Sound picture guiding method for manual feeding production line

A production line and feeding technology, applied in the direction of comprehensive factory control, general control system, comprehensive factory control, etc., can solve the problems of worker omission, low work efficiency, difficult to achieve, etc., to ensure the start-up rate and reduce the feeding jam. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is further described in conjunction with embodiment and accompanying drawing now.

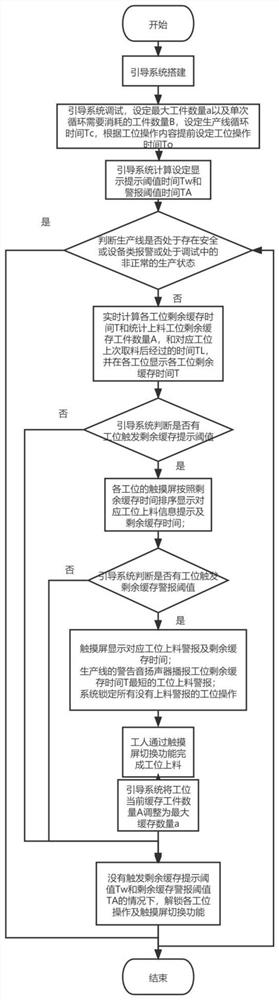

[0042] as attached figure 1 Shown, the present invention comprises the following steps:

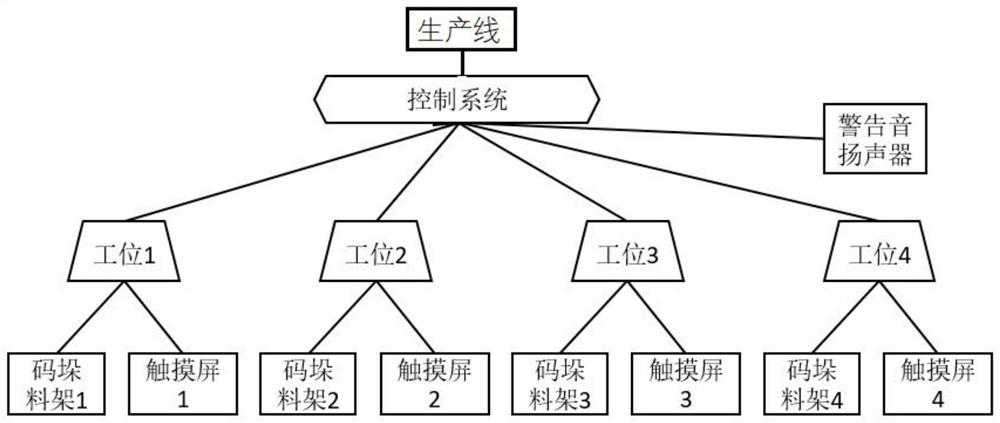

[0043] S1. Build the guidance system on the feeding production line, adapt and control different stations, each station corresponds to a palletizing rack and a touch screen, and install several warning sound speakers around the feeding production line;

[0044] S2. Use the guidance system to set and collect the maximum number of workpieces a that can be accommodated by each station and the palletizing rack when it is full, and the number of workpieces that need to be consumed in a single cycle B, and set the cycle time of the production line Tc , set the station operation time in advance according to the station operation content To ;

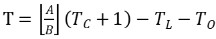

[0045] S3. Use the guidance system to calculate and set the display prompt threshold time Tw and Alarm Threshold Time T A ;

[0046] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com