Full-wet recovery process of waste lithium batteries

A waste lithium battery, all-wet technology, applied in the direction of battery recycling, waste collector recycling, recycling technology, etc., can solve the problems of high waste gas treatment pressure, cumbersome process flow, high equipment investment, etc. Short, low equipment investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

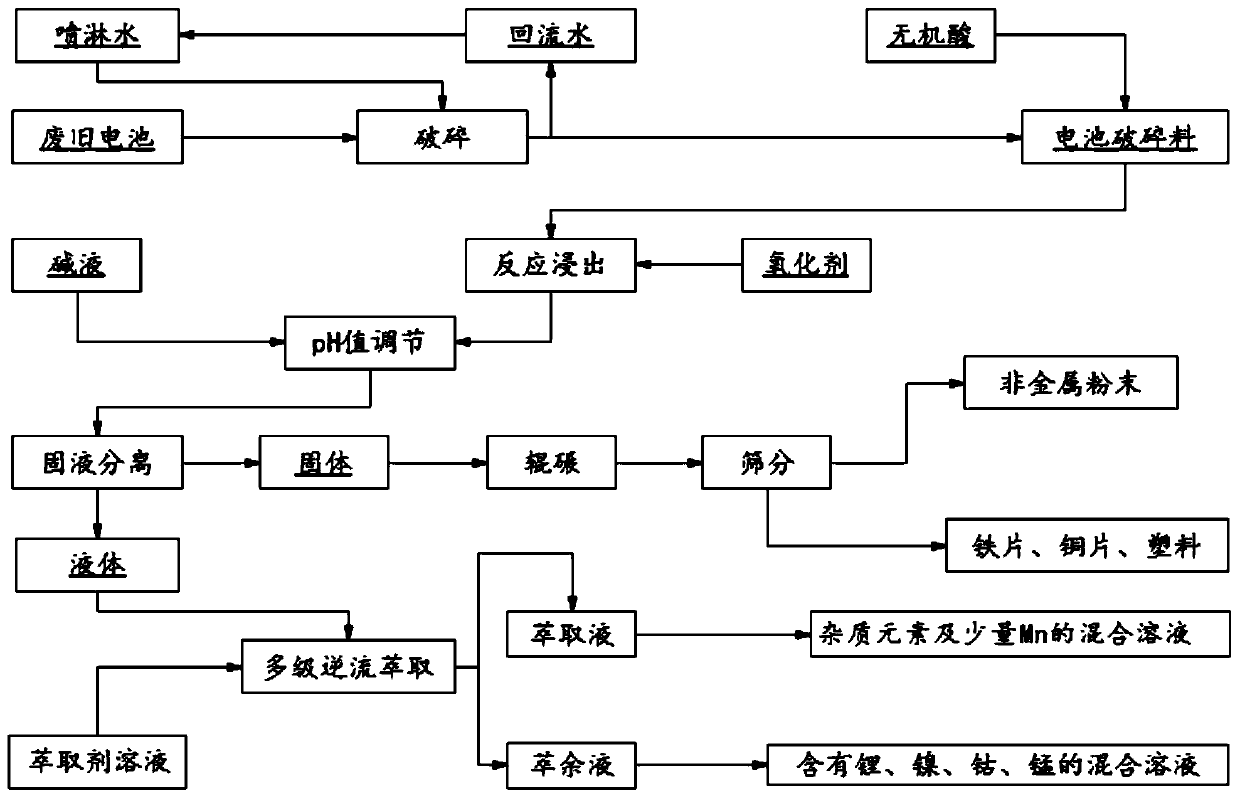

[0038] Embodiment 1 of the present invention is: a kind of all-wet recycling process of waste lithium battery, such as figure 1 As shown, it specifically includes the following steps:

[0039] (1) Add 1.5kg of water to the spray water storage tank, turn on the spray water, and put 100 waste soft-packed ternary (nickel-cobalt-manganese) lithium-ion batteries weighing about 31.11g / piece into the shredder for the second stage Crushing, the particle size of the crushed material is about 0.1-2cm, the crushed material enters the receiving bin with the spray water, removes the plastic and diaphragm floating above the liquid level of the receiving bin tank, and the spray water collected in the tank Perform reflux spraying according to the reflux ratio of 0.1:1.

[0040] (2) The material in the receiving bin of the crusher is transferred to the reaction kettle by the screw elevator and the water pump, the stirring tank rotating speed is 300r / min, and the reaction temperature is 20°C, ...

Embodiment 2

[0045] Embodiment 2 of the present invention is: an all-wet recovery process for waste lithium batteries, specifically comprising the following steps:

[0046] (1) Add 0.88kg of water to the spray water storage tank, turn on the spray water, and put 100 waste cylindrical 18650 ternary lithium (nickel-cobalt-manganese) ion batteries with a weight of about 44g / piece into the shredder for the second stage Crushing, the particle size of the crushed material is about 0.1-5cm, the crushed material enters the receiving bin with the spray water, removes the plastic and diaphragm floating above the liquid level of the receiving bin tank, and the spray water collected in the tank Perform reflux spraying according to the reflux ratio of 0.5:1.

[0047] (2) Transfer the material in the receiving bin of the crusher to the reaction kettle through the screw elevator and the water pump. The rotation speed of the stirring tank is 600r / min, the reaction temperature is 60°C, and the speed is 0.7...

Embodiment 3

[0052] Embodiment 3 of the present invention is: a full-wet recovery process of waste lithium batteries, specifically comprising the following steps:

[0053] (1) Add 2.5kg of water into the spray water storage tank, turn on the spray water, put 100 waste lithium cobaltate soft pack batteries weighing about 50g / each into the shredder for secondary crushing, and the crushed The particle size of the material is about 0.1-5cm. The broken material enters the receiving bin with the spray water to remove the plastic and diaphragm floating above the liquid level of the tank in the receiving tank. The spray water collected in the tank is carried out according to the reflux ratio of 0.2:1. Backflow spray.

[0054] (2) The material in the crusher receiving bin is transferred to the reaction kettle by the screw elevator and the water pump, the stirring tank rotating speed is 400r / min, and the reaction temperature is 30°C, and 12.25kg nitric acid (wt%) is added in 4h =68%), carry out lea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com