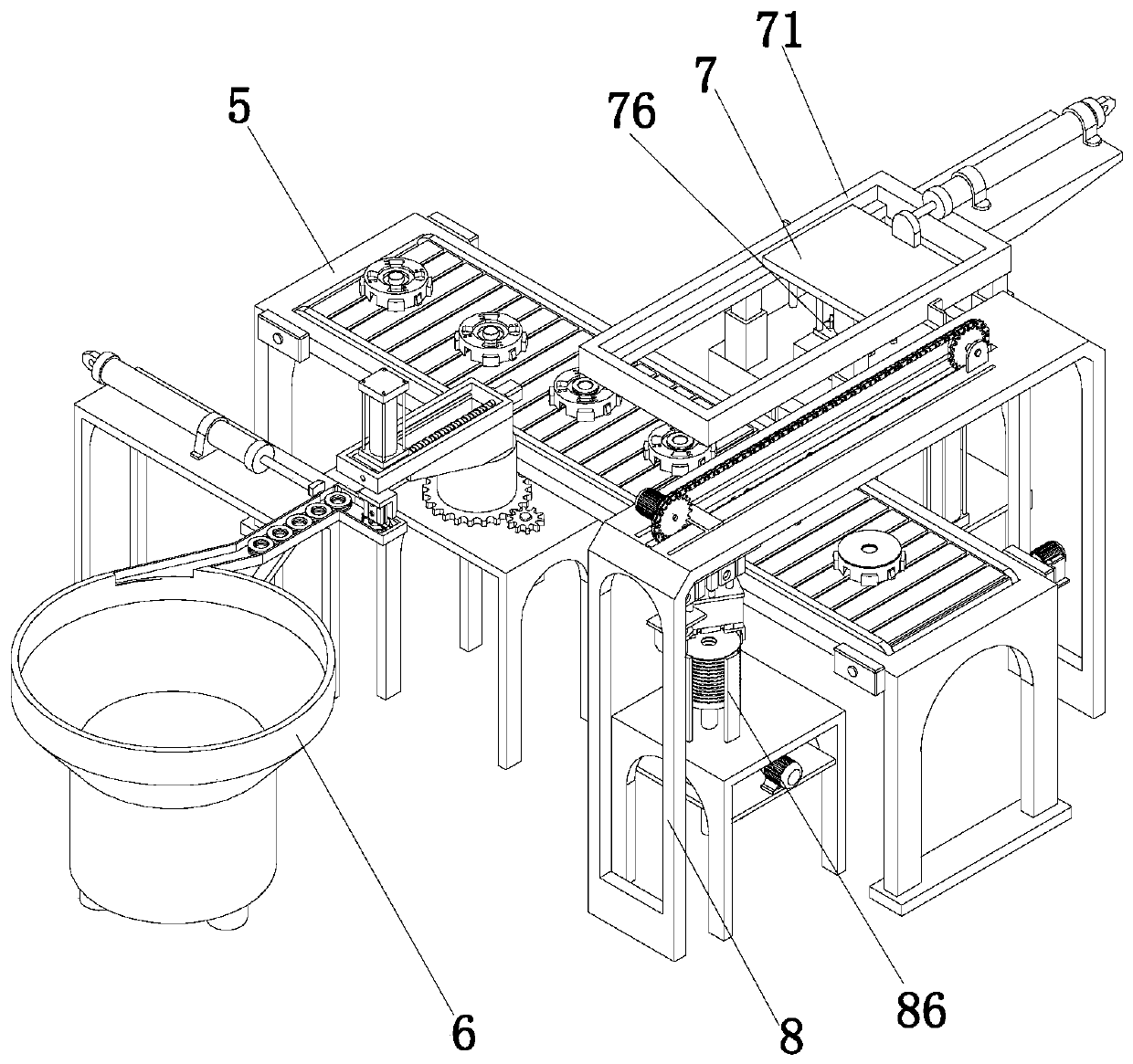

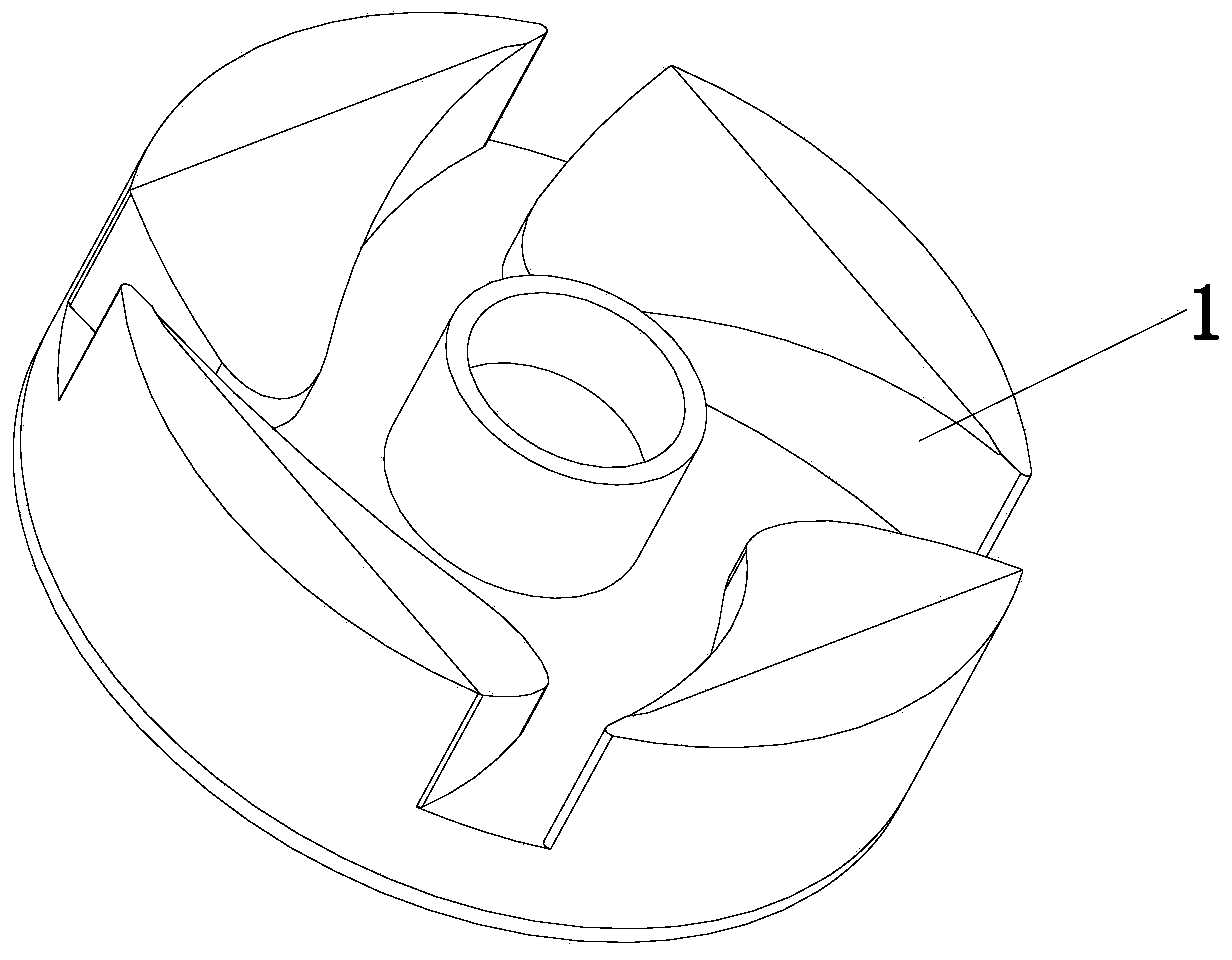

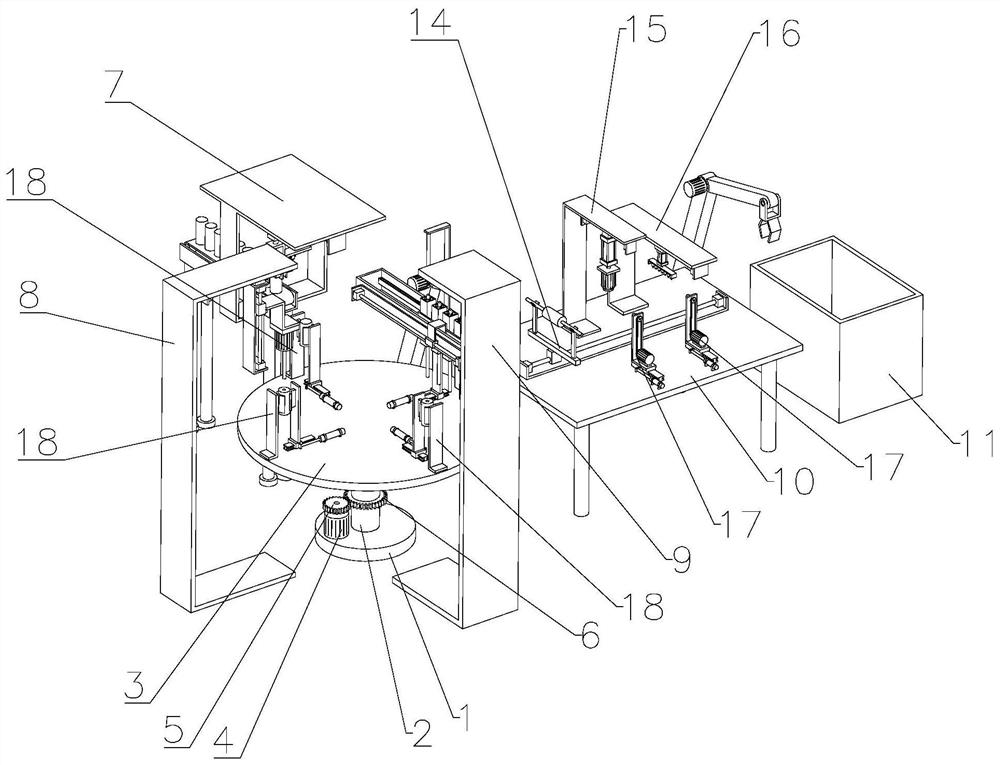

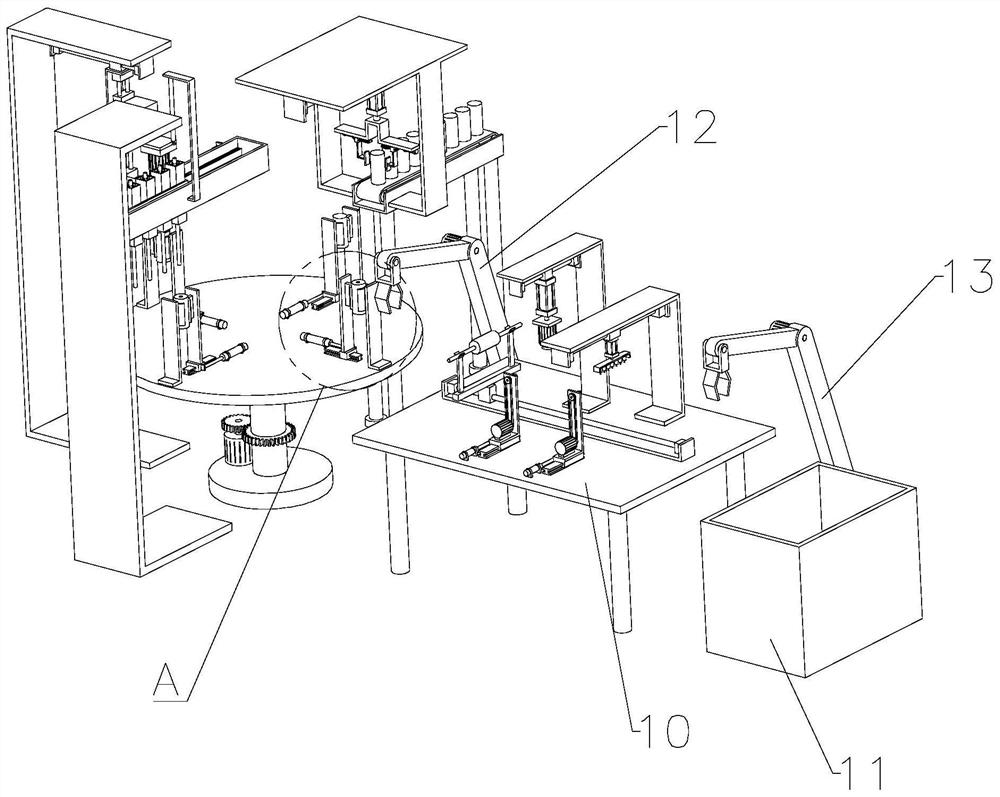

Production process of centrifugal blood pump rotor

ActiveCN110893546AReduce laborHigh degree of automationWelding/cutting auxillary devicesAssembly machinesElectric machineryImpeller

The invention discloses a production process of a centrifugal blood pump rotor, and belongs to the technical field of medical instrument production processes. The method comprises the following stepsthat 1, motor magnets and impellers are fed; 2, bearing magnetic stacks are pressed into the impellers; 3, the four motor magnets are pressed into the impellers, specifically, a conveying belt moves the pressed impellers to the position under a motor magnet mounting mechanism, and the motor magnet mounting mechanism presses the motor magnets into the impellers; and 4, a base is pressed onto the impellers and welded and formed. According to the method, the steps of bearing magnetic pile press fitting, motor magnet mounting and base welding of the centrifugal blood pump rotor can be automatically completed, the four motor magnets can be installed in the impellers at the same time through the motor magnet mounting mechanism, and workers do not need to install the motor magnets one by one; theprocess is ingenious in design and smooth in procedure connection, the produced products are good in consistency and high in yield, more than 70% of labor can be saved in the whole process, and a high economic value is achieved.

