Patents

Literature

37results about How to "Change wind speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

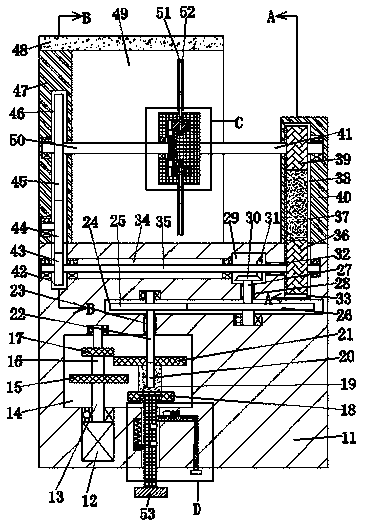

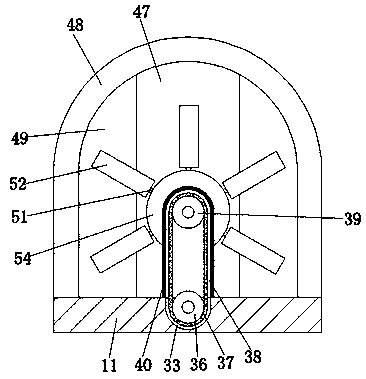

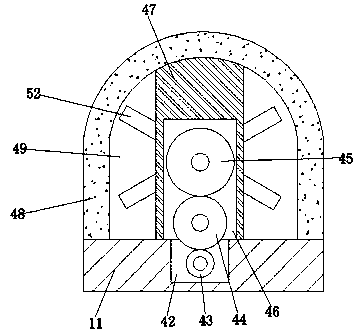

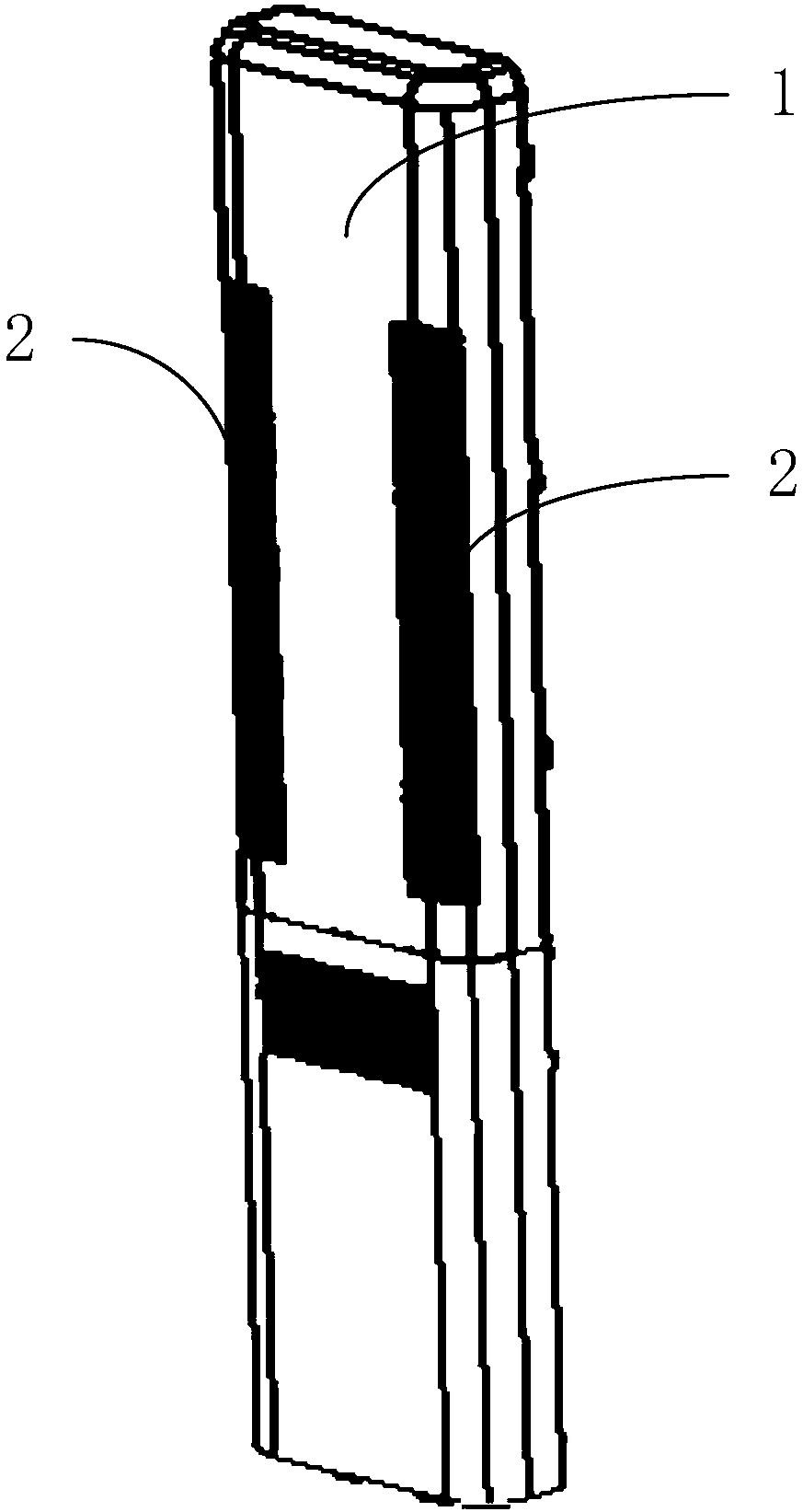

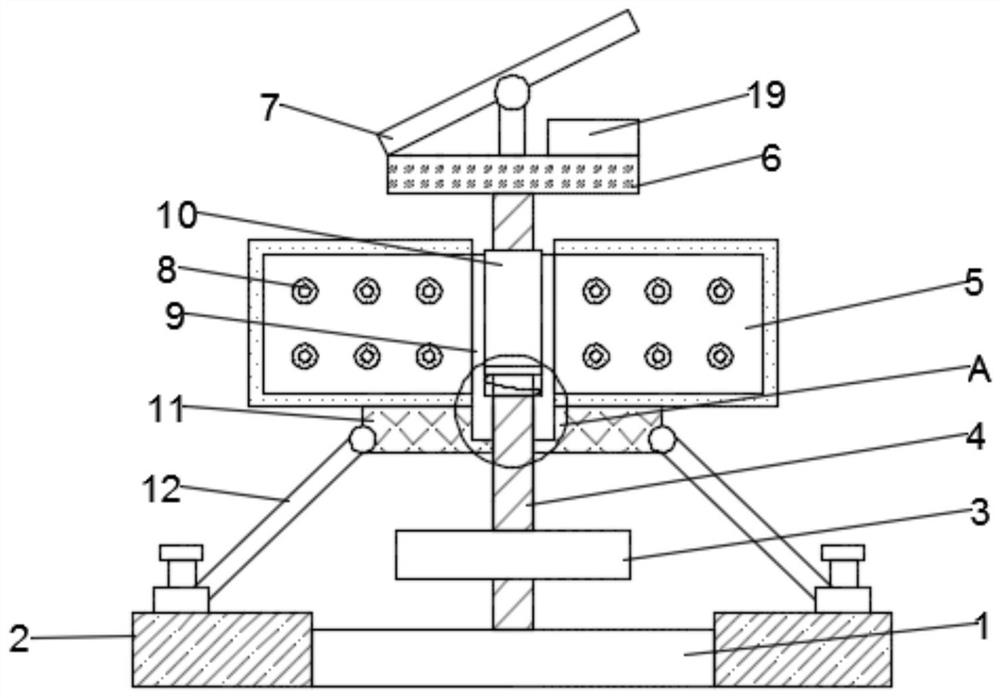

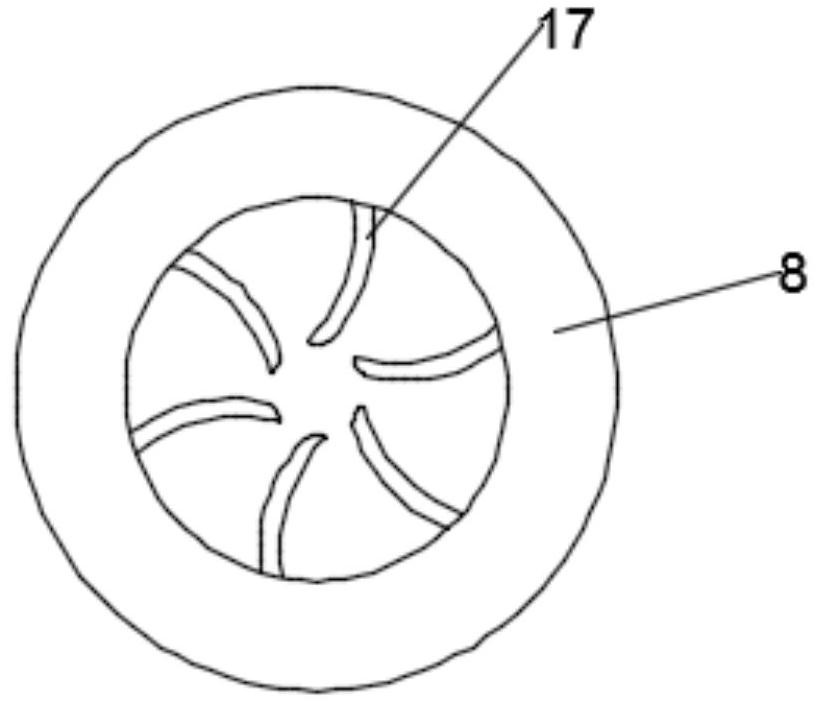

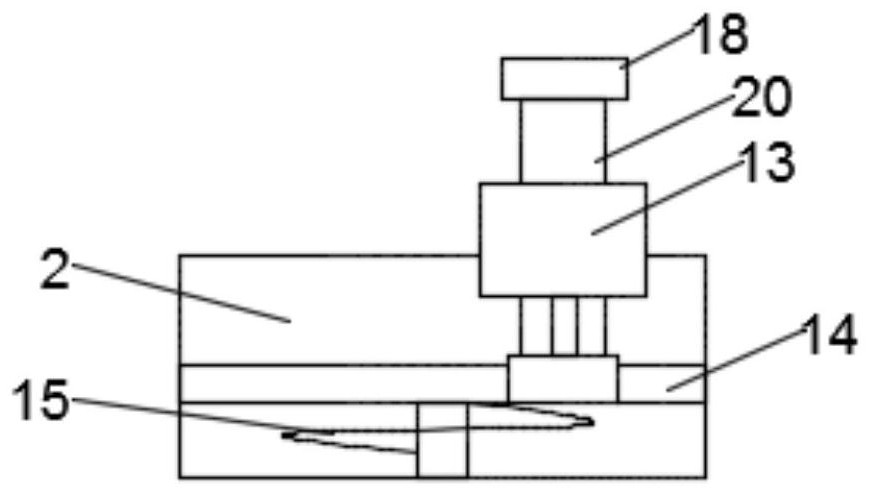

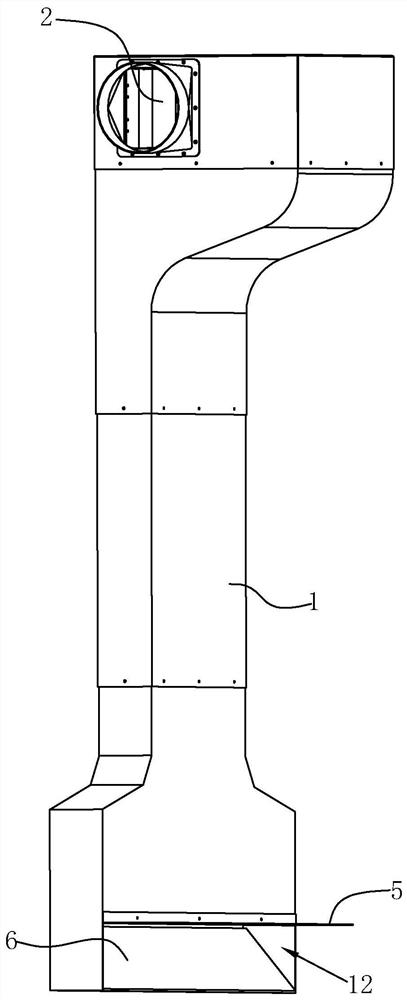

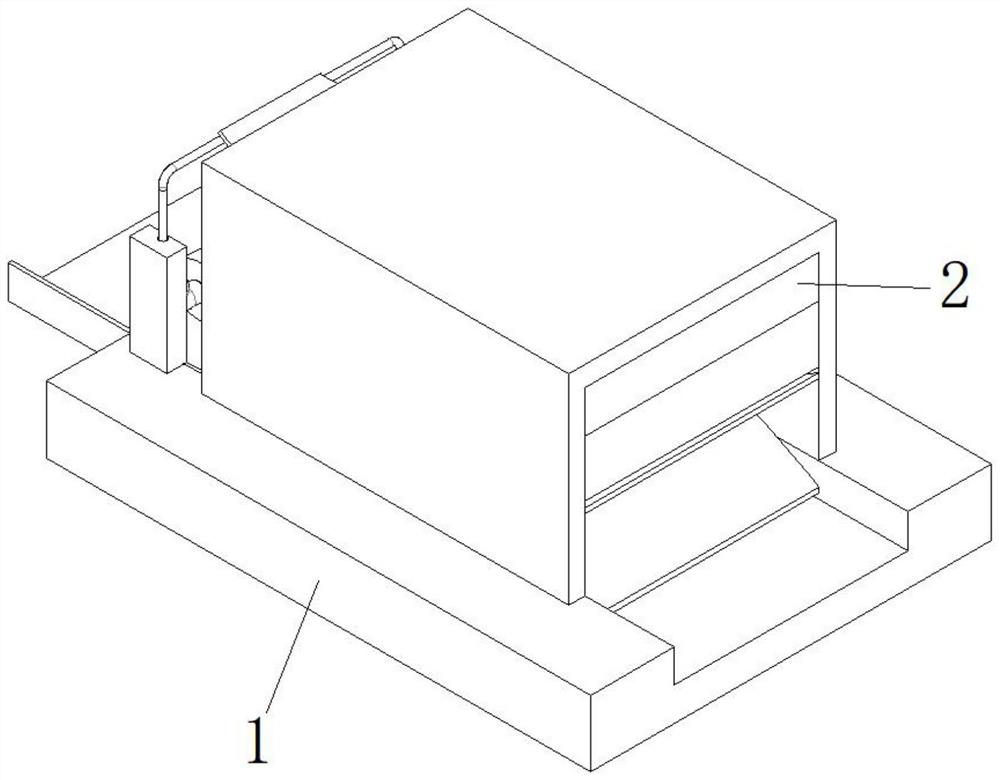

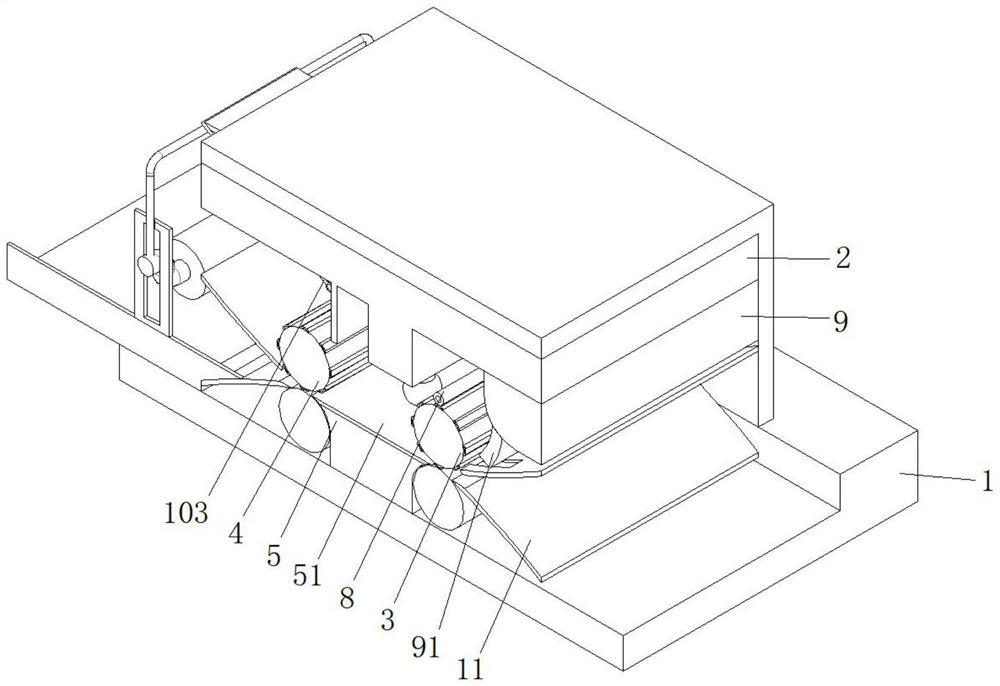

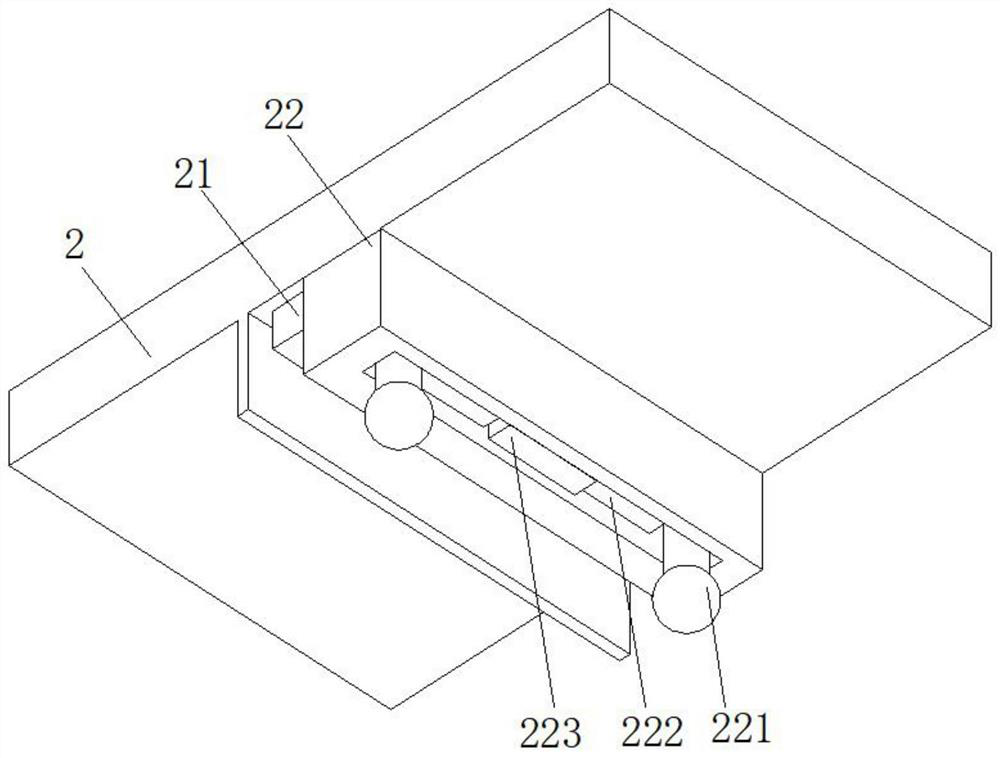

Tunnel ventilator

InactiveCN109281848AImprove securitySimple structureTunnel/mines ventillationPump controlControl theoryMotor shaft

The invention discloses a tunnel ventilator, which includes a base. A ventilation device is arranged at the upper end of the base, the base is internally provided with a switching and variable speed device, the switching and variable speed device includes a switching structure and a variable speed structure, the switching structure comprises a variable speed cavity formed in the base, a high-speeddriving straight gear is rotatably arranged in the variable speed cavity, a motor is fixedly arranged in the inner wall of the lower side of the variable speed cavity, the lower end of the high-speeddriving straight gear is connected to the motor through a motor shaft in a power fit mode, and the upper end of the high-speed driving straight gear is fixedly connected with a low-speed driving straight gear through a fixing connecting shaft. According to the tunnel ventilator, operation is easy, use is convenient, not only can the wind speed be manually adjusted, but also the wind direction canbe changed, the probability that wind in the same direction resonates in a tunnel is reduced, and safety of tunnel operation is improved.

