Method for turning off secondary absorption concentrated acid pump without stopping production

A secondary absorption, concentrated acid technology, applied in chemical instruments and methods, sustainable manufacturing/processing, inorganic chemistry, etc., can solve the problems of rising production costs and affecting the comprehensive competitiveness of enterprises, and achieve the improvement of operation rate and elimination of Equipment idling and system heating power consumption to meet the effect of cleaner production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

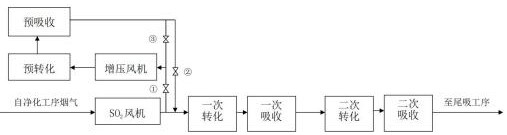

[0025] The method for turning on the secondary absorption concentrated acid pump without stopping production comprises the following steps:

[0026] 1) Confirm that the vibration value of the main pump for secondary absorption of concentrated acid exceeds 4.5mm / s, and judge that the abnormal operation of the main pump cannot meet the normal operating conditions, and it is really necessary to turn on the secondary absorption standby concentrated acid pump;

[0027] 2) Determine the pumping time: one of the two converters is in the discharge period, and the other converter is in the stop blowing sampling or feeding period;

[0028] 3) The amount of Aisa furnace material is reduced to less than 60% of the normal production amount;

[0029] 4) Acid system SO 2 Main fan speed adjustment, SO 2 The speed of the fan is reduced from 46HZ to 38HZ, the opening of the pre-reforming air intake valve and the pre-reforming air return valve are opened from about 50% to 80%, the opening of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com