A combined detachable movable smoke hood for an annular cooler

A technology of movable fume hood and ring cooler, which is applied in the direction of furnace components, treatment of discharged materials, waste heat treatment, etc. It can solve the problems of waste heat utilization, low operating life, serious air leakage rate, etc., so as to ensure the operation rate and save costs , Improve the effect of smoke temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

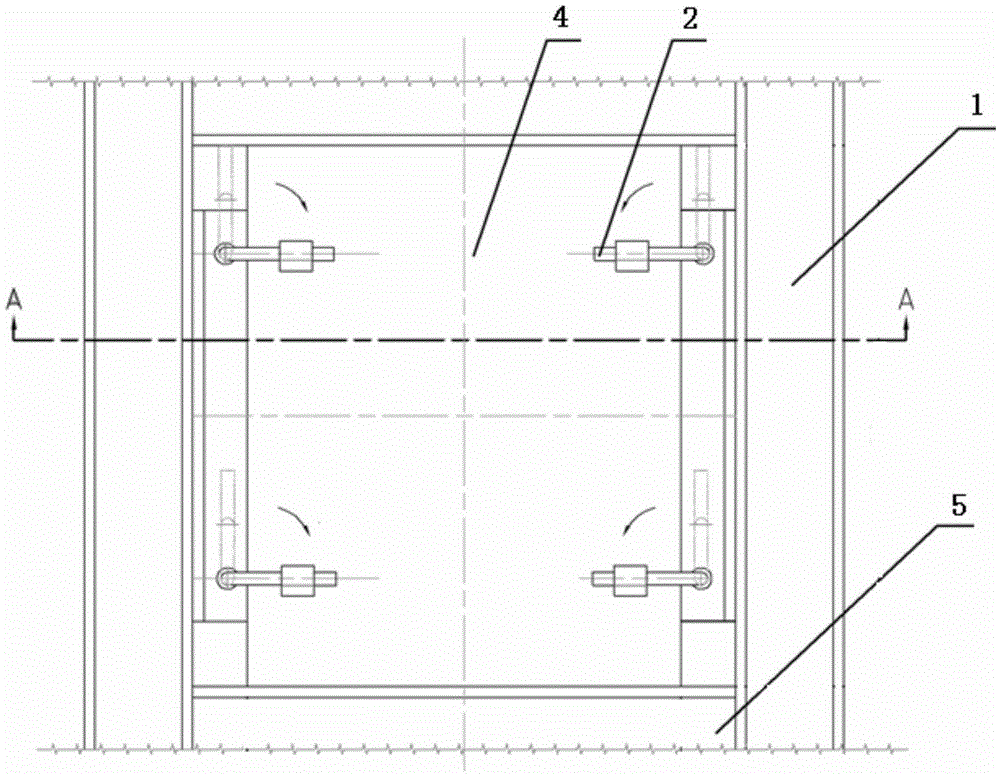

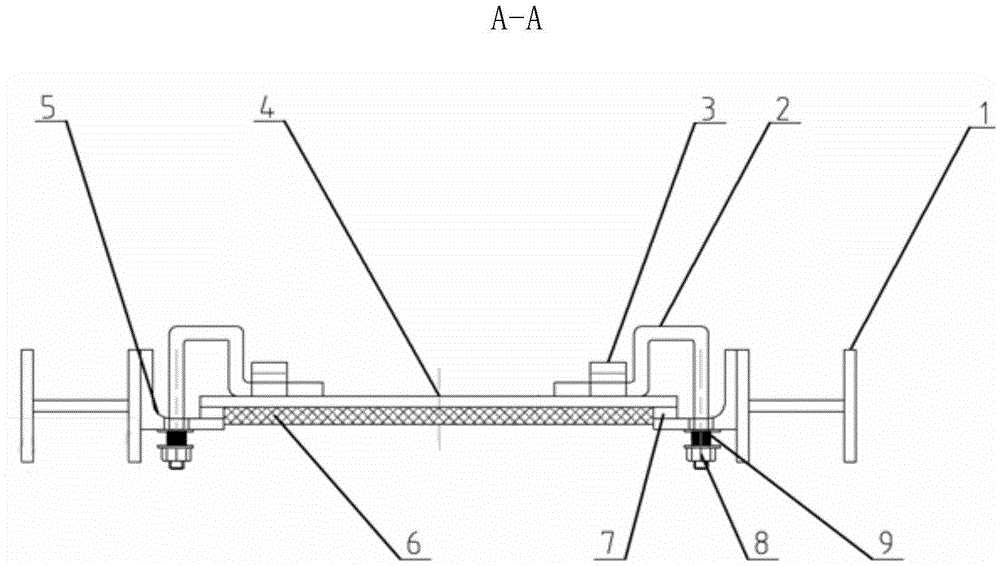

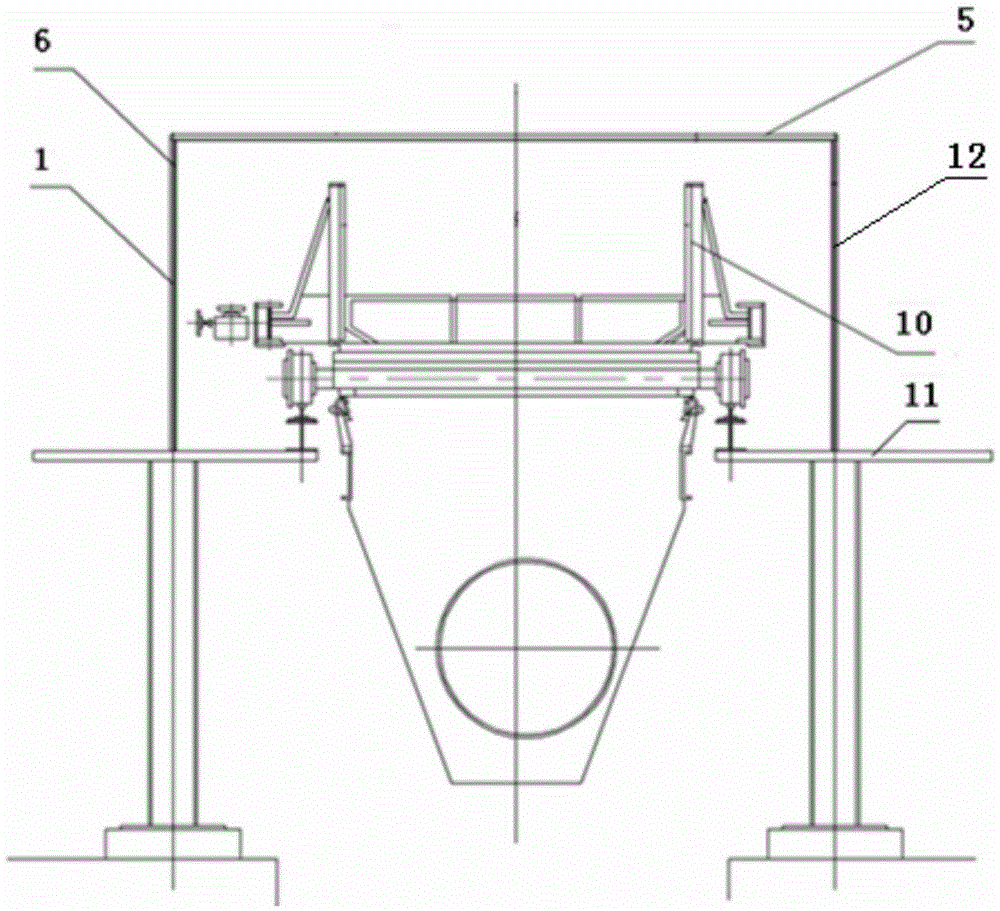

[0011] A kind of combined detachable circular cooler movable fume hood of the embodiment of the present invention is described in further detail below in conjunction with accompanying drawing: Take a steel factory 180m 2 Taking the sintered ring cooler as an example, the main frame column 1 and the frame beam 5 are HW100×100×8 steel, with a distance of 400mm, forming an arc along the direction of the ring cooler, and using angle steel L70×70 between the main frame columns 1 ×8 back-to-back welded frame beams 5 with a distance of 500mm, two ∮15 round holes are opened on each angle steel, fastening fasteners 2 are installed, movable baffles 4 are mounted on frame beams 5, and then rotated to tighten Fasten the fastener 2 to firmly press the baffle door on the frame. The fastening fastener 2 is terminated by an M12 hexagonal nut, and is connected with a threaded ∮12 round steel. The round steel is covered with a 15mm spring 9, and the upper end of the round steel is bent into a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com