Owner:姚莉萍

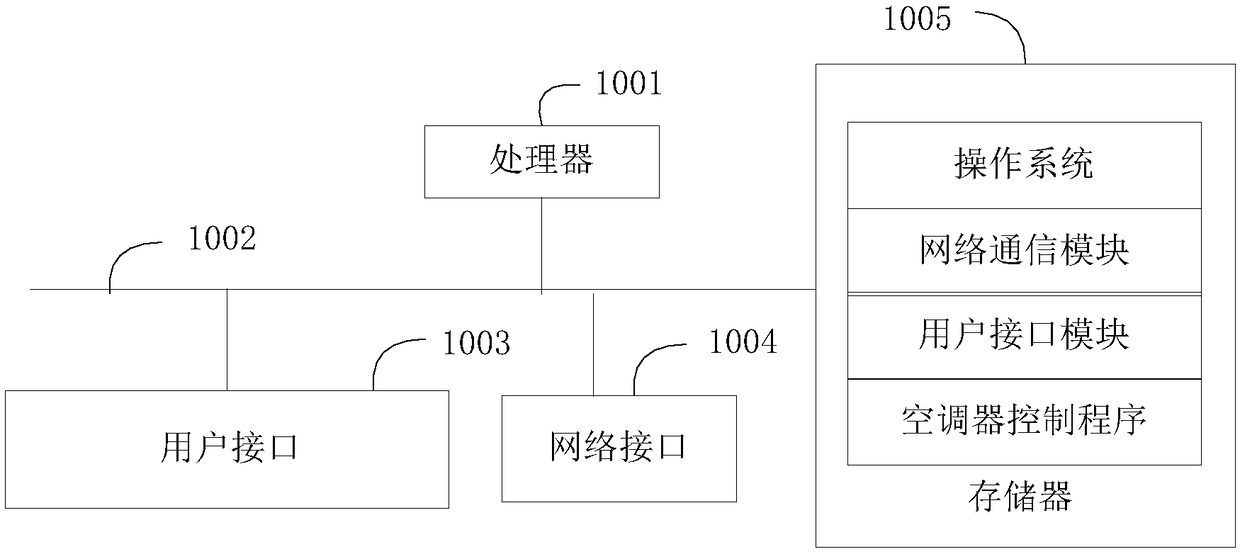

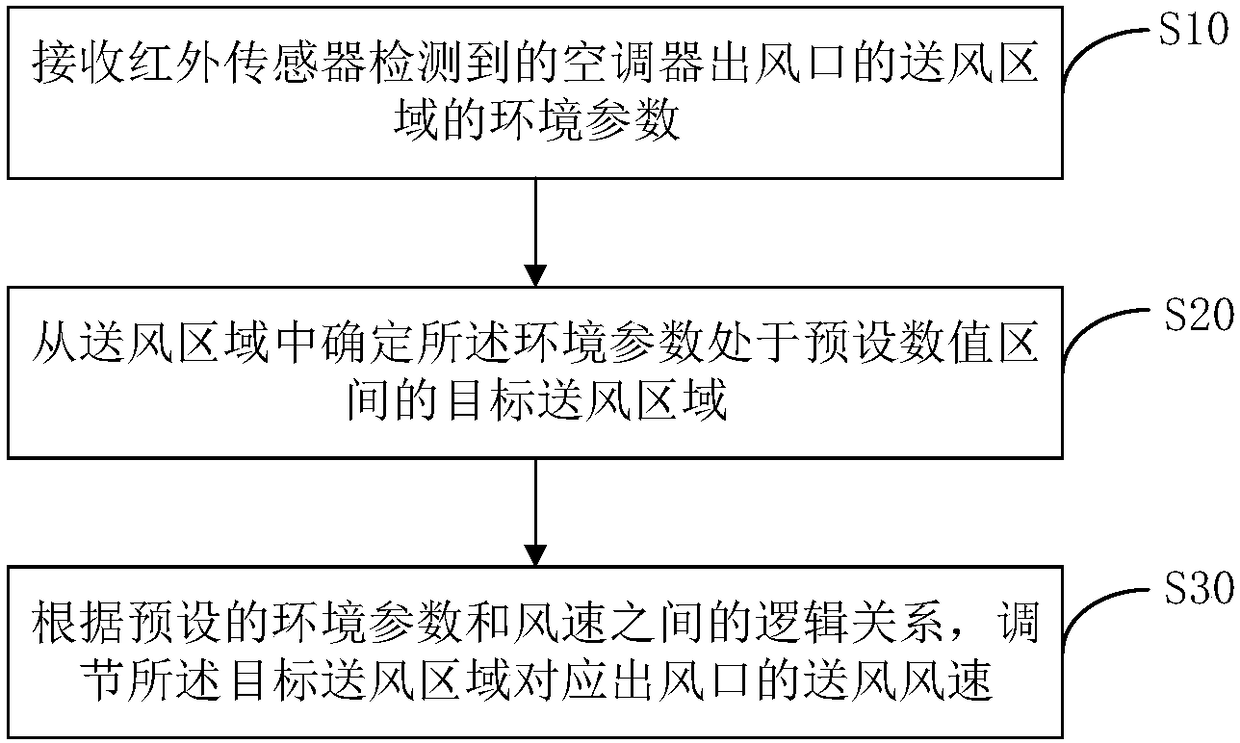

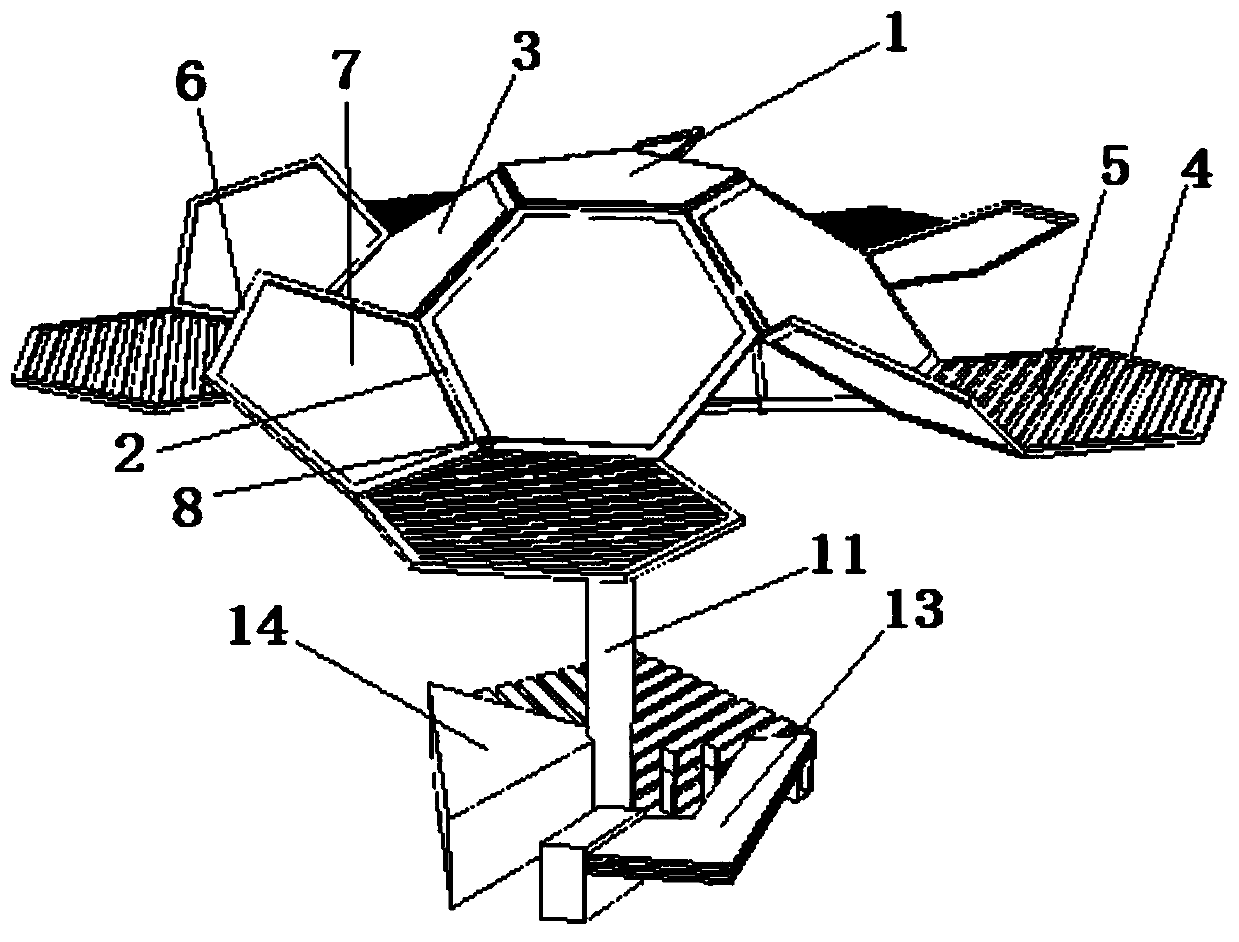

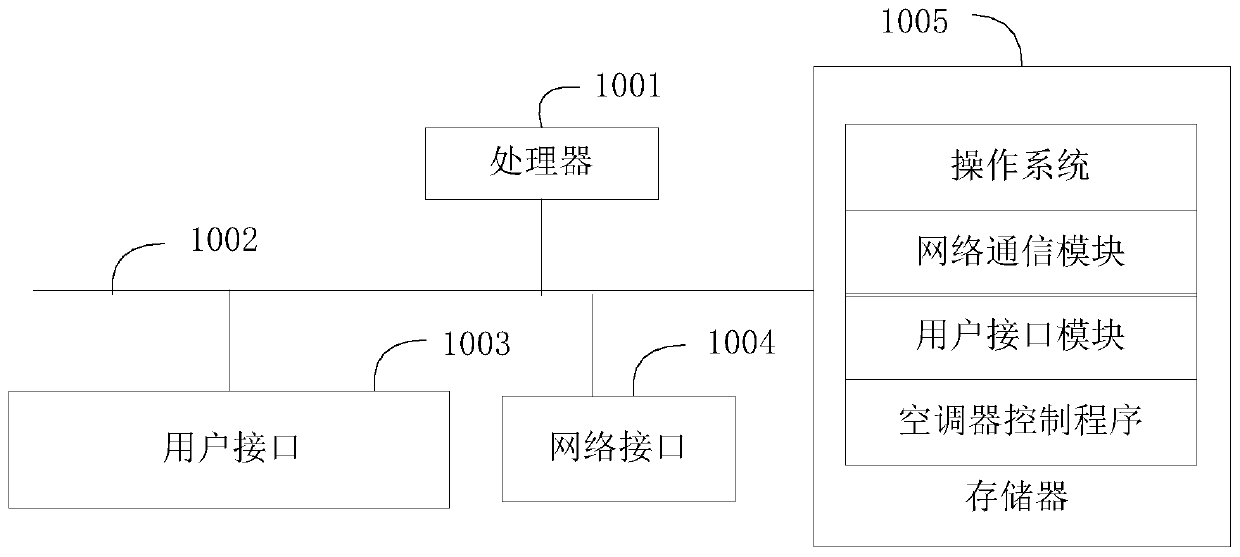

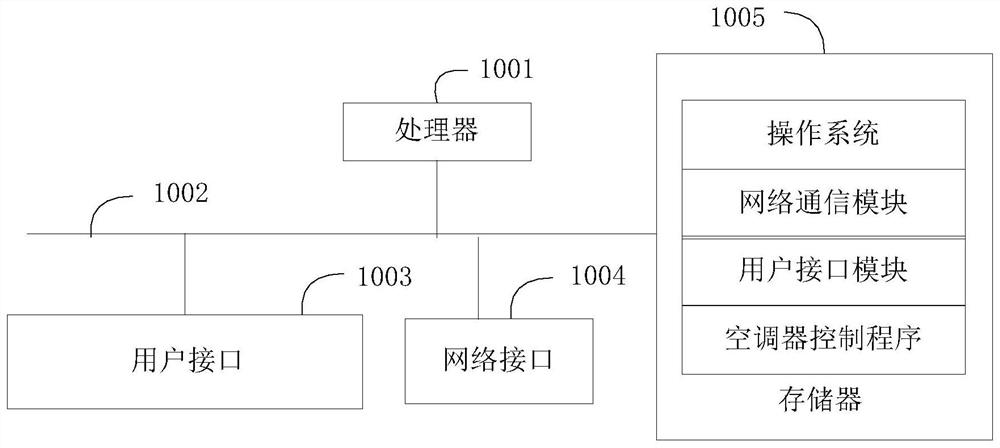

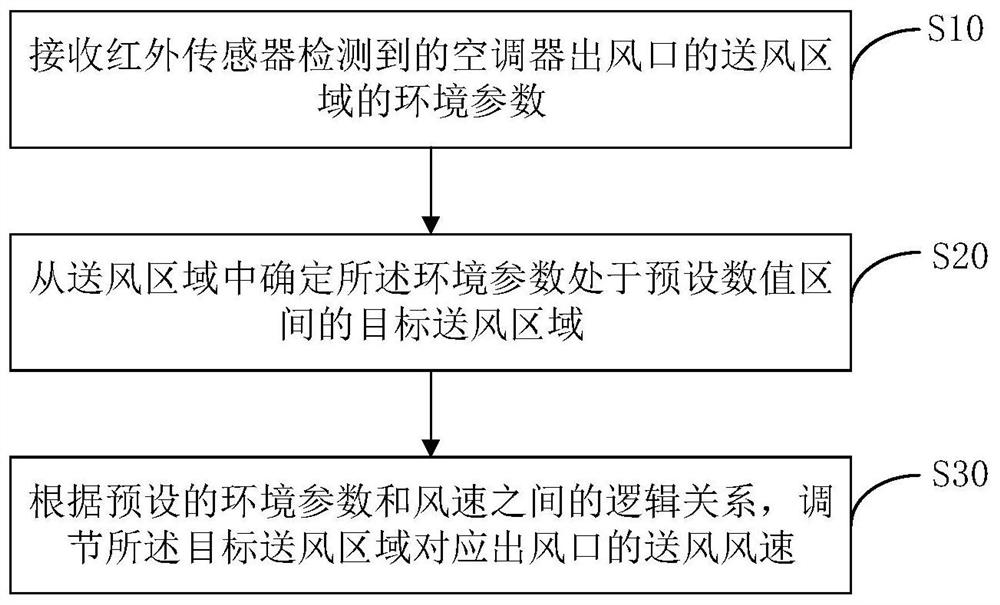

Air conditioner control method, terminal, air conditioner and computer readable storage medium

ActiveCN108489034AImprove experienceIntelligent adjustment of wind speedMechanical apparatusSpace heating and ventilation safety systemsEngineeringComputer terminal

The invention discloses an air conditioner control method, a terminal, an air conditioner and a computer readable storage medium. The air conditioner control method comprises the steps of receiving environmental parameters of air supply areas of air outlets of the air conditioner detected by an infrared sensor, determining a target air supply area with the environmental parameter being located ina preset numerical zone from the air supply areas, and adjusting the air supply velocity of the air outlet corresponding to the target air supply area according to a logical relationship between a preset environmental parameter and the air velocity. According to the logical relationship between the environmental parameter of each air supply area and the air velocity, the air velocity of the corresponding air outlet is intelligently controlled, so that the problem that in the prior art, during a cooling or heating process of the air conditioner, in order to achieve the aim of cooling or heating, the air velocity of the air outlets is unchanged, so that the human comfort experience is influenced is effectively solved; and in addition, air outlet modes of other air outlets with the environmental parameters being not located in the preset numerical zone are unchanged, and the user experience is improved while a cooling or heating function is realized.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

