Patents

Literature

249results about How to "Improve quenching efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorinated dye stabilizers in fluorinated dielectric solvent

InactiveUS7141688B2Improve quenching efficiencyImprove solubilityGroup 1/11 element organic compoundsReactive dyesSolubilitySolvent

The present invention is directed to novel fluorinated dye stabilizers having both high quenching efficiency and solubility in halogenated solvents. These dye stabilizers have shown a significantly effect on improving the dye fastness in hostile photooxidation conditions.

Owner:E INK CALIFORNIA

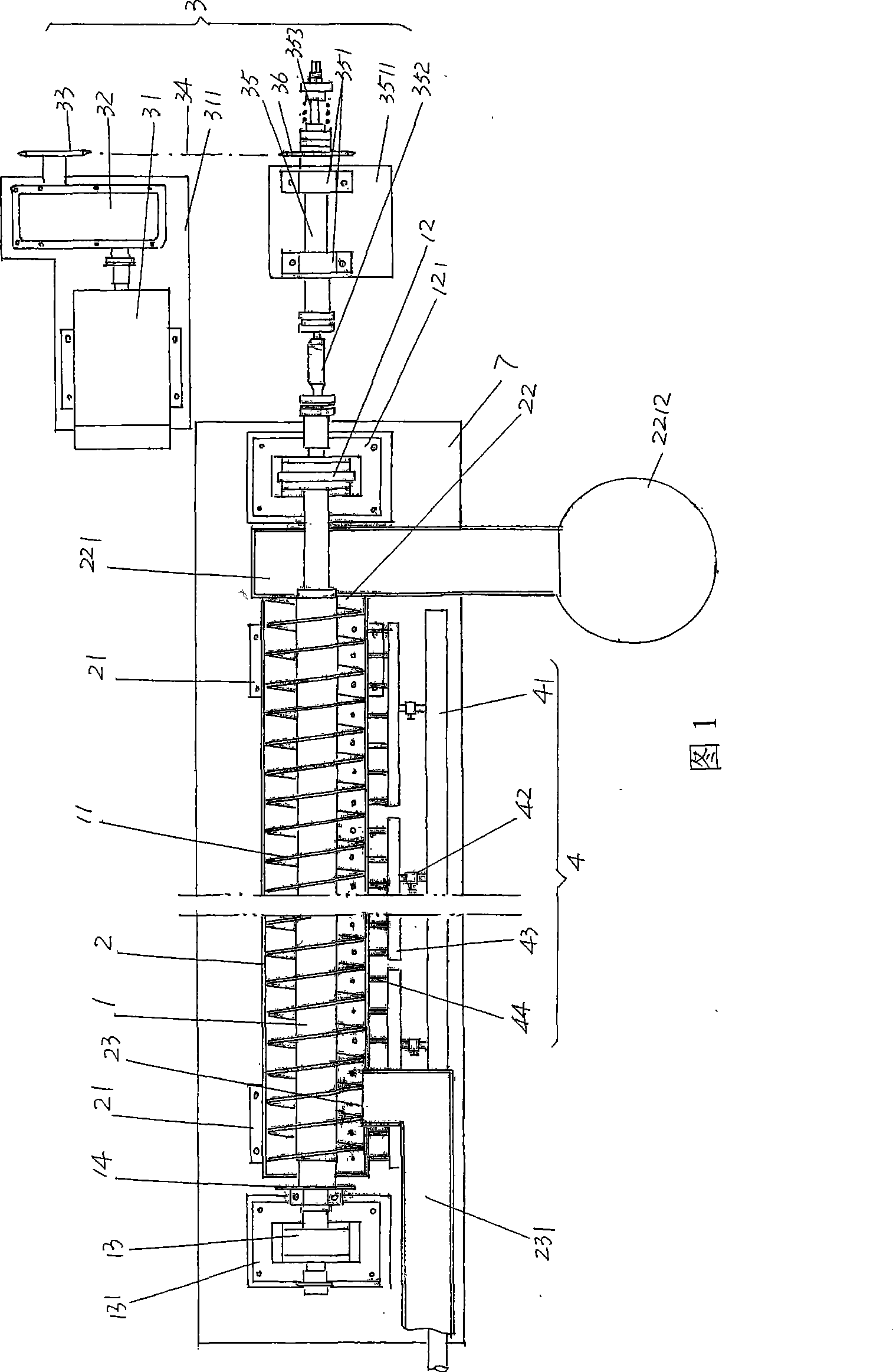

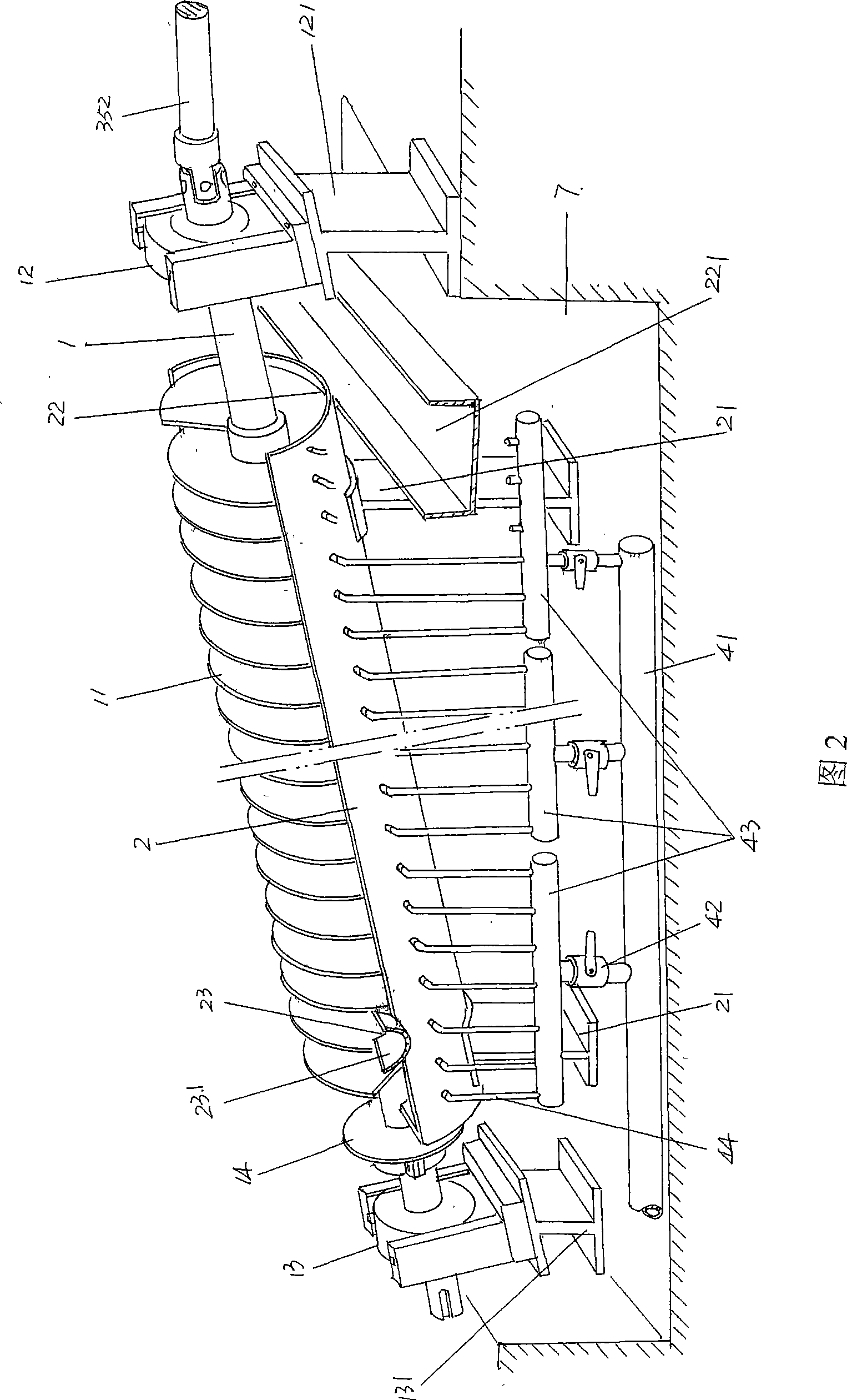

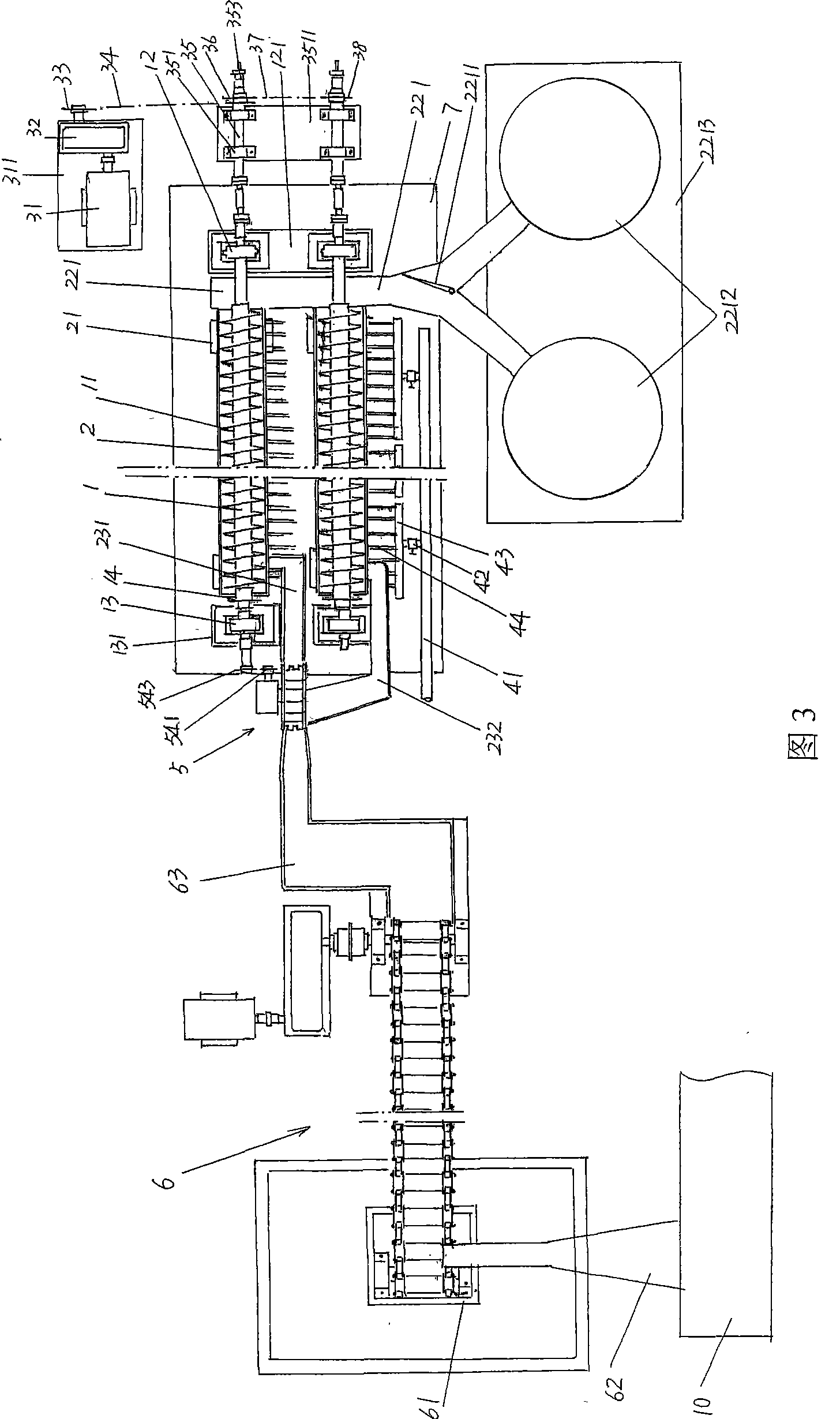

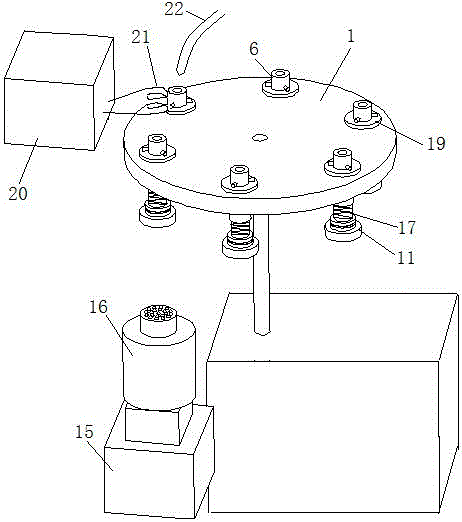

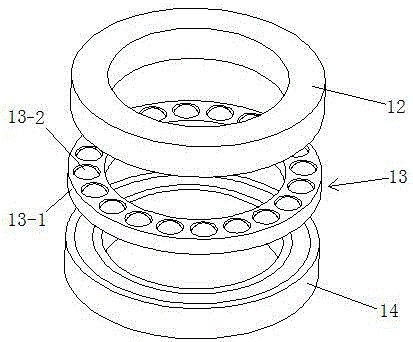

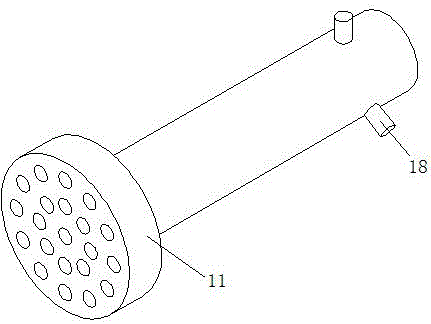

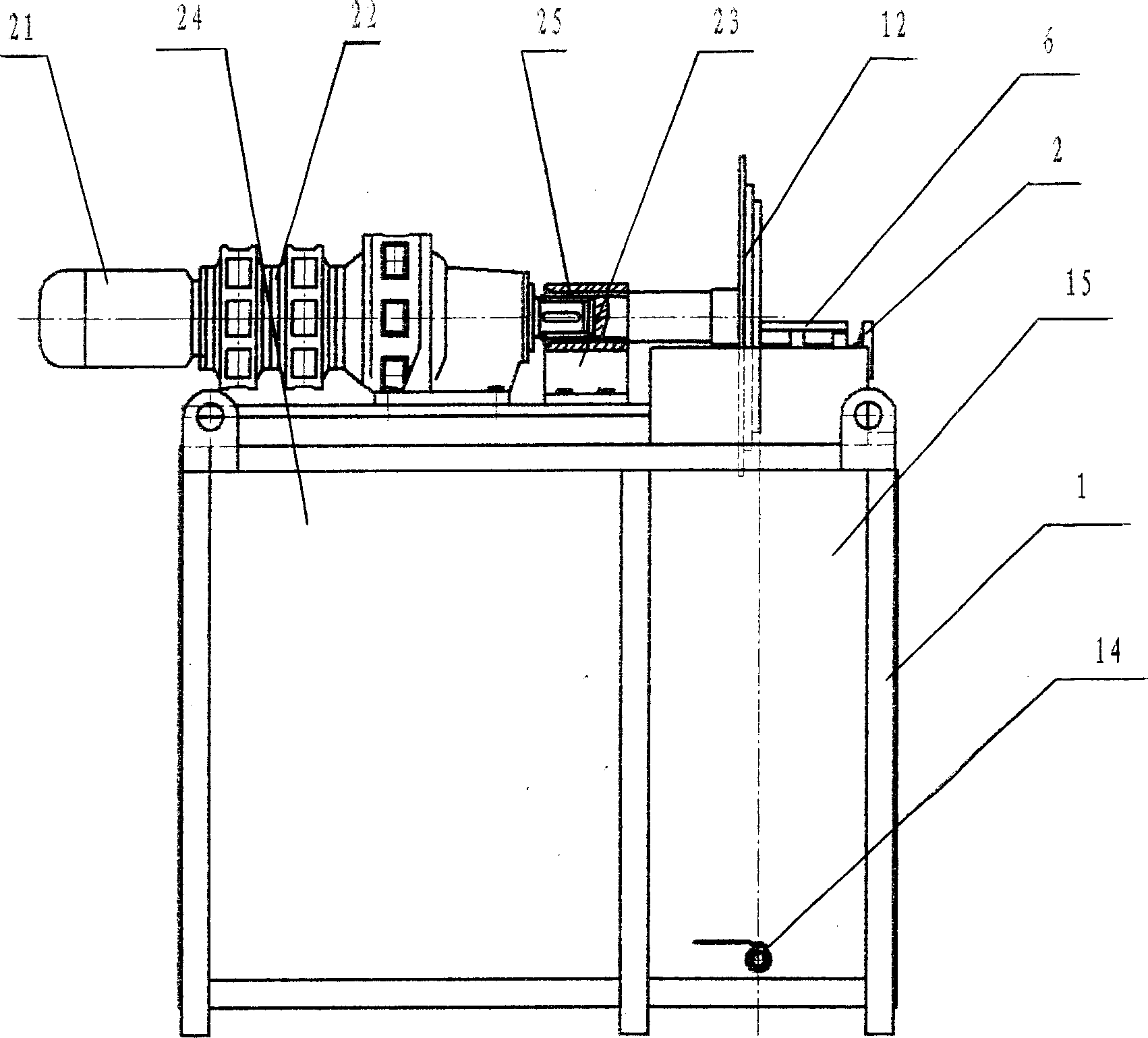

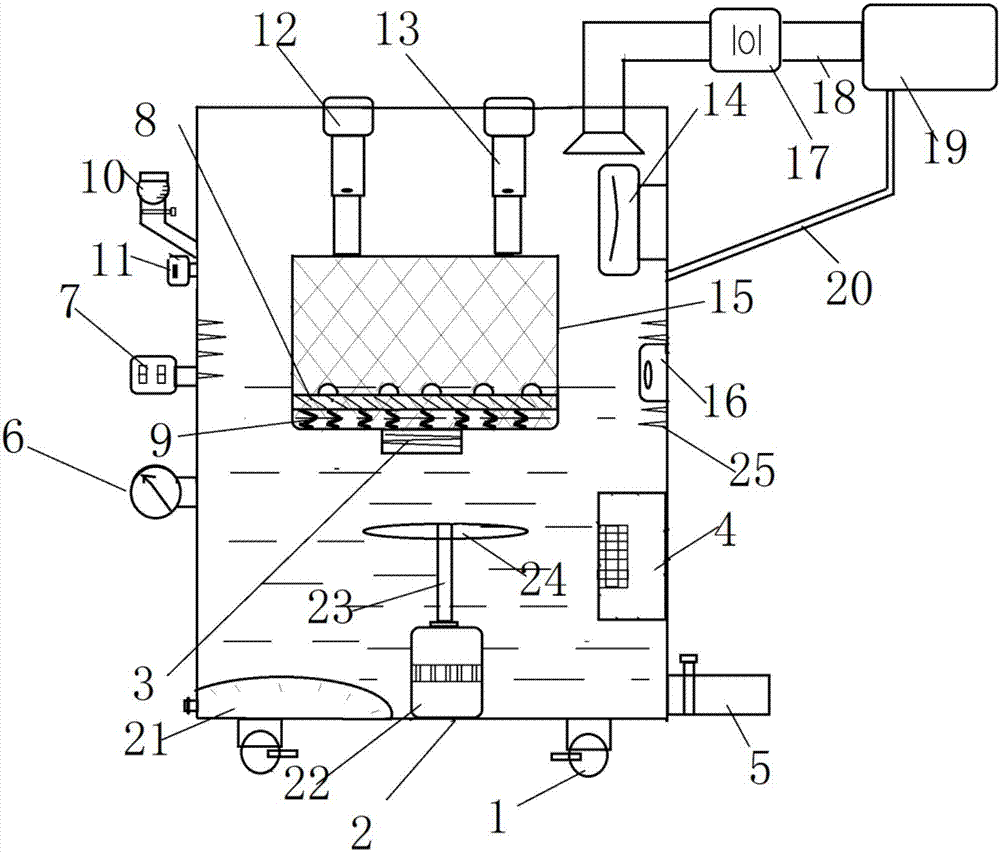

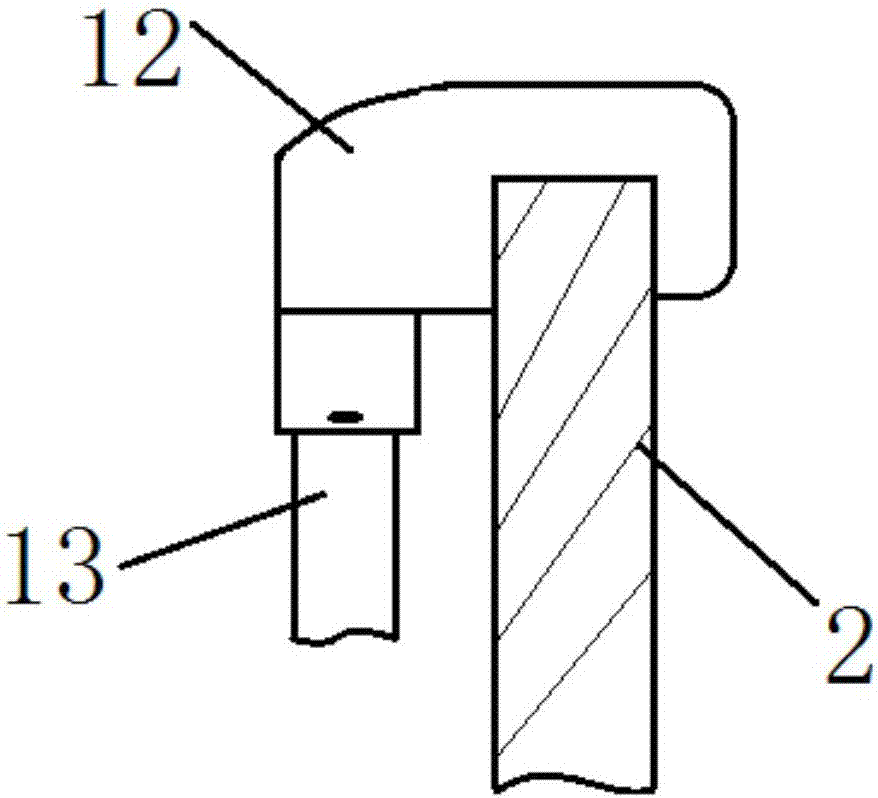

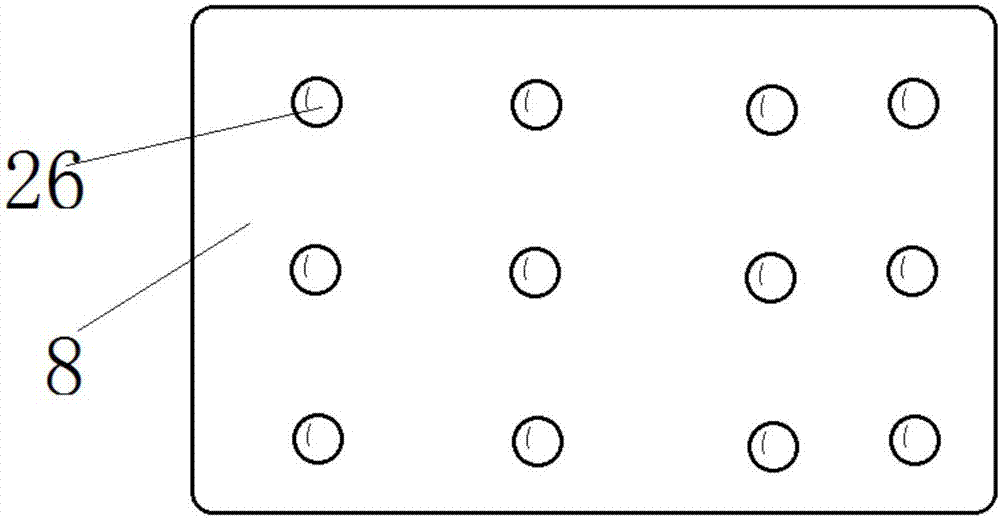

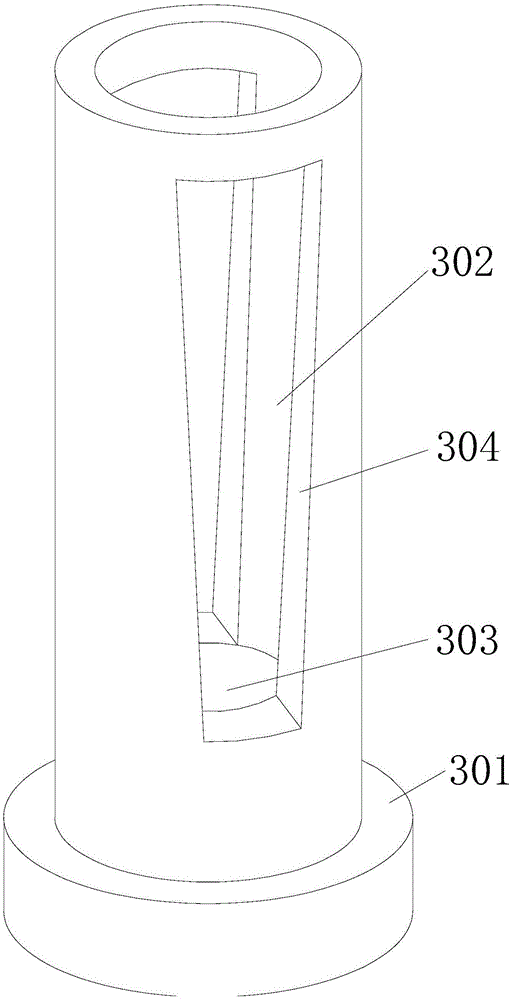

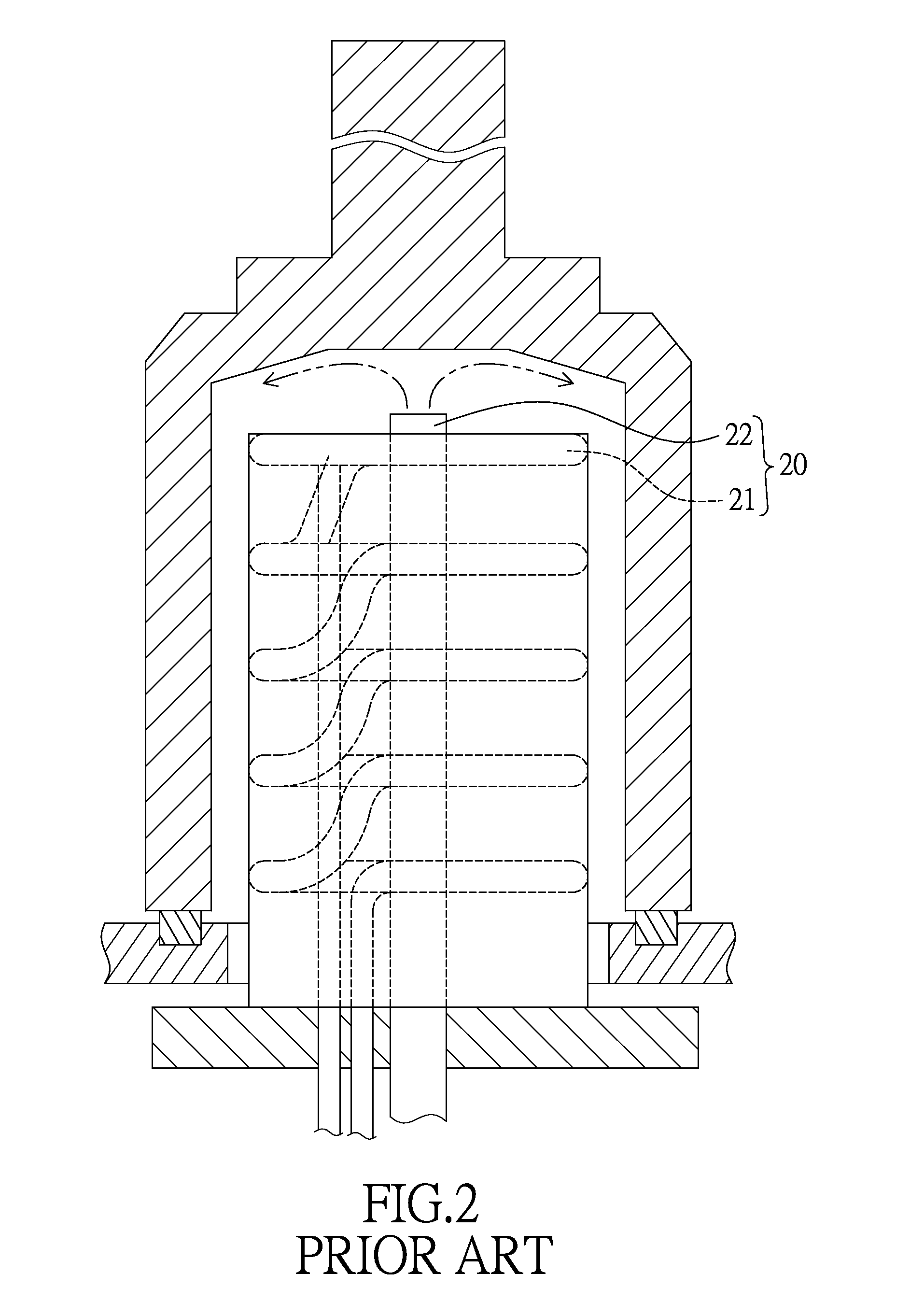

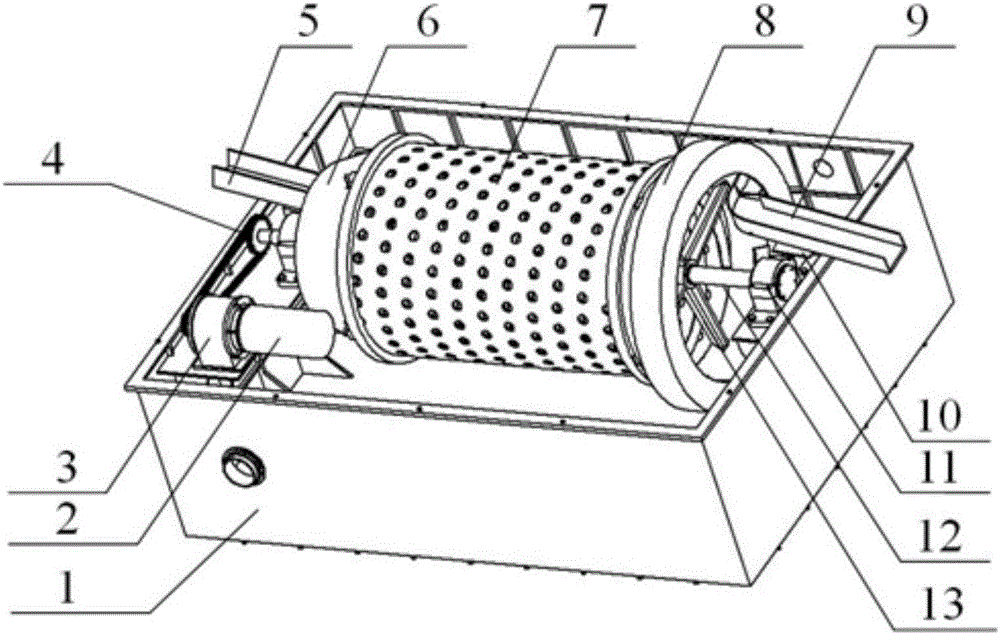

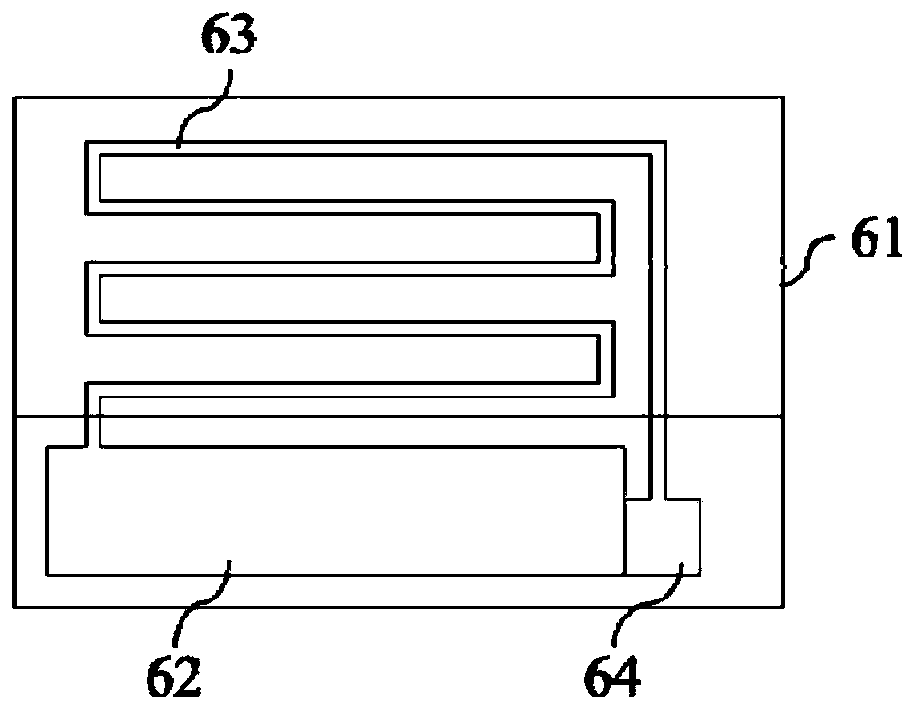

Quenching mechanism of steel ball quenching machine

InactiveCN100497667CSame quenching timeUniform quenching effectFurnace typesHeat treatment furnacesSteel ballHardness

