Cleaning method of concentration system for wet process phosphoric acid purifying process

A purification process and concentration system technology, which is applied in the cleaning field of the concentration system used in the wet phosphoric acid purification process, can solve the problems of affecting the system load, reducing the heat exchange efficiency, and high safety risks, and achieves equipment investment saving, corrosion inhibition, and security. The effect of run rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A cleaning method for a concentration system used in a wet-process phosphoric acid purification process, comprising the following steps:

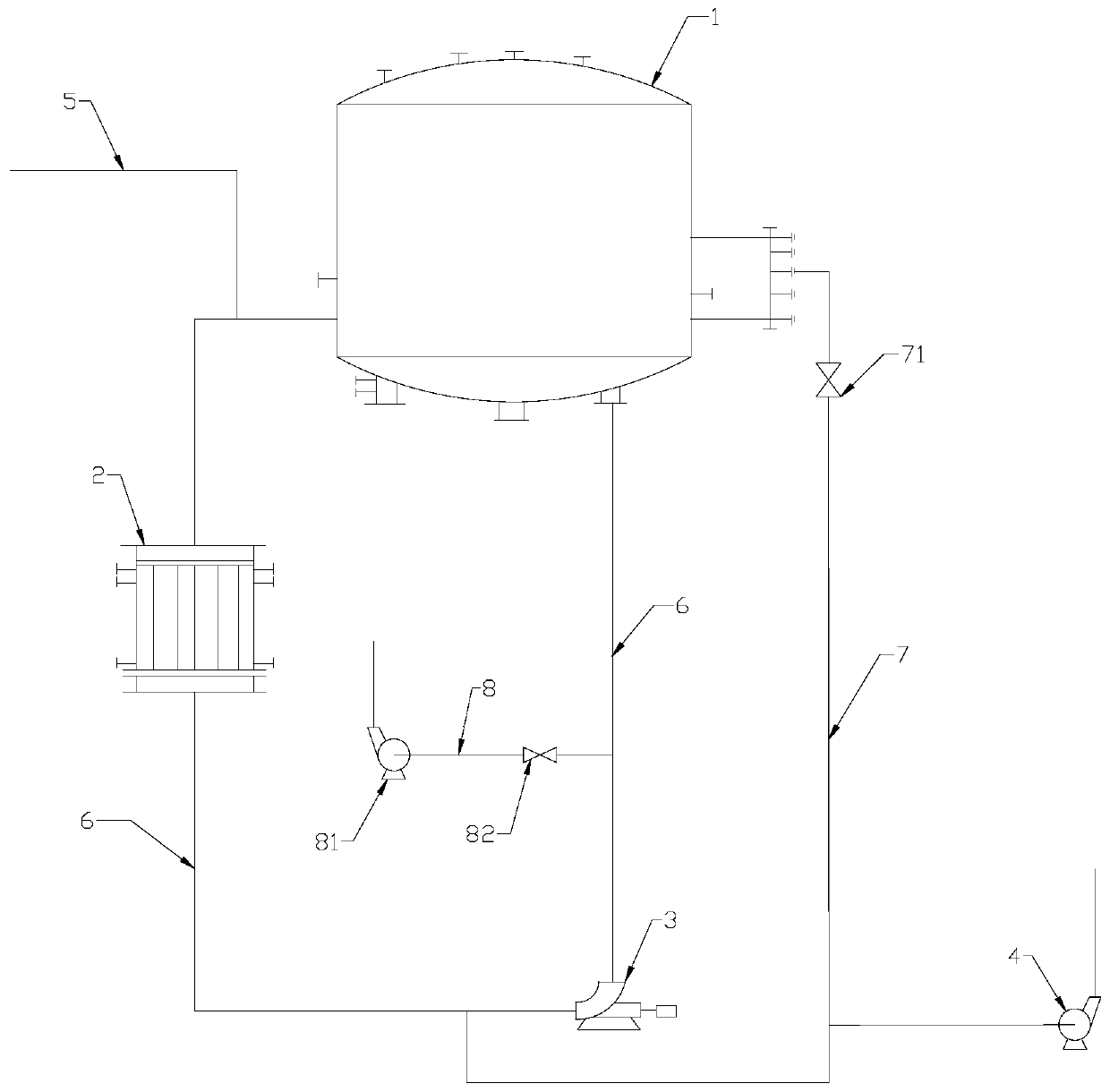

[0020] The circulation pipe 6 at the inlet of the circulation pump 3 is connected with a cleaning liquid pipe 8 , and a cleaning liquid delivery pump 81 and a valve 82 are arranged on the cleaning liquid pipe 8 , and the prepared cleaning liquid is connected to the cleaning liquid pipe 8 .

[0021] The above-mentioned cleaning solution is a mixed solution containing sulfuric acid, fluosilicic acid, pickling corrosion inhibitor, sodium molybdate, penetrating agent and sulfamic acid. The mass fraction of sulfuric acid in the mixed solution is 2%, the mass fraction of fluosilicic acid is 6%, the mass fraction of pickling corrosion inhibitor is 0.2%, the mass fraction of sodium molybdate is 0.2%, and the mass fraction of penetrant is 0.2%, the mass fraction of sulfamic acid is 0.2%.

[0022] The specific process of cleaning is as follow...

Embodiment 2

[0024] A cleaning method for a concentration system used in a wet-process phosphoric acid purification process, comprising the following steps:

[0025] The circulation pipe 6 at the inlet of the circulation pump 3 is connected with a cleaning liquid pipe 8 , and a cleaning liquid delivery pump 81 and a valve 82 are arranged on the cleaning liquid pipe 8 , and the prepared cleaning liquid is connected to the cleaning liquid pipe 8 .

[0026] The above-mentioned cleaning solution is a mixed solution containing sulfuric acid, fluosilicic acid, pickling corrosion inhibitor, sodium molybdate, penetrating agent and sulfamic acid. The mass fraction of sulfuric acid in the mixed solution is 3%, the mass fraction of fluosilicic acid is 7%, the mass fraction of pickling corrosion inhibitor is 0.1%, the mass fraction of sodium molybdate is 0.1%, and the mass fraction of penetrant is 0.1%, the mass fraction of sulfamic acid is 0.1%.

[0027] The specific process of cleaning is as follow...

Embodiment 3

[0029] A cleaning method for a concentration system used in a wet-process phosphoric acid purification process, comprising the following steps:

[0030] The circulation pipe 6 at the inlet of the circulation pump 3 is connected with a cleaning liquid pipe 8 , and a cleaning liquid delivery pump 81 and a valve 82 are arranged on the cleaning liquid pipe 8 , and the prepared cleaning liquid is connected to the cleaning liquid pipe 8 .

[0031] The above-mentioned cleaning solution is a mixed solution containing sulfuric acid, fluosilicic acid, pickling corrosion inhibitor, sodium molybdate, penetrating agent and sulfamic acid. The mass fraction of sulfuric acid in the mixed solution is 4%, the mass fraction of fluosilicic acid is 8%, the mass fraction of pickling corrosion inhibitor is 0.3%, the mass fraction of sodium molybdate is 0.3%, and the mass fraction of penetrant is 0.3%, the mass fraction of sulfamic acid is 0.3%.

[0032] The specific process of cleaning is as follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com