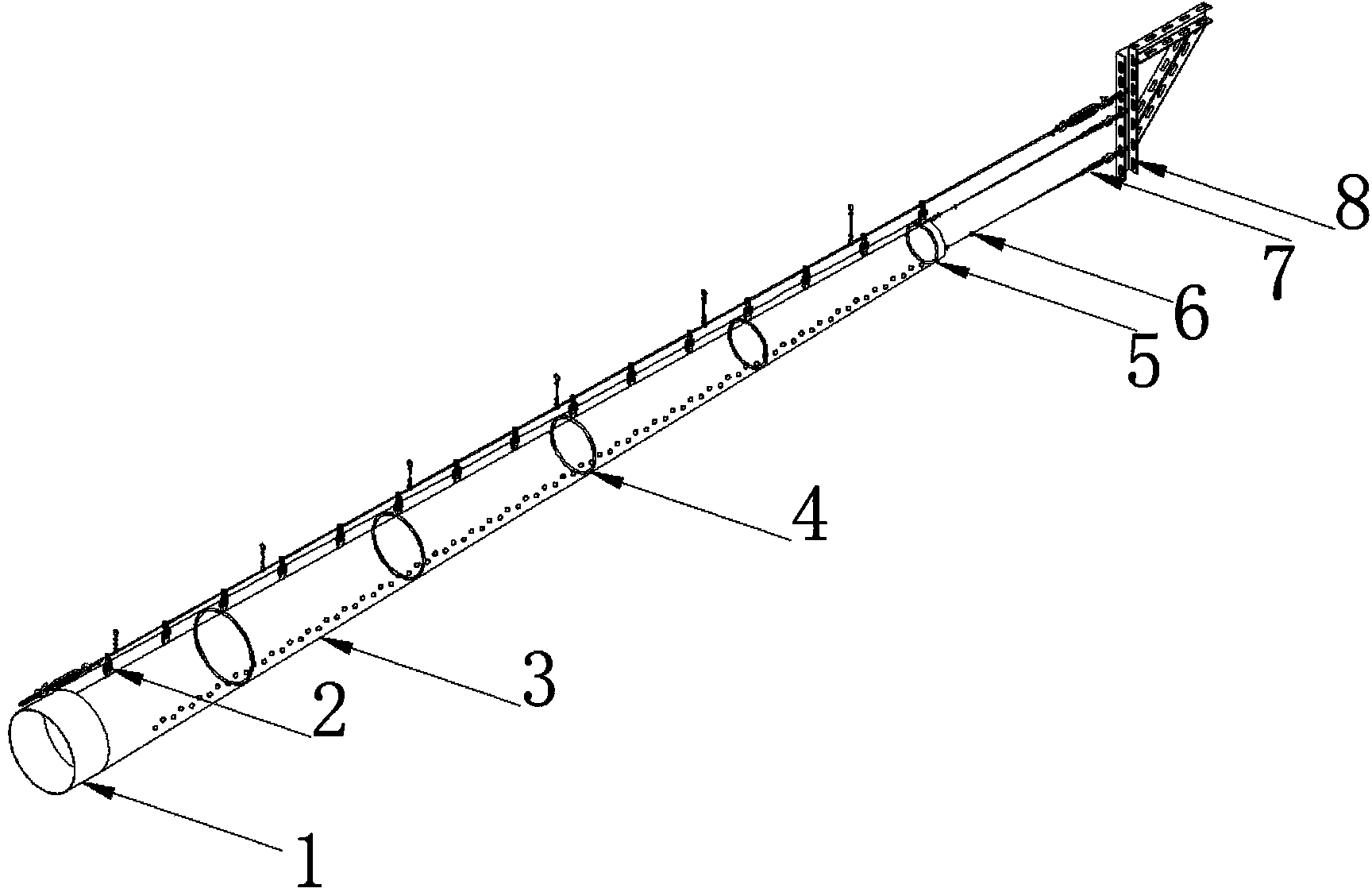

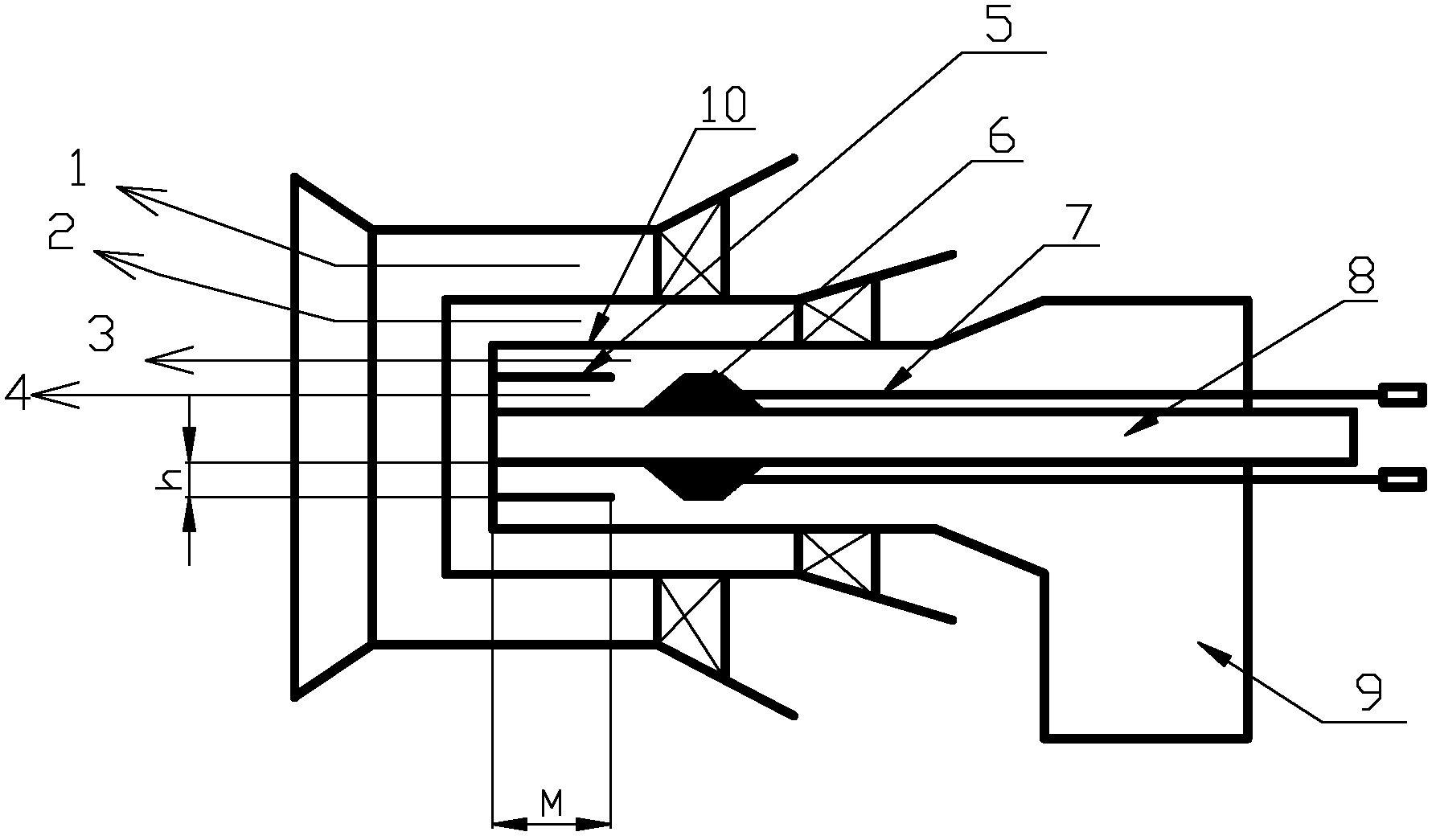

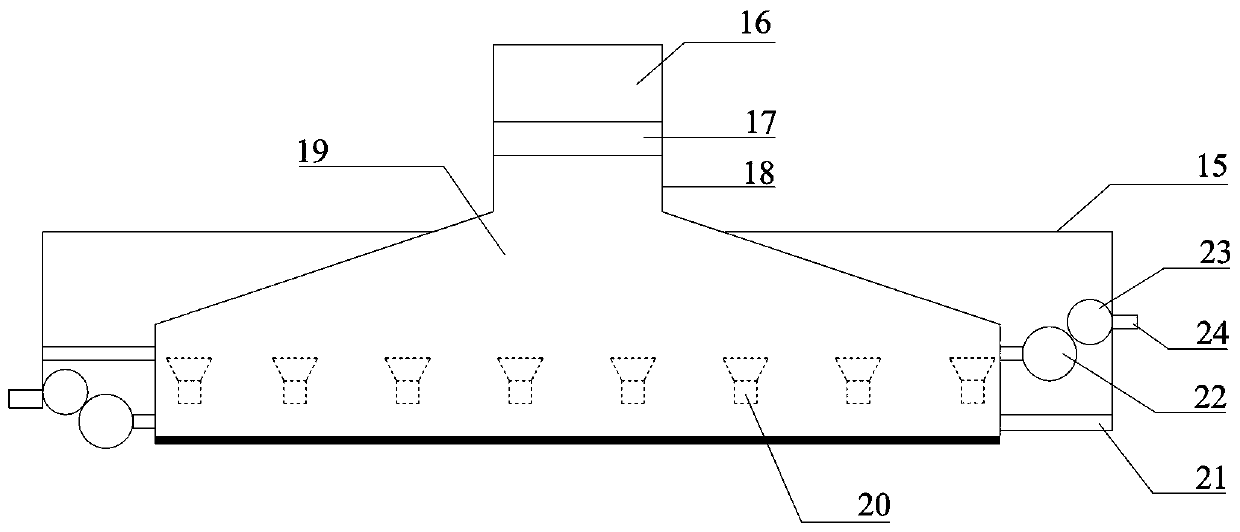

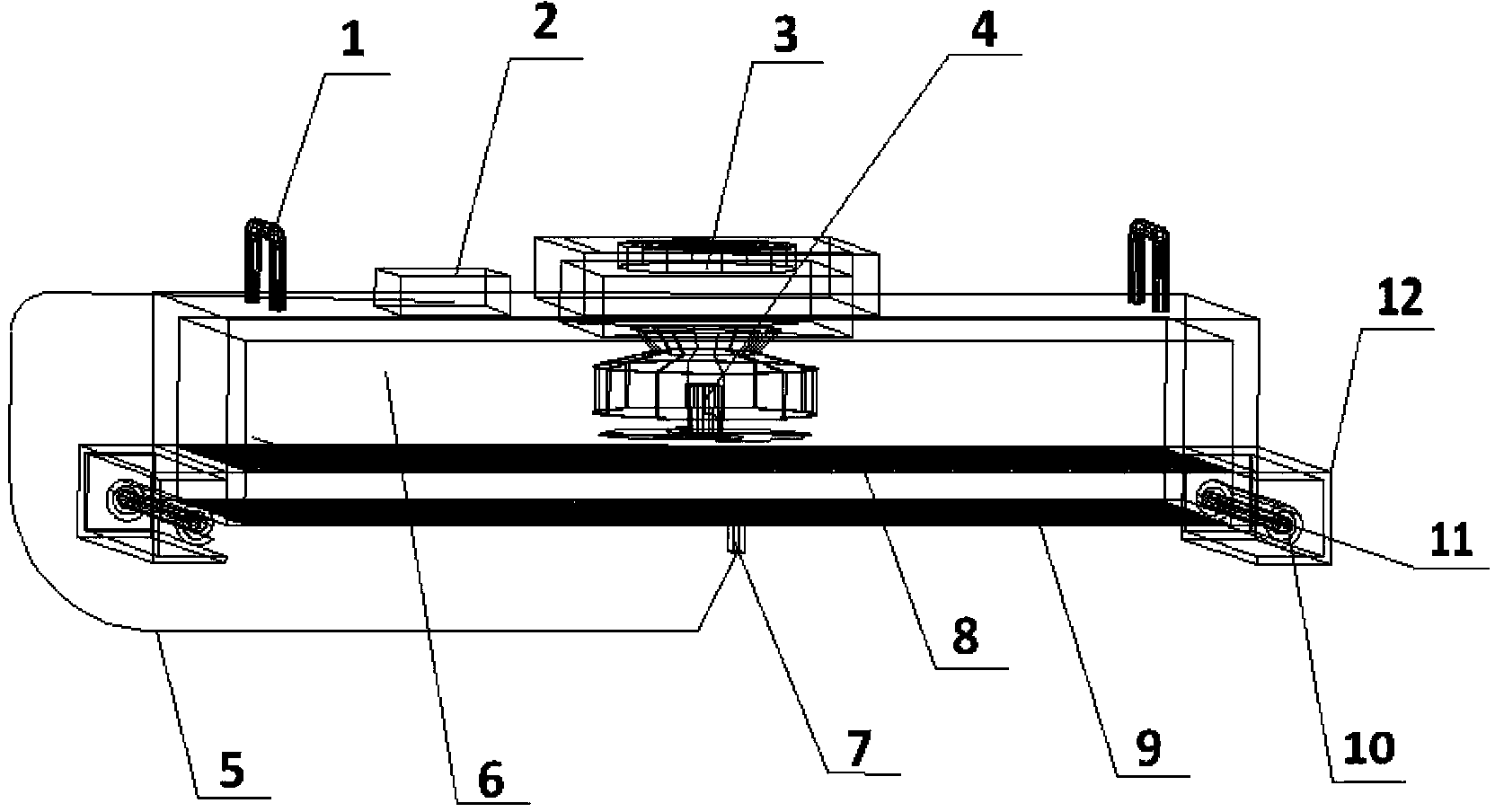

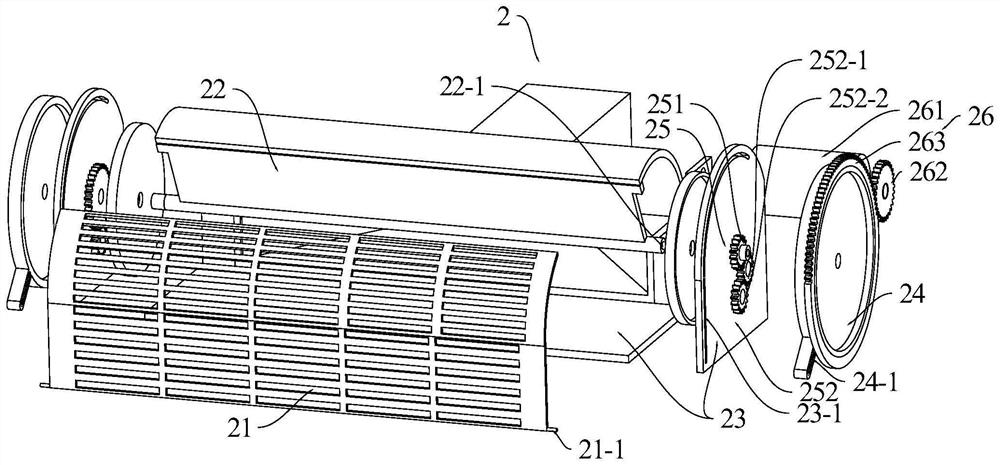

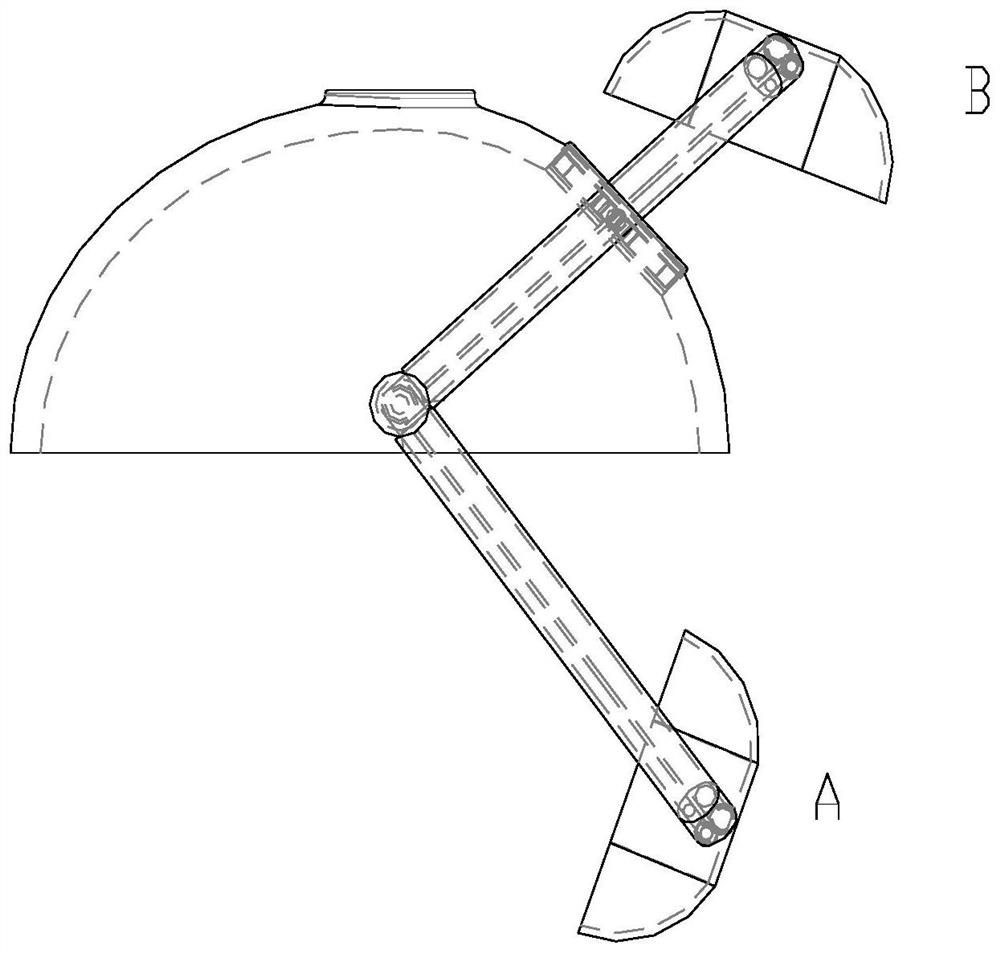

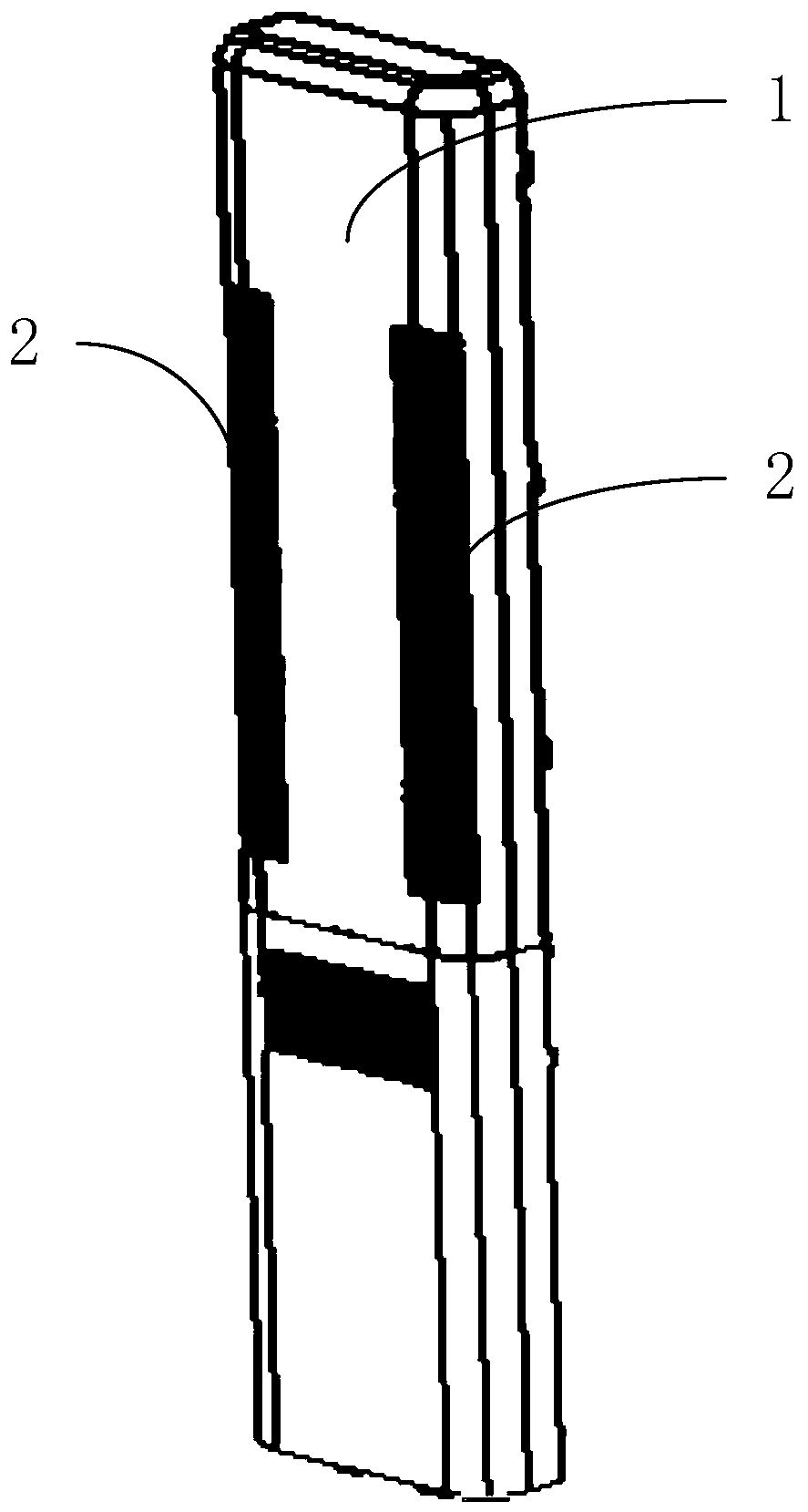

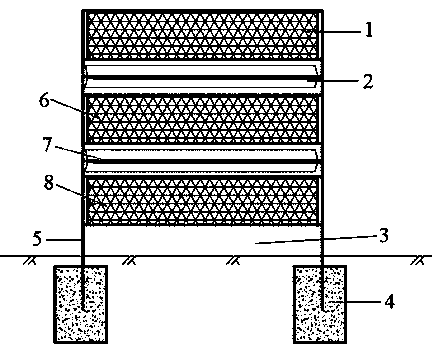

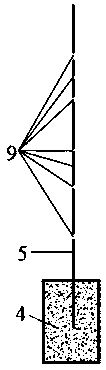

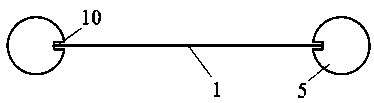

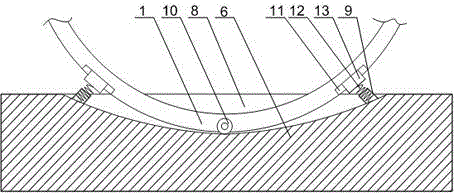

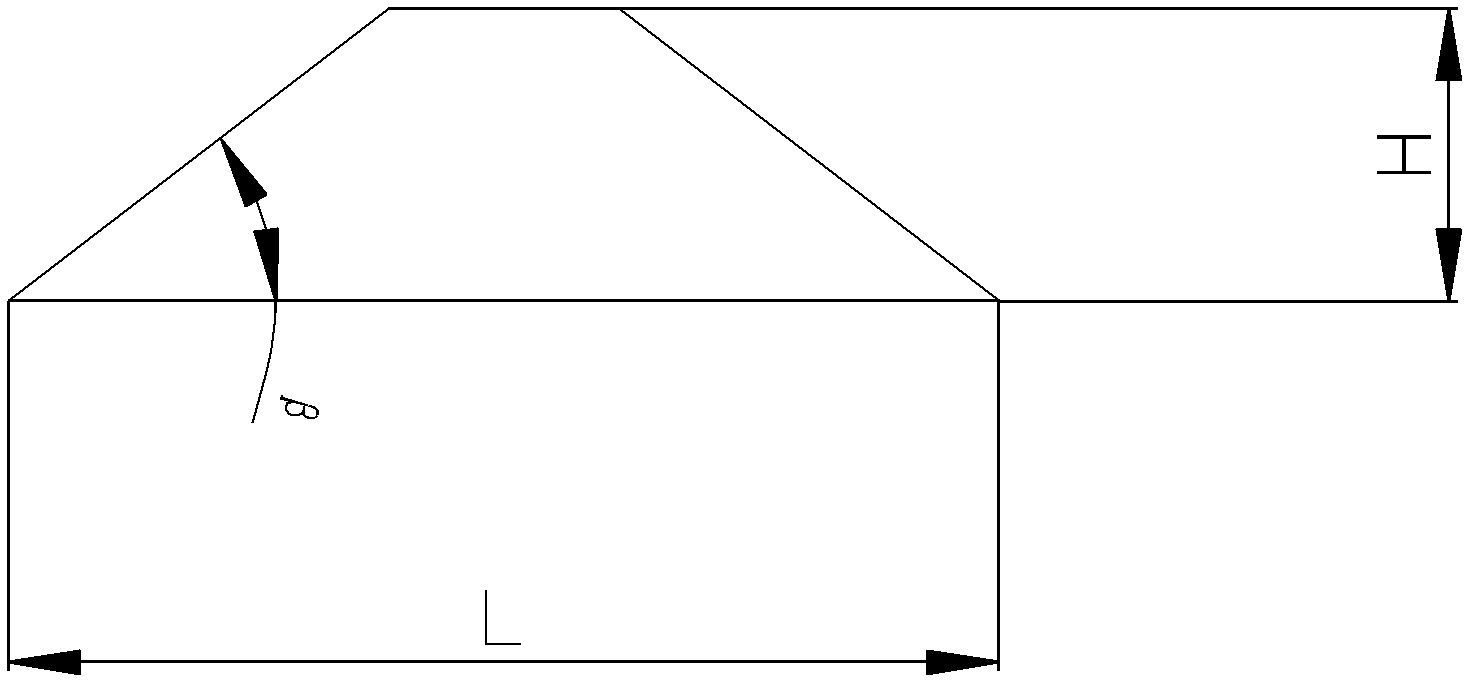

Fiber fabric supported mean-speed air pipe system

InactiveCN104373713AReduce differential pressureRun smoothlyPipe supportsFlexible pipesFiberArchitectural engineering

The invention relates to a fiber fabric supported mean-speed air pipe system. An air pipe unit of the air pipe system is a taper air pipe. The pipe diameter of the air pipe unit gradually decreases from the inlet to the tail end along the process. The air pipe system comprises hanging hooks, tension rings, a hanging steel rope and a tail end support. Air pipes are hung and fixed to the hanging steel rope through the hanging hooks. The tail ends of the air pipes are fixed to the tail end support through the steel rope via stretching. The tension rings used for supporting are installed in the air pipes. The pipe diameter of the air pipes is adjusted along the process, the taper is adjusted, and then the air conveying character in the air pipes is changed along the process. Meanwhile, the air pipe system is provided with a supporting structure and is circular under the non-working state.

Owner:DURKEESOX WUHAN AIR DISTRIBUTION SYST

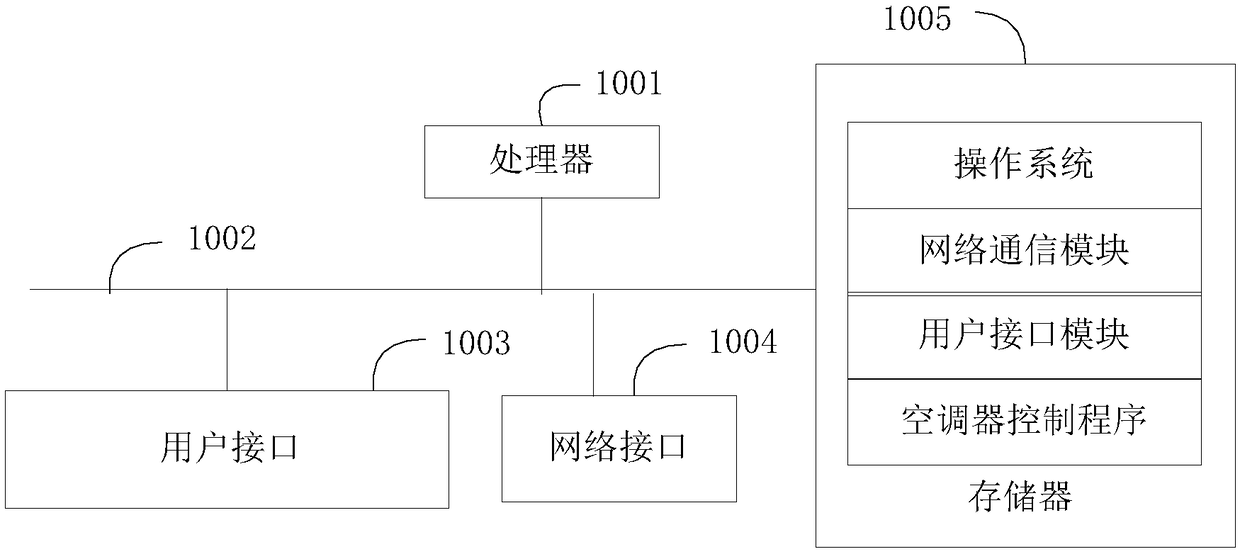

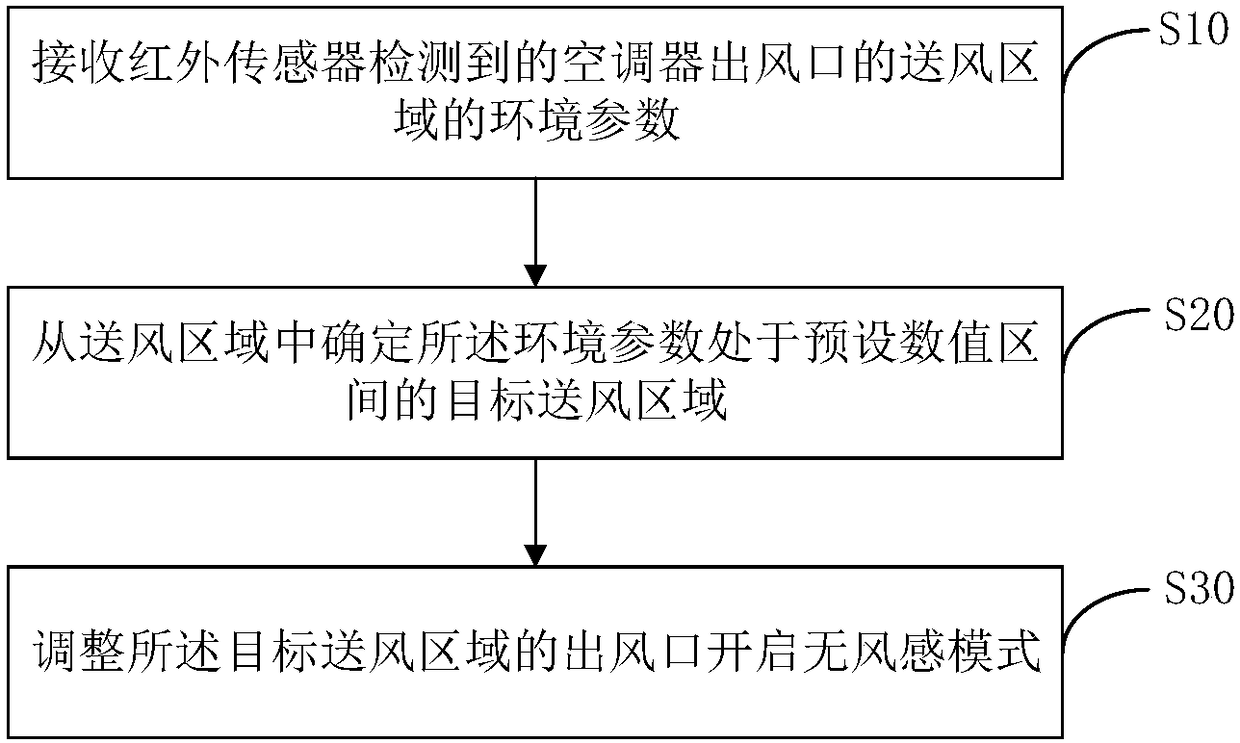

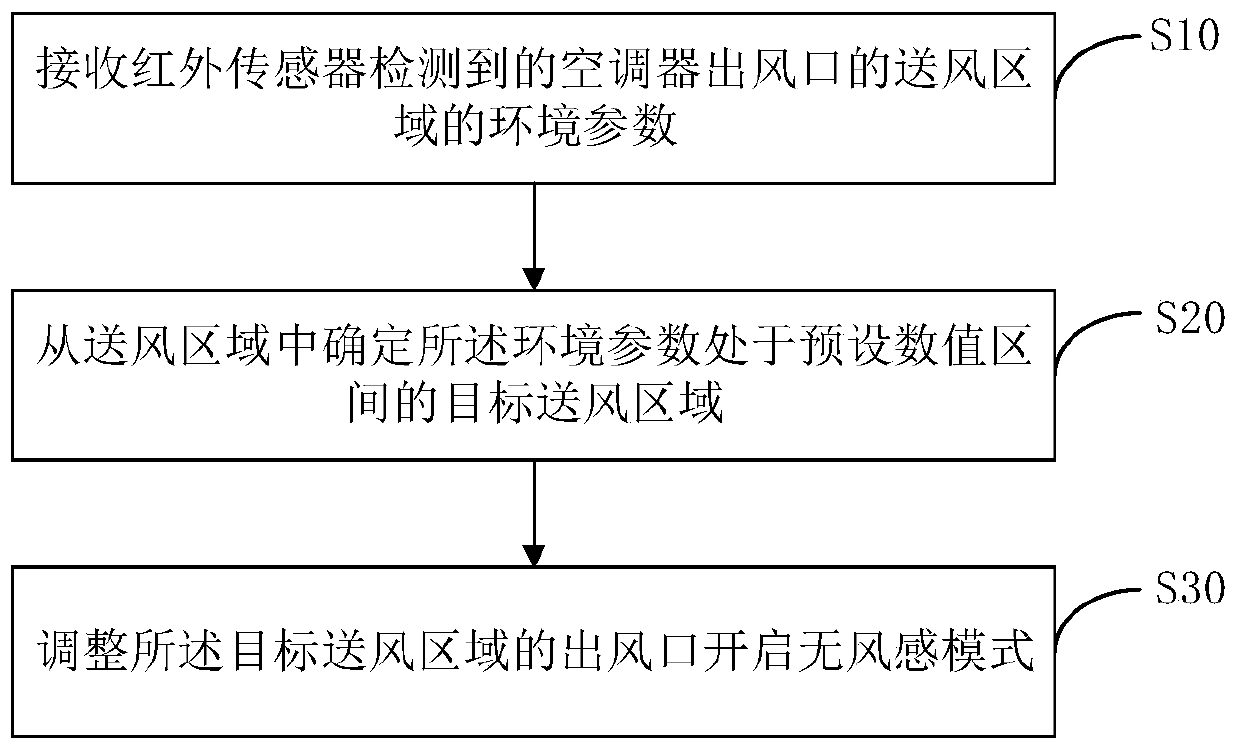

Air conditioner control method, terminal, air conditioner and computer readable storage medium

ActiveCN108458444AImprove experienceAvoid technical problems that cannot meet individual needsMechanical apparatusSpace heating and ventilation safety systemsRefrigerationAir line

The invention discloses an air conditioner control method, a terminal, an air conditioner and a computer readable storage medium. The air conditioner control method comprises the steps that environment parameters of air feeding areas of air outlets of the air conditioner detected by an infrared sensor are received, the target air feeding areas with the environment parameters being in the preset value range are confirmed from the air feeding areas, and the air outlets of the target air feeding areas are adjusted to start a windless mode. By means of the air conditioner control method, the terminal, the air conditioner and the computer readable storage medium, according to the environment parameters of all the air feeding areas, whether the corresponding air outlets start the windless mode or not is intelligently controlled, the problems in the prior art that in the refrigeration or heating process of the air conditioner, to realize the purpose of cooling or heating, wind of the air outlet blows directly to the human body, and the comfort experience degree of the human body is affected are effectively solved, by means of starting of the windless mode, concentrated air flow of the airoutlets is made to be dispersed into many fine air lines, furthermore, the air outlet mode of the other air outlets with the environment parameters being not in the preset value range remains unchanged, the function of refrigeration or heating is realized, and the experience degree of users is improved at the same time.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

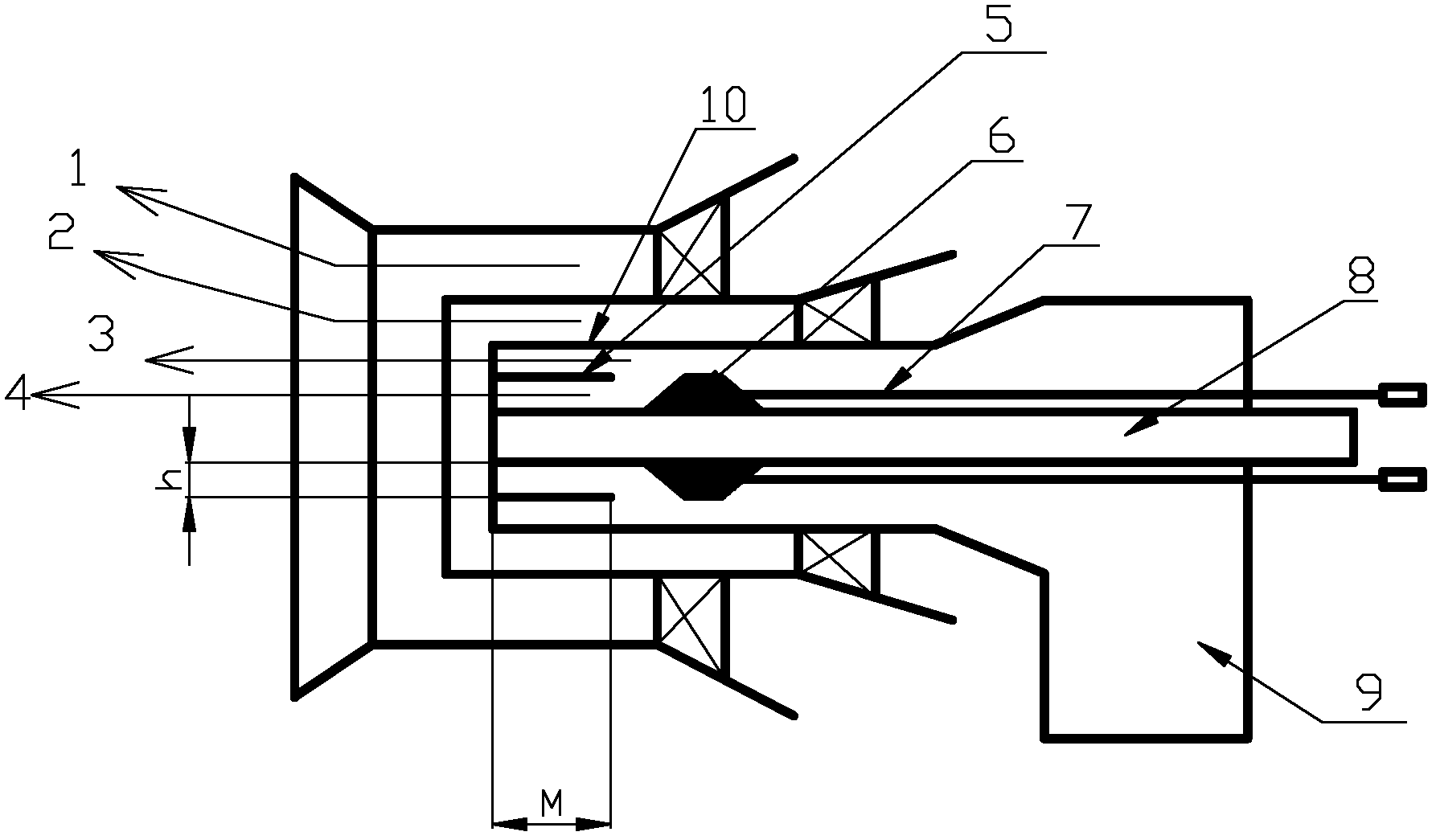

Variable-section cyclone burner

The invention discloses a variable-section cyclone burner, which comprises a central air duct. A primary air pipe is sleeved outside the central air duct, a partition sleeve is sleeved at an outlet of the primary air pipe and divides the primary air pipe into an inner space and an outer space, an annular sliding stopper is mounted on the central air duct, and the annular sliding stopper is connected with a pull rod arranged on the outside of the cyclone burner. As the primary air is divided into inner primary air and outer primary air by the partition sleeve additionally mounted at the outlet of the primary air pipe of the cyclone burner and the annular sliding stopper is mounted on the central air duct, when the annular sliding stopper is pulled backwards, the inner primary air and the outer primary air ventilate simultaneously, ventilation area is expanded, primary air speed is reduced, and the requirement for reducing air speed is met; and further, when the annular sliding stopper is pushed forwards, a passage of the inner primary air is blocked, only a passage of the outer primary air ventilates, ventilation area is reduced, and accordingly primary air speed is increased.

