Patents

Literature

31results about How to "Guaranteed operating rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

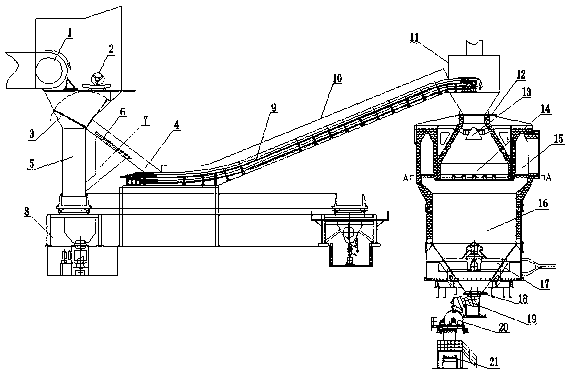

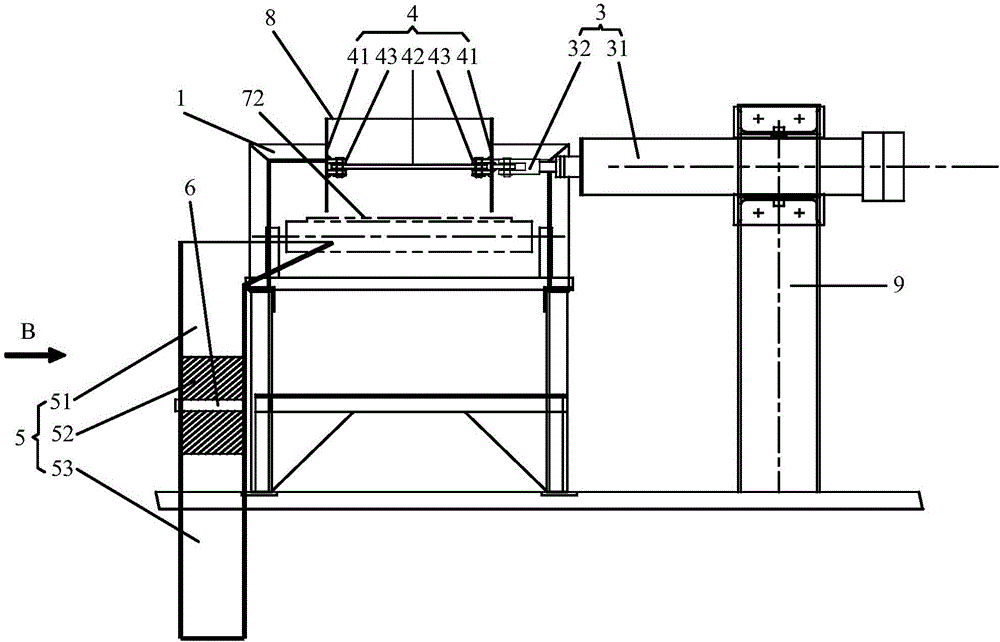

Furnace type cooling and heat exchange device for sintered ores

ActiveCN103234349AGuaranteed operating rateImprove qualityCharge manipulationIncreasing energy efficiencyCooling effectFlap valve

