Variable cross-section Rosen piezoelectric transformer

A piezoelectric transformer and variable cross-section technology, applied in the field of piezoelectric transformers, can solve problems such as suboptimal conversion efficiency, achieve compact structure, improve transformation efficiency, and be easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

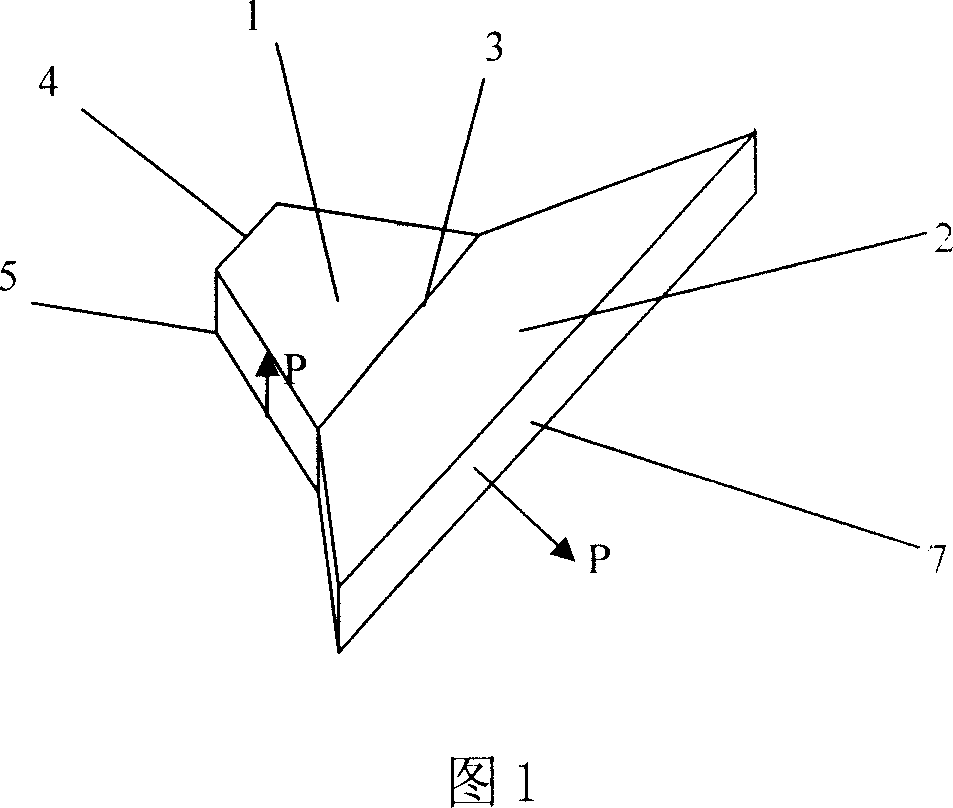

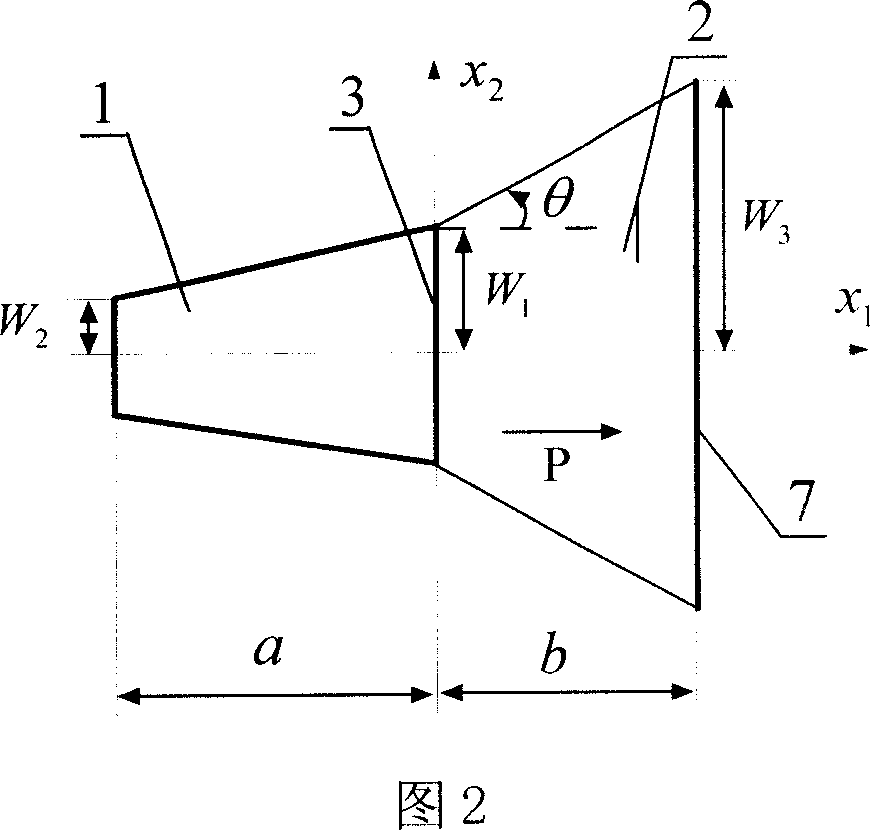

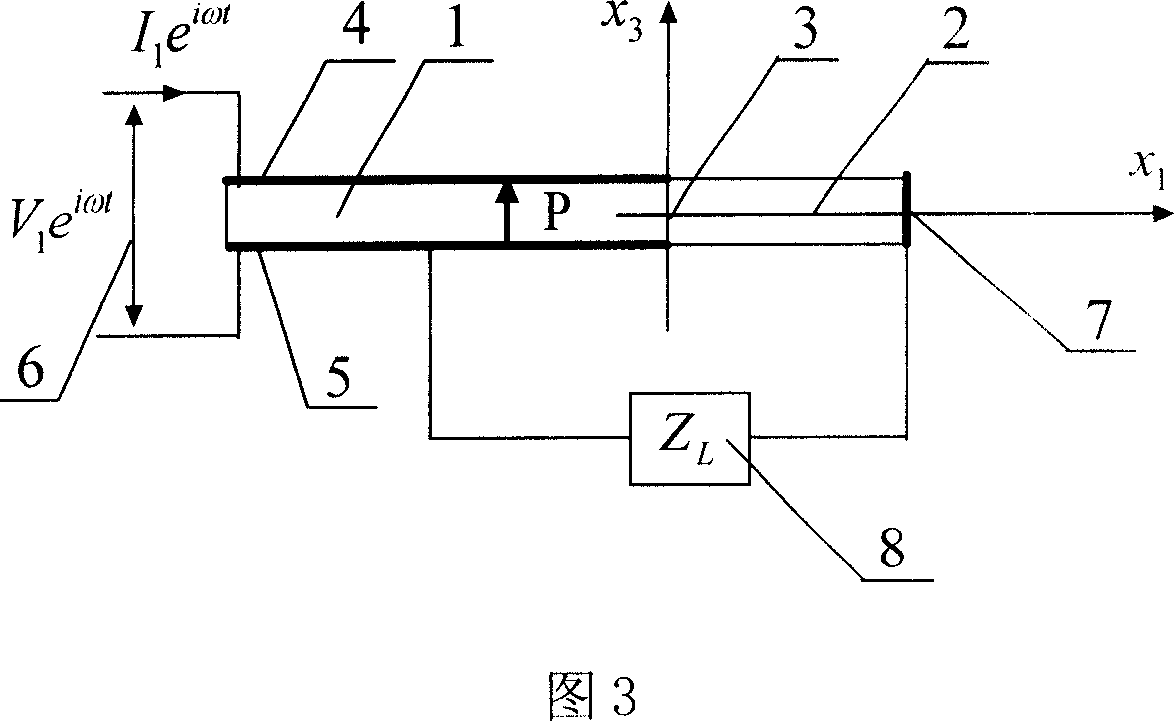

[0018] Referring to Figures 1, 2, and 3, the first isosceles trapezoidal piezoelectric sheet constitutes the input end 1 of the piezoelectric transformer, and the second isosceles trapezoidal piezoelectric sheet constitutes the output end 2, and the input end 1 and output end 2 are along the interface 3 stick together. The polarization direction P of the input end 1 is polarized along the thickness direction, and metal electrodes 4 and 5 are arranged on the upper and lower surfaces of the input end 1, and the electrodes 4 and 5 form an input interface 6 connected to an external power source. The polarization direction P of output 2 is along x 1 Polarized in the axial direction (length direction), the end face of the output end 2 is arranged with a metal electrode 7, and the electrodes 5 and 7 are connected with the external electronic instrument Z L 8 connected. Figures 2 and 3 show the top view and sectional view of the present invention, from the top view: the width of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com