Owner:CHANGSHU FEIFAN METALWORK

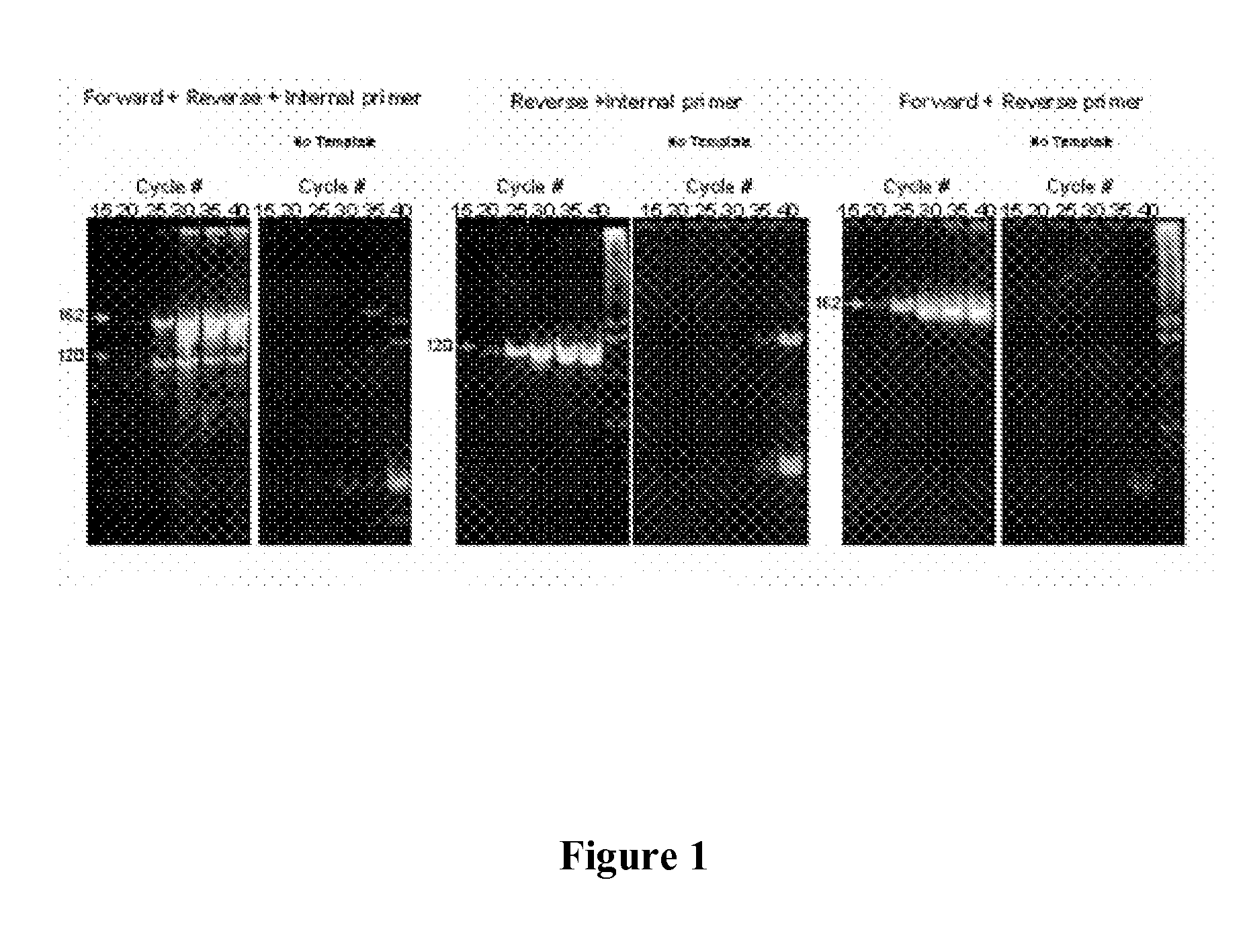

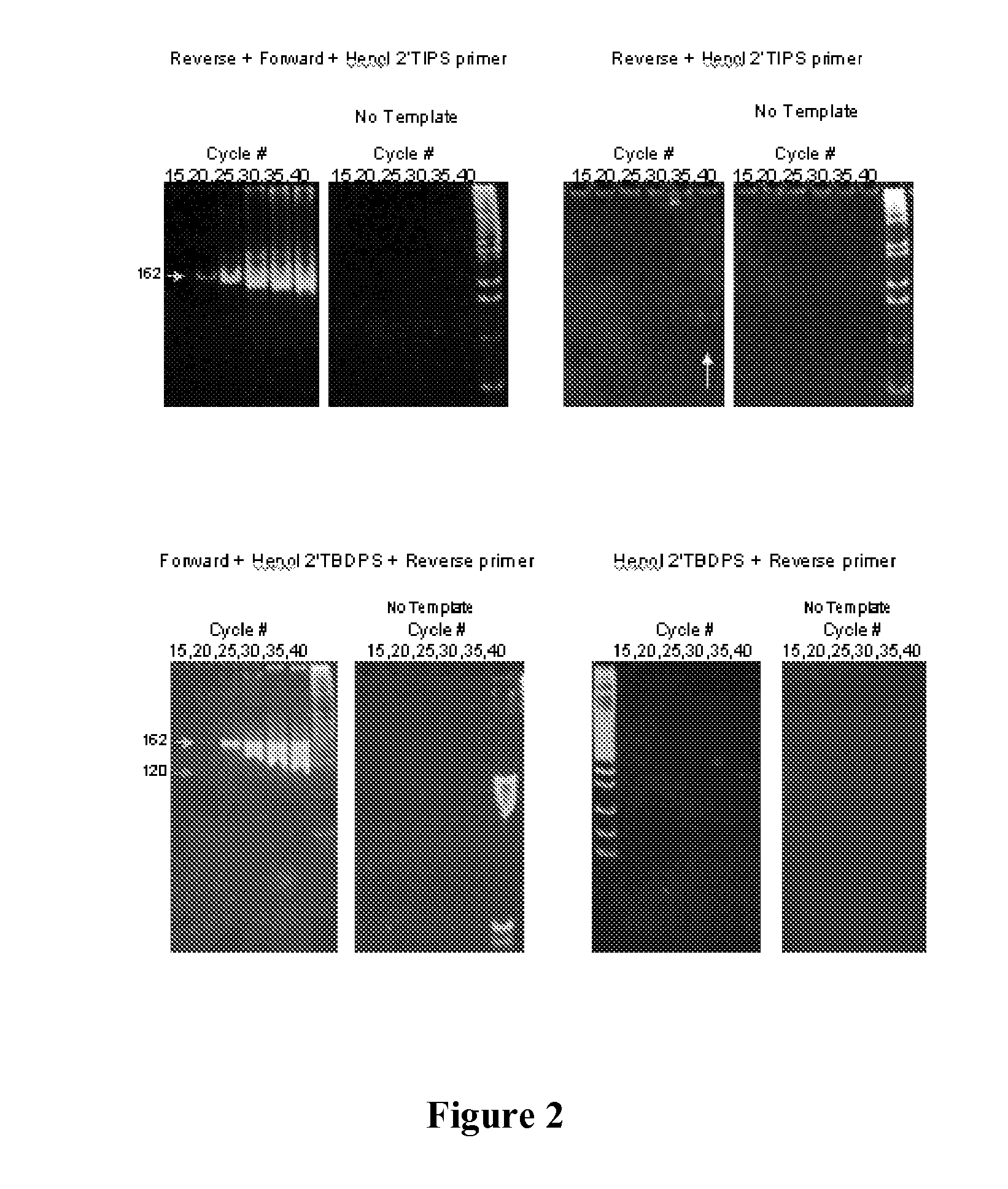

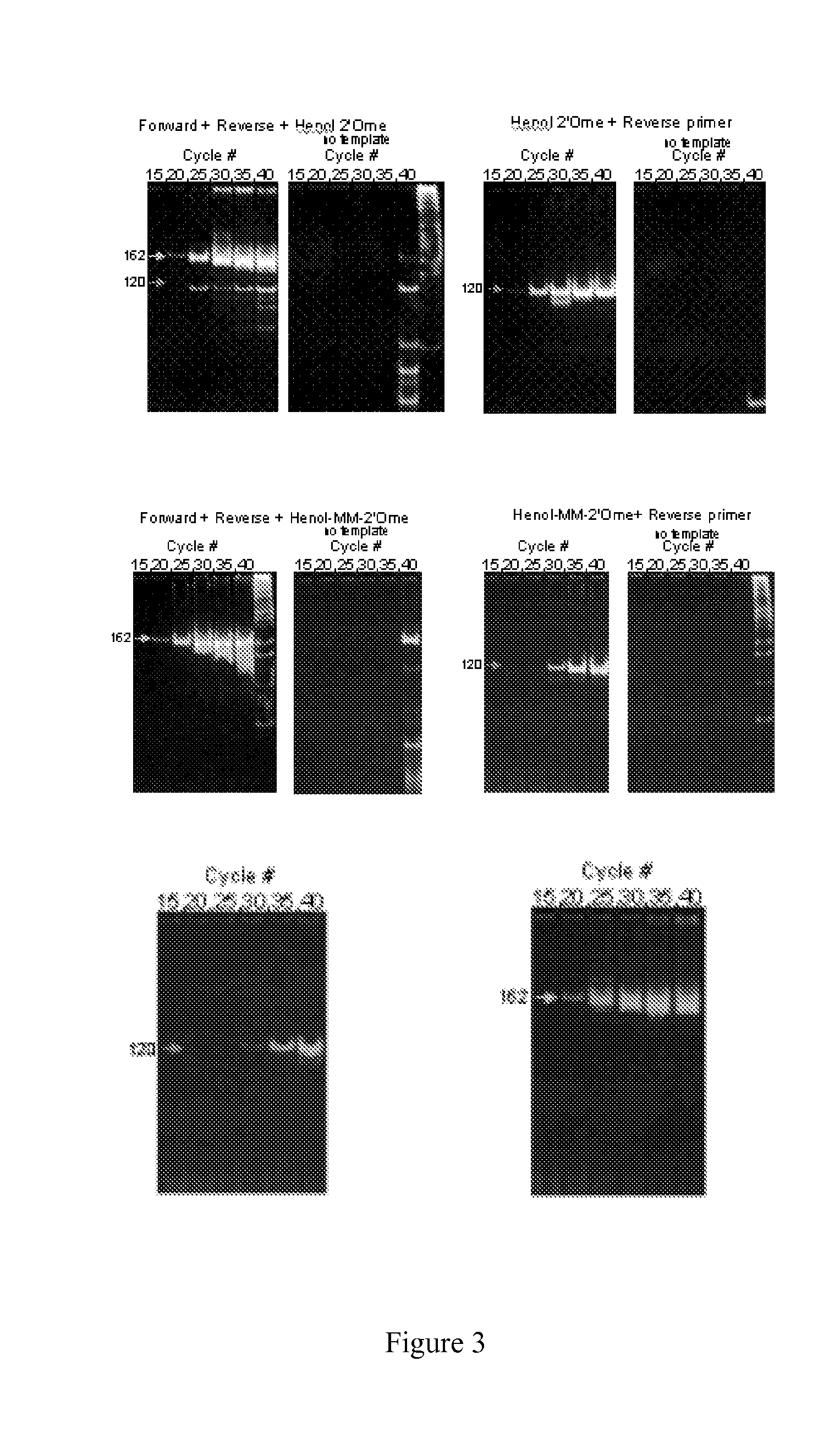

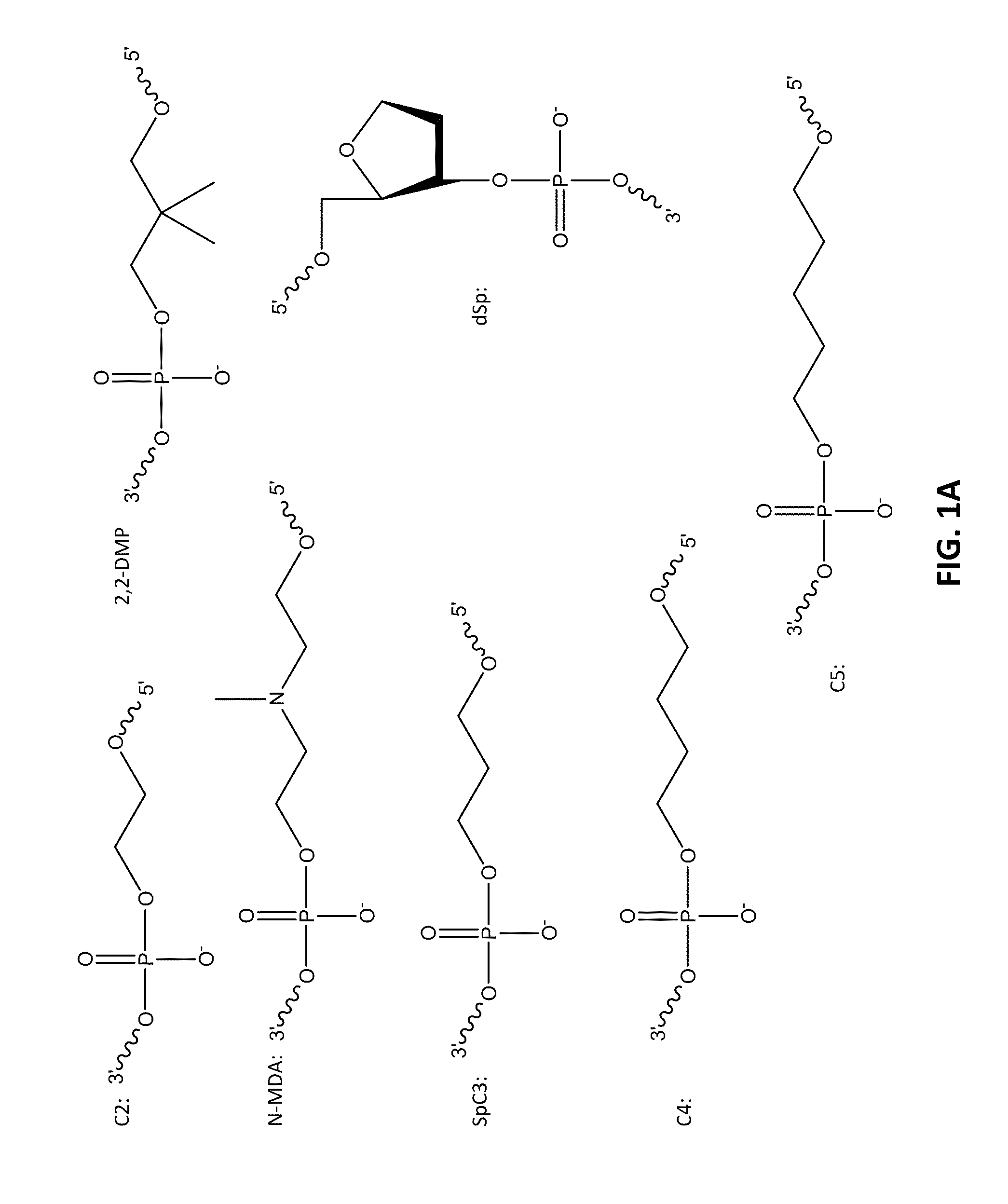

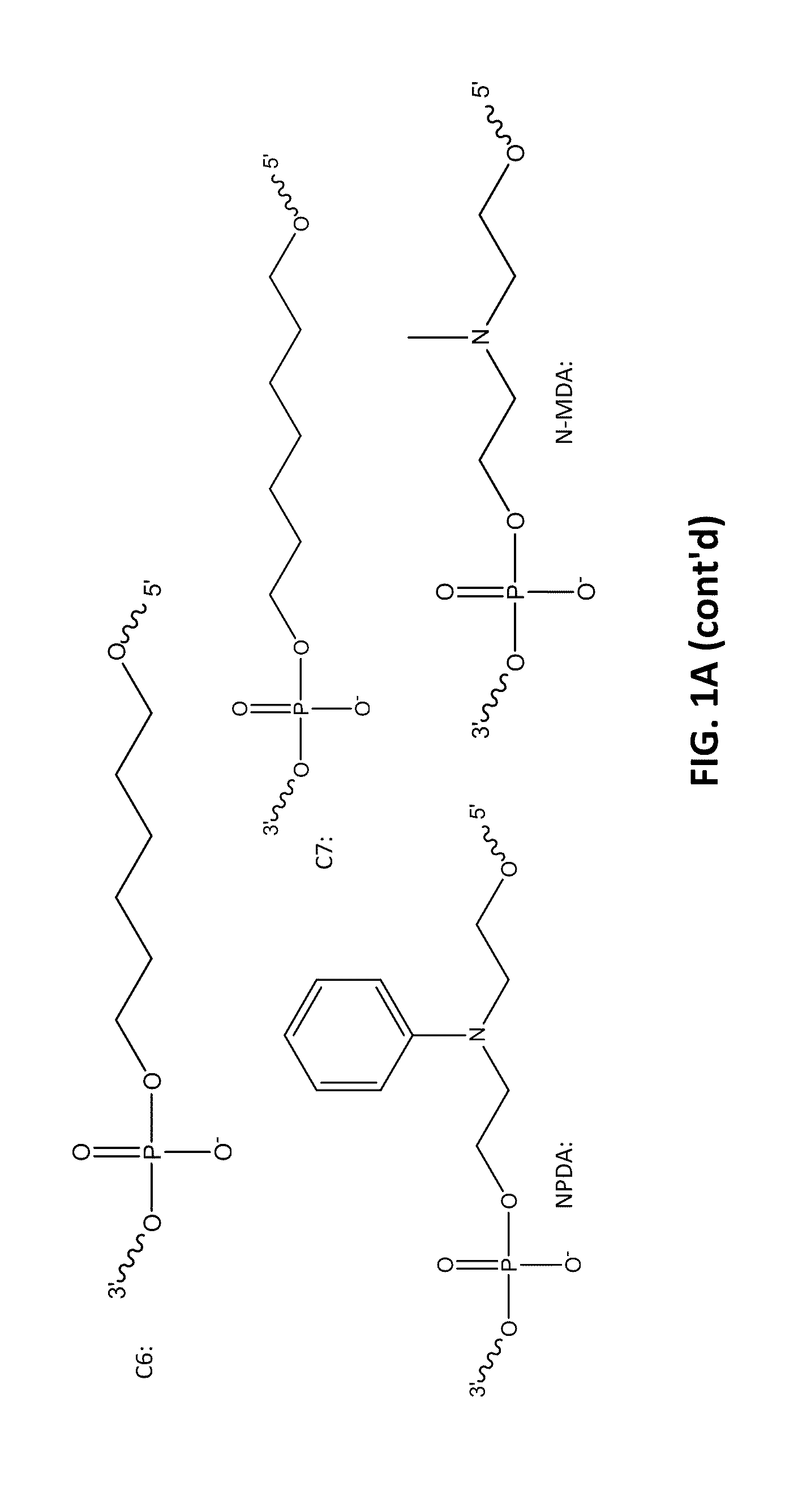

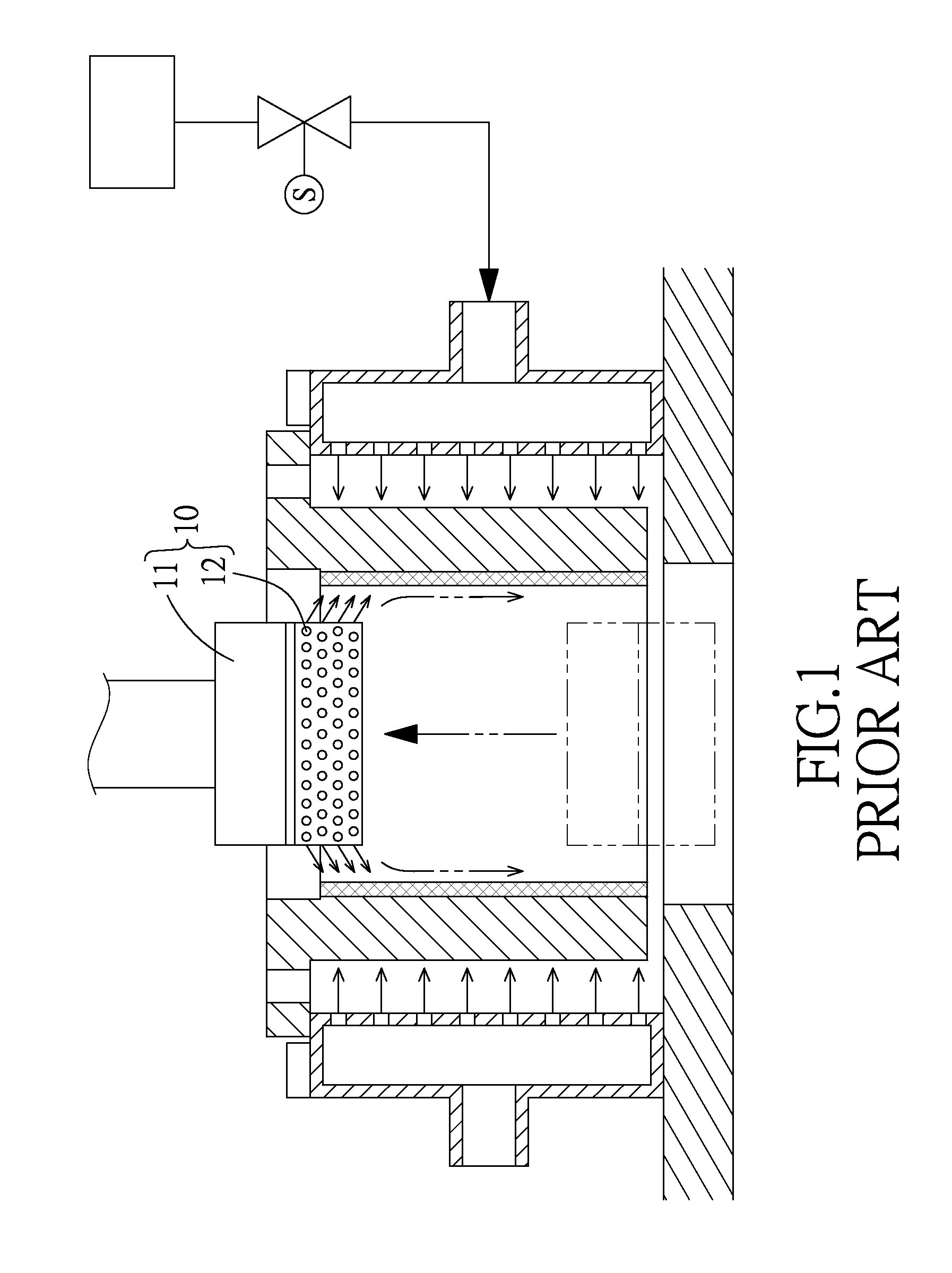

Nucleic acid monomers with 2'-chemical moieties

InactiveUS20070218490A1Enhanced efficiencyImprove stabilityMonoazo dyesSugar derivativesOligonucleotideFluorescence

The invention provides nucleic acid monomers with a 2′-modification that are useful for the incorporation of dyes or blocking groups. The monomers can be incorporated on the 3′-end of a dual labeled probe to inhibit PCR polymerase extension during PCR. The polymerase is inhibited from extending the probe at the 3′-hydroxyl group when the monomer is present; there is no need to add a chemical moiety to the 3′-hydroxyl or remove the 3′-hydroxyl. The monomers can also be incorporated internally or at the 5′-end of the oligonucleotide. A detectable label, such as a fluorescent or quenching dye, can be incorporated on the 2′-position of such monomers.

Owner:INTEGRATED DNA TECHNOLOGIES

Multi-irradiation laser quenching method and device

The invention discloses a laser quenching method and device. According to the method, single heating in the conventional laser quenching technology is changed into multi-irradiation heating, or even high-frequency multi-irradiation heating by combining multi-irradiation heating with a quick scanning function of a rotating mirror; the heat conduction process caused by input of laser energy is injected into the surface of a workpiece within short heating time in a multi-stacking mode, so that the accumulation of the laser energy absorbed by a metal base body is increased, and the accumulation of the heat conduction depth is also increased. The device comprises a laser device, a control system, a light guide system, a mechanical motion device and a laser processing head. Even if technical parameters adopt high laser power, and when the scanning speed is high, and an irradiation interval exists, the surface temperature of the metal is always controlled to be below a melting point, and heat can be effectively and continuously expanded from the surface of the workpiece into the workpiece; and therefore, on the premise that the surface of the metal is prevented from being melted, the depth of an austenitizing region on the surface of the workpiece is increased, and the laser quenching efficiency is obviously improved.