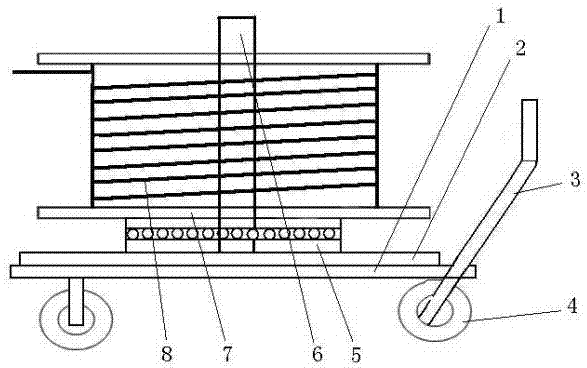

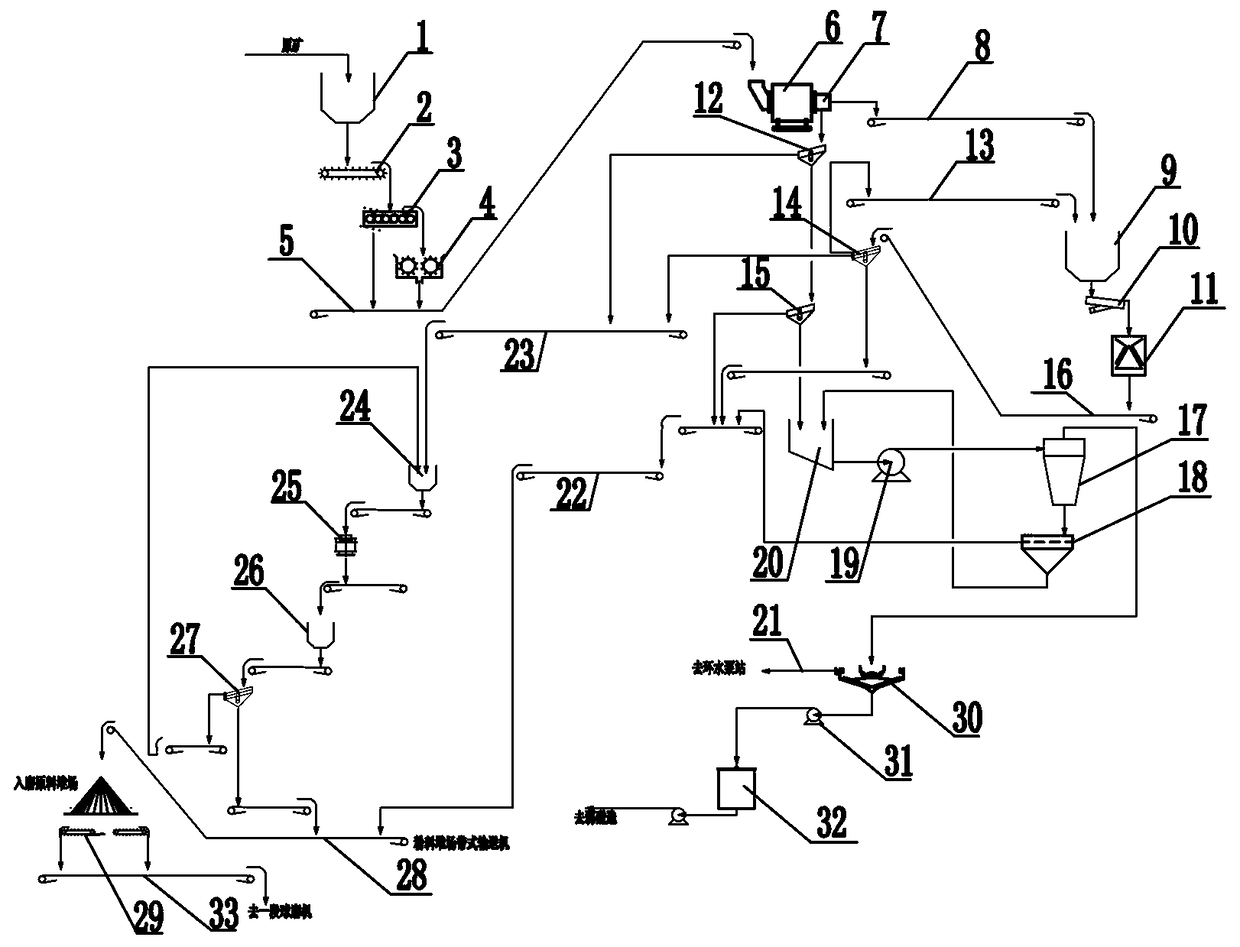

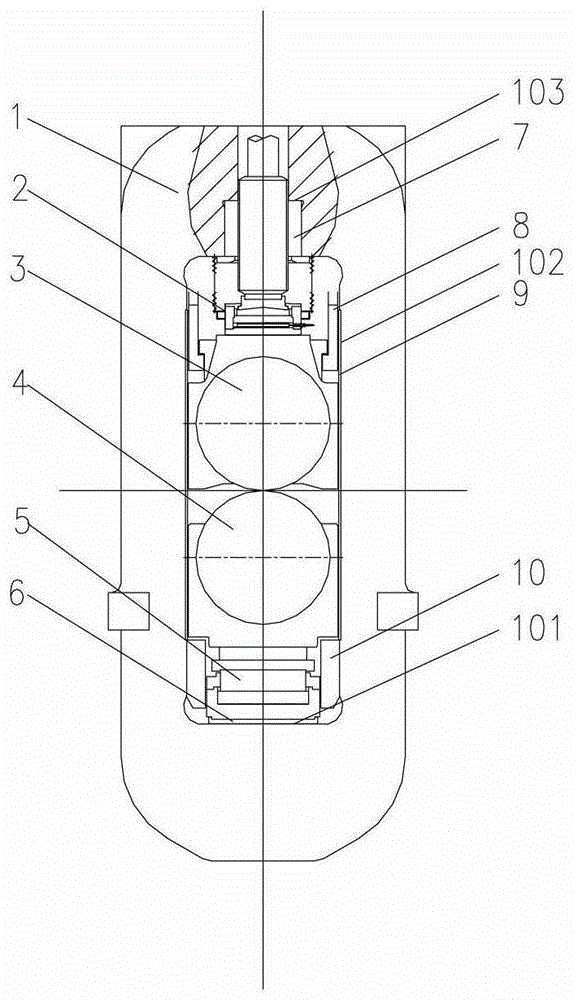

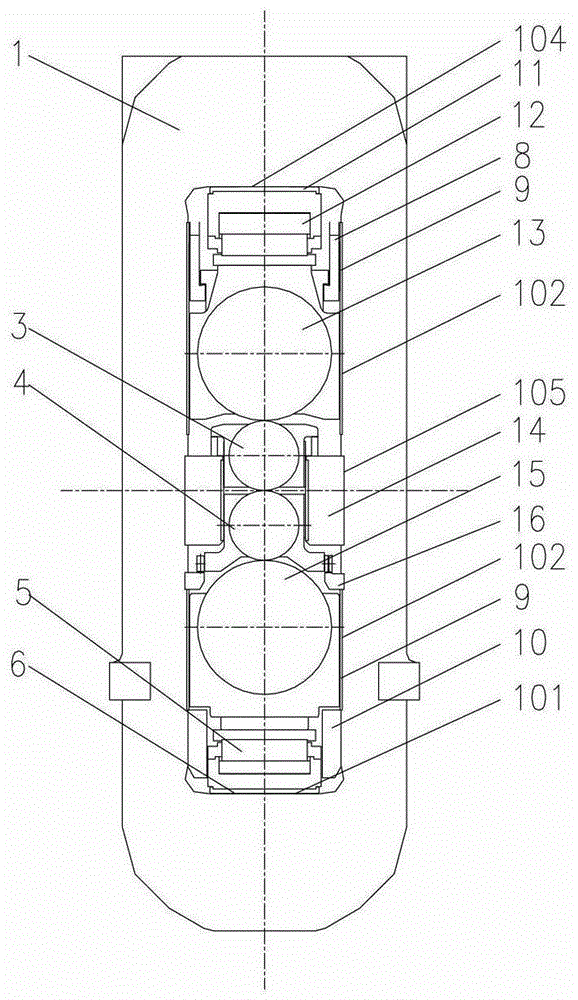

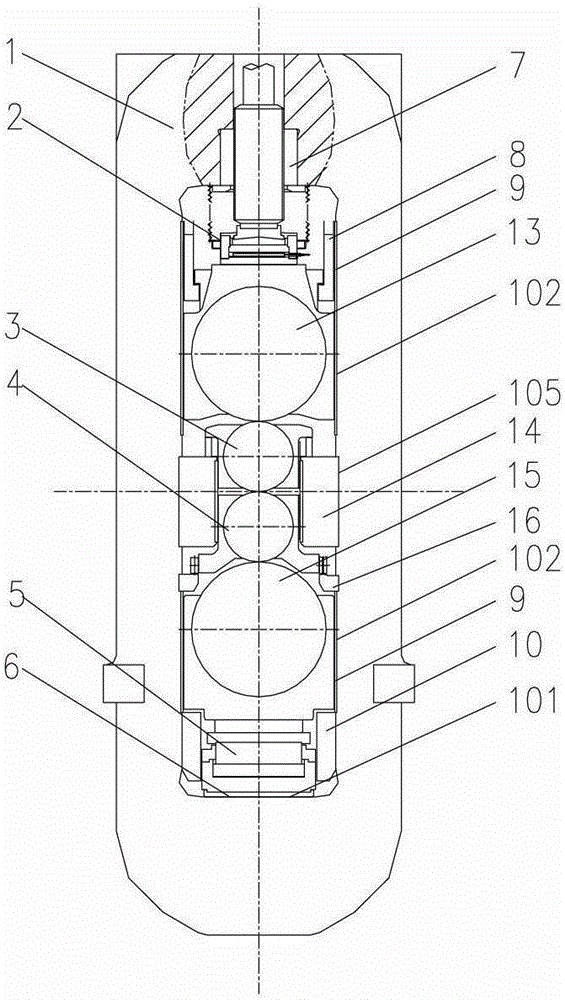

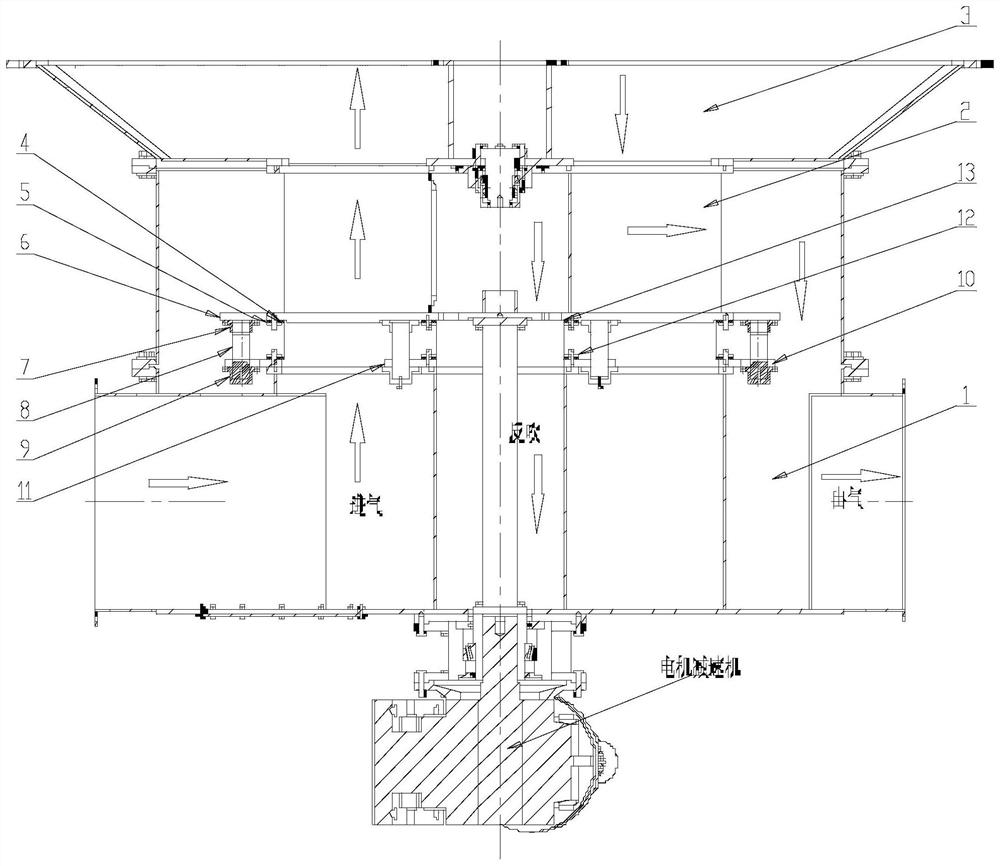

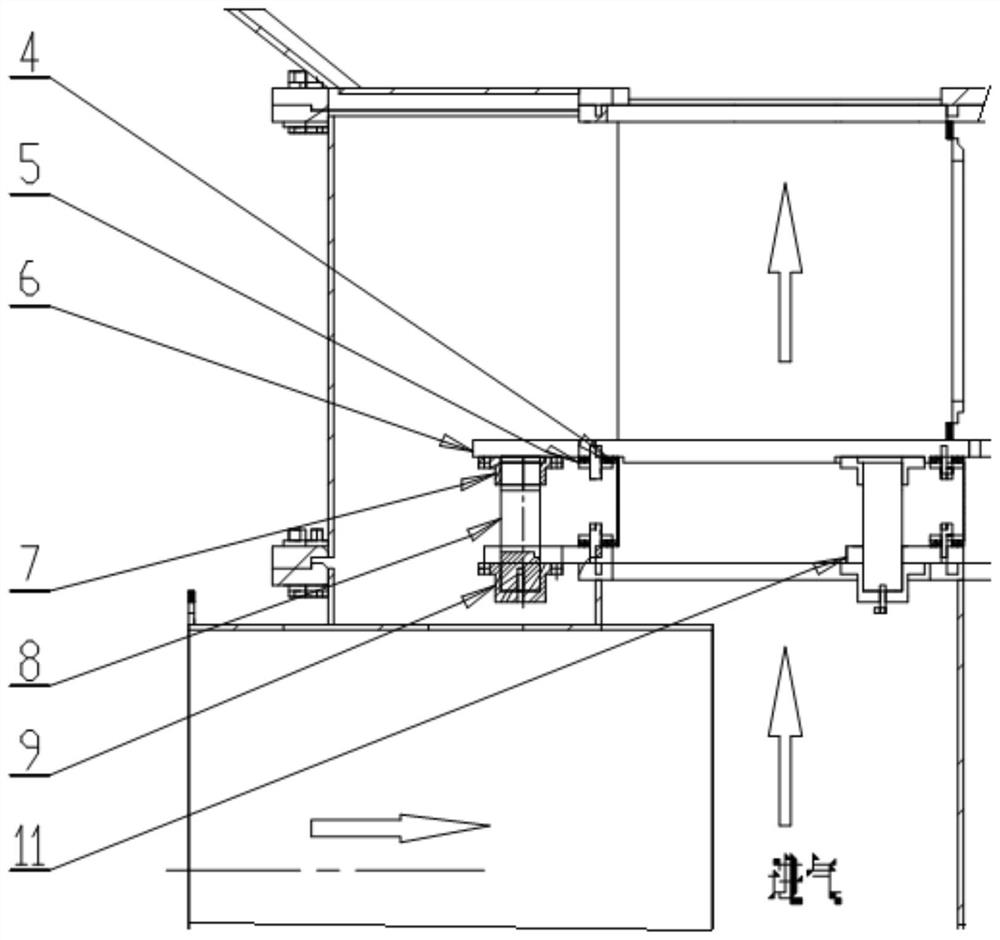

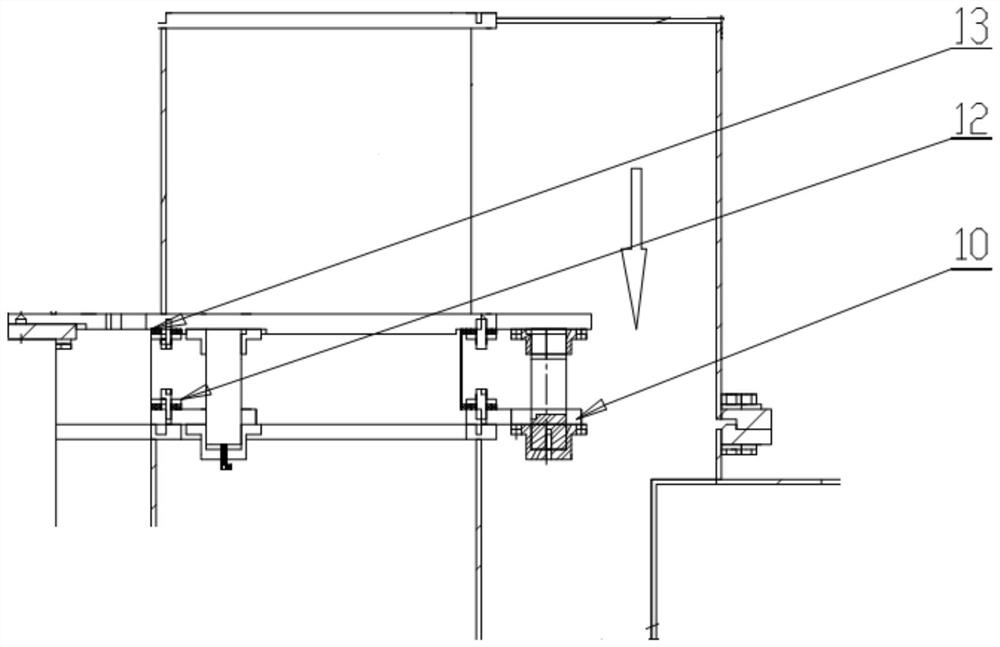

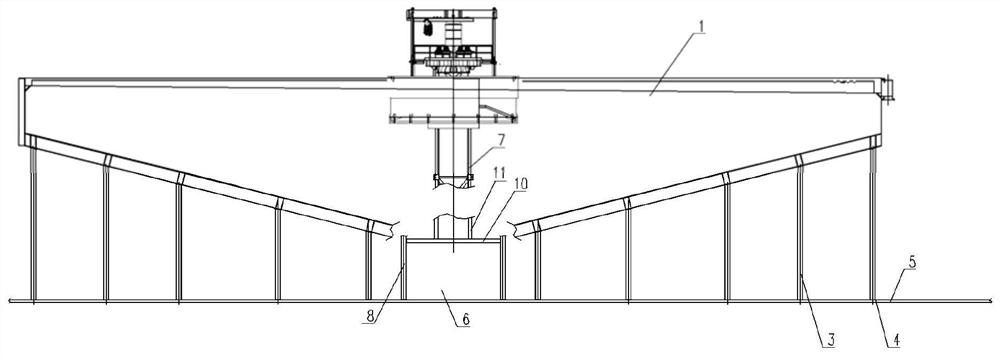

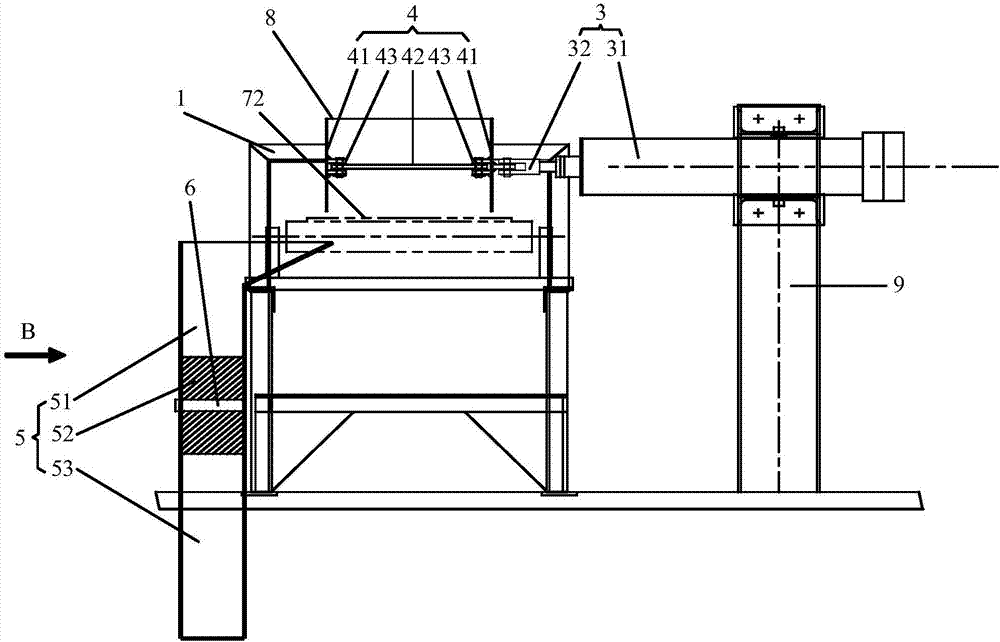

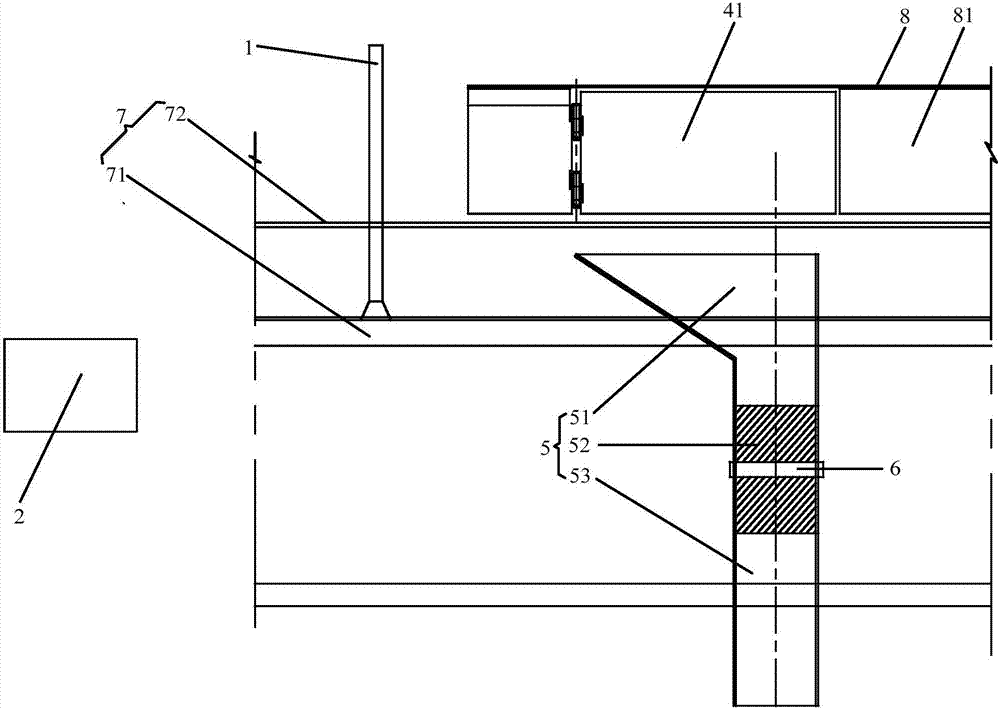

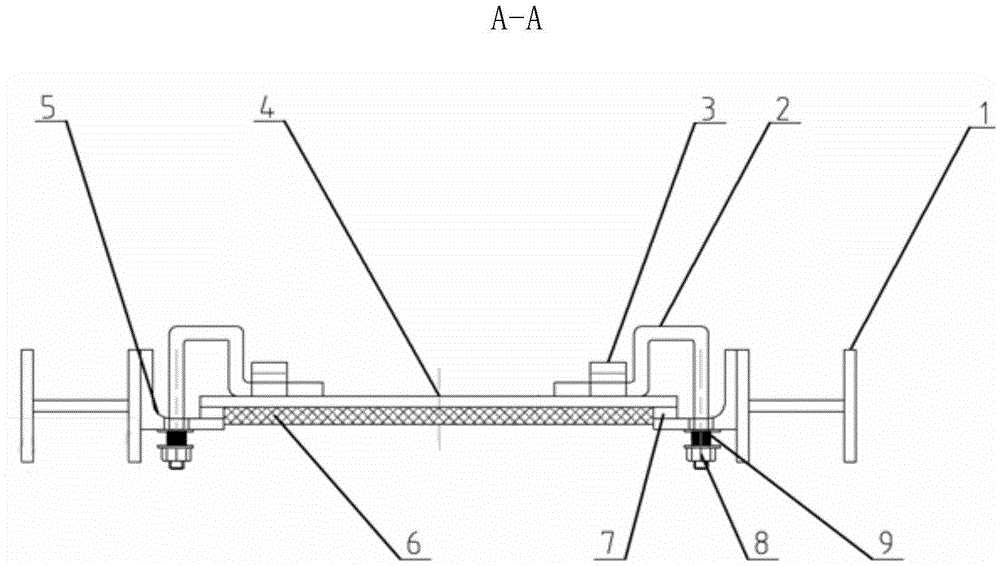

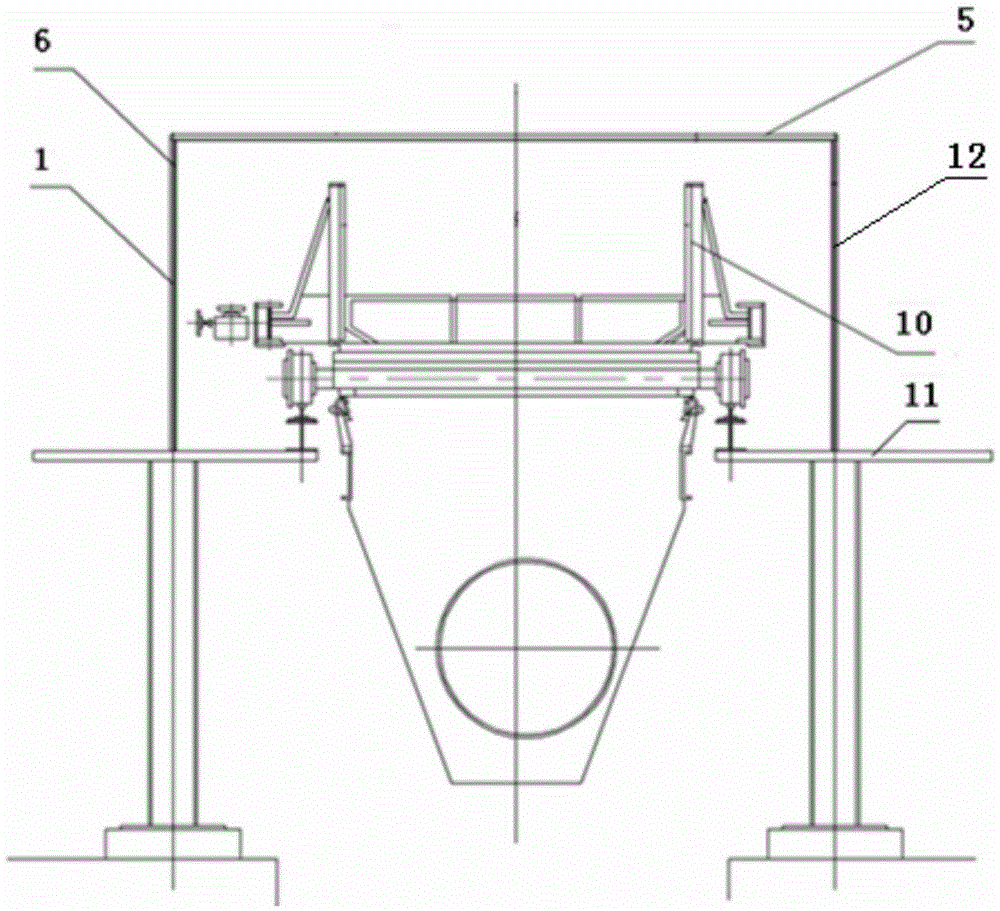

The invention discloses a furnace type cooling and heat exchange device for sintered ores and relates to the technical field of cooling devices of sintered ores. A single-roll crusher is arranged at an outlet of a sintering machine, a flap valve is arranged under the single-roll crusher, the bottom of the flap valve is arranged at the connection position of a furnace cooling system chute and an annular cooling system chute / a belt cooling system chute, the flap valve can be switched between the furnace cooling system chute and the annular cooling system chute / the belt cooling system chute, a hot vibration screen also serves as the bottom wall of the furnace cooling system chute, a hot return mine chute is connected under the hot vibration screen and is connected with the annular cooling system chute / the belt cooling system chute, an outlet of the furnace cooling system chute is connected with one end of a chain-scraper conveyor, the other end of the chain-scraper conveyor is connected with a fire door of a cooling furnace, and a heat-insulating cover is arranged above the chain-scraper conveyor. By the aid of the device, the cooling effect and the waste heat utilization ratio of sintered ores are effectively improved, and the furnace cooling system device can be arranged in a remote distance without being limited by fields.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

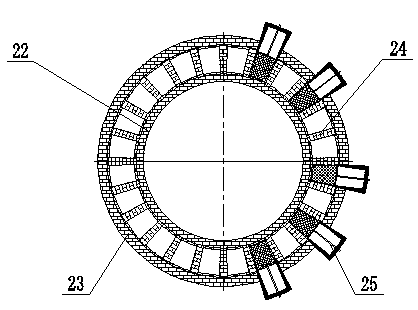

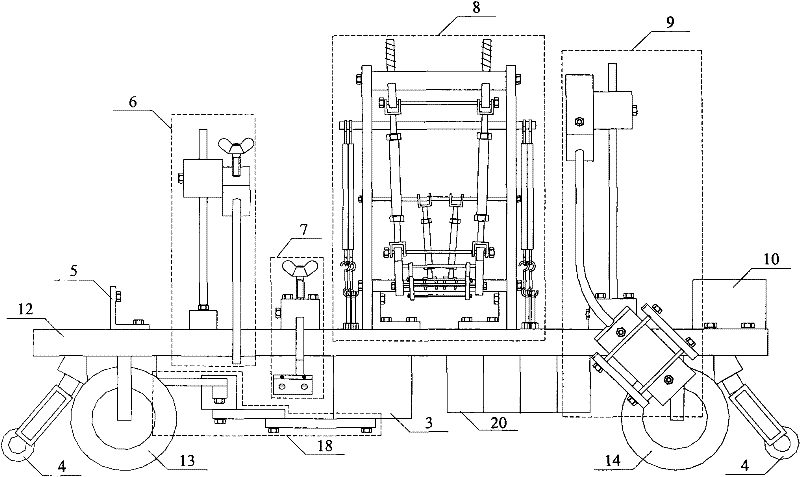

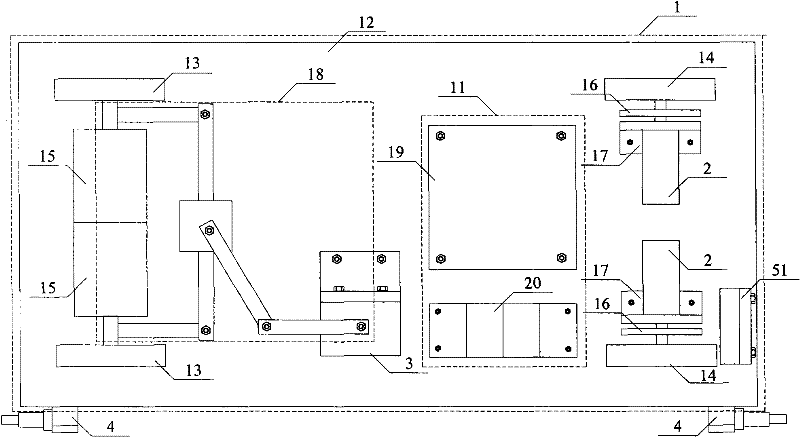

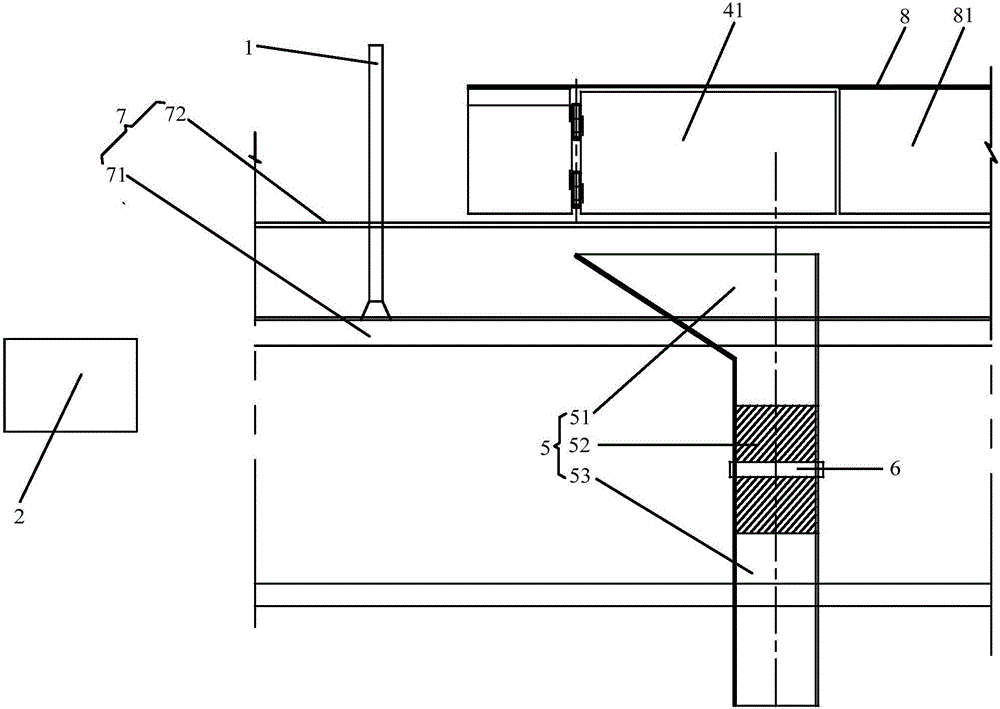

Automatic magnetic particle testing unit for toe cracks at inner wall of straight welded pipe

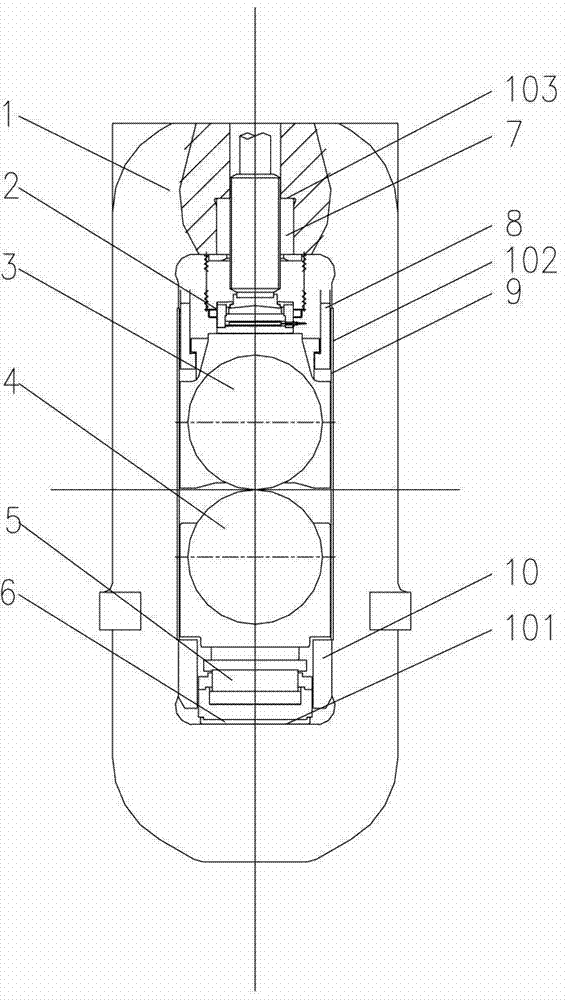

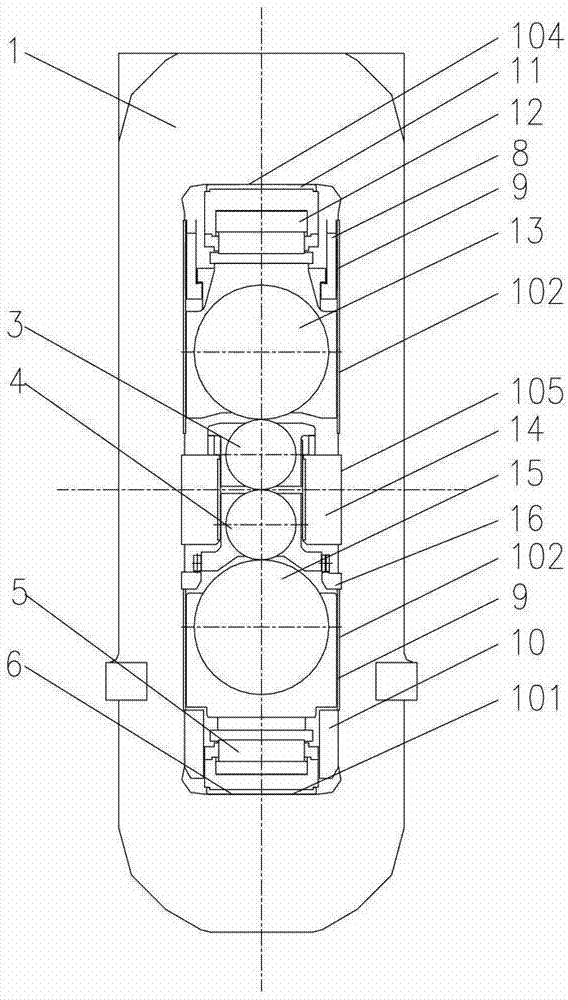

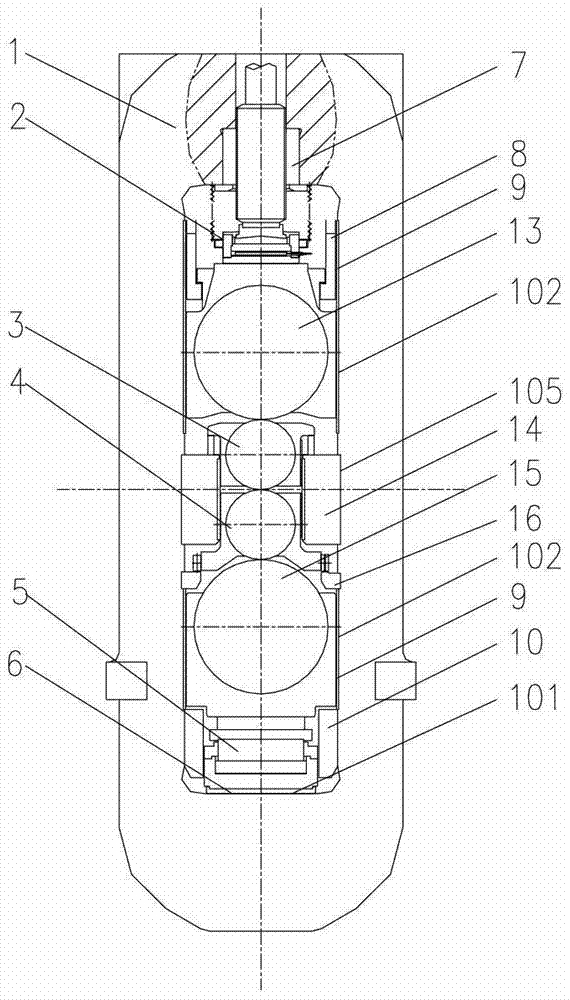

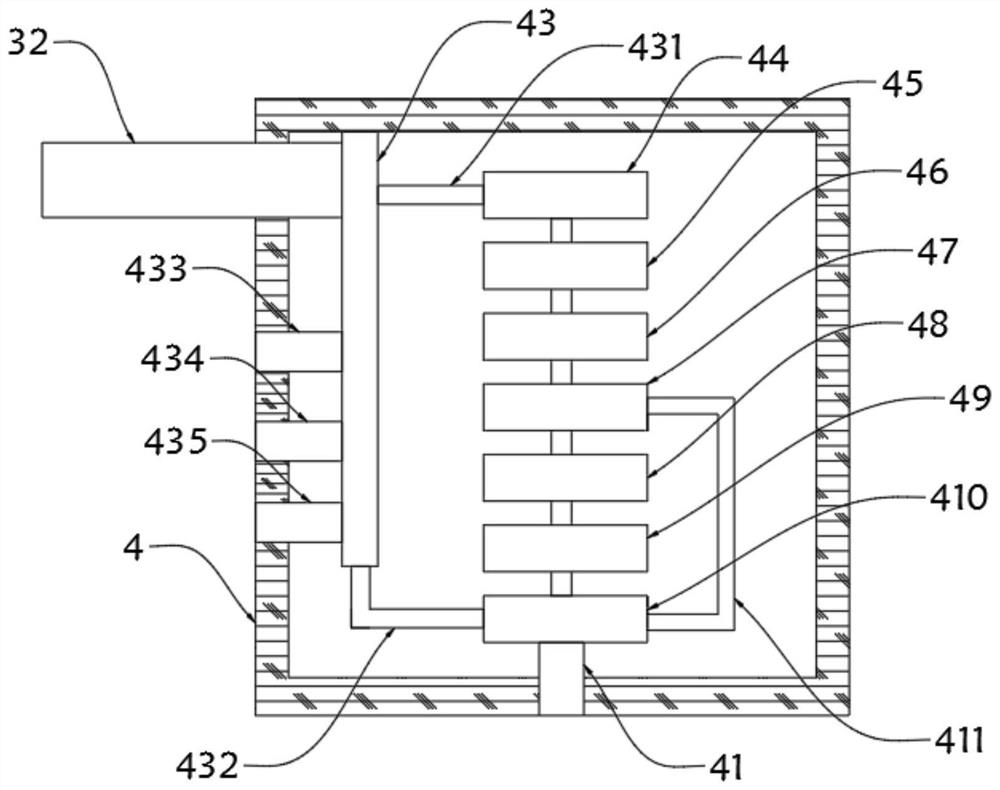

InactiveCN102346151ARapid Batch DetectionAutomatic detection speed adjustableOptically investigating flaws/contaminationMaterial magnetic variablesDrive wheelTransformer