Owner:SHANDONG ZHONGSHI YITONG GRP

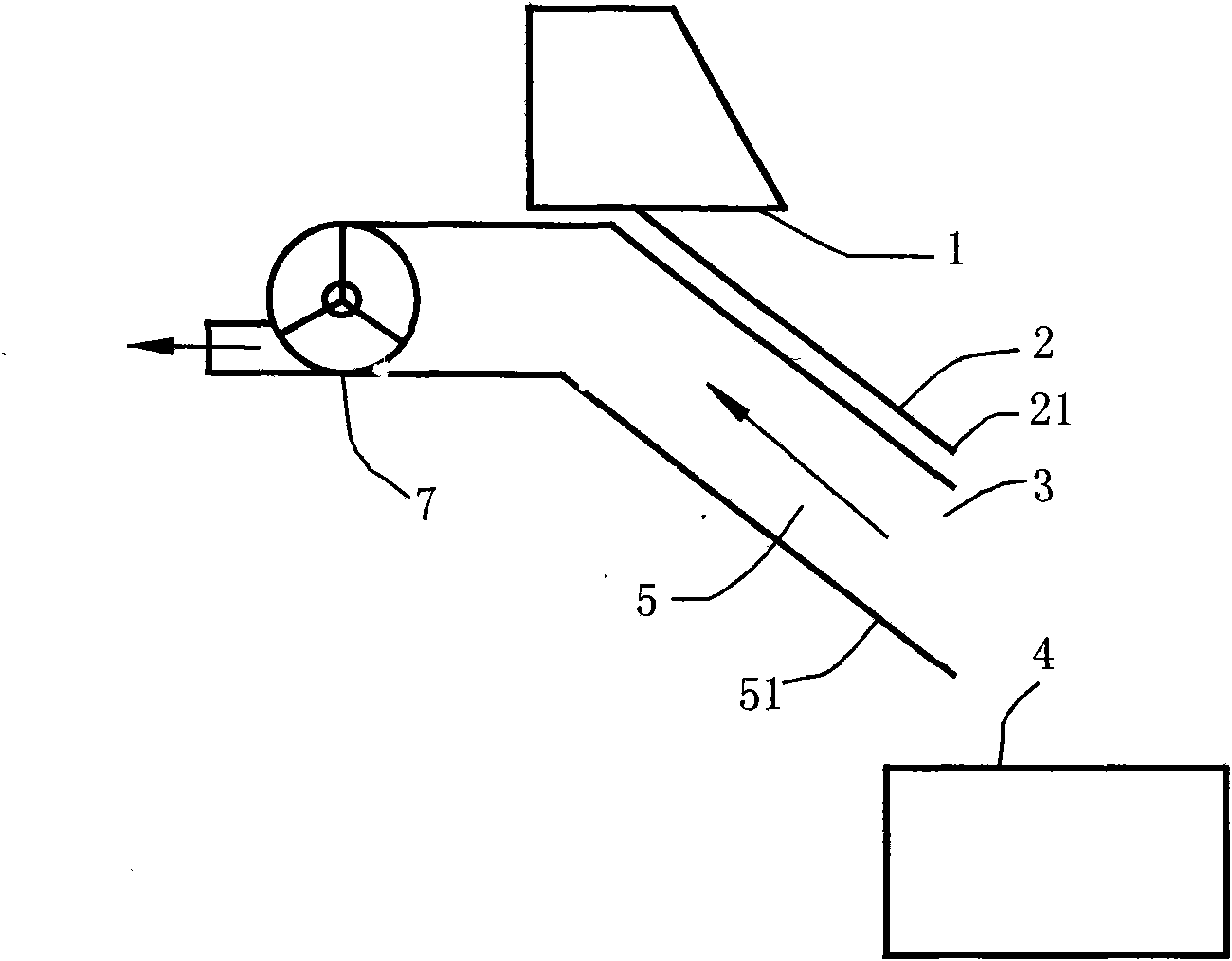

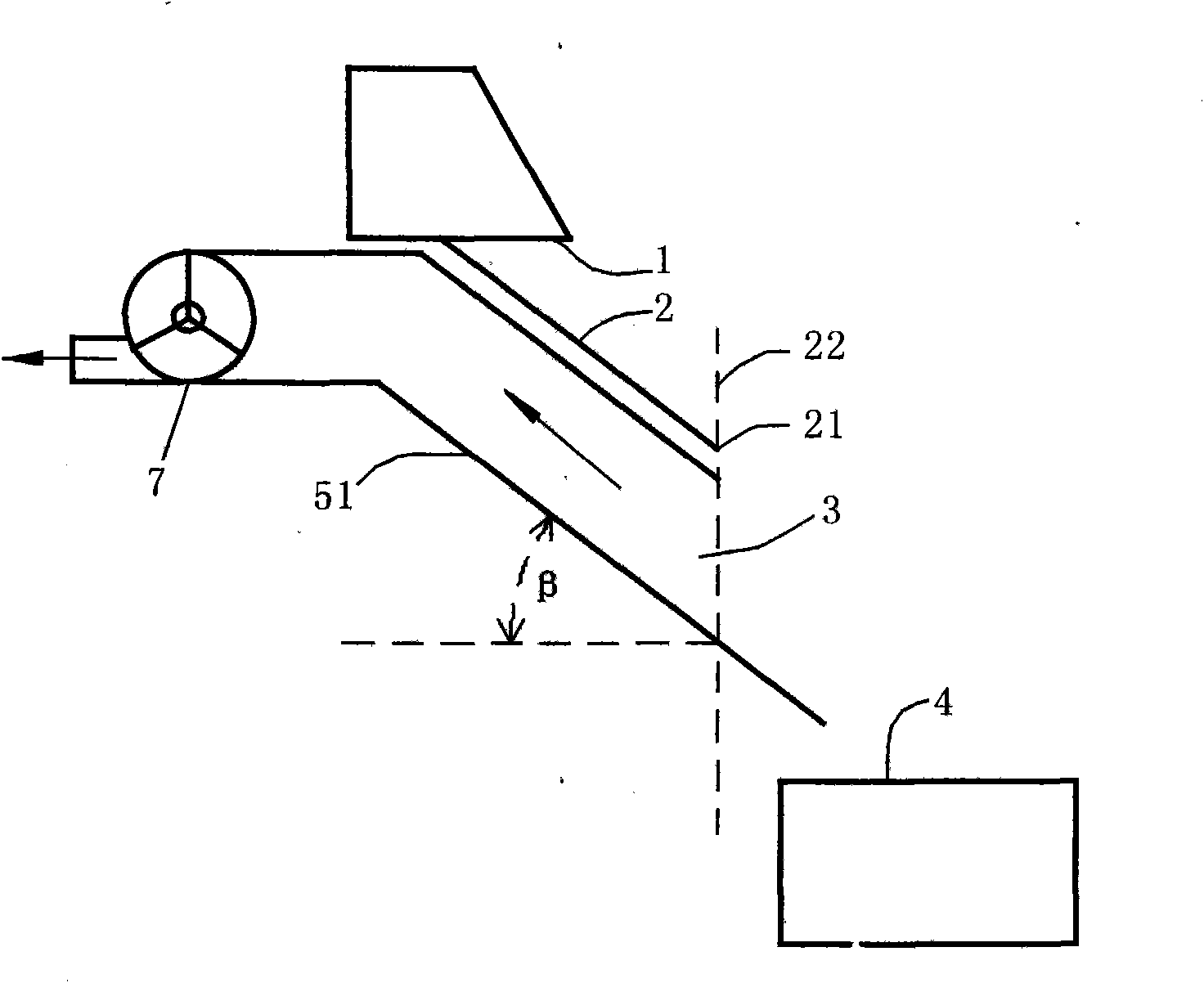

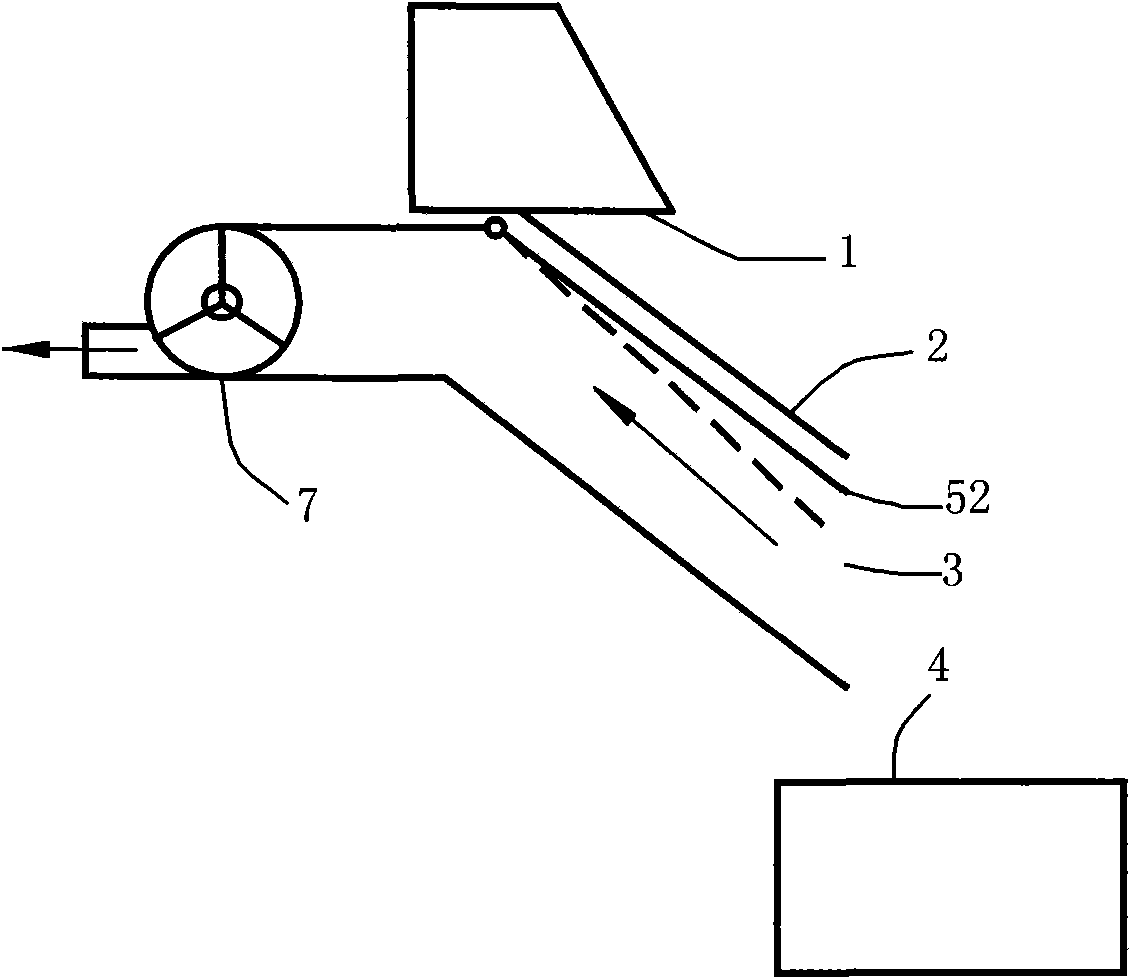

Oblique winnowing device of reaping machine

InactiveCN101563980AAdjustable cross-sectional areaChange wind speedThreshersSuction forceAir volume

The invention aims to provide an oblique winnowing device of a reaping machine. The oblique winnowing device comprises a seed dropping port. A downwardly-oblique dispersing and sliding plate is arranged below the seed dropping port. An air suction port is arranged along the lower side below the dispersing and sliding plate. The air suction port is connected with an air pipe with an upwardly-oblique bottom plate. By arranging the dispersing and sliding plate below the seed dropping port, the oblique winnowing device fully disperses grains during the dropping; by arranging the air suction port below the dispersing and sliding plate, the oblique winnowing device achieves concentrative wind amount, high wind speed and strong suction force; and by connecting the air suction port with the air pipe with the upwardly-oblique bottom plate, the oblique winnowing device not only can ensure that impurities are completely sucked away and separated, but does not lose the seeds, thus realizing seed purification with high efficiency and low loss.

Owner:双峰县神手微型收割机制造厂

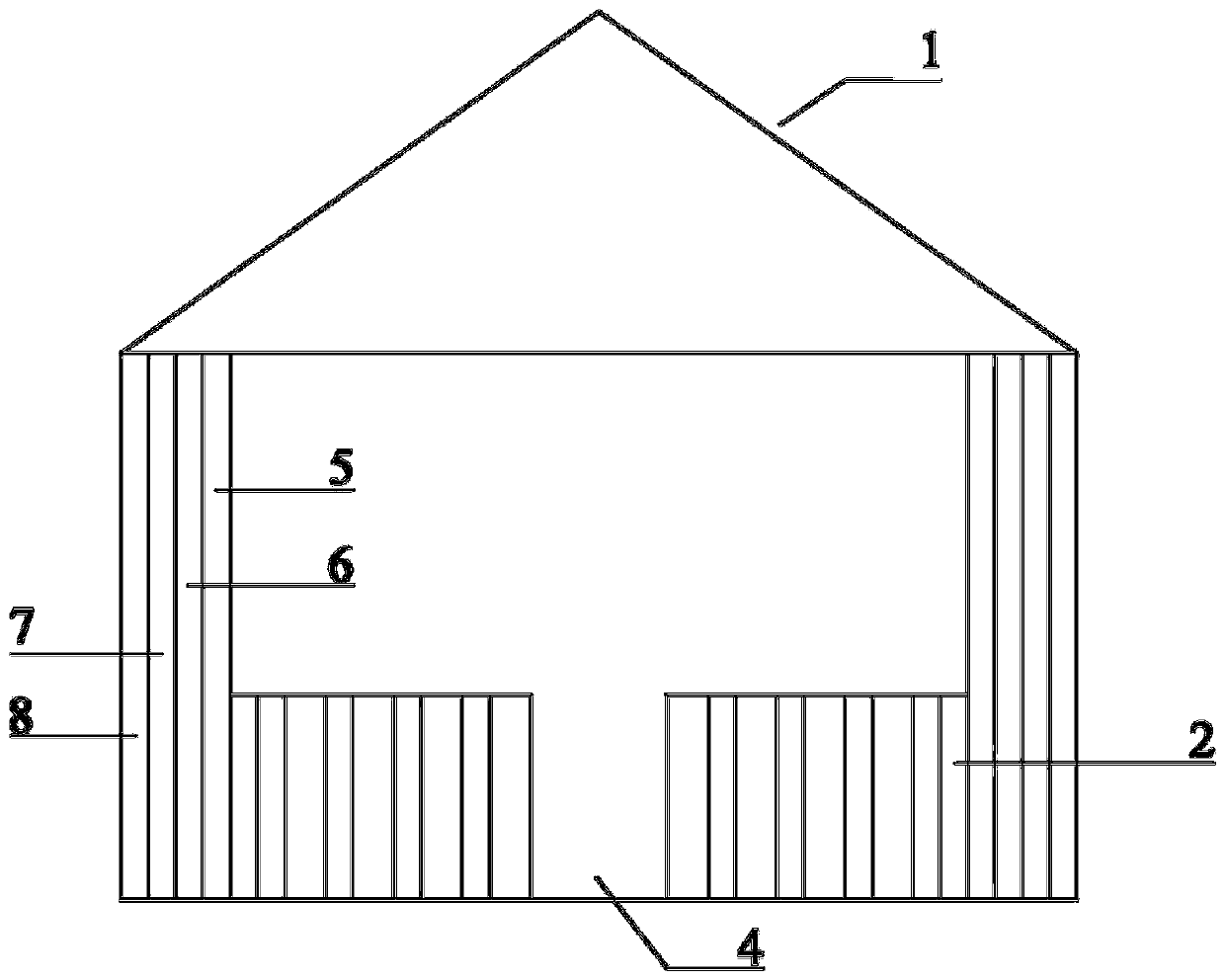

Heating system of hog house

The invention discloses a heating system of a hog house. The heating system comprises a combustion furnace, an air intake pipeline and an exhaust gas discharge pipeline. The combustion furnace is utilized for heating air. Meanwhile, exhaust gas is conveyed to the combustion furnace by an exhaust pipe and combusted. Additionally, heat exchange between exhaust gas heat and clean air is achieved. Because of fully-utilized heat, temperature of the hog house is ensured in order to prevent pollution of discharged exhaust gas. Additionally, hot air is delivered to the hog house by convection and hotair is guided to flow. The direction and quantity of hot air can be controlled. Therefore, hot air can be delivered to all directions instead of concentrating in one direction. Excessively high localtemperature is avoided. Balanced delivery of hot air is ensured. Therefore, healthy growth of a hog is ensured.