Owner:韶关市武江区冠启自动化设备设计有限公司

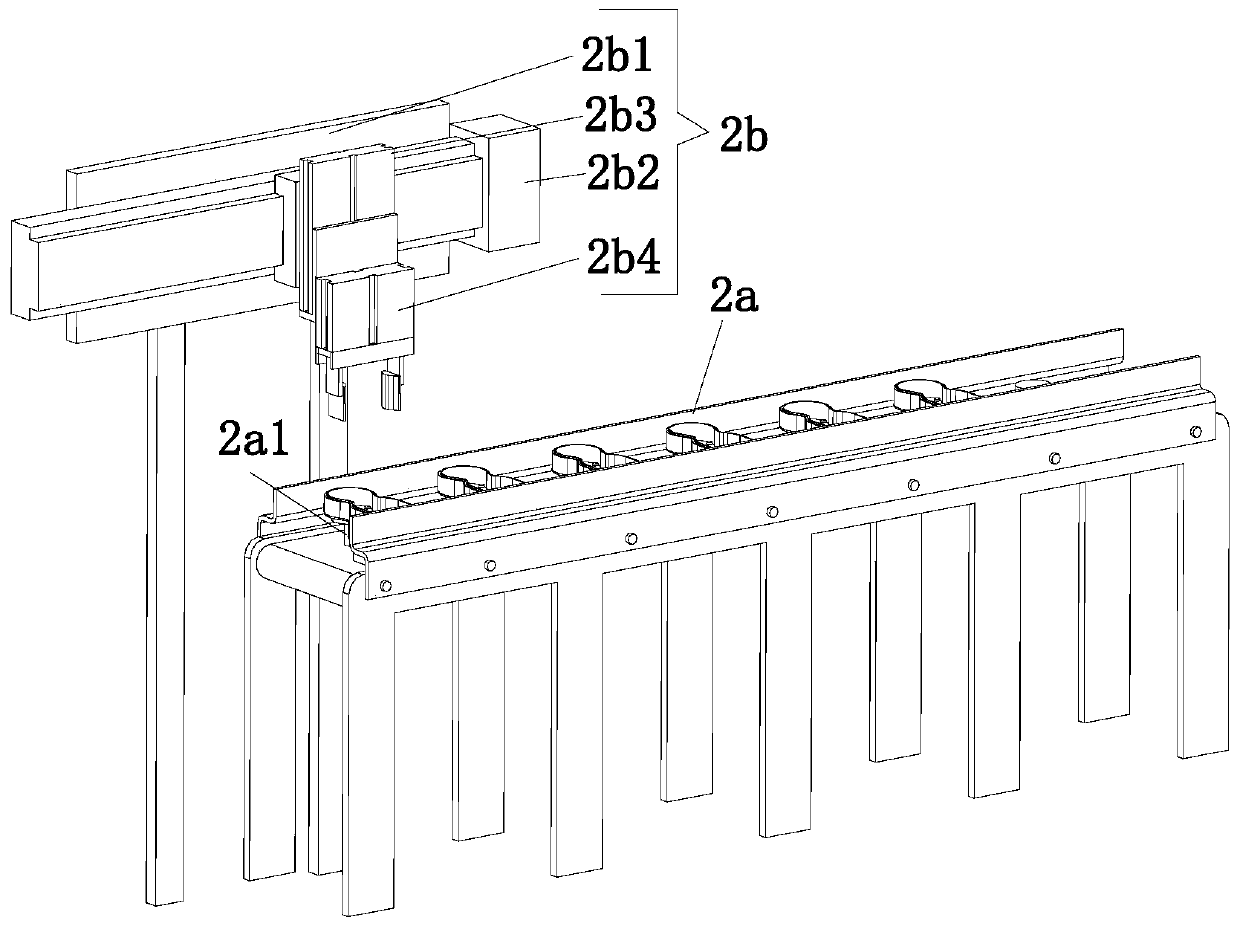

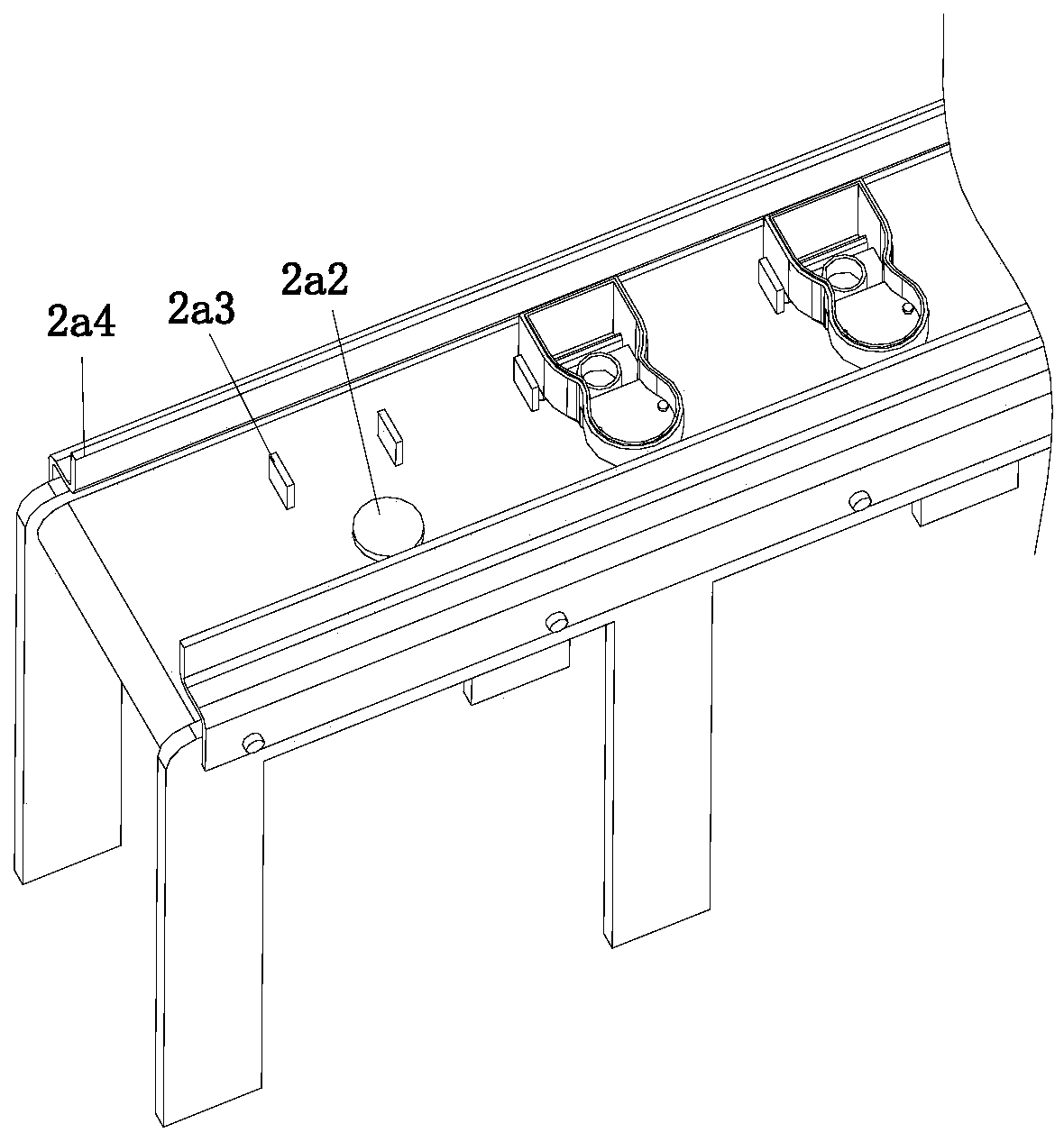

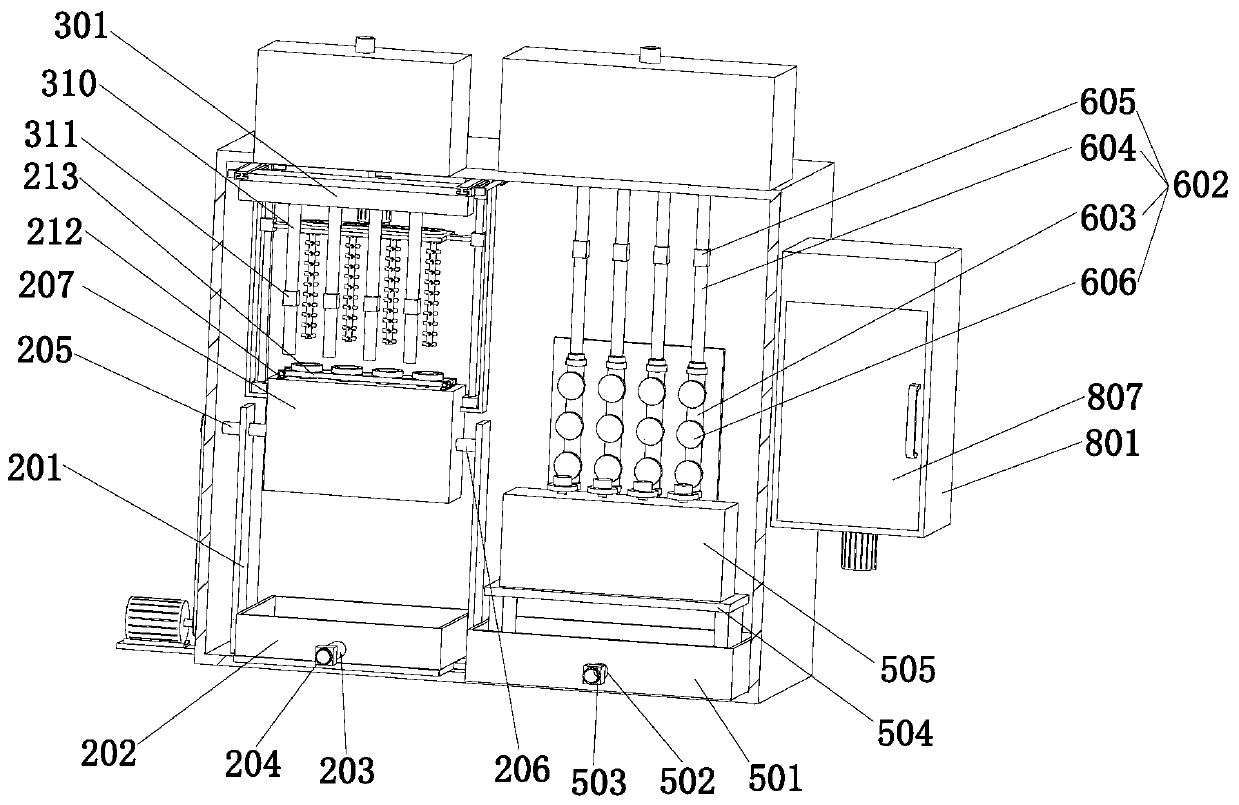

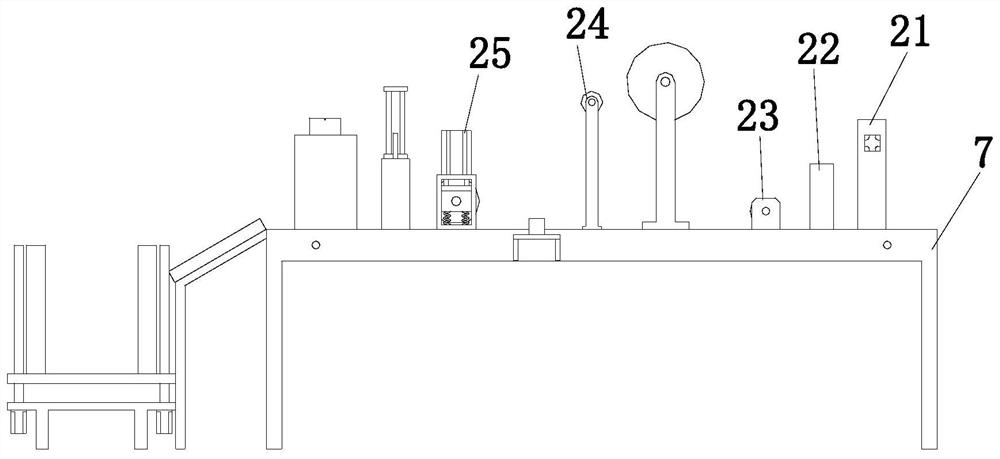

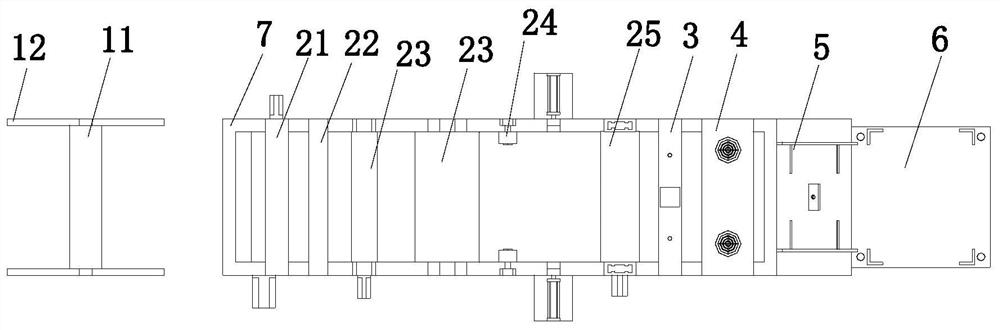

Automatic tire pressure sensor production process

ActiveCN111168384AReduce labor costsEasy to removeLiquid surface applicatorsAssembly machinesProcess engineeringMechanical engineering

The invention relates to the field of tire pressure sensor production processes, in particular to an automatic tire pressure sensor production process. The automatic tire pressure sensor production process comprises the following steps of S1, automatically feeding a bottom shell; S2, automatically feeding a battery pack; S3, compressing the battery pack and the bottom shell; S4, assembling a circuit board and an antenna; S5, assembling a shell cover; and S6, carrying out automatic discharging. The automatic tire pressure sensor production process has the beneficial effects that corresponding parts are sequentially transferred to a rotating device through a feeding device, a conveying device, an assembling device and a mounting device, and after the multiple parts are assembled on the rotating device, workpieces on the rotating device are removed through a discharging device to complete automatic production, so that the expenditure of labor cost is saved, the process is ingenious in design and smooth in procedure connection; and compared with manual assembly, the efficiency is improved by 10-12 times or above, and the yield reaches 99.99%.

Owner:三森电子股份有限公司

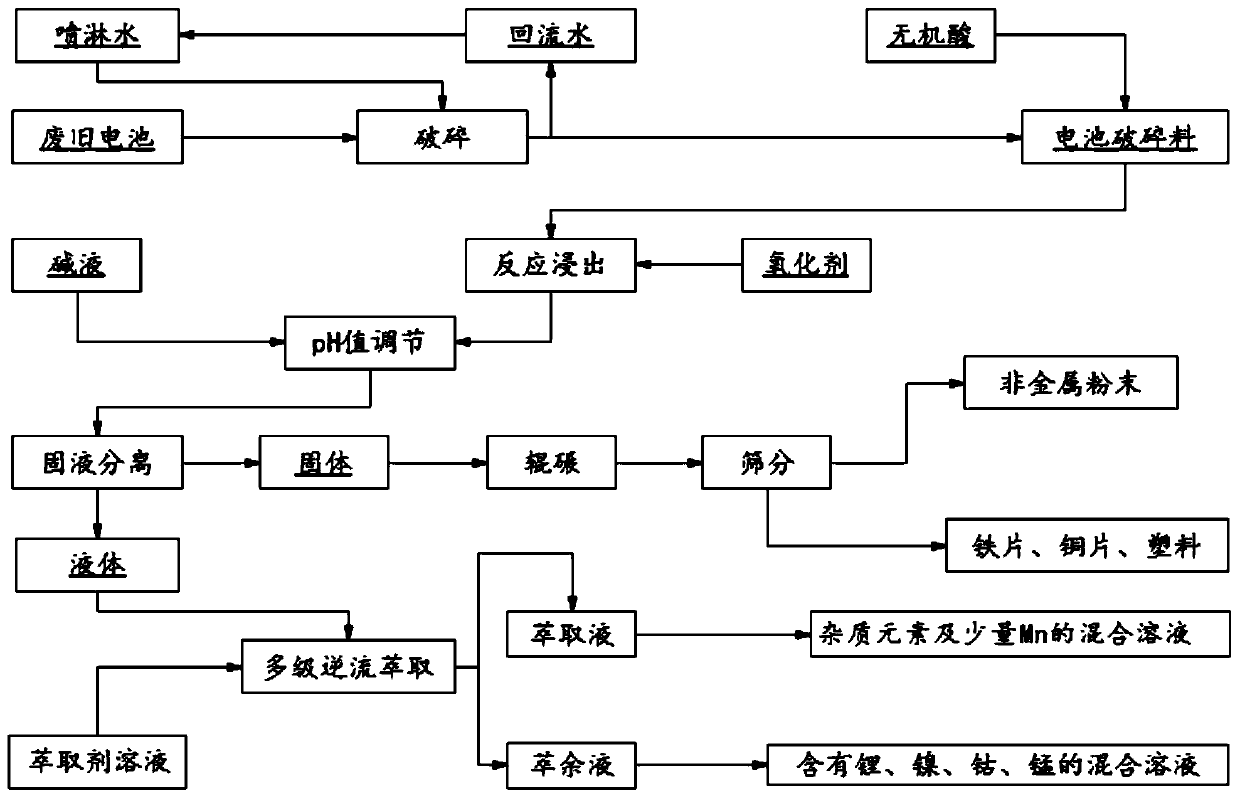

Full-wet recovery process of waste lithium batteries

ActiveCN110724818AReduce outputAvoid pollutionWaste accumulators reclaimingProcess efficiency improvementEnvironmental engineeringLithium-ion battery

The invention discloses a full-wet recovery process of waste lithium batteries. The full-wet recovery process comprises the following steps of wet charged crushing, direct leaching of battery scraps,in-situ impurity removal of leachate, deep impurity removal, material re-preparation and the like. The process can realize recovery of waste lithium ion batteries through a short process, and has theadvantages of high recovery rate of nickel, cobalt, manganese and lithium element, low equipment investment, small waste gas and waste water yield and the like.