The invention relates to a testing unit for a straight welded pipe, in particular to an automatic magnetic particle testing unit for toe cracks at inner wall of the straight welded pipe, comprising a car body consisting of a sweep template, a driving wheel, a stop block, a supporting plate, universal wheels and a guide bar which are connected with each other coaxially, and a rotary bearing, a driving motor, a control part, a steering engine, a position switch arranged on the two ends of one end of the car body, and a transformer bearing, a camera bearing, a sprayer bearing, a crossed yoke, an ultraviolet lamp bearing, and a water pump water tank bearing which are successively arranged on the top of the sweep template from left to right, wherein, the upper end of the stop block is fixedly connected with the two sides of the rear end of the sweep template bottom in parallel, the output end of the steering engine is fixedly connected with the universal wheels through the guide bar, the upper end of the rotary bearing is fixedly connected with the two sides of the rear end of the sweep template bottom in parallel, the lower end of the rotary bearing is fixedly connected with one end of the supporting plate, the other end of the supporting plate is fixed connected with the sweep template bottom, and output shaft of the driving motor is respectively connected with the two driving wheels fixedly. The invention can completely takes the place of manual work to carry out automatic magnetic particle testing, and has the advantages of compact structure and convenient operation.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE +1

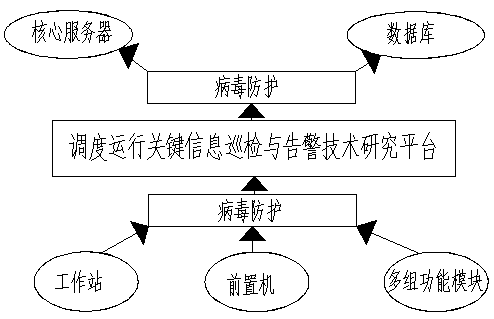

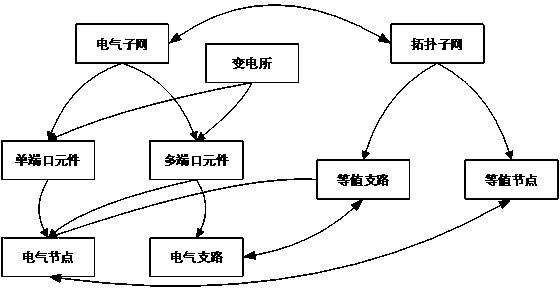

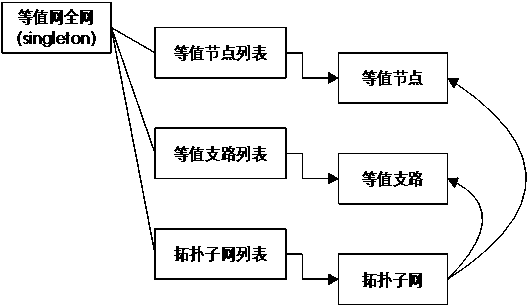

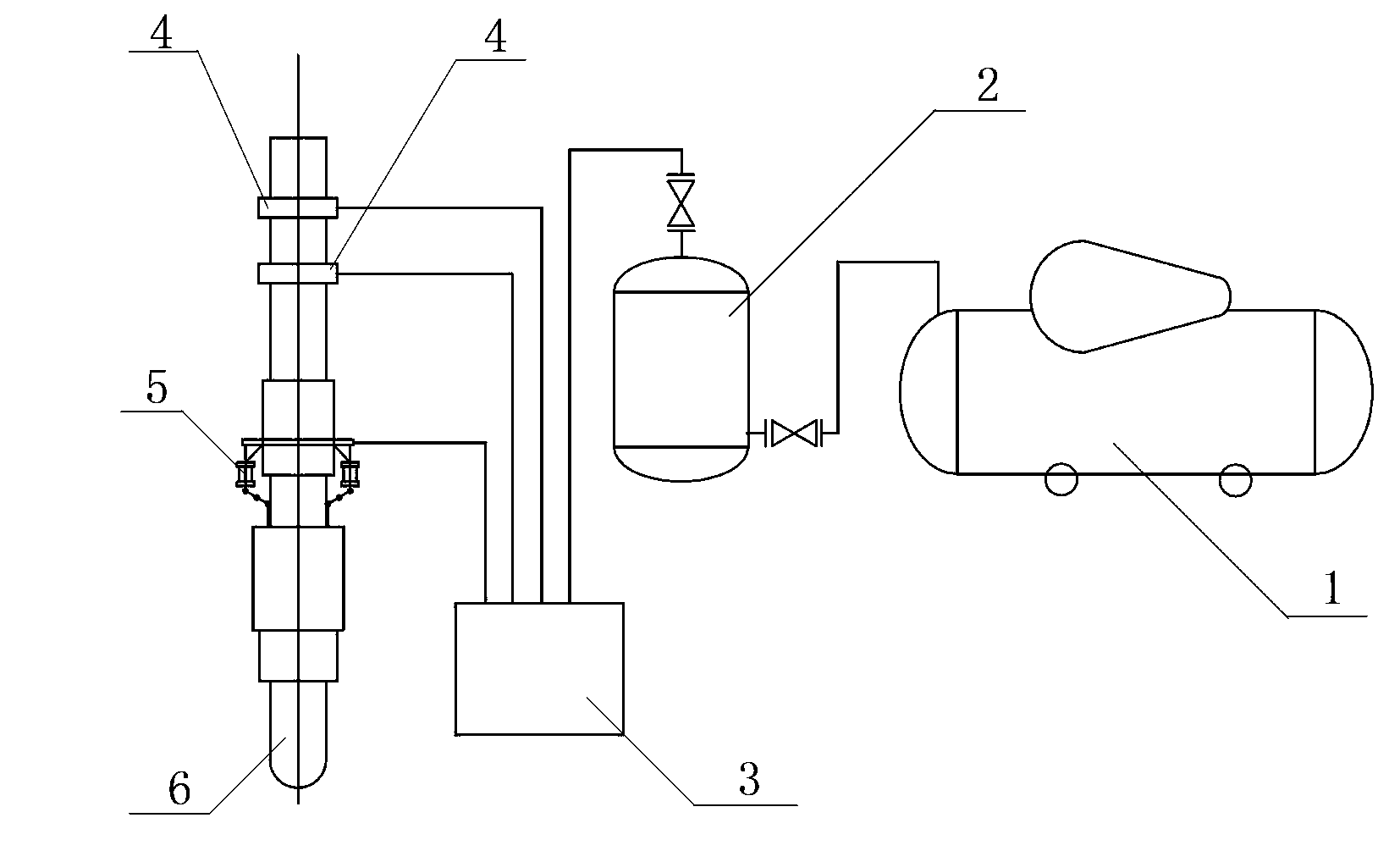

EMS grid monitoring system based on big data

InactiveCN108683187AShort response timeReduce workloadAc network circuit arrangementsTechnology researchPower equipment

The invention provides an EMS grid monitoring system based on big data, comprising a dispatching running key information inspection and alarm technology research platform, and the dispatching runningkey information inspection and alarm technology research platform includes a core server, a database, a virus protection, a front-end processor, a workstation and multiple sets of function modules. The EMS grid monitoring system reduces the response time of the abnormal processing of the power equipment, provides the abnormality and fault handling plan for the on-duty personnel, collects various fault phenomena and corresponding processing methods, improves the fault processing level, shortens the fault processing time, avoids or reduces the occurrence of the grid accident, and generates hugeeconomic benefits; centralized management of power grid operation failures is realized, the workload of power running personnel and the incidence of power grid accidents are reduced, and the operatingrate of system equipment and the reliability of system operation are ensured.

Owner:PUYANG POWER SUPPLY COMPANY STATE GRID HENAN ELECTRIC POWER +1

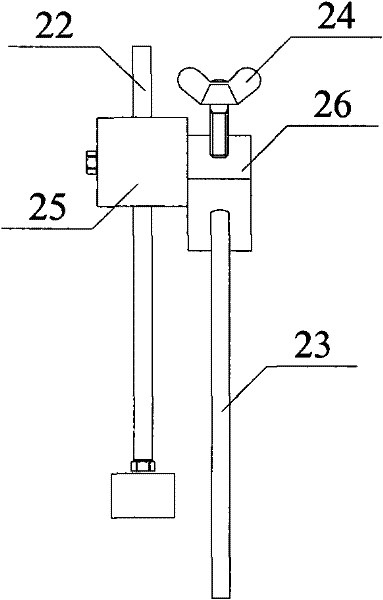

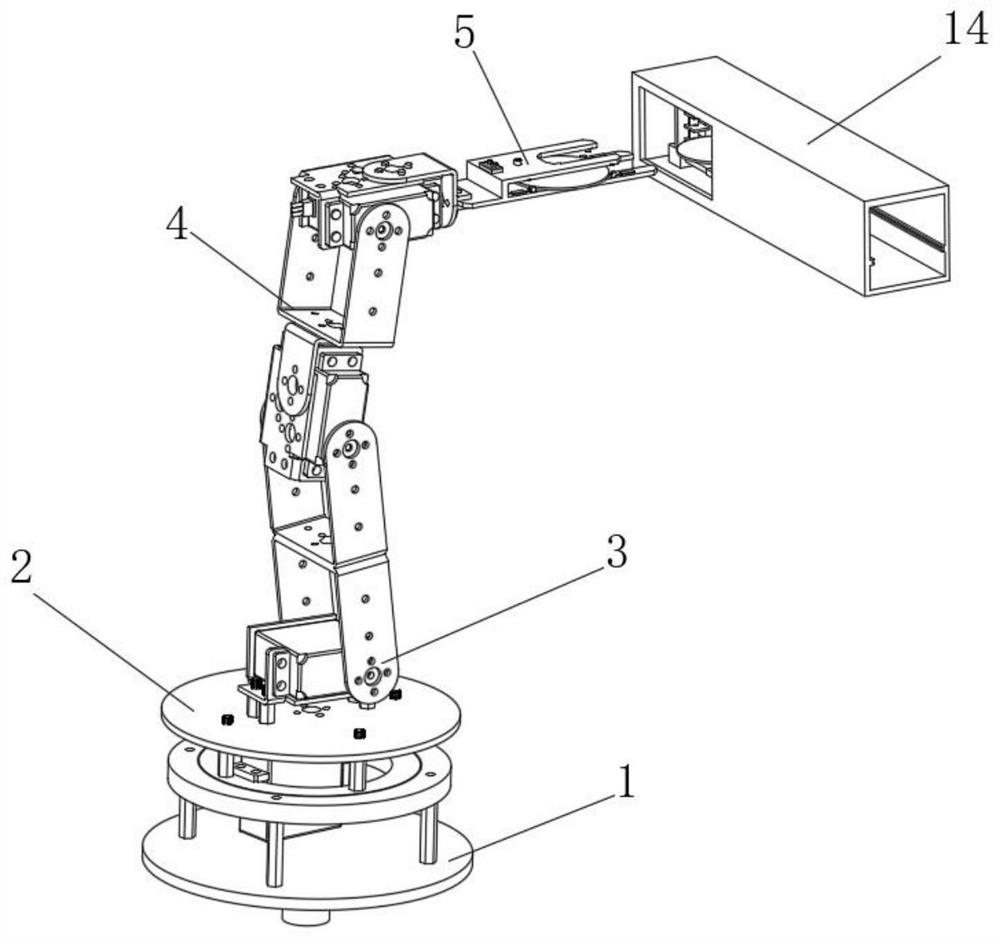

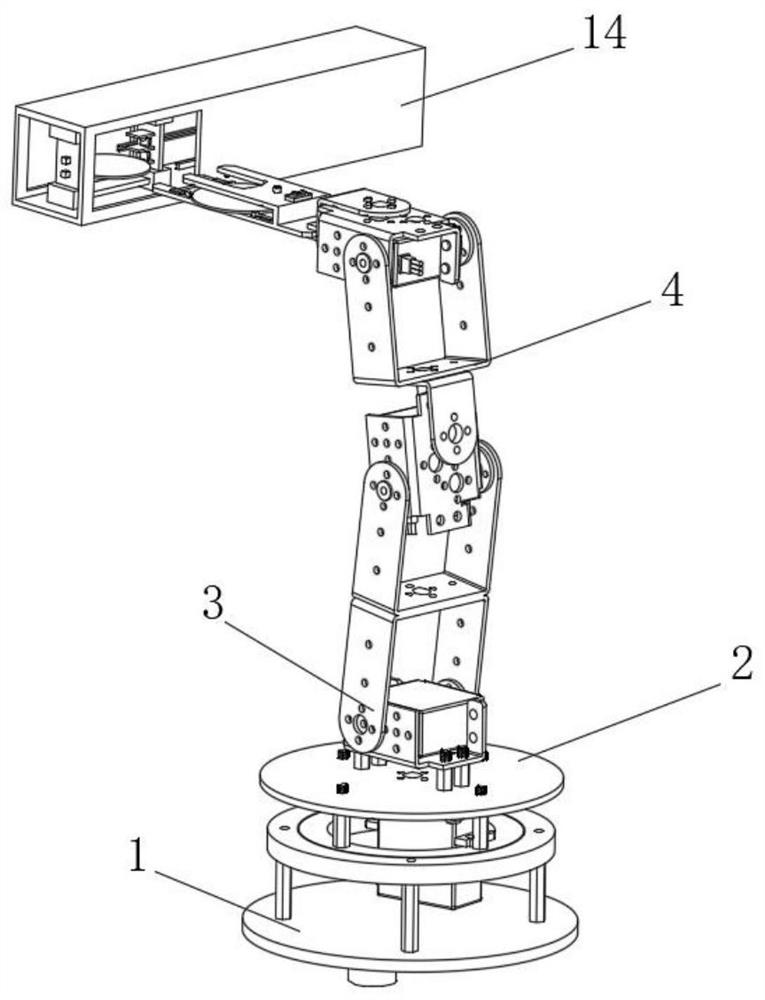

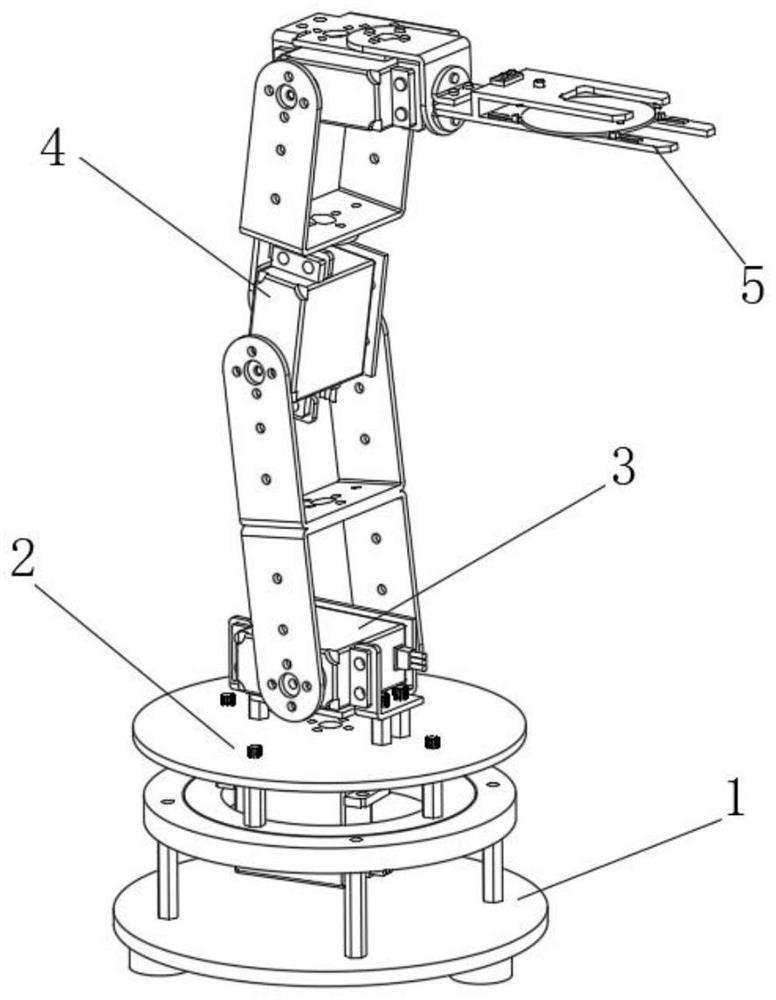

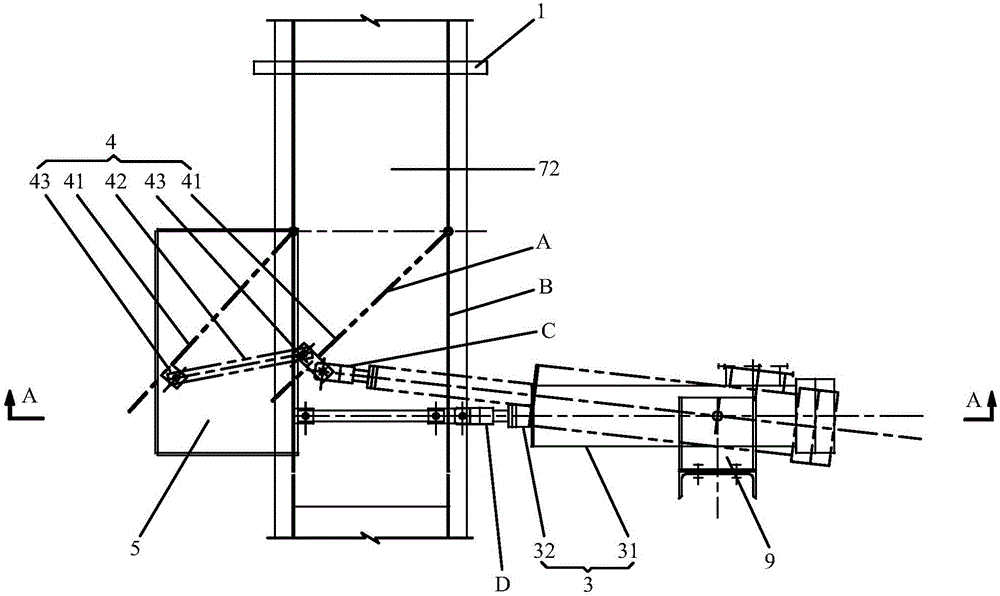

Manipulator and method for acquiring and transmitting wafers thereof

InactiveCN113478463AImprove crawling efficiencyAvoid crawlingProgramme-controlled manipulatorSemiconductor/solid-state device manufacturingPhysicsManipulator

The invention relates to the field of semiconductor equipment, and discloses a manipulator and a method for acquiring and transmitting wafers thereof. When the wafers are transported in a transport channel, the wafers are pushed to a set position by arranging a horizontal guide rail, a first infrared transmitting end and the like, so that the wafers can be directly taken out by a mechanical claw subsequently, and therefore, real-time detection of the relative position of the wafers during transmission in the transmission channel is avoided, and meanwhile, the problems that time and labor are wasted and the transmission efficiency is reduced by adjusting the position of a mechanical claw to adapt to grabbing of the wafers with different deviation degrees, and the wafer position deviation is caused if a clamping assembly fails in the wafer transfer process of the mechanical claw are avoided. By arranging the second infrared transmitting end and the like, the relative position of the wafer is detected and adjusted in real time in the process that the wafer is operated by the mechanical claw, and a situation that the operation of the mechanical claw is stopped after accidental deviation occurs, so that the time is delayed, and the operation rate of the mechanical claw is reduced is avoided.