Owner:WUHAN HIVALUE INTELASER LTD

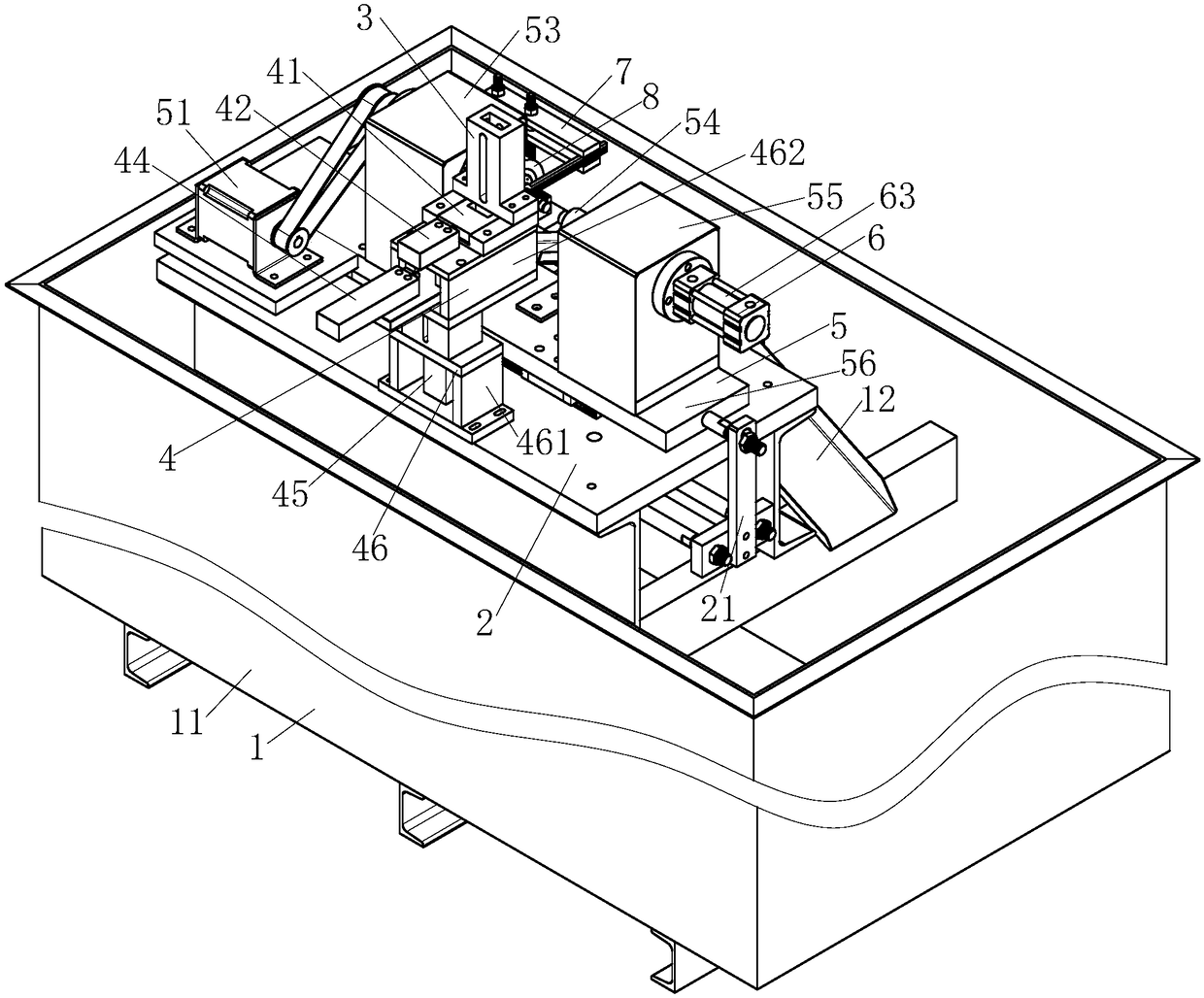

Rotating disc type automatic quenching device

ActiveCN106048166ANot easy to separateNo stickingIncreasing energy efficiencyQuenching devicesElectric machineCooling pipe

The invention discloses a rotating disc type automatic quenching device, and belongs to the technical field of heat treatment equipment. The rotating disc type automatic quenching device comprises a rotating disc. The rotating disc is driven by a driving device and is horizontally arranged. At least three slipways are uniformly distributed on the rotating disc and around the central axis of the rotating disc. Pushing rods capable of sliding up and down along the slipways are arranged in the slipways. A quenching induction coil and a cooling pipe orifice are sequentially arranged on the rotating disc in the rotating direction of the rotating disc, are arranged on the movement loci of the pushing rods and are respectively opposite to the two adjacent pushing rods. A motor, driven by a pneumatic cylinder II to move up and down, is arranged below the rotating disc and at a corresponding position of the quenching induction coil. A quick connecting device for transmitting torque is arranged at the upper end of an output shaft of the motor and the lower ends of the pushing rods. Heating, cooling and taking and placing of parts are conducted synchronously and do not affect one another, the quenching efficiency is improved greatly, and besides, quenching parts uninterruptedly rotate at constant speed in the quenching induction coil along with the pushing rods, and are guaranteed to be heated more uniformly.

Owner:邯郸市翔天数控工程有限公司

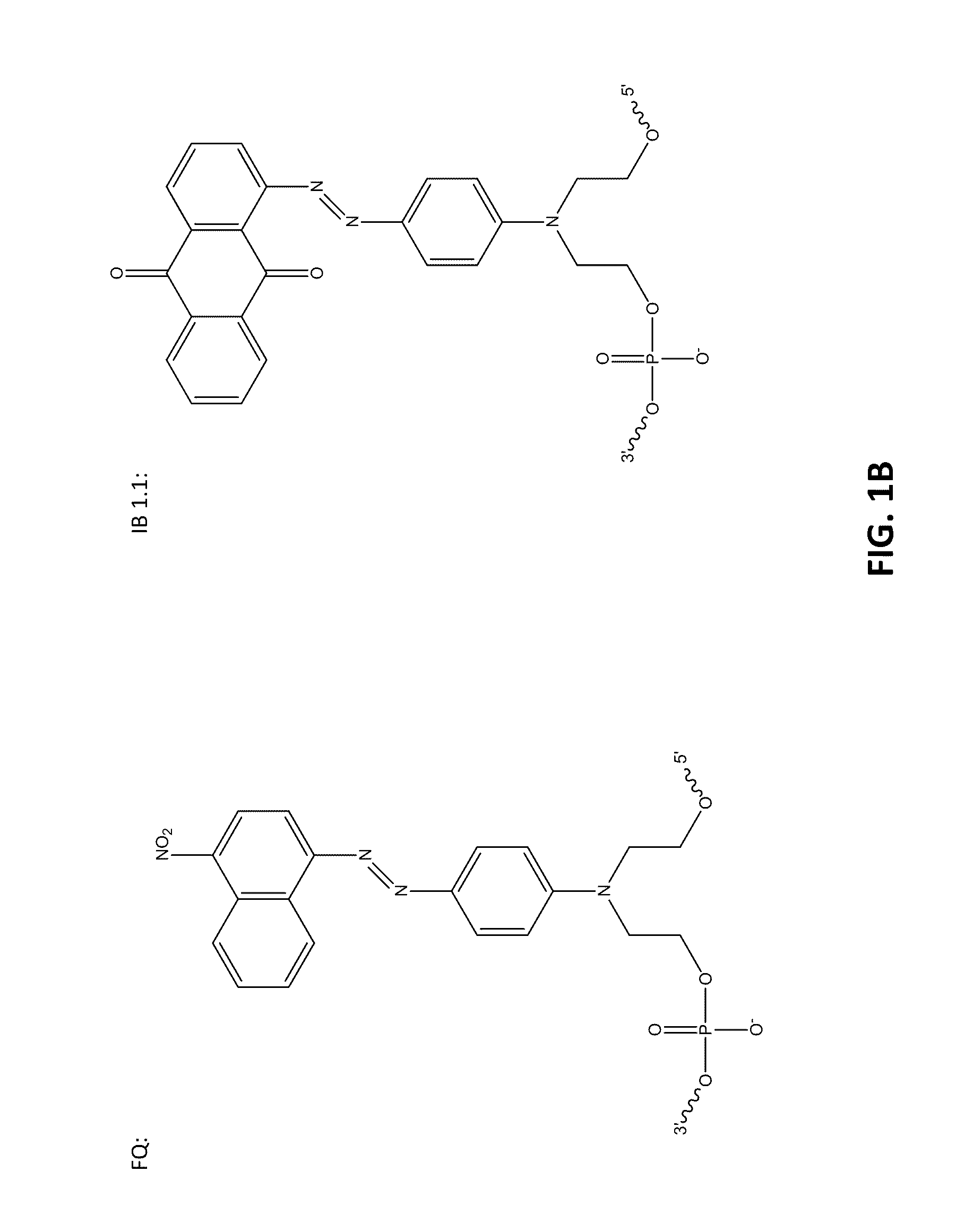

Methods for enhancing nucleic acid hybridization

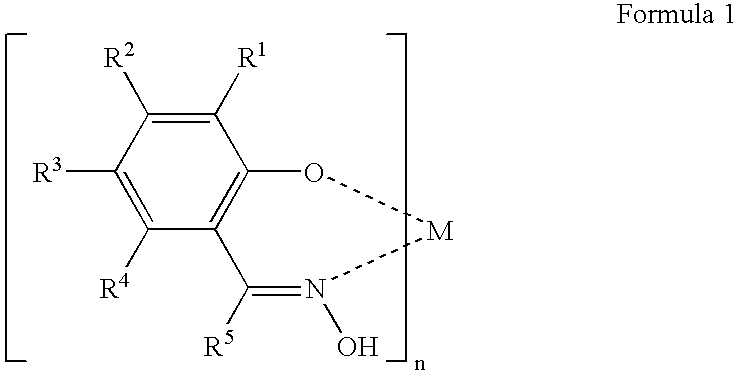

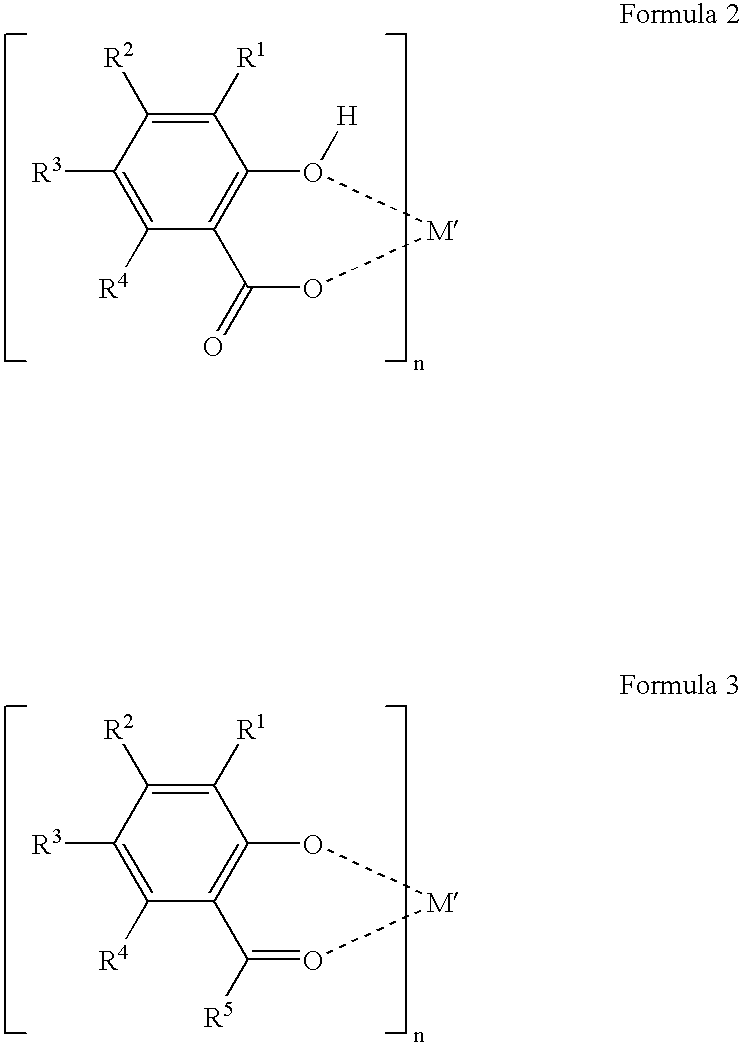

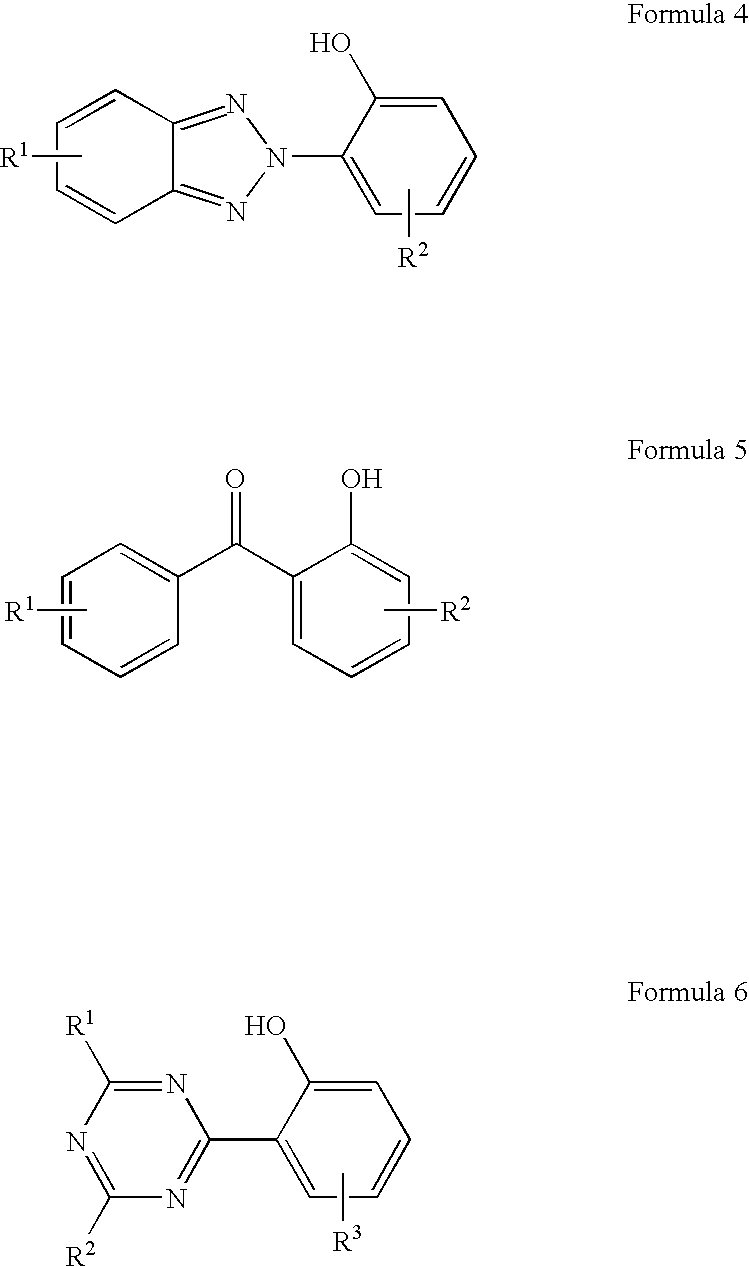

ActiveUS20110236898A1Improve quenching efficiencyImprove efficiencySugar derivativesMicrobiological testing/measurementArylHydrogen

A composition comprising an oligonucleotide having the structure 5′-Y1-L1-X-L2-Y2-3′. Y1 comprises a sequence of one or more DNA or RNA nucleotides, including a first nucleotide N1 having a 3′ phosphate covalently linked to L1. Y2 comprises a sequence of one or more DNA or RNA nucleotides, including a second nucleotide N2 having a 5′ phosphate covalently linked to L2. L1 and L2 each independently are a direct bond or a C1-C7 alkyl, alkynyl, alkenyl, heteroalkyl, substituted alkyl, aryl, heteroaryl, substituted aryl, cycloalkyl, alkylaryl, or alkoxyl group. X isR1 is a hydrogen or a C1-C8 alkyl. M is a label or ligand comprising a fused polycyclic aromatic moiety.

Owner:INTEGRATED DNA TECHNOLOGIES

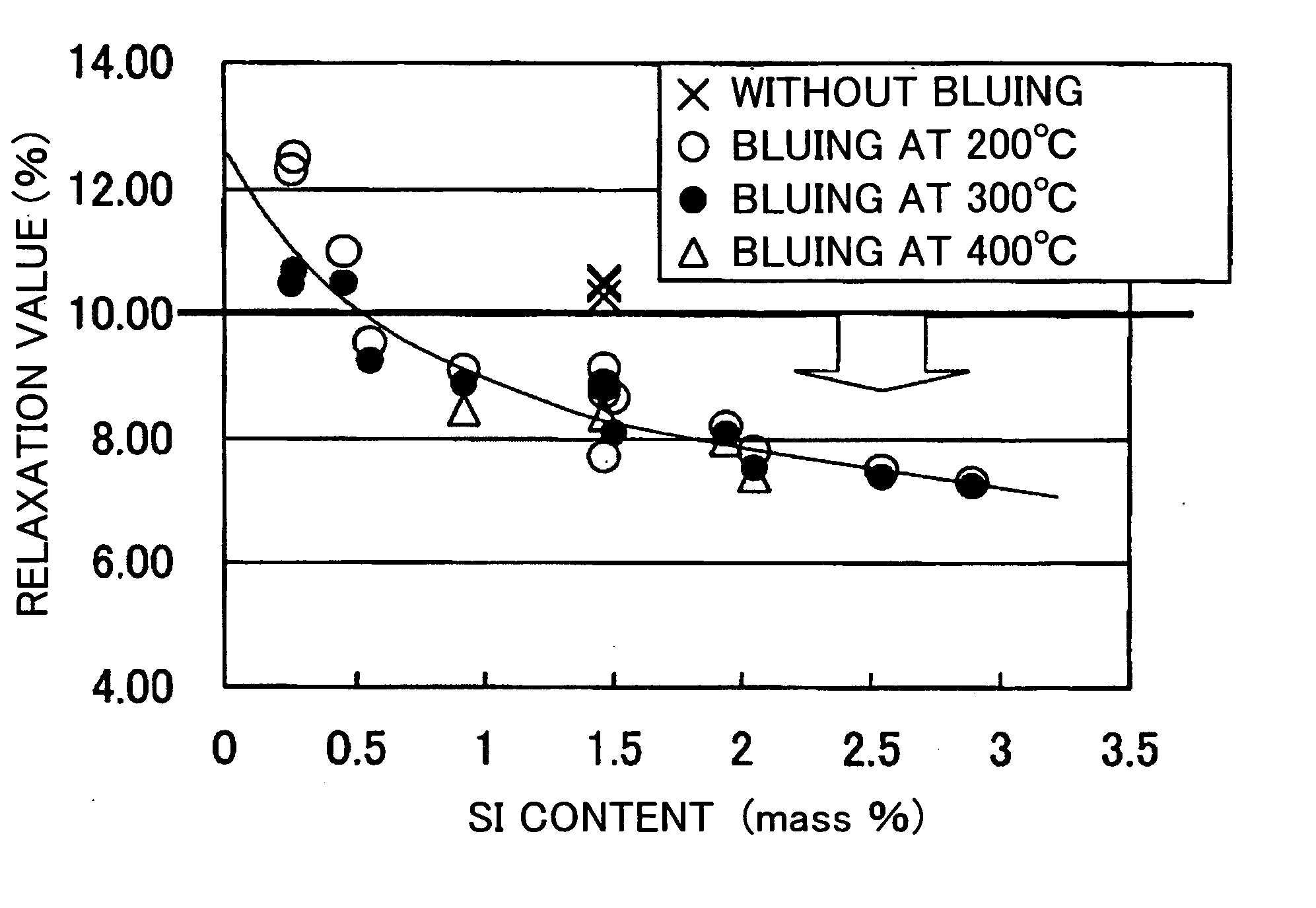

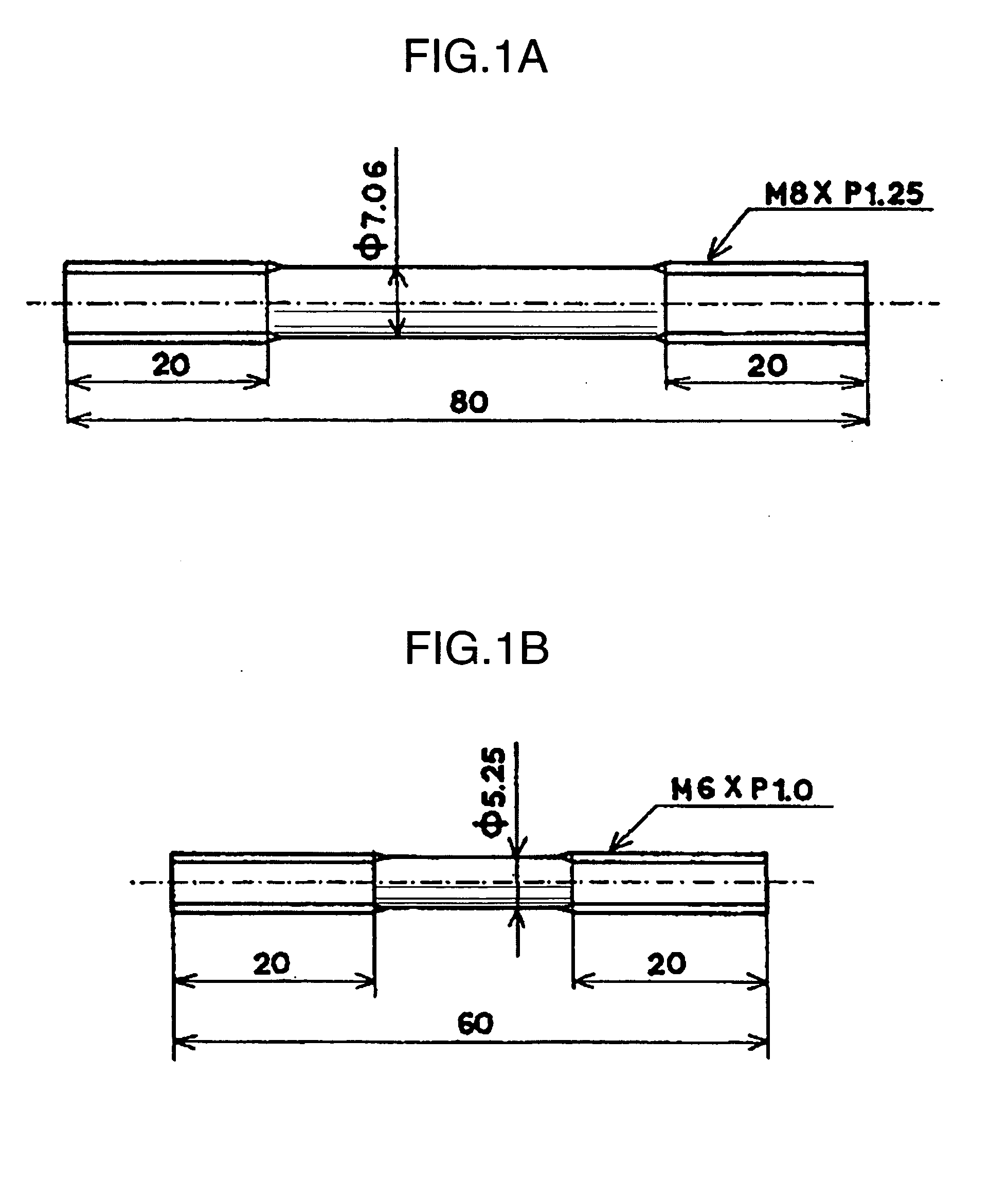

High-strength bolt superior in delayed fracture and resistance and relaxation resistance

Disclosed is a high-strength bolt having a tensile strength of 1,200 N / mm2 or more and superior in delayed fracture resistance and relaxation resistance, prepared by wire-drawing a bolt steel containing the following elements: C: 0.5 to 1.0% (mass %, the same shall apply hereinafter), Si: 0.55 to 3%, Mn: 0.2 to 2%, P: 0.03% or less (but not 0%), S: 0.03% or less (but not 0%), and Al: 0.3% or less (but not 0%), and containing proeutectoid ferrite, proeutectoid cementite, bainite and martensite at a total areal rate of less than 20% and pearlite in balance; cold-heading the wire into a bolt shape; and then bluing the bolt in a temperature range of 100 to 500° C.

Owner:HONDA MOTOR CO LTD +2

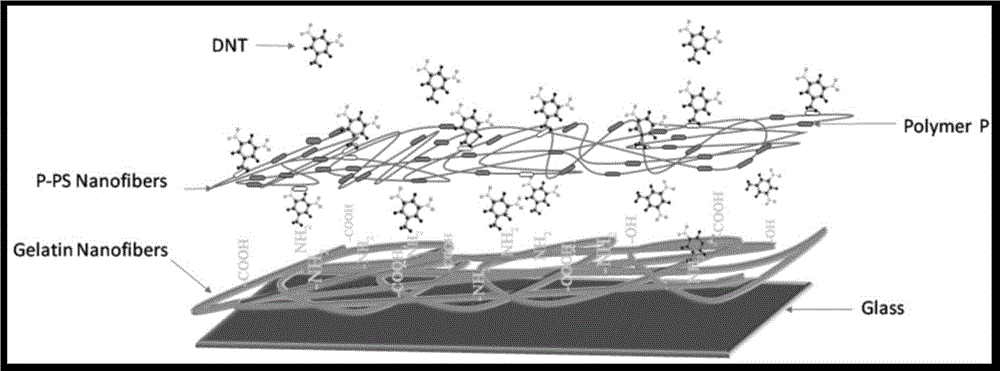

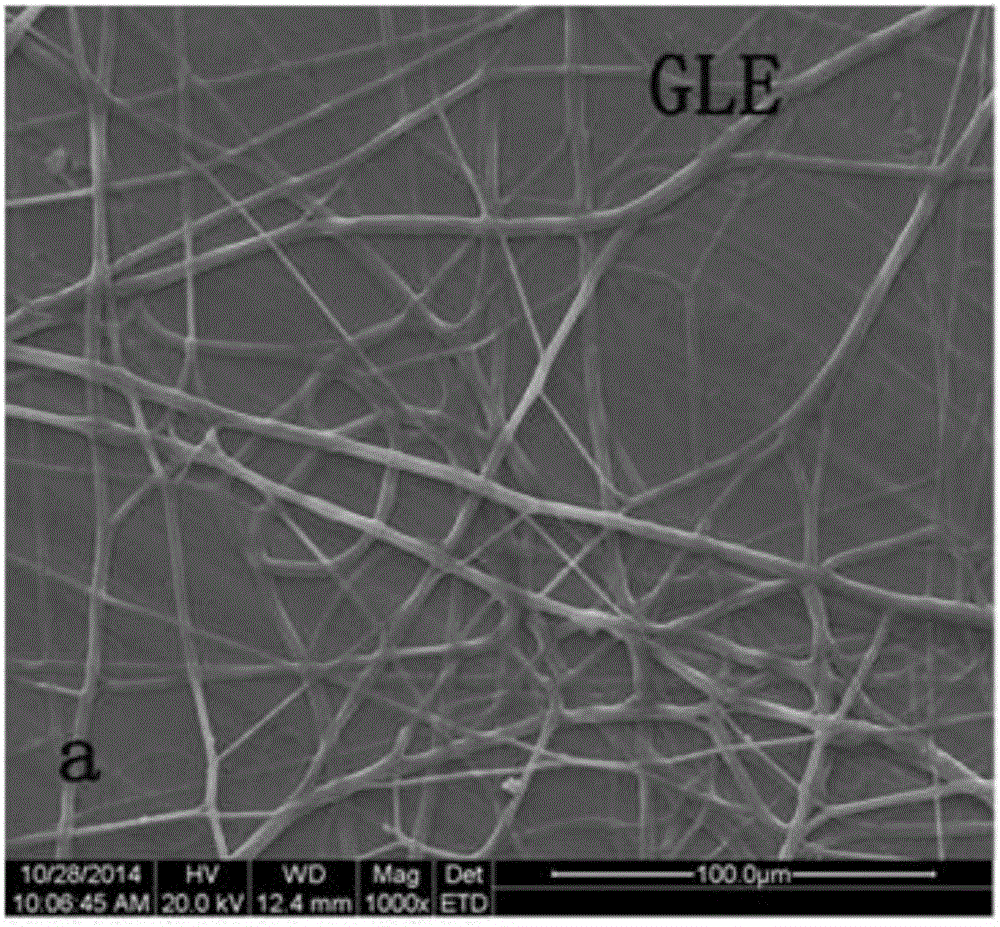

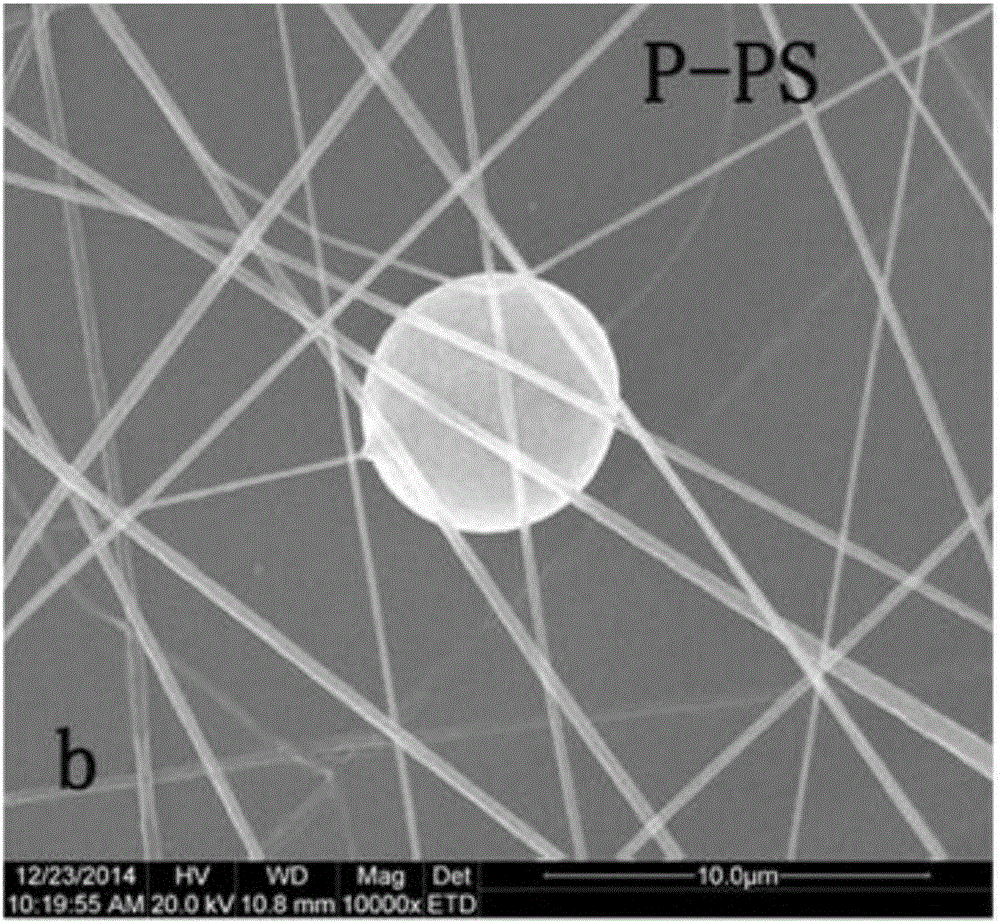

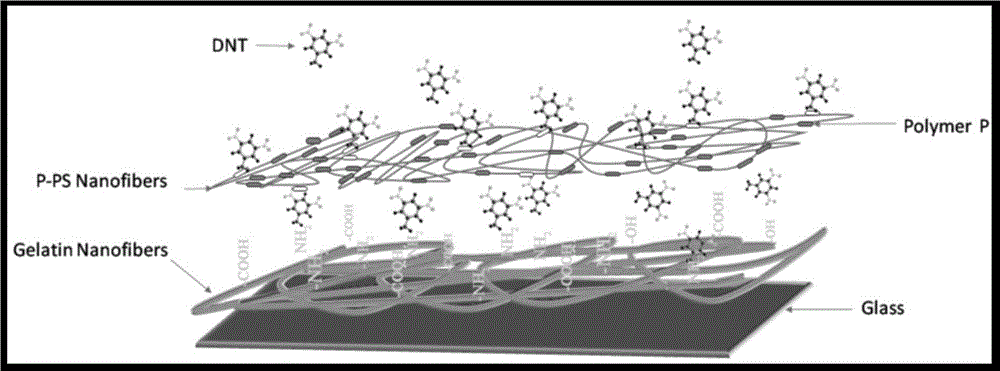

Fluorescent sensing polymer material for detecting nitryl explosives and preparation method

InactiveCN105713184AImprove Sensing PerformanceImprove permeabilityNon-woven fabricsLuminescent compositionsPolymer scienceTerthiophene

The invention discloses a fluorescent sensing polymer material for detecting nitryl explosives and a preparation method. The preparation method of the material comprises the following steps: taking 2,5- dibromo thiophene, poly(phenyleneethynylene) polymer and 2,7-dibromo-9,9-diphenylfluorene as raw materials; and polymerizing to obtain the fluorescent sensing polymer material. 9,9-Diphenylfluorene and thiophene monomer are introduced to synthesize the poly(fluorenyleneethynylene) polymer (PFEs). The 9,9-diphenylfluorene unit is introduced in the poly(phenyleneethynylene) polymer to weaken Pi-Pi stacking between skeletons, permeability of the polymer is improved, the polymer has rigid steric hindrance, meanwhile, the thiophene unit is introduced to enable the polymer to be rich in electrons, and an electron transfer function of the electrons between the nitro-aromatic compounds and the sensor is promoted.