Owner:佛山市辉华生物科技有限公司

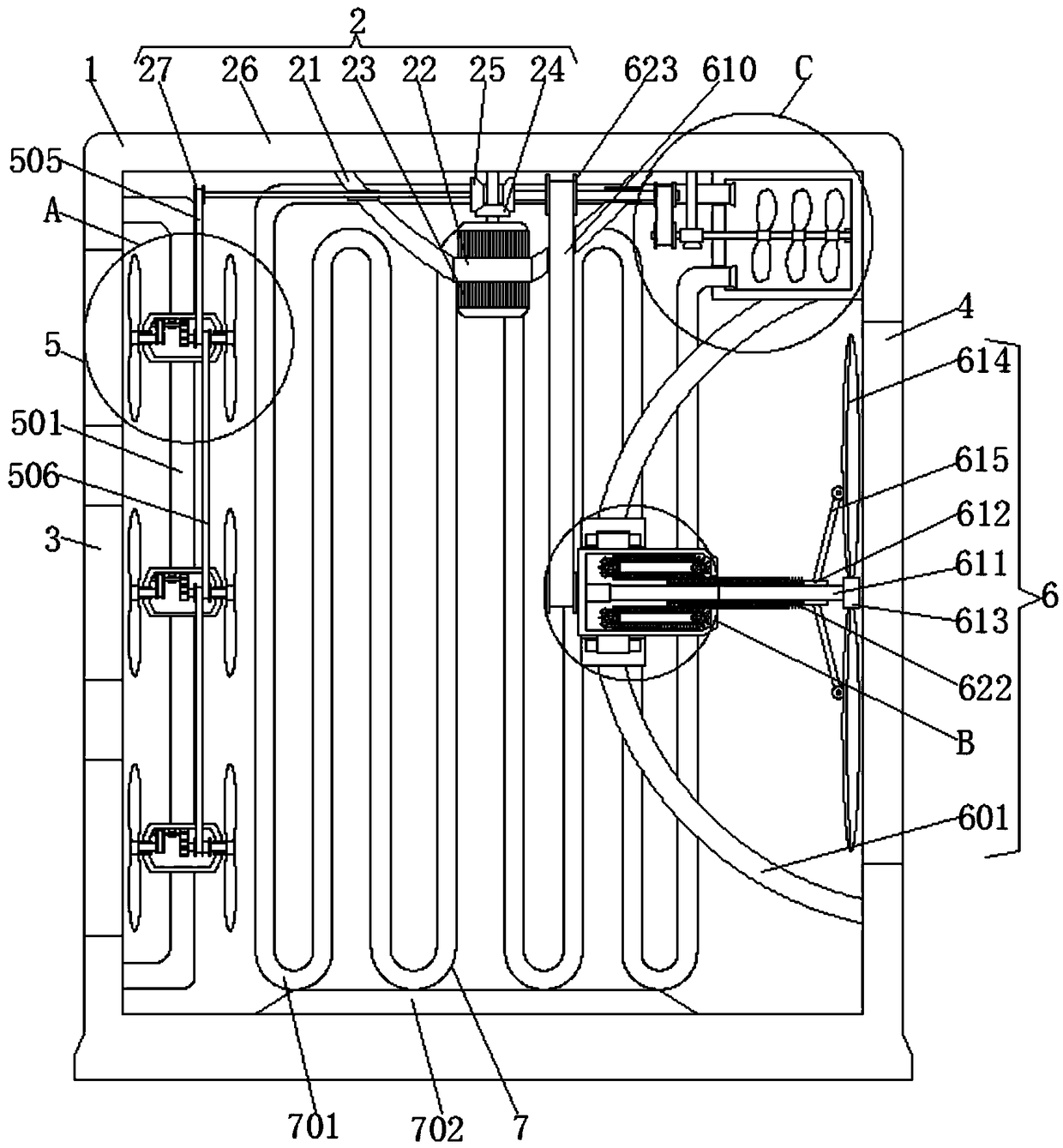

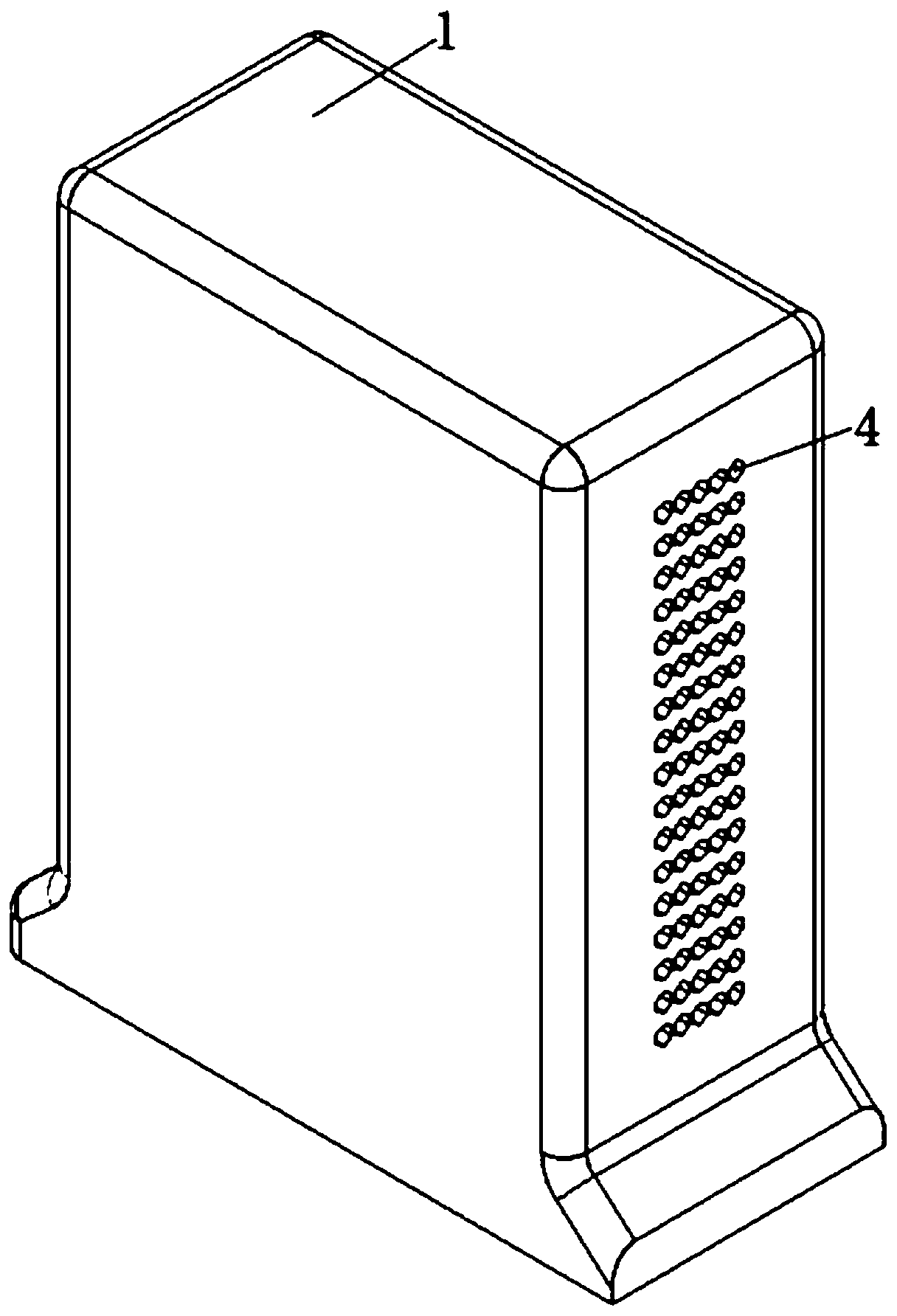

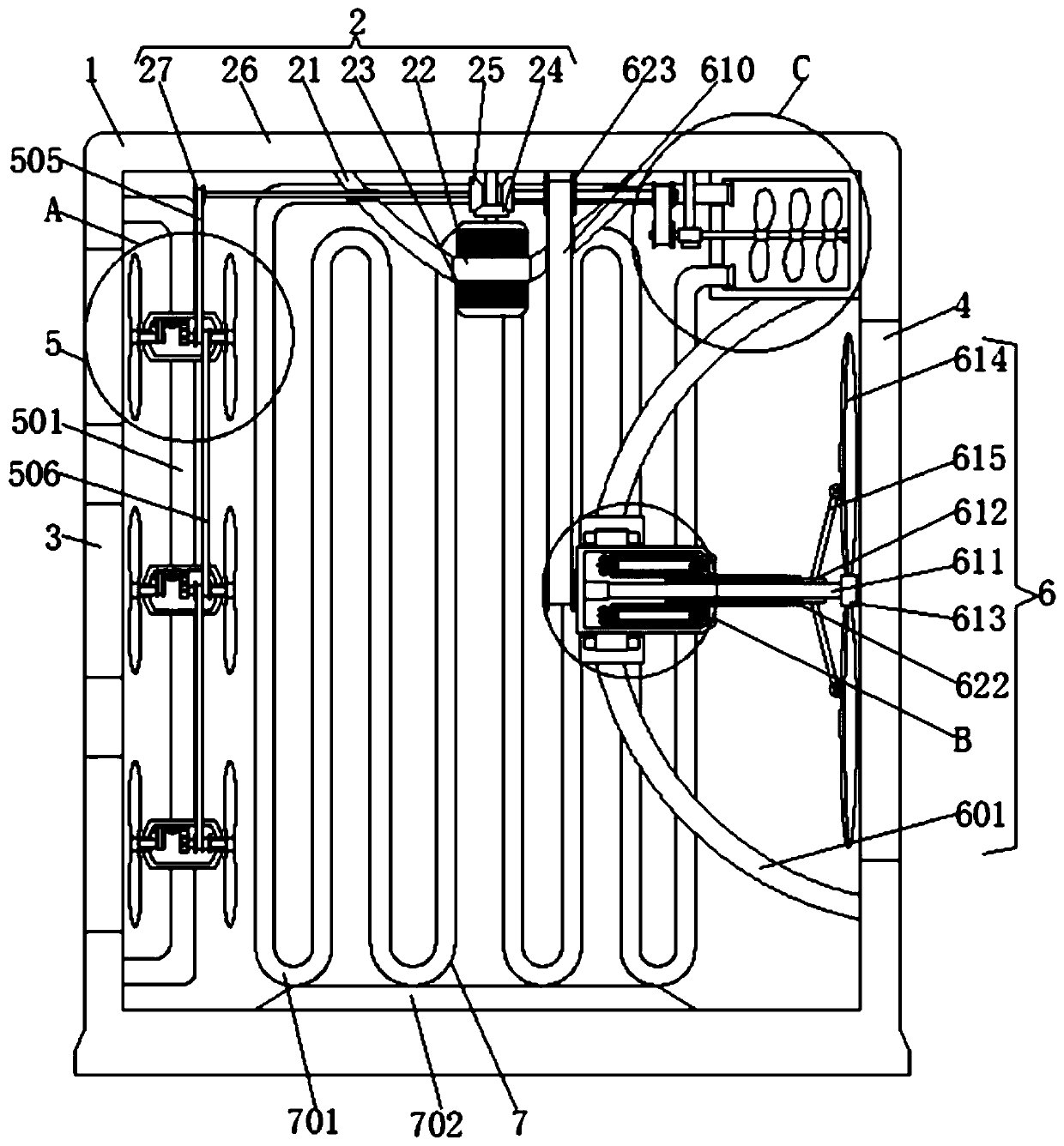

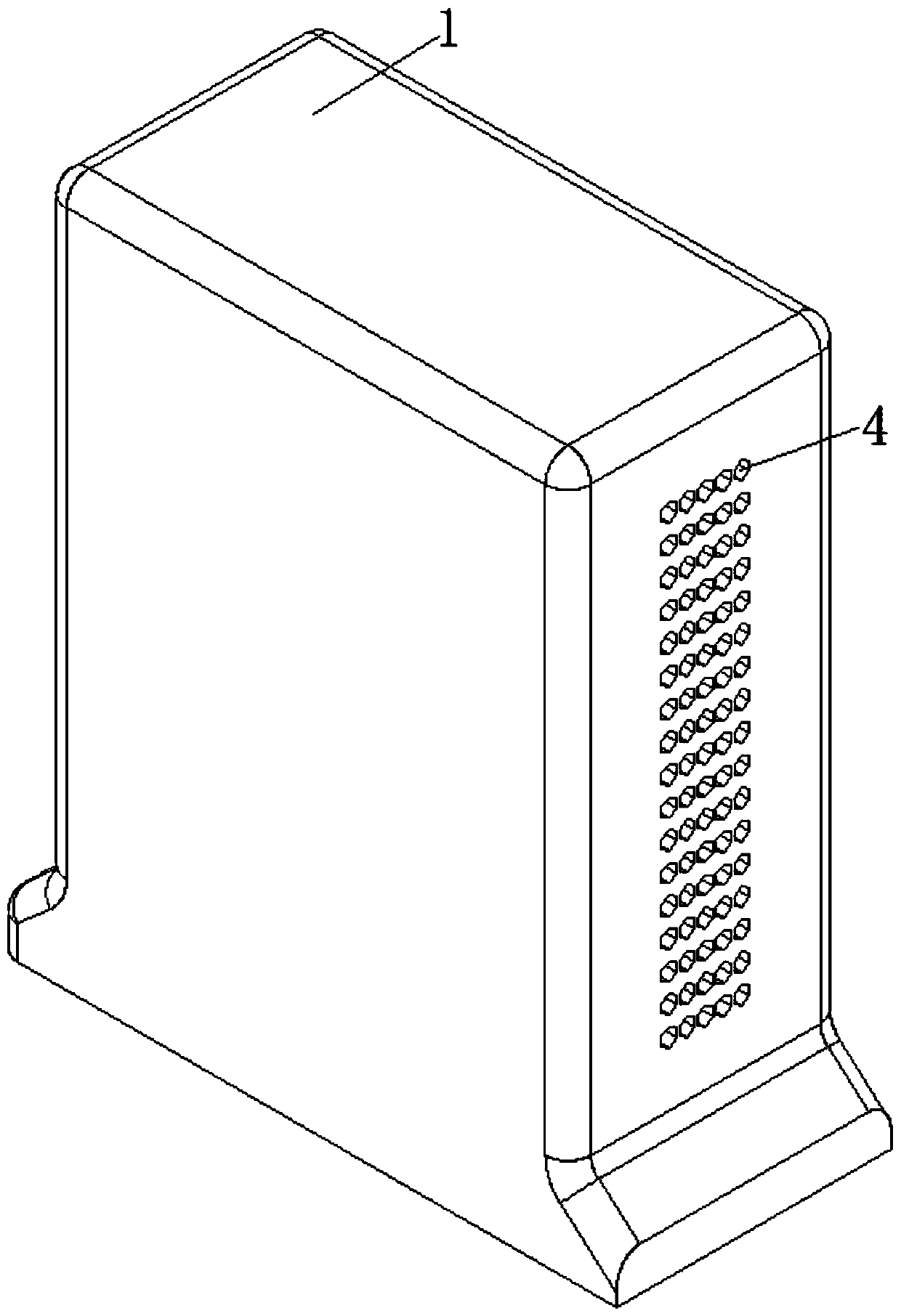

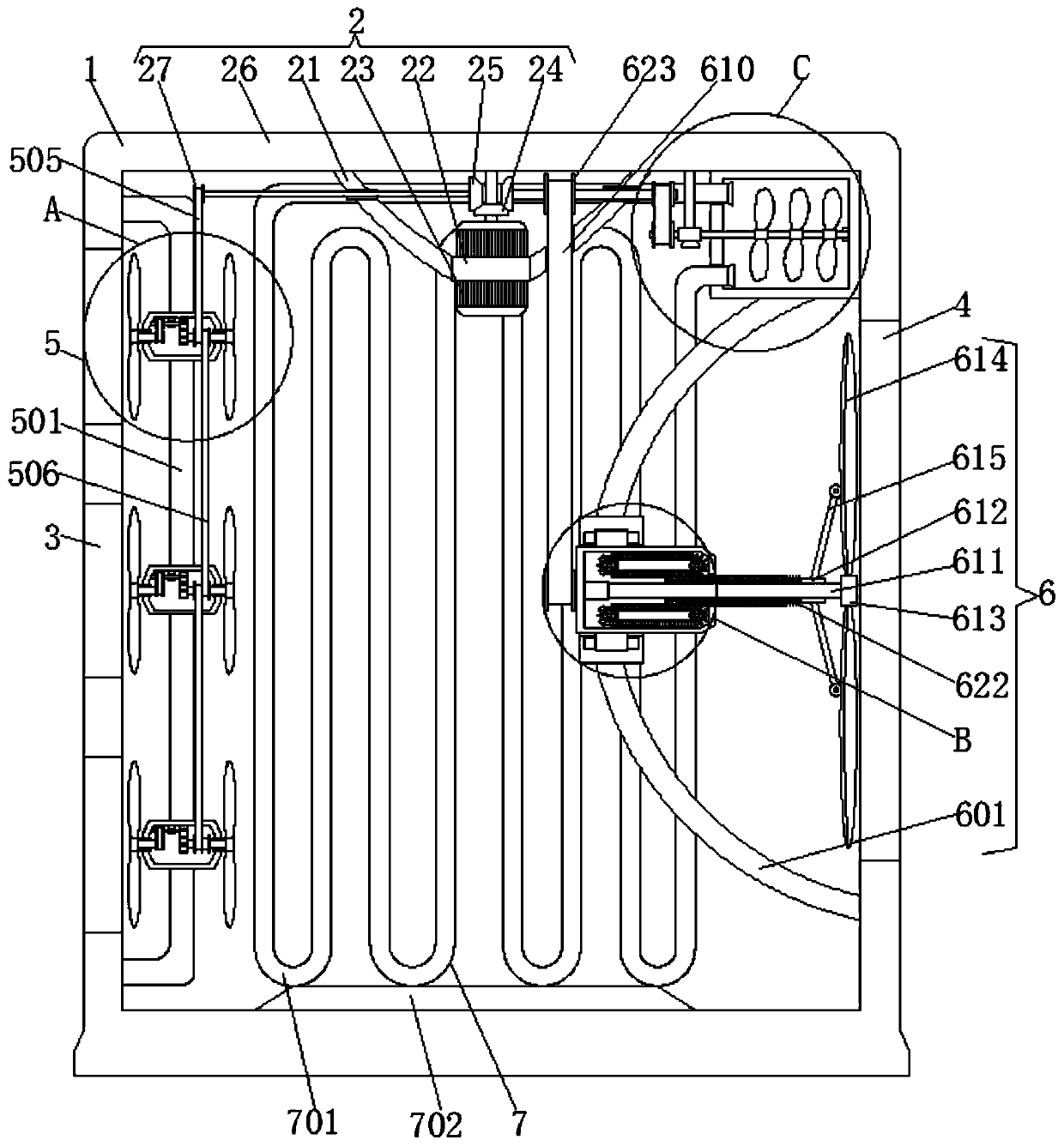

Disturbed flow type bidirectional ventilated water-cooled computer case

ActiveCN108776535AEasy dischargeSpeed up the flowDigital processing power distributionComputer engineeringAirflow

The invention relates to the technical field of computers, in particular to a disturbed flow type bidirectional ventilated water-cooled computer case. The technical problem to be solved by the invention is low heat dissipation efficiency of the conventional case. In order to solve the above technical problem, the invention provides a disturbed flow type bidirectional ventilated water-cooled computer case, comprising a case body, wherein a total driving mechanism is fixedly connected to the top of the inner wall of the case body, a plurality of air vents and a plurality of air inlets are respectively formed in two sides of the case body, a disturbed flow ventilation device is fixedly connected to the air vents on one side of the inner wall of the case body, and the output end of the total driving mechanism is movably connected with the input end of the disturbed flow ventilation device. In the technical solution, the disturbed flow device can extract the hot airflow inside the case during starting and disturb the airflow to cause the airflow to flow disorderly, so that the airflow can spread to all corners of the case, and the hot airflow inside the case can be discharged quickly.

Owner:深圳华创电科技术有限公司

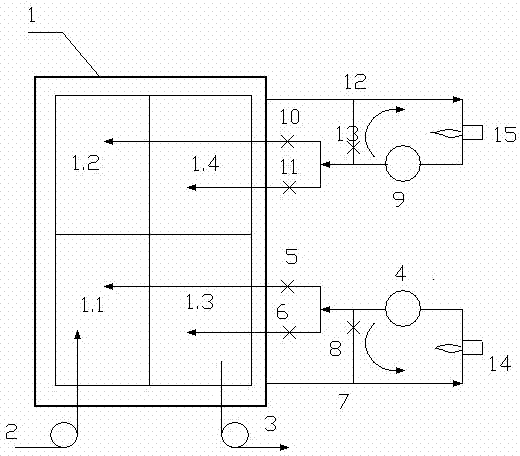

Impregnated tire fabric thermal treatment device and implementing method thereof

ActiveCN103924410AChange timeChange wind speedTextile treatment machine arrangementsHeating timeThermal treatment

The invention relates to an impregnated tire fabric thermal treatment device and an implementing method thereof. The impregnated tire fabric thermal treatment device comprises a main oven, an outer circulating system, a tire fabric lead-in roll and a tire fabric lead-out roll. The main oven is divided into four drying blocks. The outer circulating system is provided with a fan, hot air of the main oven is provided by a heating device, and the outer circulating system is used for adjusting air speed and heating time when the tire fabric speed is changed. By the modified impregnated tire fabric oven, energy source can be saved, air speed and treatment time of the tire fabric can be adjusted by vehicle speed, production of defective tire fabrics is greatly reduced, automation degree is high and labor intensity of workers is reduced.

Owner:JIANGSU HONGSHENG NEW MATERIAL

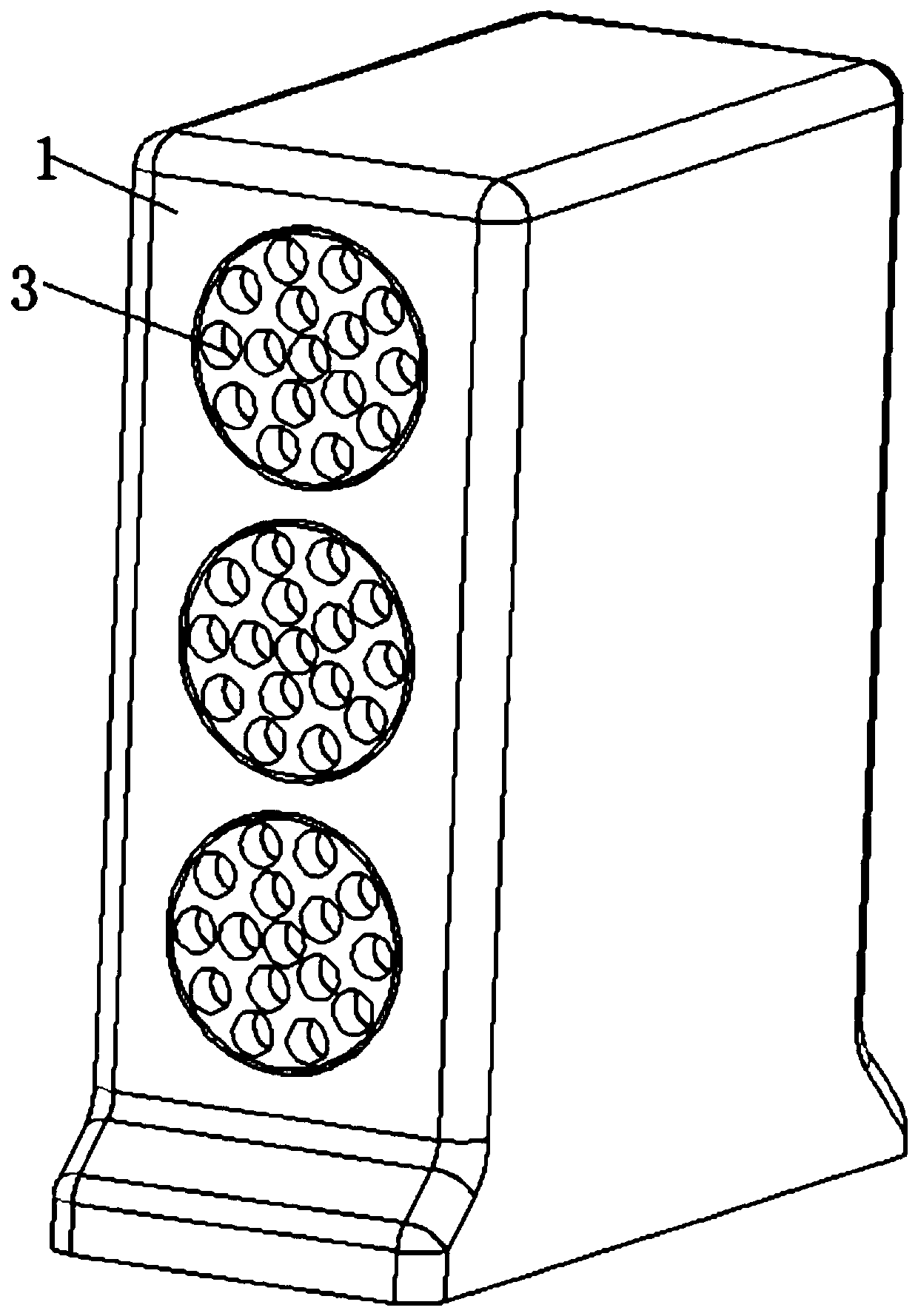

Water-cooled computer mainframe box and cooling method thereof

InactiveCN111103952AEasy dischargeSpeed up the flowDigital processing power distributionMechanical engineeringPhysics

Owner:崔永平

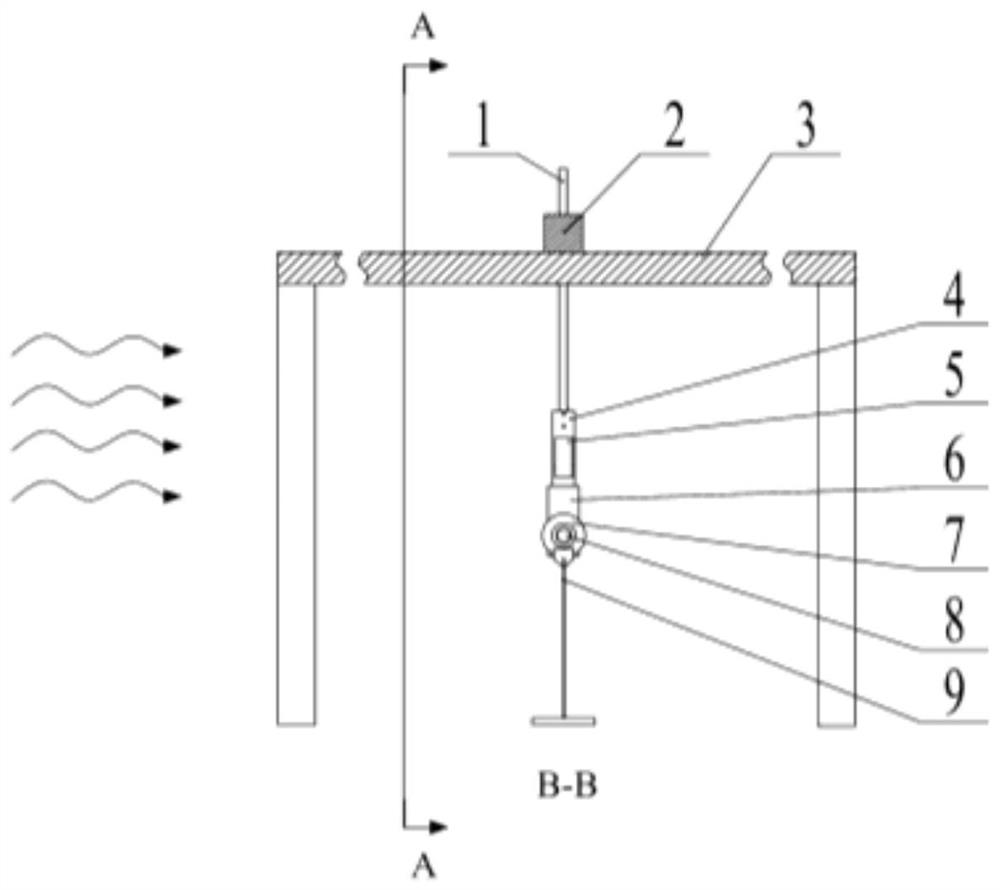

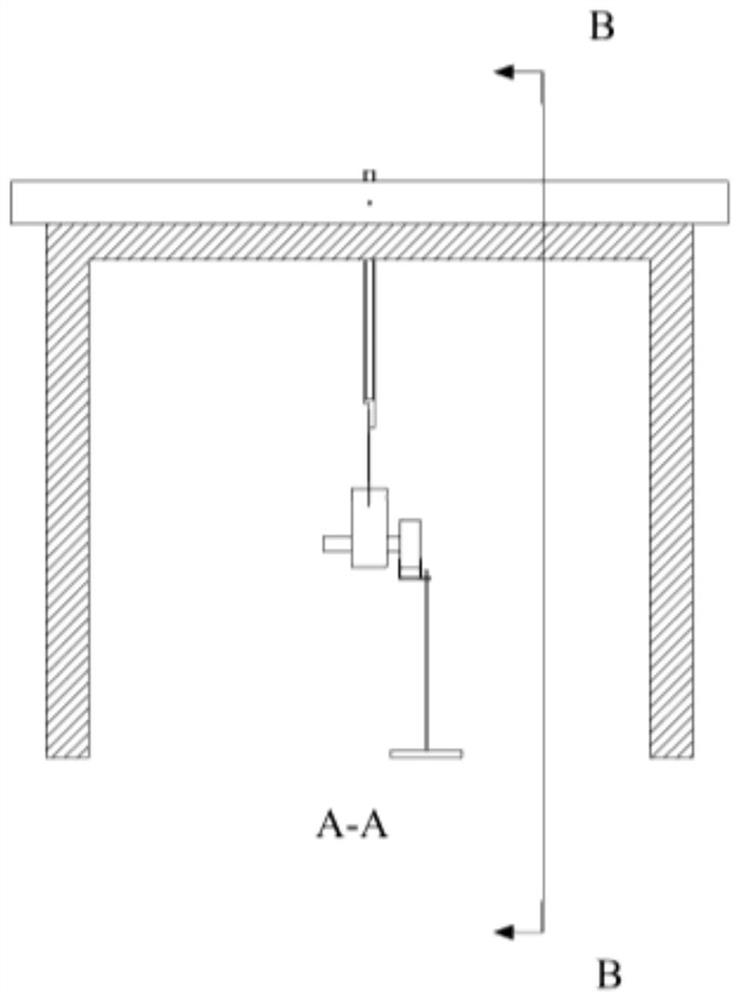

Piezoelectric hybrid electromagnetic energy collector testing device and testing method thereof

ActiveCN111929515ASolve vibration instabilityChange wind speedAerodynamic testingElectrical testingPhysicsMagnet

The invention discloses a piezoelectric hybrid electromagnetic energy collector testing device. The testing device comprises a wind tunnel, a cross beam traverses the top of the wind tunnel, the crossbeam is connected with a cantilever beam through a connecting rod, and the cantilever beam is located in the wind tunnel. A piezoelectric fiber sheet is adhered to the cantilever beam, and the piezoelectric fiber sheet is electrically connected with an external load resistor. The end, away from the connecting rod, of the cantilever beam is fixedly connected with an end mass block. Cylindrical magnets are attracted to the two sides of the end mass block. The two cylindrical magnets are opposite to each other, a clamping frame is arranged close to the cylindrical magnets, a coil is arranged atthe end, close to the cylindrical magnets, of the clamping frame, and the coil is electrically connected with the external load resistor. The testing method of the piezoelectric hybrid electromagneticenergy collector testing device solves the problem that in the prior art, vibration of a collector is unstable.