Owner:G H S ADVANCED EQUIP TECH CO LTD

Cleaning method of concentration system for wet process phosphoric acid purifying process

InactiveCN109877097AReduce labor intensityReduce security risksCleaning using liquidsSodium molybdatePhosphoric acid

The invention discloses a cleaning method of a concentration system for a wet process phosphoric acid purifying process. The cleaning method comprises the following steps: connecting a cleaning liquidpipe to a circulating pipe at the inlet of a circulating pump; arranging a cleaning liquid delivery pump and a valve on the cleaning liquid pipe; preparing a cleaning liquid and connecting the cleaning liquid to the cleaning liquid pipe; opening the valve to start the cleaning liquid delivery pump, wherein the cleaning liquid enters an evaporating room; when the cleaning liquid in the evaporatingroom reaches a preset liquid level, closing the valve on the cleaning liquid pipe and starting the circulating pump; after the cleaning liquid flows circularly in the concentration system for 10-15 min, opening a discharging valve, and starting a discharging pump to discharge the cleaning liquid to finish cleaning. The cleaning liquid is a mixed solution containing sulfuric acid, fluosilicic acid, a pickling corrosion inhibitor, sodium molybdate, a penetrant and sulfamic acid. The method disclosed by the invention is simple and convenient to operate, saves the labor force, cleans the concentration system effectively, so that the cleaning time is shortened, damage of scale blocks hit to fall off to concentration equipment in a conventional method is avoided, too, and the operating rate ofthe equipment is guaranteed.

Owner:WENGFU DAZHOU CHEM CO LTD

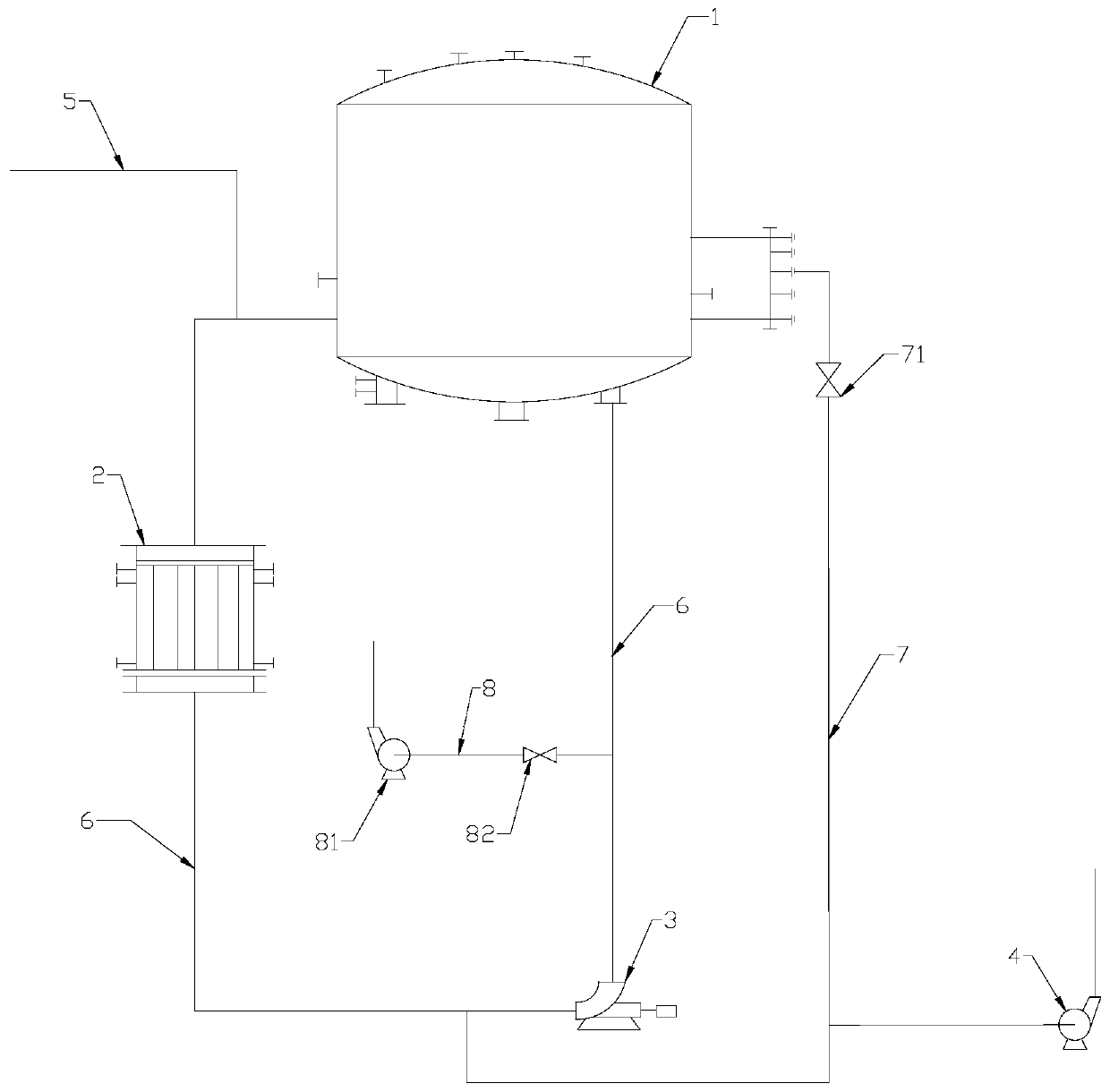

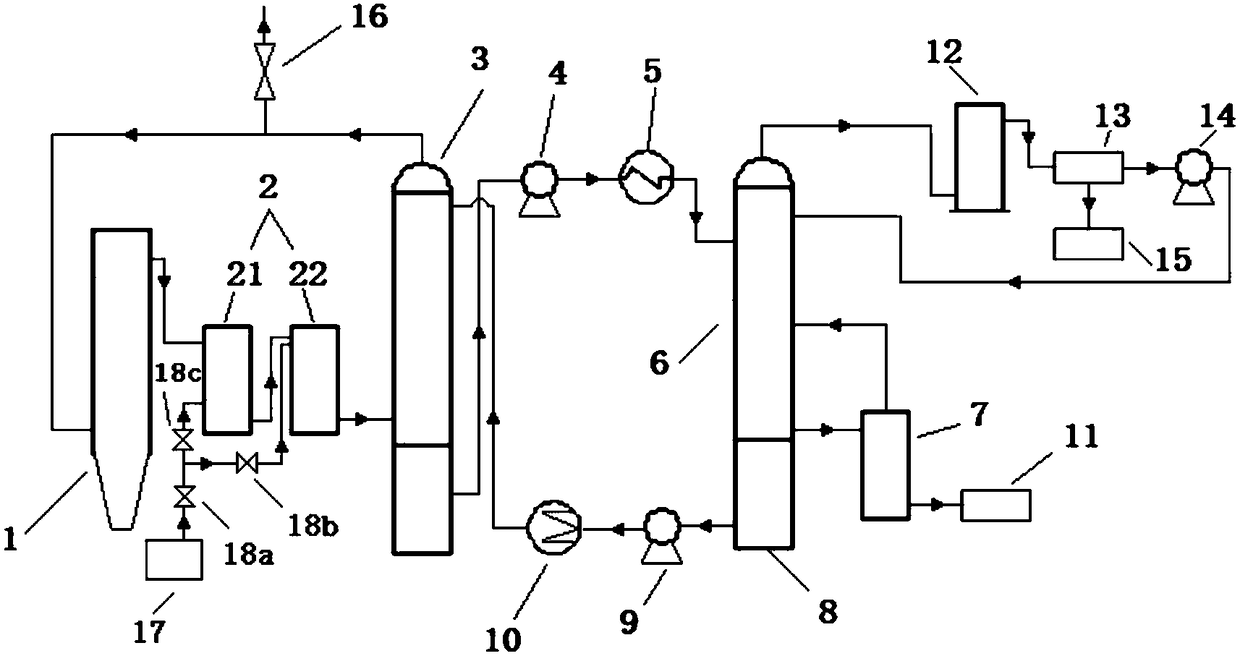

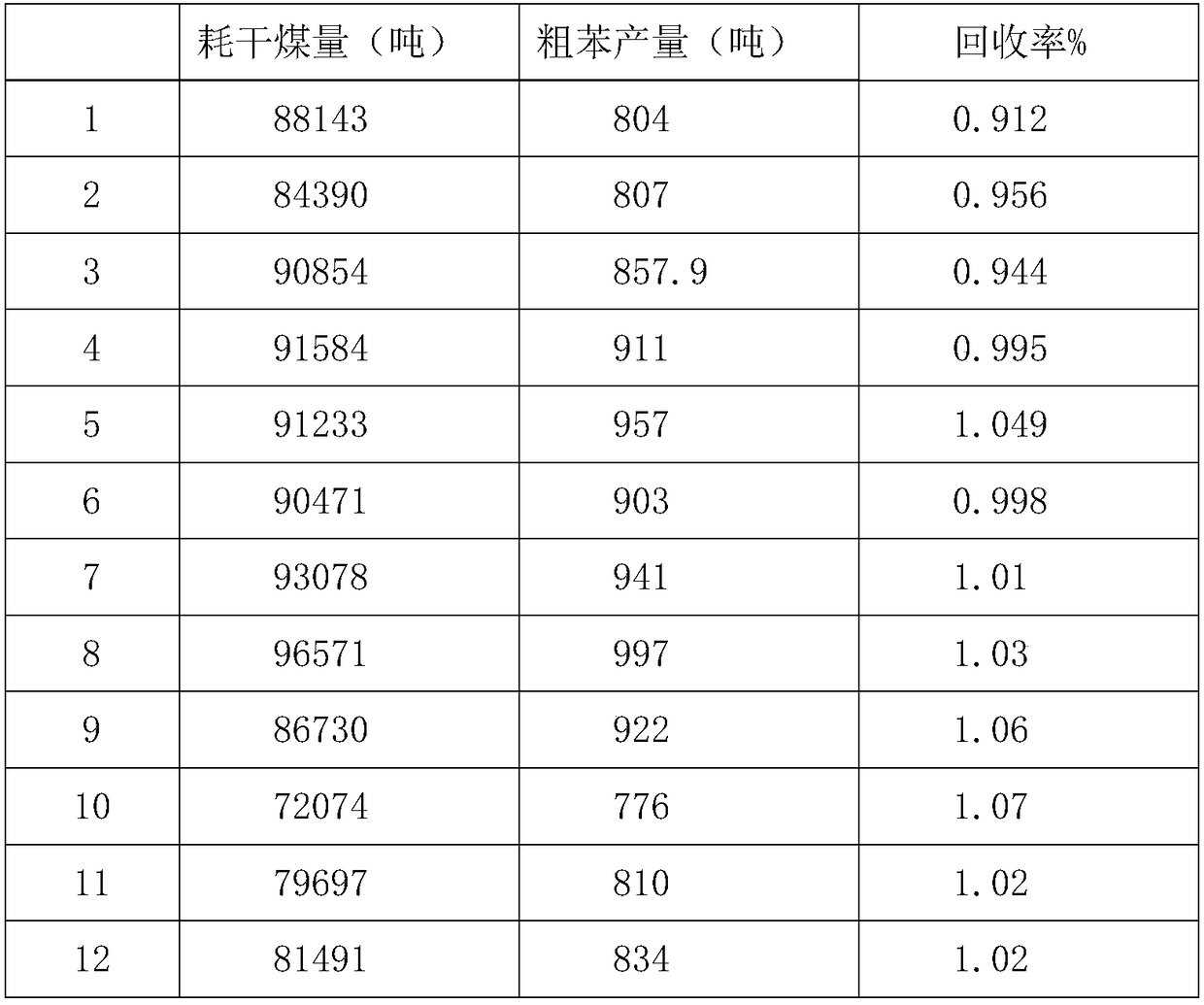

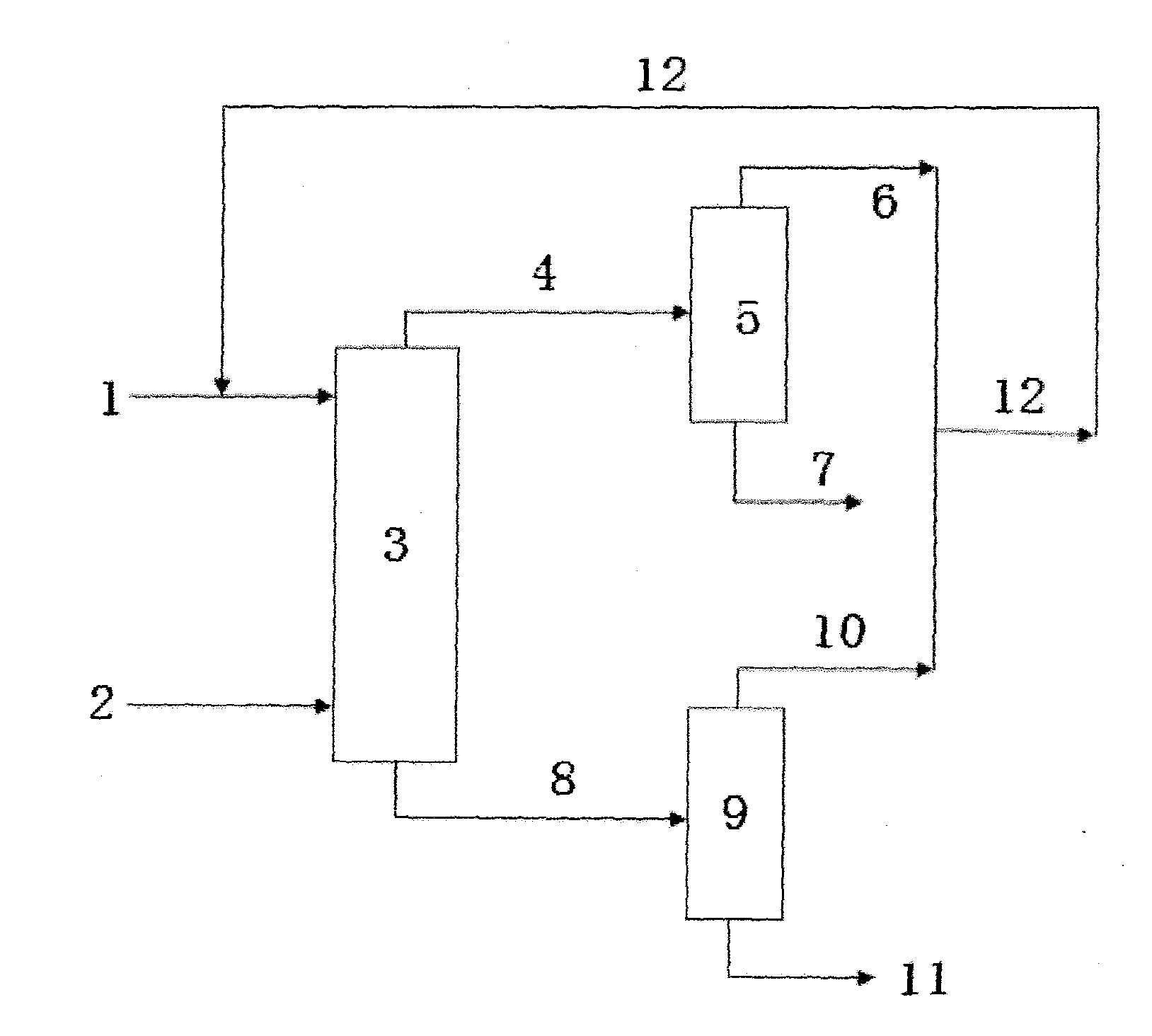

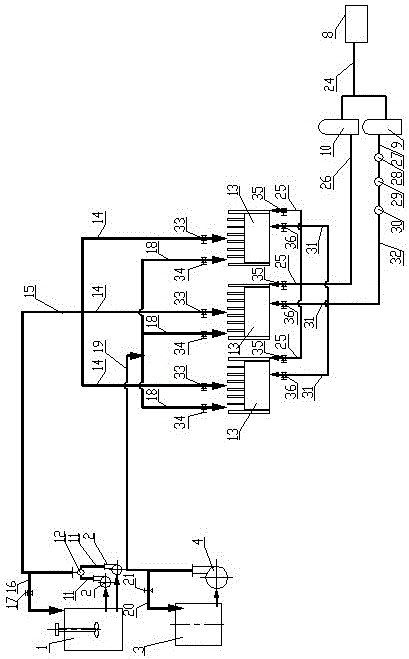

Coke oven gas treatment system and crude benzol recovery method

ActiveCN108441268AHigh recovery rateStable pressureChemical industryGas purification by liquid washingRecovery methodSlag

The invention relates to a coke oven gas treatment system. The treatment system comprises a former process unit (2), a benzol scrubber (3), a rich oil pump (3), a heat exchange and heating system (5),a debenzolization tower (6), a regenerator (7), a lean oil storage tank (8), a lean oil pump (9), a cooler (10), a slag storage tank (11), an oil-water separator (12), a reflux tank (13), a reflux pump (14), a crude benzol measuring tank (15) and an automatic clean gas exhaust system (16), wherein the former process unit (2) comprises a primary cooler (21) and a final cooler (22). By means of theprimary cooler and the final cooler with online cleaning capacity as well as the automatic clean gas exhaust system, crude benzol recovery rate is increased.

Owner:李劲松

By-pass metal removing device

ActiveCN106179734ASensitivity adjustableEfficient removalMagnetic separationMetal impuritiesMechanical engineering

The invention discloses a by-pass metal removing device. The by-pass metal removing device comprises a first metal detector, a control cabinet, a driving mechanism, a metal removing mechanism, a metal discharging part and a second metal detector; the first metal detector is used for detecting metal impurities on a conveying track and sends first alarm signals; the control cabinet receives the first alarm signals and sends first control commands to the driving mechanism; the driving mechanism drives the metal removing mechanism to move according to the first control commands, so that a conveying path of the metal removing mechanism is separated from the conveying track, and the metal impurities are conveyed along the conveying path of the metal removing mechanism and fall into the metal discharging part; the second metal detector is used for detecting the metal impurities falling into the metal discharging part and sends second alarm signals; the control cabinet receives the second alarm signals and sends second control commands to the driving mechanism; and the driving mechanism drives the metal removing mechanism to move according to the second control commands, so that the conveying path of the metal removing mechanism overlaps with the conveying track.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

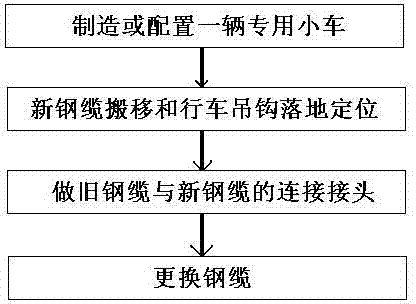

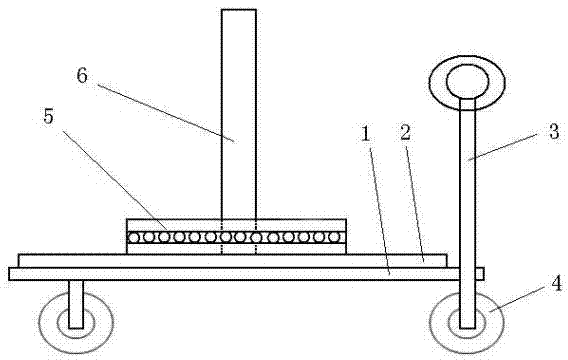

Method for quick replacement of driving steel cable

The invention is a method for rapid replacement of traveling steel cables. , Coil the new steel cable on the cable drum and place it on the center cylinder and turntable of the trolley, move the steel cable drum to the working position with the trolley, and position the crane hook on the ground; ③ Make the old steel cable and the new steel cable The connecting joint should be able to pass through the trough structure of the hoist on the hook; ④ Replace the steel cable and use the lifting and rotation of the traveling winch to make the old and new steel cables connected to one end in and the other out. After the steel cable is completely replaced, the connecting wire of the joint is cut off, and the two ends of the new steel cable are fixedly connected to complete the replacement of the steel cable. The positive effects of the present invention are: the new steel cable is convenient to move, quick to replace, reduces labor intensity of workers and downtime of equipment, improves production efficiency, and has a wide range of applications.

Owner:上海宏钢电站设备铸锻有限公司

Rolling mill housing with surface hardened layers

ActiveCN103084400ACorrosion resistanceImpact resistantMetal rolling stand detailsMetal rolling arrangementsEconomic benefitsSlide plate

The invention discloses a rolling mill housing with surface hardened layers. The rolling mill housing with the surface hardened layers comprises a housing body, wherein a window is formed in the housing body. A first working surface corresponding to a lower yoke contacting position of the housing and a second working surface corresponding to a sliding plate contacting position are arranged on a frame wall of the window, and the first working surface and the second working surface are both provided with surface hardened layers. A third working surface corresponding to a screw-down nut contacting position is further arranged on the frame wall of the window and a fourth working surface corresponding to an upper yoke contacting position of the housing and a fifth working surface corresponding to a working roller bending roller balance device contacting position are further arranged. The third, the fourth and the fifth working surface are provided with surface hardened layers. The rolling mill housing with the surface hardened layers protects the working surfaces of the housing and reduces the increasing of a gap of the rolling mill due to injury of the housing surface, the rolling mill is stable in working, impact is reduced, and probability of torsional vibration of a transmission system is reduced. In addition, the service life is prolonged, cost of online repair when a defect occurs is reduced, servicing time is reduced, servicing cost is reduced, and operation rate and economic benefit are improved.

