A bypass metal removal device

A technology of metal removal and metal removal, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of wrongly removing magnetite and ineffective removal of metal impurities, etc., and achieve the effect of ensuring the operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

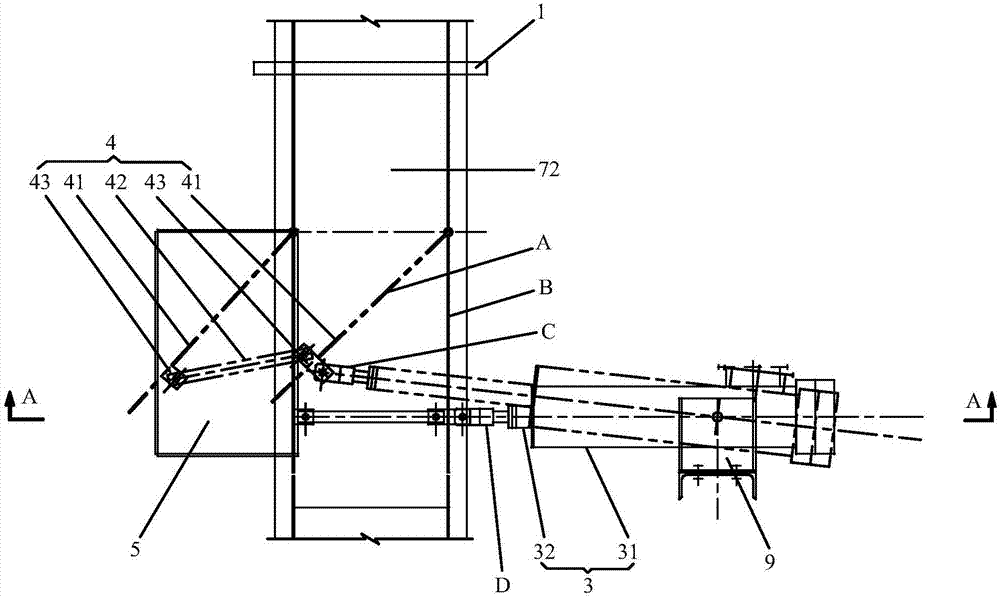

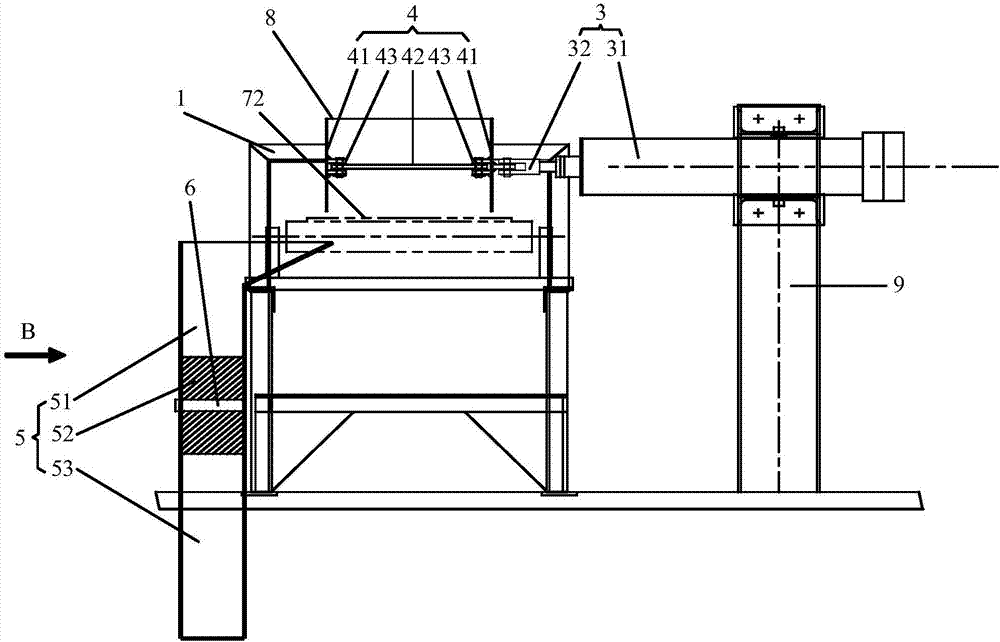

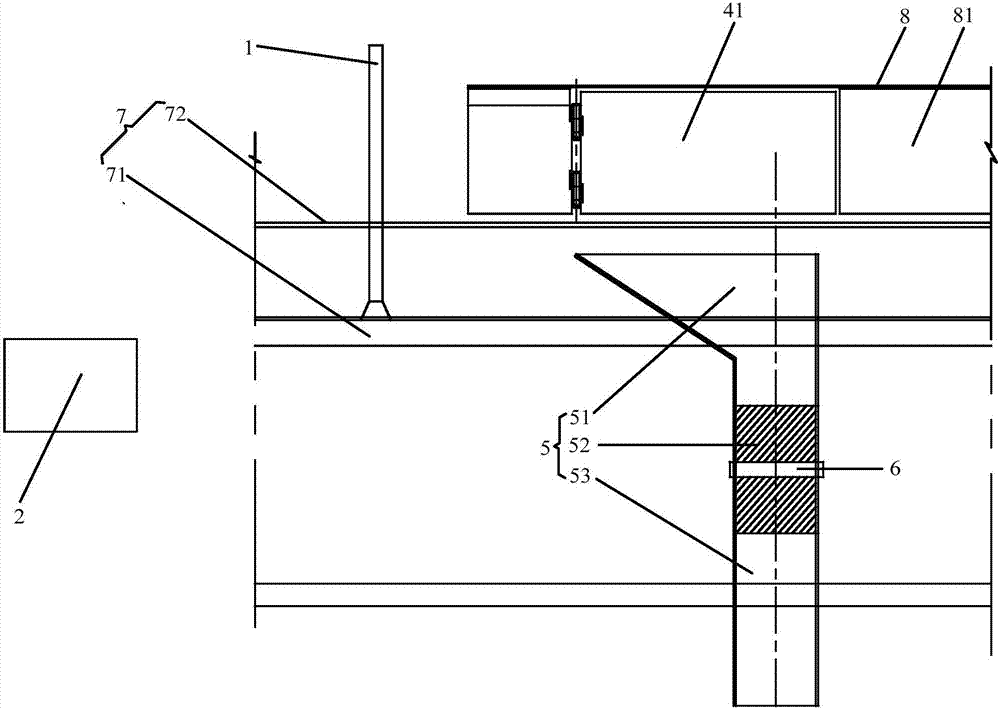

[0037] In order to solve the problems existing in the prior art, such as figure 1 shown, and see figure 2 and image 3 , the embodiment of the present invention provides a bypass metal removal device, the bypass metal removal device includes: a first metal detector 1, a control box 2, a drive mechanism 3, a metal removal mechanism 4, a metal discharge part 5 and a second metal detector 6;

[0038] The first metal detector 1 is installed on the longitudinal beam 71 of the belt conveyor 7, and is used to detect metal impurities transported on the transport track 72 of the belt conveyor 7, and sends a first alarm signal; the control box 2 is used for Receive the first alarm signal and send the first control instruction to the drive mechanism 3 according to the first alarm signal; The control command drives the metal removal mechanism 4 to move, so that the material delivery path of the metal removal mechanism 4 is separated from the transport track 72; When separated from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com