Rotating disc type automatic quenching device

A quenching device and turntable technology, which is applied in the direction of quenching devices, energy efficiency improvement, heat treatment equipment, etc., can solve the problems of difficult control of metal workpieces, low yield of metal quenching treatment, difficulty in ensuring hardened layer, etc., and achieve rotation angle control Precise, smooth turntable rotation, smooth sliding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with embodiment the present invention is described in further detail:

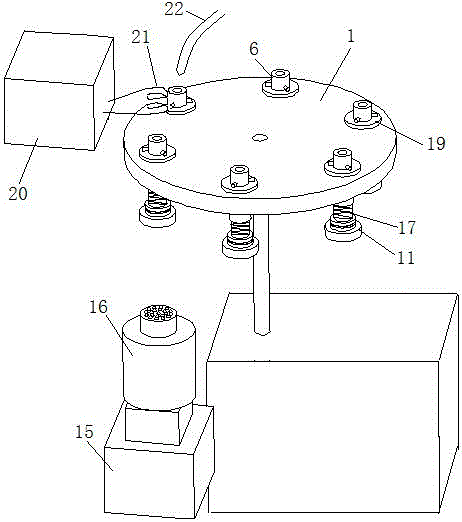

[0035] Such as figure 1As shown, the turntable type automatic quenching device includes a horizontal turntable 1 driven by a driving device. At least 3 slideways are evenly distributed around the central axis of the turntable 1 on the turntable 1. A sliding sleeve 19 is fixed inside the slideway. Inside the slide sleeve 19 There is a pusher rod 6 that slides up and down along the slideway. The center of the pusher rod 6 is provided with a positioning groove 7 for fixing the quenching parts. Some of the quenching parts are of spherical structure, and the quenching parts of the spherical structure are placed on the pusher of the plane. It is difficult to realize positioning on the rod, and the positioning groove 7 better solves the problem of difficult positioning of spherical quenched parts. A quenching induction coil 21 and a cooling nozzle 22 are sequentially arranged above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com