Owner:MCC CAPITAL ENGINEERING & RESEARCH +1

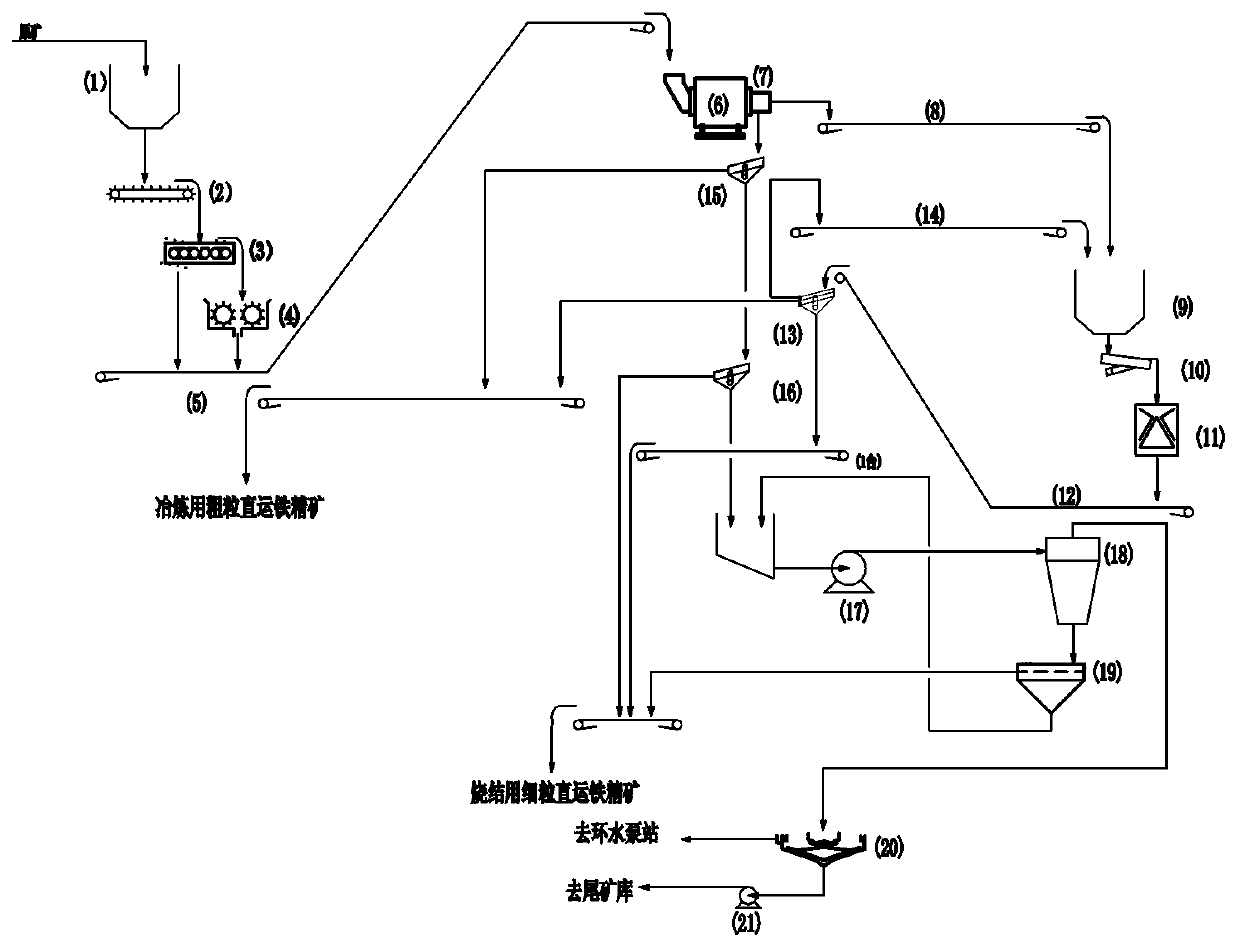

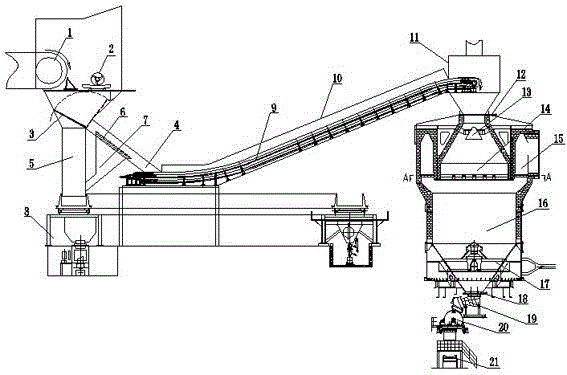

Crushing, screening and washing process of high-mud and high-water surface mixed hematite

ActiveCN109158202AReduce consumptionConforms to the energy-saving principle of more crushing and less grindingGrain treatmentsWet separationGranularityClosed loop

The invention relates to a crushing, screening and washing process of high-mud and high-water surface mixed hematite. The crushing, screening and washing process comprises the steps of performing three crushing processes including coarse crushing, intermediate crushing and fine crushing on mixed hematite of which the iron grade is 30% to 35%, the slime content is 20% to 40% and the granularity is0 to 750 mm in a raw ore stock bin, wherein in the coarse crushing process, a roller type screening machine and a double-geared roller crusher are adopted to screen to deslime and crush, and then a rotary drum washer and a drum screen are adopted to wash to deslime and perform dry and wet separation; in the intermediate crushing process, an intermediate crushing cone crusher and a dry double-layervibrating screen closed loop are adopted to treat oversize products of the drum screen, and undersize products of the drum screen are treated by a two-stage wet single-layer vibrating screen, a cyclone unit and a dewatering screen so as to obtain selected pulp; and in the fine crushing process, a fine cone crusher and a linear vibrating screen are adopted to obtain feed raw materials. According to the crushing, screening and washing process, the problems of adhesion and blockage of minerals are effectively solved, and the energy consumption is greatly reduced.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

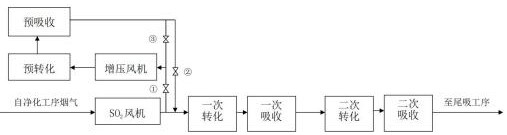

Method for turning off secondary absorption concentrated acid pump without stopping production

PendingCN113636527AShorten the operation time of pouringImprove work rateChemical industrySulfur compoundsThermodynamicsFlue gas

The invention relates to a method for turning off a secondary absorption concentrated acid pump without stopping production, and belongs to the technical field of smelting flue gas acid making. By adjusting the production load of the smelting furnace and increasing the pre-conversion absorption and the primary conversion absorption production load, a standby pump is turned off when the secondary conversion absorption does not bear the production load, continuous and stable operation of a production organization is ensured, the production load of the smelting furnace can be gradually recovered when the standby pump normally operates, the operation rate of a production system is ensured, equipment idling and system temperature rise electric energy consumption are completely prevented, and the relevant standard requirements of clean production, energy conservation and consumption reduction are met.

Owner:楚雄滇中有色金属有限责任公司 +1

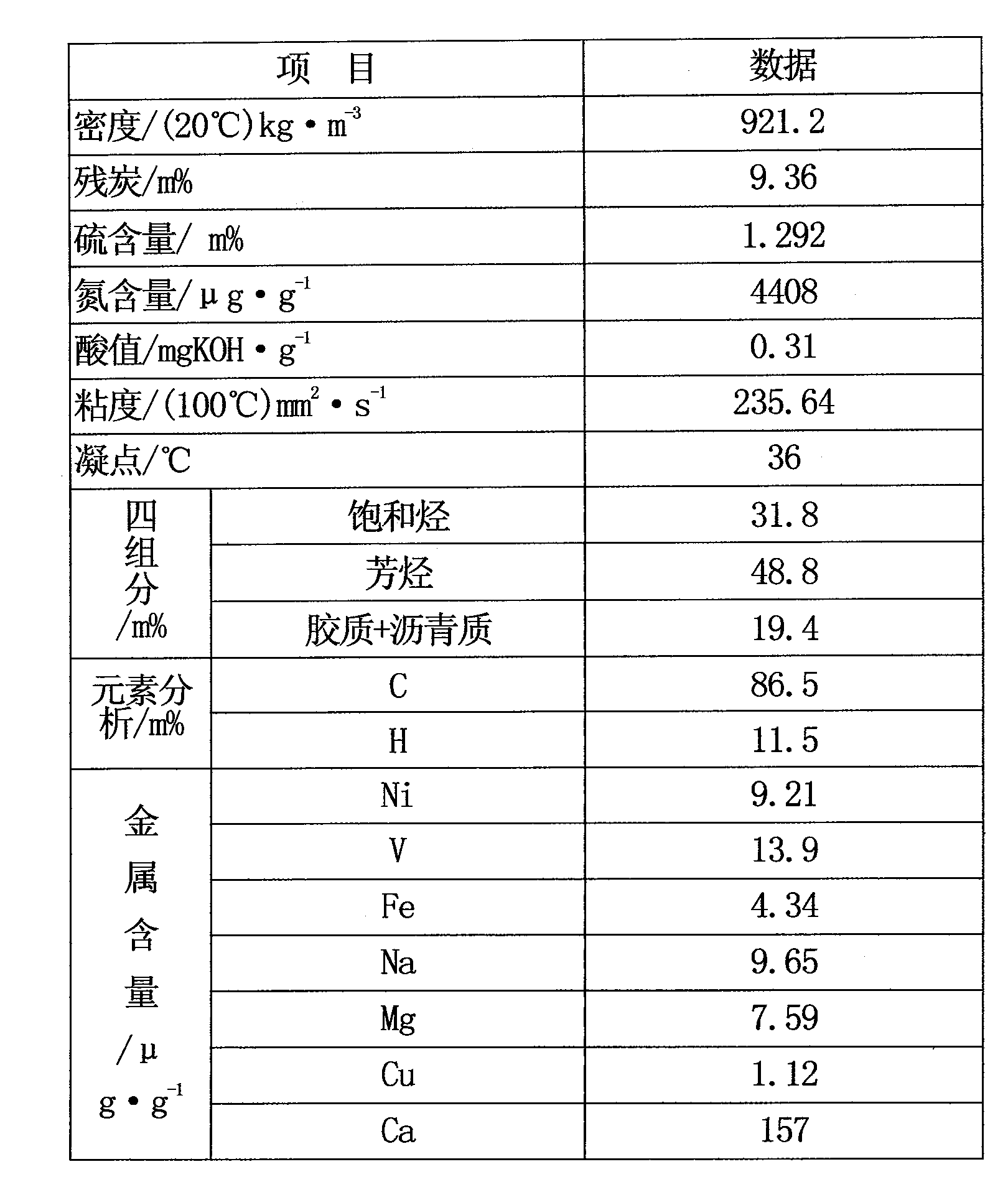

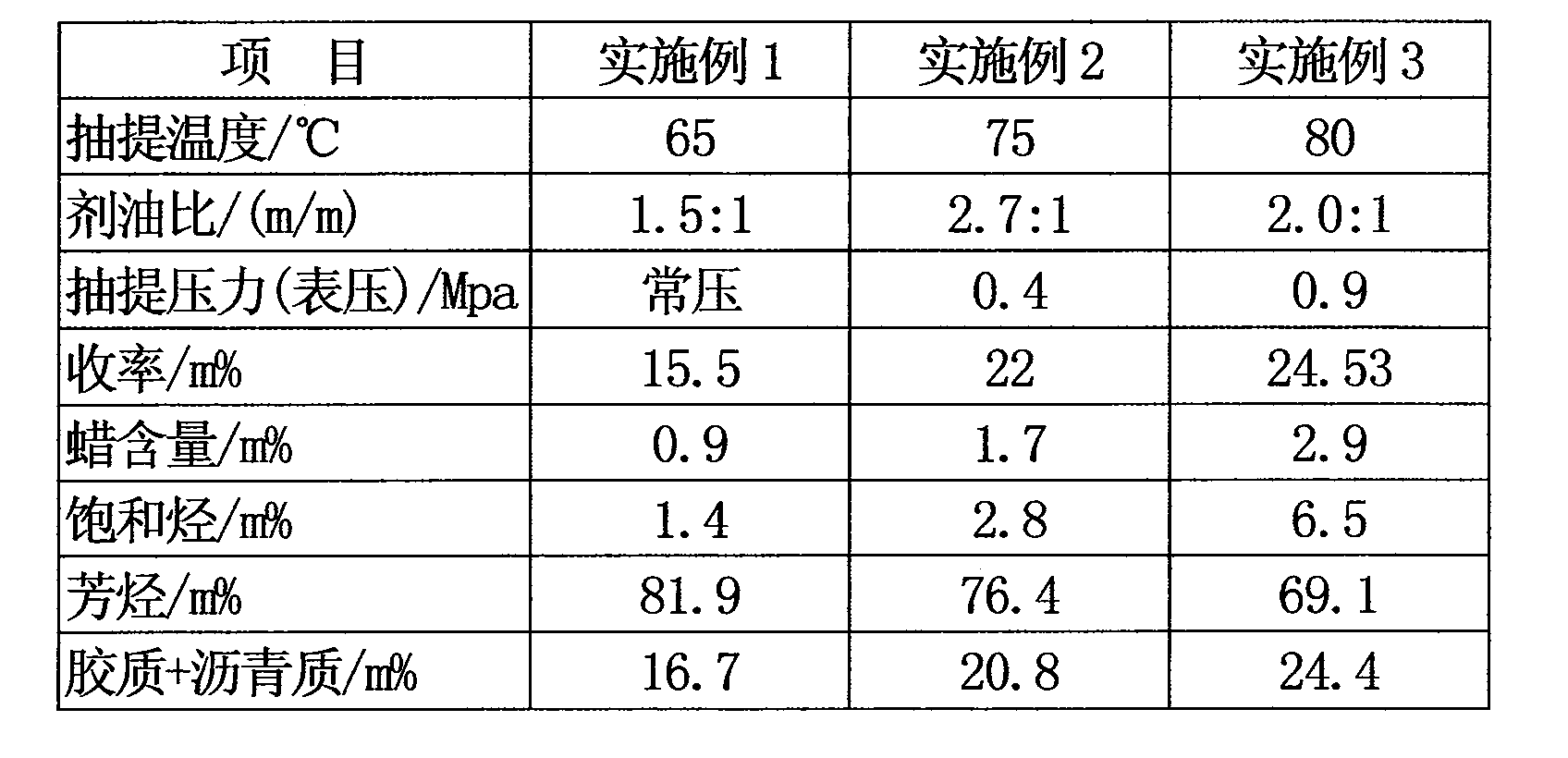

Novel method for obtaining concoction soft component of high-grade road asphalt

InactiveCN101880548BIncrease profitIncrease added valueTreatment with plural serial refining stagesProcess engineeringRaffinate

Owner:CHINA PETROLEUM & CHEM CORP +1

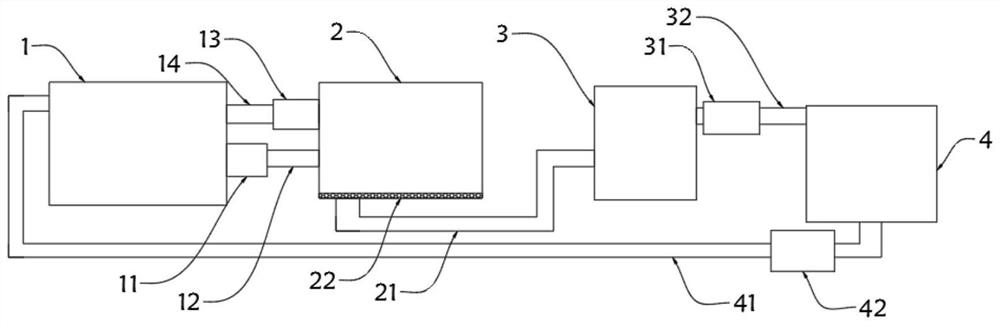

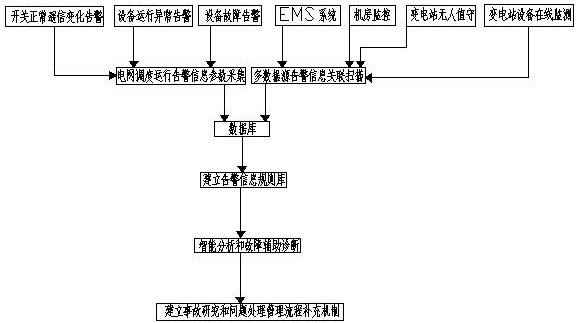

Systems for the filter press process and its control

ActiveCN104190126BGuaranteed equipment availabilityReduce in quantityFiltration separationFiltrationAir compressor

The invention relates to a filter pressing technology and control system. The filter pressing technology and control system comprises filter pressing machine sets, a feeding system, a flushing water system, a material discharging and liquid draining system, a compressed air system and an electrical control system, and is characterized in that a plurality of groups of feeding pumps are arranged at the outlet of a feeding stirring groove of the feeding system, each feeding pump is connected with each filter pressing machine in each filter pressing machine set through a spherical reversing check valve, a plurality of flushing water pumps are arranged at the outlet of a flushing water tank of the flushing water system, each filter pressing machine set share one flushing water pump, flushing water inlet pipes in each filter pressing machine set are connected to flushing water pump water outlet pipes in parallel, an air storage tank for an instrument and an air storage tank for blowing and drying are arranged at the outlet of an air compressor of the compressed air system, blowing and drying air inlet pipes of the filter pressing machines are connected to the outlet pipeline of the air storage tank for blowing and drying in parallel, and air inlet pipes for the instrument of the filter pressing machines are connected to the outlet pipeline of air handling equipment in parallel. The system is low in equipment and capital construction investment, high in operation rate, simple to operate and high in degree of automation.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

A rolling mill archway with a surface hardened layer

ActiveCN103084400BCorrosion resistanceImpact resistantMetal rolling stand detailsMetal rolling arrangementsEconomic benefitsSlide plate

The invention discloses a rolling mill housing with surface hardened layers. The rolling mill housing with the surface hardened layers comprises a housing body, wherein a window is formed in the housing body. A first working surface corresponding to a lower yoke contacting position of the housing and a second working surface corresponding to a sliding plate contacting position are arranged on a frame wall of the window, and the first working surface and the second working surface are both provided with surface hardened layers. A third working surface corresponding to a screw-down nut contacting position is further arranged on the frame wall of the window and a fourth working surface corresponding to an upper yoke contacting position of the housing and a fifth working surface corresponding to a working roller bending roller balance device contacting position are further arranged. The third, the fourth and the fifth working surface are provided with surface hardened layers. The rolling mill housing with the surface hardened layers protects the working surfaces of the housing and reduces the increasing of a gap of the rolling mill due to injury of the housing surface, the rolling mill is stable in working, impact is reduced, and probability of torsional vibration of a transmission system is reduced. In addition, the service life is prolonged, cost of online repair when a defect occurs is reduced, servicing time is reduced, servicing cost is reduced, and operation rate and economic benefit are improved.

Owner:MCC CAPITAL ENGINEERING & RESEARCH +1

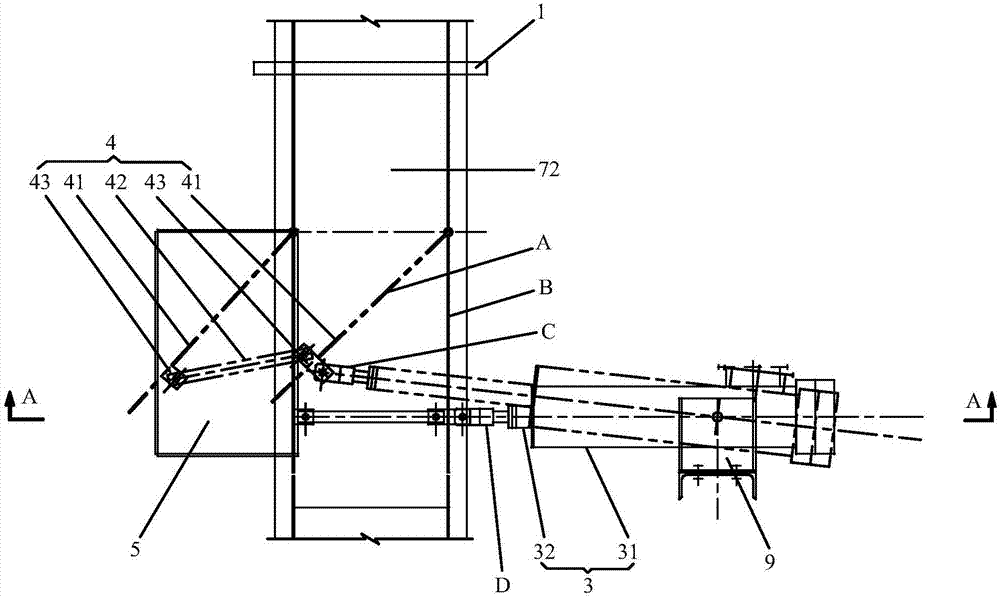

A rotary rto rotary valve and regenerative organic waste gas incinerator

The invention discloses a rotary RTO rotating valve and a heat storage type organic waste gas incineration furnace. The rotary RTO rotating valve comprises a stator, a rotor and an air separation area; an inner cylinder of the stator and an inner cylinder of the rotor are connected through an inner cylinder seal soft connecting module; and an outer cylinder of the stator and an outer cylinder of the rotor are connected through an outer cylinder seal soft connecting module. The lower stator and rotor are not hardly fitted in synchronous rotating operation; through this structure, the wear of outer cylinder sealing rings and inner cylinder sealing rings is delayed, and the service life is prolonged; and through adding of the seal soft connecting mechanisms, the manual maintenance convenienceis greatly improved.