Owner:XIAN UNIV OF TECH

Rotatable windshield device for highway bridge

ActiveCN109183637BPlay the role of buffer protectionAvoid destructionProtective constructionBridge structural detailsAir velocityAgricultural engineering

The invention discloses a rotatable windshield device for highway bridges, which belongs to the technical field of traffic safety and solves the problem that the angle adjustment of the windshield in the existing device is inconvenient, and the windshield angle cannot be adjusted according to changes in seasons and weather. , which weakens the problem of windshield effect; its technical characteristics are: including a base, a support column and a windshield, the middle position of the upper surface of the base is fixed and welded with a support column, the upper part of the support column is sleeved with a bearing seat, and the bearing seat It is rotatably connected with the support column, and a torsion spring is installed at the bottom of the bearing seat; the outer surface of the bearing seat is fixedly connected with an external threaded sleeve with bolts, and the two side walls of the external threaded sleeve are fixed with welded windshields; the present invention can avoid The windshield breaks under the impact of strong cross winds, prolonging the service life of the windshield, and at the same time, it can enhance the gripping ability of the base when the wind speed is high, and enhance the stability of the base.

Owner:江西九江长江公路大桥有限公司

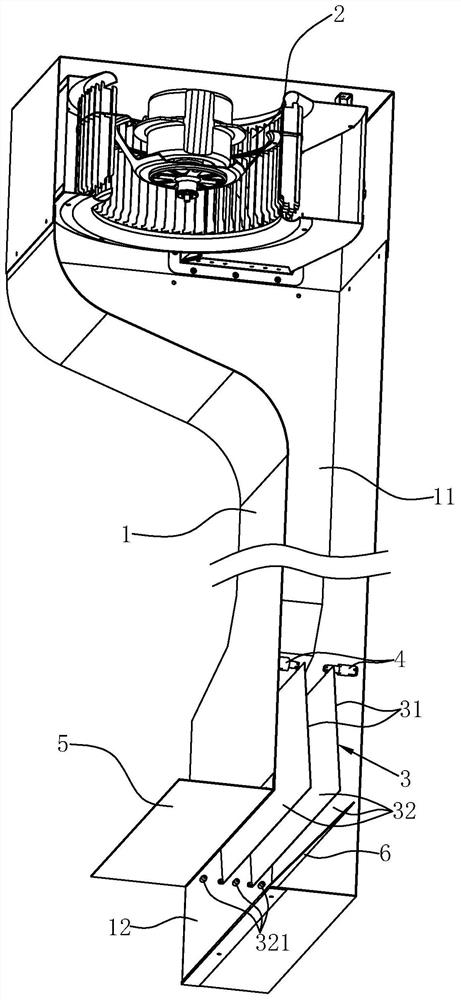

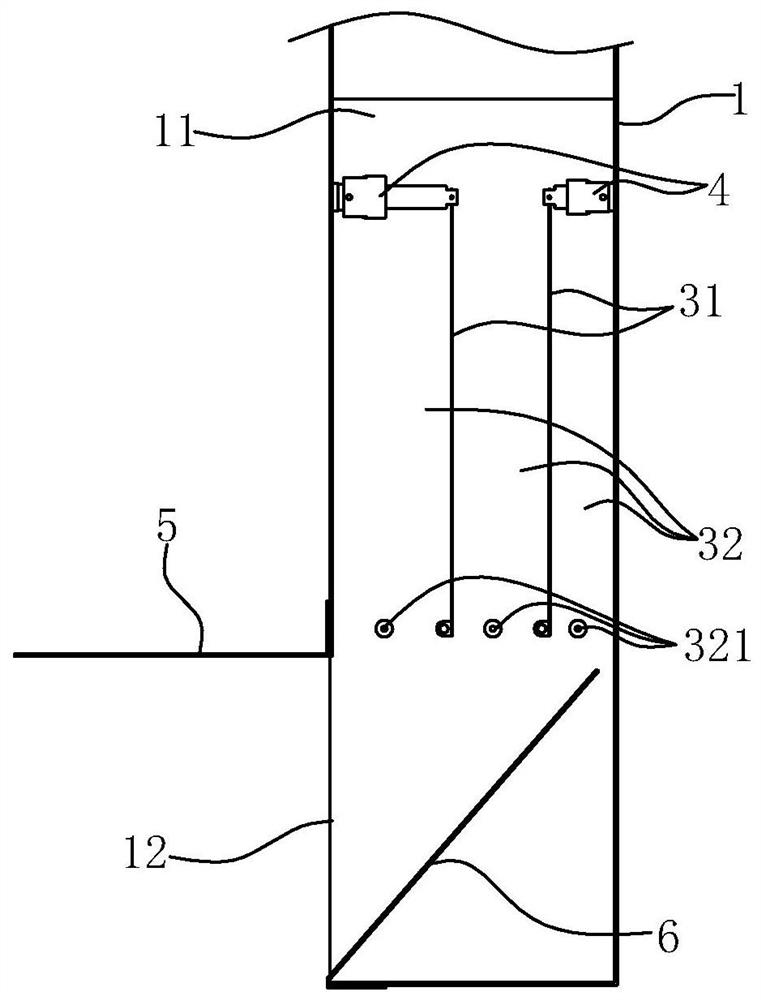

Range hood and working method

ActiveCN113446641AReduce lossesAchieve regulationDomestic stoves or rangesLighting and heating apparatusAir volumeAir velocity

The invention relates to a range hood. The range hood comprises a machine shell with an air channel and a fan arranged in the air channel, wherein a suction opening is formed in the lower portion of the machine shell; an air guide component is arranged at the position, close to the suction opening, in the machine shell and comprises at least one flow guide plate; the area, close to the suction opening, in the machine shell is divided into at least two air inlet channels through the flow guide plates; the flow guide plates are connected to the interior of the machine shell in a front-back swinging mode; a driving mechanism capable of driving the flow guide plates to swing is further arranged on the machine shell; and air velocity transducers are arranged on the machine shell and correspond to the air inlet channels. The invention further provides a working method of the range hood, after the range hood is started, the thickness value of the upper end of each air inlet channel is correspondingly adjusted according to the air speed data of each air inlet channel, and then air speed balance is achieved. According to the range hood and the working method thereof, vortexes can be reduced, air volume loss can be reduced, and noise can be lowered.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

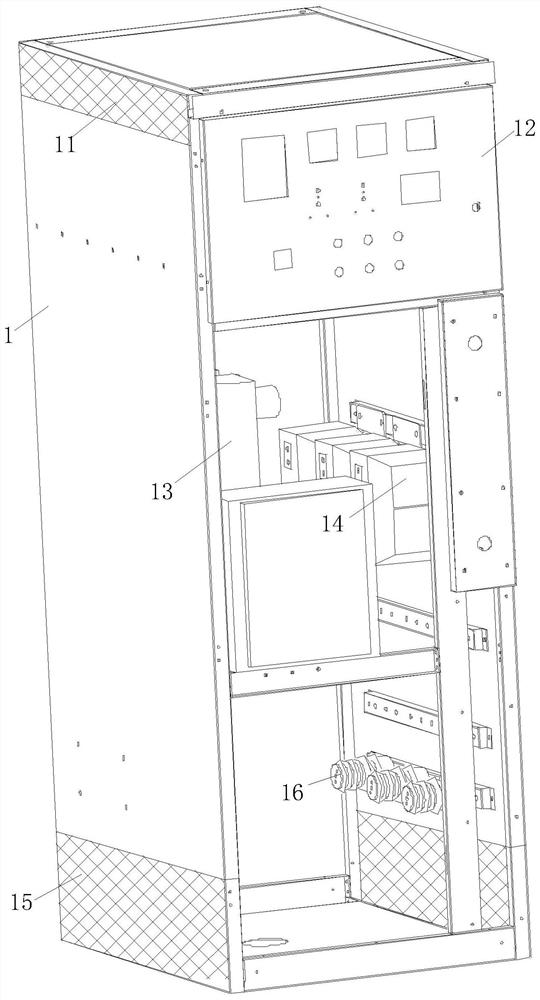

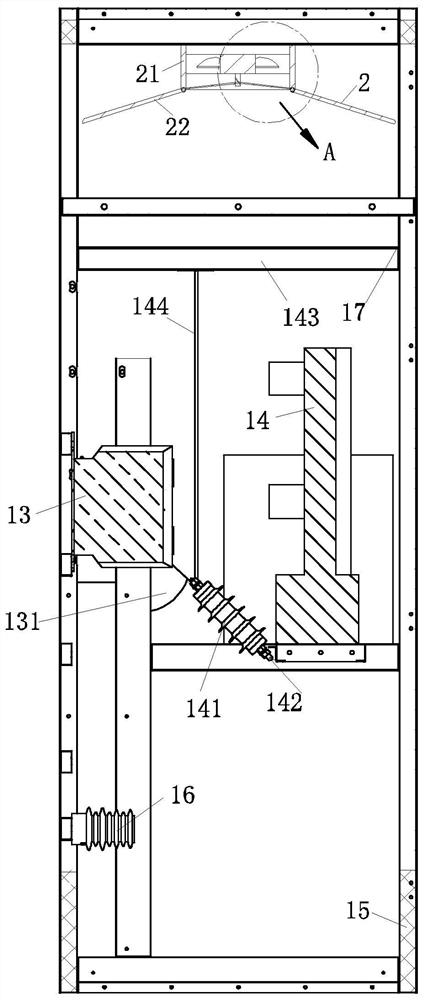

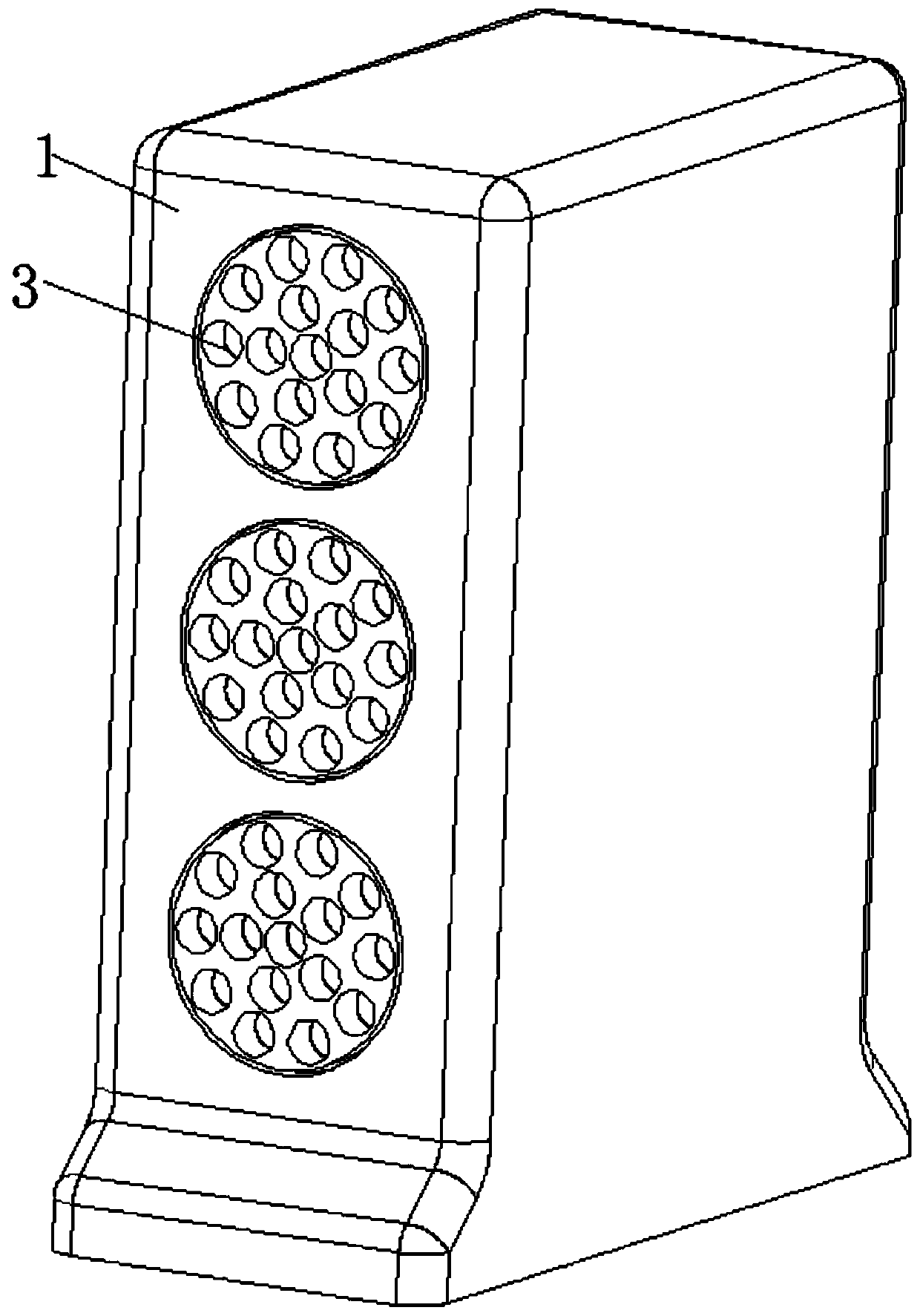

High-voltage power cabinet with good heat dissipation effect

ActiveCN111917035AGood cooling effectGood ventilationSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringAir velocity

The invention relates to the technical field of power cabinets, in particular to a high-voltage power cabinet with a good heat dissipation effect. The cabinet comprises a cabinet body, a PLC is fixedon the upper side wall of the cabinet body, air inlet hoods are arranged above the two side walls of the cabinet body, and air exhaust hoods are arranged below the two side walls of the cabinet body;air can be conveniently fed through the arranged air inlet hoods when a draught fan rotates, the air inlet hoods are arranged on the side walls of the cabinet body, dust can be prevented from enteringthe cabinet body, and water drops can be prevented from entering the cabinet body from the air inlet hoods at the top of the cabinet body when moisture regaining occurs to the cabinet body. The arranged exhaust hoods can exhaust air flowing from the top out of the cabinet body, circulation of air in the cabinet body is ensured, an arranged heat dissipation mechanism can rapidly blow air into thecabinet body, and when the heat dissipation mechanism carries out exhausting, the air speed in the cabinet body can be changed, so the heat dissipation effect of the cabinet body is improved; therefore, the air flowing speed in the cabinet body can be changed, and the ventilation effect of the cabinet body is better.

Owner:广东中盛纳科技有限公司

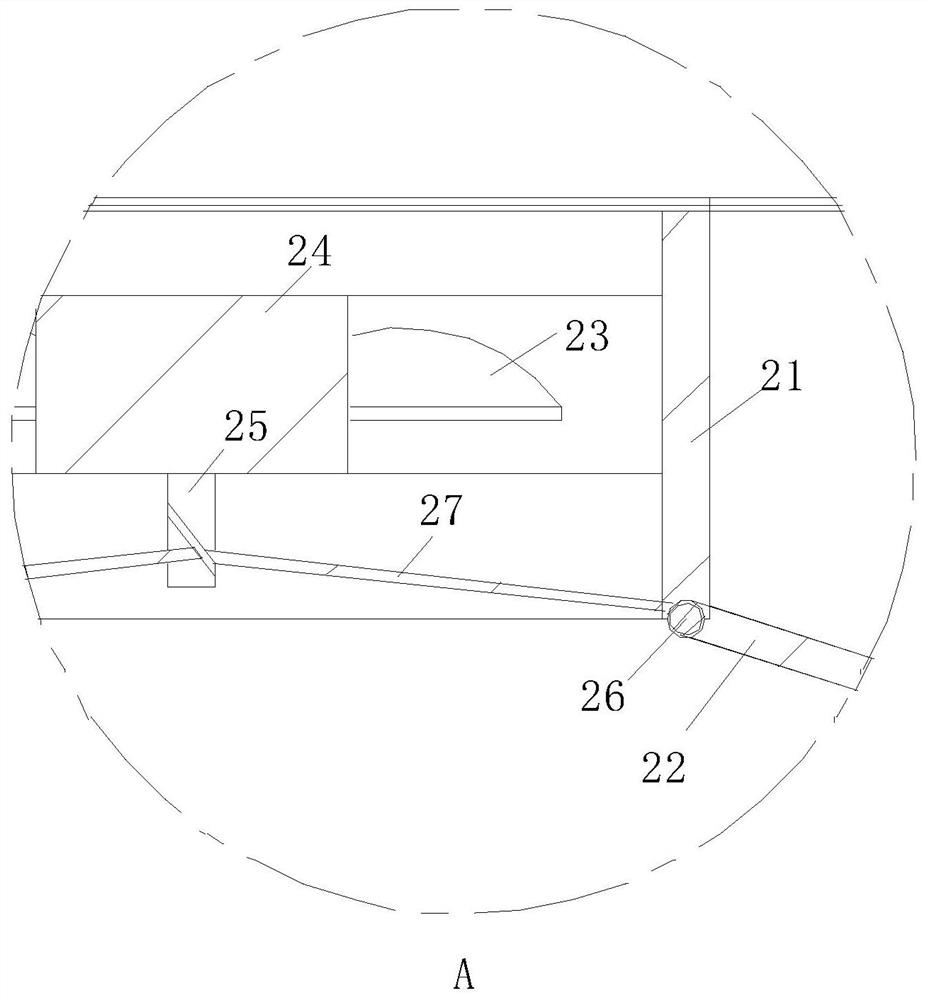

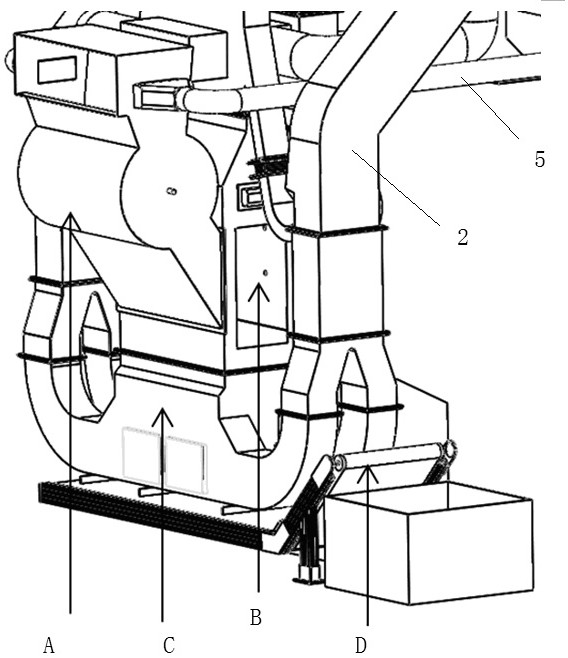

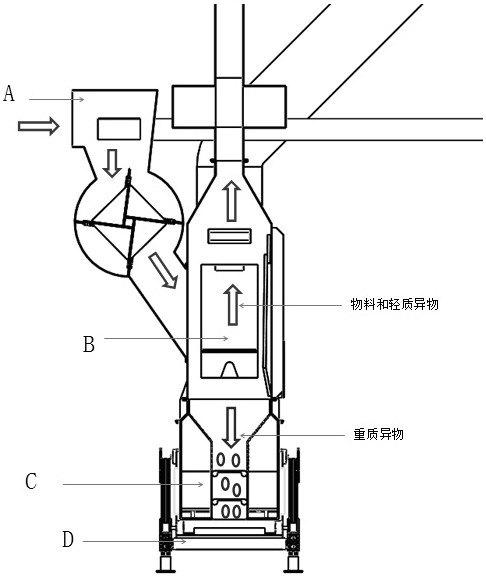

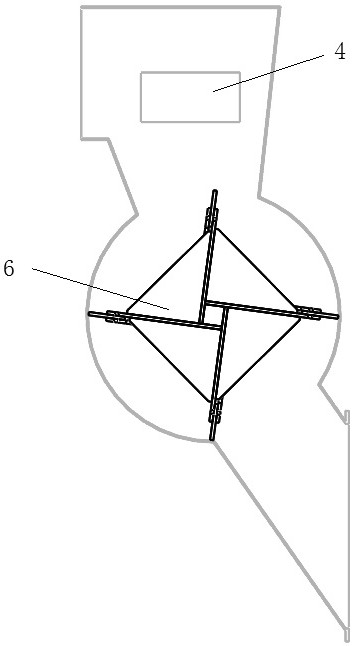

Heavy foreign matter removing device

The invention relates to a heavy foreign matter removing device, which comprises a feeding device A arranged at the end of a feeding vibration groove; the feeding device A is connected with the side face of a vertical air distribution chamber B; the lower end of the vertical air distribution chamber B is connected with the upper end of an air uniformizing device C, and the two ends of the air uniformizing device C are both connected with bifurcated pipelines; and each bifurcated pipeline is connected with a circulating fan through an air supply pipeline, and a heavy foreign matter conveying device D is located at the bottom of the air uniformizing device C. By greatly changing the flight path of materials, a heavy foreign matter is separated from materials through the gravity of the heavyforeign matter and then automatically discharged through an automatic device, tobacco leaf caking and tobacco stems can be well removed, and meanwhile, when the materials and the light foreign matterare blown upwards, the cross section of the vertical air distribution chamber can be changed by operating a pipeline reducing mechanism, so that the flow and the air speed of air are changed, the airsupply requirements under different conditions are met, and flexibility and variability are achieved.

