Backfill grouting double liquid and backfill grouting method

A technology of grouting and grouting behind the wall, which is used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of failure to achieve early strength, long cementation time, and inability to quickly suppress subsidence, and achieve difficult material separation, The effect of fast cementation and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

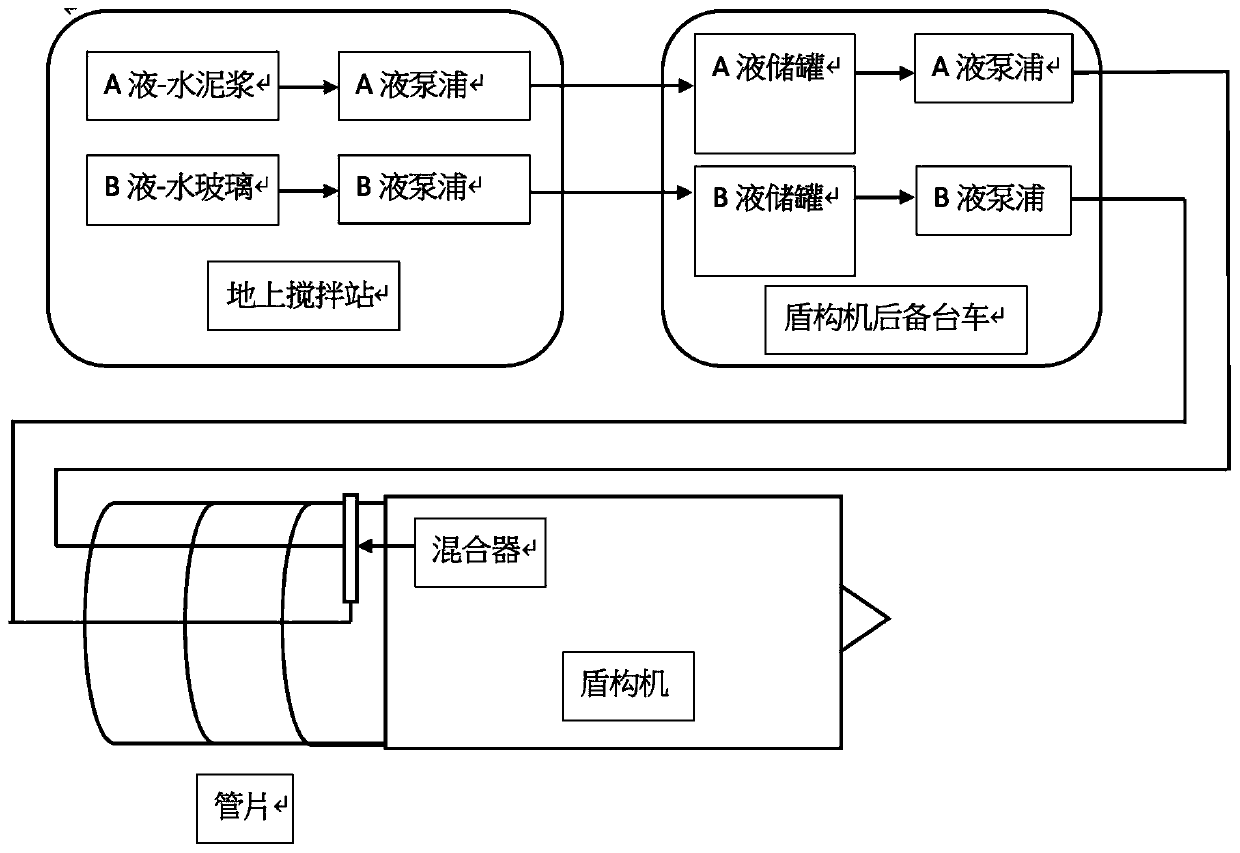

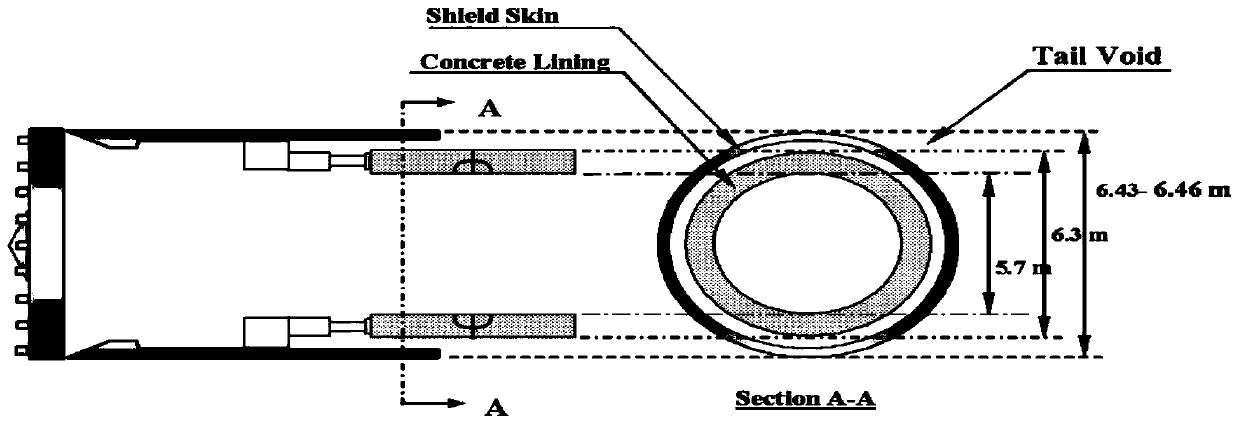

[0070] Cement 230kg, bentonite 30kg, stabilizer 3kg and water 842kg are placed in mixing station, carry out mixing slurry making under the condition of 250rpmrpm, obtain A liquid; With described A liquid and B liquid (water glass 97kg) according to volume ratio 10: 1. Send them to the head of the shield machine through the above-ground grouting pump, and then input them to the grouting mixing system through the underground grouting pump for mixing and filling the shield tail gap.

[0071] According to the test method of GB / T50107-2010, the back grouting test body of embodiment 1 is carried out compressive strength measurement, and concrete results are shown in Table 1;

[0072] Carry out cementing time measurement to the grouting test body behind the wall of embodiment 1, the specific method is to pack A liquid and B liquid in two containers, calculate the time from the mixing of the two liquids, continue to dump alternately, and record the cementing time. For specific results,...

Embodiment 2

[0077] Cement 220kg, bentonite 30kg, stabilizer 3kg and water 848kg are placed in mixing station, under 250rpm condition, carry out mixing slurry making, obtain A liquid; With described A liquid and B liquid (water glass 97kg) according to volume ratio 10: 1. Send them to the head of the shield machine through the above-ground grouting pump, and then input them to the grouting mixing system through the underground grouting pump for mixing and filling the shield tail gap.

[0078] According to the test method of GB / T50107-2010, the back grouting test body of embodiment 2 is carried out compressive strength measurement, and concrete results are shown in Table 2;

[0079] Carry out cementing time measurement to the grouting test body behind the wall of embodiment 2, the specific method is to put A liquid and B liquid in two containers, calculate the time from the mixing of the two liquids, continue to dump alternately, record the cementing time, the specific results are shown in ...

Embodiment 3

[0083] 240kg of cement, 30kg of bentonite, 3kg of stabilizer and 836kg of water are placed in the mixing station, and mixed and slurryed under the condition of 250rpm to obtain liquid A; the liquid A and liquid B (water glass 104kg) are mixed according to the volume ratio of 10:1 They are sent to the head of the shield machine through the above-ground grouting pump, and then input to the grouting mixing system through the underground grouting pump for mixing and filling the shield tail gap.

[0084] According to the test method of GB / T50107-2010, the back grouting test body of embodiment 3 is carried out compressive strength measurement, and concrete results are shown in Table 3;

[0085] Carry out cementing time measurement to the grouting test body behind the wall of embodiment 3, the specific method is to pack A liquid and B liquid in two containers, calculate the time from the mixing of the two liquids, continue to dump alternately, record the cementing time, the specific r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com