Owner:QILU UNIV OF TECH

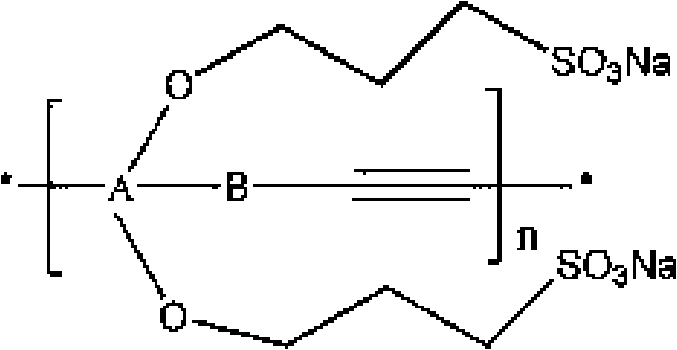

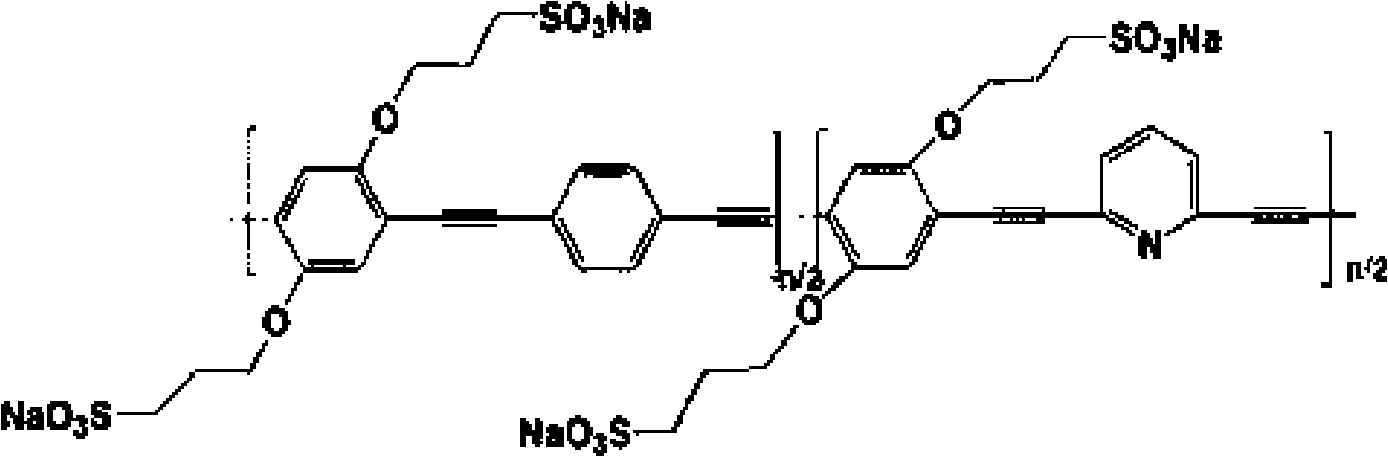

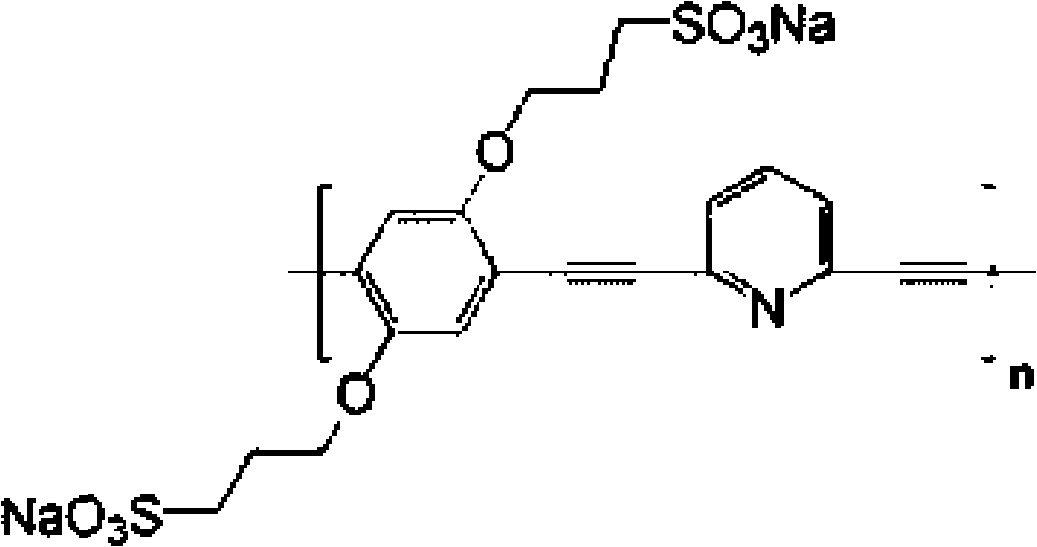

Water soluble fluorescent conjugated polymer and synthesis method thereof

InactiveCN101671427AImprove rigidityImprove flexibilityLuminescent compositionsSolubilityPolyelectrolyte

The invention discloses a water soluble fluorescent conjugated polymer and a synthesis method thereof. The polymer has a conjugated main chain with hydrophobicity and ionic type functional group sidechains with hydrophilicity, wherein the ionic type functional group side chains with hydrophilicity are sulfonate and nitrobenzene; and the conjugated main chain introduces a single pyridine functional group. The invention introduces the single pyridine functional group at the conjugated main chain, thus being beneficial to aggregation of polymers, forming a three-dimensional structure and effectively improving the rigidity of the conjugated main chain; in addition, a pyridine ring can form complex with most of metallic ions so as to lead the polymeric molecule to have better quenching efficiency; further, the invention combines excellent optical performance of the conjugated polymer and water solubility of polyelectrolyte and provides a platform for designing a high-efficiency fluorescentprobe.