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

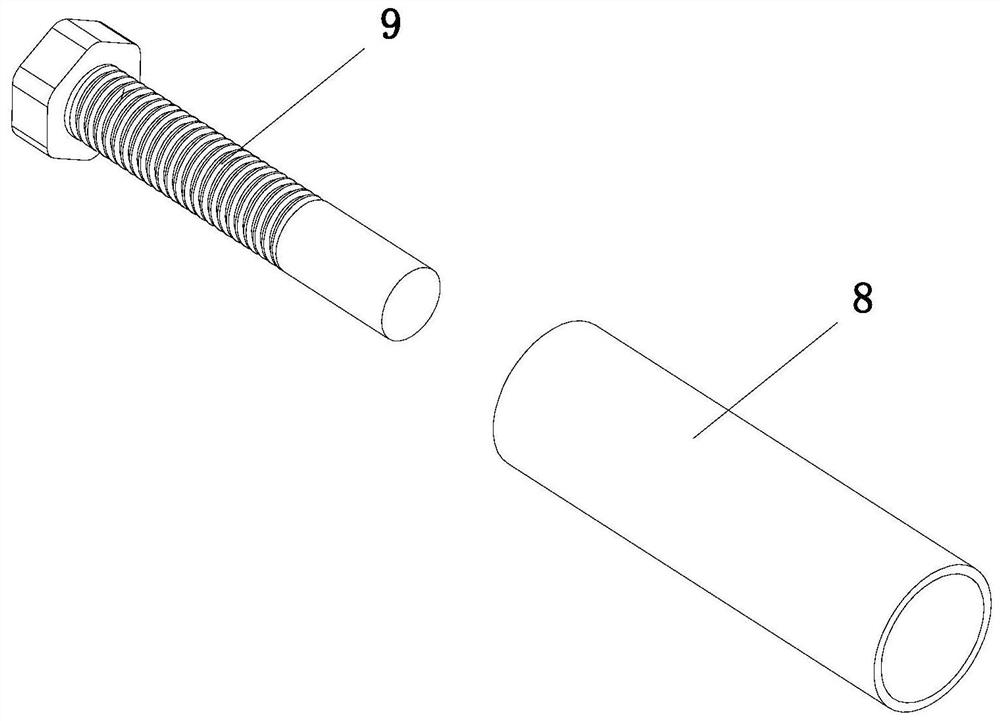

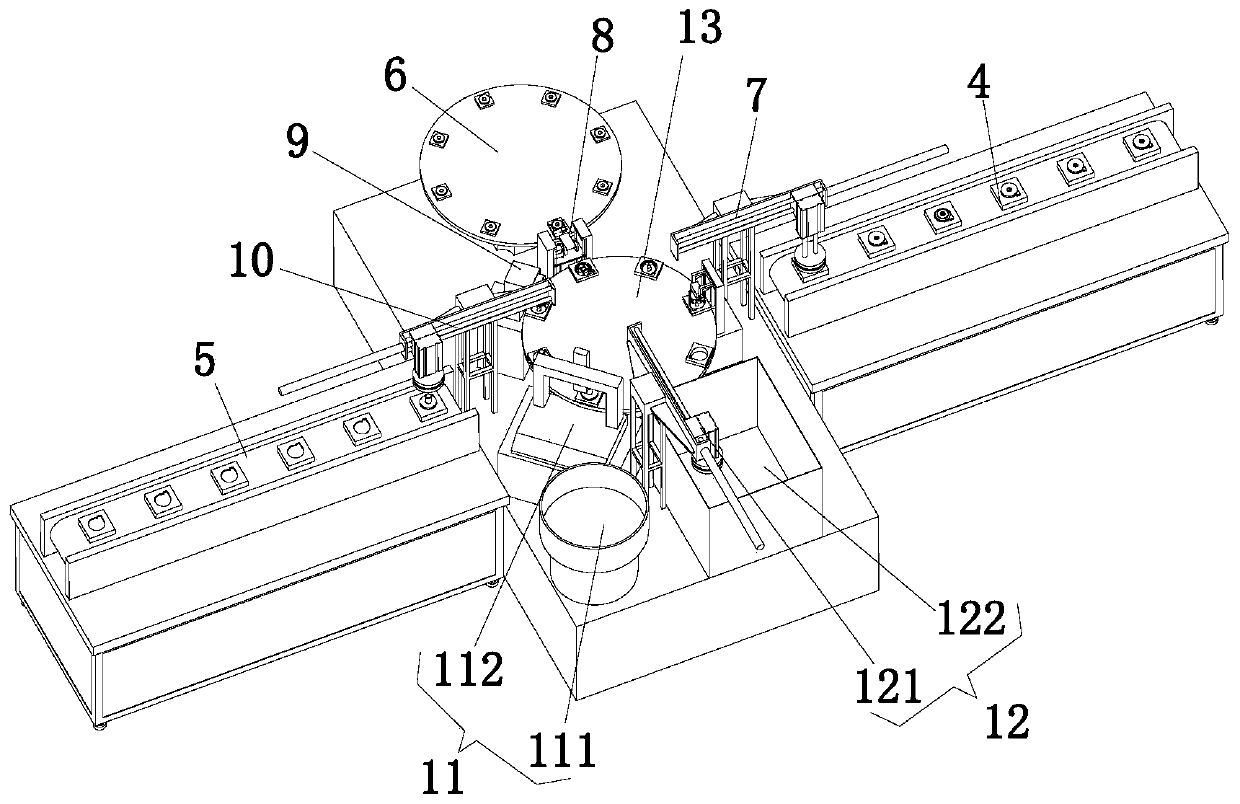

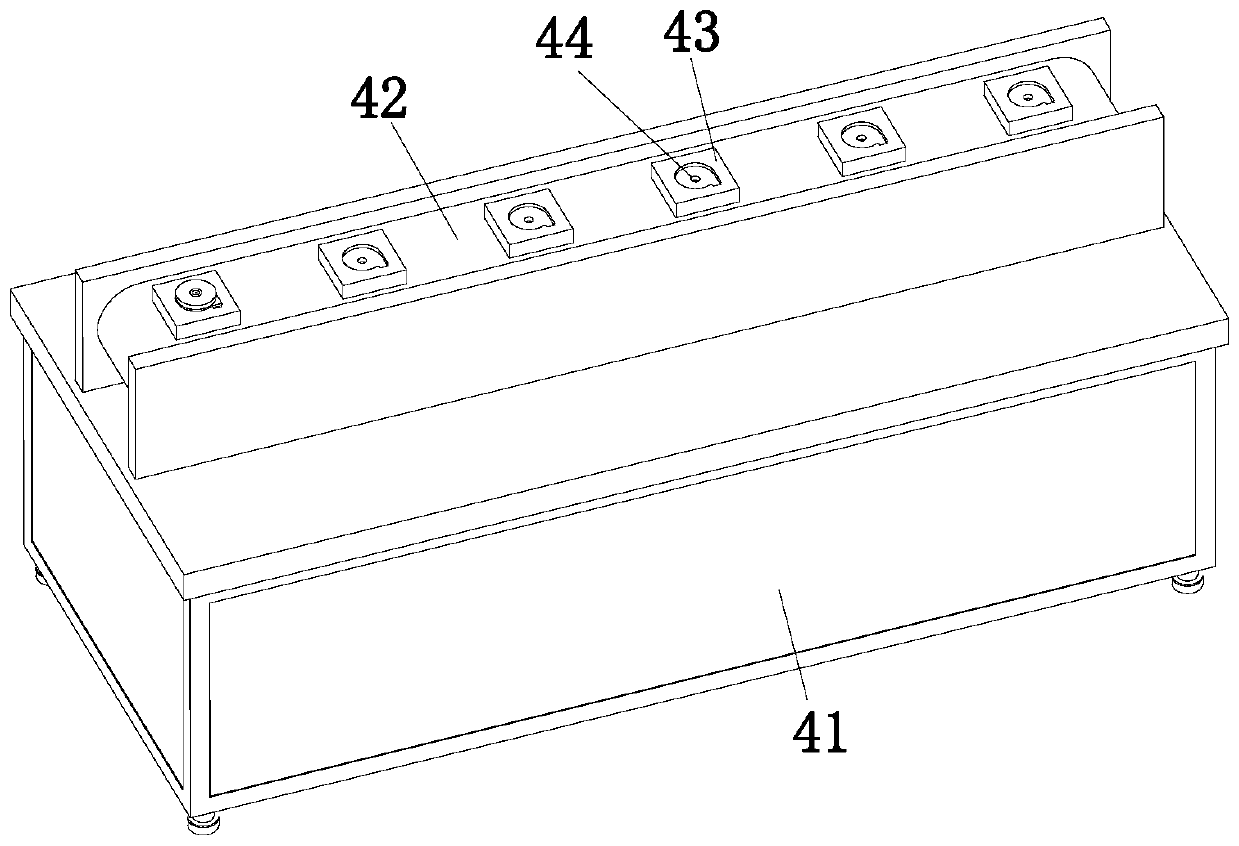

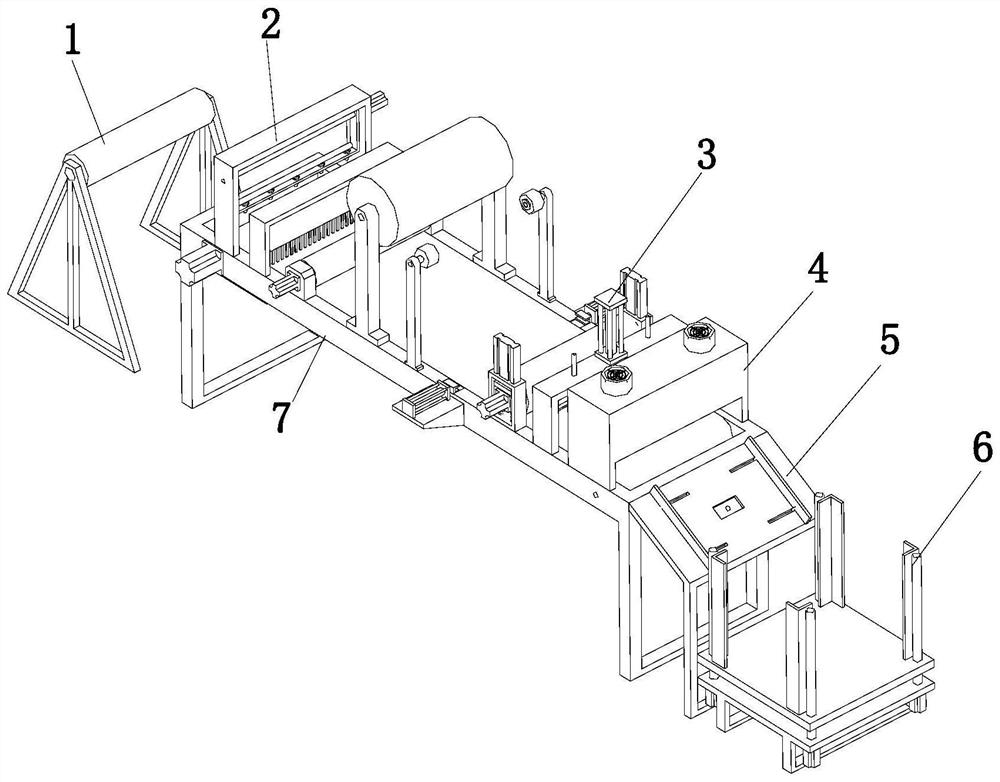

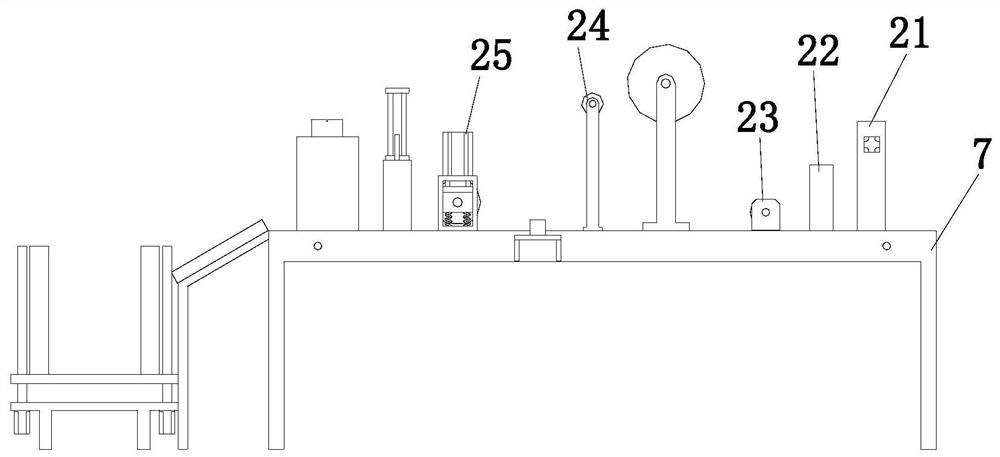

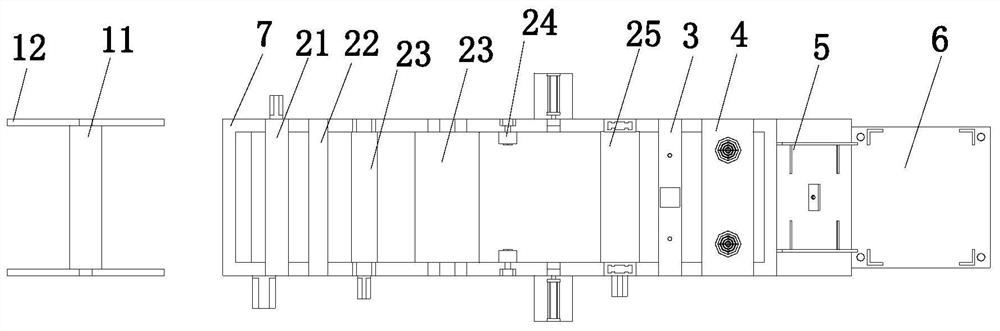

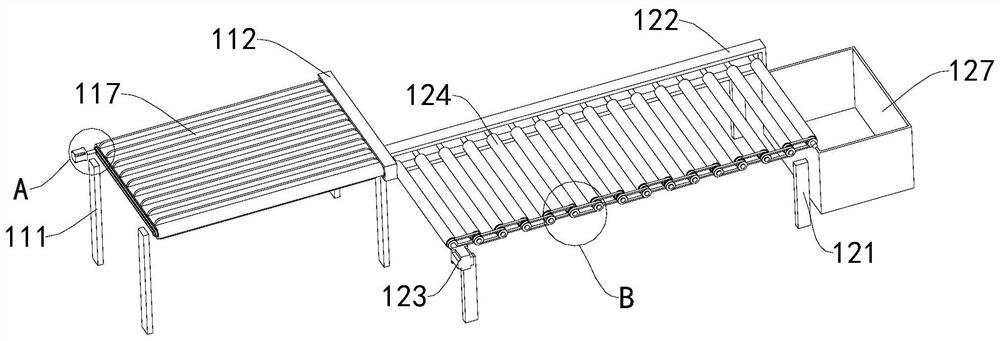

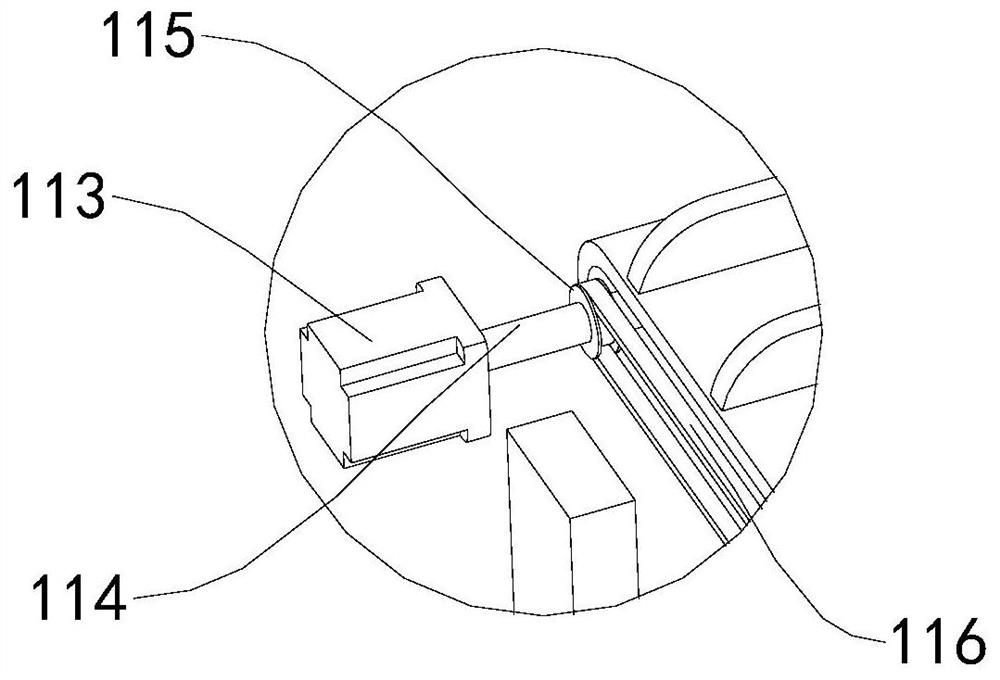

Automatic net sleeving process for fastener

InactiveCN112793832ARealize automatic feeding processRealize automatic network settingIndividual articlesProcess engineeringIndustrial engineering

The invention discloses an automatic net sleeving process for a fastener, which relates to the technical field of fasteners. The automatic net sleeving process comprises the following steps that 1, the fastener is automatically fed; 2, the fastener located on a conveying belt is rotated and corrected; 3, the fastener is limited; 4, the fastener is clamped to move towards a net outlet; 5, a net sleeve is discharged from the net outlet; 6, the net sleeve is twisted to achieve opening; 7, the fastener is moved into the net sleeve to complete automatic sleeving; and 8, the sleeved fastener is automatically discharged and boxed. The automatic net sleeving process is ingenious in design, connection between procedures is smooth, manual labor is reduced, production efficiency is improved, requirement for automatic sleeving operation of the fasteners of different sizes can be met, and equipment stability and practicability are high.

Owner:谢三保

Automatic barbell weight producing process

InactiveCN112429524AImprove work efficiencyRealize automated productionDumb-bellsRotary pressesProcess engineeringCooperative work

The invention discloses an automatic barbell weight producing process, and relates to the technical field of barbell weight production. The automatic barbell weight producing process comprises the following steps of 1, automatically putting a barbell weight into an overturning and fixing mechanism, 2,driving a fixing assembly to conduct overturning operation, 3, clamping and fixing the barbell weight, 4, automatically spraying paint on the barbell weight, 5, automatically conducting air-drying on the paint on the barbell weight, 6, automatically conducting printing on the barbell weight, and 7, automatically discharging and collecting the barbell weight. The automatic barbell weight producing process is ingenious in design, smooth in procedure connection and high in automation degree, automatic barbell weight production is achieved through cooperative work of all the mechanisms, barbell weights do not need to be manually carried by workers one by one for production, and paint sprayingand printing operation does not need to be manually conducted on the barbell weights; and one person can take charge of one machine, so that the labor is saved, the labor intensity is greatly lowered,the production efficiency is greatly improved, and the economic value is remarkable.