Owner:MH ROBOT & AUTOMATION

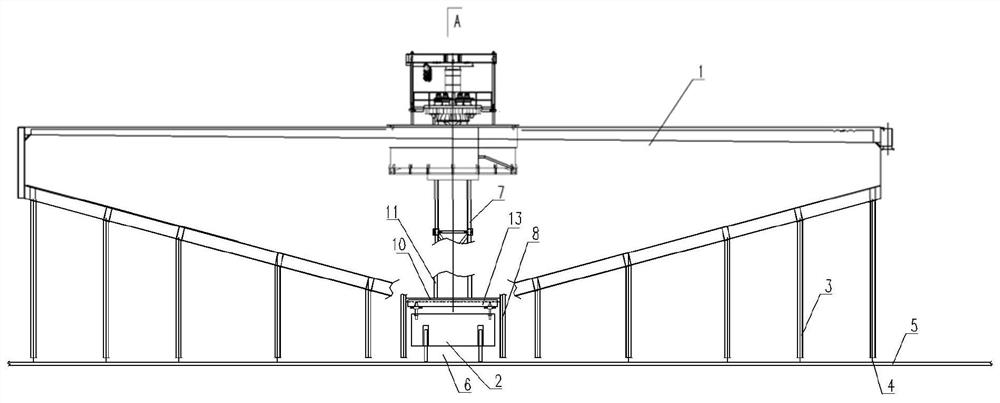

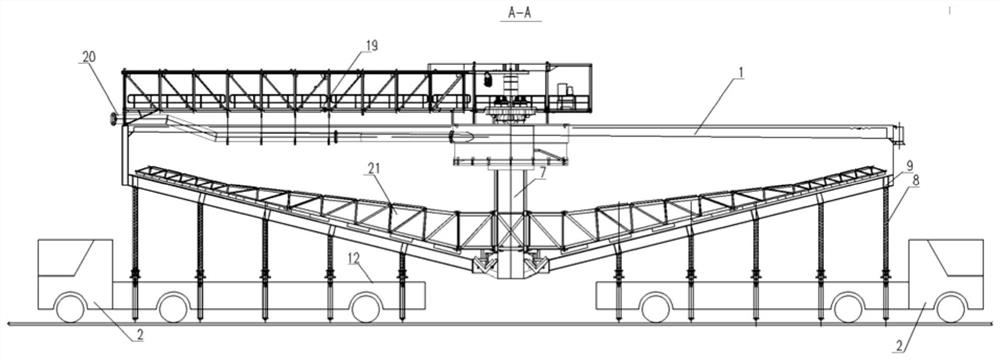

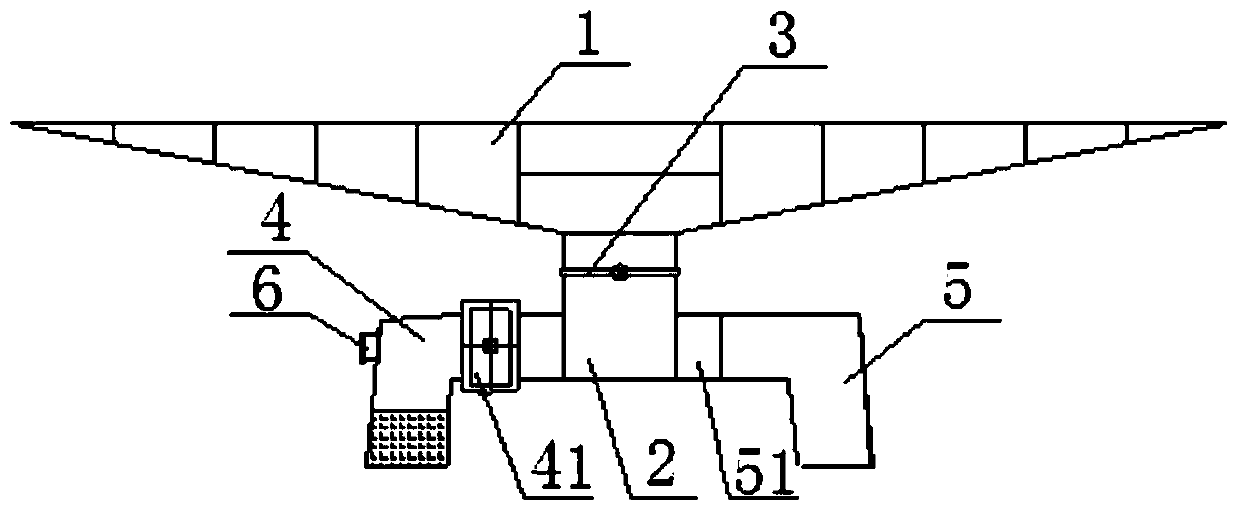

Device and method for anti-tipping clamping groove type traction thickener

InactiveCN113000197ARealize recycling nearbyAchieve reuseMachine supportsWet separationIn vehicleStructural engineering

The invention discloses a device and method for an anti-tipping clamping groove type traction thickener. The device comprises two access channels, a supporting structure and a moving mechanism , wherein the two access channels are arranged below the thickener, are positioned on the same axis and are respectively positioned on two sides of a central column; the supporting structure is used for supporting the thickener and comprises a plurality of pairs of upright posts arranged at equal intervals along the access channels, and each pair of upright posts is respectively positioned on two sides of the access channels; the tops of the upright posts are fixed with the bottom of a pool body, and a cross beam is fixedly connected between each pair of upright posts; the moving mechanism completes movement of the thickener through the supporting structure and comprises two carrier vehicles and a plurality of clamping grooves which are formed in vehicle plates of the carrier vehicles through lifting structures and used for clamping the cross beams; and each clamping groove is formed in the width direction of the vehicle plates. The device is simple in structure and convenient to move, rapid movement of the thickener can be achieved, construction of a full-modular movable separation plant of an open-air iron-rich mine is promoted, the raw ore transportation cost and the road construction cost are reduced, and repeated utilization of ore separation facilities is achieved.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

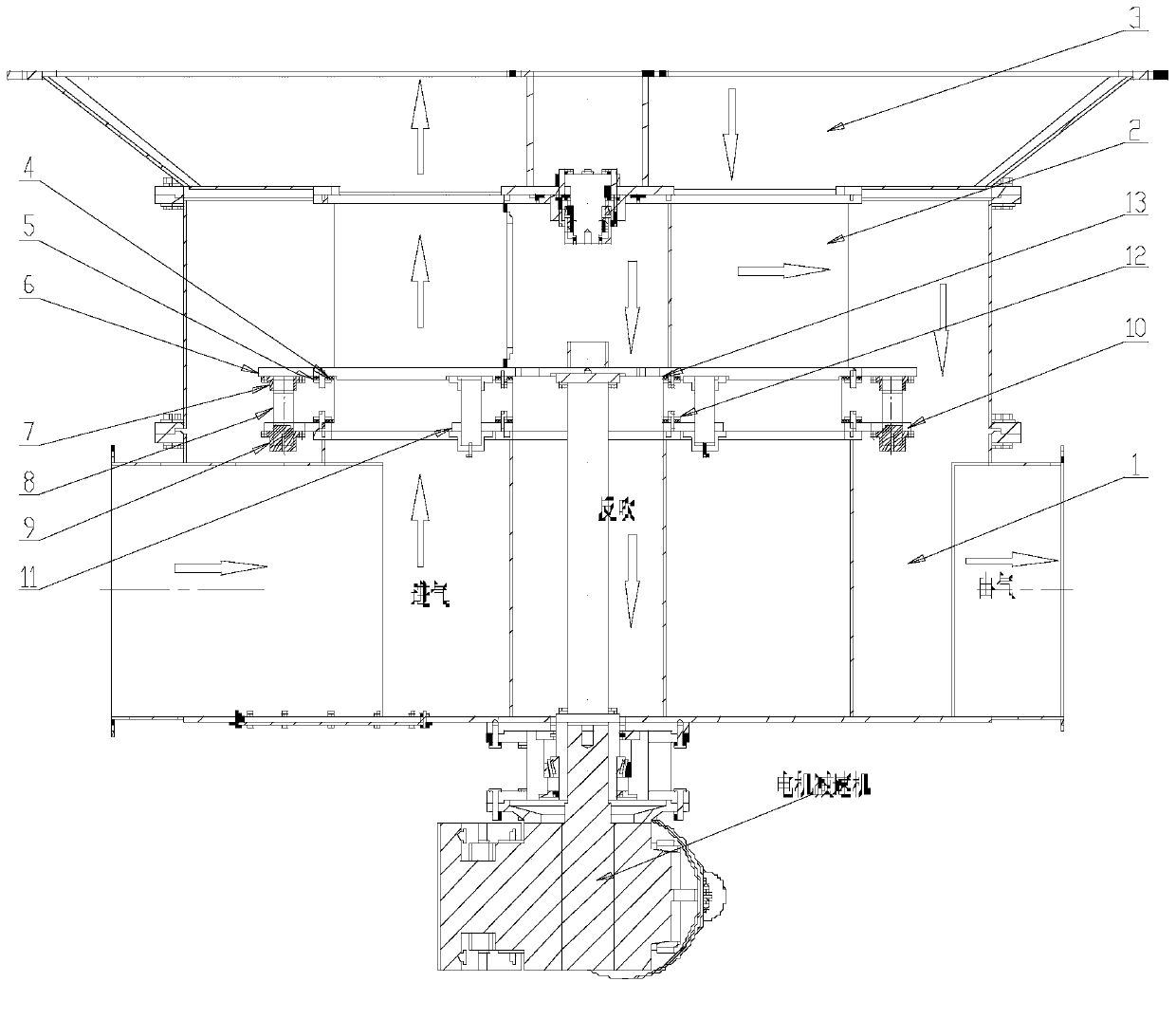

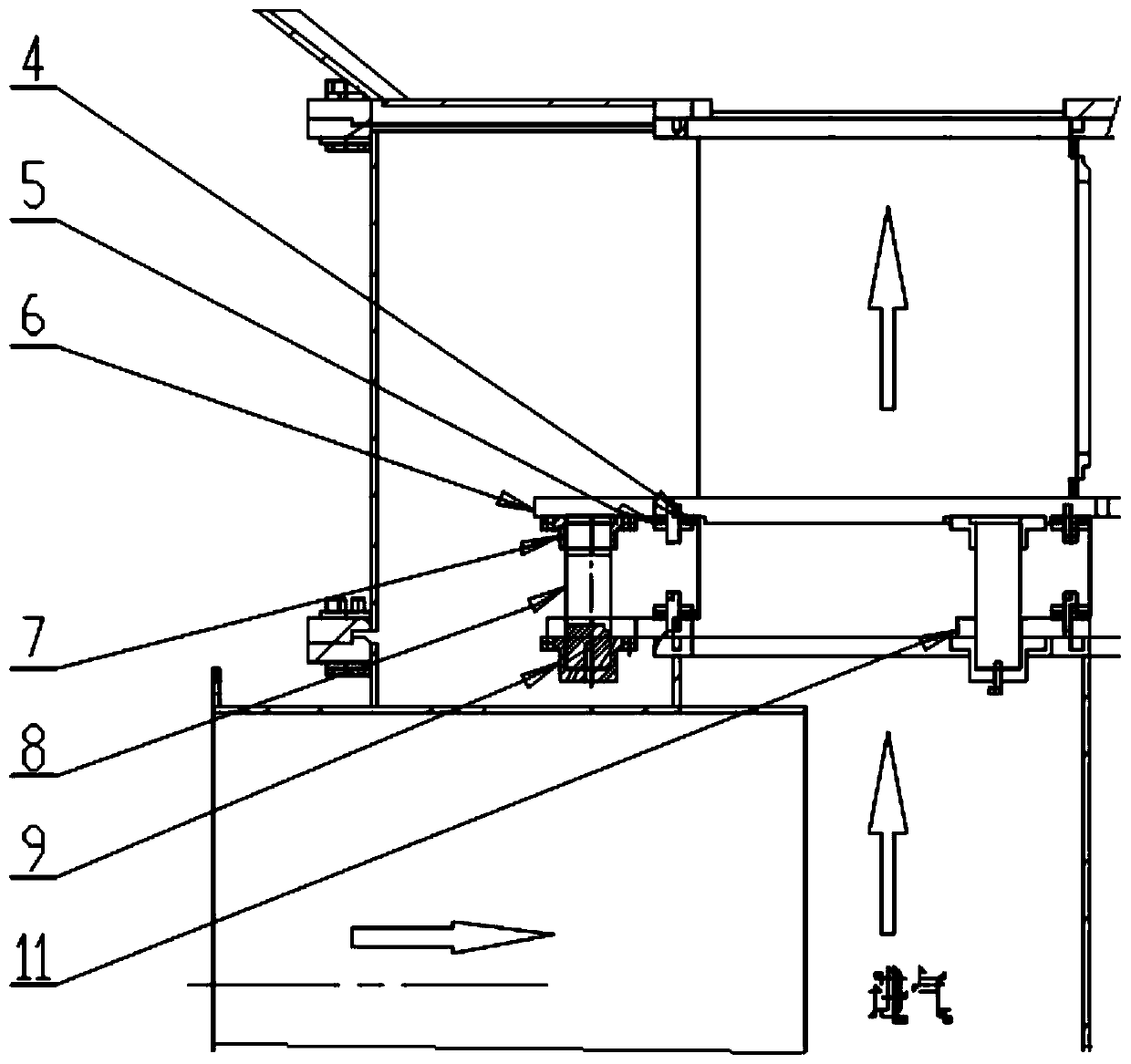

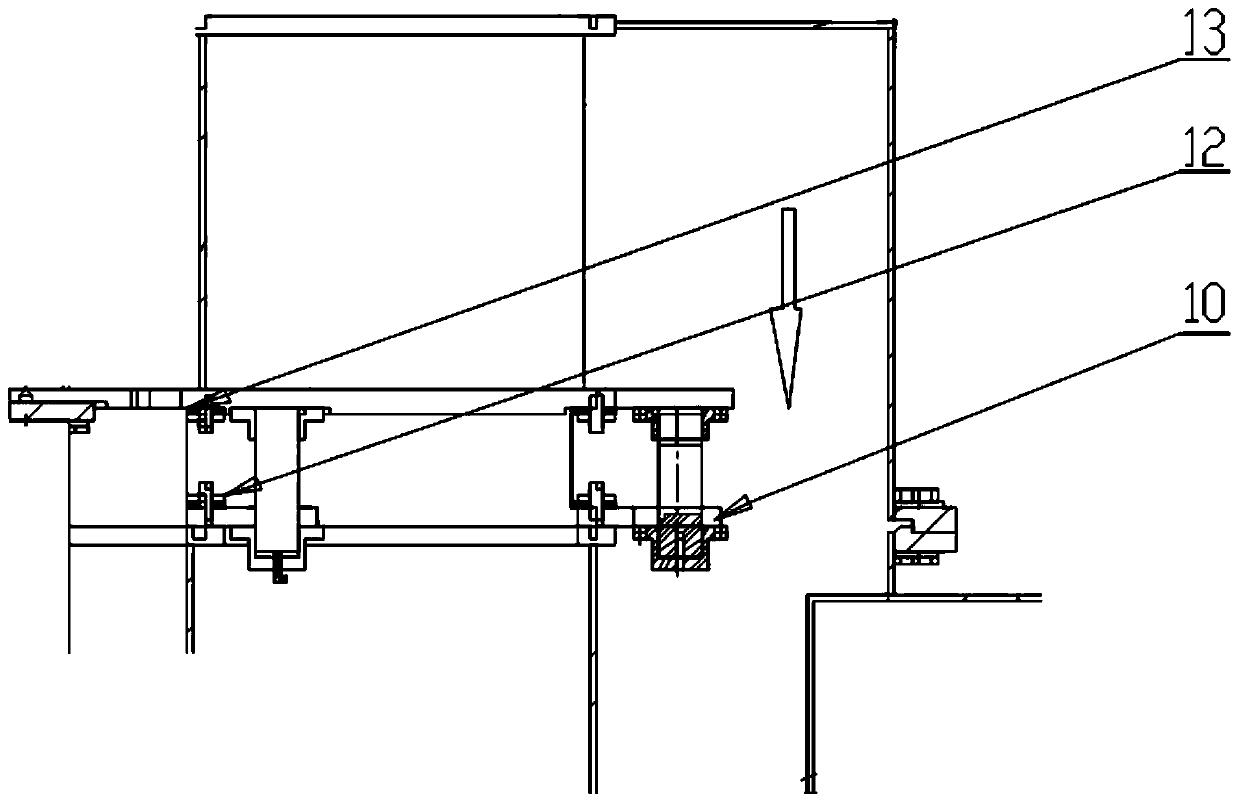

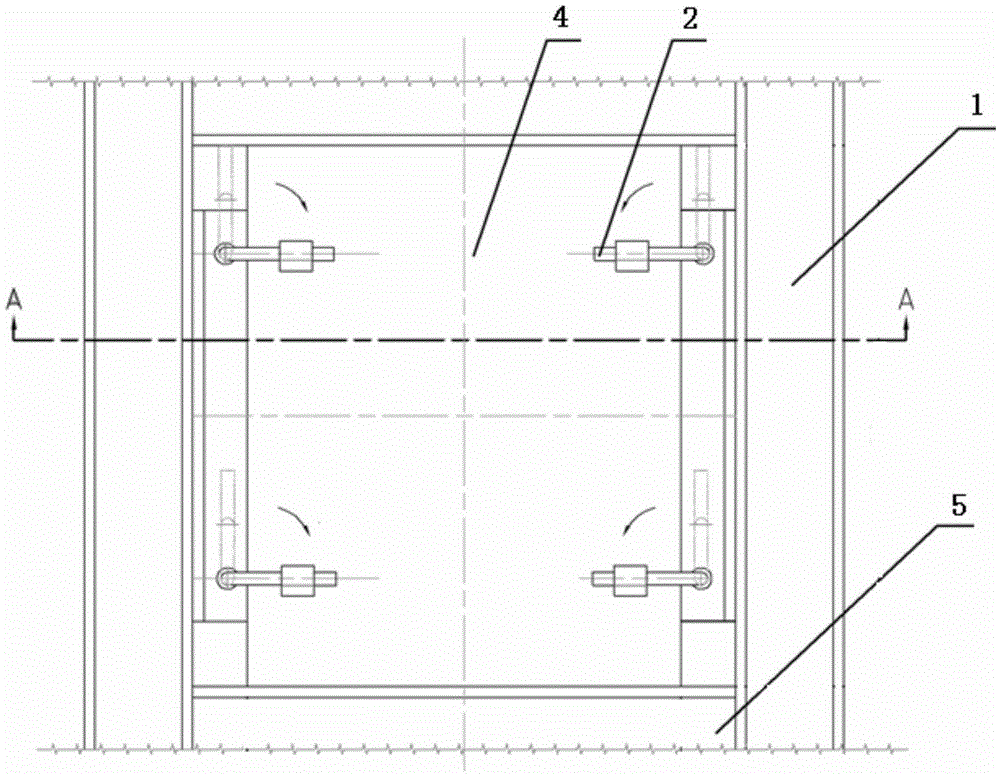

A material circulation system for dry desulfurization

ActiveCN105921000BGuaranteed operating rateEmission reductionSpindle sealingsDispersed particle separationPneumatic valveEngineering

The invention provides a material circulating system for dry desulfurization. The material circulating system at least comprises an ash hopper, an aerating box, a chute and a pin pump. A discharging port of the ash hopper is connected with the top face of the aerating box and further provided with a gate valve. One side of the aerating box is connected with the chute through a material discharging pipe which is provided with a material circulating valve, and the other side of the aerating box is connected with the pin pump through an ash discharging pipe which is provided with an ash discharging pneumatic valve. The material discharging pipe is formed by connecting a transverse pipe and a vertical pipe, the transverse pipe is connected with the side wall of the aerating box, the vertical pipe is connected with the chute, a blockage removing hole is formed in the side wall of the vertical pipe, and the central line of the blockage removing hole coincides with the central line of the transverse pipe. The blockage removing hole is detachably provided with a sealing cover. Blockage removing can be completed online through the blockage removing hole, the maintenance time is shortened, and thus emission of atmospheric pollutants can be reduced to the maximum while the running rate of a desulfurization system is ensured.