Owner:HUNAN NORMAL UNIVERSITY

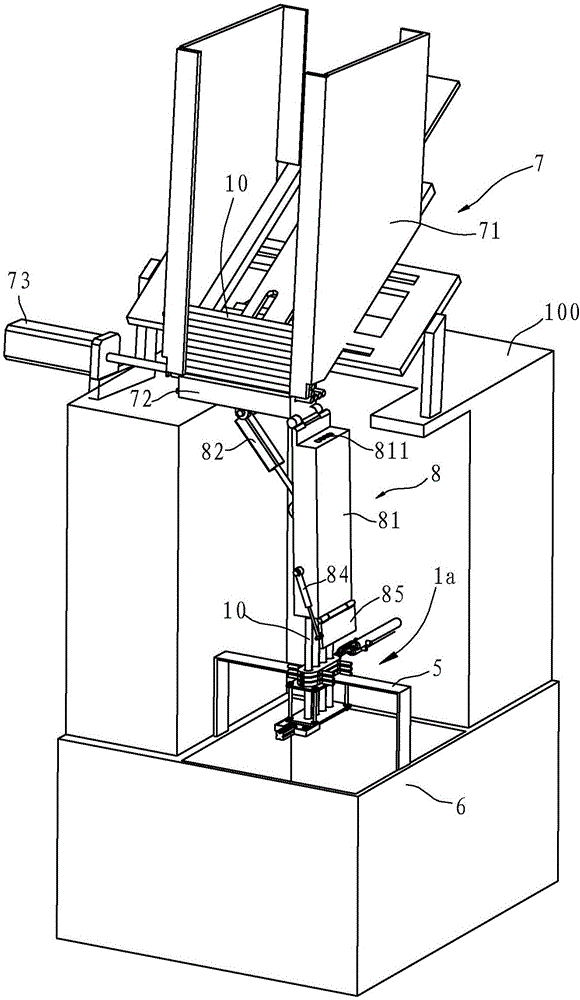

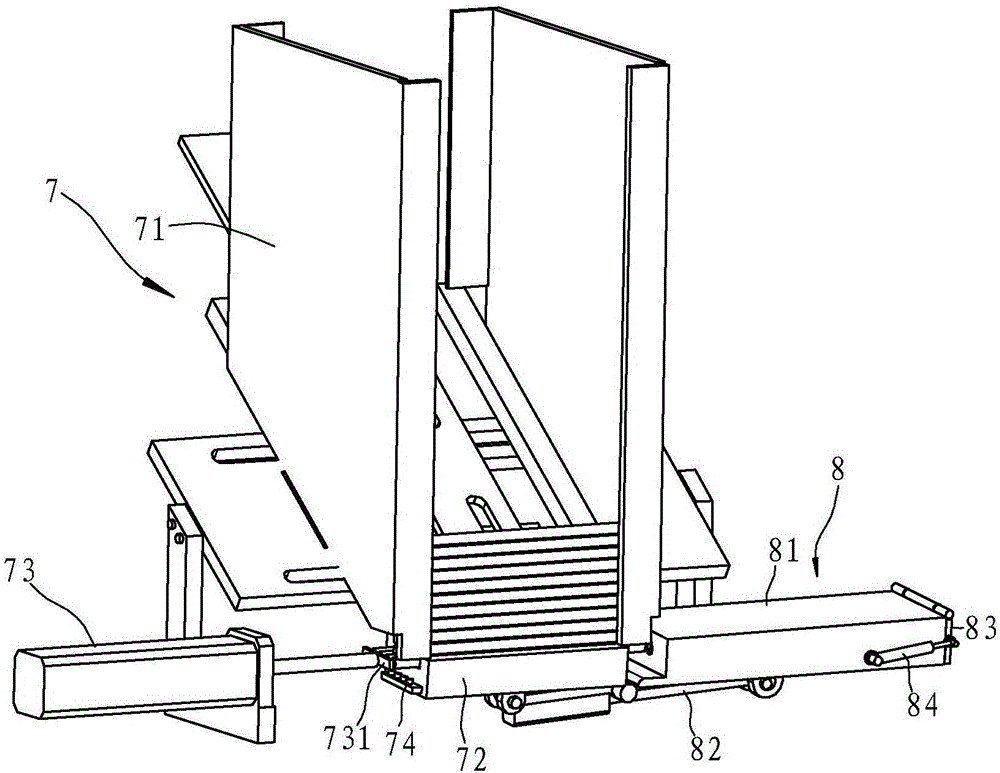

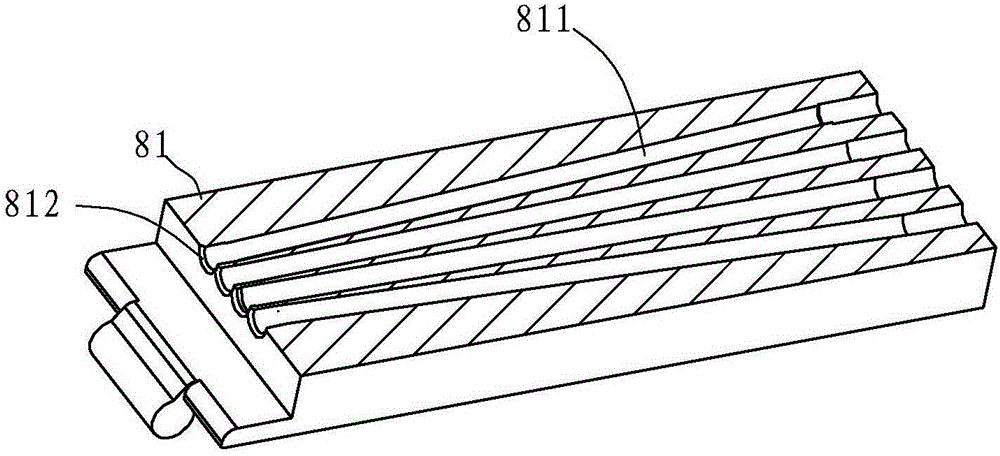

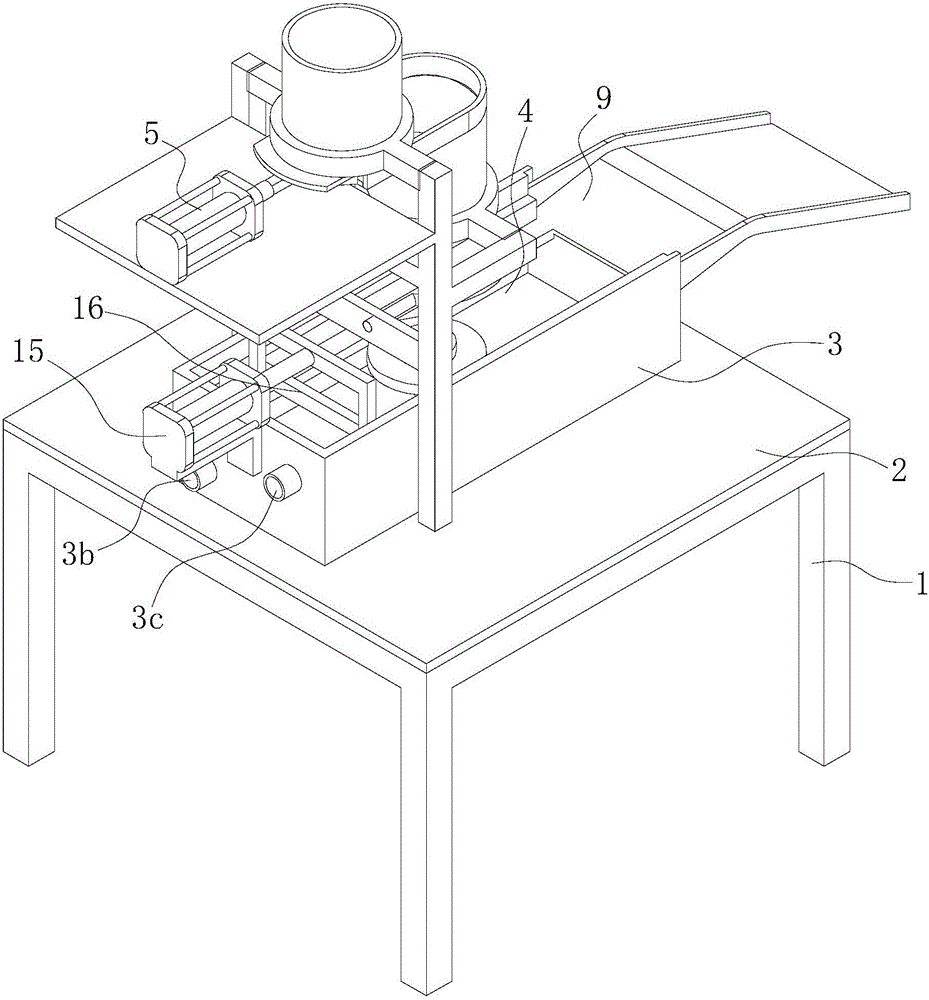

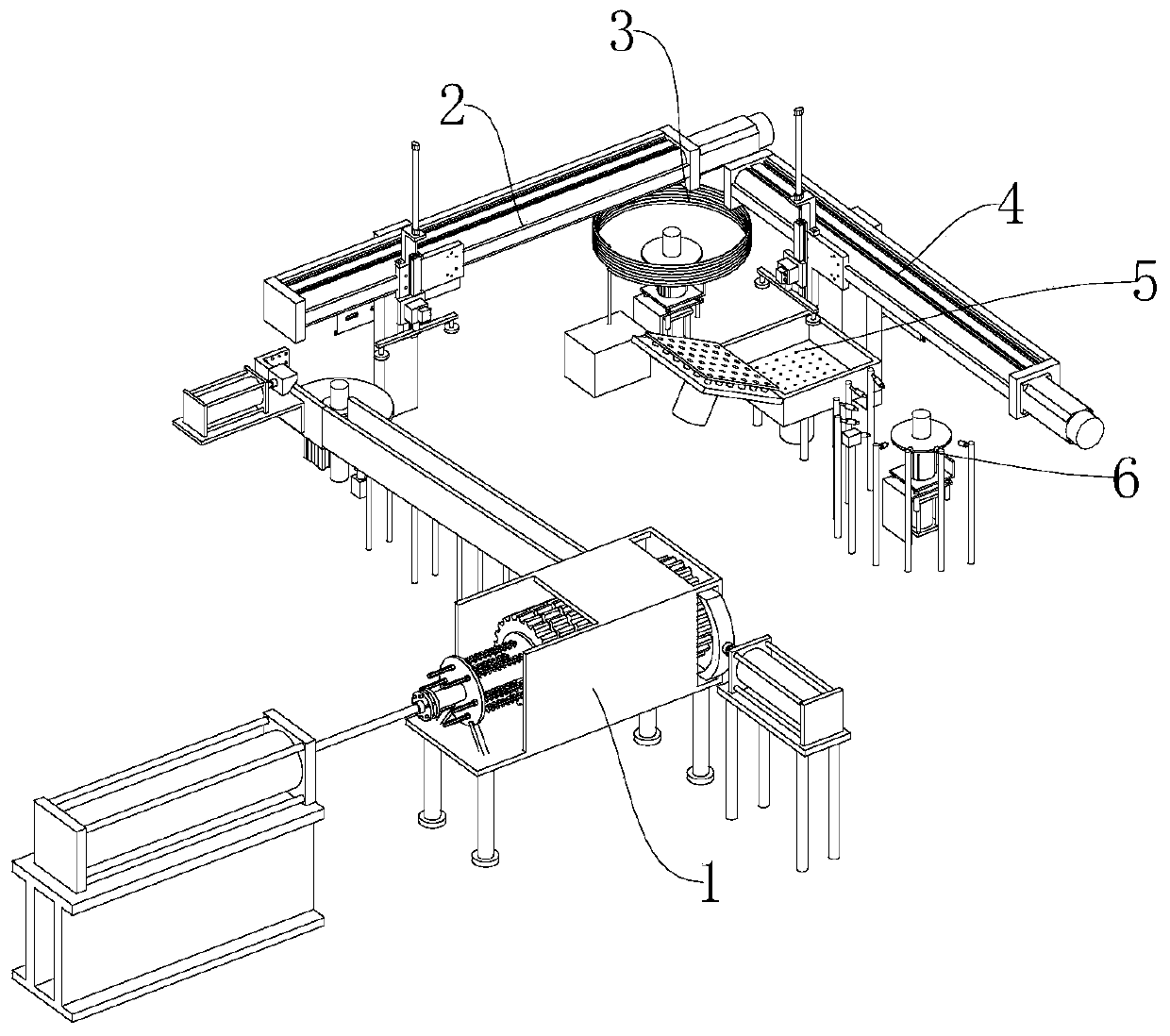

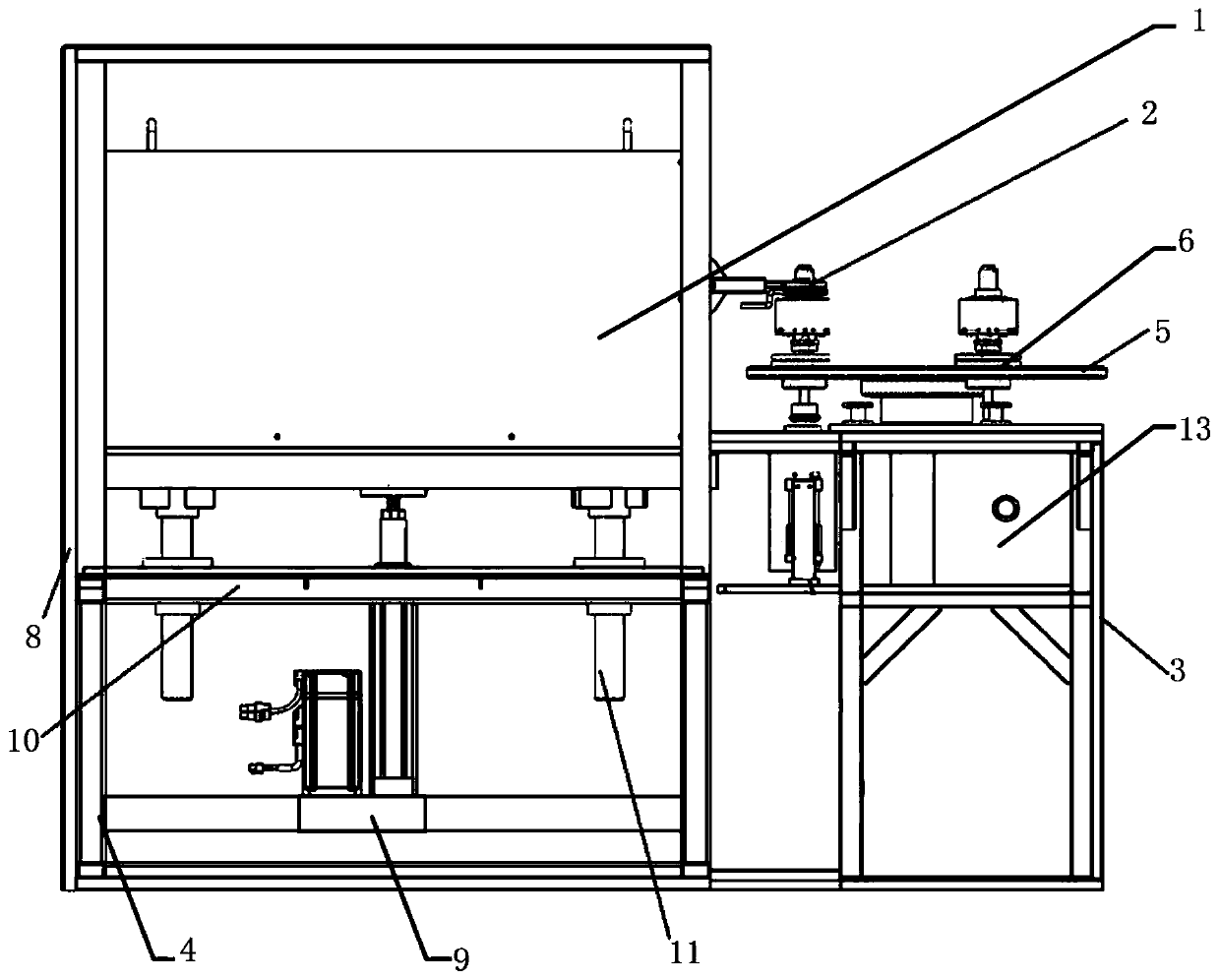

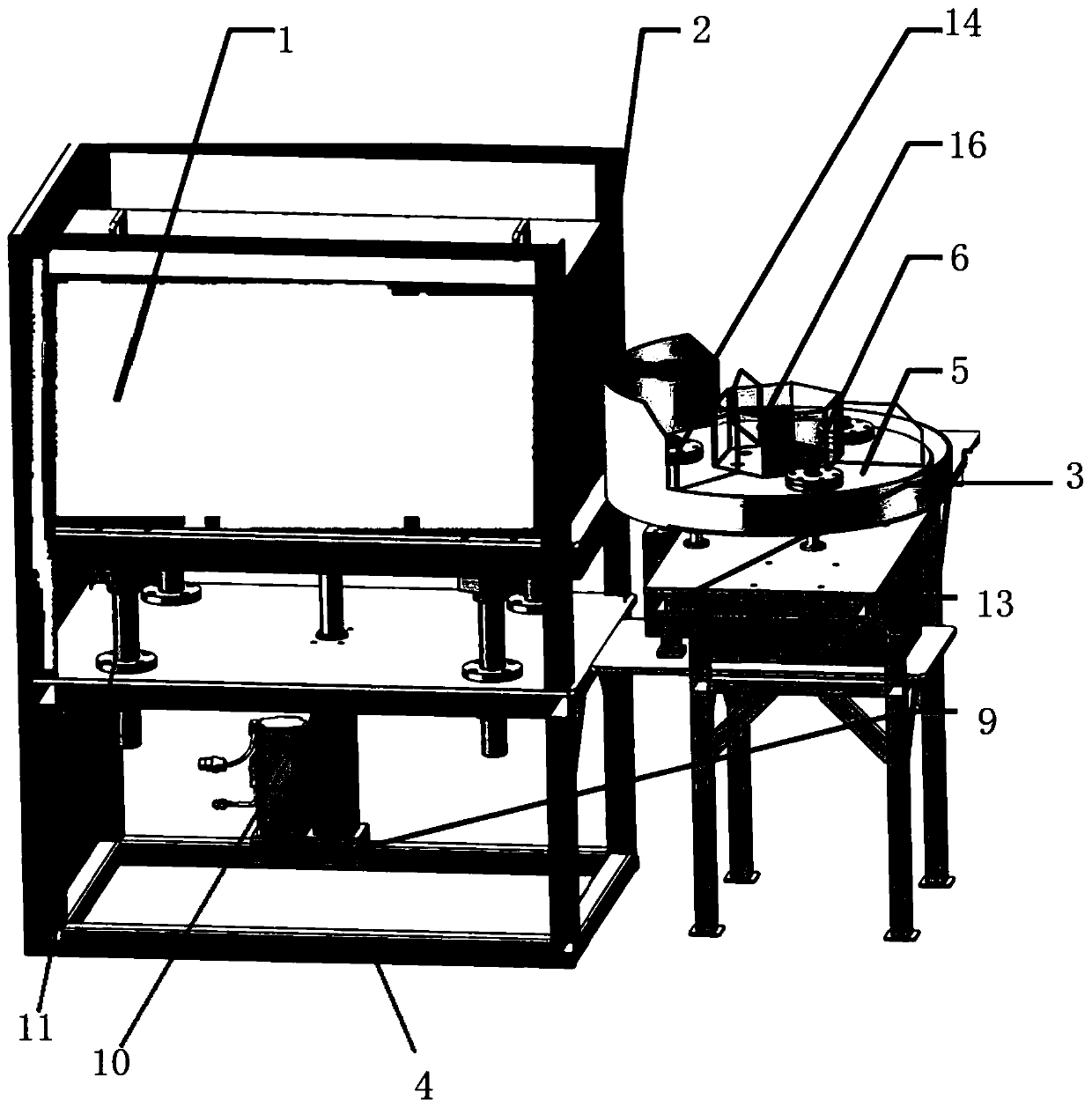

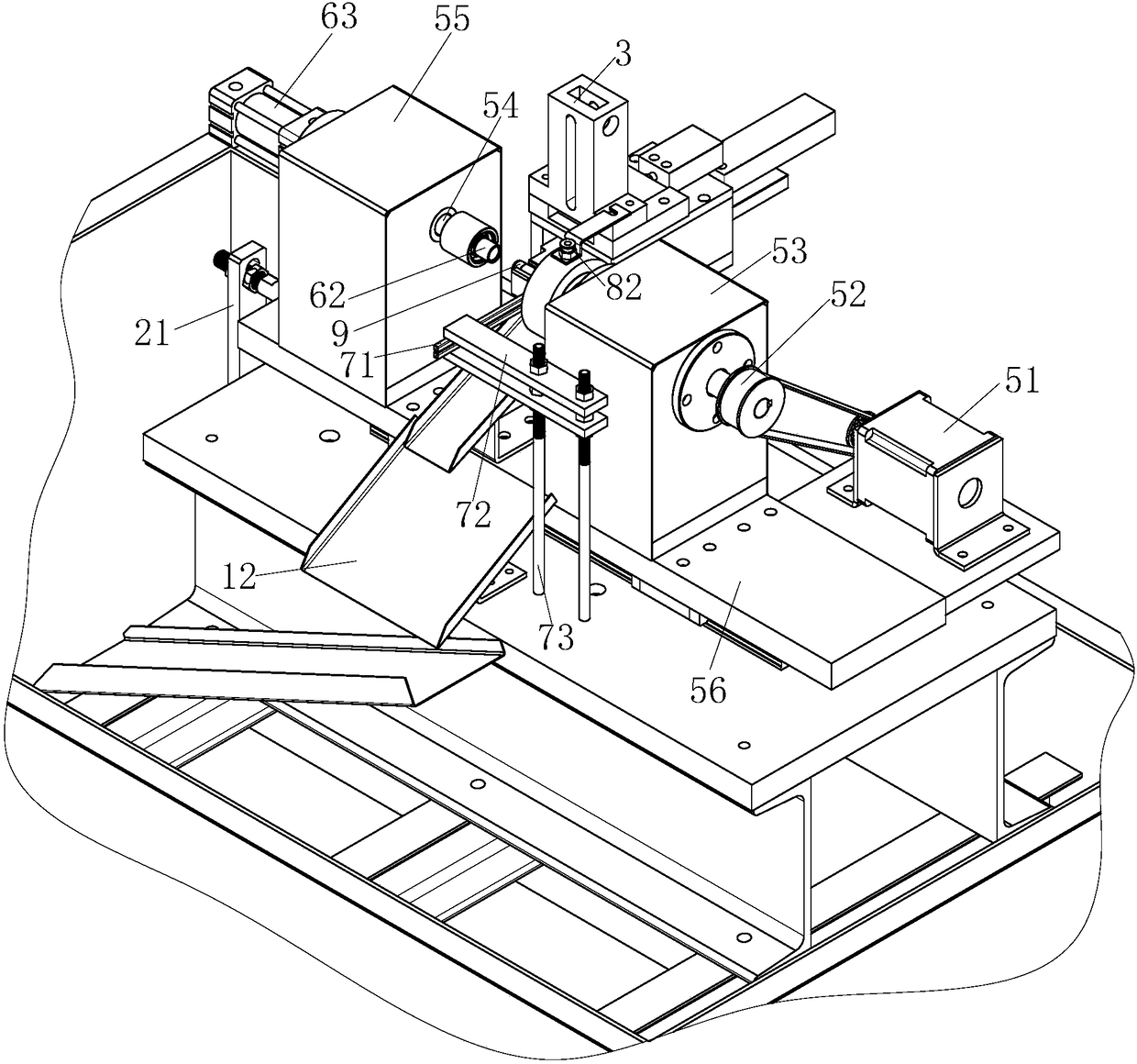

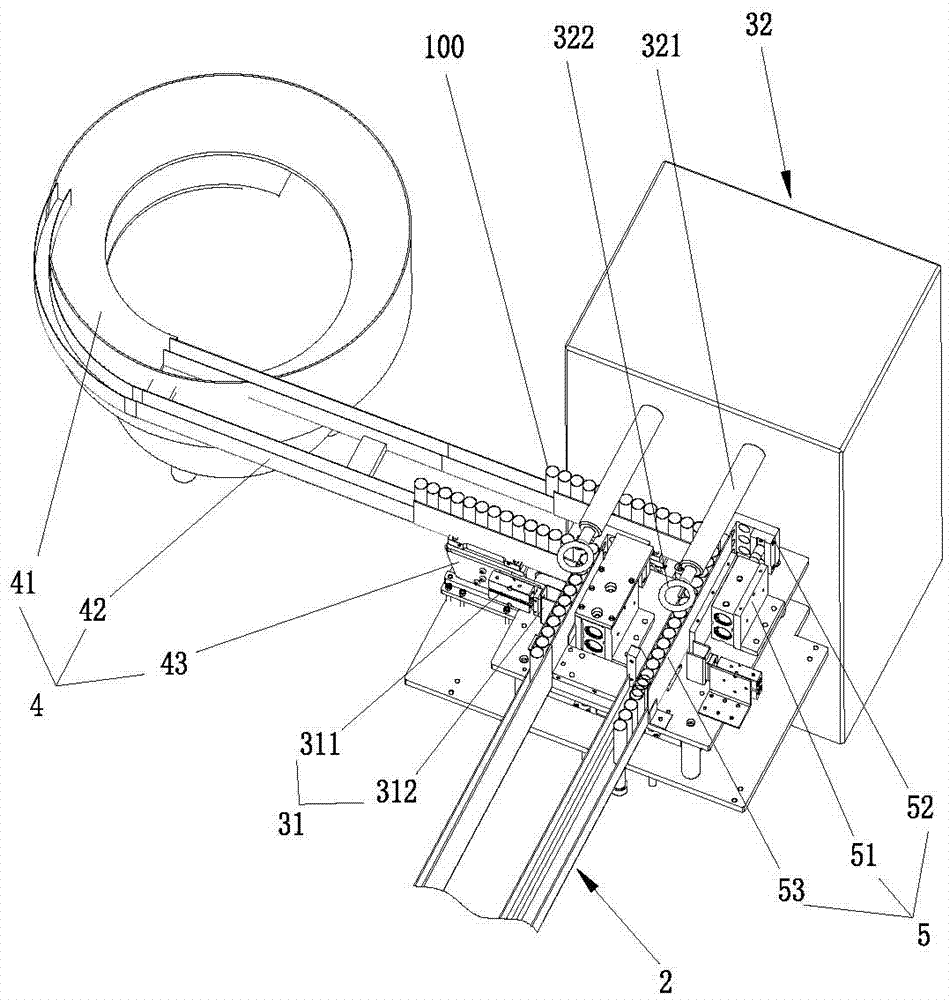

Automatic shaft quenching device

ActiveCN106119508ASimple structureImprove quenching efficiencyFurnace typesHeat treatment furnacesInduction heaterInductor

An automatic shaft quenching device is characterized by comprising a working face, a feeding mechanism, an aggregating box, a support frame, a quenching mechanism, a high-frequency induction heater, a steering component and a controller, wherein the feeding mechanism can horizontally output workpieces; the steering component comprises a steering block, a steering cylinder, a cover plate and a plate pushing cylinder; one end of the steering block is hinged to one side of the feeding mechanism; channels used for accommodating the workpieces and allowing the workpieces to pass through are arranged in the steering block; the feeding ends of the channels are connected with the discharging end of the feeding mechanism; and after the steering block rotates by 90 degrees, the discharging ends of the channels are located right above through holes of an inductor. Compared with the prior art, the automatic shaft quenching device has the following advantages, the integral structure is simple, simultaneous feeding, steering, quenching, cooling and discharging are automatically realized by the controller, the quenching efficiency is improved, the labor intensity is greatly lowered, and potential safety hazards are reduced.

Owner:NINGBO VISTART INTELLIGENT TECH

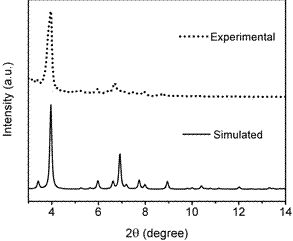

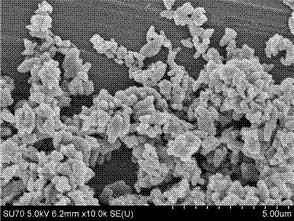

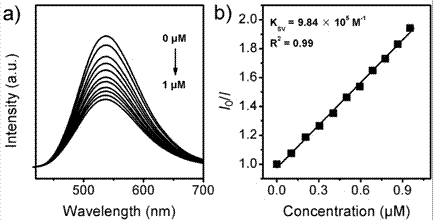

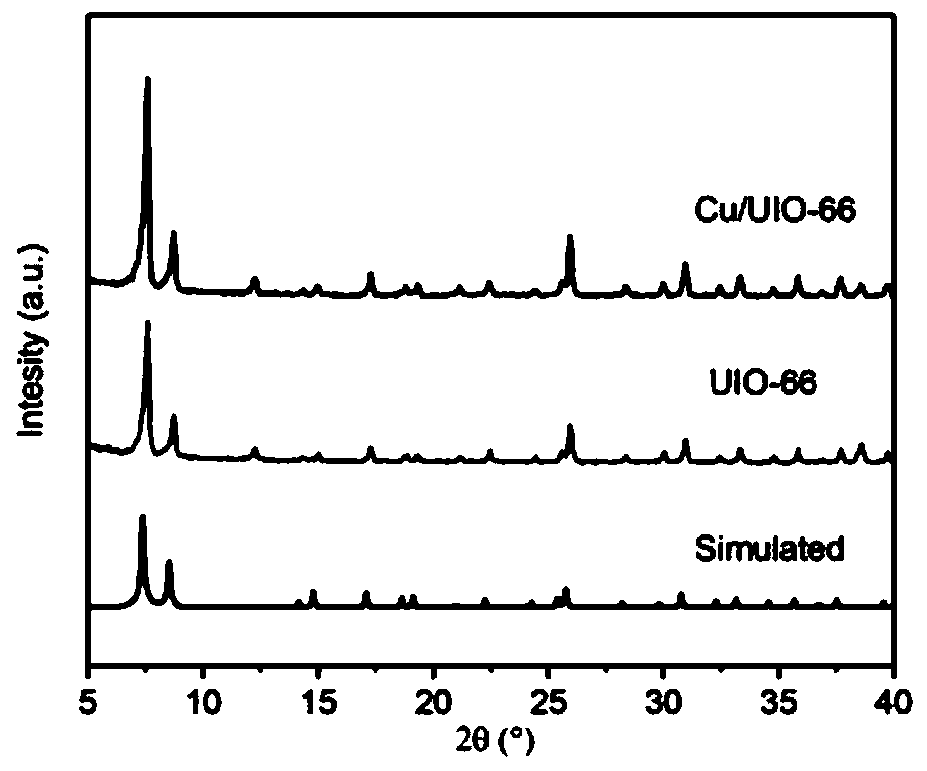

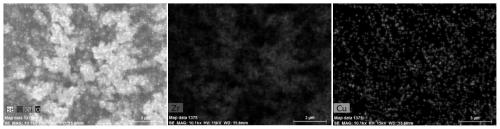

New fluorescence detection method of tetracycline based on zirconium-based MOF(Metal-organic framework)

ActiveCN107290316AImprove quenching efficiencyReduce excitation energyFluorescence/phosphorescencePhotoinduced electron transferMetal-organic framework

The invention belongs to the technical field of chemical sensing, and particularly relates to a new fluorescence detection method of tetracycline based on a zirconium-based MOF(Metal-Organic framework). By using the zirconium-based metal-organic framework (Zr-MOF) with good water and heat stability and excellent luminescent performance as a detection platform, selective adsorption enrichment and fluorescent response of the Zr-MOF on the tetracycline in a water body are utilized, so that high-sensitivity and high-selectivity detection on the tetracycline can be realized. Meanwhile, the detection method has a low detection limit. Compared with other detection methods of the tetracycline, the detection method disclosed by the invention has the advantages of simple and quick operation, no need of expensive and complicated instruments and equipment, and the like; therefore, the practicability is high, and the application range is wide. The fluorescent response of the zirconium-based MOF on the tetracycline is based on electron transfer between the zirconium-based MOF and the tetracycline, and fluorescence quenching on the zirconium-based MOF is caused by photoinduced electron transfer between the zirconium-based MOF and the tetracycline.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Surface hardening treatment method for large-power low-speed diesel engine piston bar

ActiveCN101148688AHigh heating and quenching efficiencyImprove quenching efficiencyFurnace typesIncreasing energy efficiencyMicro structureLow speed

The surface hardening treatment process for piston rod of great power low speed diesel engine includes continuous surface heating to 900-940 deg.c in an intermediate frequency inducing heater of the quenching apparatus, quenching through spraying water, tempering through heating to 200-270 deg.c, and rotating the piston rod while heating in the inducing heater and spraying water. The present invention has high quenching efficiency, environment friendship, homogeneous heating and quenching, and capacity of reaching required surface hardness, quench hardened layer depth and micro structure.

Owner:DALIAN MARINE DIESEL

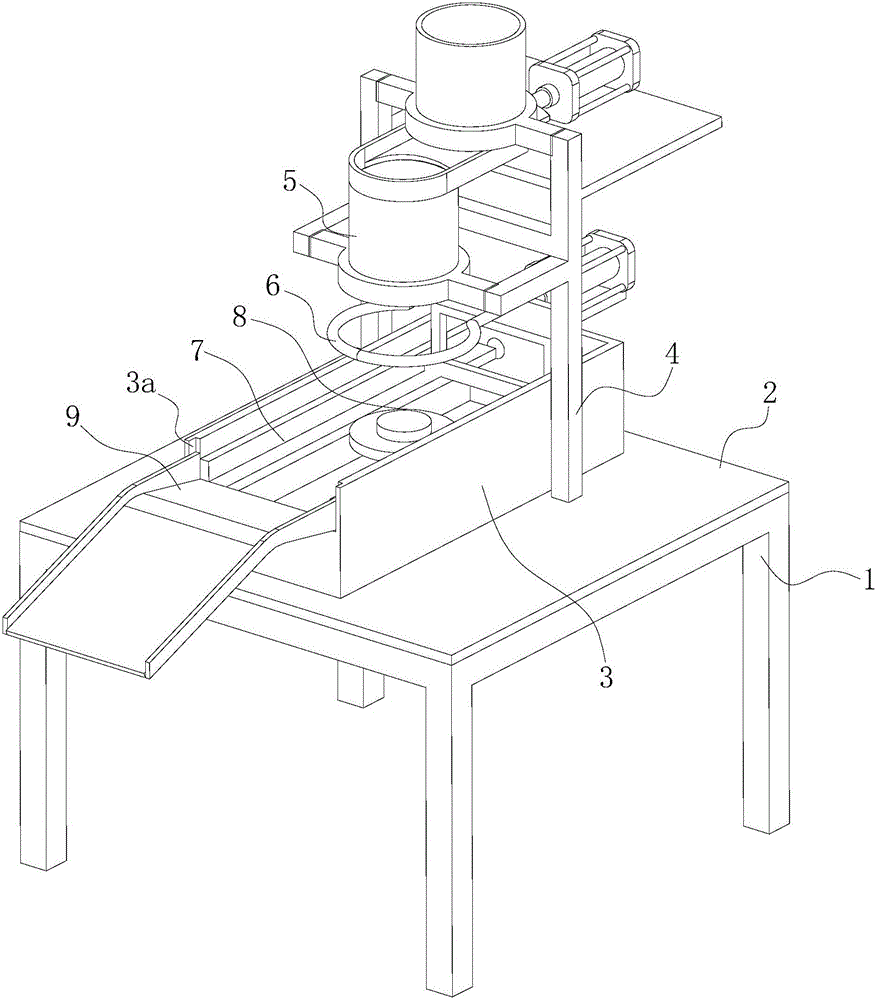

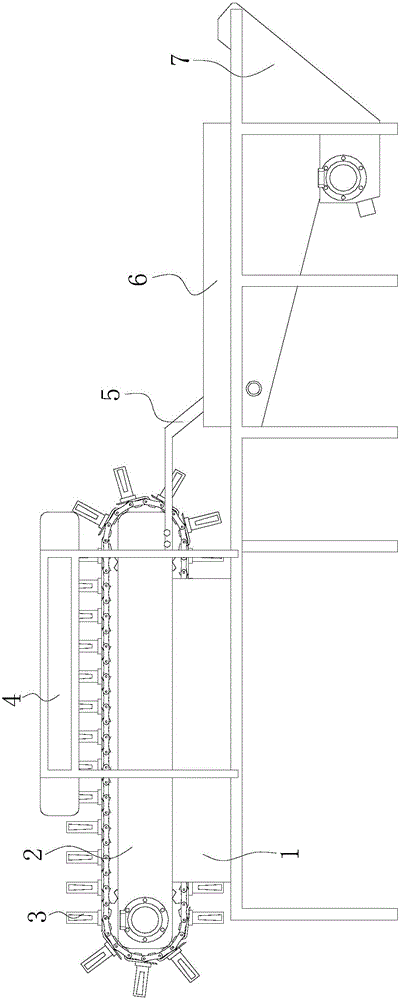

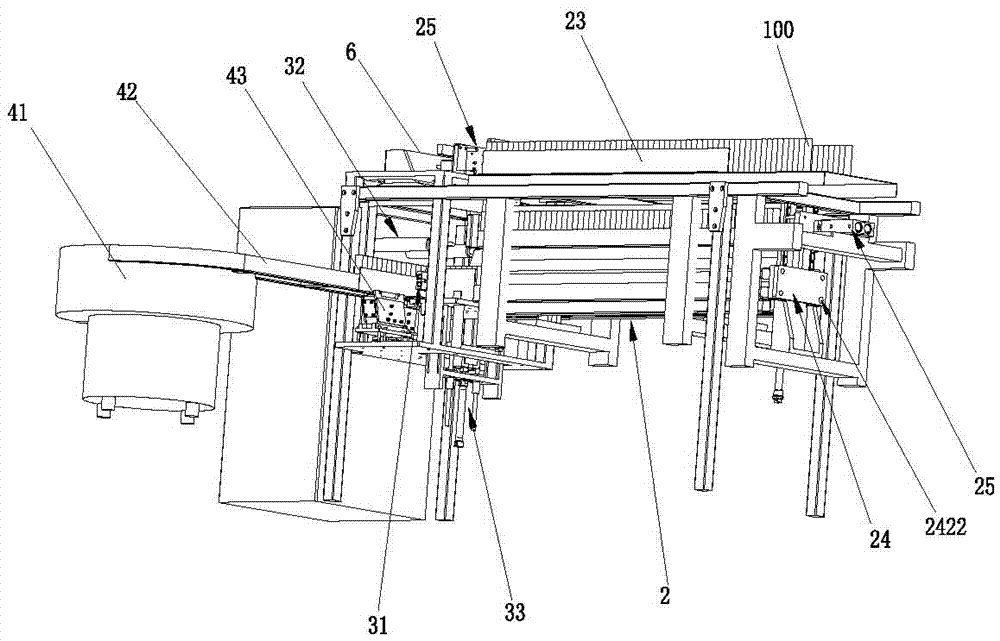

Automatic quenching production line for annular parts

InactiveCN105018709ARealize automatic feeding processReasonable structural designFurnace typesHeat treatment furnacesProduction lineEngineering

The invention discloses an automatic quenching production line for annular parts. The automatic quenching production line for the annular parts comprises a supporting frame. An installing plate is fixed to the upper end of the supporting frame. A cooling pool is fixed to the upper end of the installing plate. Slide ways are fixed to the left end and the right end of the inner wall of the cooling pool. A fixing frame is arranged at the upper end of the cooling pool. A heating ring is fixed to the fixing frame. An automatic feeding device is arranged above the heating ring. A driven gear is installed at the lower end of the installing plate. A telescopic cylinder is fixed to the lower end of the driven gear. A positioning convex block is fixed to the upper end of the telescopic cylinder. A motor installing plate is fixed to the left side of the lower end of the installing plate. A motor is fixed to the motor installing plate. A driving gear is fixed to a shaft of the motor in a key connection manner. The automatic quenching production line has the beneficial effects of being reasonable in structural design, convenient to use and the like, automatic feeding of the parts can be achieved, quenching treatment is performed on the parts, the automation degree is high, the quenching quality is good, the quenching efficiency is improved, and production cost is saved.

Owner:安徽旭虹机械设备有限公司

Technique for oil quenching casting sphere made from high chrome alloy

This invention relates to an art for oil-quenching high-chromium alloy cast ball. The high-chromium alloy cast ball and cast-section are heated to quenching temp., then tapped out of the furnace, proceeding oil-quenching, oil temp. being controlled <120 deg.C, when temp. of the product being lowered below 300 deg.C, the cast ball and cast section are taking out of the oil-cell. The wear-resisting high-chromium cast ball and cast section treated by using this method are better than that of prior art treatment in various kinds of technical index, wherein: quenching hardness=60-65 deg.C, difference (between center and surface) of hardness <2.0 RHc, ball falling test >3000 times. This quenching art overcomes prior art defect. The product treated by this method has excellent wear-resisting property and longer service-life.

Owner:ANHUI FENGXING WEAR RESISTANT MATERIALS CO LTD

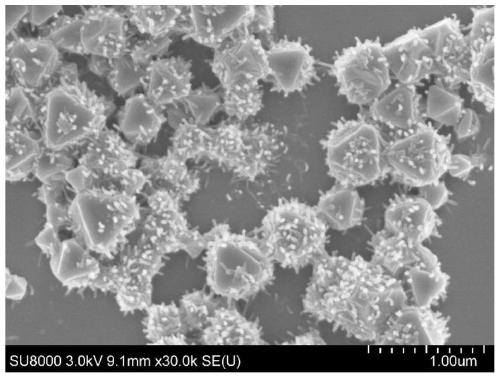

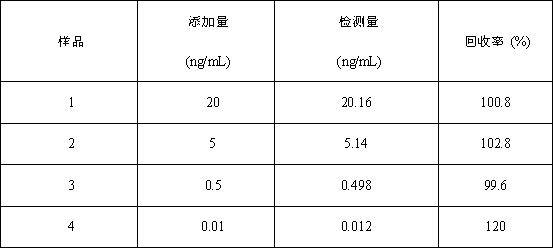

Method for synchronous fluorescence detection of chloramphenicol based on Cu/UiO-66 metal organic framework quenching

ActiveCN111398235AQuenching is strongDouble quenchingFluorescence/phosphorescenceLuminescent compositionsFluoProbesMetal-organic framework

The invention relates to the field of chemical sensors, in particular to a synchronous fluorescence detection method for chloramphenicol based on Cu / UiO-66 metal organic framework quenching. The method comprises the following steps: 1, dissolving a chloramphenicol aptamer fluorescent probe marked with a fluorophore in a buffer solution to prepare a reaction solution A; 2, uniformly dispersing a copper-zirconium bimetal organic framework material Cu / UiO-66 into a buffer solution to obtain a reaction solution B; 3, mixing the prepared reaction solution A and reaction solution B with a proper amount of buffer solution to obtain a mixed solution C; and 4, adding a certain amount of a solution with chloramphenicol content to be detected into the mixed solution C, reacting for a period of time,and detecting the fluorescence intensity through synchronous fluorescence scanning to realize quantitative detection of chloramphenicol. The method for detecting chloramphenicol, which is implementedby using the method, has the advantages of simplicity, rapidness, high sensitivity, strong specificity, low detection limit and the like.

Owner:HUBEI UNIV FOR NATITIES

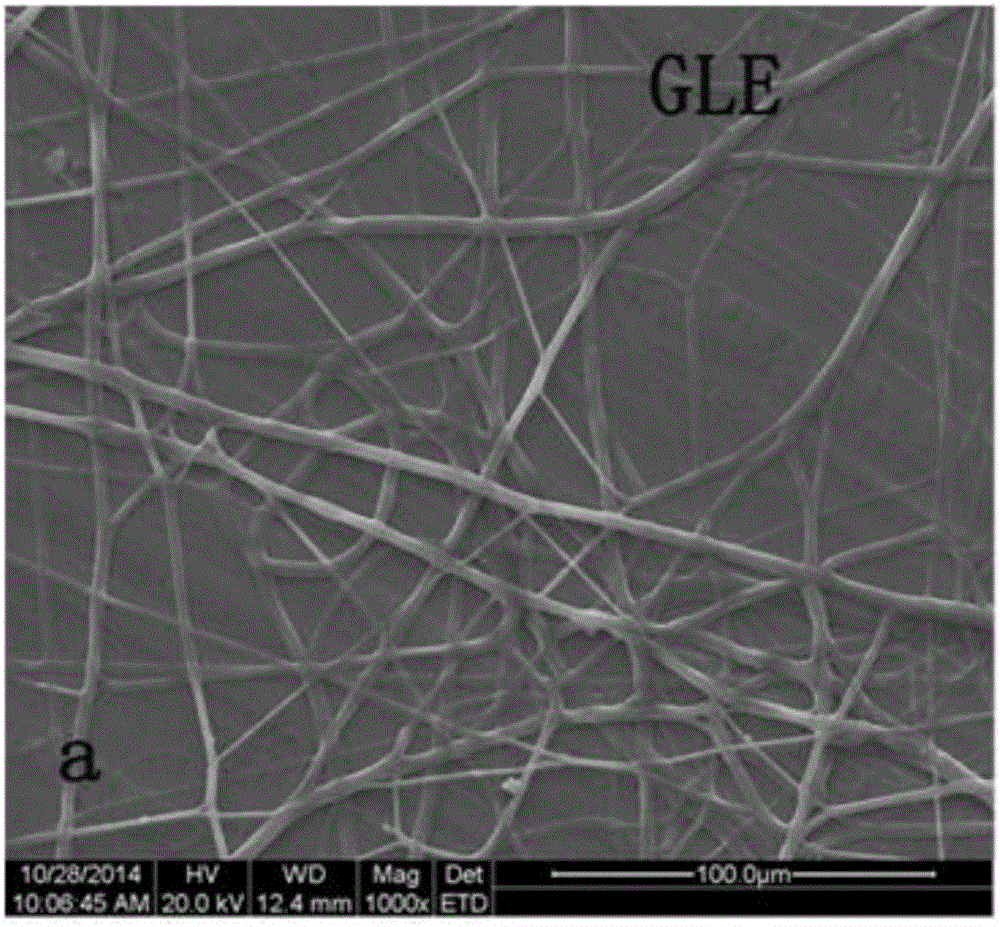

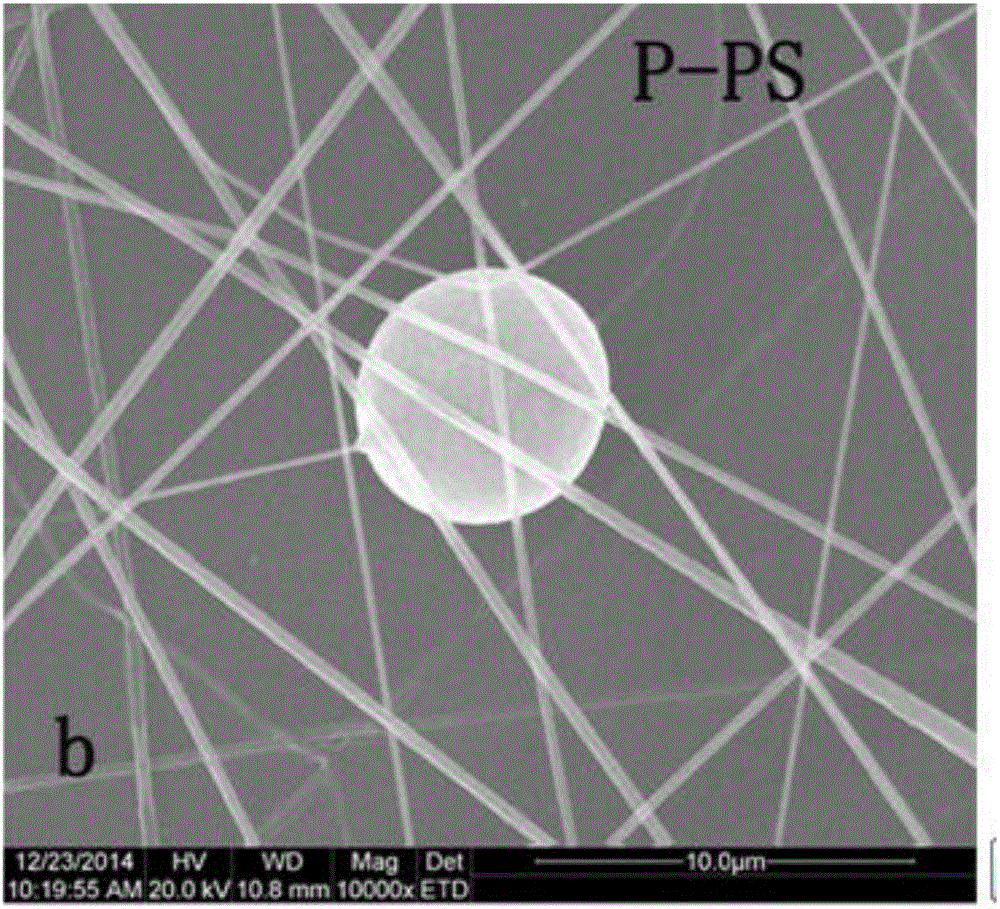

Double-layered electrostatic spinning film sensor for detecting nitryl explosives

InactiveCN105717079AImprove Sensing PerformanceImprove permeabilityFluorescence/phosphorescenceFluorescencePolystyrene

Owner:QILU UNIV OF TECH

High-frequency gear quenching equipment

InactiveCN111593192AImprove delivery efficiencyAvoid troubleSpraying apparatusIncreasing energy efficiencyGear wheelEngineering

The invention relates to the field of gear machining, in particular to high-frequency gear quenching equipment. The high-frequency gear quenching equipment comprises a conveying mechanism, and gear parts for being arranged in order to be quenched. The gear parts are fed one by one, a first carrying mechanism is used for receiving and grabbing the gear parts from the conveying mechanism and is usedfor transferring the gear parts, and a high-frequency quenching mechanism is used for receiving the gear parts conveyed by the first carrying mechanism and carrying out high-frequency induction heating and quenching on the gear parts. A second carrying mechanism is used for receiving and grabbing the gear parts quenched by the high-frequency quenching mechanism and is used for transferring the gear parts, and an air cooling mechanism is used for receiving the gear parts conveyed by the second carrying mechanism and cooling the gear parts. An oil smearing mechanism is used for receiving the gear parts conveyed by the second carrying mechanism and smearing the surfaces of the gear parts with oil. According to the high-frequency gear quenching equipment, assemble line work is carried out, the gear parts can be automatically settled, conveyed and placed, manual taking and placing are replaced, high safety is achieved, and the production efficiency is improved.