Owner:程敏英

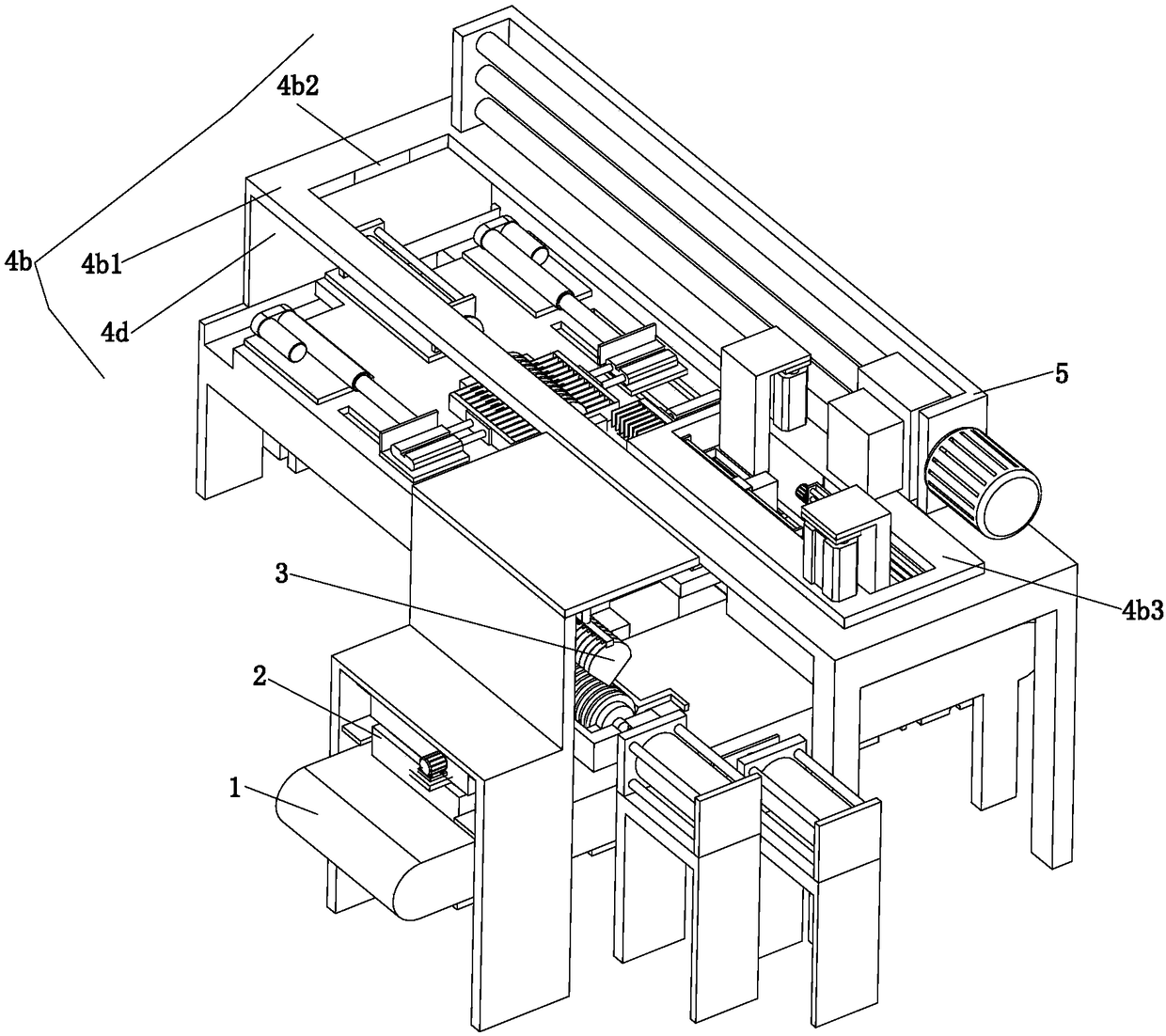

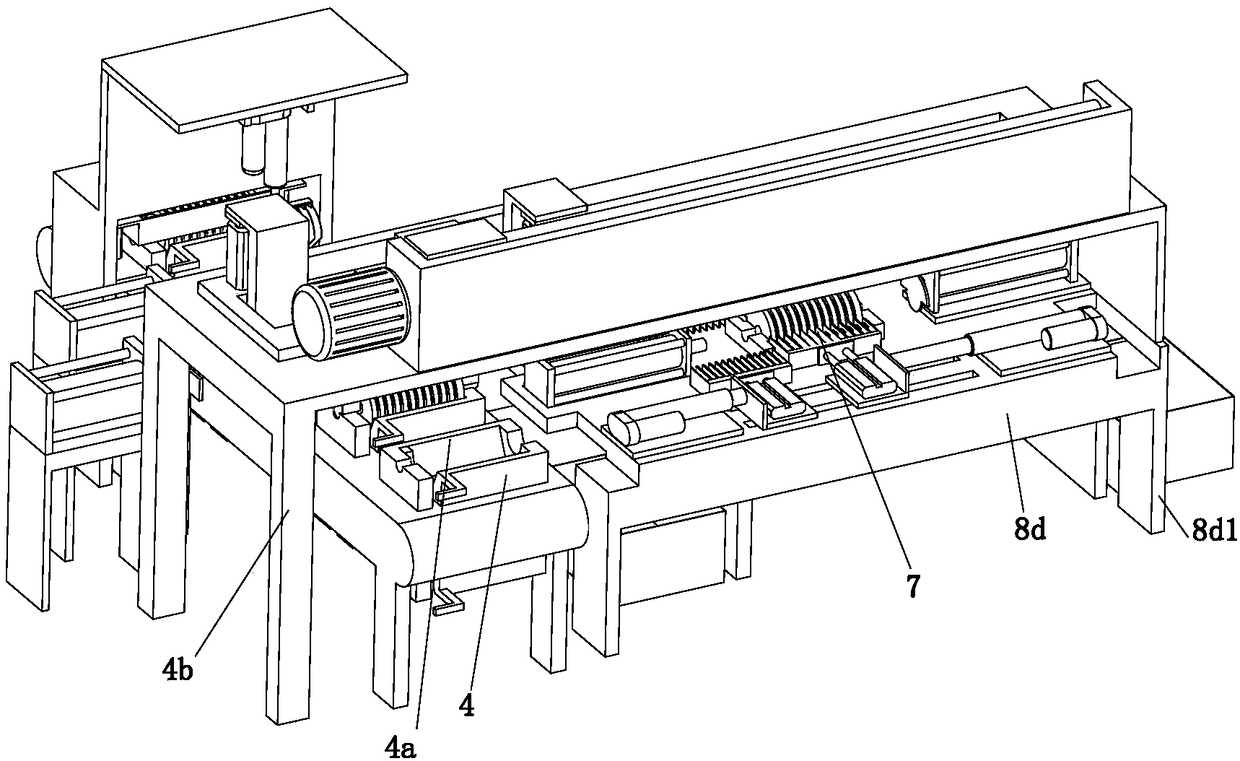

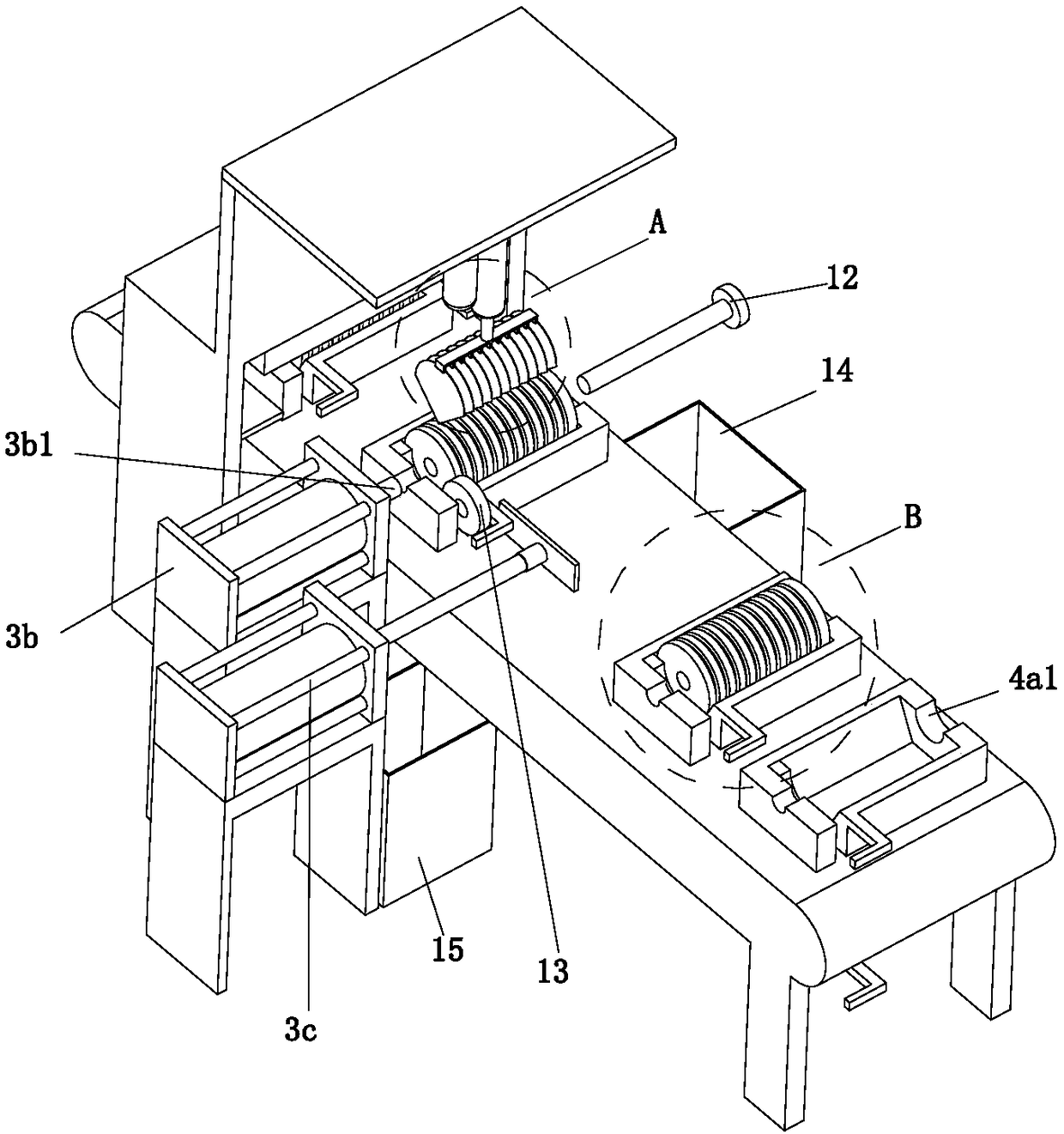

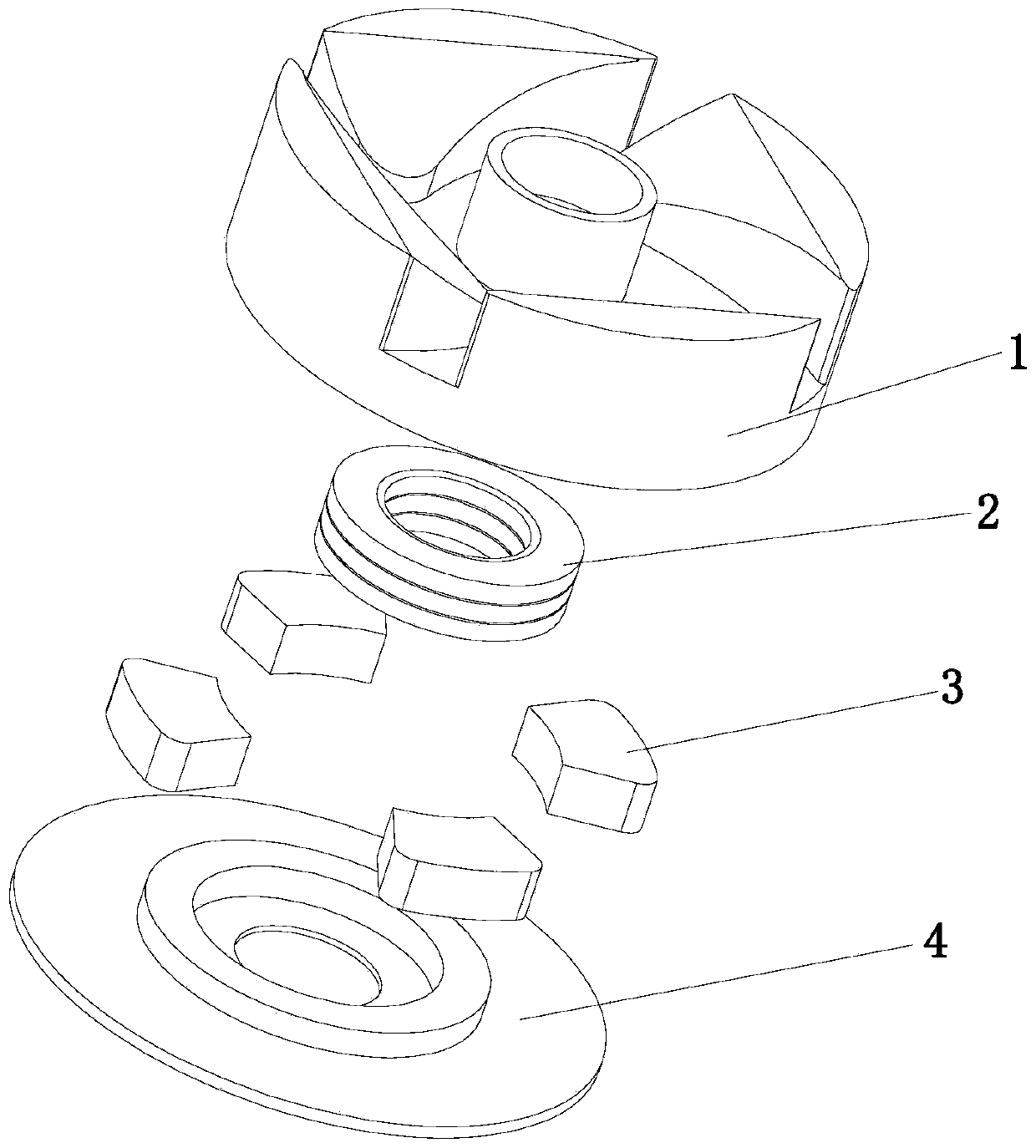

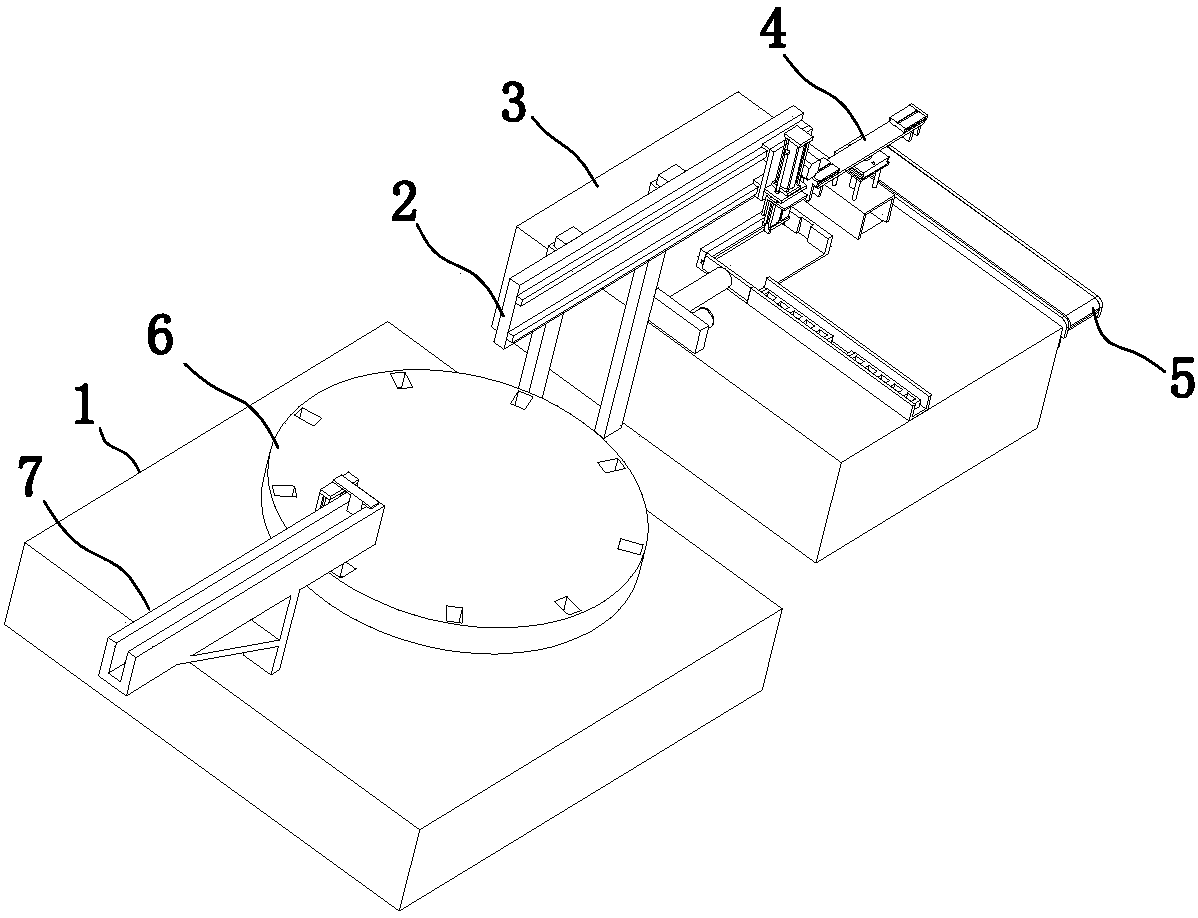

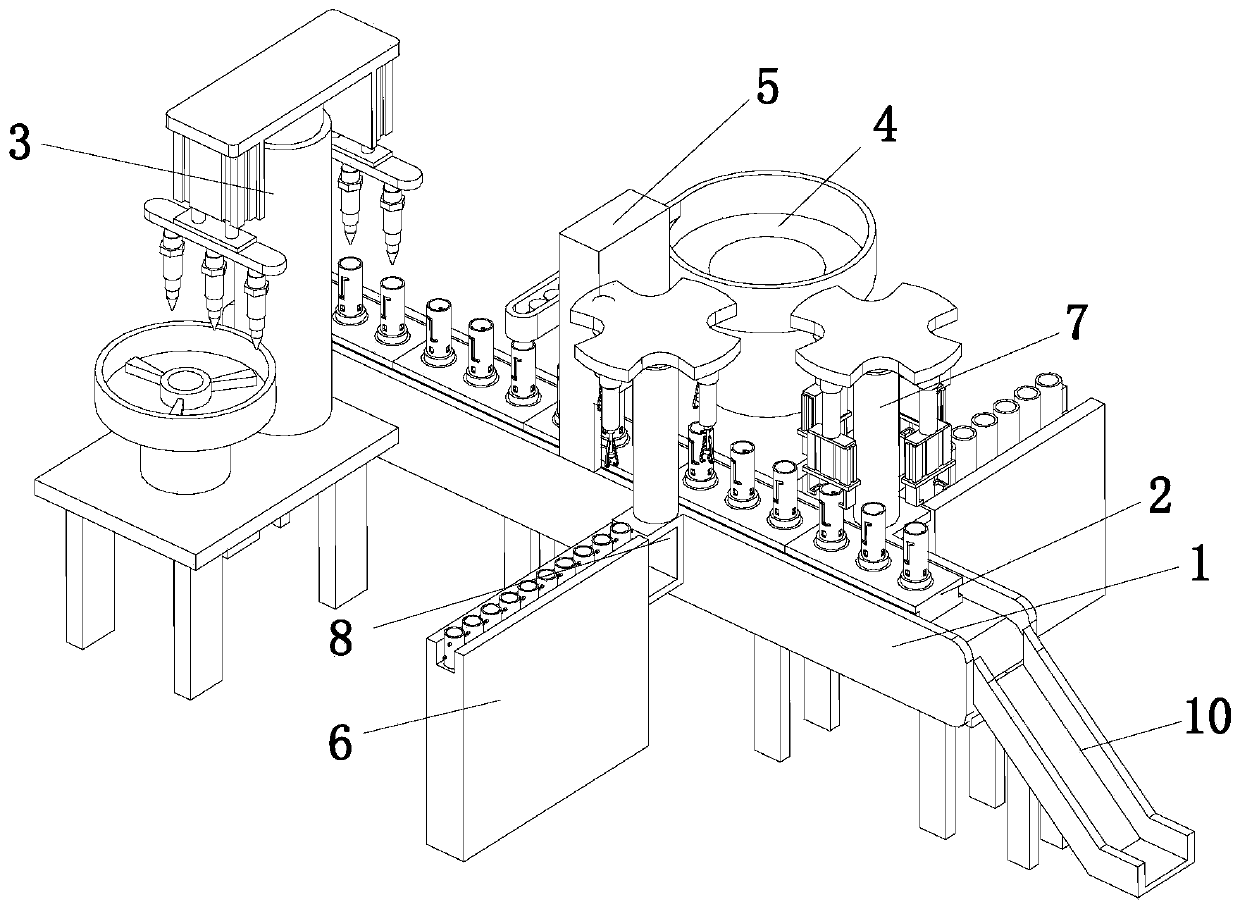

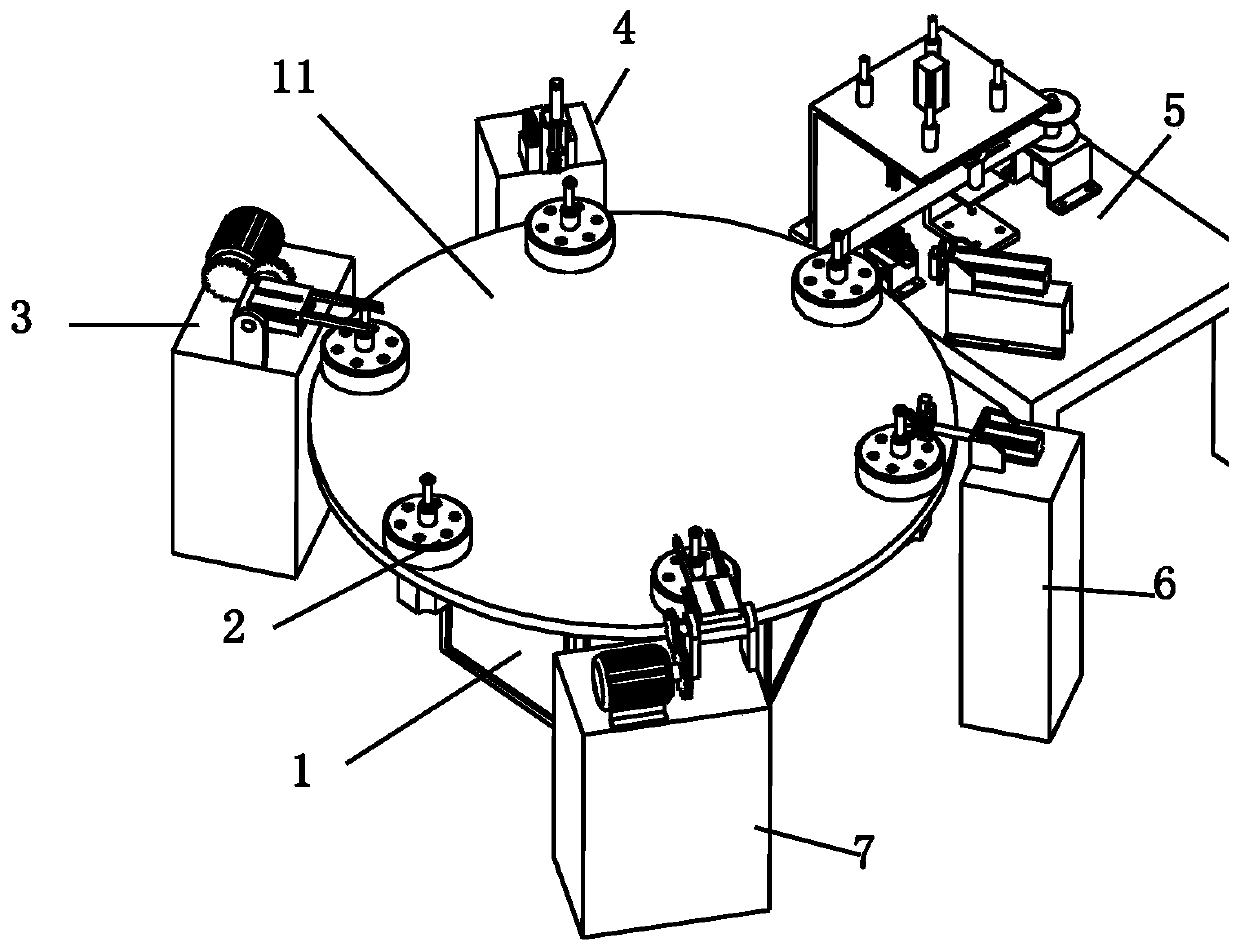

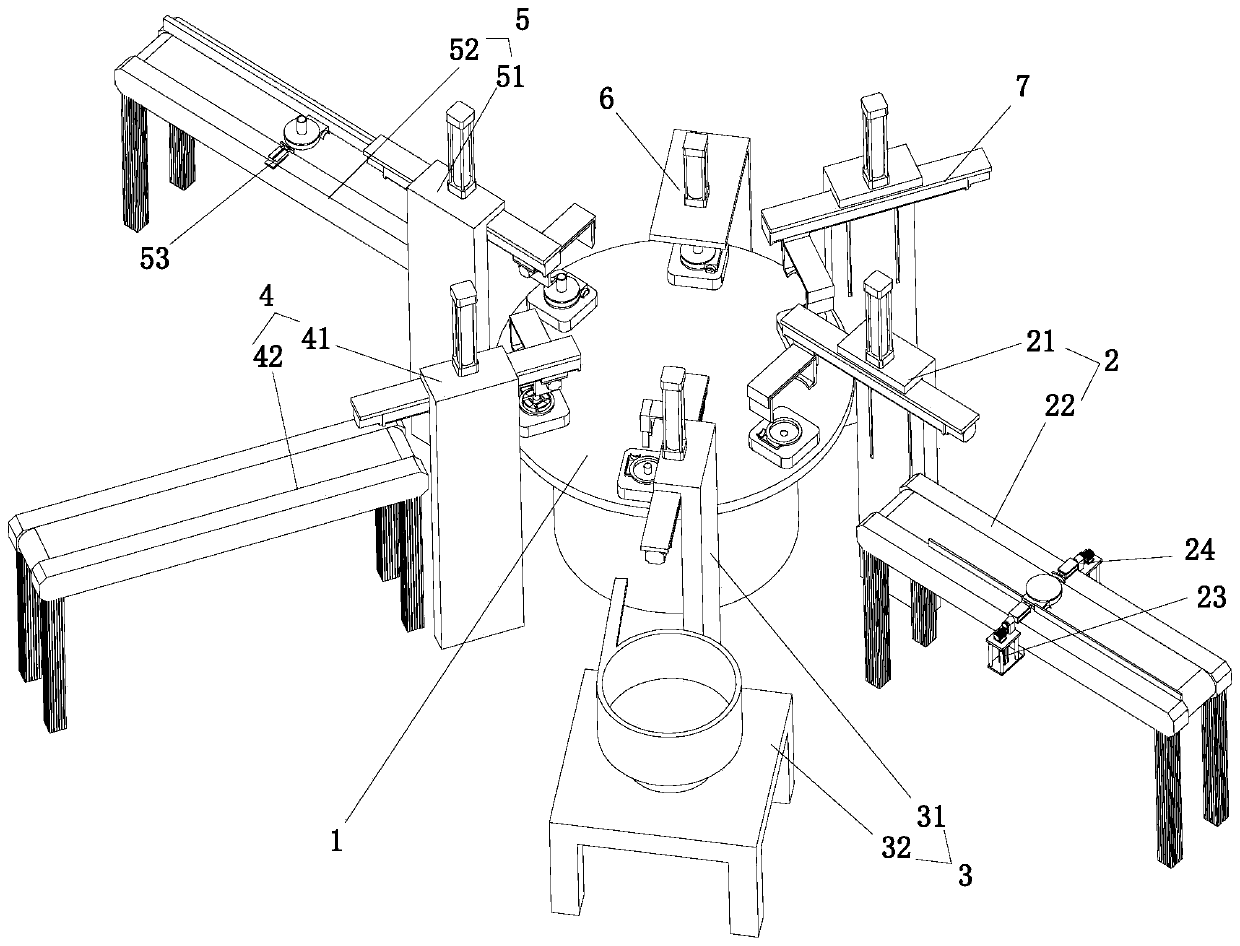

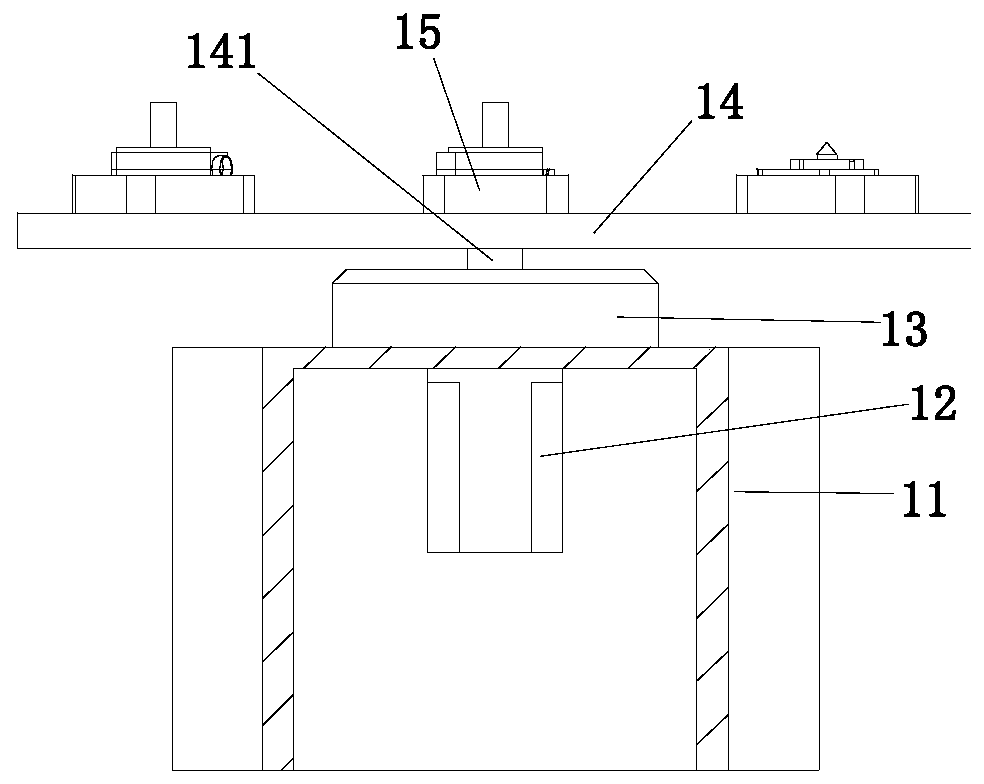

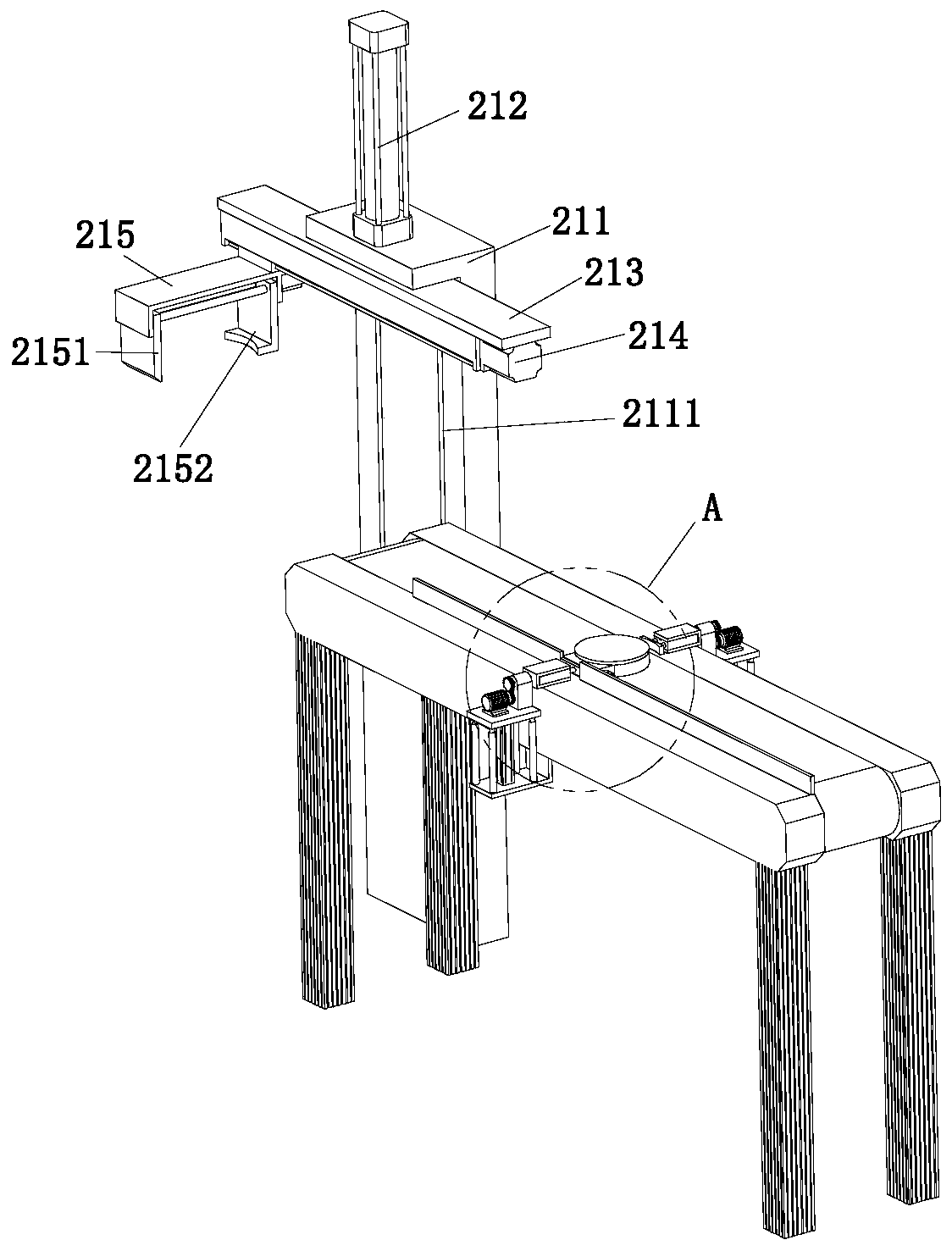

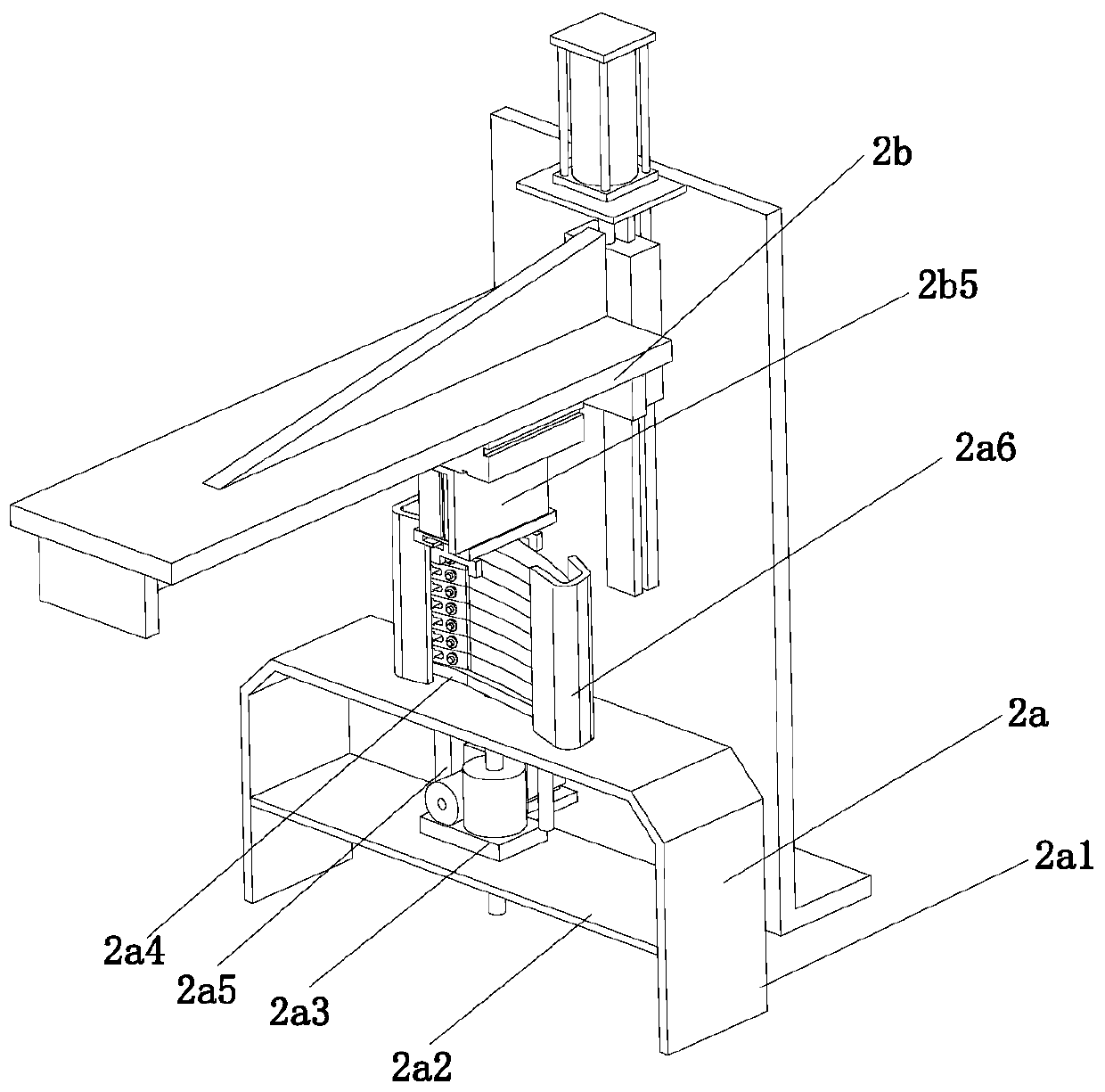

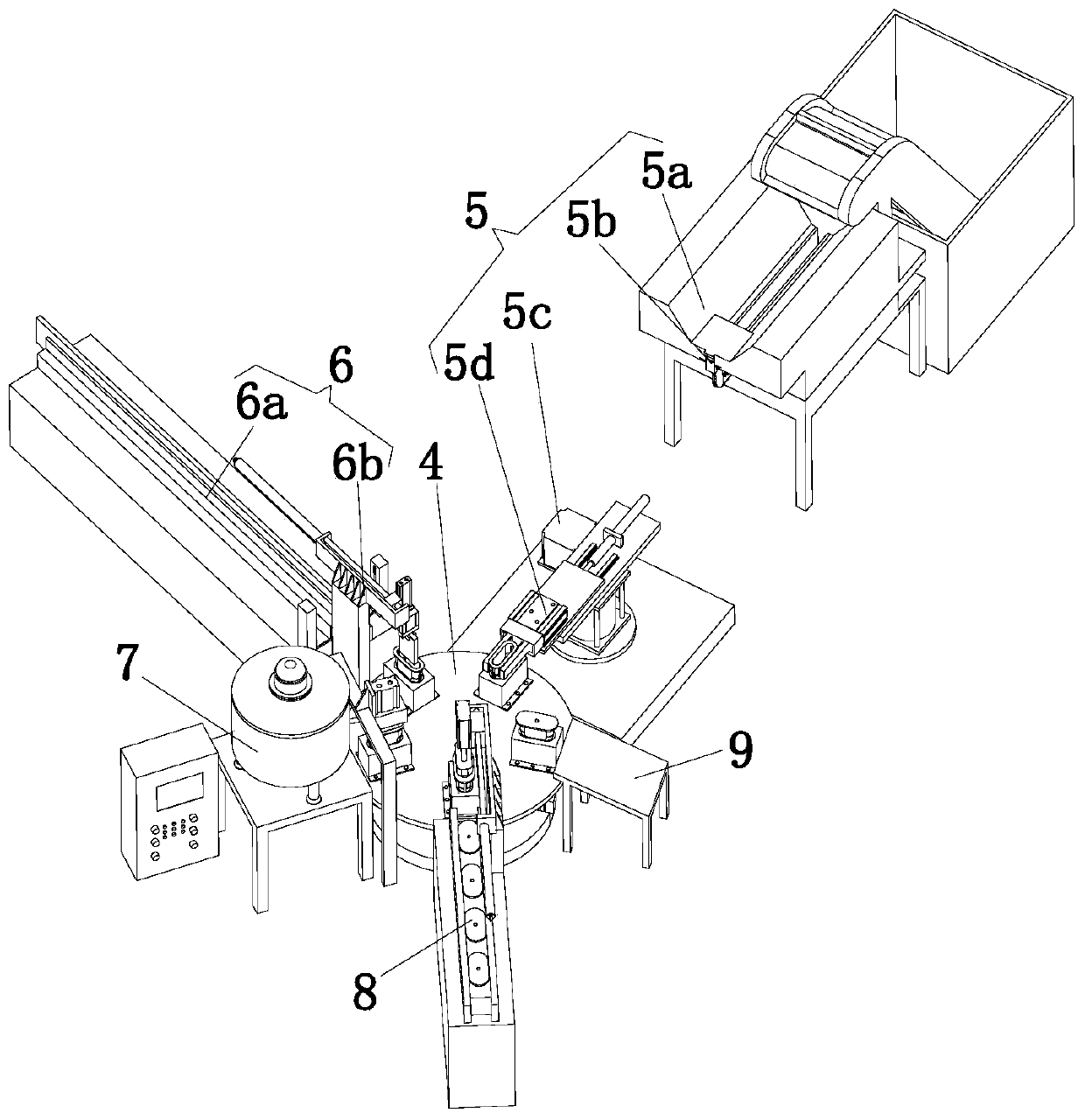

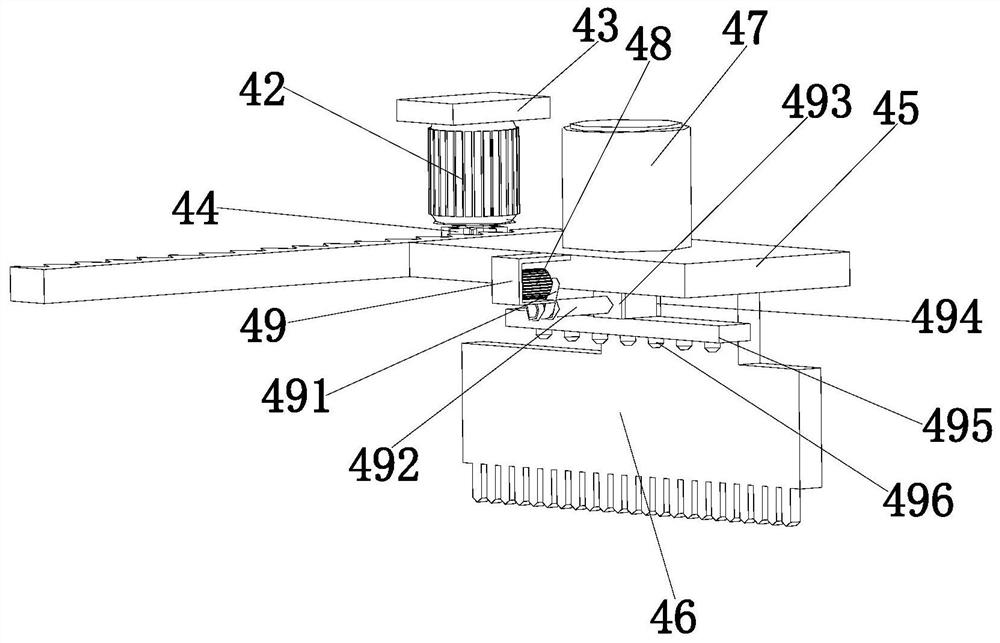

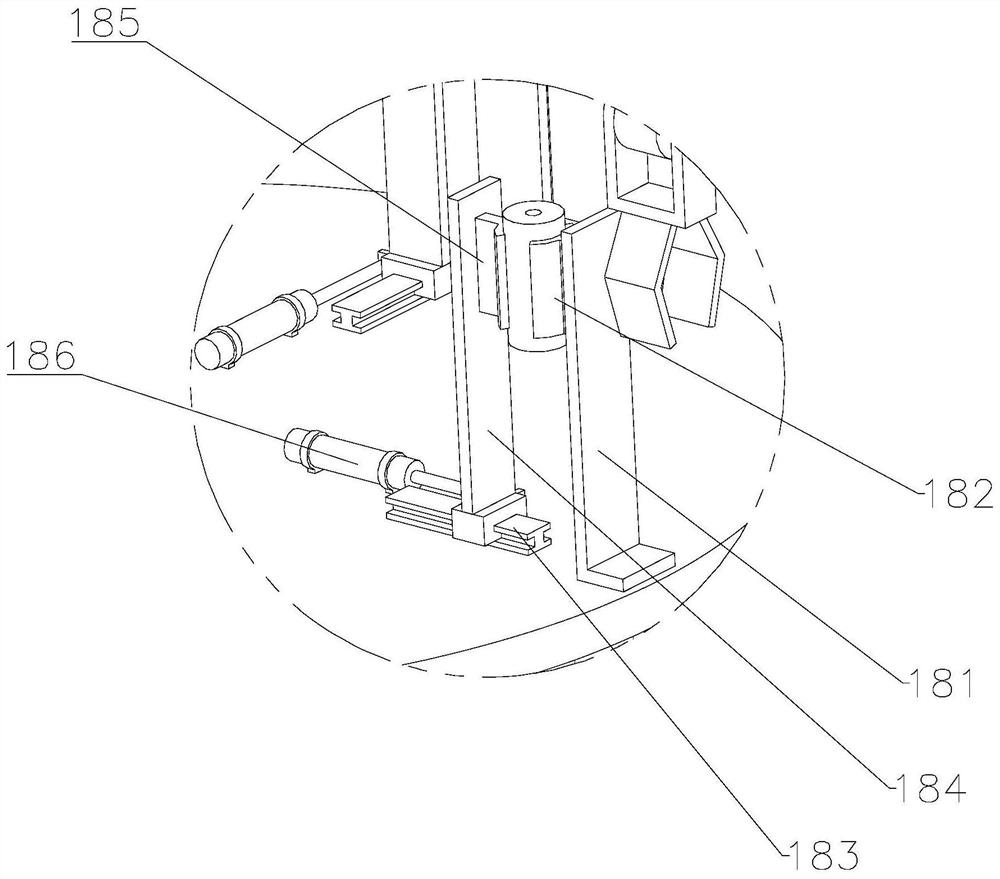

Automatic assembling process for centrifugal blood pump rotor

ActiveCN111085851ASolve efficiency problemsAddress the degree of automationAssembly machinesMetal working apparatusImpellerBlood pump

The invention discloses an automatic assembling process for a centrifugal blood pump rotor and belongs to the technical field of assembling equipment. The automatic assembling process comprises a conveyor belt, a bearing magnetic pile press-fitting mechanism, a motor magnet mounting mechanism and a base mounting mechanism. A plurality of limiting assemblies are arranged on the conveyor belt. The motor magnet mounting mechanism comprises a sliding plate, a worktable, a pushing assembly, a lifting assembly, a clamping assembly and a bearing frame. The clamping assembly comprises a mounting plate, a four-jaw air cylinder and a limiting column arranged at the bottom of the mounting plate. A limiting plate is mounted at the bottom of each clamping jaw of the four-jaw air cylinder. An arc-shapedgroove is formed in the limiting plate. Four bearing rods are arranged between the mounting plate and the sliding plate. According to the automatic assembling process, steps of press-fitting bearingmagnetic piles, mounting motor magnets and a base for the centrifugal blood pump rotor can be finished automatically. Four motor magnets can be mounted in an impeller simultaneously by the motor magnet mounting mechanism, and it is not needed to mount the motor magnets one by one by a worker.

Owner:韶关市武江区冠启自动化设备设计有限公司

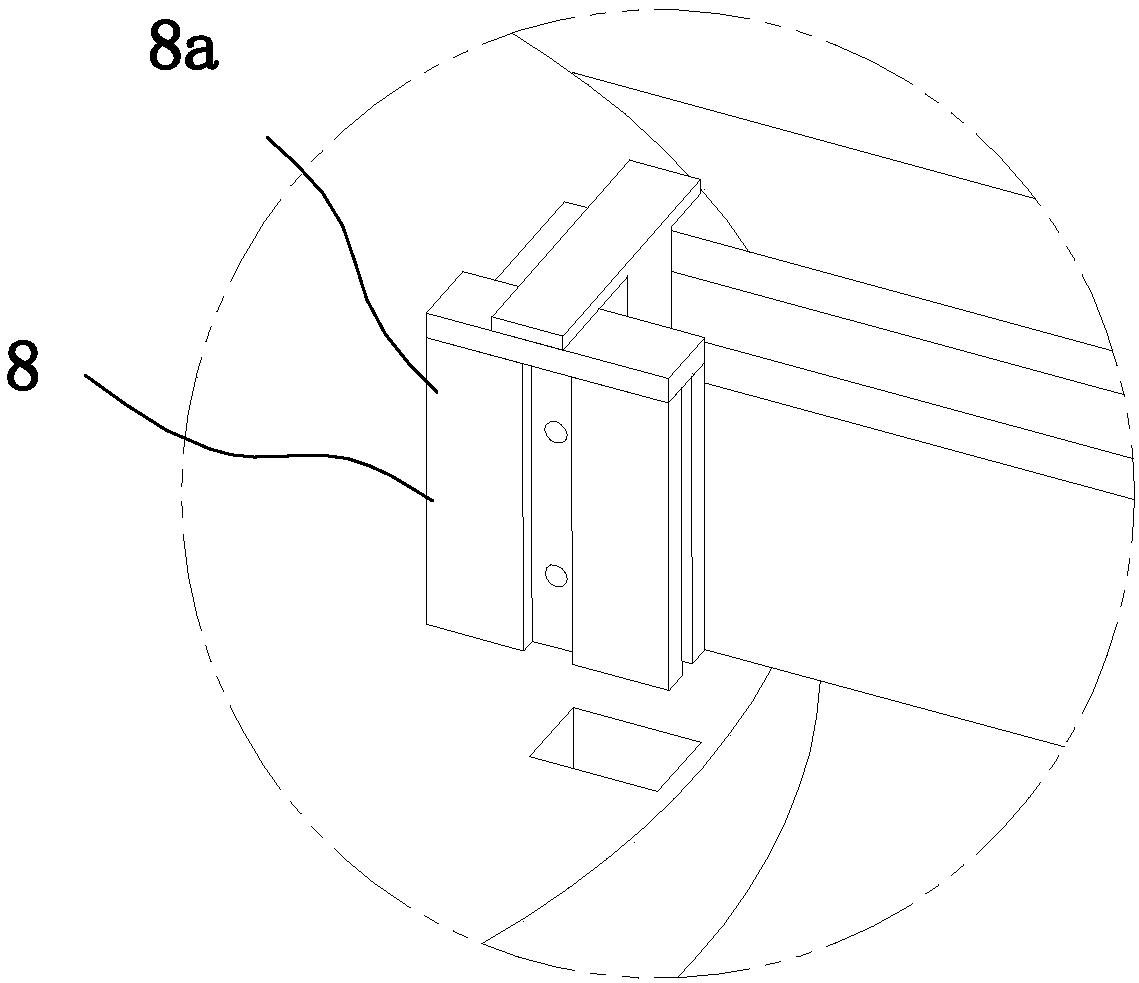

Positioning transferring device and technology for lighter automatic stacking machine

ActiveCN108146678AIngenious process designThe process is simple and reliableIndividual articlesStack machineEngineering

The invention relates to the field of lighter production, in particular to a positioning transferring device for a lighter automatic stacking machine. The positioning transferring device is arranged on a bearing platform and comprises a supporting assembly, a translation assembly, a lifting assembly and a gas clamp. The translation assembly is located on the upper section of the supporting assembly and slidably matched with the supporting assembly, and the lifting assembly is located by the side of the translation