Extruder device for automatically controlling and adjusting extrusion amount in rubber injection molding screw

A technology of extrusion volume and extruder, which is applied in the field of extruder device for automatic control and adjustment of extrusion volume, which can solve problems such as unstable cross-sectional area of products, poor adaptability to different rubbers, failure of vacuuming, etc. The effects of precise movement, avoidance of vacuum failure, and precise flow control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

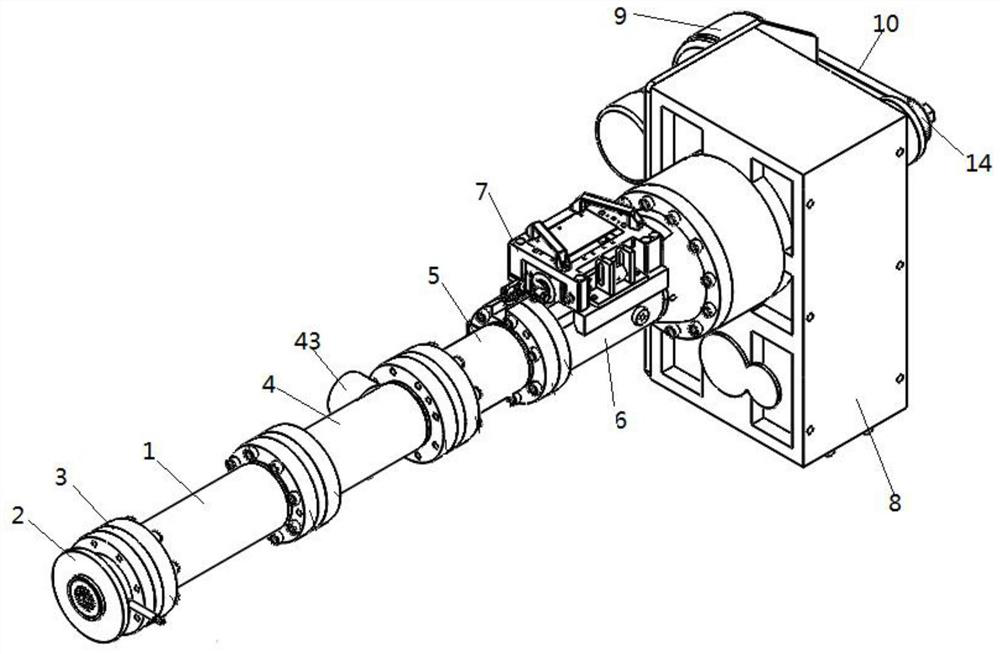

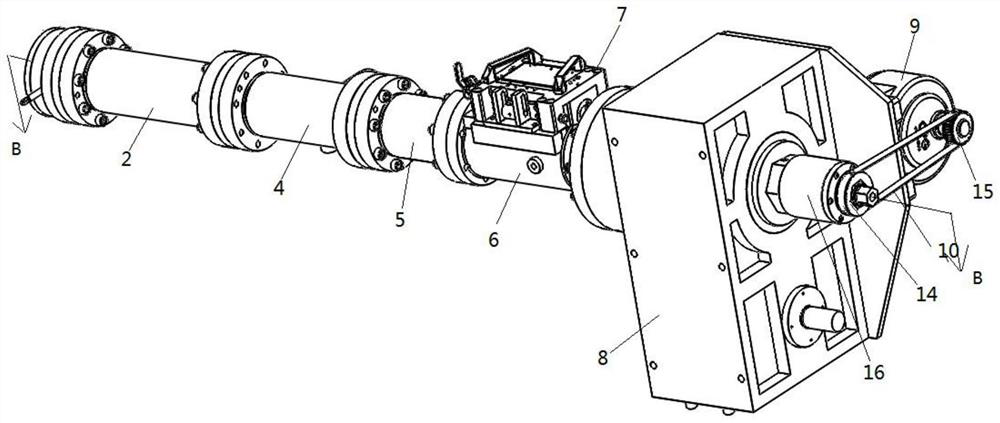

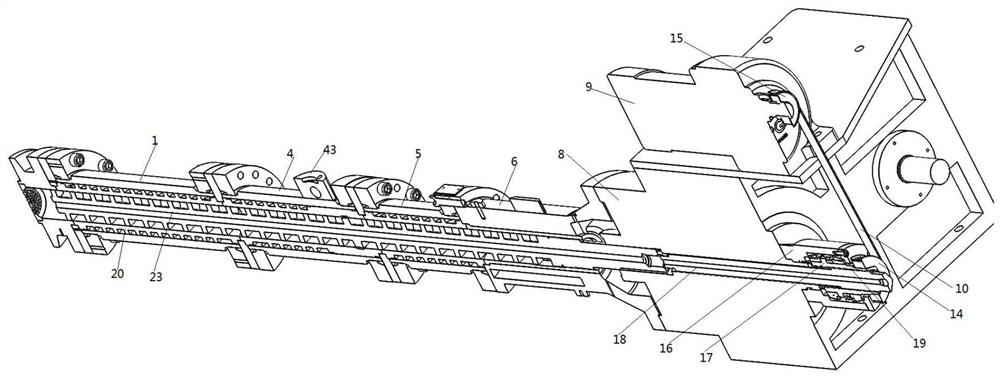

[0028] In order to facilitate the understanding of the technical solution of the present invention, the following describes in detail in conjunction with the accompanying drawings and specific embodiments.

[0029] see Figure 1-10 , an extruder device for automatically controlling and adjusting the extrusion volume in a rubber injection molding screw, which includes a barrel and a speed reducer 8, and the barrel is fixedly connected to the output end of the speed reducer 8;

[0030] A steel sleeve 20 is sleeved in the barrel, a spiral channel is formed between the steel sleeve 20 and the barrel, a screw 23 is sleeved in the steel sleeve 20, and an exhaust ring is arranged on the screw 23 231, the maximum circumscribed circle of the exhaust ring 231 is greater than the diameter of the circumscribed circles at both ends, and an exhaust ring groove 201 matching the exhaust ring 231 is dug on the inner wall of the steel sleeve 20, the exhaust ring 231 The largest circumscribed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com