Owner:邹立川

Electrochemiluminescence sensor for detecting insulin by quenching CdS hybridized TiO2 nanoribbon through gold-curcumin nanoparticles

ActiveCN110907511AReduce dosageShort response timeMaterial electrochemical variablesElectrochemical responsePotassium persulfate

The invention relates to an electrochemiluminescence sensor for detecting insulin by quenching a CdS hybridized TiO2 nanoribbon through gold-curcumin nanoparticles. According to the present invention,the potassium persulfate and the hydrogen peroxide are used as the co-reactants together, so that the electrochemiluminescence property of the CdS hybridized TiO2 nanoribbon is enhanced. In order tosensitively detect the insulin, the invention designs a sandwich type quenching type electrochemiluminescence immunosensor, and the gold-curcumin composite ZIF-8 is adopted as a quenching agent, so that the electrochemiluminescence intensity of the CdS hybrid TiO2 nanoribbon is reduced. The quenching mechanism is mainly that the curcumin consumes the hydroxyl radicals generated in an electrochemical reaction process, and the luminous intensity of the luminescent material is further reduced through energy transfer, so that the dual quenching of an electrochemiluminescence signal is realized; the insulin with different concentrations can be combined with different amounts of secondary antibody marker gold-curcumin composite ZIF-8, so that the electrochemiluminescence intensity change of thesensor is different. The linear range of insulin detection is 0.3 pg / mL-20 ng / mL, and the detection limit is 0.09 pg / mL.

Owner:UNIV OF JINAN

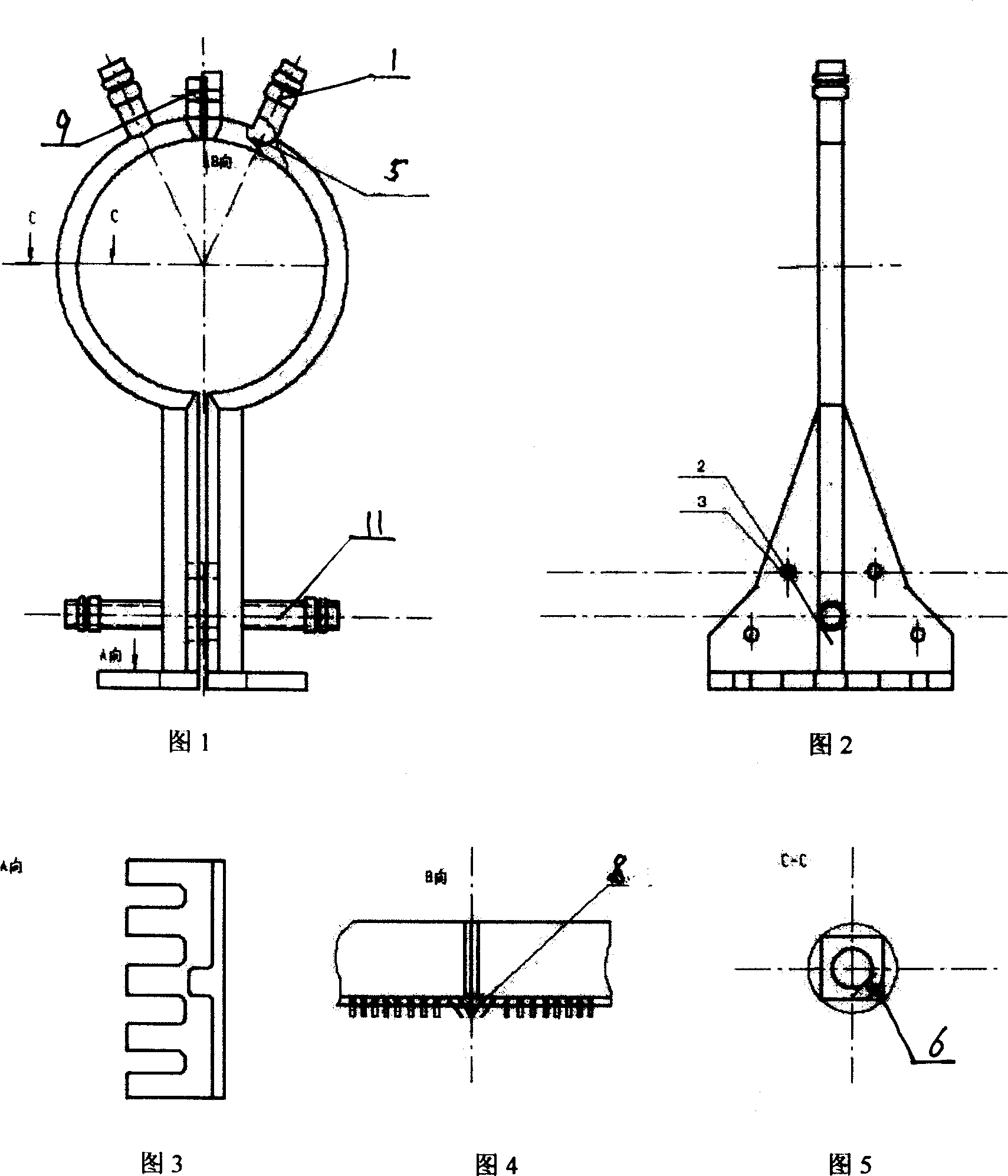

Gear synchronous quenching device

PendingCN110144437AImprove quenching efficiencyTimely heatingFurnace typesIncreasing energy efficiencyEngineeringQuenching

The invention discloses a gear synchronous quenching device. The device comprises a quenching power supply extension machine, an annular sensor and a clamping tooling used for clamping to-be-quenchedgears. The annular sensor is fixed to the quenching power supply extension machine and connected with a quenching power supply extension machine output power supply. A lifting mechanism is arranged atthe lower end of the quenching power supply extension machine. An annular water pouring ring is arranged at the lower end of the annular sensor and fixed to the outer wall of the quenching power supply extension machine. A plurality of water pouring nozzles are formed in the inner wall of the annular water pouring ring. The clamping tooling comprises a rotating turntable and self-rotating toolingbodies uniformly arranged on the rotating turntable along a rotating turntable rotary shaft. The to-be-measured gears are mounted on the self-rotating tooling bodies correspondingly and driven by theself-rotating tooling bodies to rotate. The to-be-measured gears are heated uniformly through heating of the annular sensor, residual stress produced due to non-uniform heating of the to-be-measuredgears is prevented, meanwhile, the to-be-measured gears are quenched by means of the annular water pouring ring, quenching can be performed in time, deformation produced because of the long time duration between part heating and quenching, and the gear synchronous quenching device is simple in structure and can be used for greatly improving the gear quenching efficiency.

Owner:西安北辰亿科电子科技有限公司

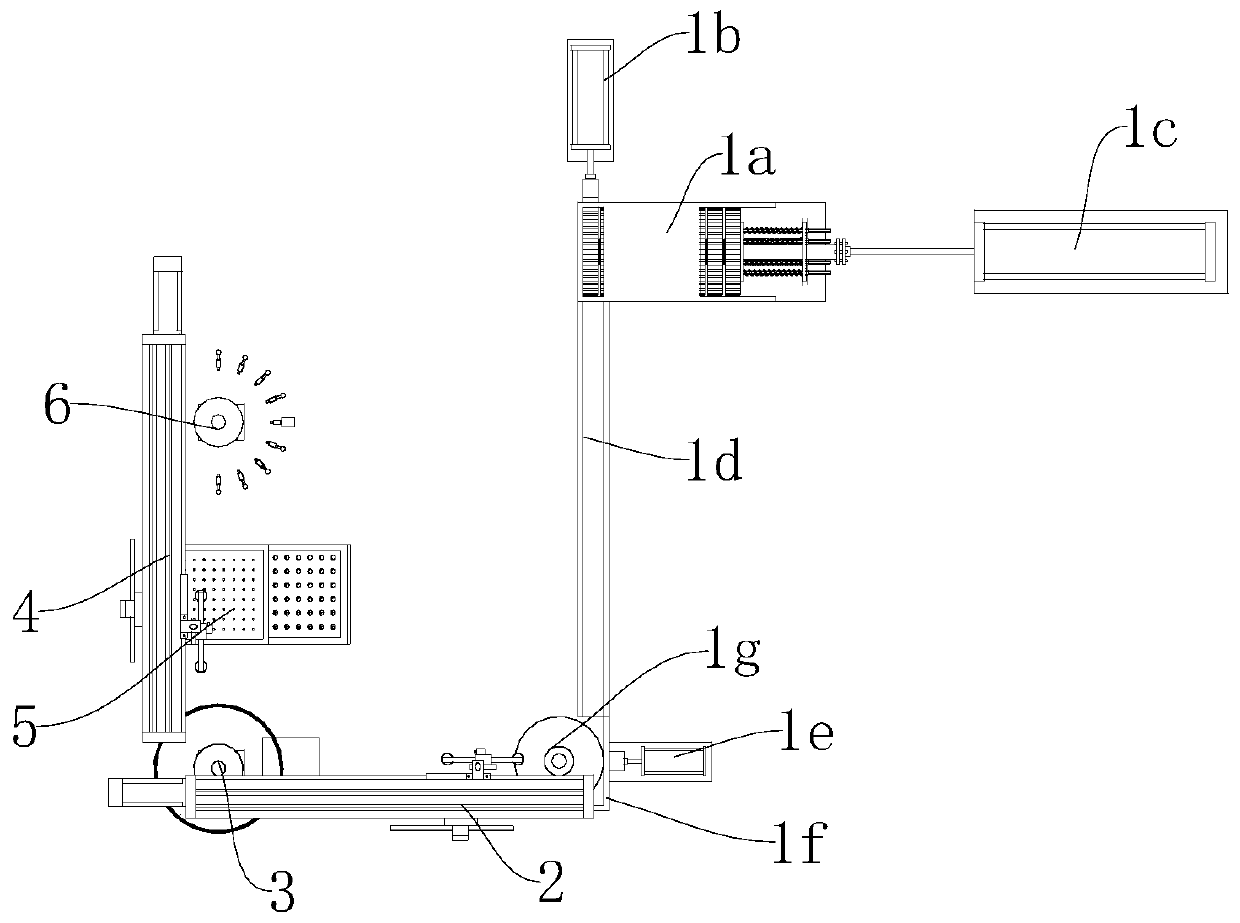

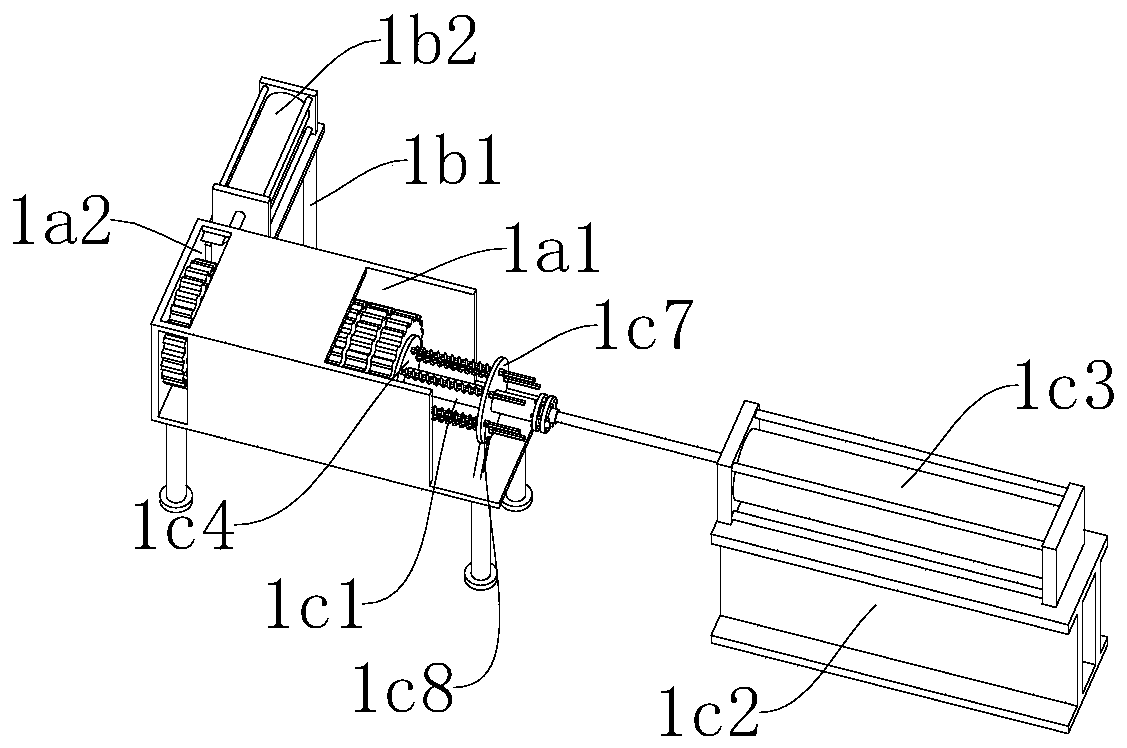

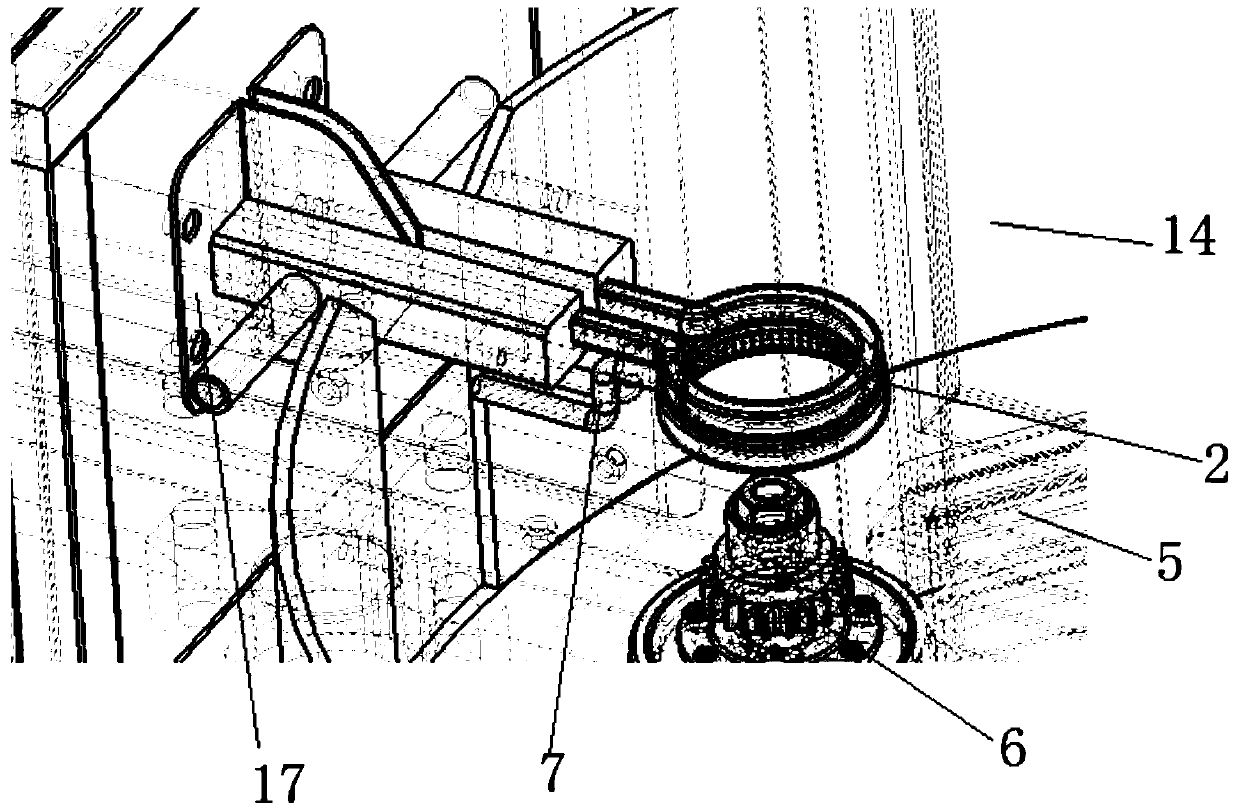

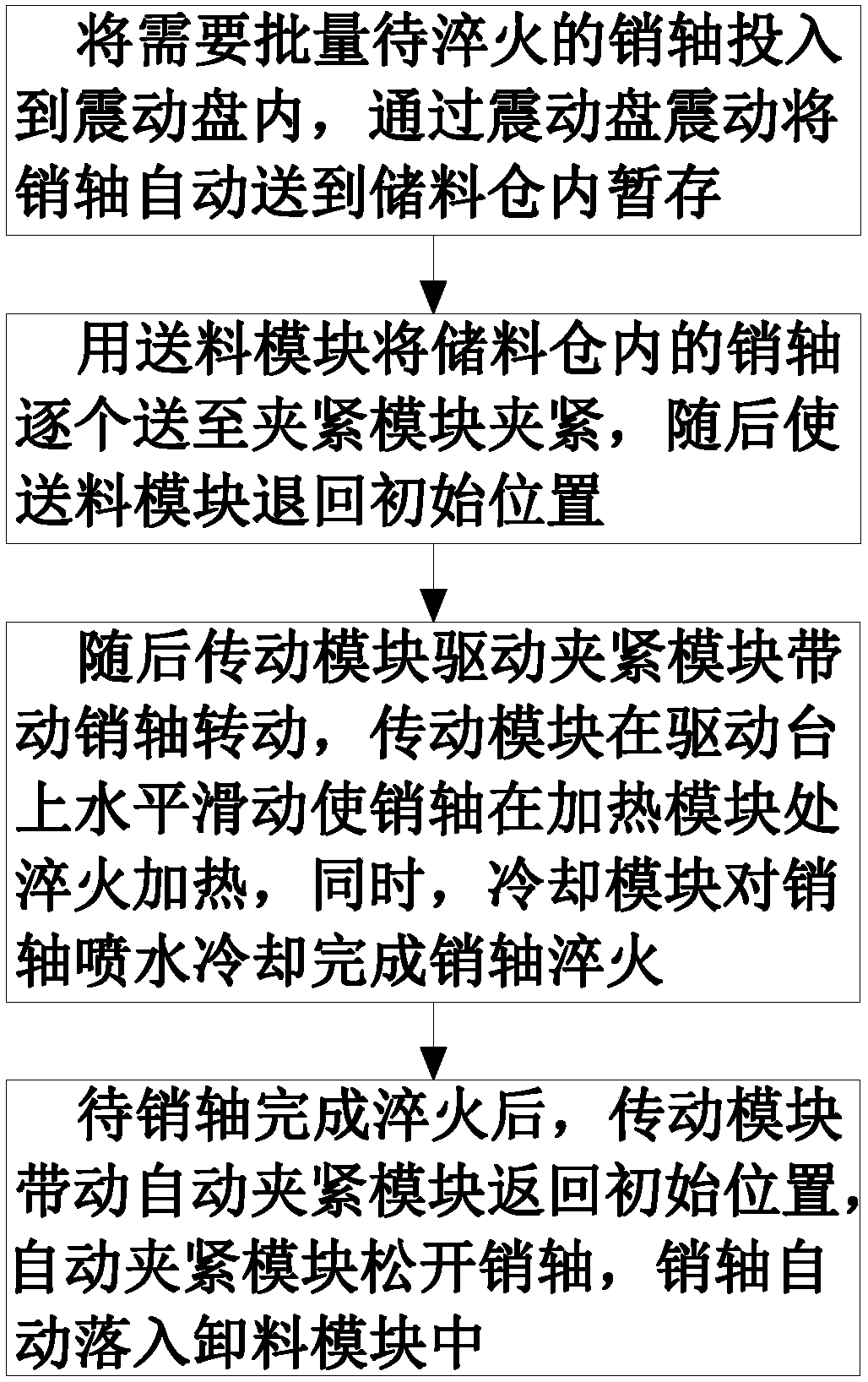

Pin shaft quenching method

ActiveCN108531704AImprove quenching efficiencyContinuous and stable deliveryIncreasing energy efficiencyFurnace typesQuenchingHeat treated

The invention relates to the technical field of pin shaft heat treatment, in particular to a pin shaft quenching method. The pin shaft quenching method comprises the following steps that to-be-quenched pin shafts are put into a storage bin to be temporarily stored, the pin shafts in the storage bin are fed to a clamping module to be clamped one by one through a feeding module, and then the feedingmodule returns back to the initial position; and a transmission module drives the clamping module to drive the pin shafts to rotate, the transmission module horizontally slides on a driving platformto enable the pin shafts to be quenched and heated at a heating module, at the same time, a cooling module sprays water to cool the pin shafts, pin shaft quenching is completed, the transmission module drives the automatic clamping module to return to the initial position, the automatic clamping module loosens the pin shafts, and the pin shafts automatically fall into a discharging module. According to the pin shaft quenching method, the pin shaft quenching method is improved through an automatic induction pin shaft quenching machine, therefore, full automation is achieved in the pin shaft quenching process, manual operation is not needed, and the pin shaft quenching efficiency and the pin shaft overall quality are improved.

Owner:ANHUI JIXI HUISHAN CHAIN TRANSMISSION

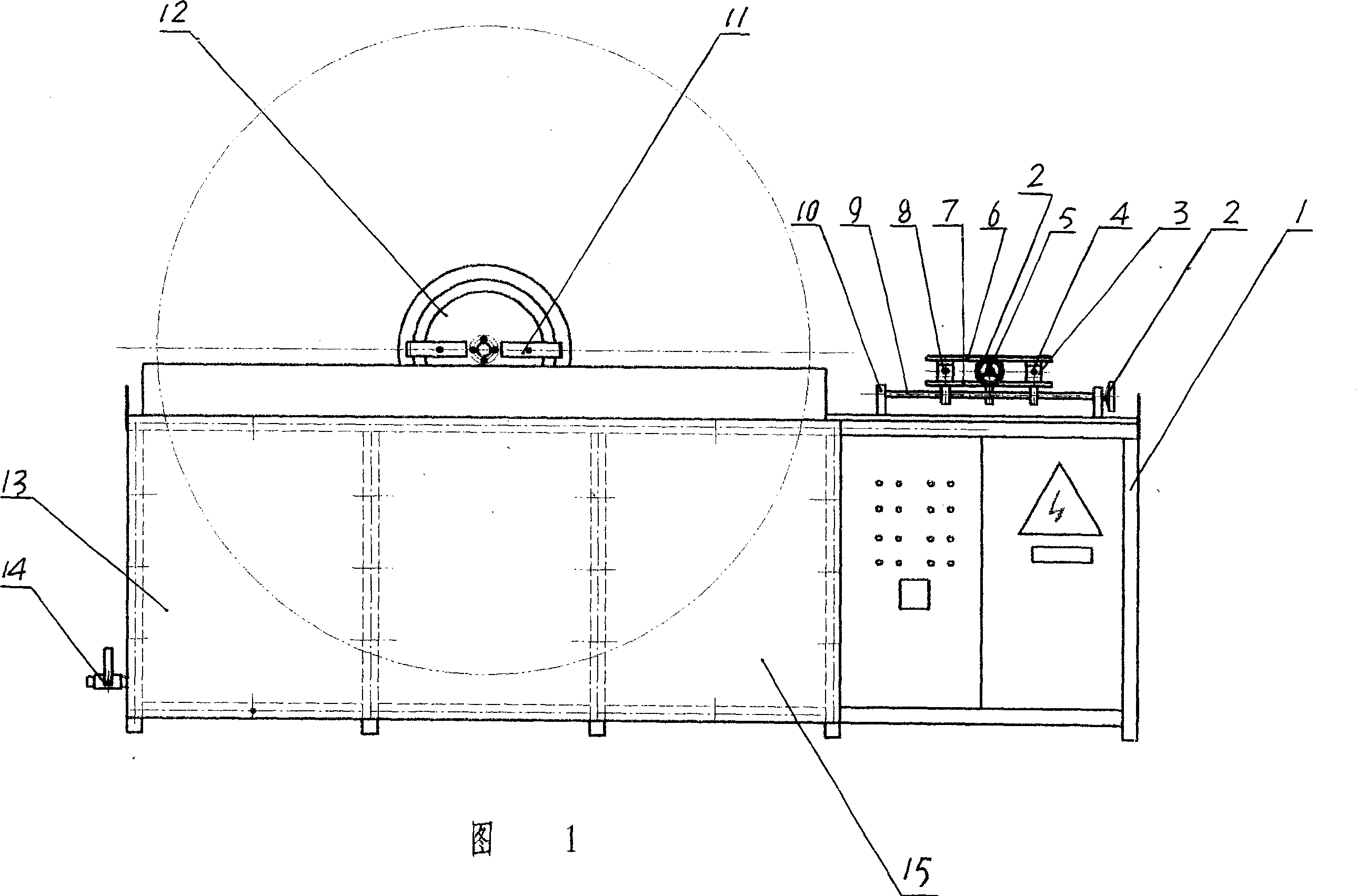

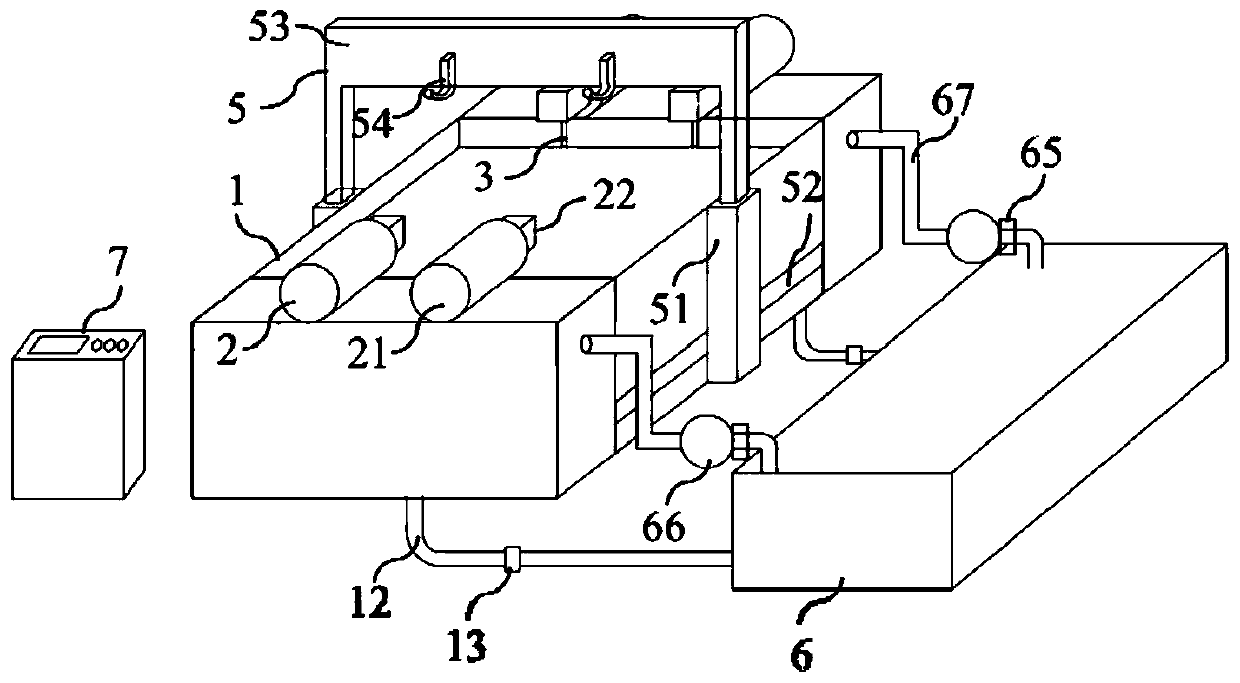

Saw blade quenching machine

InactiveCN1912151AReasonable structureEasy to useFurnace typesHeat treatment furnacesAgricultural engineeringWater resources

The invention relates to a saw disc movable quenching machine which belongs to saw blade heat-treating mechanism. Its features are that the integral combination type engine base has tank structure which is made up of main water tank, quenching water tank, circulating water tank and electric cabinet; the middle of upper cover plate of the main water tank is orderly set electromotor, cycloidal-pin gear speed reducer, plain bearing housing, and saw blade dead plate from the back to front; the upper cover plate of the electric cabinet is zoom type spaying frame whose mounting plate is set cooling water nozzle, flame thrower nozzle, and high pressure air nozzle; the circulating water circuit is set between the quenching water tank and the circulating water tank, main water tank and circulating tank; the electric cabinet is set computer plate to control the corresponding operation. Thus it has the advantages of safe, saving water resource, and lowering the cost.