assembly and fixedly connected with the translation assembly. The gas clamp is located under the lifting assembly and fixedly connected with the lifting assembly. The positioning transferring device further comprises a positioning piece located at the top of the bearing platform,and the positioning piece comprises a positioning jig, a pushing piece, a positioning block and a second conveyor belt for conveying the positioning jig. The positioning jig is located on the secondconveyor belt, and the pushing piece is located by the side of the output end of the second conveyor belt. The positioning block is located in front of the output end of the second conveyor belt. According to the positioning transferring device, lighters are transferred into inserting grooves of the positioning jig one by one through the gas clamp, the accuracy rate reaches 99.9% or above, the technology is simple and reliable, and the efficiency is 8-10 times or above of the manual efficiency.

Owner:邵东县莲花打火机制造有限公司

Automatic balance steel dispensing assembly process for lipstick cartridge

InactiveCN111173817APrevent coagulationFirmly connectedLiquid surface applicatorsMaterial gluingProcess engineeringIndustrial engineering

The invention relates to the field of lipstick tube production processes, in particular to an automatic balance steel dispensing assembly process for a lipstick cartridge. The process comprises the following steps of 1, automatic feeding of a sleeve; 2, automatic dispensing in the sleeve; 3, automatic feeding of the balance steel; 4, pressing the balance steel; 5, automatically assembling a cup; 6, automatic and spiral assembling between a collar and the sleeve; and 7, automatic discharging. The process is ingenious in design and high in automation level, so that manual labor is reduced, and production efficiency is improved.

Owner:赖星

Automatic cleaning technology for biopharmacy test tubes

InactiveCN111545542ACreate pollutionInto the test tubeHollow article cleaningFlexible article cleaningProcess engineeringIndustrial engineering

The invention discloses an automatic cleaning technology for biopharmacy test tubes, and relates to the technical field of biopharmacy. The automatic cleaning technology comprises the following stepsthat firstly, the to-be-cleaned test tubes are clamped and limited; secondly, the interiors of the test tubes are automatically cleaned; thirdly, the test tubes with the interiors cleaned rotate by 180 degrees; fourthly, the exteriors of the test tubes are automatically cleaned; and fifthly, the cleaned test tubes are dried. The technology design is ingenious, procedure linkage is smooth, large-batch automatic test tube cleaning can be achieved, the test tube cleaning efficiency is improved by 10-15 times or above, the time spent on cleaning by research personnel is greatly shortened, and thework efficiency is improved.

