Oblique winnowing device of reaping machine

A harvester and winnowing technology, applied to agricultural machinery and tools, threshing equipment, applications, etc., can solve the problems of difficult separation of stem impurities, unsatisfactory technical effects, and inability to be fully removed, etc., to achieve low-loss cleaning , less interference, less likely effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below, the present invention will be further described in conjunction with the accompanying drawings.

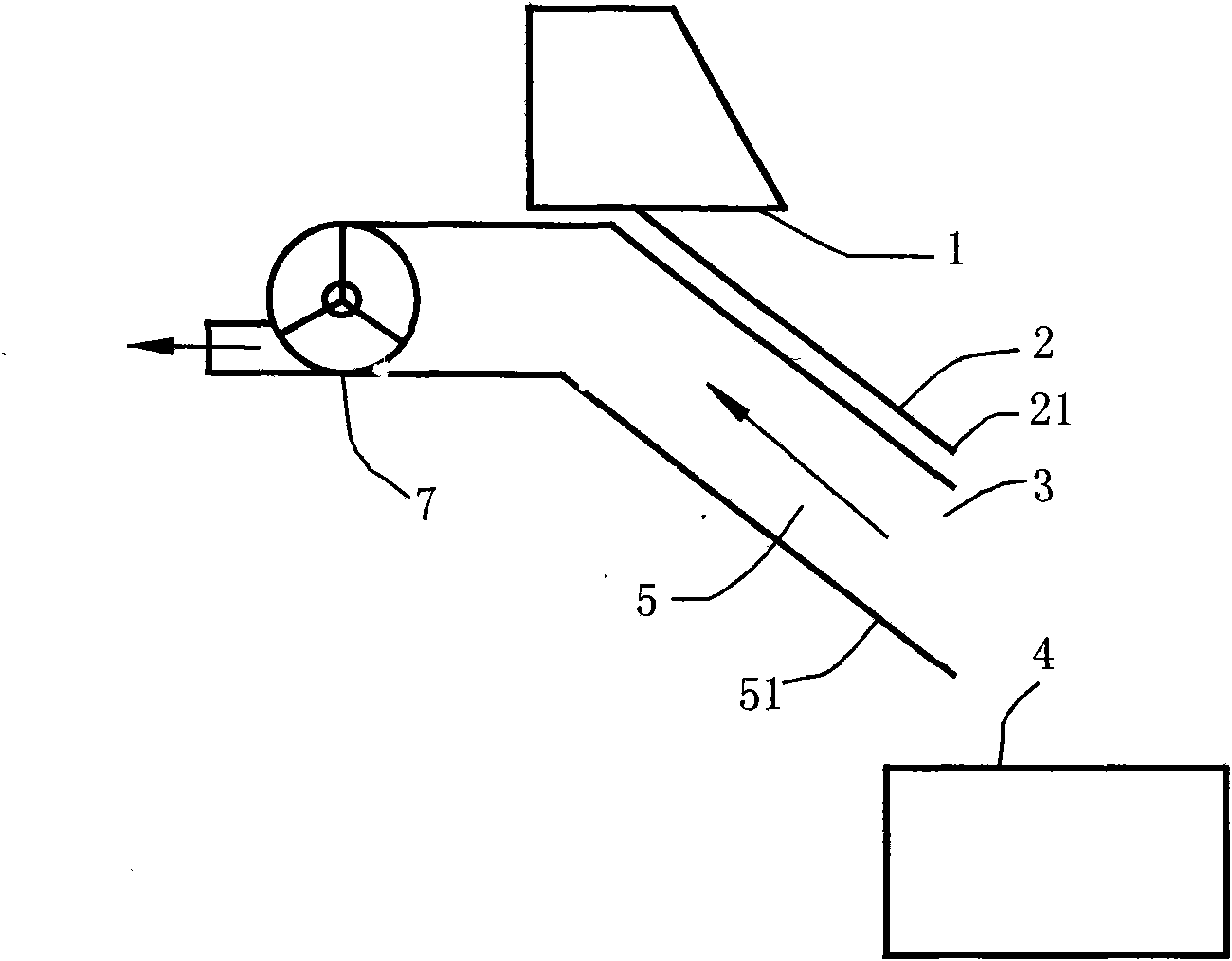

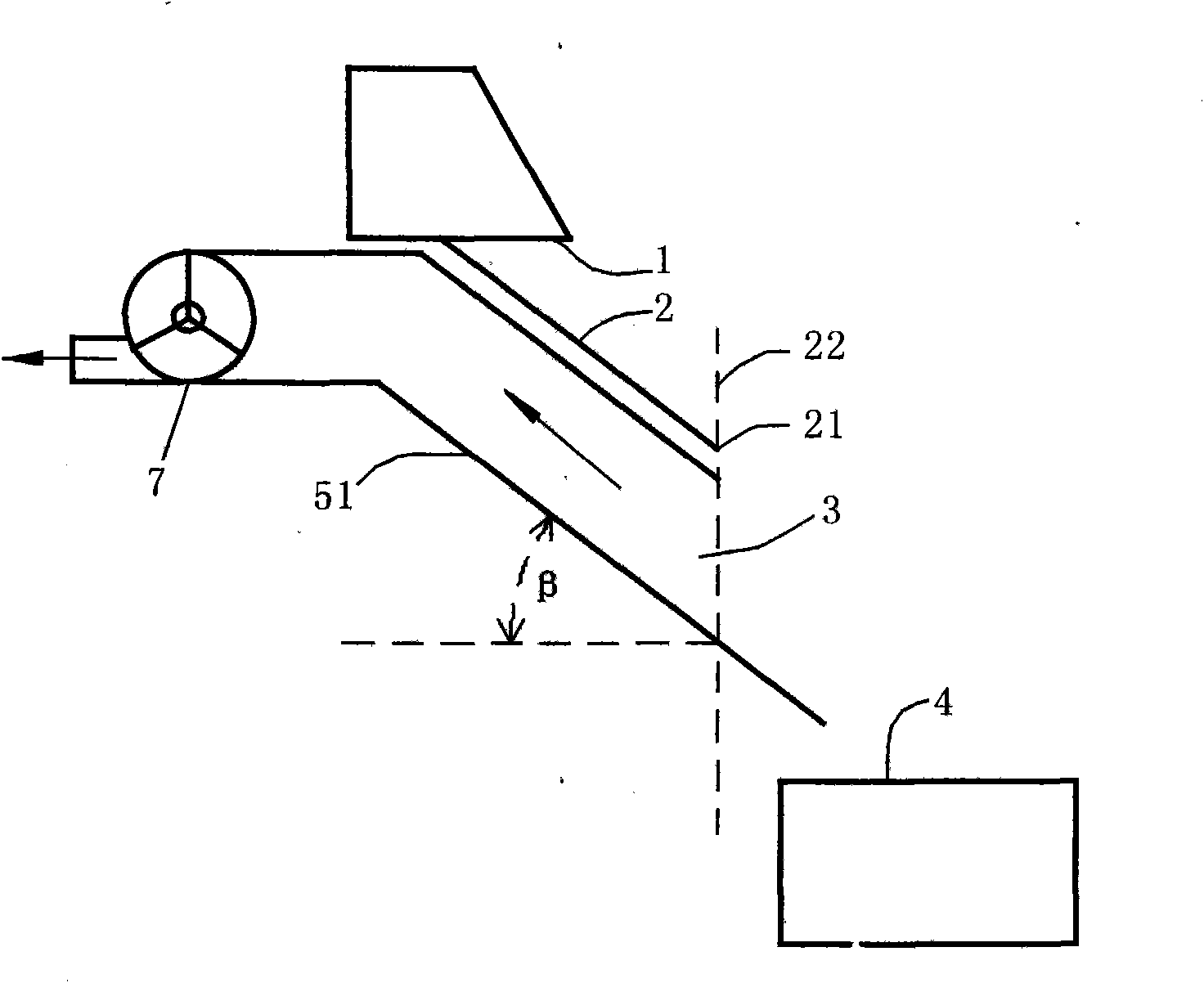

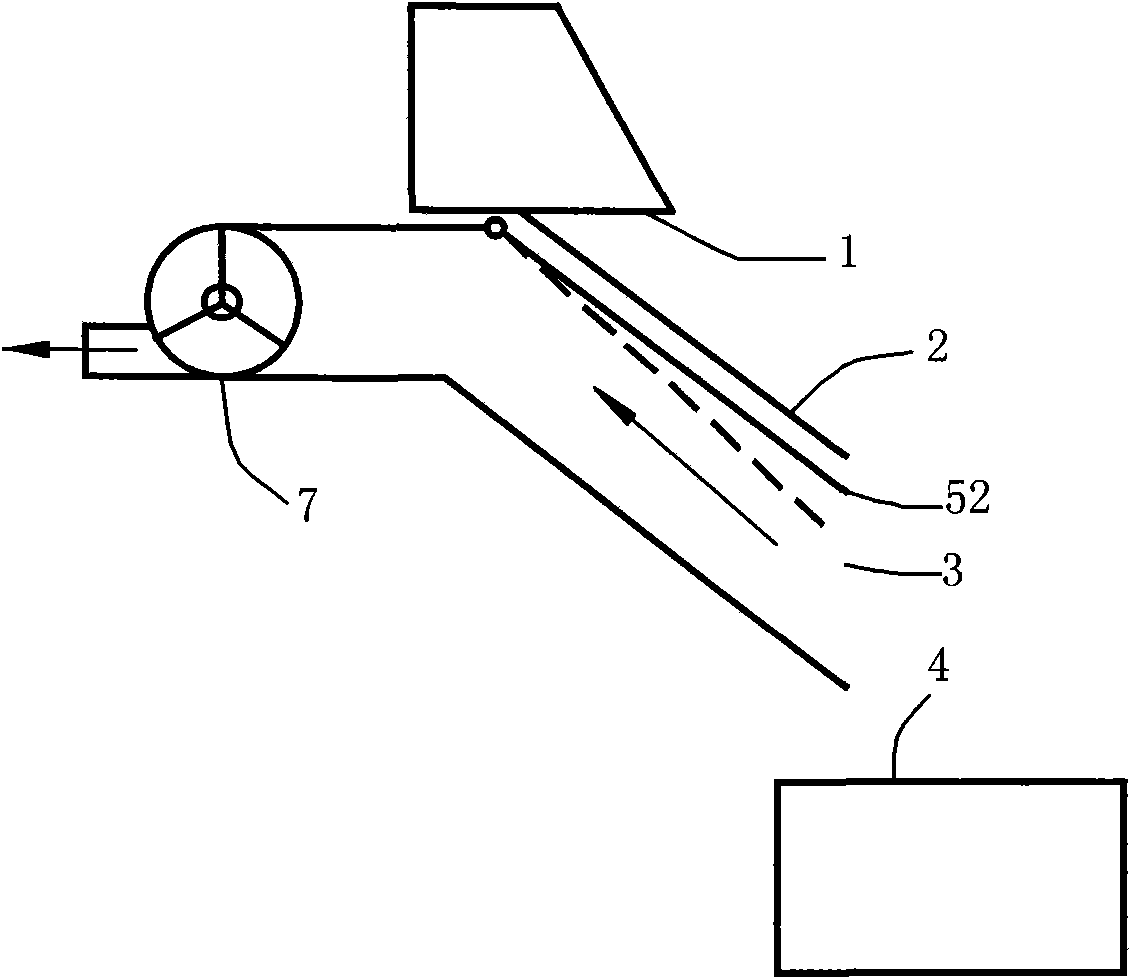

[0018] figure 1 It shows the first embodiment of the oblique winnowing device of the harvester, which includes a seed drop port 1, and an inclined downward scattering slide plate 2 is arranged below the seed drop port 1, and an air suction port 3 is arranged below the lower edge 21 of the scattering slide plate 2, and the suction The tuyere 3 is connected to the upwardly inclined air duct 5 of the bottom plate 51 , and the air duct 5 communicates with the air suction device 7 .

[0019] After the grains are discharged from the seed drop port 1, they fall onto the loose slide plate 2, collide with the spread slide plate 2 and slide down along the spread slide plate 2. Falls down into the suction area of the air suction port 3 in a waterfall shape. The air volume of the air suction port 3 is concentrated and the wind speed is high. After the inhaled grain enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com