Owner:MCC BAOSTEEL TECH SERVICE

Rail-mounted mobile thickener

InactiveCN113171633ASolve the problem of relocationReduce weightSedimentation separationMarine engineeringStructural engineering

The invention provides a rail-mounted mobile thickener, which comprises a thickener body erected on the ground through steel supporting columns, wherein paired steel columns are arranged on the lower portion of the pool body of the thickener body along one diameter of the pool body at equal intervals, the paired steel columns are symmetrical about the diameter, a rotating shaft is connected between the lower portions of the two steel columns of each pair of steel columns, wheels are connected to the two ends of each rotating shaft, a rectangular rail foundation pit is dug in the ground below the pool body, a sinking rail is arranged in the rail foundation pit, the wheels are arranged on the sinking rail, a traction locomotive is connected to the paired steel columns at the edge of the pool body, an earth surface track is arranged between the sinking track and a moving destination, and the traction locomotive travels on the earth surface track. According to the invention, the difficulty in moving the thickener with small and medium diameters is solved.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

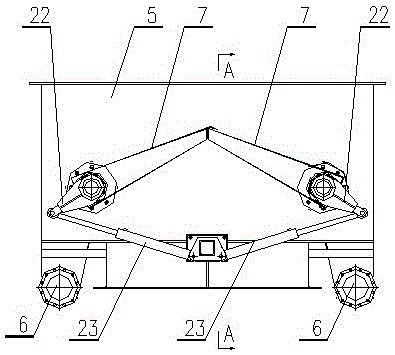

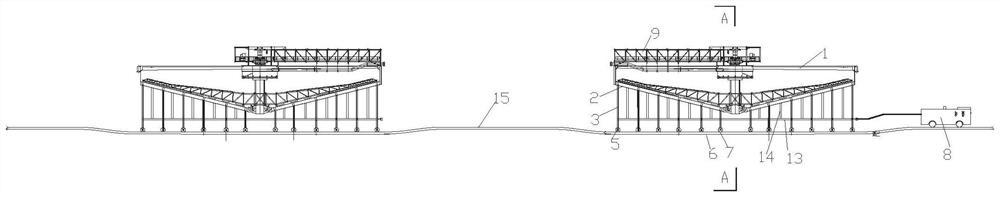

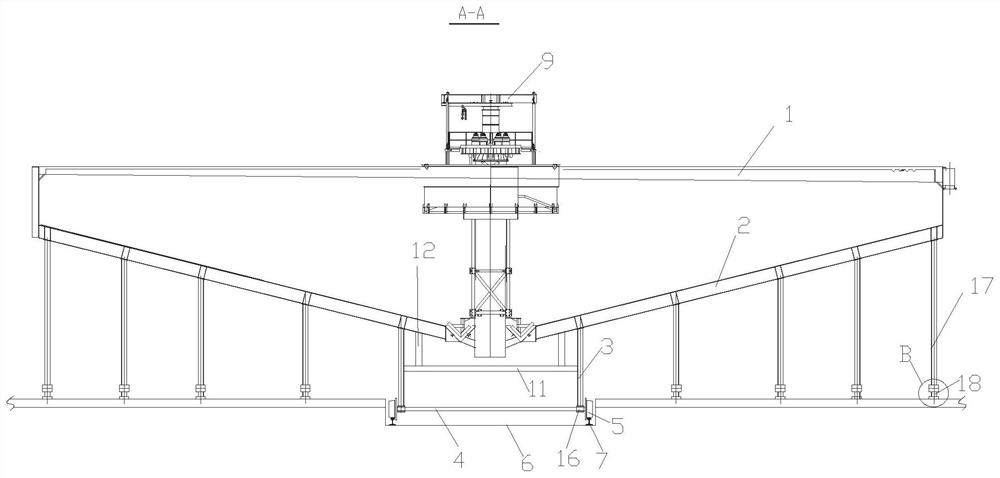

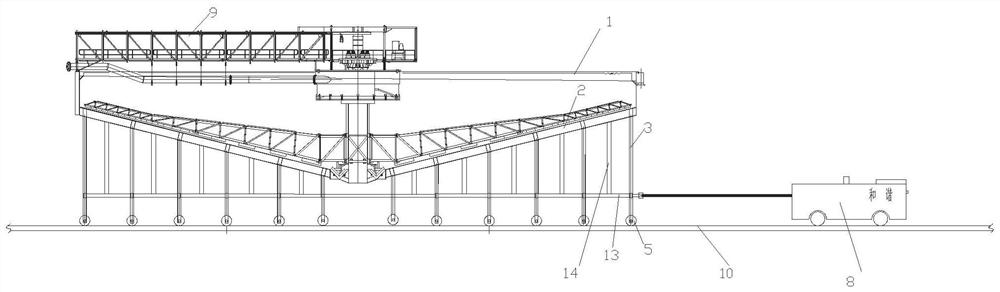

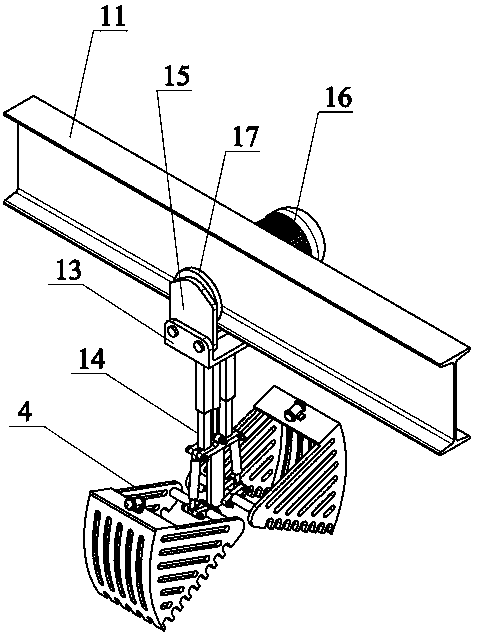

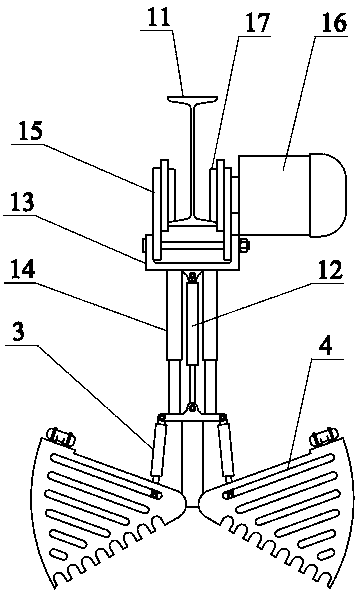

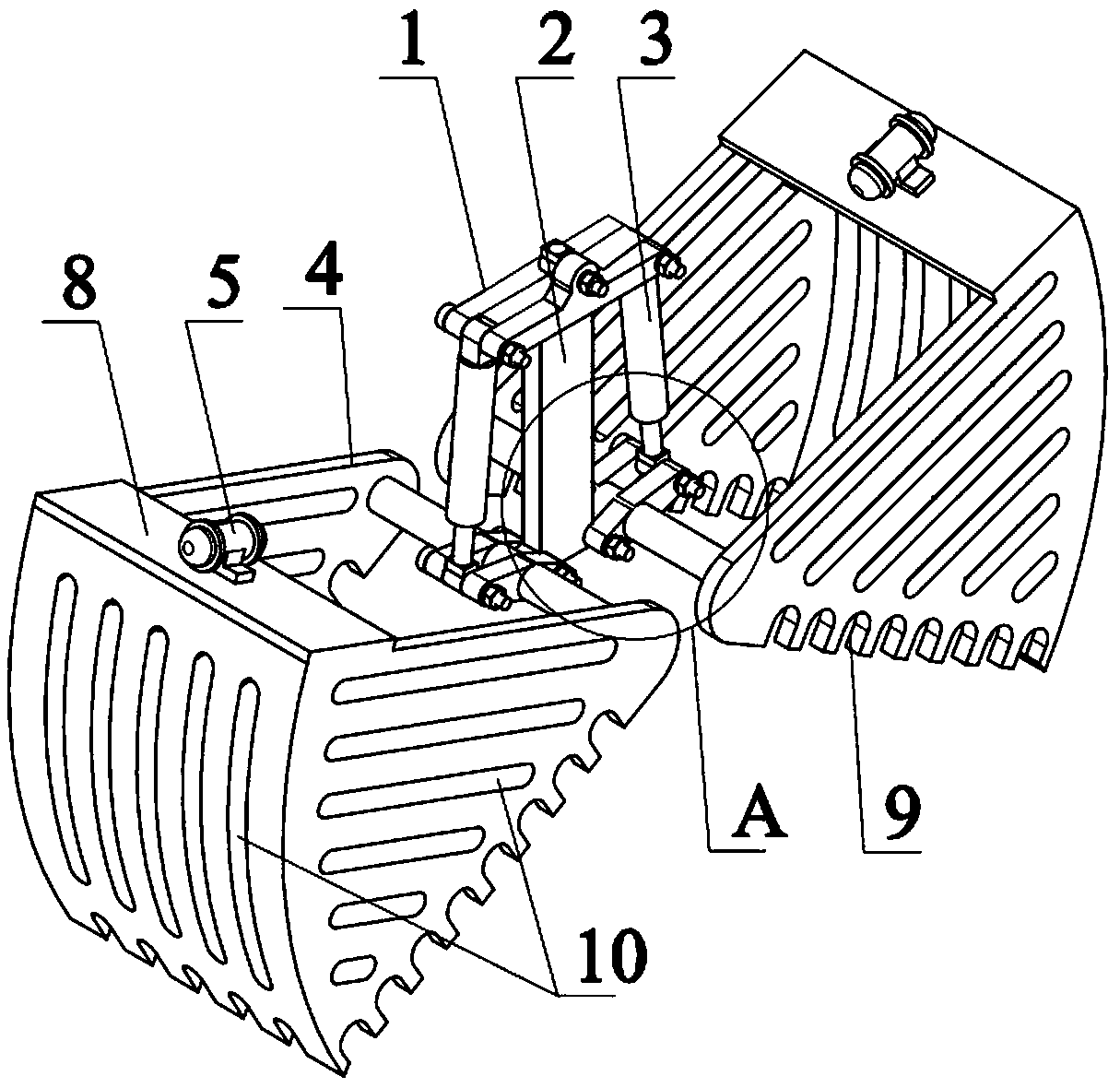

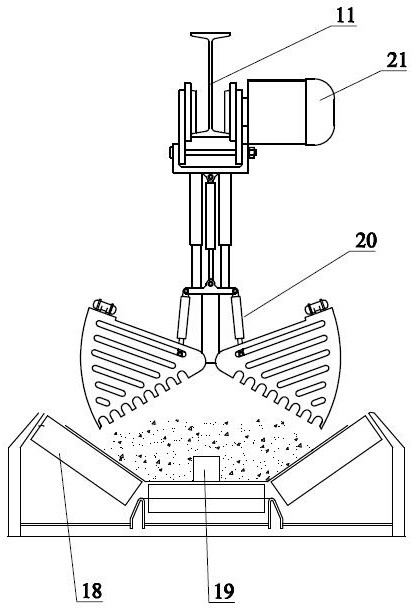

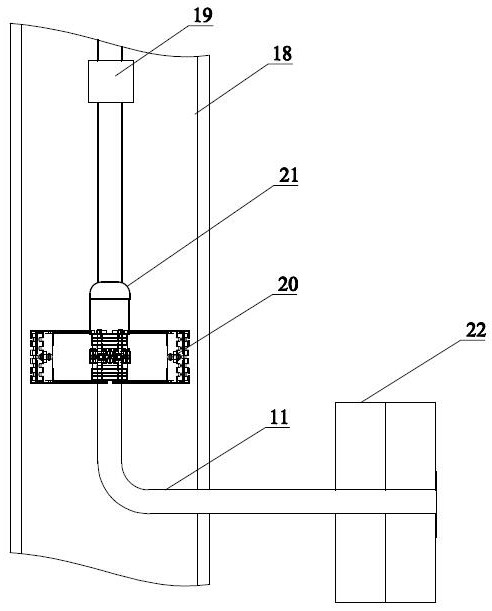

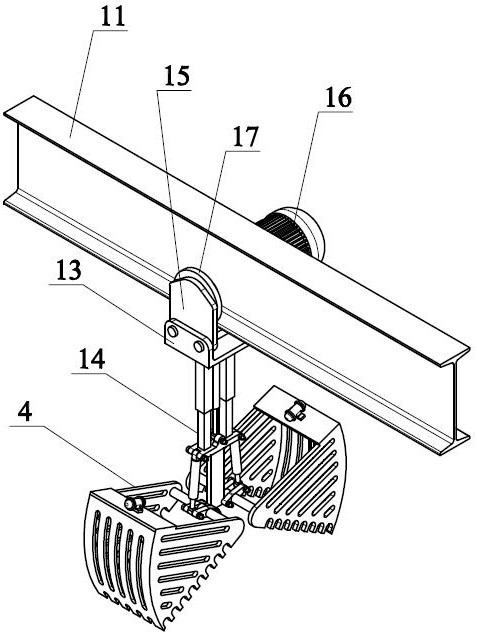

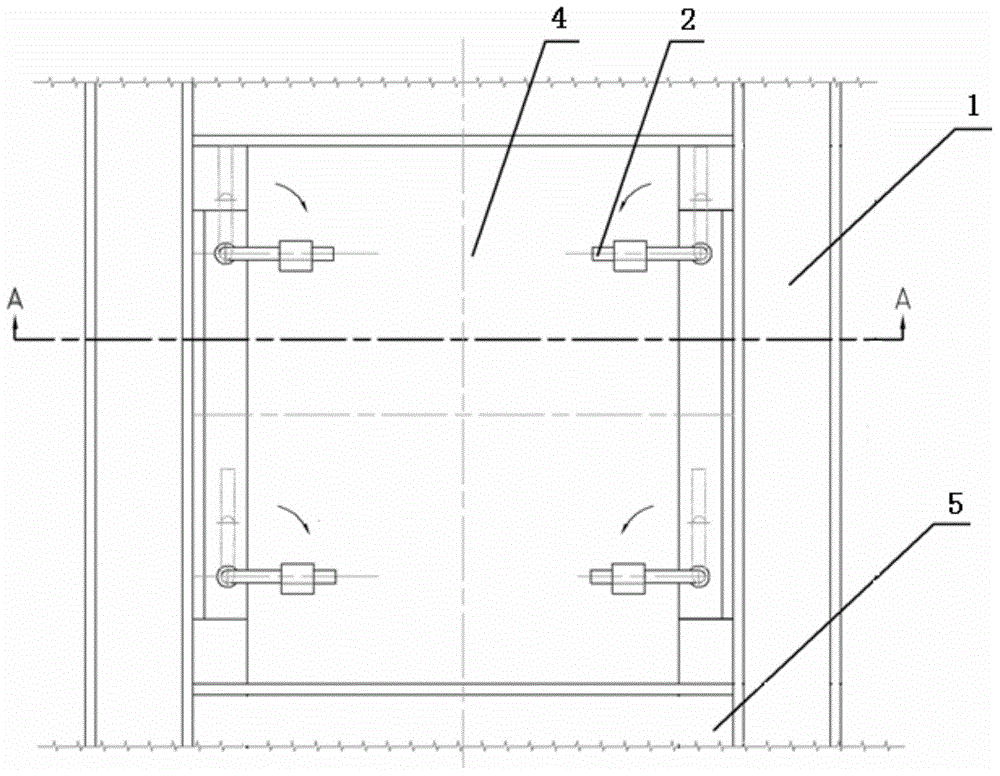

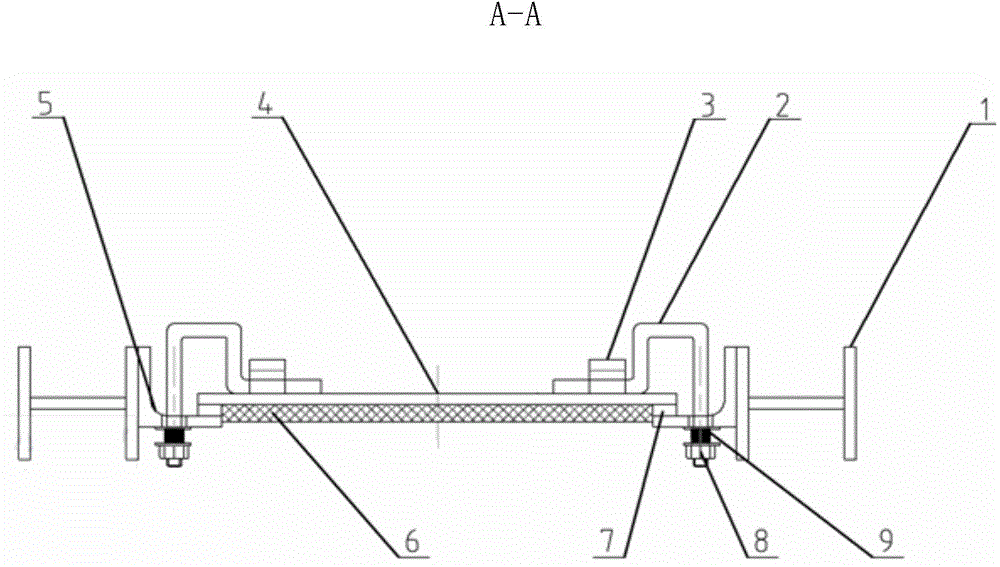

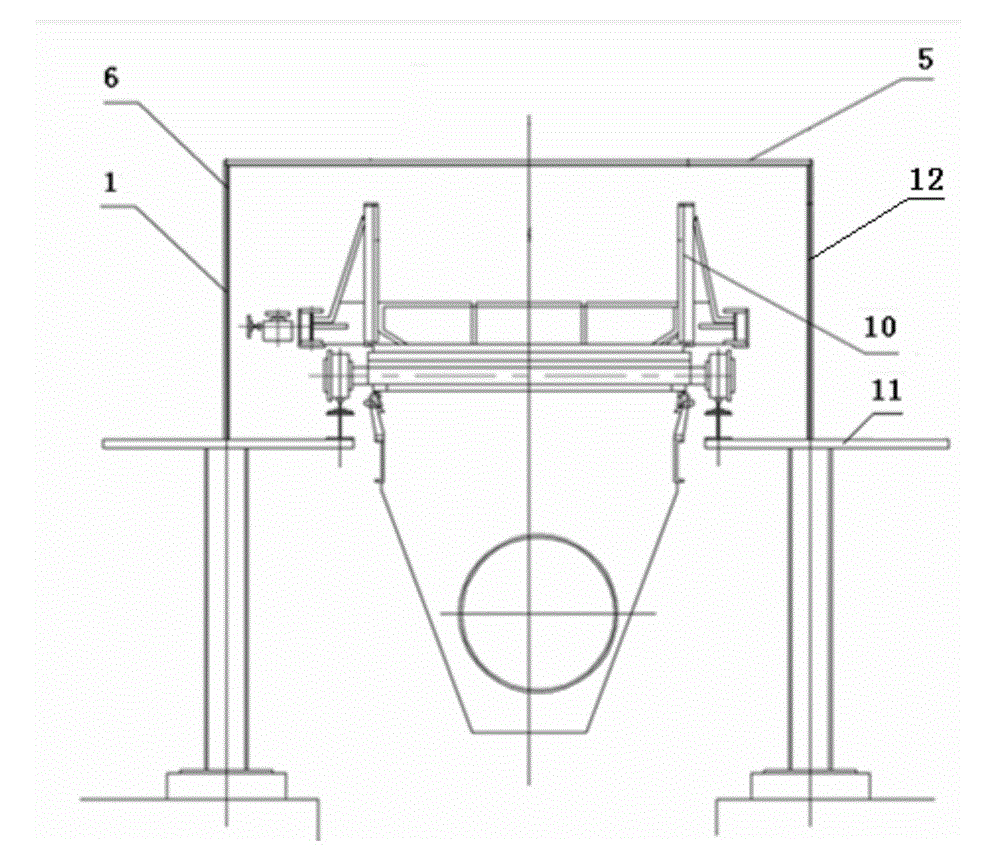

Intelligent iron remover grab bucket trolley

PendingCN110525918AAdaptableEfficient removalConveyorsControl devices for conveyorsIron removalEngineering

The invention provides an intelligent iron remover grab bucket trolley. The grab bucket trolley is installed on the sliding rail in a sliding mode. The grab bucket trolley comprises an iron removing mechanism arranged at the bottom end of a sliding rail in a sliding mode, a walking mechanism used for driving the iron removing mechanism to slide in the arrangement direction of the sliding rail anda controller. The magnetic iron removal principle of the magnetic iron remover is different from that of a traditional iron remover; the adaptability to metal objects is high; frequent shutdown of thebelt conveyor and manual picking-out caused by incomplete iron removal of a traditional magnetic iron remover are avoided; the trolley can effectively remove non-ferromagnetic metal or weakly magnetic metal such as high manganese steel, alloy steel, stainless steel and the like, and can remove metal objects at the middle lower part and the lower part of a material layer of the belt conveyor and large metal objects at the middle part and the lower part of the material layer of the belt conveyor, so that the conveying operation rate is ensured, and the safety of downstream crushing equipment isguaranteed.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

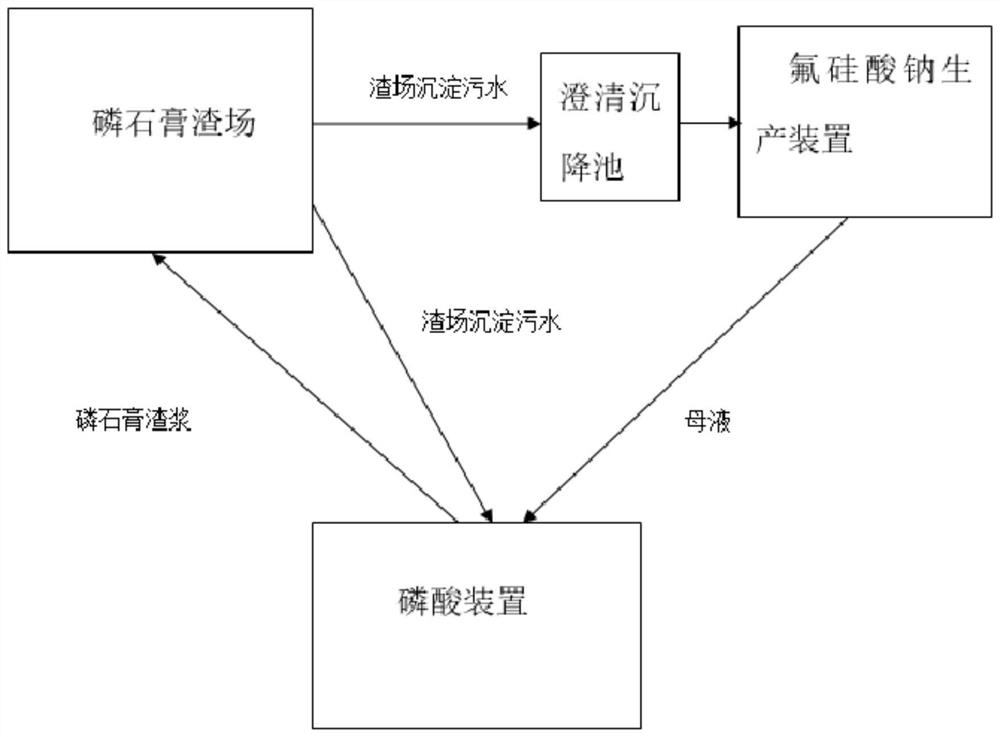

Process for precipitating sewage in ardealite slag field for sodium fluosilicate production

ActiveCN113603249AReduce storage pressureReduce generationWater/sewage treatment by centrifugal separationUsing liquid separation agentWater useIndustrial waste water

The invention discloses a process for precipitating sewage in an ardealite slag field for sodium fluosilicate production. The process comprises the following steps: S1, conveying ardealite slag slurry generated in phosphoric acid production to the ardealite slag field for stockpiling; s2, in the stockpiling process, the ardealite slag slurry naturally settles under the action of gravity for liquid-solid separation; s3, collecting a liquid phase into a water return pool; s4, returning to a sodium fluosilicate production device for sodium fluosilicate production; s5, after the sewage is naturally settled, the settled sewage in the ardealite slag field is conveyed into a sodium fluosilicate production device, the sewage generated by the sodium fluosilicate production device is returned to the phosphoric acid production device again, and finally water balance is formed. According to the process for precipitating sewage in the ardealite slag field for sodium fluosilicate production, any natural water such as fresh process water and the like is completely replaced and no longer used, qualified recycled water is treated, water is saved, industrial wastewater is reduced, the water storage pressure of the slag field is relieved, water balance in the whole process is adjusted, and the current production and environmental protection requirements are met.