Owner:NANJING TUZHI AUTOMATION TECH

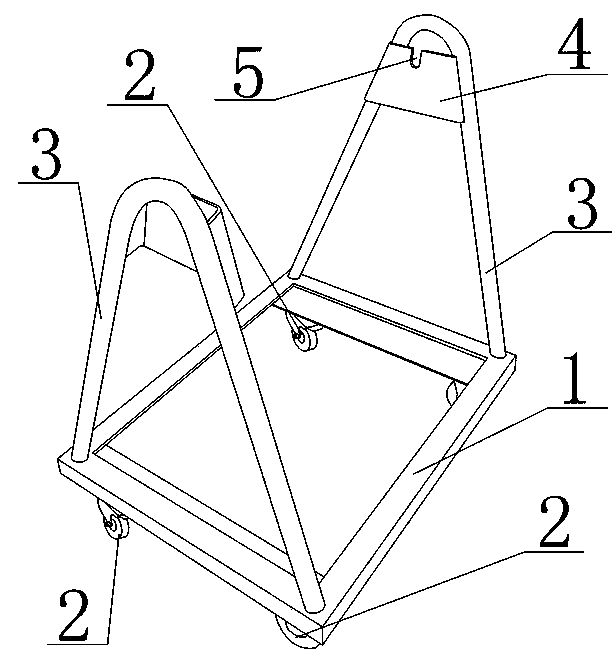

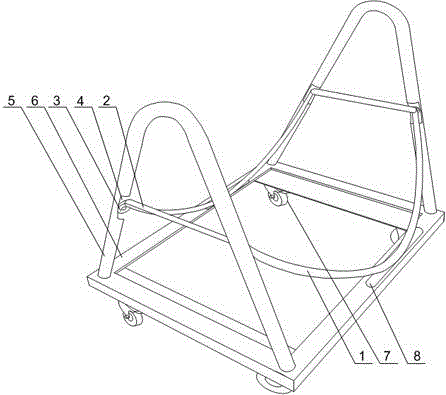

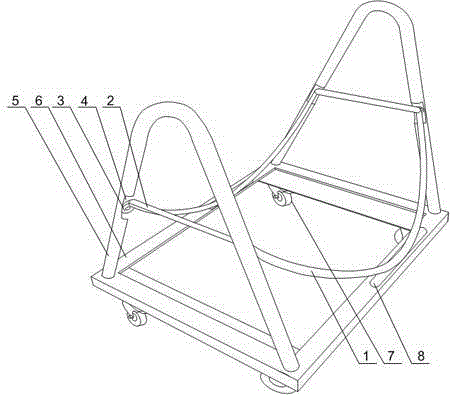

Air blower support for simulating automobile operating environment

InactiveCN103629485AEasy to testEasy ventilation performanceStands/trestlesOperating environmentWind speed

The invention discloses an air blower support for simulating an automobile operating environment. The air blower support comprises a flat plate frame formed by connecting steel in sequence, wherein four wheels are arranged on the bottom of the flat plate frame, the upper surface of the flat plate frame is provided with two parallel supports, the two supports are parallel with each other, hanging plates are installed on inner sides of the two supports, and hanging holes are arranged in the hanging plates. According to the air blower support, the hanging plates are arranged on the two supports, the two hanging plates are parallel with each other oppositely, the hanging holes are arranged in the two hanging plates, two hanging rods are installed on side faces of a blower, the hanging rods are inserted into the two hanging holes to form the blower making the hanging rods as supporting points, an air source capable of being pushed on the ground is formed, power of the blower can be regulated to change the air speed, and the purpose of flexibly simulating the environment is realized.

Owner:CHENGDU IYASAKA TECH DEV

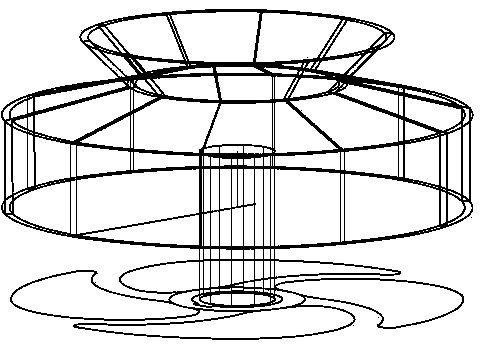

Fan filter unit with fixed surface air speed and controllable area

The invention relates to a fan filter unit with fixed surface air speed and controllable area. The fan filter unit comprises a device casing, the bottom of the device casing is provided with an air outlet, the top of the device casing is provided with a circular air suction port, a fan is arranged below the circular air suction port, a filter is arranged below the fan, and an air speed sensor is arranged at the center below the filter and is connected with a controller through a lead, wherein the controller is arranged on the top of the device casing and used for controlling rotation speed of the fan. The fan filter unit breaks through the conventional method of controlling air quantity by changing air speed via area fixing type, senses and monitors the air speed of the air outlet by means of the sensor and timely feeds the air speed back to the controller, and the controller can immediately transmits signals to enable rotary shafts on two sides of a box to rotate in or out to adjust the area of a windward side, so that air quantity can be changed, air speed can be stabilized, and airflow distribution can be constant.

Owner:LINKWELL SCI & TECH CO LTD

Vehicle-mounted air conditioner for new energy vehicle

InactiveCN114590105AImprove experienceChange wind speedAir-treating devicesVehicle heating/cooling devicesIn vehicleVentilation duct

The vehicle-mounted air conditioner for the new energy vehicle comprises an air conditioner box and a plurality of air outlet assemblies, and all the air outlet assemblies are connected with the air conditioner box through ventilation pipelines; the air outlet assembly comprises a fixing base, and an air inlet channel and an air outlet are formed in the fixing base. The air outlet assembly further comprises a soft air plate and an air guide plate. The air guide plate is arranged on the upper edge of the outlet of the air inlet channel, is rotationally connected with the fixed seat and can change the size of the air outlet area of the air outlet; the soft air plate is in sliding connection with the fixed seat and can be switched between a staggered state and a shielding state relative to the air outlet; the soft air plate and the air guide plate work in a matched mode, when soft air is needed, the air guide plate rotates to the maximum air outlet area state, and the soft air plate is automatically switched to the shade state, when direct blowing air is needed, the air guide plate rotates to the minimum air outlet area state, and the soft air plate is automatically switched to the staggered state, and therefore under the condition that the power of the air conditioner is not changed, the air conditioner can be directly blown. The wind speed is changed, and the user experience is improved to a great extent.

Owner:李清龙

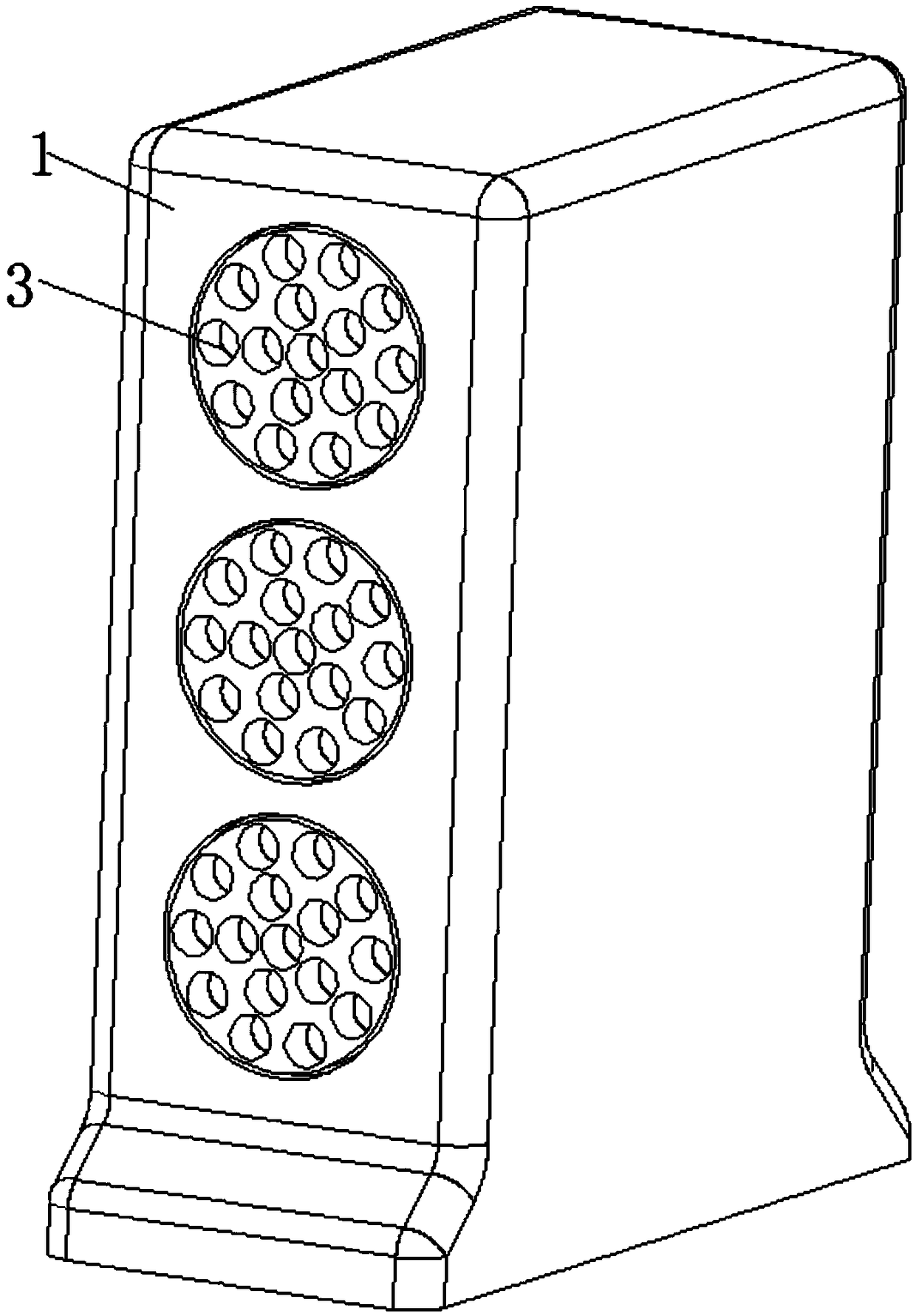

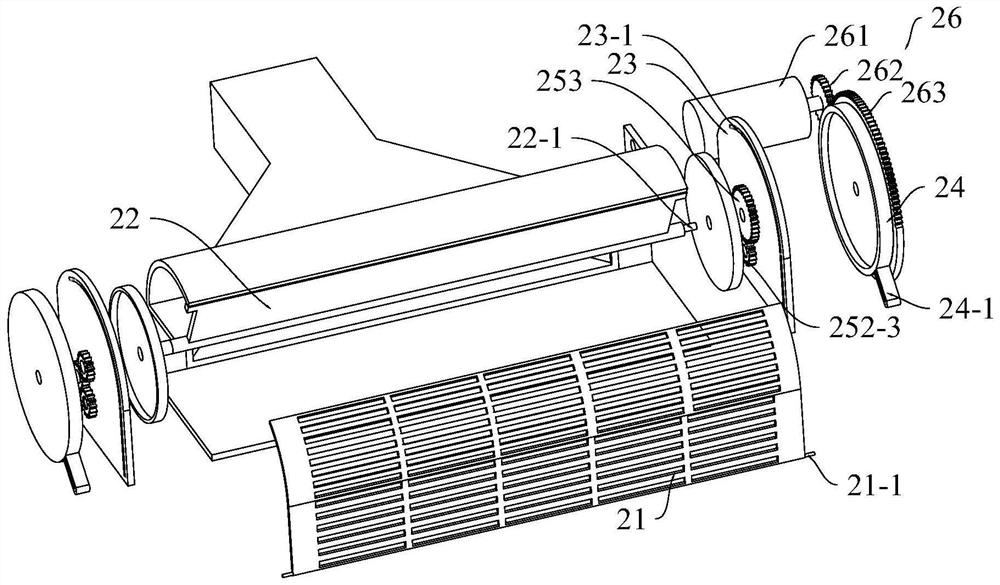

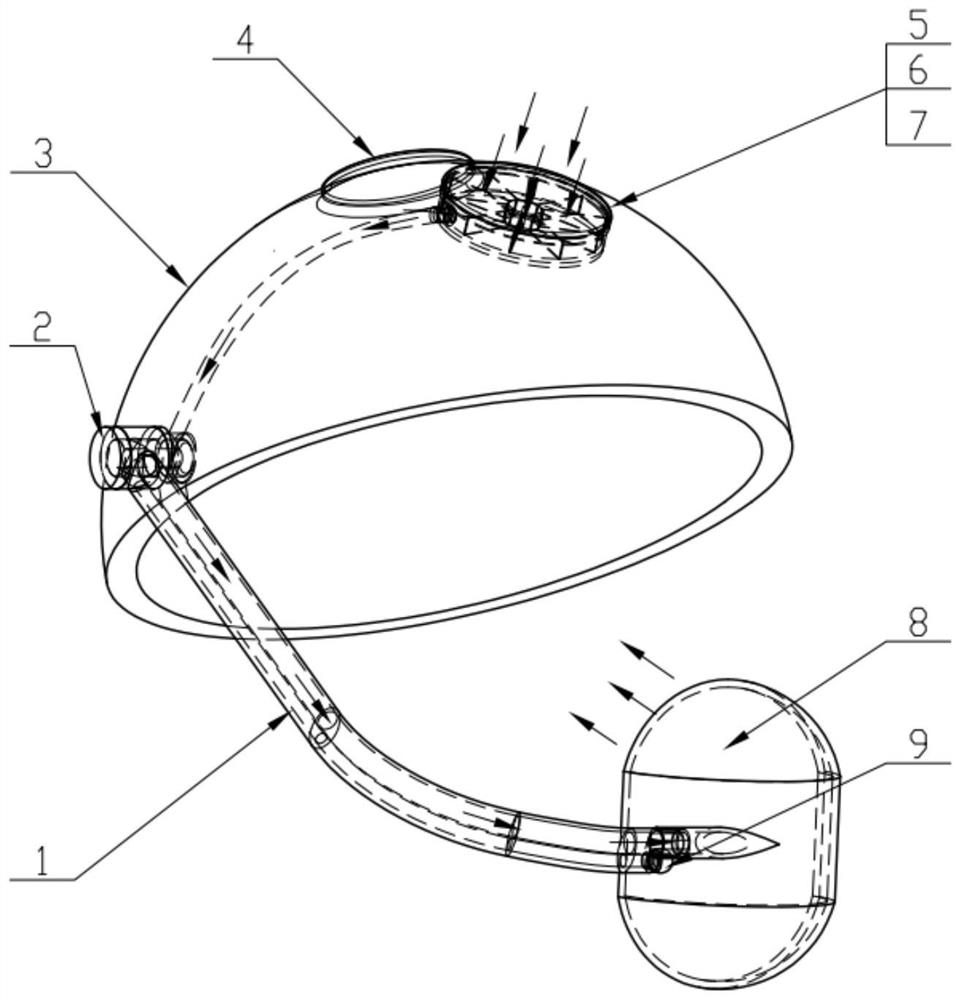

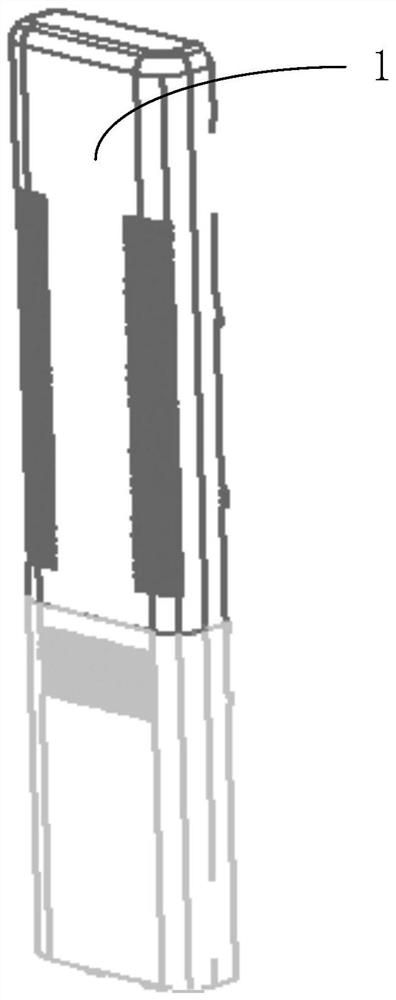

Head-mounted low-resistance active particle preventing respirator

InactiveCN114699670AFast and convenient statusAdjustable stateBreathing filtersBreathing masksPhysical medicine and rehabilitationNose

The invention discloses a head-mounted low-resistance active particle prevention respirator. The helmet and mask separated design is adopted, wearing is convenient, the weight is concentrated on the head through the helmet type respirator, compression of the ear hanging type mask on the ears is reduced, and wearing is convenient and stable; the storage state and the use state of the mask can be quickly and conveniently converted, the distance between the mask and the mouth and the nose can be adjusted, and a semi-closed space is formed between the mask and the mouth and the nose. The mask with the bionic structure is adopted, the mask is attached to the face of the human body, the low-resistance filtering device composed of the filtering unit and the active ventilation unit is adopted, active particles and fine particles such as haze are effectively removed, meanwhile, the active ventilation mode is utilized, the breathing resistance is reduced, the comfort of free breathing of the human body is improved, and water vapor cannot be generated on glasses.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Multifunctional intelligent document scanner

The invention discloses a multifunctional intelligent document scanner, and relates to the technical field of document scanning. The multifunctional intelligent document scanner comprises a transmission table and a scanner body, the scanner body is fixed to the top of the transmission table, the top of the transmission table is arranged in a concave shape, and two right transmission rollers and two left transmission rollers are arranged at the top of the transmission table. According to the multifunctional intelligent document scanner, light rays emitted by the lamp holder can be reflected by arranging the reflective lens, when no paper exists on the top of the reflective lens, the reflective capability of the reflective lens is high, reflected light rays sensed by the light sensing module are also high, at the moment, the control switch enables the scanning module to be closed, and when paper exists on the reflective lens, the control switch controls the scanning module to be opened. The light reflected by the reflective lens is weaker, and the reflected light sensed by the photosensitive module is weaker, at the moment, the control switch enables the scanning module to be started, so that automatic scanning of a document is realized, and the whole scanner does not need to be manually opened and closed during periodical multiple times of scanning.

Owner:陈昌乐

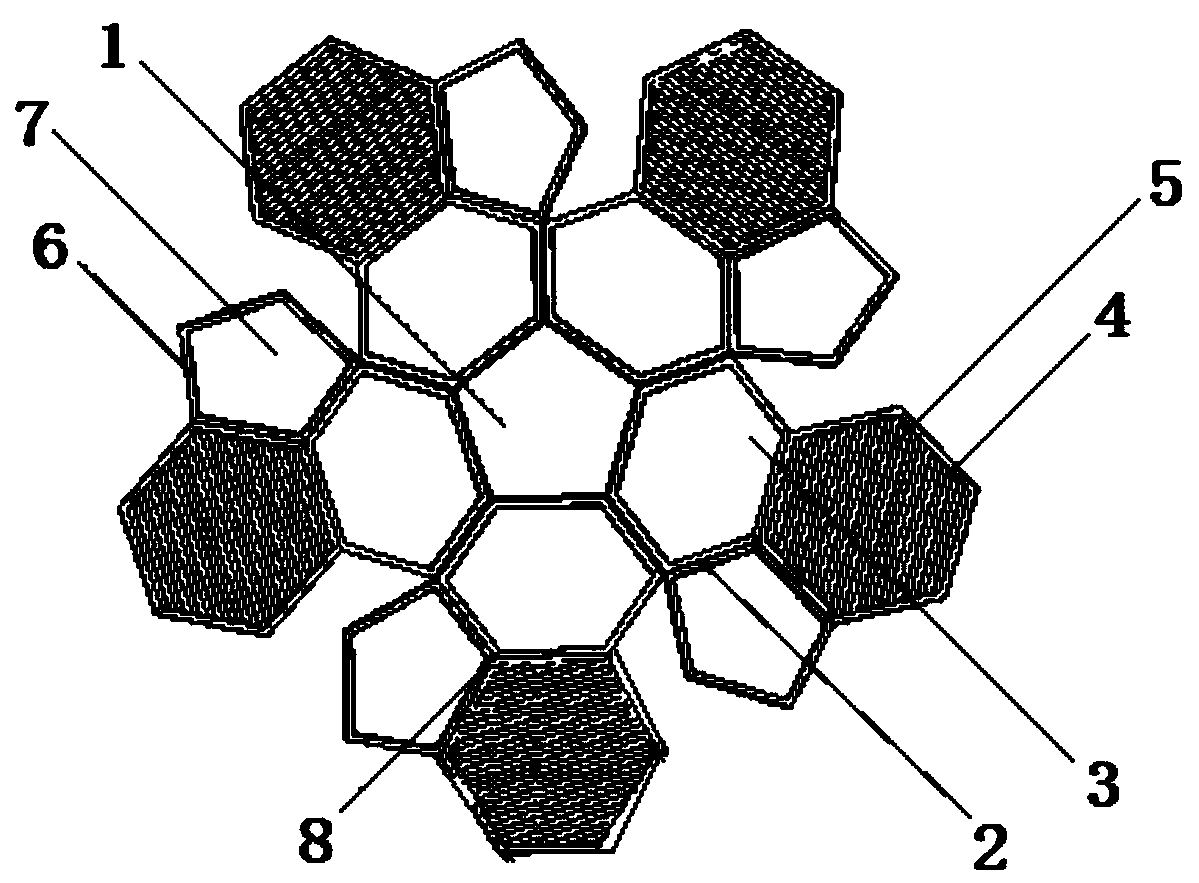

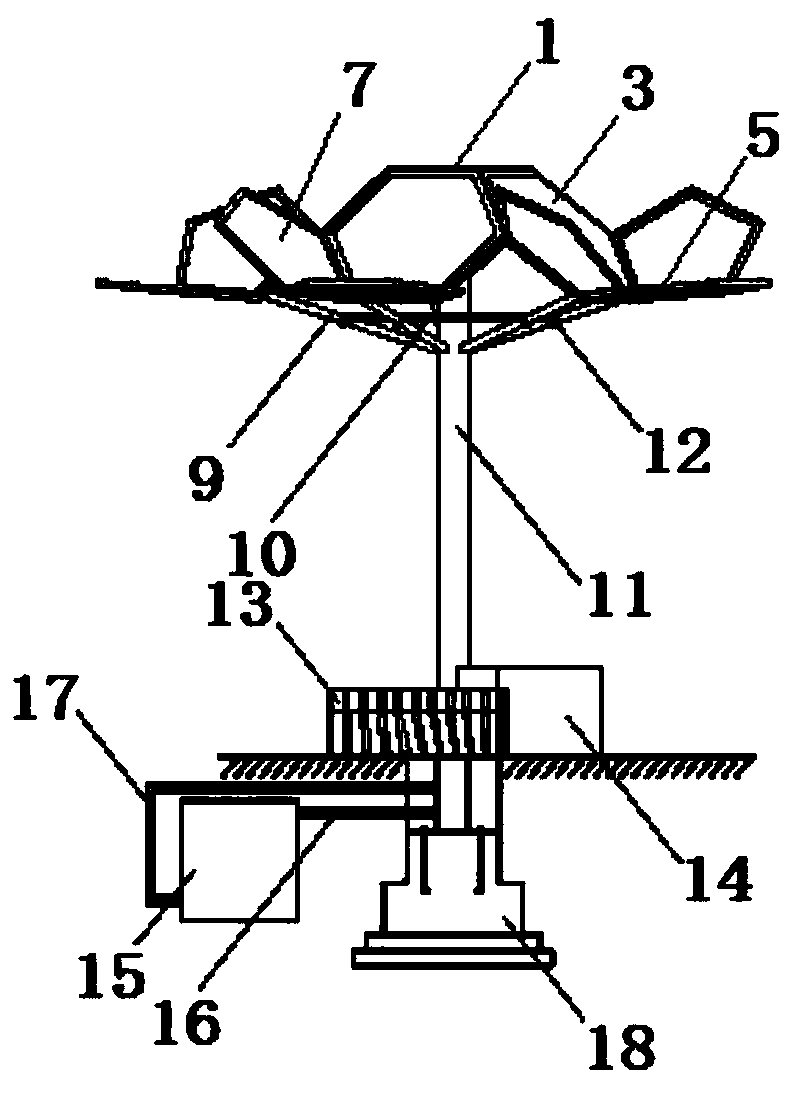

A kind of micro-climate adjustment pavilion

ActiveCN107060385BReduce the temperatureReduce humidityGeneral water supply conservationSimultaneous control of multiple variablesStructural engineeringSolar battery

The invention discloses a micro-climate regulating pavilion, which belongs to the field of climate regulating facilities. Based on the pavilion base structure, a regular pentagonal roofing steel plate, five regular hexagonal solar panels, and five regular hexagonal electric control panels are arranged on the top of the pavilion. Louvers and five regular pentagonal shading panels; the pillars include a central column fixed under the roofing steel plate, a side support rod connecting the central column and the circumference of the top of the pavilion, and a horizontal connecting rod surrounding the inner side of the side support rod. The present invention is based on the components of the pavilion that the climate adjustment pavilion itself has, and combines the rainwater recycling system and the spray device on the top edge of the pavilion. In this way, the climate humidity and temperature under the pavilion can be automatically adjusted according to the spray switch; in addition, the top part of the pavilion is set It is a movable louver that can be opened or closed, and the electric control louver can be opened or closed to adjust the shade area, wind speed and temperature under the pavilion. The electricity needed for these climate-conditioning devices is provided by solar power plants installed on the pavilion roof and under the seats.