Owner:黄波

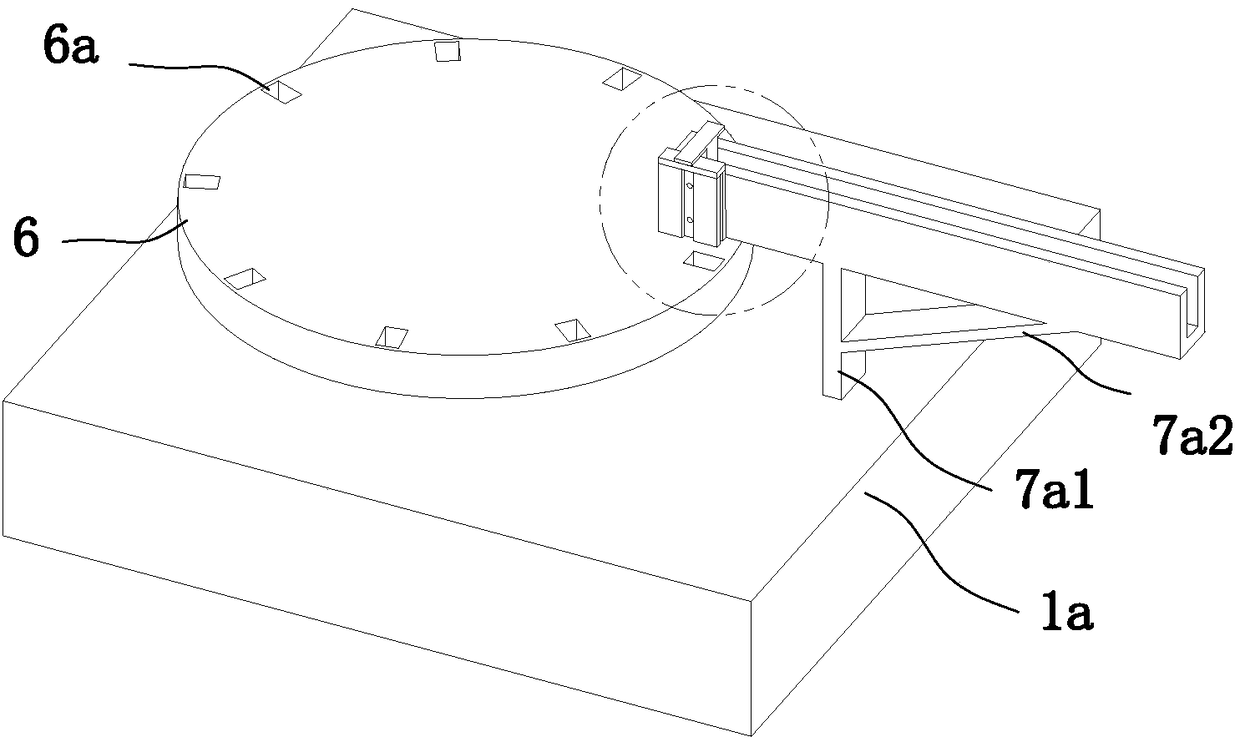

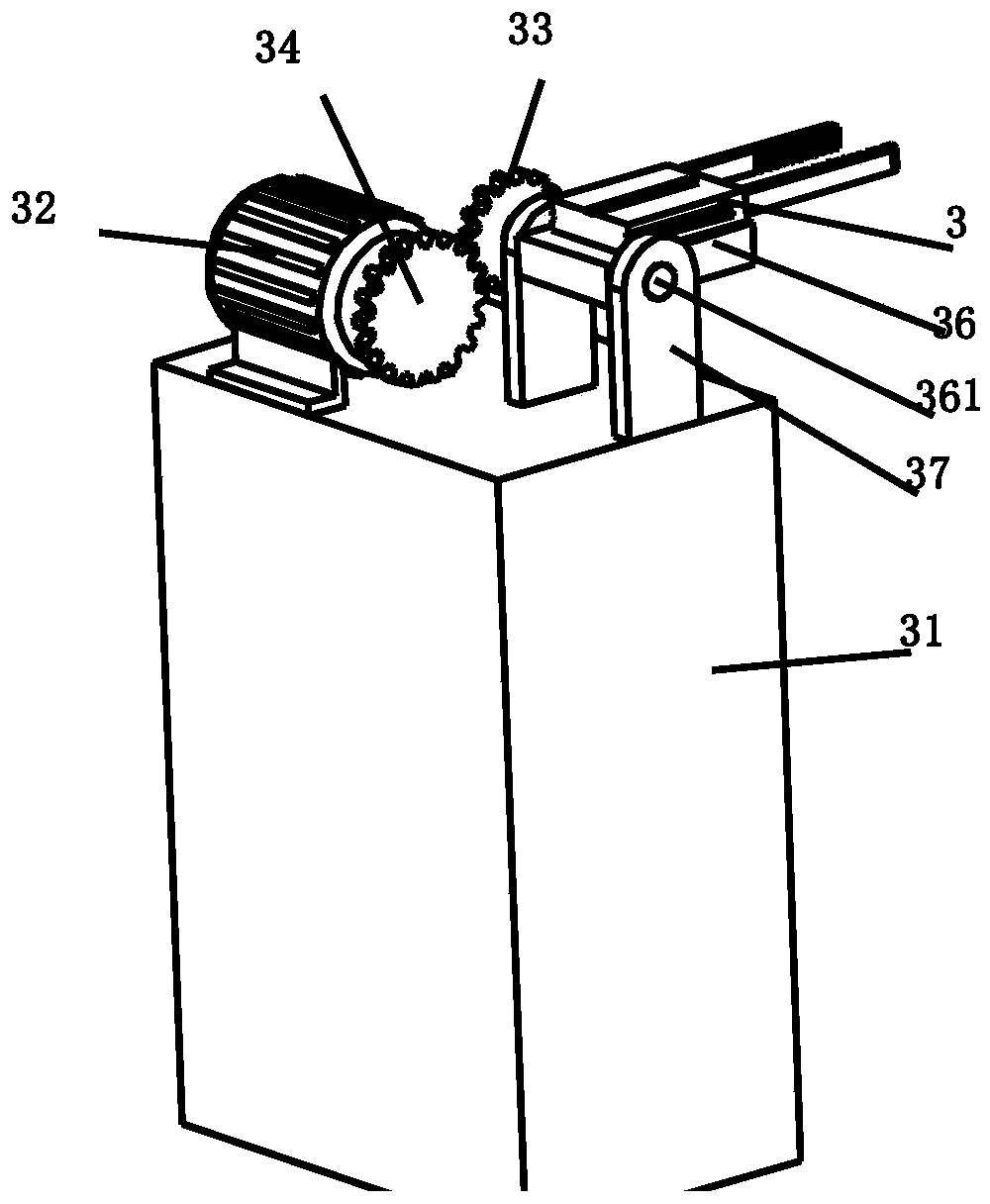

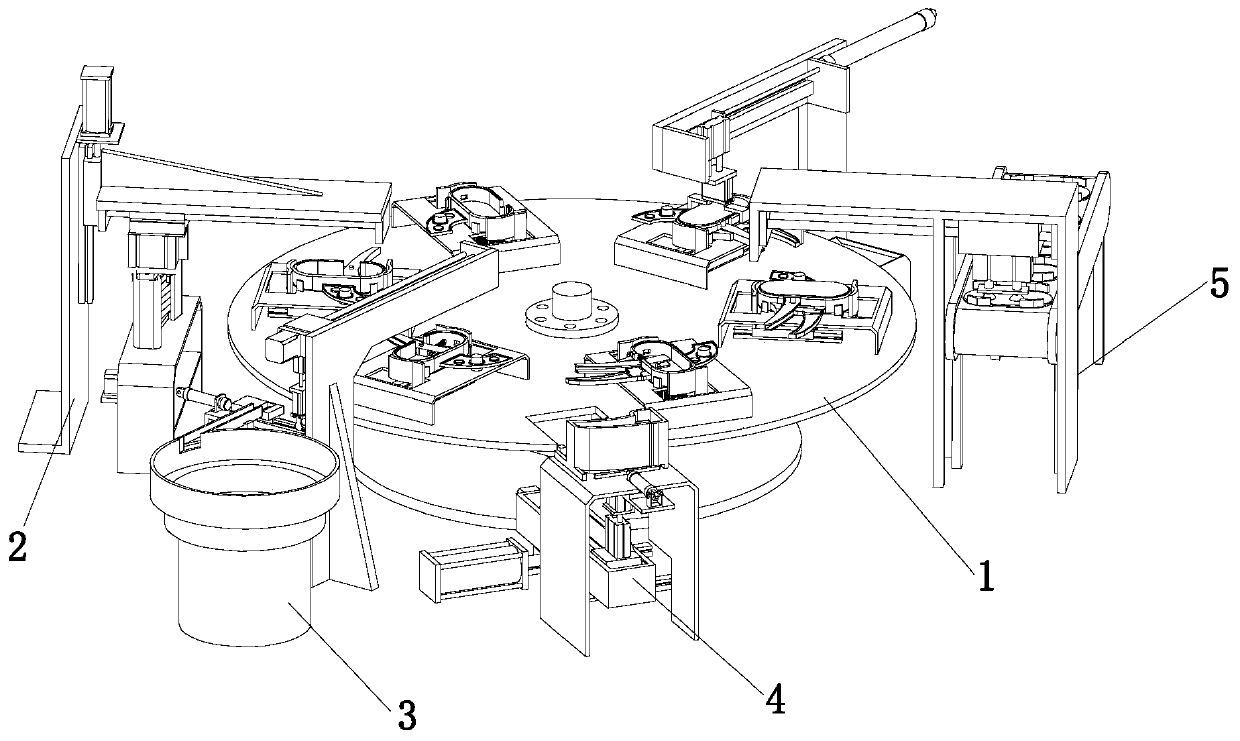

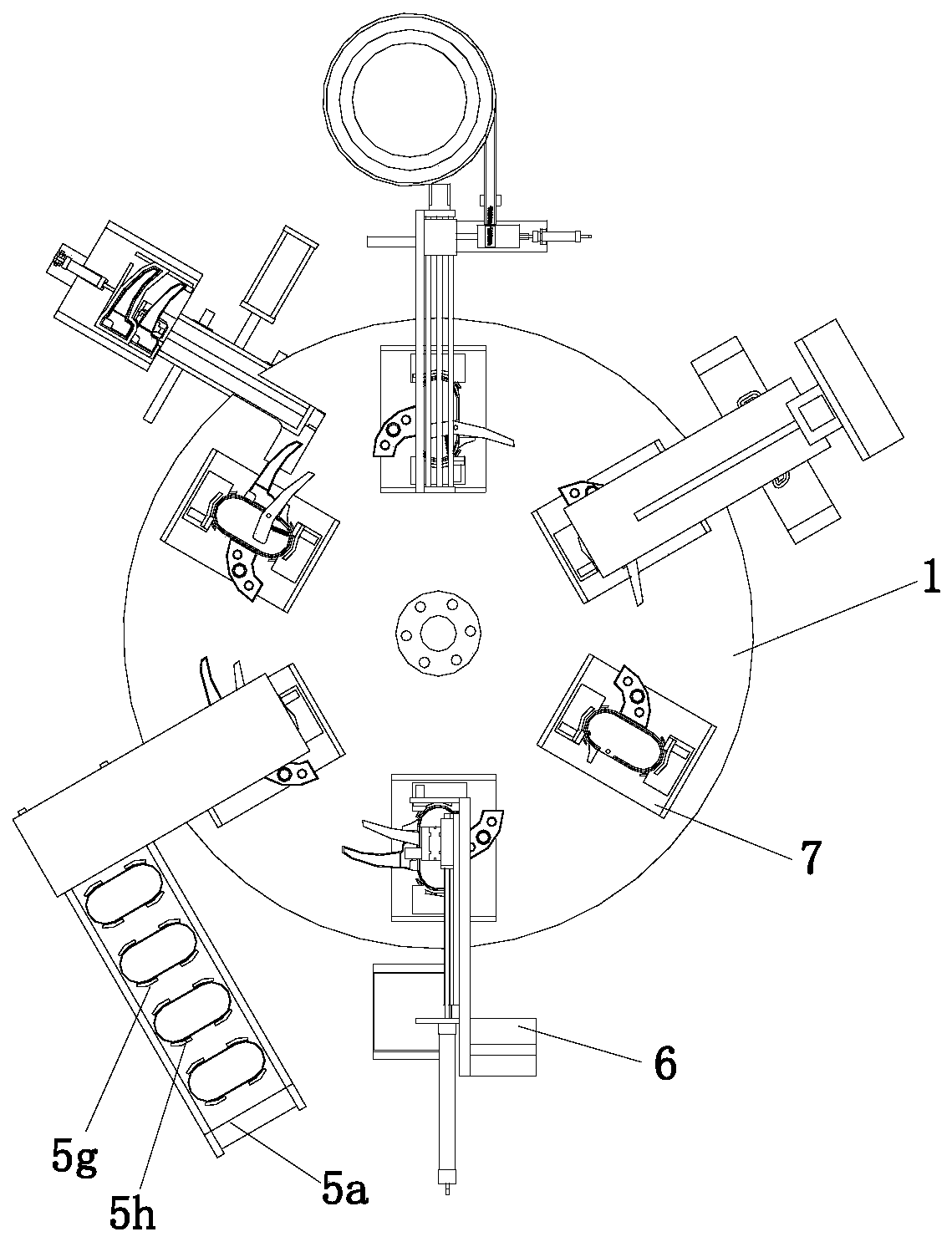

Fast lead automatic production process

ActiveCN110480278AQuick and automatic transport awayRapid automated productionOther angling devicesMetal working apparatusFishingMechanical engineering

The invention discloses a fast lead automatic production process and belongs to the technical field of fishing equipment. The fast lead automatic production process includes the following steps that firstly, a lead leather base is automatically fed; secondly, the surface of the lead leather base is roughened, specifically, a rotating disk rotates to a lead leather base roughening station, a lead leather base roughening device is used for performing roughening operation on the lead leather base on a material rolling device, so that the surface of the lead leather base is roughened, and the combining force between lead leather and the lead leather base is improved; thirdly, the lead leather is fed, rolled and cut, specifically, the rotating disk rotates to a lead leather feeding station anda material rolling station, and the lead leather is automatically wound, cut and pulled through cooperation of a lead leather feeding device and the material rolling device; fourthly, fast lead wherethe lead leather is wound is chamfered, specifically, the rotating disk rotates to a grinding station, and due to cooperation of a grinding device and the material rolling device, the upper and lowerends of the fast lead after the lead leather is wound are subjected to chamfering operation; and fifthly, automatic discharging is performed. The process is ingenious in design, connection between themechanisms is smooth, and compared with the process for making fast lead manually, the efficiency is improved by ten times or above.

