Range hood and working method

A range hood, working method technology, applied in the direction of removing oil fume, heating method, household heating, etc., can solve the problems of eddy current, large difference in gas flow rate, large air volume loss, etc., to reduce air volume loss, reduce noise, Reduce the effect of eddy currents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

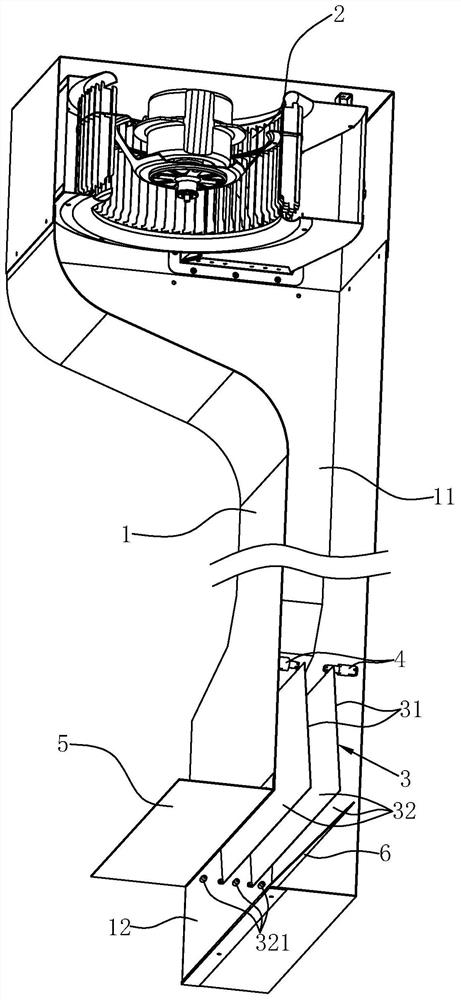

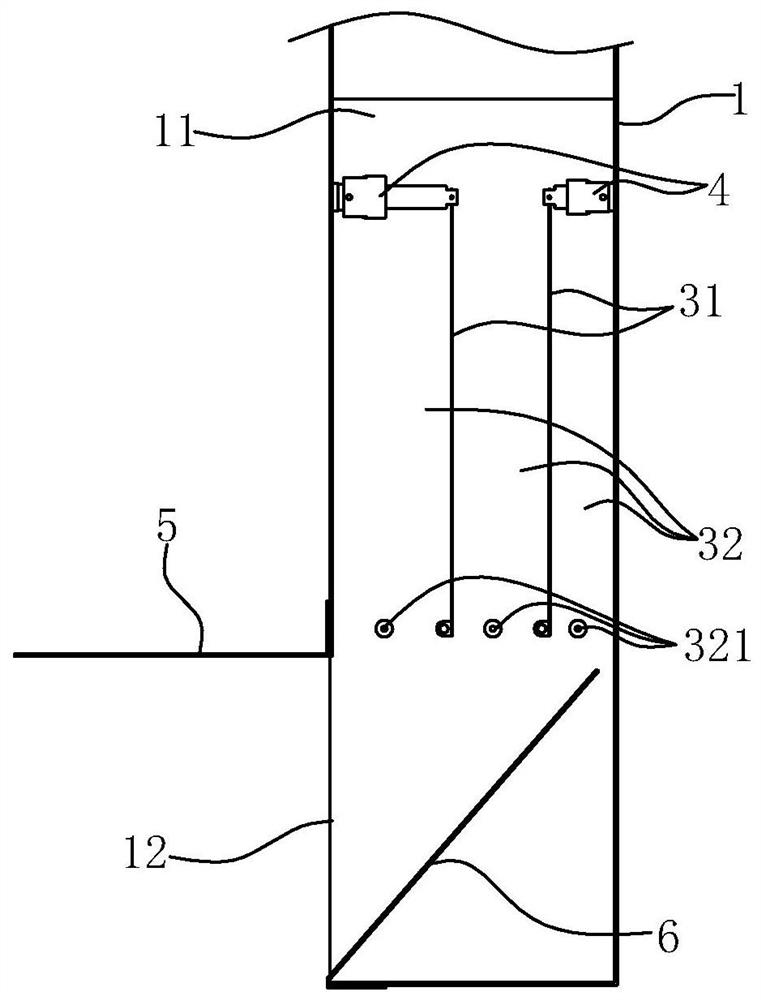

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0025] Terms expressing directions are used in the description and claims of the present invention, such as "front", "rear", "upper", "lower", "left", "right", "side", "top", "Bottom" and the like are used to describe various exemplary structural parts and elements of the present invention, but these terms are used herein for explanatory purposes only, based on the exemplary orientations shown in the drawings. Since the disclosed embodiments of the present invention can be arranged in different directions, these terms indicating directions are for illustration only and should not be regarded as limitations. For example, "up" and "down" are not necessarily limited to the opposite direction or consistent direction.

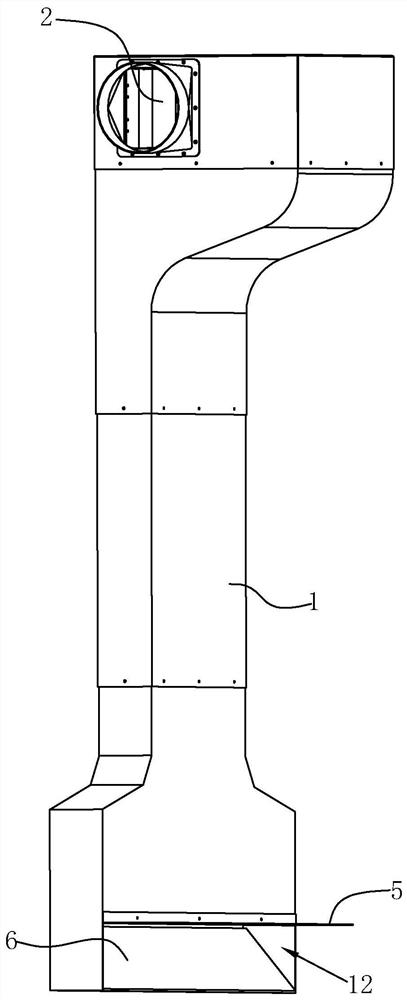

[0026] Such as figure 1 and figure 2 As shown, the range hood in this embodiment includes a casing 1 with an air duct 11 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com