Owner:南京海文景观设计工程有限公司

Air conditioner control method, terminal, air conditioner, and computer-readable storage medium

ActiveCN108458444BImprove experienceAvoid technical problems that cannot meet individual needsMechanical apparatusSpace heating and ventilation safety systemsProcess engineeringRefrigeration

The invention discloses an air conditioner control method, a terminal, an air conditioner and a computer readable storage medium. The air conditioner control method comprises the steps that environment parameters of air feeding areas of air outlets of the air conditioner detected by an infrared sensor are received, the target air feeding areas with the environment parameters being in the preset value range are confirmed from the air feeding areas, and the air outlets of the target air feeding areas are adjusted to start a windless mode. By means of the air conditioner control method, the terminal, the air conditioner and the computer readable storage medium, according to the environment parameters of all the air feeding areas, whether the corresponding air outlets start the windless mode or not is intelligently controlled, the problems in the prior art that in the refrigeration or heating process of the air conditioner, to realize the purpose of cooling or heating, wind of the air outlet blows directly to the human body, and the comfort experience degree of the human body is affected are effectively solved, by means of starting of the windless mode, concentrated air flow of the airoutlets is made to be dispersed into many fine air lines, furthermore, the air outlet mode of the other air outlets with the environment parameters being not in the preset value range remains unchanged, the function of refrigeration or heating is realized, and the experience degree of users is improved at the same time.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

Double-layer turbulent flow type snow blocking wall

InactiveCN111501590AImprove efficiencyExtended service lifeProtective constructionEngineeringMechanical engineering

The invention discloses a double-layer turbulent flow type snow blocking wall. The wall comprises two stand columns arranged side by side. A first snow blocking net, a first spoiler, a second snow blocking net, a second spoiler and a third snow blocking net are sequentially arranged between the two stand columns from top to bottom. Gaps are formed between the first spoiler and the first snow blocking net and between the first spoiler and the second snow blocking net, gaps are formed between the second spoiler and the second snow blocking net and between the second spoiler and the third snow blocking net, when the snow blocking device is used, the third snow blocking net is adjacent to the ground, and gaps are formed between the third snow blocking net and the ground. The snow blocking wallis high in snow blocking efficiency, long in service life, capable of reducing maintenance cost, wide in application range, capable of adapting to various complex working conditions and capable of meeting the snow prevention requirement of engineering construction.

Owner:NORTHWEST RES INST CO LTD OF C R E C +1

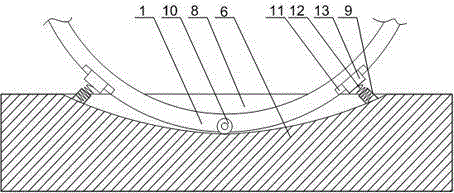

Air blower support used for automobile testing

InactiveCN104100809AEliminate unwanted effectsImprove stabilityPortable framesVibration suppression adjustmentsStopped workAir blower

The invention discloses an air blower support used for automobile testing. The air blower support comprises a square base and two balance adjusting structures, two side frames are mounted on the base and are parallel to each other, a groove is formed in each side strip, two arc-shaped plates are mounted between the side frames, small rollers are connected on the end portions of two ends of the arc-shaped plates, crescent grooves are formed in the base, the bottoms of the arc-shaped plates are slidably arranged in the crescent grooves through rollers, and the balance adjusting structures are arranged between the crescent grooves and the arc-shaped plates. The balance adjusting structures sequentially eliminate undesirable effect generated by vibration of the left end and the right end of an air blower, and sudden stress generated when the air blower is just started can be eliminated when the small rollers slide back and forth in the grooves, so that the arc-shaped plates and the air blower are enabled to maintain balance in the whole process from the time when the air blower starts to work to the time when the same stops working, and an air source capable of stably pushing on the ground is formed; the air blower is adjustable in power and changeable in air speed.

Owner:成都万顺达模具零件有限公司

Air conditioner control method, terminal, air conditioner, and computer readable storage medium

ActiveCN108489034BImprove experienceIntelligent adjustment of wind speedMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsAir velocity

The invention discloses an air conditioner control method, a terminal, an air conditioner and a computer readable storage medium. The air conditioner control method comprises the steps of receiving environmental parameters of air supply areas of air outlets of the air conditioner detected by an infrared sensor, determining a target air supply area with the environmental parameter being located ina preset numerical zone from the air supply areas, and adjusting the air supply velocity of the air outlet corresponding to the target air supply area according to a logical relationship between a preset environmental parameter and the air velocity. According to the logical relationship between the environmental parameter of each air supply area and the air velocity, the air velocity of the corresponding air outlet is intelligently controlled, so that the problem that in the prior art, during a cooling or heating process of the air conditioner, in order to achieve the aim of cooling or heating, the air velocity of the air outlets is unchanged, so that the human comfort experience is influenced is effectively solved; and in addition, air outlet modes of other air outlets with the environmental parameters being not located in the preset numerical zone are unchanged, and the user experience is improved while a cooling or heating function is realized.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

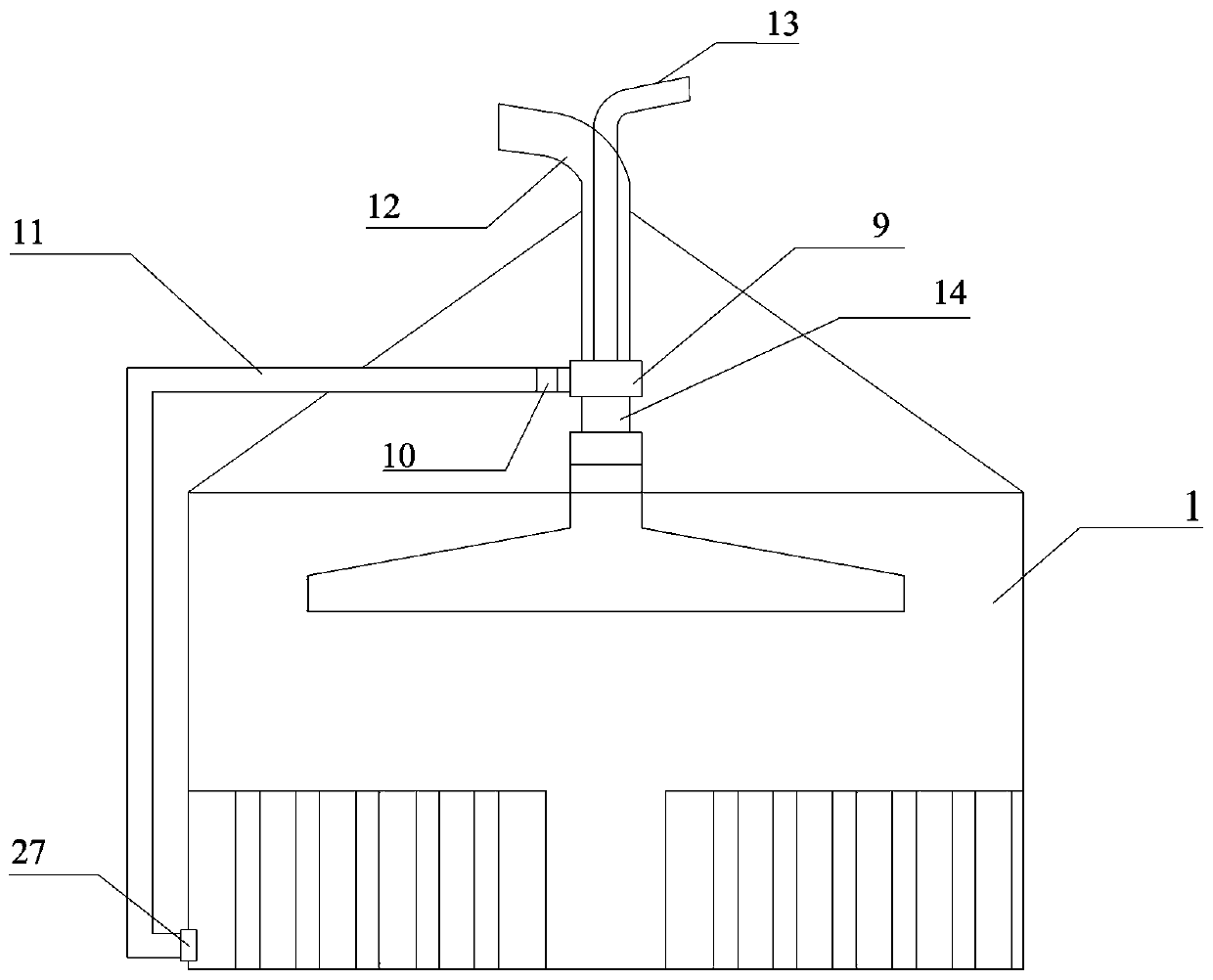

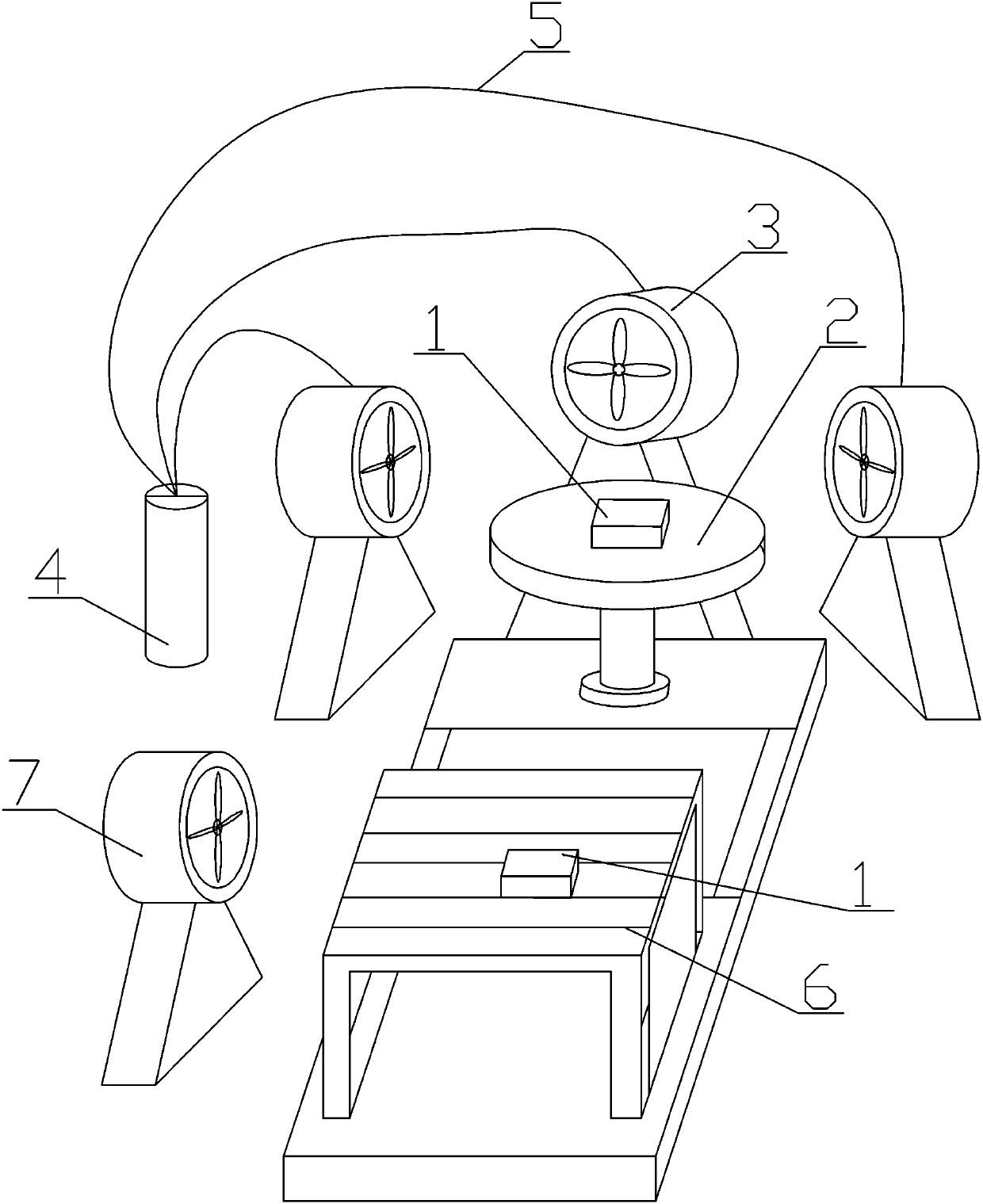

Rotary Spray Quenching Technology of High Chromium Wear-resistant Iron Castings

ActiveCN108396114BImprove quenching efficiencyGuarantee the quality of quenchingQuenching agentsWear resistantHeat conservation

The invention provides a high-chromium wear resistant casting iron part rotary spraying quenching process. The high-chromium wear resistant casting iron part rotary spraying quenching process comprises the following steps that the first step, a casting workpiece to be quenched is placed inside a high-temperature furnace to be heated to raise the temperature, and heat preservation is performed fora while; the second step, the high-temperature casting workpiece in the first step is placed on a rotary workbench; the third step, the rotary workbench is started, and the casting workpiece is drivenby the rotary workbench to rotate at high speed; the fourth step, spraying devices located on the side surfaces of the rotary workbench are started, and water is supplied for the spraying devices through a water supplying device and water supplying pipes; the fifth step, the water after atomization is sprayed to the surface of the rotating casting workpiece through the spraying devices, and rapidcooling treatment is performed on the casting workpiece; the sixth step, the casting workpiece after rapid cooling treatment in the fifth step is transferred onto an air cooling rack; the seventh step, an air cooling device is started, and the casting workpiece after rapid cooling treatment is cooled through the air cooling device. By means of the high-chromium wear resistant casting iron part rotary spraying quenching process, the surface wear resistant performance of high-chromium casting parts is greatly enhanced.

Owner:宜昌楚疆铸造有限公司

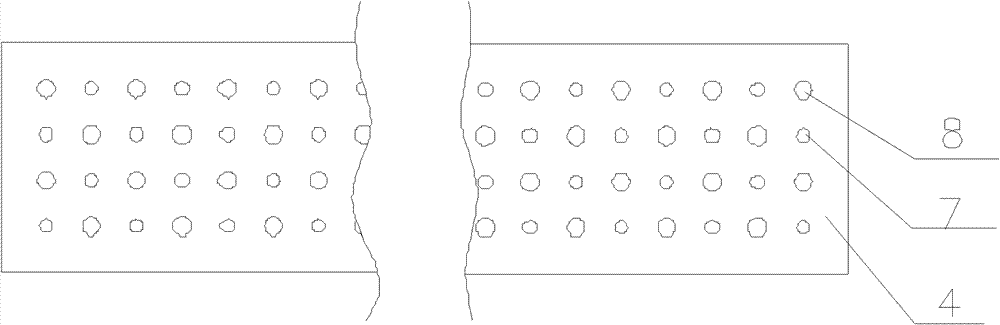

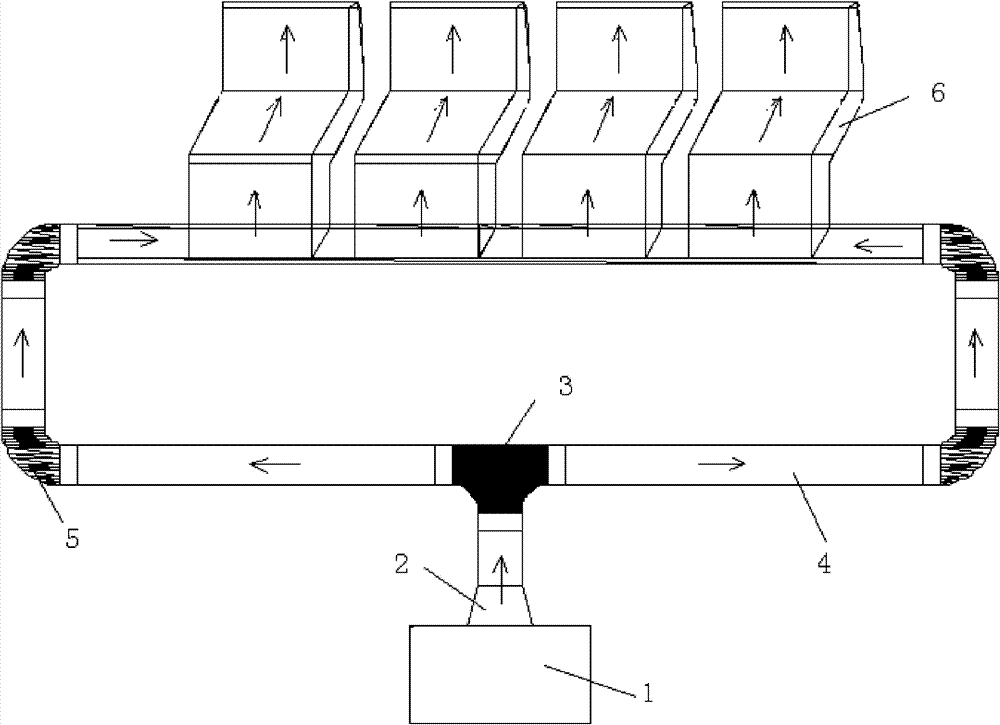

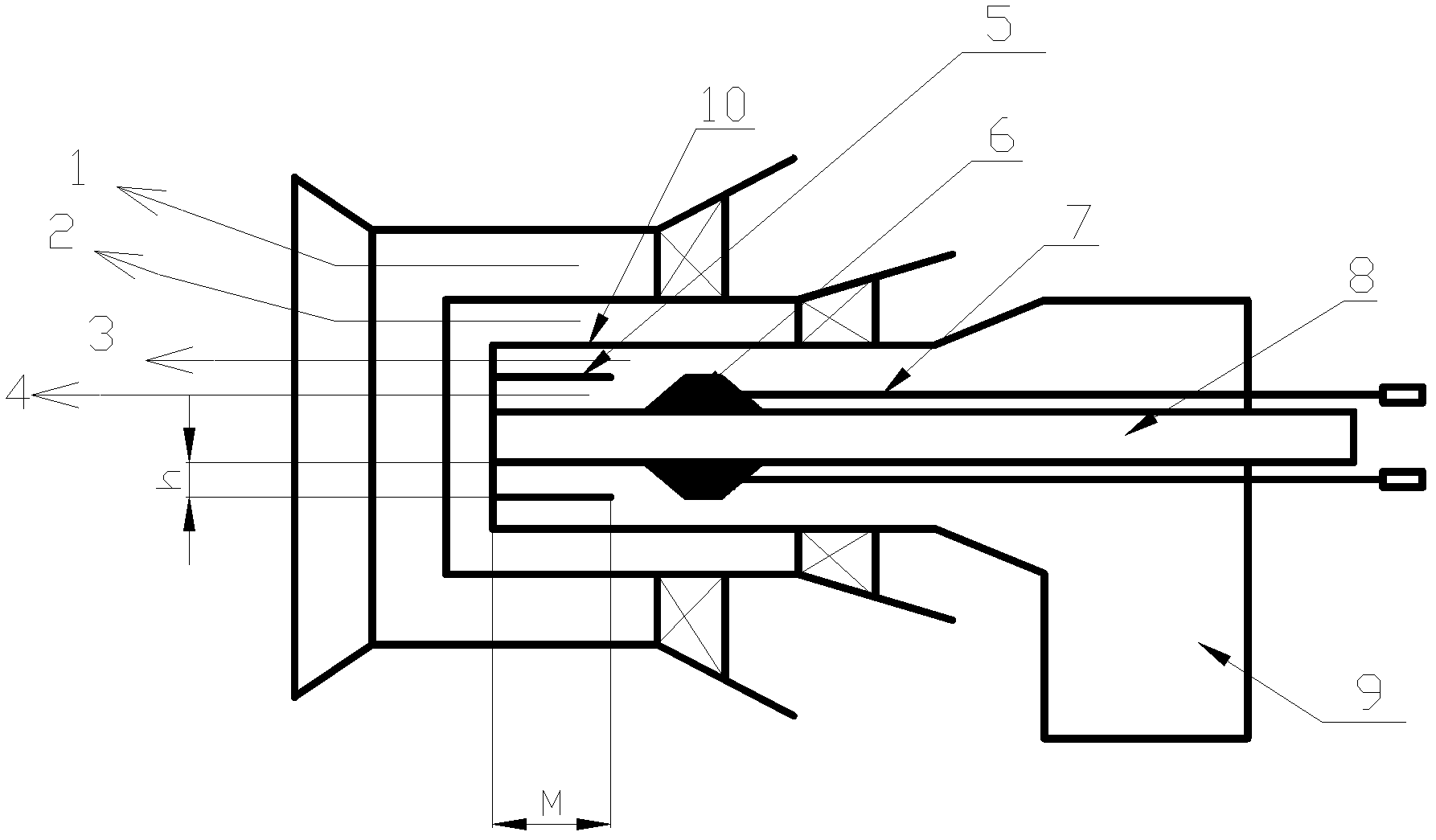

Air speed control device used in plastic cracking test of concrete

ActiveCN101986137BChange wind speedWind speed controlWeather/light/corrosion resistancePipeline.airEvaporation

The invention discloses an air speed control device used in a plastic cracking test of concrete. The device comprises an air source, wherein the air source is connected with a return pipeline for uniformly mixing air; the return pipeline is provided with more than one return pipeline air outlet; and the return pipeline air outlet is provided with a plurality of air outlet holes which are formed uniformly and is connected with an air outlet pipe (6). The air speed at the air outlet is varied by varying the model number of a centrifugal blast blower and the angle between the upper surface of the outlet of the air outlet pipe and a horizontal plane, so that effective control over the air speed is realized, the problems of instable and non-uniform air speed caused by a fan are solved and the accuracy and repeatability of a test result are enhanced. The air speed control device can be used in the plastic cracking test of the concrete and a water evaporation test of the concrete in a plastic state, such as the effects of different curing modes and curing agents on the water evaporation of the concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS

Blower brackets for automotive testing

InactiveCN104100809BEliminate unwanted effectsImprove stabilityPortable framesVibration suppression adjustmentsStopped workEngineering

Owner:成都万顺达模具零件有限公司

A water-cooled computer main chassis with turbulence type two-way ventilation

ActiveCN108776535BEasy dischargeSpeed up the flowDigital processing power distributionThermodynamicsEngineering

The invention relates to the technical field of computers, in particular to a disturbed flow type bidirectional ventilated water-cooled computer case. The technical problem to be solved by the invention is low heat dissipation efficiency of the conventional case. In order to solve the above technical problem, the invention provides a disturbed flow type bidirectional ventilated water-cooled computer case, comprising a case body, wherein a total driving mechanism is fixedly connected to the top of the inner wall of the case body, a plurality of air vents and a plurality of air inlets are respectively formed in two sides of the case body, a disturbed flow ventilation device is fixedly connected to the air vents on one side of the inner wall of the case body, and the output end of the total driving mechanism is movably connected with the input end of the disturbed flow ventilation device. In the technical solution, the disturbed flow device can extract the hot airflow inside the case during starting and disturb the airflow to cause the airflow to flow disorderly, so that the airflow can spread to all corners of the case, and the hot airflow inside the case can be discharged quickly.

Owner:深圳华创电科技术有限公司

Variable-section cyclone burner

InactiveCN102506426BIncrease wind speedChange wind speedPulverulent fuel combustion burnersCycloneBreathing

The invention discloses a variable-section cyclone burner, which comprises a central air duct. A primary air pipe is sleeved outside the central air duct, a partition sleeve is sleeved at an outlet of the primary air pipe and divides the primary air pipe into an inner space and an outer space, an annular sliding stopper is mounted on the central air duct, and the annular sliding stopper is connected with a pull rod arranged on the outside of the cyclone burner. As the primary air is divided into inner primary air and outer primary air by the partition sleeve additionally mounted at the outlet of the primary air pipe of the cyclone burner and the annular sliding stopper is mounted on the central air duct, when the annular sliding stopper is pulled backwards, the inner primary air and the outer primary air ventilate simultaneously, ventilation area is expanded, primary air speed is reduced, and the requirement for reducing air speed is met; and further, when the annular sliding stopper is pushed forwards, a passage of the inner primary air is blocked, only a passage of the outer primary air ventilates, ventilation area is reduced, and accordingly primary air speed is increased.

Owner:SHANDONG ZHONGSHI YITONG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com