Owner:云南弘祥化工有限公司

A sorting process for surface skarn-type hematite

ActiveCN109013077BIncrease incomeGood beneficiation indexSievingGas current separationSeparation technologyMining engineering

The invention relates to a separation technology of ground surface skarn type hematite. The technology is characterized by comprising coarse breaking work, ore washing desliming and dry and wet separation work, medium breaking work, wet type screening work and continuous two-segment water removal and grading work. According to the technology, grade of raw ore with 53 to 55% iron grade can be improved to 58% successfully without grinding and separation, the comprehensive concentrate recycling rate can reach 73 to 77%, the comprehensive iron recovery rate is much higher than the 70% recovery rate of traditional hematite mineral separation, the good mineral separation index is obtained, and in order to obtain the higher earnings, the guarantee is provided. The raw ore is subject to effectivedesliming, the slurry blockage problem can be solved, and two kinds of produced raw materials of smelting and sintering ores can be directly transported outwards.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

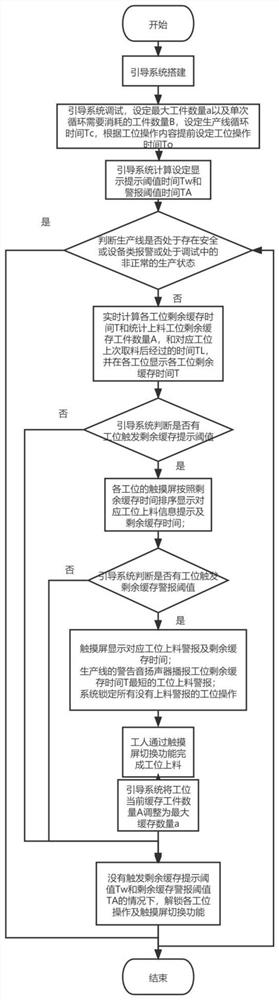

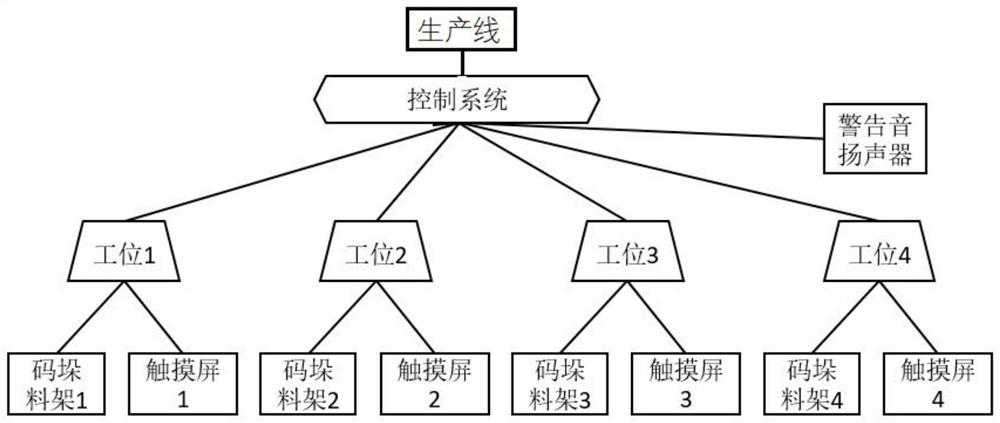

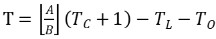

Sound picture guiding method for manual feeding production line

PendingCN114371673AGuaranteed operating rateReduce feeding lagAlarmsTotal factory controlProduction lineTouchscreen

The invention relates to the technical field of production line guiding systems, in particular to a sound picture guiding system and method for a manual feeding production line. A sound picture guiding method for a manual feeding production line is characterized by comprising the following steps that S1, a guiding system is set up on the feeding production line, each station corresponds to a stacking material frame and a touch screen, and a plurality of warning sound loudspeakers are installed around the feeding production line; s2, the maximum workpiece number a and the workpiece number B needing to be consumed in a single circulation are set through a guiding system, the production line circulation time Tc is set, and the station operation time To is set; s3, calculating and setting display prompt threshold value time Tw and alarm threshold value time TA by utilizing a guiding system; compared with the prior art, guiding, prompting and warning of feeding work of an operator are achieved in various modes of sound, pictures, operation limitation and the like. And feeding lagging and line stopping caused by the problem of the manual operation process sequence are reduced, and the starting rate of a production line is guaranteed.

Owner:SHANGHAI TRACTOR & INTERNAL COMBUSTION ENGINE

A power grid dispatching alarm monitoring system based on big data

ActiveCN108923531BShort response timeReduce workloadCircuit arrangementsCharacter and pattern recognitionPower gridMonitoring system

The present invention proposes a large data-based power grid dispatching alarm monitoring system, including a monitoring center server and an EMS system. The EMS system includes a database, a workstation, a workstation server, and a front-end processor. The workstation and the front-end processor transmit data to the database. The monitoring center server retrieves alarm information from the database. The invention improves the fault handling level, shortens the fault processing time, avoids or reduces the occurrence of power grid accidents, generates huge economic benefits, realizes the centralized management of power grid operation faults, and reduces the workload of power operation duty personnel while reducing the occurrence rate of power grid accidents , to ensure the operating efficiency of system equipment and the reliability of system operation.

Owner:PUYANG POWER SUPPLY COMPANY STATE GRID HENAN ELECTRIC POWER +1

Electrode gas-pressure holding-release system for calcium carbide manufacture

InactiveCN103723730AGuaranteed continuityGuaranteed operating rateCalcium carbidePressure systemEngineering

The invention discloses an electrode gas-pressure holding-release system for calcium carbide manufacture. The electrode gas-pressure holding-release system comprises an air pressure device. The gas pressure device comprises an air compressor, a gas storage tank, a valve group, a clamping device and a release device. The air compressor of the gas pressure device is connected to a gas inlet of the gas storage tank by a pipe. A gas outlet of the gas storage tank is connected to the valve group. An electrode is provided with the clamping device and the release device. Gas inlets of the clamping device and the release device are connected to the valve group by pipes. In use of the above structure, the electrode air-pressure holding-release system utilizes the air pressure system to replace an original oil hydraulic system for electrode compaction and release, solves the problems of the existing oil hydraulic system, guarantees continuity and an operation rate of calcium carbide manufacture, improves an operation environment, improves a calcium carbide production capacity, reduces energy consumption of calcium carbide production and saves a production cost of the enterprise.

Owner:HUBEI SHANSHUI CHEM

A bypass metal removal device

ActiveCN106179734BSensitivity adjustableEfficient removalMagnetic separationMetal impuritiesMechanical engineering

The invention discloses a by-pass metal removing device. The by-pass metal removing device comprises a first metal detector, a control cabinet, a driving mechanism, a metal removing mechanism, a metal discharging part and a second metal detector; the first metal detector is used for detecting metal impurities on a conveying track and sends first alarm signals; the control cabinet receives the first alarm signals and sends first control commands to the driving mechanism; the driving mechanism drives the metal removing mechanism to move according to the first control commands, so that a conveying path of the metal removing mechanism is separated from the conveying track, and the metal impurities are conveyed along the conveying path of the metal removing mechanism and fall into the metal discharging part; the second metal detector is used for detecting the metal impurities falling into the metal discharging part and sends second alarm signals; the control cabinet receives the second alarm signals and sends second control commands to the driving mechanism; and the driving mechanism drives the metal removing mechanism to move according to the second control commands, so that the conveying path of the metal removing mechanism overlaps with the conveying track.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Furnace type cooling and heat exchange device for sintered ores

ActiveCN103234349BGuaranteed operating rateImprove qualityCharge manipulationFurnace typesCooling effectFlap valve

The invention discloses a furnace type cooling and heat exchange device for sintered ores and relates to the technical field of cooling devices of sintered ores. A single-roll crusher is arranged at an outlet of a sintering machine, a flap valve is arranged under the single-roll crusher, the bottom of the flap valve is arranged at the connection position of a furnace cooling system chute and an annular cooling system chute / a belt cooling system chute, the flap valve can be switched between the furnace cooling system chute and the annular cooling system chute / the belt cooling system chute, a hot vibration screen also serves as the bottom wall of the furnace cooling system chute, a hot return mine chute is connected under the hot vibration screen and is connected with the annular cooling system chute / the belt cooling system chute, an outlet of the furnace cooling system chute is connected with one end of a chain-scraper conveyor, the other end of the chain-scraper conveyor is connected with a fire door of a cooling furnace, and a heat-insulating cover is arranged above the chain-scraper conveyor. By the aid of the device, the cooling effect and the waste heat utilization ratio of sintered ores are effectively improved, and the furnace cooling system device can be arranged in a remote distance without being limited by fields.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Rotary RTO rotating valve and heat storage type organic waste gas incineration furnace

ActiveCN110686250AReduce wearExtended service lifeIncinerator apparatusRotary valveProcess engineering

The invention discloses a rotary RTO rotating valve and a heat storage type organic waste gas incineration furnace. The rotary RTO rotating valve comprises a stator, a rotor and an air separation area; an inner cylinder of the stator and an inner cylinder of the rotor are connected through an inner cylinder seal soft connecting module; and an outer cylinder of the stator and an outer cylinder of the rotor are connected through an outer cylinder seal soft connecting module. The lower stator and rotor are not hardly fitted in synchronous rotating operation; through this structure, the wear of outer cylinder sealing rings and inner cylinder sealing rings is delayed, and the service life is prolonged; and through adding of the seal soft connecting mechanisms, the manual maintenance convenienceis greatly improved.

Owner:MH ROBOT & AUTOMATION

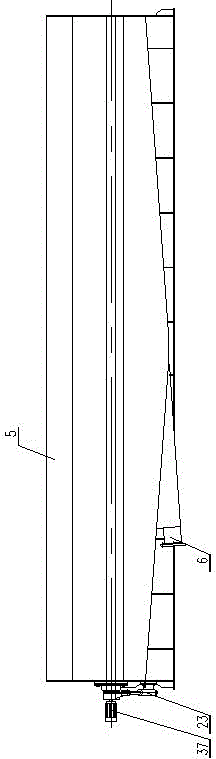

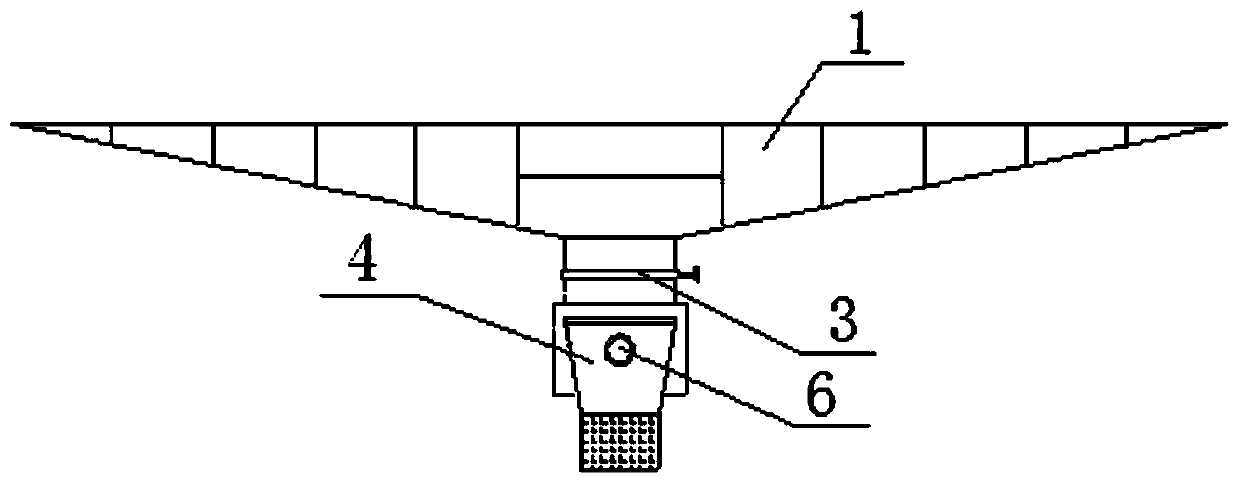

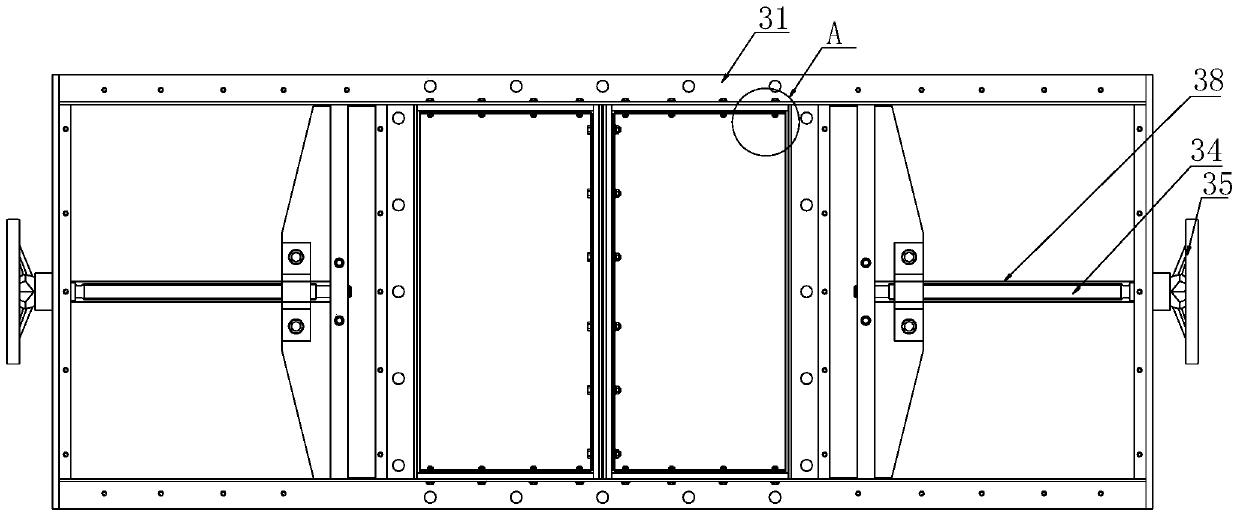

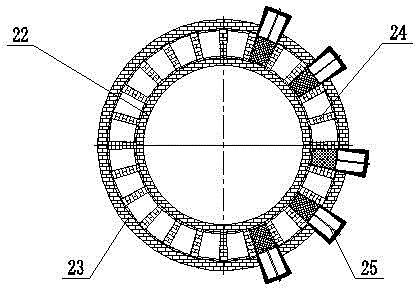

A combined detachable movable smoke hood for an annular cooler

ActiveCN104390475BGuaranteed operating rateReduce difficultyHandling discharged materialWaste heat treatmentRefractoryEngineering

The invention provides a combined detachable movable smoke hood of an annular cooler. The combined detachable movable smoke hood of the annular cooler comprises a trolley, a traveling platform and a movable smoke hood, wherein the movable smoke hood mainly comprises main framework columns, a frame beam, a movable baffle, a refractory lining, fasteners, buckles, sealing asbestos washers, springs, washers and hexagon nuts; a smoke hood body is mounted on the traveling platform of the annular cooler, hoods the trolley, and mainly comprises a main structural column, the frame beam and a movable baffle door; the refractory lining is arranged in the movable baffle; each fastener is provided with the corresponding buckle. The combined detachable movable smoke hood of the annular cooler has the advantages that the problem that the smoke hood of the annular cooler is short in service life is solved; the problem of sealing difficulty of the annular cooler caused by waste heat utilization is solved; the smoke hood body is fixedly arranged on the platform of the annular cooler, so that a chimney can be mounted on the smoke hood body; by virtue of a frame-baffle combination structure, a heat preservation layer can be replaced at any time on line when being disengaged; the smoke hood body is suspended over the trolley and hoods the trolley, so that the problem of sealing difficulty between the trolley and the smoke hood is solved.

Owner:中冶大地工程咨询有限公司

A mine intelligent iron removal system and iron removal method

ActiveCN110525917BAdaptableEfficient removalConveyorsControl devices for conveyorsIron removalMetal detectors

The invention provides a mine intelligent iron removal system and an iron removal method. When the metal detector detects that a metal object passes through the feeding belt, the metal detector sendsan iron arrival signal to a controller; the controller controls an iron removal mechanism to accelerate firstly; when the speed is increased to be the same as that of the feeding belt, materials are grabbed; at the moment, the iron removal mechanism and the feeding belt are relatively static; the problem that the metal object cannot be grabbed since the feeding belt and the iron removal mechanismmove in the material grabbing process of the iron removal mechanism. Moreover, due to the fact that a traditional magnetic iron removal principle is not adopted, non-ferromagnetic metal or weakly magnetic metal such as high manganese steel, alloy steel and stainless steel can be effectively removed, and metal objects on the middle lower portion and the lower portion of a material layer of the beltconveyor and large metal objects on the middle portion and the lower portion of the material layer of the belt conveyor can be removed. The adaptability to metal objects is high, and the problems offrequent shutdown and manual picking-out of the belt conveyor due to incomplete iron removal of a traditional magnetic iron remover are solved.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Combined detachable movable smoke hood of annular cooler

ActiveCN104390475AGuaranteed operating rateReduce difficultyHandling discharged materialWaste heat treatmentRefractoryEngineering

The invention provides a combined detachable movable smoke hood of an annular cooler. The combined detachable movable smoke hood of the annular cooler comprises a trolley, a traveling platform and a movable smoke hood, wherein the movable smoke hood mainly comprises main framework columns, a frame beam, a movable baffle, a refractory lining, fasteners, buckles, sealing asbestos washers, springs, washers and hexagon nuts; a smoke hood body is mounted on the traveling platform of the annular cooler, hoods the trolley, and mainly comprises a main structural column, the frame beam and a movable baffle door; the refractory lining is arranged in the movable baffle; each fastener is provided with the corresponding buckle. The combined detachable movable smoke hood of the annular cooler has the advantages that the problem that the smoke hood of the annular cooler is short in service life is solved; the problem of sealing difficulty of the annular cooler caused by waste heat utilization is solved; the smoke hood body is fixedly arranged on the platform of the annular cooler, so that a chimney can be mounted on the smoke hood body; by virtue of a frame-baffle combination structure, a heat preservation layer can be replaced at any time on line when being disengaged; the smoke hood body is suspended over the trolley and hoods the trolley, so that the problem of sealing difficulty between the trolley and the smoke hood is solved.

Owner:中冶大地工程咨询有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com