Owner:威海怡隆渔具有限公司

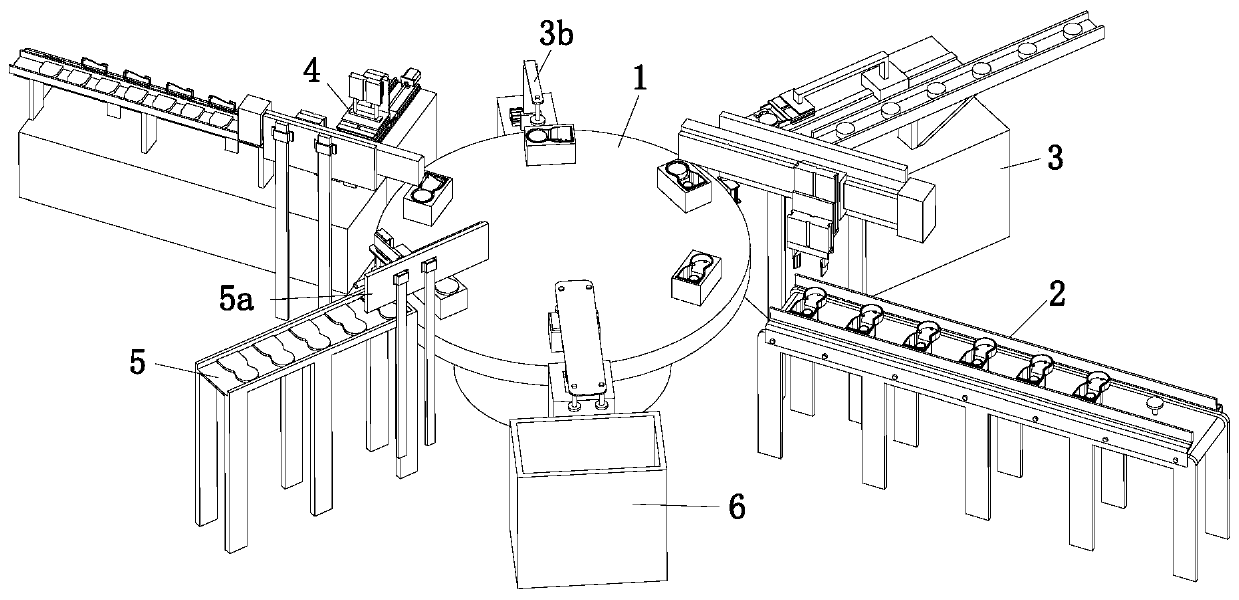

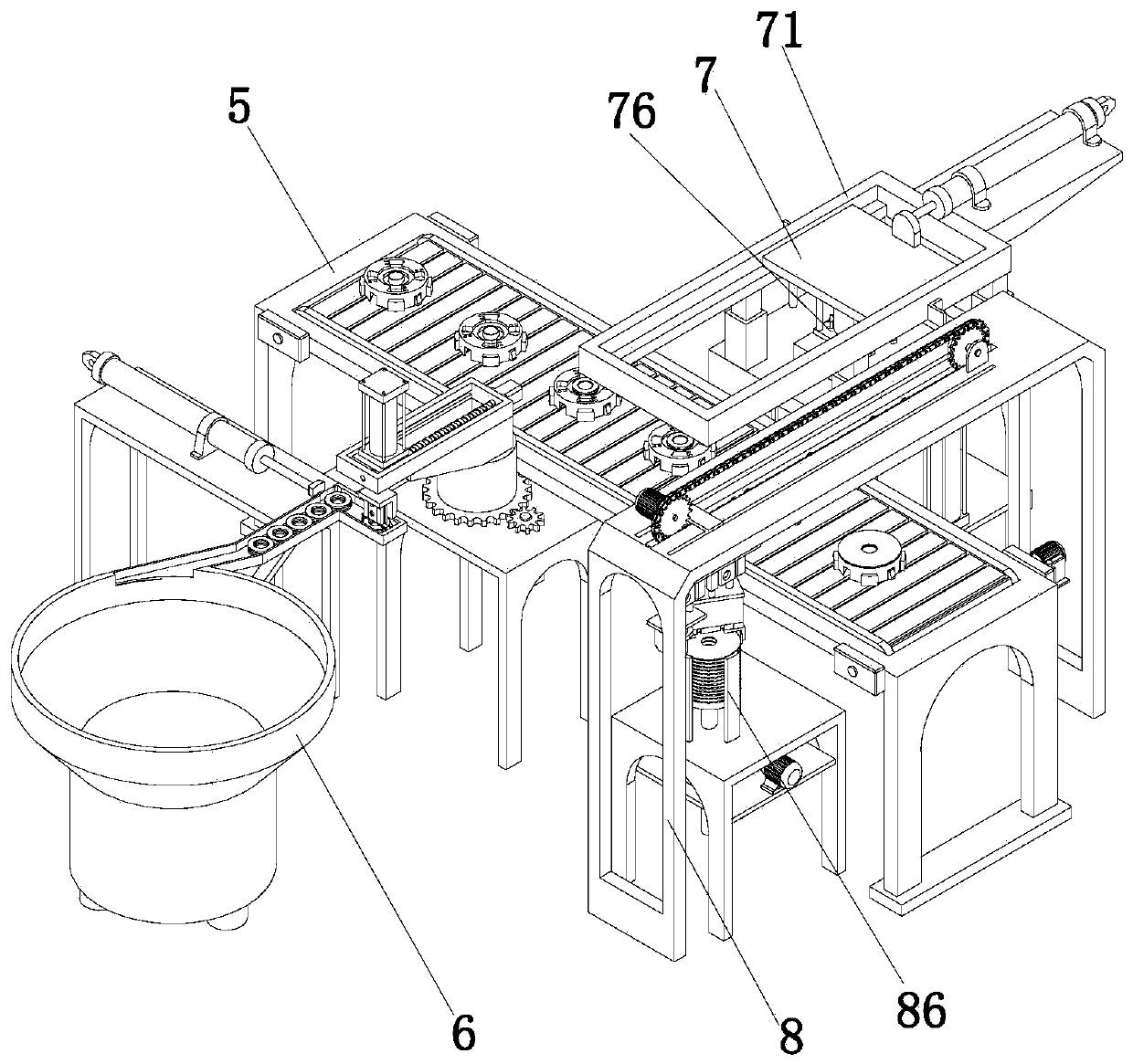

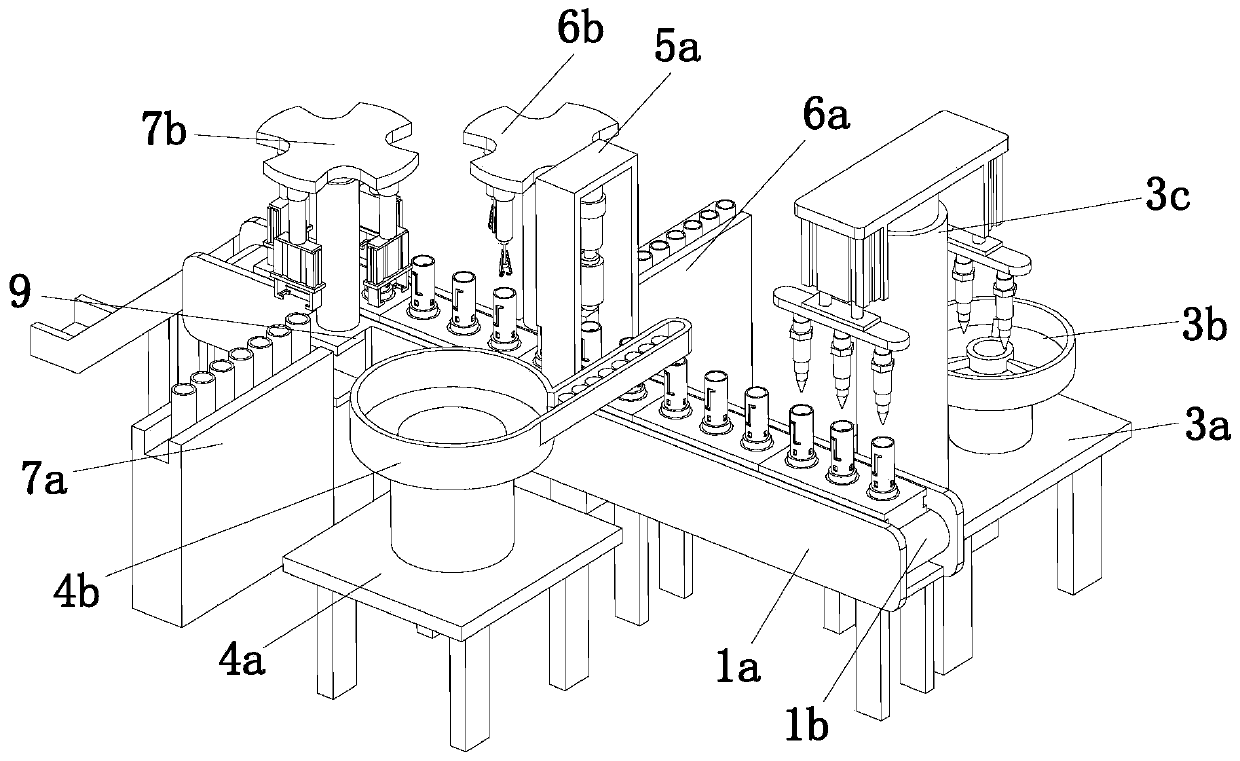

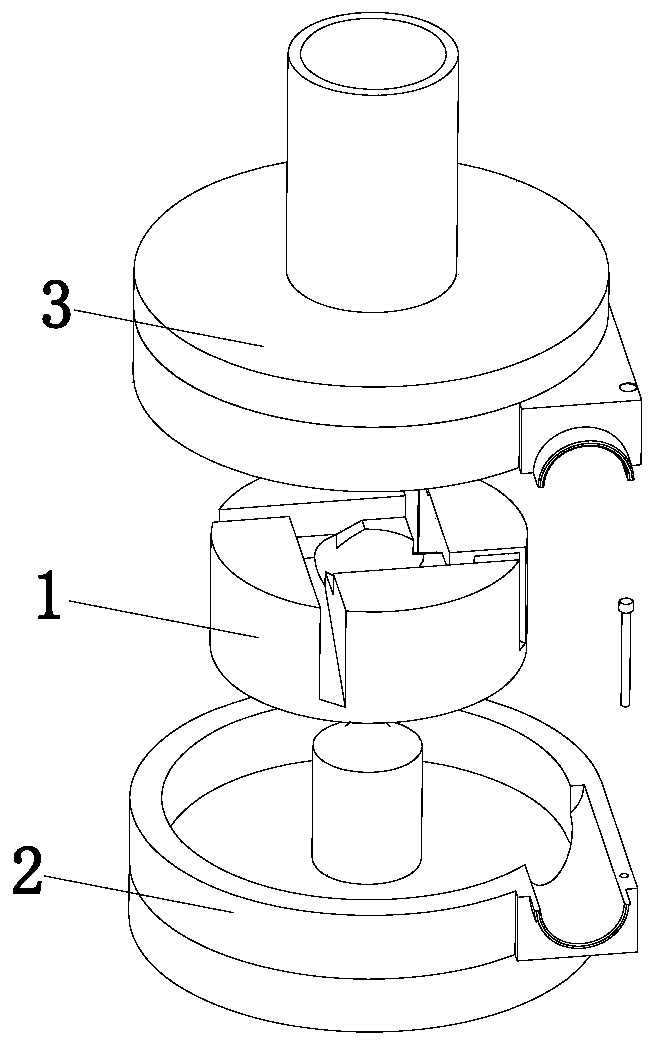

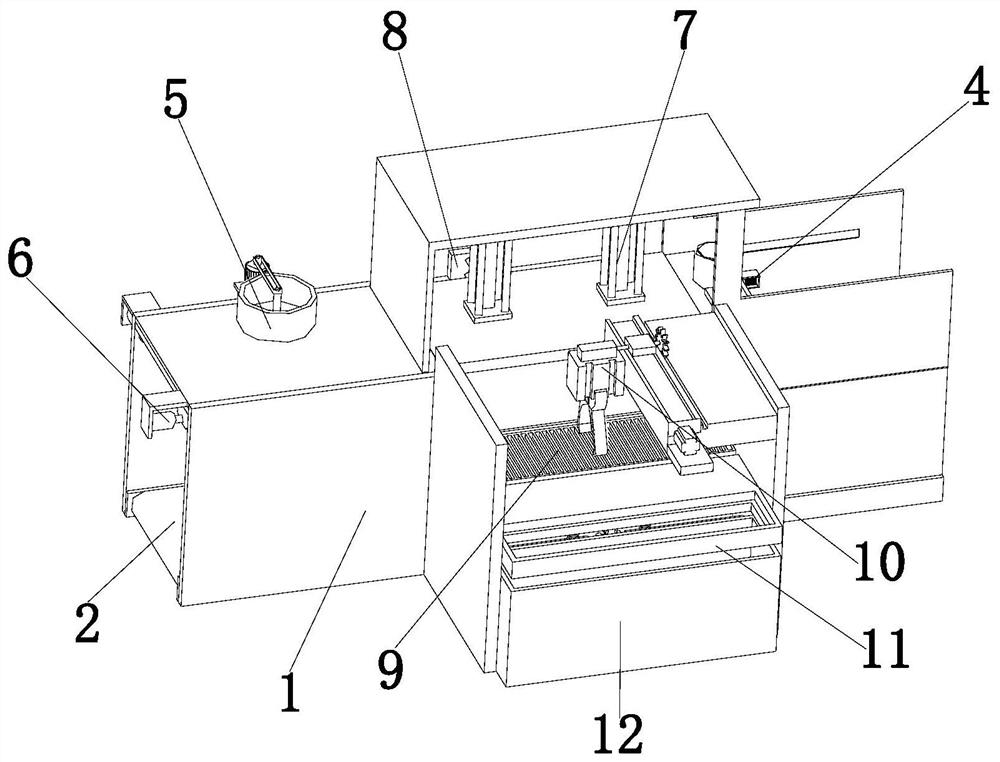

Automatic production process of magnetic suspension artificial heart or blood pump

ActiveCN111318878AIncrease productivityRealize automated assemblyBlood pumpsAssembly machinesArtificial heartBlood pump

The invention discloses an automatic production process of a magnetic suspension artificial heart or blood pump, and relates to the technical field of production of blood pumps for cardiovascular medicine departments. The automatic production process comprises the following steps of 1, feeding and positioning a lower shell; 2, assembling a central shell into the lower shell; 3, automatically assembling a blood pump rotor; 4, assembling the blood pump rotor into the lower shell; 5, assembling an upper shell on the lower shell; and 6, automatic carrying. According to the automatic production process of the magnetic suspension artificial heart or blood pump, automatic production of the magnetic suspension artificial heart or blood pump is achieved, the process steps are smoothly linked, the process design is ingenious, compared with manual production of the magnetic suspension artificial heart or blood pump, the efficiency is improved by 8-10 times, and one person can take charge of 2-3 production lines so that 80% or above of labor can be saved, the yield is high, and the good economic value is achieved.

Owner:ZHEJIANG ZHONGZAI MEDICAL TECH CO LTD

Application method of phytase in feed

InactiveCN106333084AReduced Phytase RequirementsImprove production performanceAccessory food factorsNutrientChemistry

The invention discloses an application method of phytase in feed. The application method includes the steps that prepared liquid phytase is sprayed on bentonite in the mass ratio of 1:(8-15), enzyme-containing bentonite is prepared, the enzyme-containing bentonite and particle feed are evenly stirred during feeding, and the mass ratio of stirred materials is 1:(9,800-10,500); in the particle feed, the using amount of inorganic phosphorus accounts for 35% to 40% of the original using amount. According to the application method, the requirements of high-temperature prilling for the phytase are reduced, the special extracting process of enzymes is not required, collection of the enzymes at the normal temperature can also be guaranteed, the using ratio of phytate phosphorus in pig feed is increased by 20% to 40%, and the using ratio of phytate phosphorus in poultry feed is increased by 31% to 58%; mineral elements and nutrient substances combined with phytic acid are released, the production performance of poultry is improved, and the quality of egg poultry shells is improved; the discharging amount of phosphorus in animal faces is decreased, and environment pollution is reduced; insufficient phosphorus supplying is relieved; the addition amount of the phosphorus-containing feed is saved, and the feed cost is reduced.

Owner:彭程

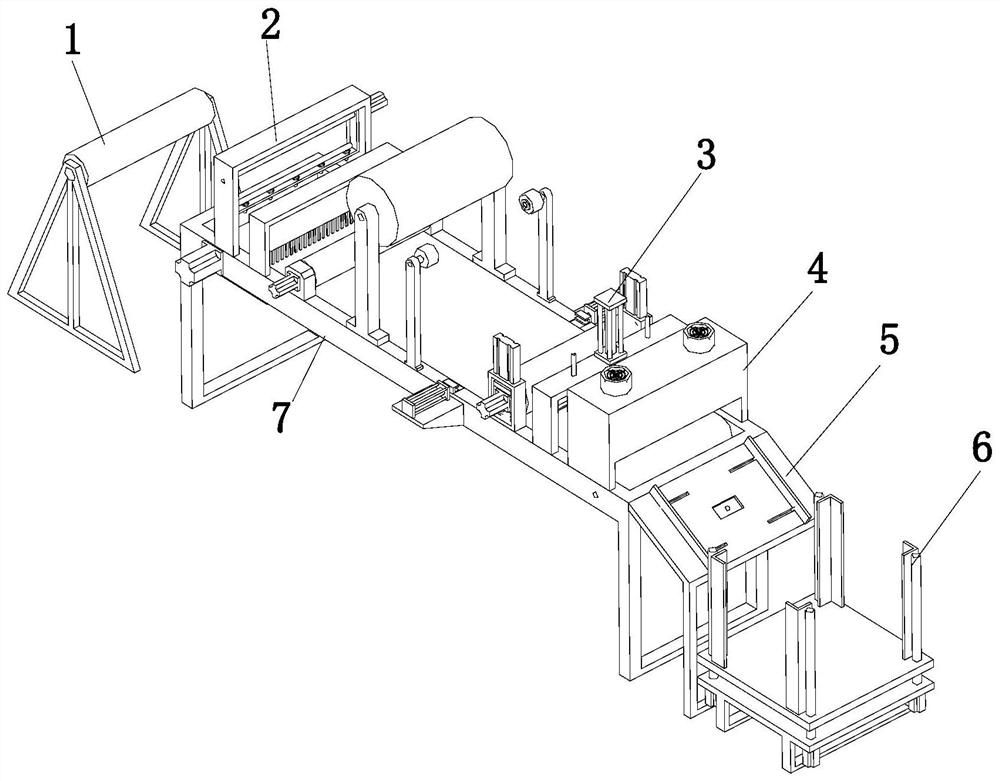

Automatic gold paper production line and process

InactiveCN111776825AHigh precisionImprove work efficiencyLiquid surface applicatorsSpraying apparatusProduction linePaper production

The invention discloses an automatic gold paper production line, and belongs to the technical field of gold paper production devices. The automatic gold paper production line comprises a conveying device, a feeding device, a gold paper attaching and edge covering device, a gold paper cutting device, a gold paper drying device, a gold paper counting device and a gold paper discharging device, wherein the conveying device is vertically arranged, the feeding device is arranged on the side of the conveying device, the gold paper attaching and edge covering device is arranged at the top of the conveying device, the gold paper cutting device is arranged at the top of the conveying device, the gold paper drying device is arranged at the top of the conveying device, the gold paper counting deviceis arranged beside the conveying device, and the gold paper discharging device is located beside the gold paper counting device. According to the gold paper production line, the conveying device, thefeeding device, the gold paper attaching and edge covering device, the gold paper cutting device, the gold paper drying device, the gold paper counting device and the gold paper discharging device arearranged, through mutual cooperation of all the devices, gold paper can be automatically produced, and the working efficiency and the gold paper processing accuracy are improved.

Owner:赖华文

Automatic production process for piano hand corrector

InactiveCN110744301ALabor savingFully automaticAssembly machinesMetal working apparatusPhysicsMechanical engineering

The invention relates to the field of production equipment for piano accessories, in particular to an automatic production process for a piano hand corrector. The automatic production process for a piano hand corrector comprises the following steps that 1, a movable clamping plate and a pressure spring are installed in a fixed jacket; 2, a fixed clamping plate is clamped on the side wall of the fixed jacket; 3, a cover plate is clamped at the top of the fixed jacket; and 4, automatic discharging is conducted. The automatic production process has the beneficial effects that the movable clampingplate and the pressure spring can be assembled on the fixed jacket separately through a movable clamping plate mechanism and a pressure spring installation mechanism, the cover plate and the fixed clamping plate can be automatically clamped on the fixed jacket through a fixed clamping plate installation mechanism and a cover plate clamping mechanism, and the fixed jacket can be automatically limited through a fixed jacket limiting mechanism, so that the labor intensity of workers is relieved; and the process design is ingenious, all procedures are sequentially conducted smoothly, the production efficiency of the piano hand corrector can be effectively improved, the automation degree is high, labor can be saved by 70% or over, and remarkable economic benefits are achieved.

Owner:李月娇

Automatic production technology of magnetic-fluid suspension type centrifugal blood pump

InactiveCN111283404AIncrease productivityHigh outputAssembly machinesMetal working apparatusBlood pumpProcess engineering

The invention discloses an automatic production technology of a magnetic-fluid suspension type centrifugal blood pump, and belongs to the technical field of blood pump production processes. The automatic production technology comprises the following steps that 1, feeding and positioning of a lower shell assembly are carried out; 2, an impeller assembly and the lower shell assembly are assembled; and 3, an upper shell assembly and the lower shell assembly are assembled, and automatic discharging is carried out. The technology is ingenious in design, the efficiency is improved by 8-10 times compared with that of manual magnetic-fluid suspension type centrifugal blood pump production, one person can be responsible for 2-3 production lines, over 80% of labor can be saved, the yield is high, and the economic value is good.

Owner:钟文奇

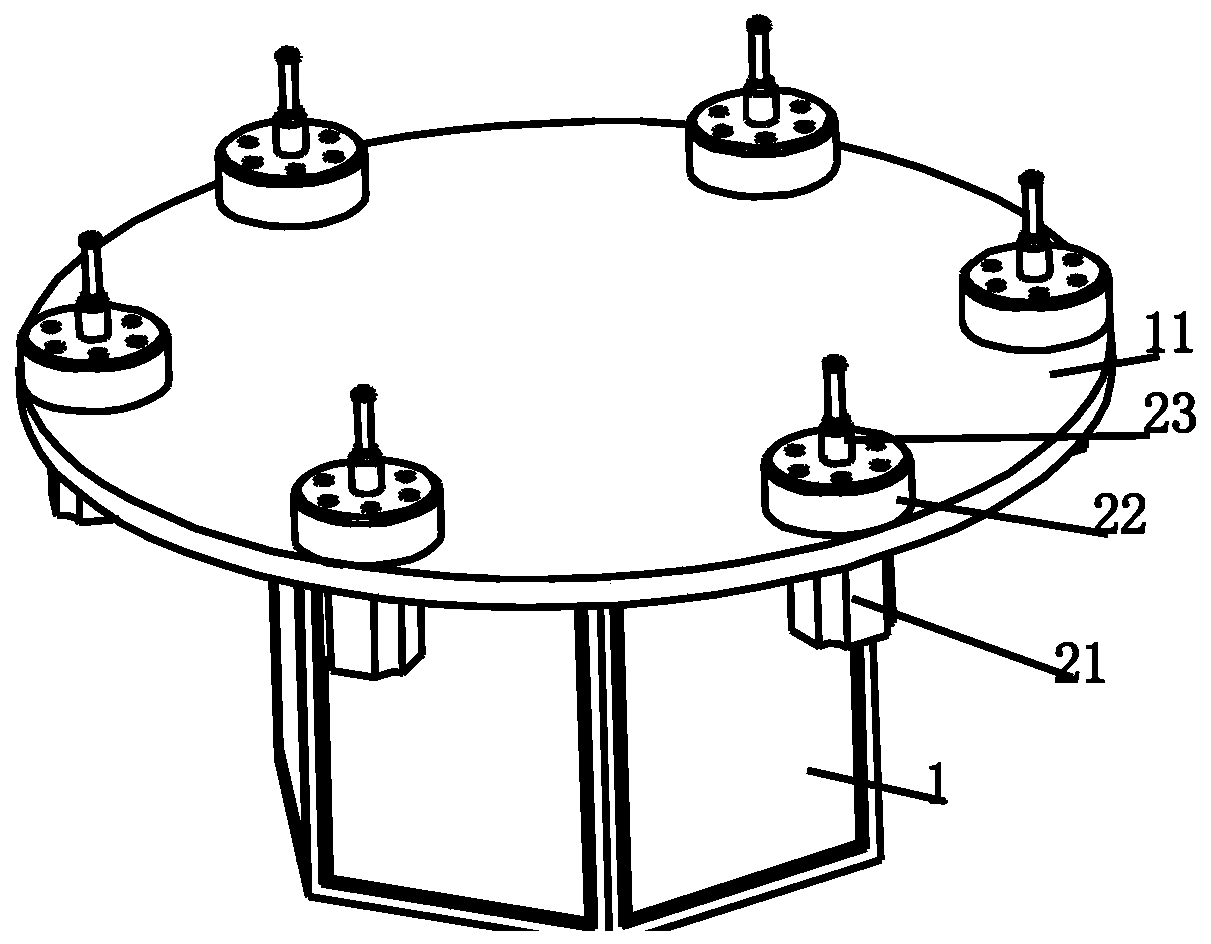

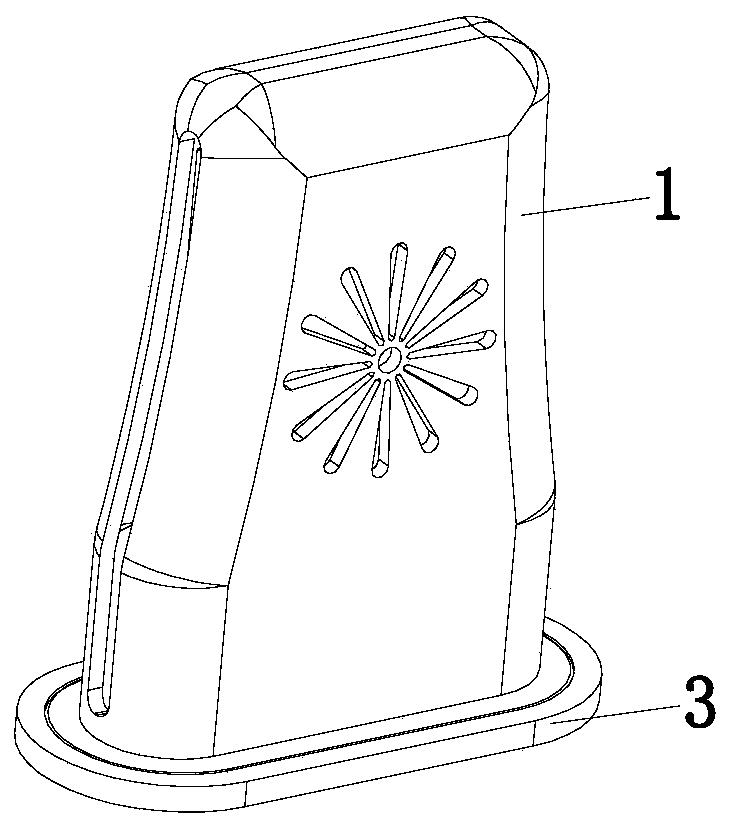

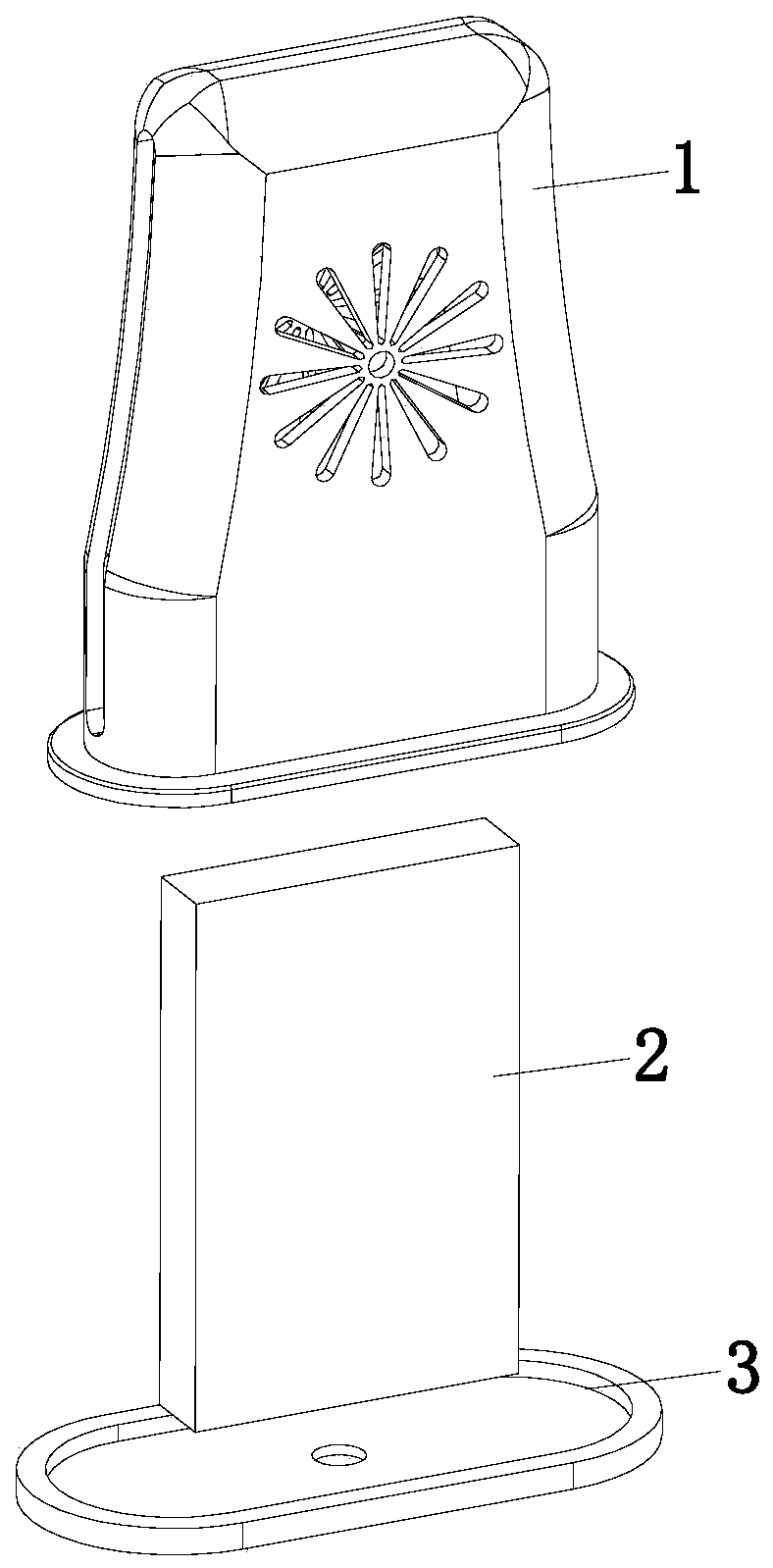

Automatic assembling mechanism for guitar humidifier and assembling technology thereof

ActiveCN110253287AImplement automatic assemblyReduce the amount of manual laborLiquid surface applicatorsAssembly machinesMechanical engineeringGuitar

The invention relates to the field of mechanism production, and specifically relates to an automatic assembling mechanism for a guitar humidifier. The mechanism comprises a rotating mechanism, a housing feeding mechanism, a sponge assembling mechanism, a gluing mechanism and a bottom cover assembling mechanism, wherein the housing feeding mechanism, the sponge assembling mechanism, the gluing mechanism and the bottom cover assembling mechanism are circumferentially distributed beside the rotating mechanism; the housing feeding mechanism comprises a feeding assembly, a limiting assembly, a driving assembly and a transferring assembly; the transferring assembly is positioned between the feeding assembly and the rotating assembly; the limiting assembly is mounted at the tail end of the feeding assembly; the driving assembly is mounted at the lower part of the transferring assembly; and the sponge assembling mechanism consisting of a sponge feeding assembly and a sponge assembling assembly is positioned between the sponge feeding assembly and the rotating mechanism. The mechanism has the beneficial effects that the guitar humidifier is automatically assembled, so that the labor workload is decreased; the production speed is increased; the production cost is decreased; and the damage of excessive volatilization of glue to workers can be avoided.