Owner:权岚

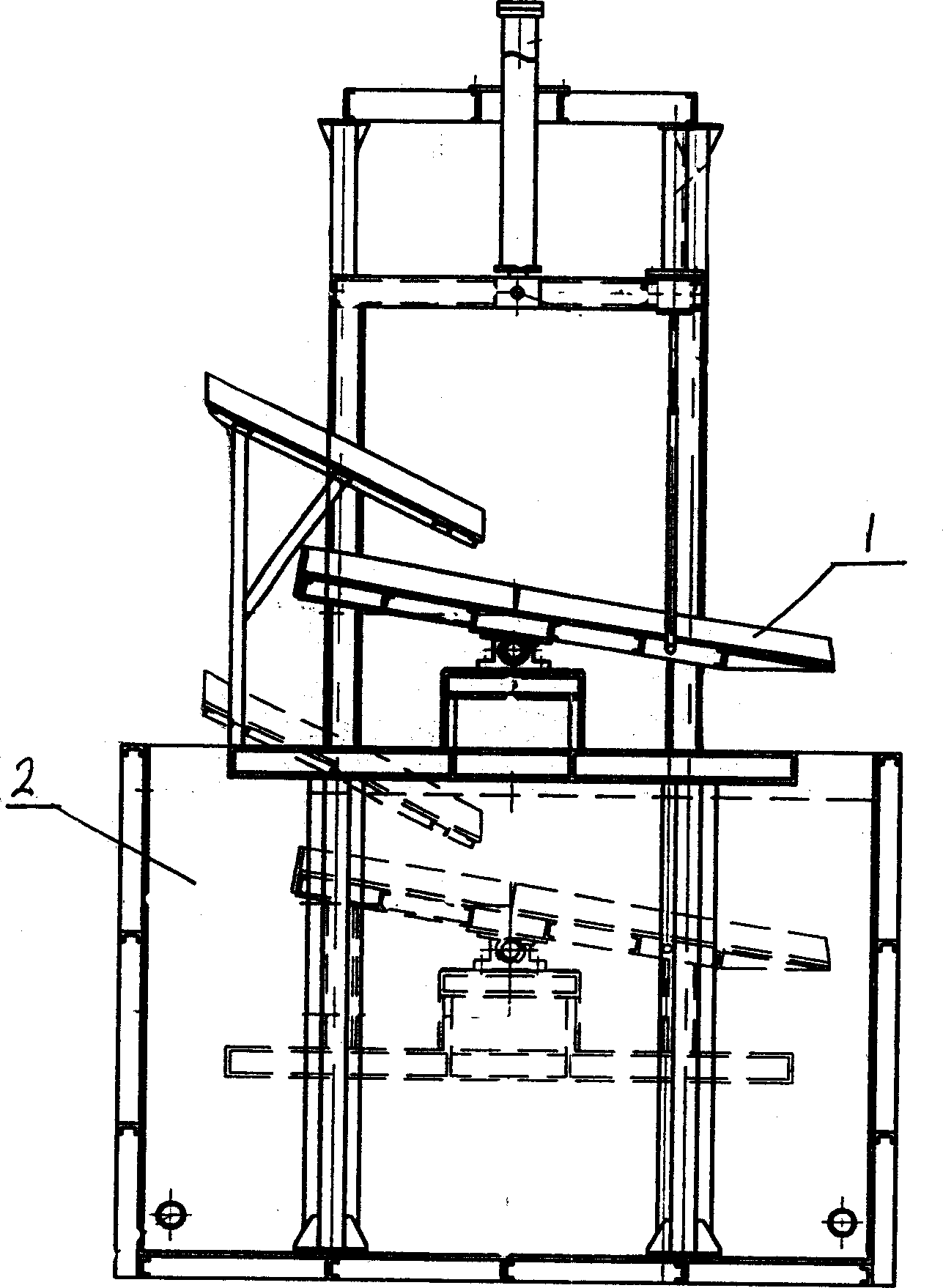

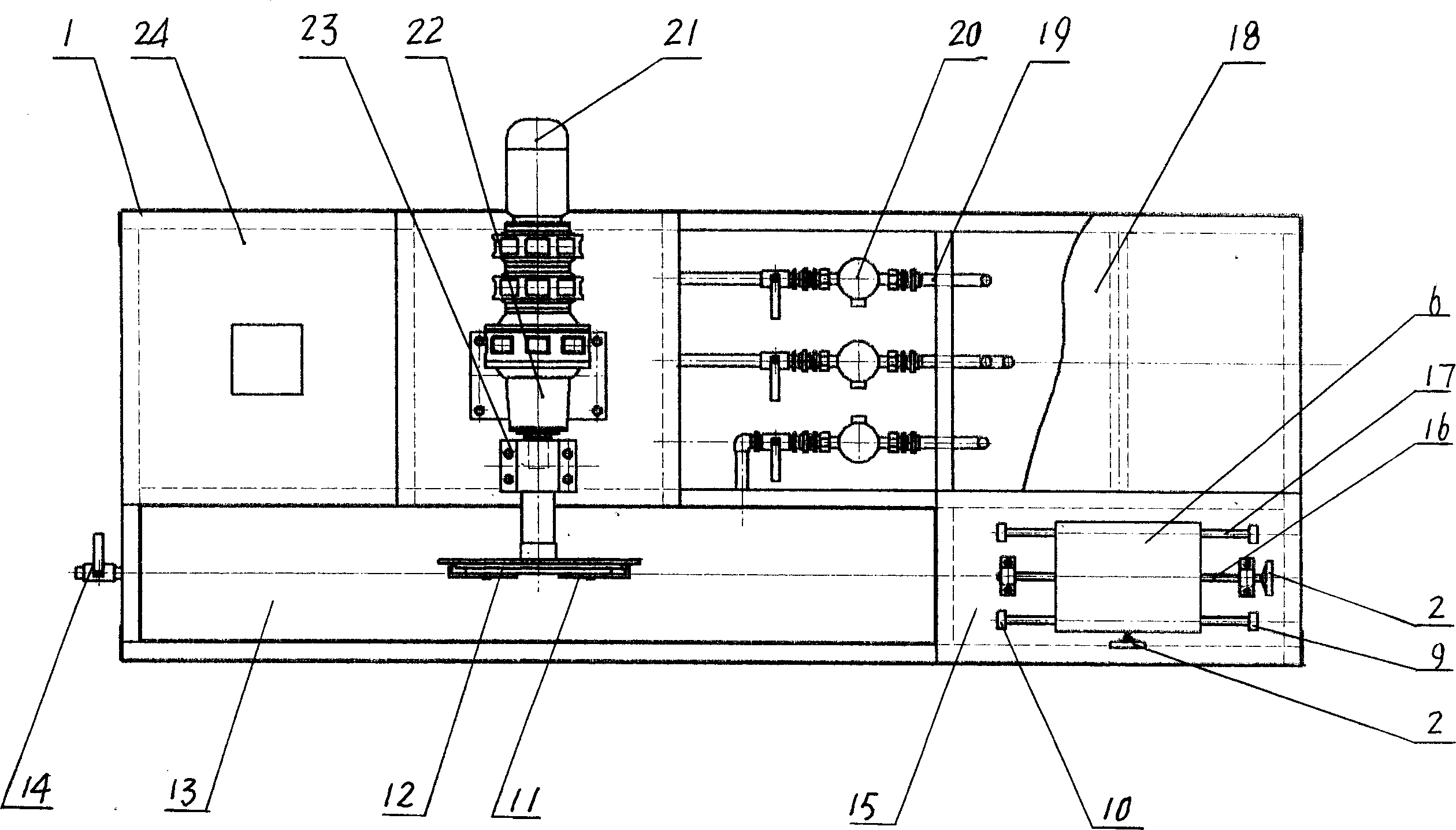

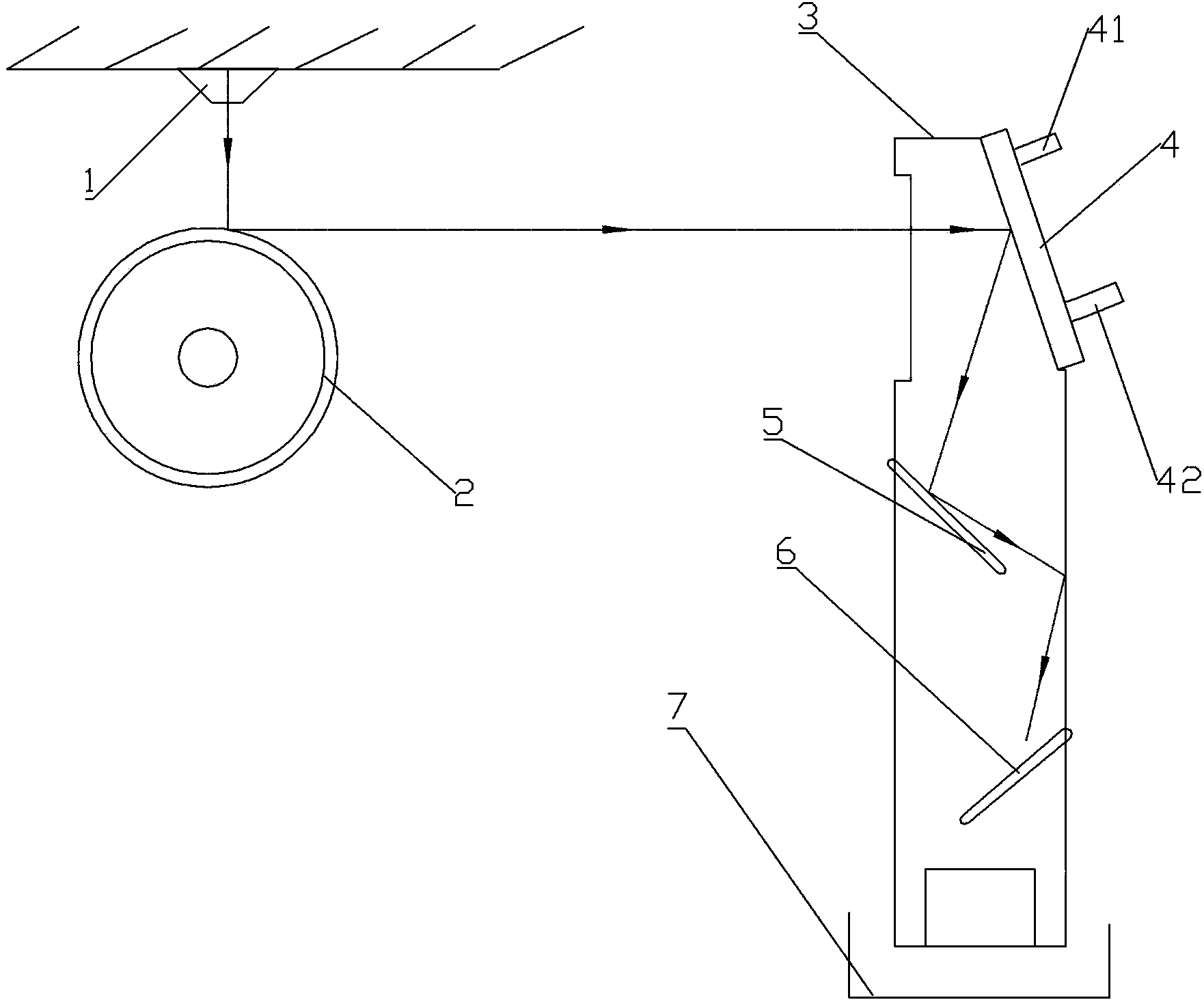

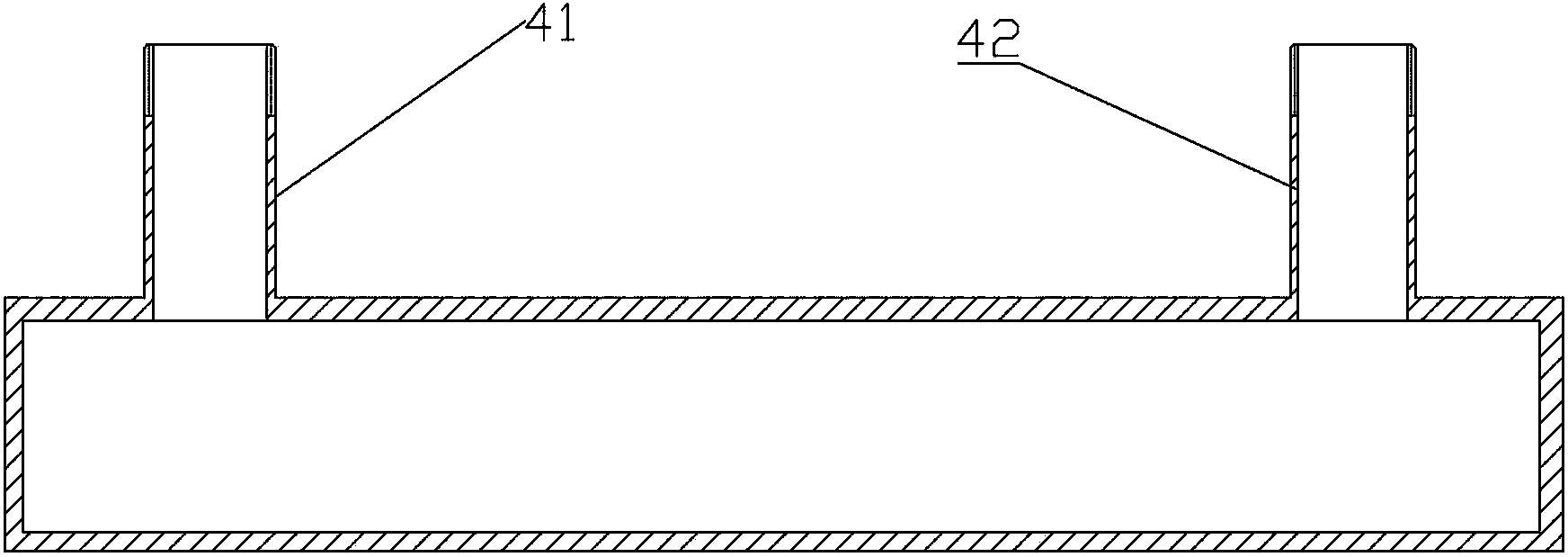

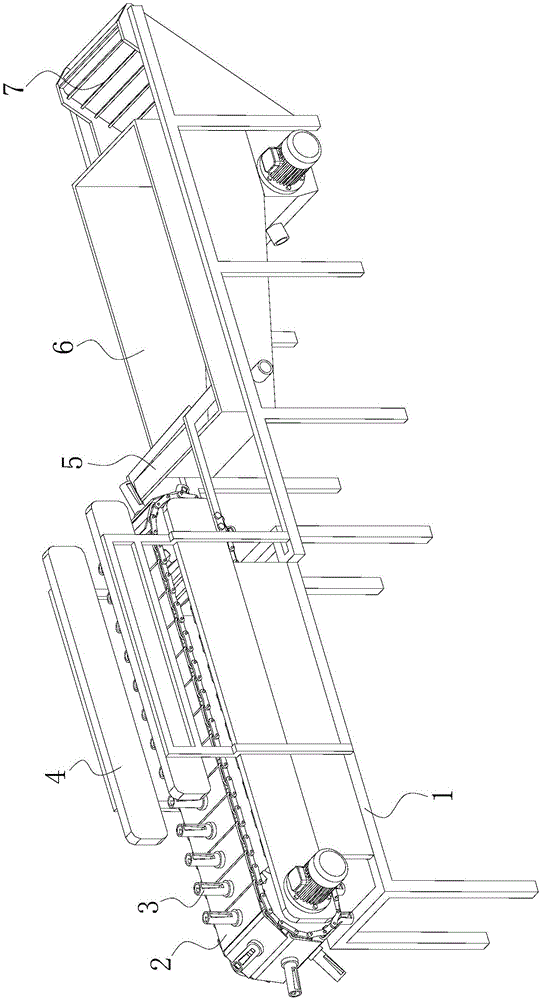

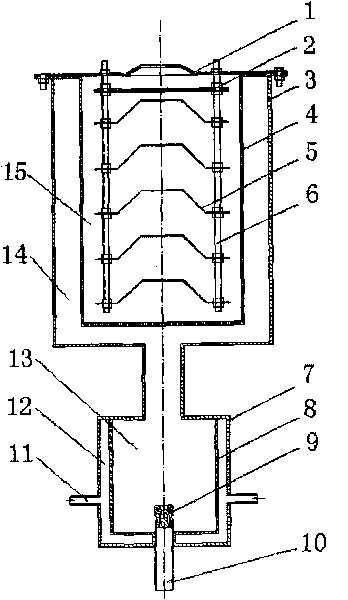

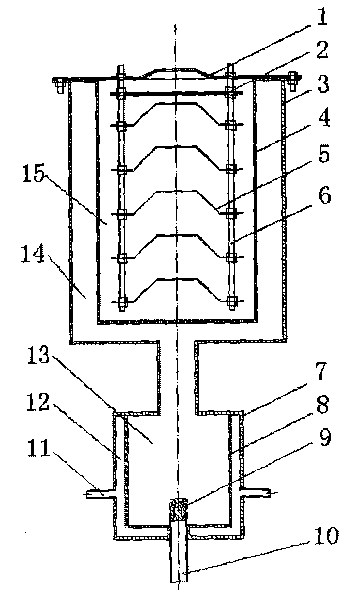

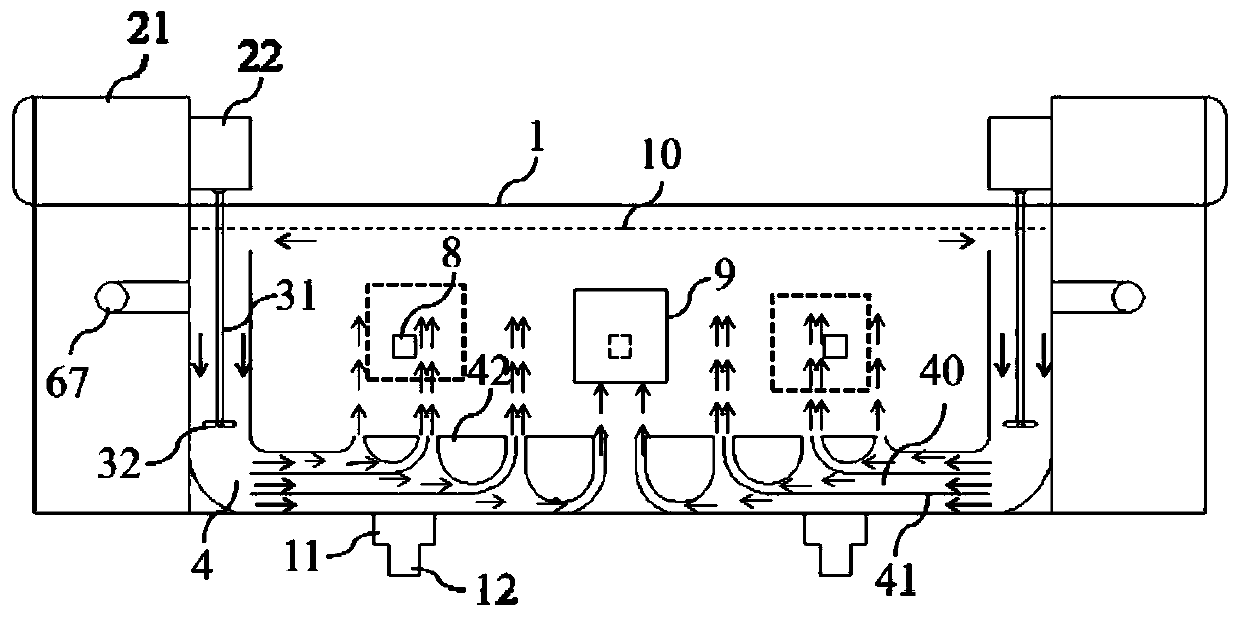

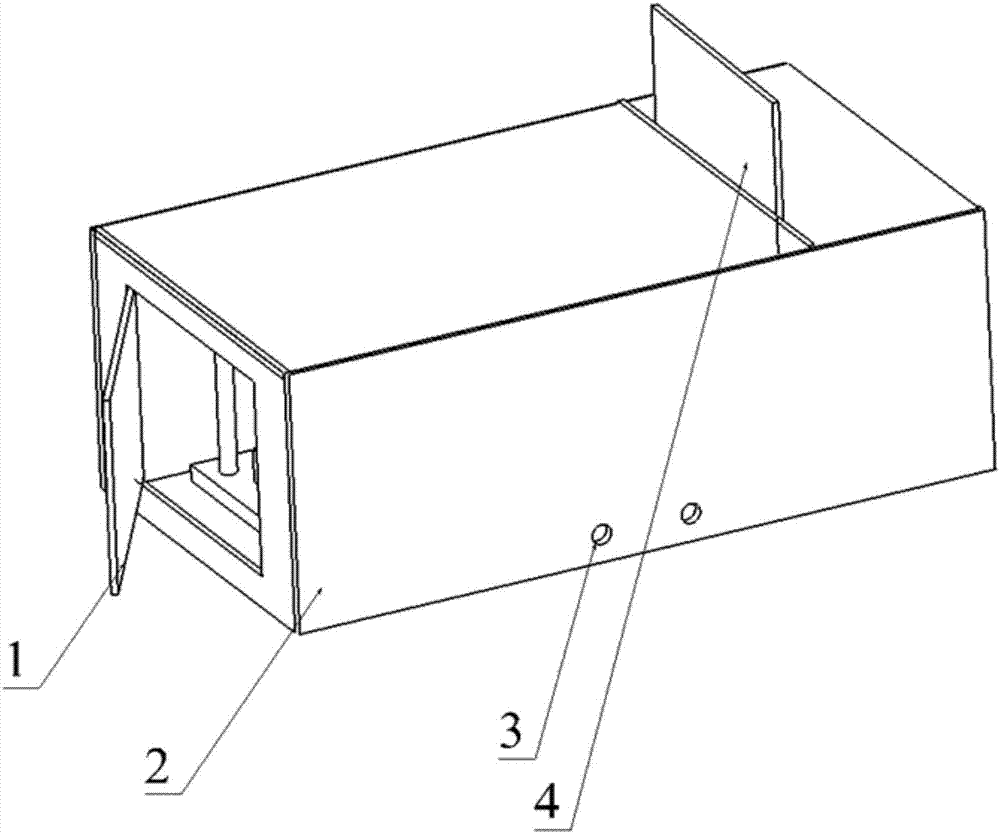

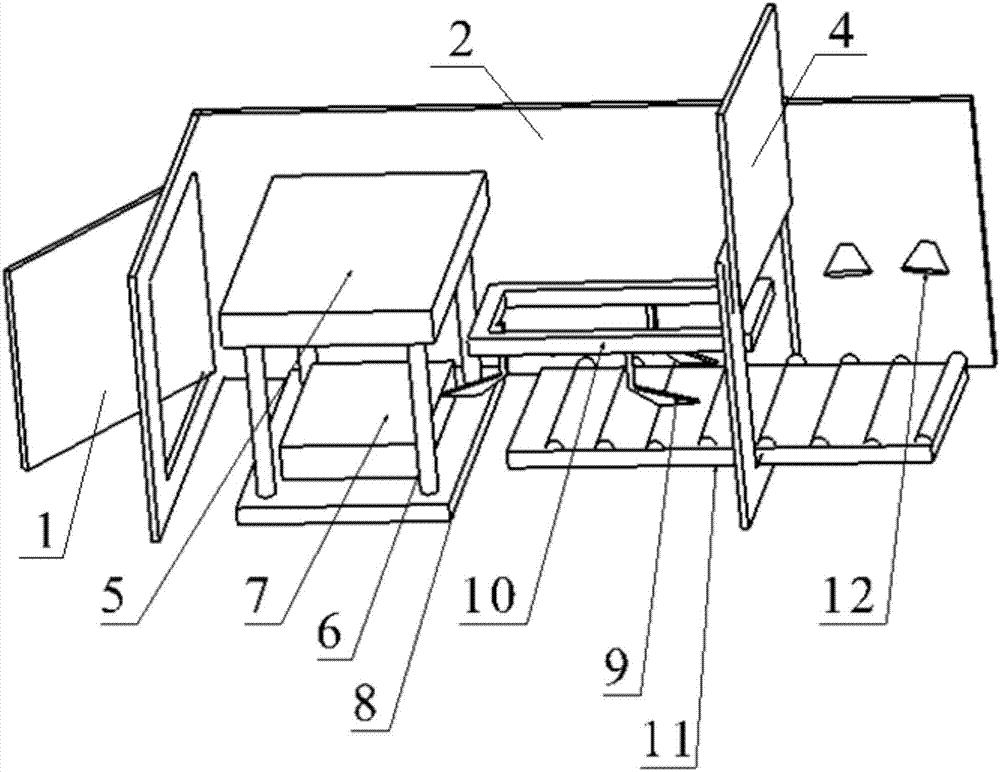

Multistage quenching process and equipment for NdFeB (neodymium iron boron) magnetic powder production

InactiveCN103817338AHigh main phase contentIncrease the main phase contentStationary conduit assembliesMagnetic materialsAtmospheric pressureQuenching

The invention discloses a multistage quenching process and multistage quenching equipment for NdFeB (neodymium iron boron) magnetic powder production, which mainly solve the technical problems that the quenching of the existing quenching device is not thorough, the quenching speed is slow, and the like. The key point of the technical scheme is that a nozzle (1) is used for ejecting supplied materials to a molybdenum wheel (2), the rotary molybdenum wheel (2) continually throws the supplied materials which are ejected from the upward side to form a high-temperature melt-spinning sheet, the high-temperature melt-spinning sheet is thrown into a charging basket (3), after the high-temperature melt-spinning sheet is thrown into the charging basket (3), the high-temperature melt-spinning sheet is stopped by a first-grade cooling plate (4) to be folded to the slanting downward side, first-grade quenching is completed, the high-temperature melt-spinning sheet is reflected from the first-grade cooling plate (4) to a second-grade cooling plate (5) to complete second-grade quenching, the high-temperature melt-spinning sheet is reflected from the inner wall of the charging basket (3) to a third-grade cooling plate (6) to complete three-grade quenching, and then flows to a nether vibrating screen (7) from a discharge hole, the high-temperature melt-spinning sheet is vibrated into a finished product gathering tank by the vibrating screen (7), the overall process of the quenching is carried out in a sealed environment which is full of inert gas, and the air pressure is kept at 2200 Pa. The multistage quenching process and the multistage quenching equipment for NdFeB magnetic powder production are mainly used for multistage rapid quenching.

Owner:湖南京湘磁业有限公司

Safe and efficient quenching device for workpieces

InactiveCN107974537AIncrease jitterEasy to viewHeat treatment process controlQuenching devicesEngineeringDrainage tubes

The invention discloses a safe and efficient quenching device for workpieces. The safe and efficient quenching device comprises a guide wheel, a box body, a vibration exciter, a cooler, a box body, aliquid drainage tube, a thermometer, a timer, a bottom plate, a spring, a solvent adding tube, a liquid level meter, a fan, a mesh basket and a condensing chamber, wherein the guide wheel is arrangedon the bottom surface of the box body; the cooler is arranged on the inner wall of the box body; the side wall of the upper end of the box body is equipped with the solvent adding tube and the liquidlevel meter; the mesh basket is arranged in the box body; a telescopic pole is arranged on the mesh basket; the top end of the telescopic pole is connected with the side wall of the top end of the boxbody through a hanger; the lower surface of the mesh basket is fixedly equipped with the vibration exciter; the bottom plate is arranged in the mesh basket; the bottom plate is connected with the bottom end inside the mesh basket through the spring; the fan is arranged on the inner wall of the upper part of the box body; a camera is arranged on the inner wall of the box body; and the condensing chamber communicates with the top end of the box body through a gas conveying tube. The safe and efficient quenching device guarantees accuracy of a casting process, avoids resource waste, quickly clears water mists, guarantees safety, improves working efficiency, is simple in structure, is convenient to use, and is beneficial for popularization.

Owner:ZHENGZHOU CHENGHE INFORMATION TECH CO LTD

Bolt quenching production line

InactiveCN105018689AFast positioningReasonable structural designFurnace typesHeat treatment furnacesProduction lineMaterial resources

The invention discloses a bolt quenching production line. The bolt quenching production line comprises a support frame, wherein a conveying belt is mounted at the upper end of the support frame; bolt fixed bases are uniformly mounted on the conveying belt; heating devices are respectively arranged at the front and back sides of the conveying belt; an unloading plate is fixed at the right end of the conveying belt through a bolt connecting mode; a cooling pool is arranged at the right lower side of the unloading plate; and a scraper plate type elevator is arranged at the bottom of the cooling pool. The bolt quenching production line has such advantages as reasonable structure design and convenience for use, can automatically quench bolts and replace the manual carrying, is high in automation degree, improves the quenching efficiency, saves both manpower and material resources, and adopts the design of the bolt fixed bases to effectively accelerate the bolt positioning speed and to improve the production efficiency.

