Vector exhaust tail pipe device, control system thereof and vehicle

A technology of exhaust tailpipe and control system, which is applied in the field of vehicles, and can solve problems such as inability to adjust in multiple directions, inability to change geometric shape, and single shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] In order to solve the problem that the exhaust back pressure cannot be reduced or increased, the existing exhaust tail pipe structure is fixed, and the exhaust tail pipe back pressure cannot be adjusted through the exhaust tail pipe. Adding a check valve can only reduce the exhaust tail pipe The diameter of the valve increases the exhaust back pressure, but cannot reduce the exhaust back pressure.

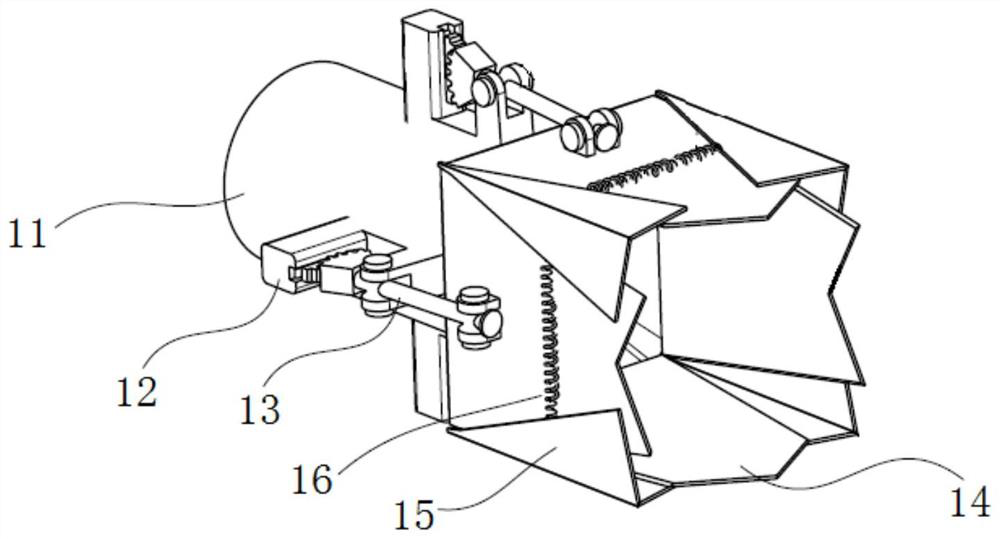

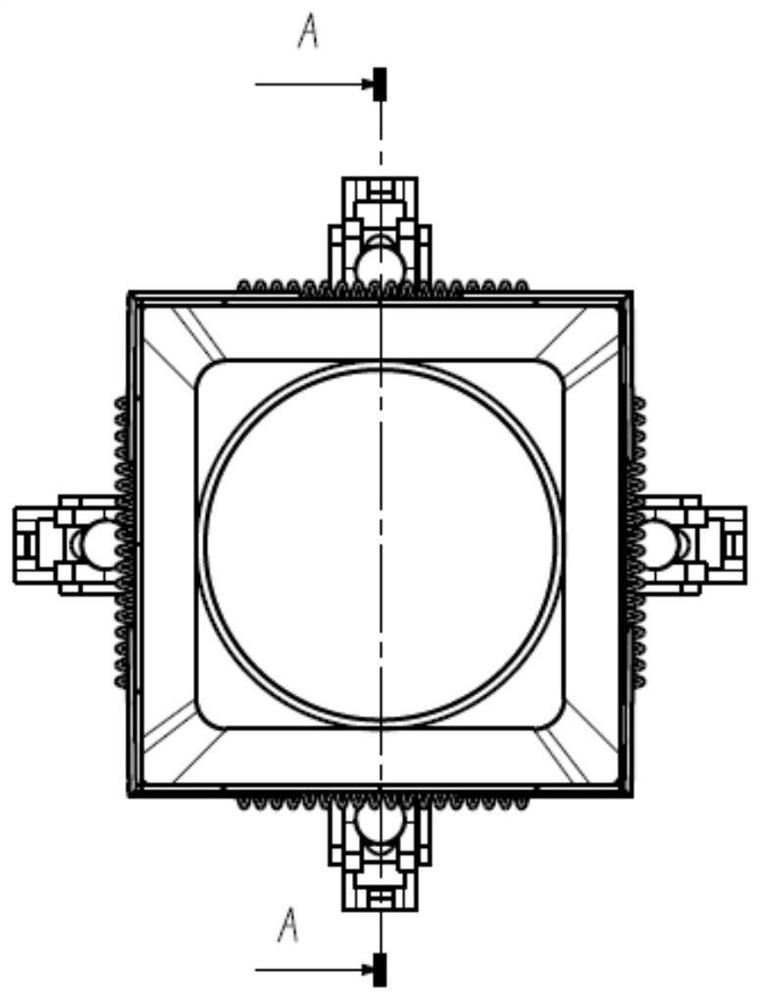

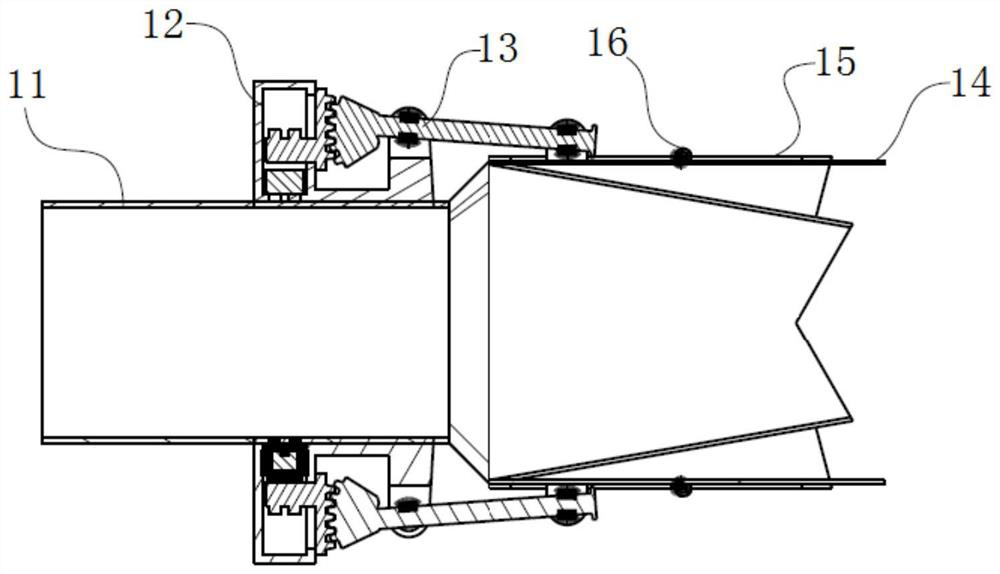

[0036] In view of the above problems, this embodiment provides a vector exhaust tailpipe device, see Figure 1-3 , the vector exhaust tailpipe device 1 in the present embodiment comprises a connection mechanism 11, a height adjustment mechanism 12, a crank rocker mechanism 13 and a plurality of air guide plates 14; the structure of the connection mechanism 11 can be any structure, and the connection mechanism 11 One end of the exhaust tail pipe is connected to the cold end 5 of the exhaust tail pipe, and the air guide plate 14 is arranged along the surface array of the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com