Owner:郭一帆

Automatic production process of refractory ceramic plate

ActiveCN111975941ARealize automatic riseReduce labor intensityDischarging arrangementFeeding arrangmentsEconomic benefitsIndustrial engineering

The invention discloses an automatic production process of a refractory ceramic plate, and belongs to the technical field of ceramic plate production. The automatic production process comprises the following steps that 1, a formwork is automatically lifted; 2, a releasing agent is automatically bushed on the surface of the formwork; 3, a powder blank is automatically fed; 4, the powder blank is automatically smoothened; 5, the powder blank is molded into the refractory ceramic plate; 6, the refractory ceramic plate is dried and shaped; 7, the refractory ceramic plate is clamped and placed on ademoulding device; and 8, the refractory ceramic plate is automatically demoulded and discharged. According to the automatic production process, the design is ingenious, the process connection is smooth, the degree of automatic is high, the labor can be saved by more than 50%, the labor intensity of workers is greatly reduced, the production efficiency is improved by 8-10 times, and significant economic benefits are achieved.

Owner:淄博龙程耐火材料有限公司

Aluminum heating element with aluminum nitride film, preparation method and heating device

InactiveCN106756758AImprove heating effectImprove thermal conductivityLighting and heating apparatusElectric heating systemHeat conductingNitrogen atmosphere

The invention relates to an aluminum heating element with an aluminum nitride film. The aluminum heating element comprises an aluminum substrate, wherein the aluminum nitride film covers the surface of the aluminum substrate. The invention further relates to a preparation method of the aluminum heating element with the aluminum nitride film. According to the method, one electrode of a pulsed power supply is connected with the aluminum substrate, and the other electrode is connected with an aluminum tool electrode; the pulsed power supply is started, and the tool electrode is moved above the aluminum substrate in a nitrogen atmosphere, so that the aluminum nitride film is formed on the surface of the aluminum substrate. According to the heating element provided by the invention, the aluminum nitride film is formed on the surface of the aluminum substrate, so that aluminum is prevented from being oxidized into aluminum oxide, the heat conducting property of the formed aluminum heating element cannot be reduced due to the aluminum oxide formed on the surface, and fast heat transfer can be realized, thereby improving the heat transfer efficiency; the production process of the heating element provided by the invention has the advantages of simplicity and low cost. The heating element provided by the invention can be applied to a heating device and has great market application values especially on a balance type heater.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

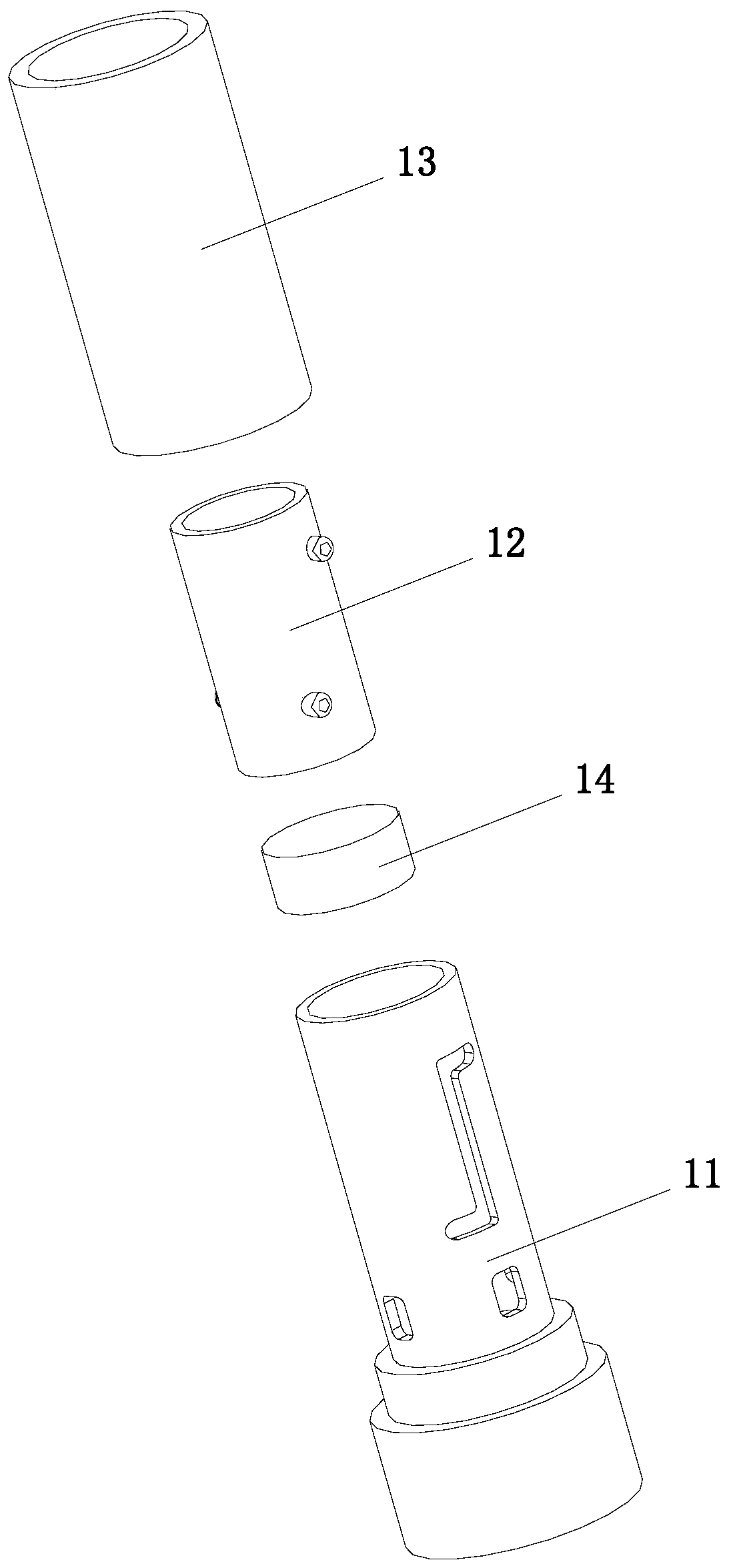

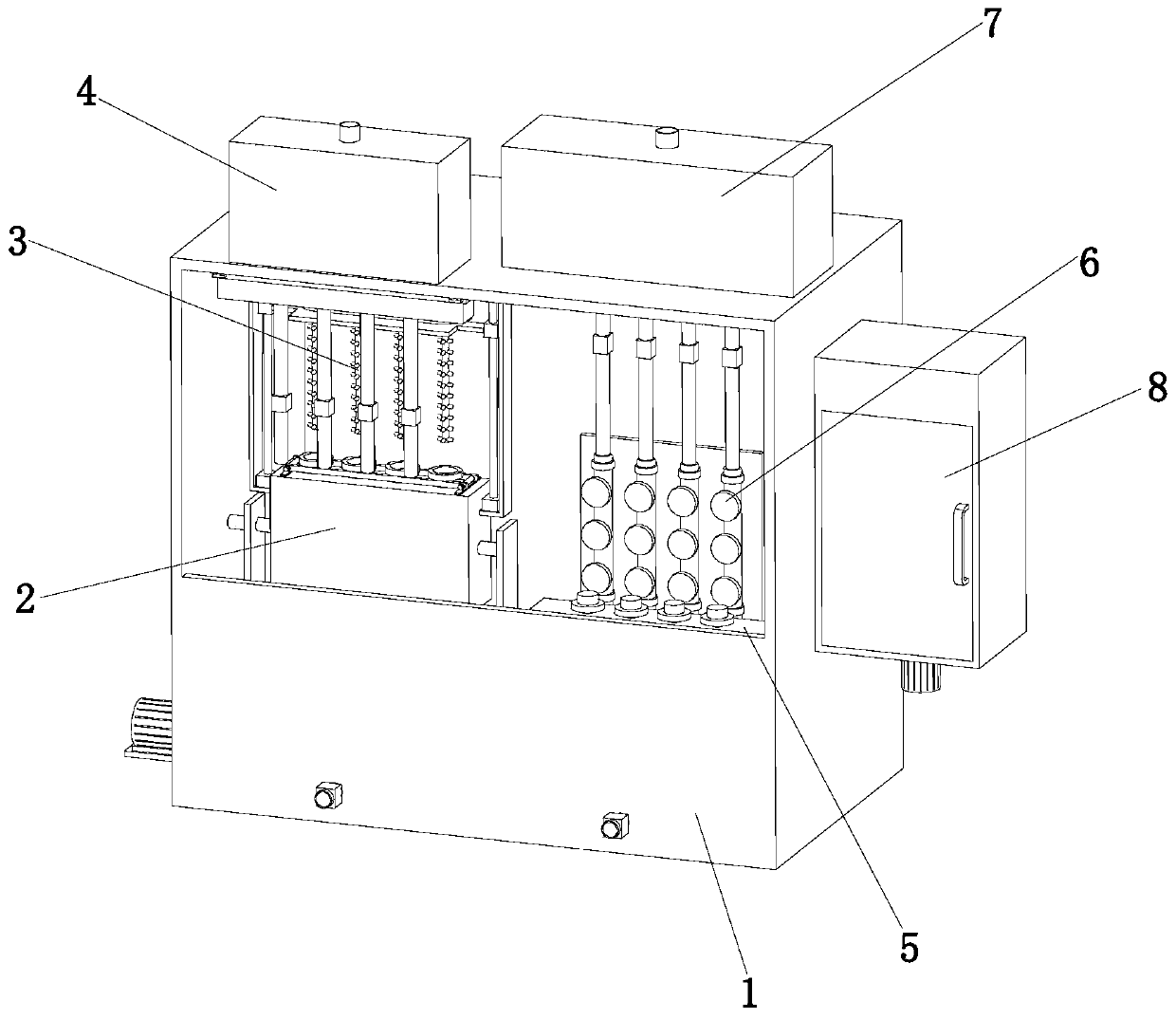

Automatic production process of root canal file

InactiveCN112044685ARealize the assemblyIngenious process designLiquid surface applicatorsColor measuring devicesEngineeringProcess engineering

The invention discloses an automatic production process of a root canal file, and belongs to the field of production processes of medical instruments in the department of stomatology. The automatic production process comprises the following steps: 1, transporting a file head and a file handle to the lower part of a lower pressing plate; 2, sleeving the file head with a rubber sleeve; 3, gluing inthe file handle; 4, assembling the file head and the glued file handle to obtain the root canal file; 5, automatically spraying paint on the file handle; 6, detecting the color and model of the root canal file; and 7, detecting the taper and the diameter of the file head of the root canal file. The automatic production process is ingenious in process design and smooth in procedure connection, assembling of the file head, the file handle and the rubber sleeve is achieved, automatic feeding and discharging steps of products are achieved, paint spraying can be conducted on the file handle of theroot canal file, color detection and taper and diameter detection can be conducted after paint spraying is conducted, the automation degree is high, labor can be saved, efficiency can be improved, andthe product yield is improved.

Owner:李汝华

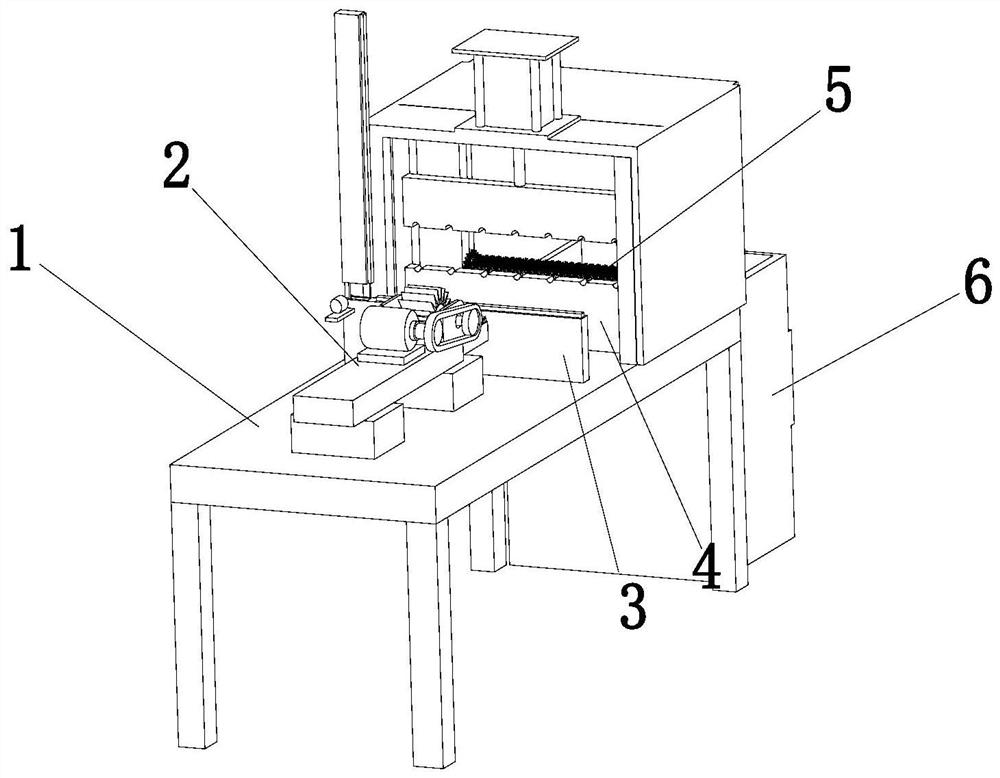

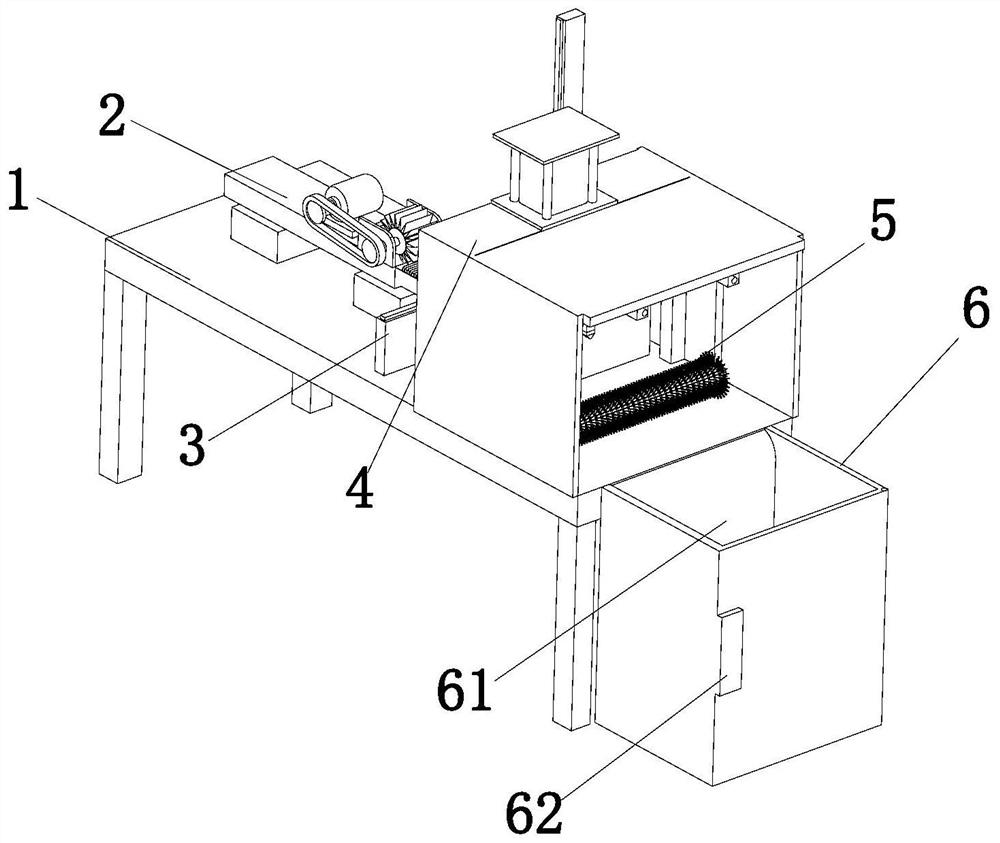

Process for automatic removal of rose thorns

InactiveCN111670714AImprove removal efficiencyReduce labor intensityCleaning using toolsThorn removersProcess engineeringRose flower

The invention relates to the technical field of rose processing technologies, in particular to a process for automatic removal of rose thorns. The process includes the following steps: Step 1, loadingand fixing the roses which need thorn removal; Step 2, performing automatic thorn removal on the roses; Step 3, cleaning the thorns of the roses automatically; and Step 4, taking out the thorn-removed roses. The process has ingenious design, smooth connection is formed among mechanism, the daily production capacity of a machine is equivalent to the production capacity of 6-8 persons, the efficiency is improved greatly, and significant economic values can be obtained.

Owner:赖梅凤

Automatic buoy production process

InactiveCN112493216AIncrease productivityAchieve installationOther angling devicesFiberProcess engineering

The invention discloses an automatic buoy production process, and belongs to the field of buoy processing. The process comprises the following steps that 1, a workpiece is automatically fed and clamped; 2, the workpiece is automatically drilled; 3, fibers are installed in holes of the workpiece; 4, the workpiece with the fibers penetrating through is placed in a workpiece moving assembly; 5, the workpiece is ground into an ellipsoid; 6, paint of different colors is automatically dispensed on the workpiece; and 7, the machined workpiece is automatically discharged. The automatic buoy productionprocess is ingenious in process design and smooth in procedure connection, full-automatic buoy production is achieved, one person can be responsible for one machine, the labor is saved, the production efficiency is greatly improved, and the automatic buoy production process has remarkable economic value.

Owner:谢旻珍

Laminating and edge covering device and process for automatic gold paper production line

InactiveCN111634104AAvoid glue overflowAffect qualityMechanical working/deformationLamination ancillary operationsPaper productionElectric machinery

The invention discloses a laminating and edge covering device of an automatic gold paper production line, and belongs to the technical field of gold paper laminating and edge covering devices. The device comprises a conveying device and a gold paper laminating and edge covering device, wherein the gold paper laminating and edge covering device comprises a paste spraying assembly, a smearing assembly, a tin foil paper attaching and covering assembly, gold paper edge covering assemblies and an attaching assembly, the paste spraying assembly is arranged at the top of the conveying device, the smearing assembly is arranged at the top of the conveying device and located beside the paste spraying assembly, the tin foil paper attaching assembly is arranged at the top of the conveying device, thegold paper edge covering assemblies are symmetrically arranged on the conveying device and located beside the tin foil paper attaching assembly, and the attaching assembly is arranged at the top of the conveying device and located beside the tin foil paper edge covering assemblies. According to the invention, the laminating motor works to drive the laminating roller to rotate on the two moving blocks, and the tin foil paper and the covered edges are tightly laminated to yellow paper, so that the situation that gold paper overflows, is damaged and wrinkles in the machining process, and consequently the subsequent use quality of the gold paper is affected is prevented.

Owner:赖华文

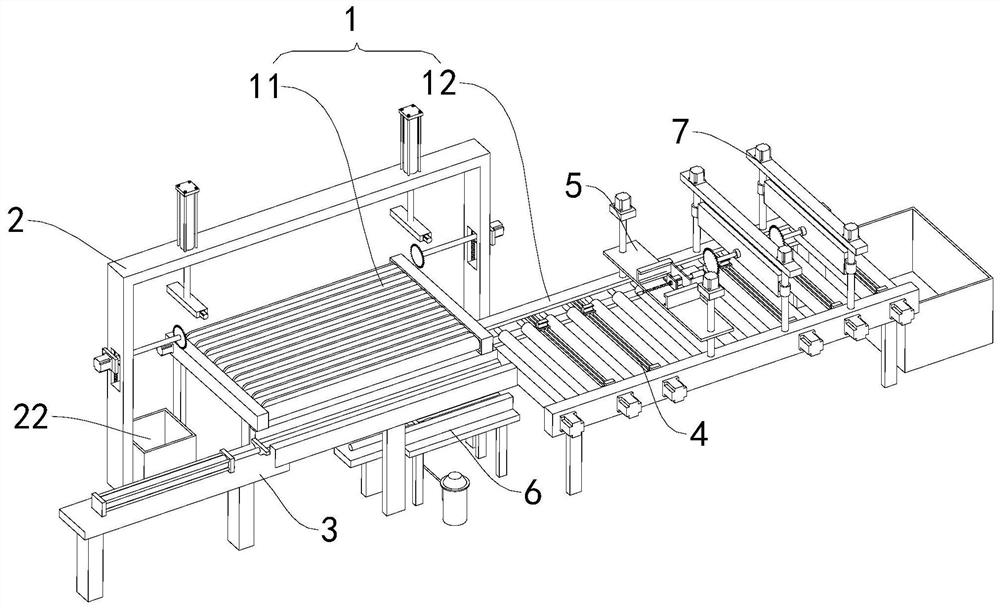

Automatic polishing fluff-removing process for inner walls of reed straws

InactiveCN112123187ARealize automatic feeding processIngenious process designPolishing machinesCane mechanical workingProcess engineeringManufacturing line

The invention relates to the technical field of reed straws, and discloses an automatic polishing fluff-removing process for the inner walls of reed straws. The automatic polishing fluff-removing process comprises the following steps: 1, automatically feeding reeds; 2, cutting the reeds to be consistent in size; 3, clamping and fixing the cut reeds through fixing assemblies; 4, automatically polishing the inner walls of the reeds; 5, absorbing and loading fluff in the reeds; 6, segmenting the polished reeds; and 7, carrying out automatic discharging and bagging on the reed straws; According tothe automatic polishing fluff-removing process, the process design is ingenious, the procedure connection is smooth, the fluff in the reeds can be collected, the fluff is prevented from falling ontoequipment and influencing the operation environment, the automation degree is high, one person can be responsible for one production line, the production efficiency is 5-8 times that of manual work, the productivity is greatly improved, and remarkable economic value is achieved.

Owner:曾德伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com