Porous-based ultrasonic-speed adsorption type compressor blade

A supersonic, adsorption technology, applied in the field of compressors, which can solve the problems of flow separation on the suction surface of the blade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

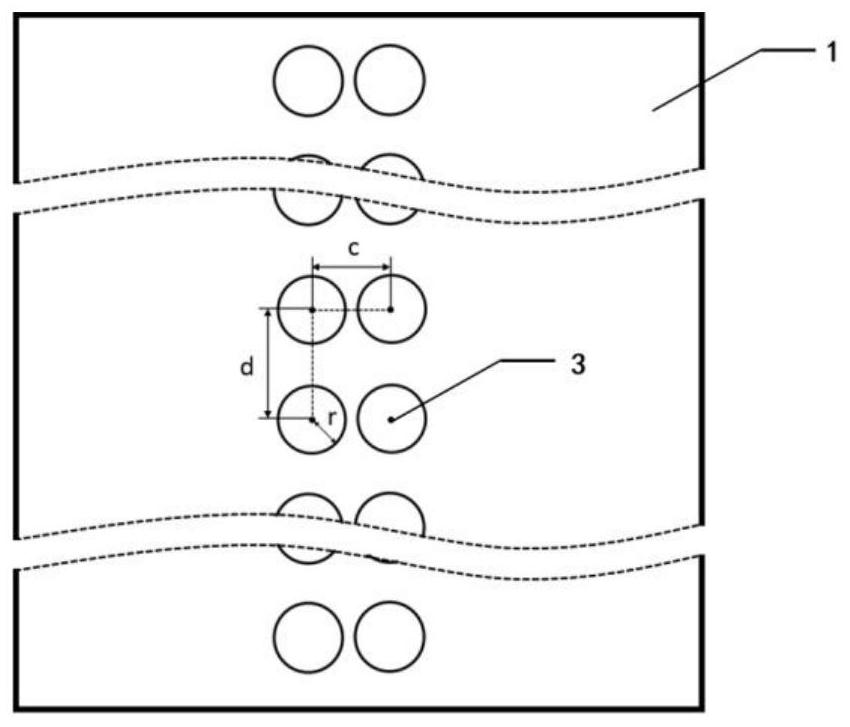

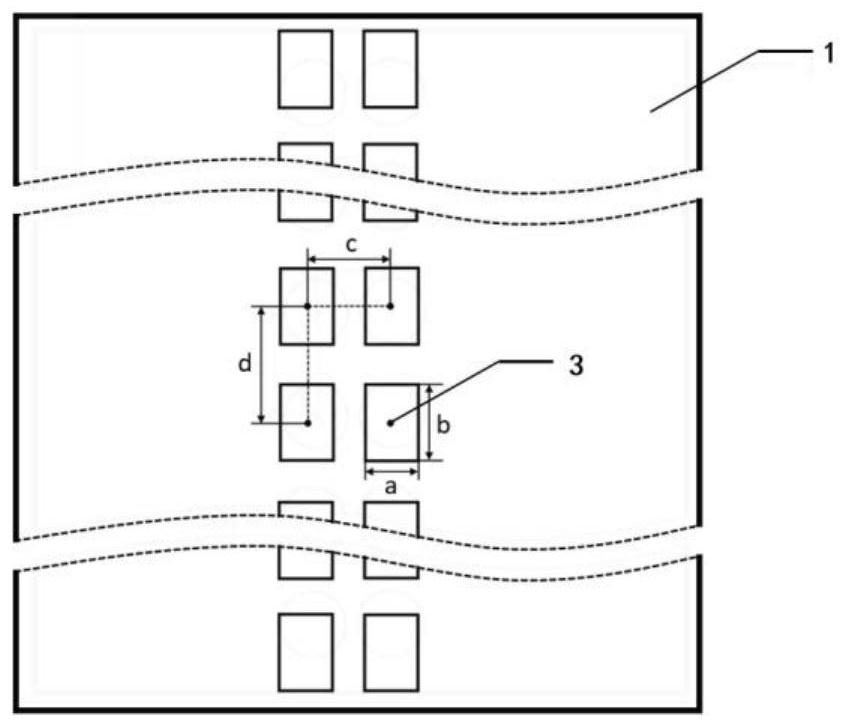

[0037] This embodiment is a porous supersonic adsorption compressor blade, the original blade of the supersonic adsorption compressor blade adopts the prior art, the inlet geometric angle is 14°, the outlet geometric angle is -14°; the blade height is 100mm , the blade chord length is 65mm.

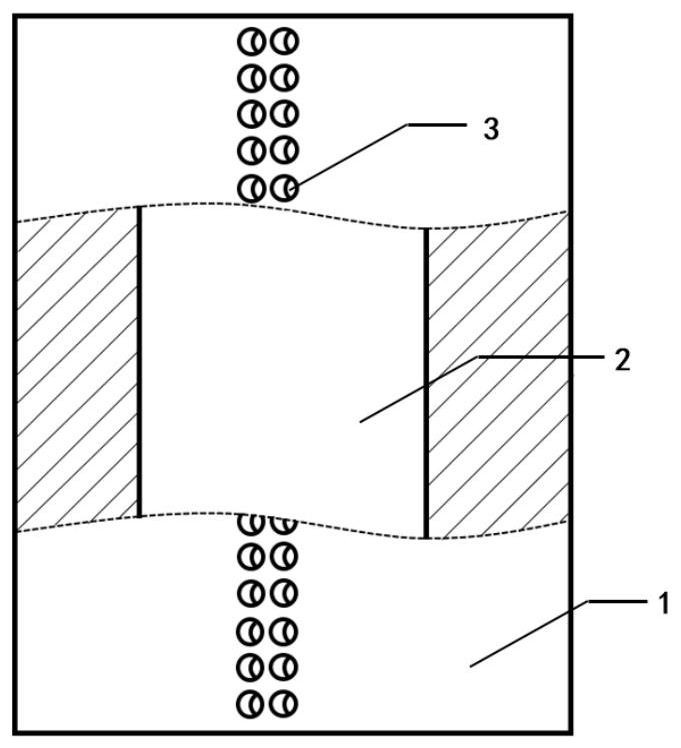

[0038] There is a suction chamber 2 between the suction surface and the pressure surface of the blade of the supersonic adsorption compressor, and the suction chamber penetrates the blade of the supersonic adsorption compressor along the span direction of the blade. The profile of the upper surface of the suction cavity is the same as the profile of the original blade suction surface of the supersonic adsorption compressor blade; the profile of the lower surface of the suction cavity is the same as the original blade pressure of the supersonic adsorption compressor blade The profiles of the surfaces are the same; the leading edge and the trailing edge of the suction chamber 2 are arc-shap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com