Owner:安徽旭虹机械设备有限公司

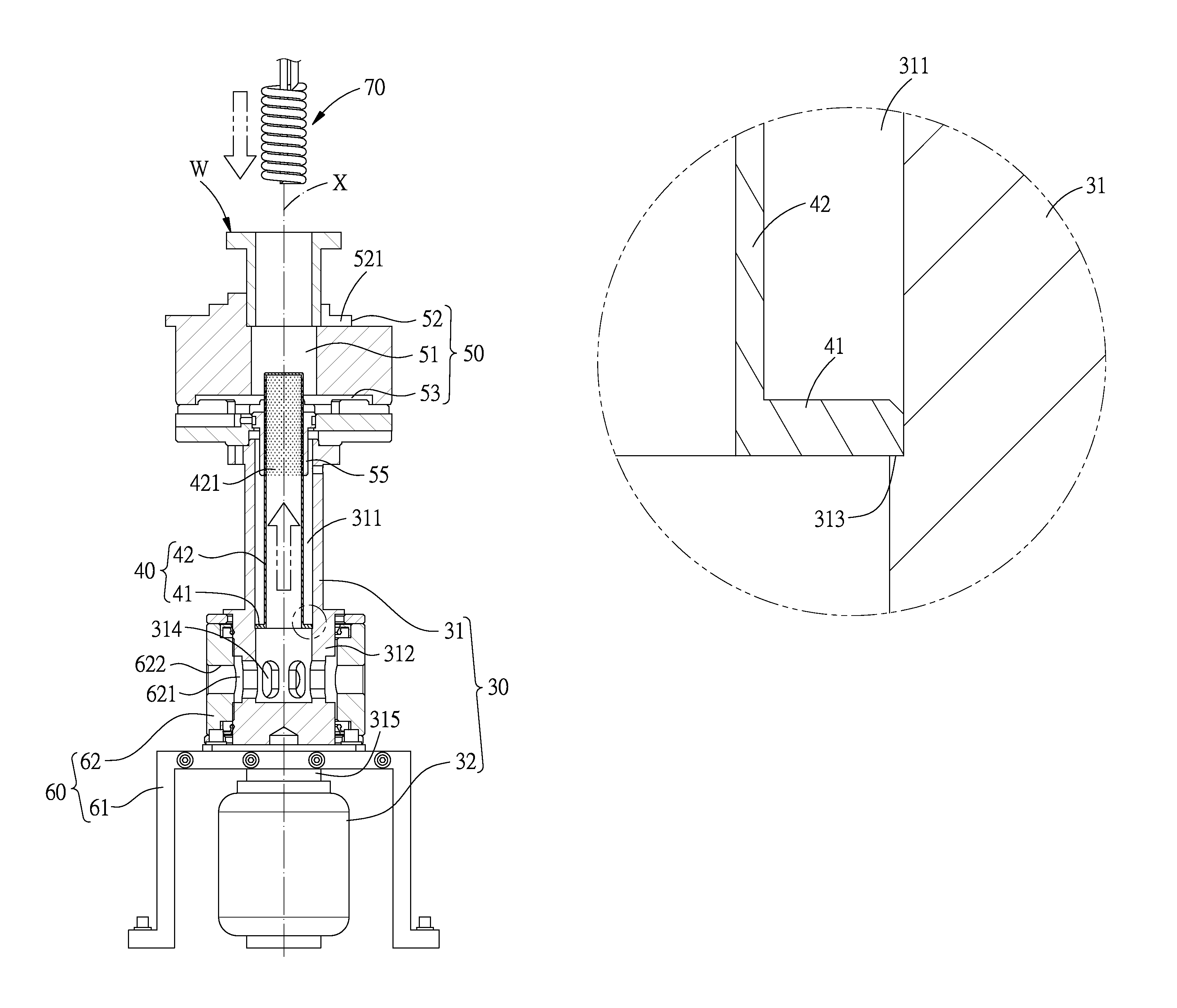

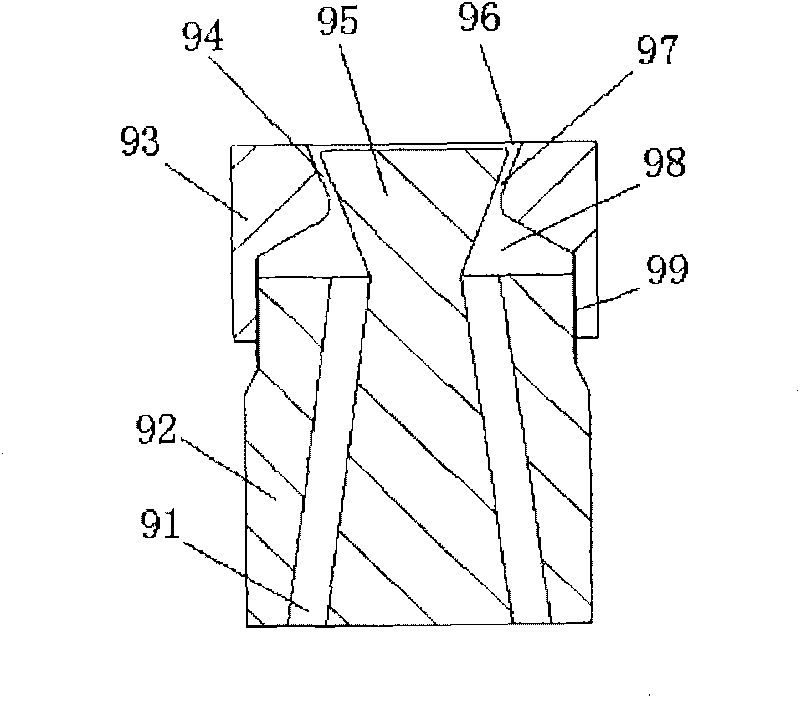

Inner-Diameter Quenching Device

ActiveUS20140251391A1Small sizeImprove quenching effectCleaning using liquidsQuenching devicesQuenchingEngineering

An inner-diameter quenching device is provided with a workpiece holding assembly for holding a workpiece to be quenched, a spray cylinder, and a heating coil. The workpiece has a central axis. The spray cylinder is disposed at a first side of the workpiece holding assembly and driven by a lifting assembly to move along the central axis into an inner diameter of the workpiece. The heating coil is disposed at a second side of the workpiece holding assembly and located on and movable along the central axis. The heating coil and the spray cylinder are separated and movable in opposite directions along the same center axis, which can further reduce the size of the quenching device, making it suitable for quenching a small inner-diameter workpiece. Besides, the spray apertures are inclined, so that the cooling liquid can be sprayed out more easily to enhance the quenching effect.

Owner:HIWIN TECH

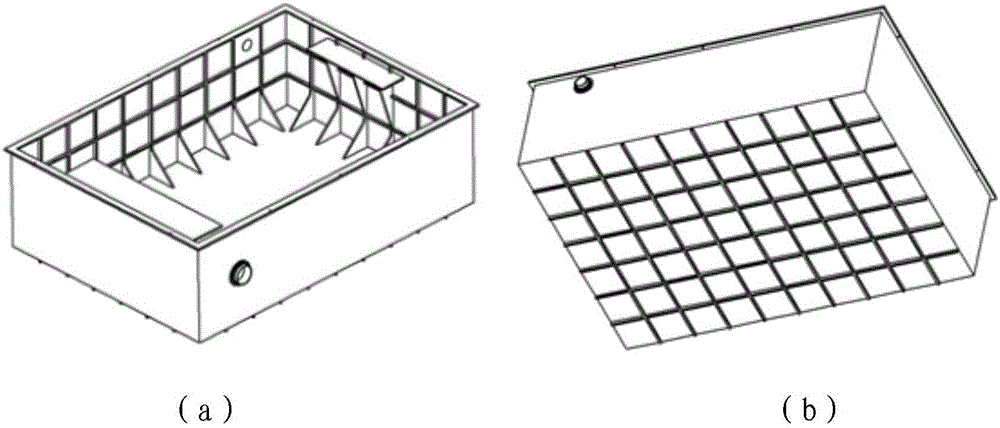

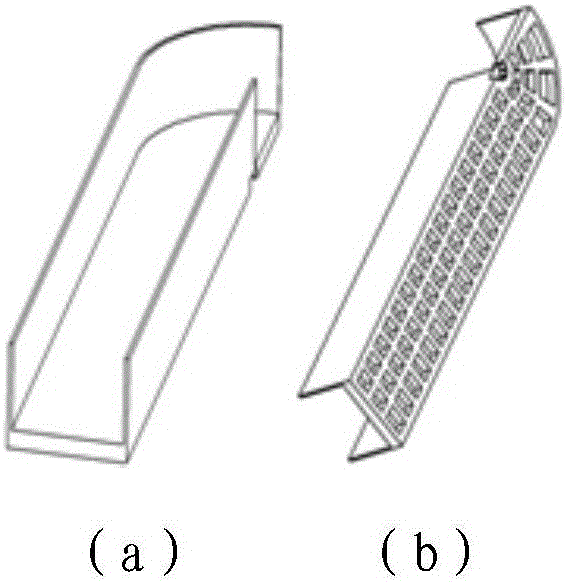

Atomization gas quenching device

InactiveCN101709360AReduce defectsUniform compositionQuenching agentsQuenching devicesLiquid mediumProduct gas

The invention provides an atomization gas quenching device, comprising a quenching box body which is provided with a cover at the top and is internally provided with an internal cylinder with holes, current collectors and carrier netting pieces are fixed in the internal cylinder at interval by supporting rods; the atomization gas quenching device is characterized in that: the atomization gas quenching device comprises an atomization box which is connected with the quenching box, the atomization box comprises an outer box body which is provided with a gas inlet and a liquid outlet, and an inner cylinder which is arranged in the outer box body and is provided with holes on the wall and is internally provided with a cavity, the liquid inlet on the box body is extended in the inner cylinder, and a nozzle is arranged on the inner end opening; the liquid medium for quenching is atomized in the atomization box through the nozzle and then is mixed with the gas, and then the atomized gas and the liquid mixed medium are provided to the quenching box, so as to improve the quenching efficiency, ensure the quenching quality and eliminate the defects on the surface of the parts; the structure is simple, the usage is convenient, the atomization effect is good, the ingredients are uniform, and the water and gas feeding can be controlled respectively, and the content ratio of the atomization composition ca be easily adjusted, so as to meet the atomization requirements of different workpieces.

Owner:KUNMING UNIV OF SCI & TECH

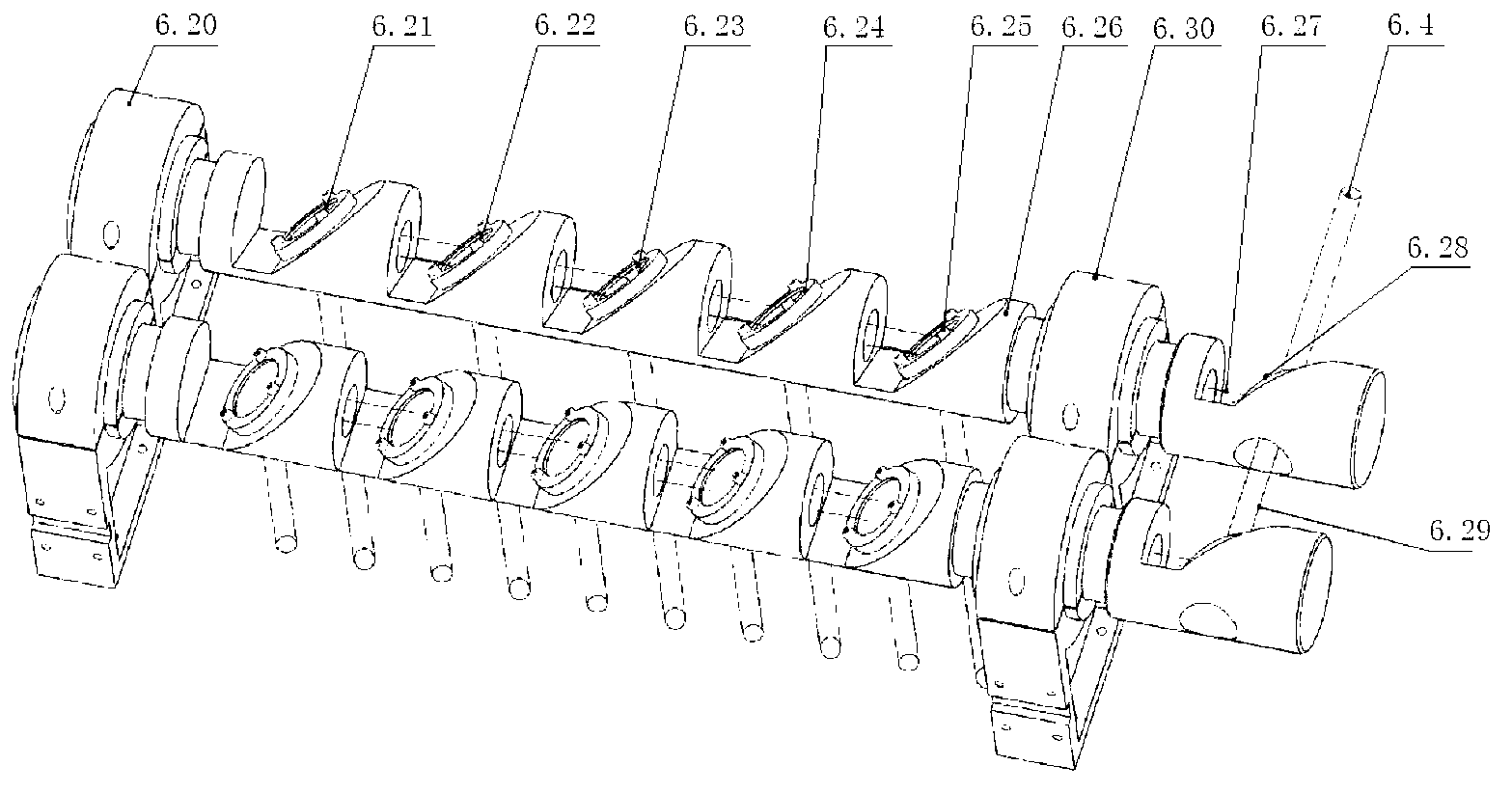

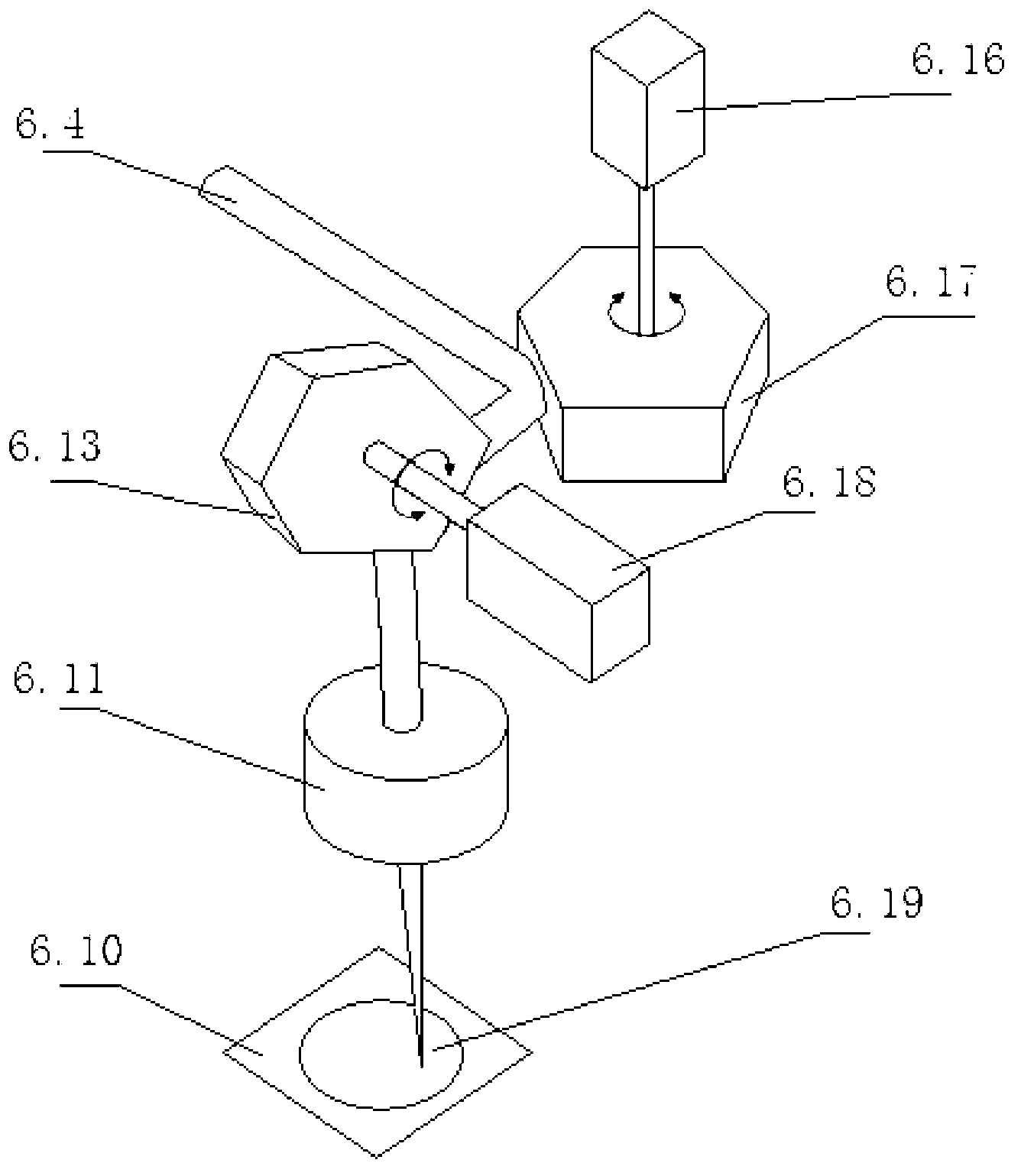

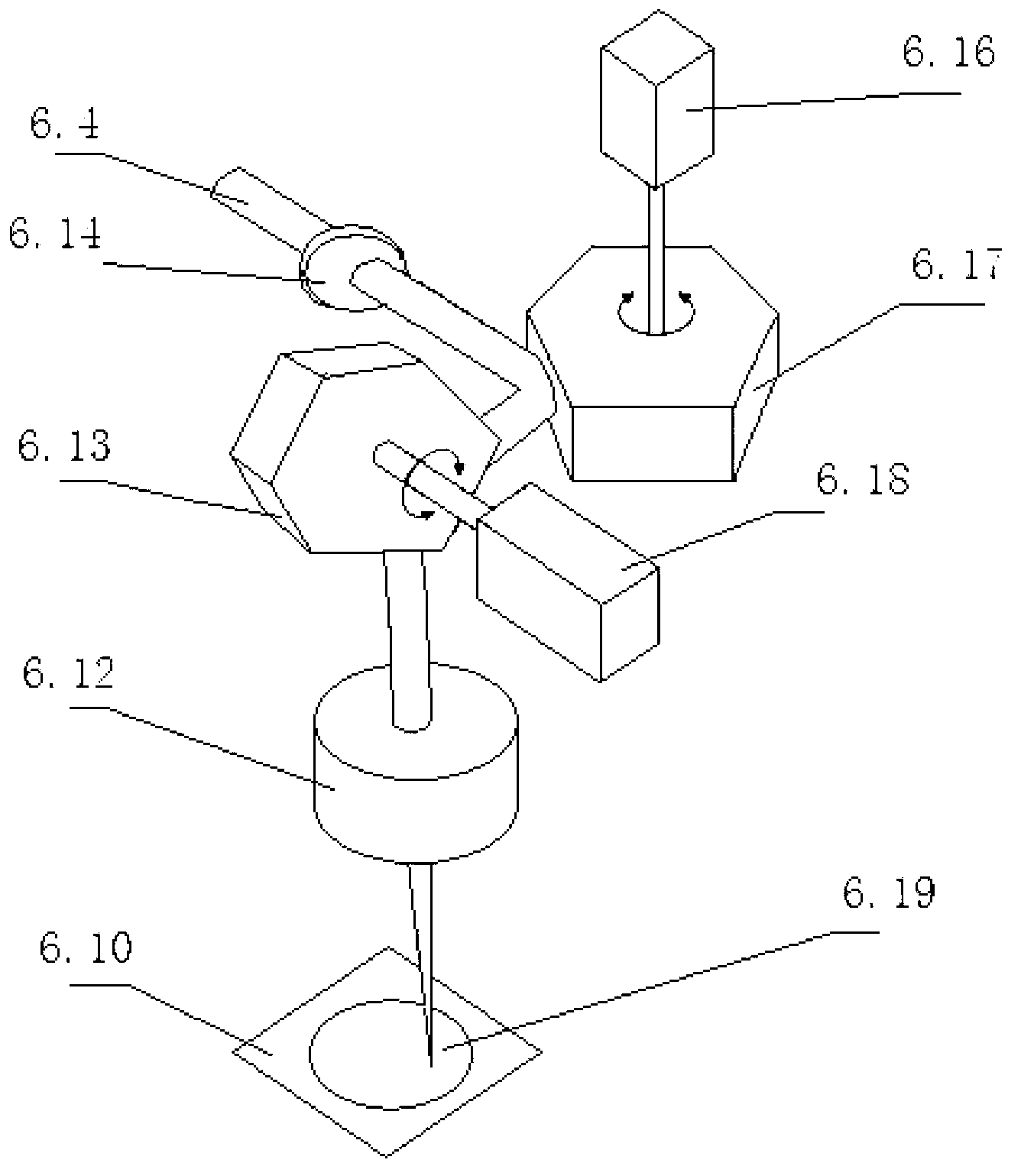

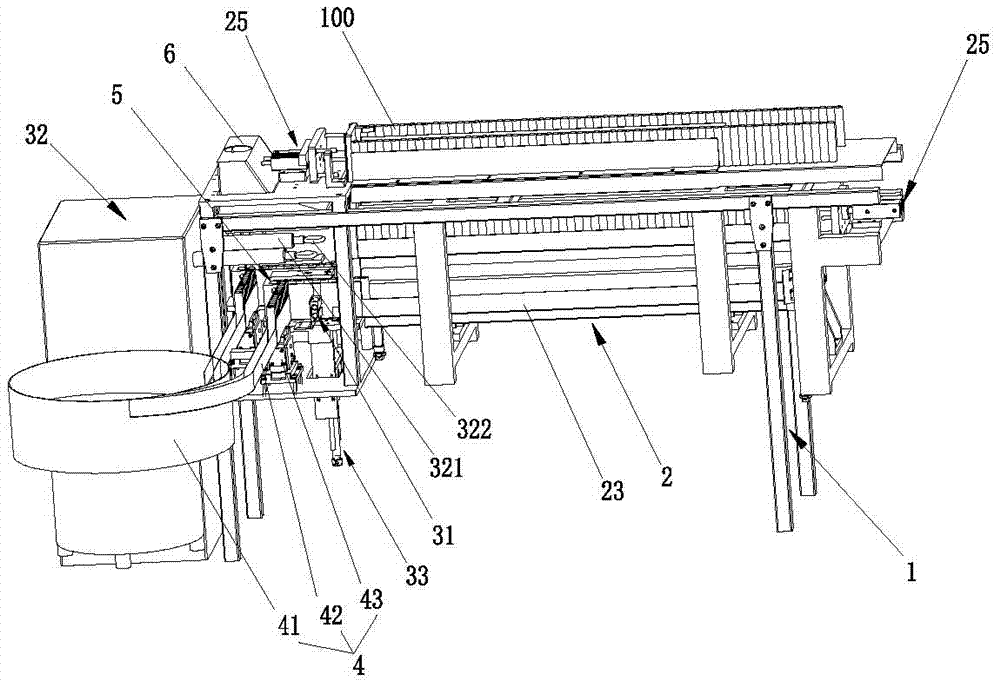

Drum device for online continuous quenching of inclined rolled steel balls

ActiveCN105671294AEnergy savingIncrease productivityFurnace typesHeat treatment furnacesQuenchingVariable frequency control

The invention discloses a drum device for online continuous quenching of inclined rolled steel balls. The drum device comprises a water tank, a variable frequency control motor, a speed reducer, a chain wheel mechanism, a ball inlet chute, a conical ball inlet drum, a columnar quenching drum, a conical ball outlet drum, a ball outlet chute, a chute bracket, a bearing base, a rotating shaft and a four-jaw spoke; the conical ball inlet drum is used for smoothly leading large-diameter steel balls, introduced by the ball inlet chute, into the columnar quenching drum; the columnar quenching drum is used for realizing spiral feeding and quenching functions of the steel balls; and the conical ball outlet drum is driven by the rotating shaft to rotate to realize the purposes of fishing the quenched steel balls and pouring the steel balls in the ball outlet chute. The drum device has the following beneficial effects: for the steel balls, with diameters of 50-65 mm, molded through high-temperature inclined rolling, the online continuous quenching is performed, so that the energy is saved, the quenching time is precisely controlled, and the quality of the steel balls is improved; and the drum device is high in quenching efficiency, stable in process, low in noise and high in automation degree, and can satisfy the large-batch continuous quenching requirement of the steel balls.

Owner:UNIV OF SCI & TECH BEIJING

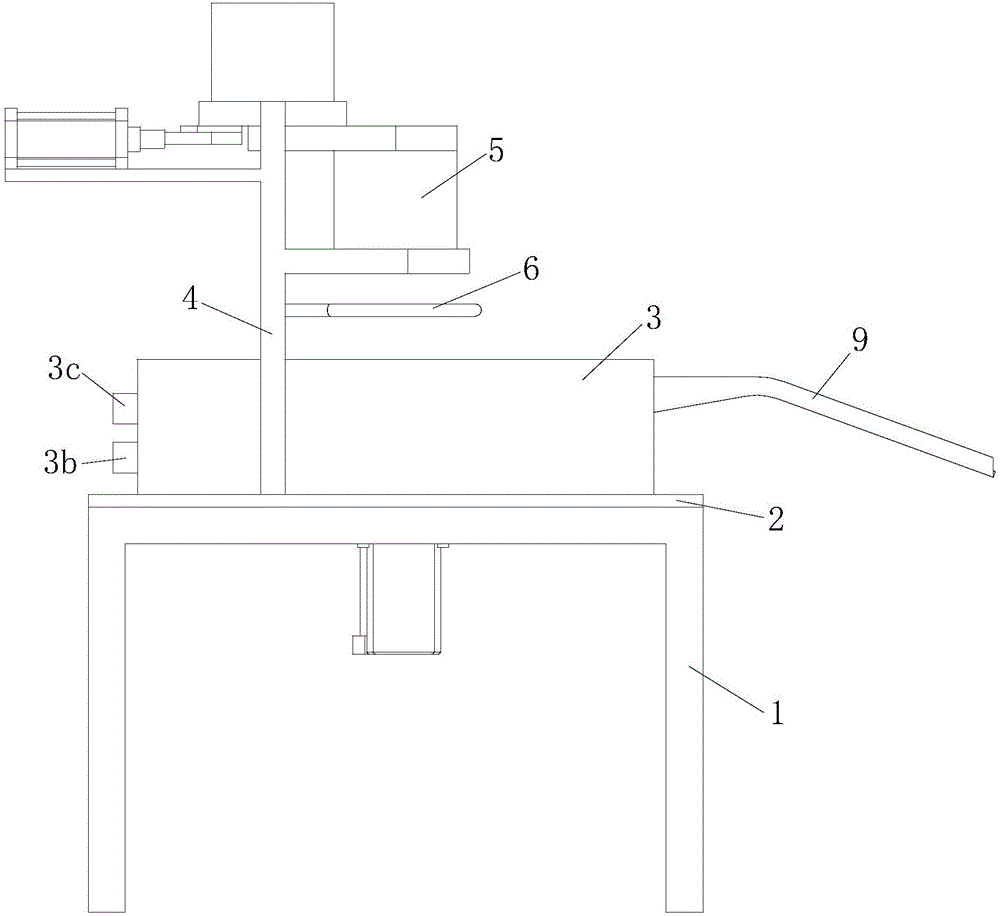

Automatic quenching machine

ActiveCN107058709AImprove quenching efficiencyGuaranteed positioning accuracyFurnace typesProcess efficiency improvementRejection rateQuenching

The invention relates to the technical field of quenching equipment, in particular to an automatic quenching machine. The automatic quenching machine comprises a rack, a feeding device, a first material pushing mechanism arranged at the discharging end of the feeding device, a material positioning mechanism for positioning of materials in the first material pushing mechanism, a material lifting mechanism for rising and falling of the positioned materials, a heating device for heating the lifted materials and a cooling device for cooling the heated materials. The cooling device is mounted on the rack, and the discharging end of the first material pushing mechanism communicates with the feeding end of the cooling device. According to the automatic quenching machine, automatic feeding, positioning, heating, cooling and outputting of pipe pieces are achieved, quenching efficiency of the pipe pieces is improved, the labor intensity of workers is relieved, the personal safety of the workers is improved, the position accuracy of the pipe pieces is ensured, the quenching quality of the pipe pieces is improved, the rejection rate of the quenched pipe pieces is decreased, and production cost is reduced.

Owner:东莞乌佩克自动化工程技术有限公司

Quenching system and method for box-type workpieces

PendingCN111270054AIncrease infiltration speedSmall footprintFurnace typesHeat treatment furnacesReciprocating motionPropeller

The invention discloses a quenching system and method for box-type workpieces, and belongs to the technical field of heat-treatment quenching equipment. According to the quenching system and method for the box-type workpieces, the quenching system comprises a quenching pool body, a stirring system and a hoisting system capable of hoisting the workpieces back and forth. Stirring devices are symmetrically mounted on the two sides of the interior of the quenching pool body from above. A guide device is arranged between the stirring devices and comprises a plurality of layers of guide plates whichare distributed symmetrically, and a liquid flow in a quenching pool is controlled by means of the thrust of propeller blades in the stirring system and quenching liquid channels formed between the multiple layers of guide plates. A circulating and cooling system is connected to the outside of the quenching pool. When the temperature of a quenching medium is higher than an upper limit of the optimal service temperature, the circulating and cooling system is started to realize circulation and cooling of the quenching liquid.

Owner:马鞍山旭阳机械有限公司

Hot stamping forming equipment

InactiveCN107309343AAvoid oxidation reactionsImprove surface qualityShaping toolsMetal-working feeding devicesHot stampingPunch press

The invention discloses hot stamping forming equipment. The hot stamping forming equipment comprises a box, a punch press and spray heads, wherein the box is provided with an entrance door and an exit door both of which can be opened and closed, an accommodating cavity is defined between the entrance door and the exit door, the wall of the box is provided with air holes communicating with the accommodating cavity, and the air holes are used for leading protective gas into the box; the punch press is mounted in the accommodating cavity and adjacent to the entrance door; and the spray heads are arranged outside the accommodating cavity and adjacent to the exit door. By adoption of the hot stamping forming equipment provided by the invention, oxidizing reaction of steel plates in the hot stamping process and in the transportation process can be effectively inhibited, the dephosphorization and quenching efficiency is high, and the surface quality of the produced steel plates is high.

Owner:BAIC MOTOR CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com