A kind of pultruded wooden core material composite sandwich panel and its production process

A composite material, pultrusion molding technology, applied in the direction of layered products, wood layered products, chemical instruments and methods, etc., can solve the problems of difficult positioning of rigid components, difficult to guarantee the connection interface of core materials, and limiting the size of sandwich panels. , to achieve the effect of strong designability, not easy interface peeling, and fast bonding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

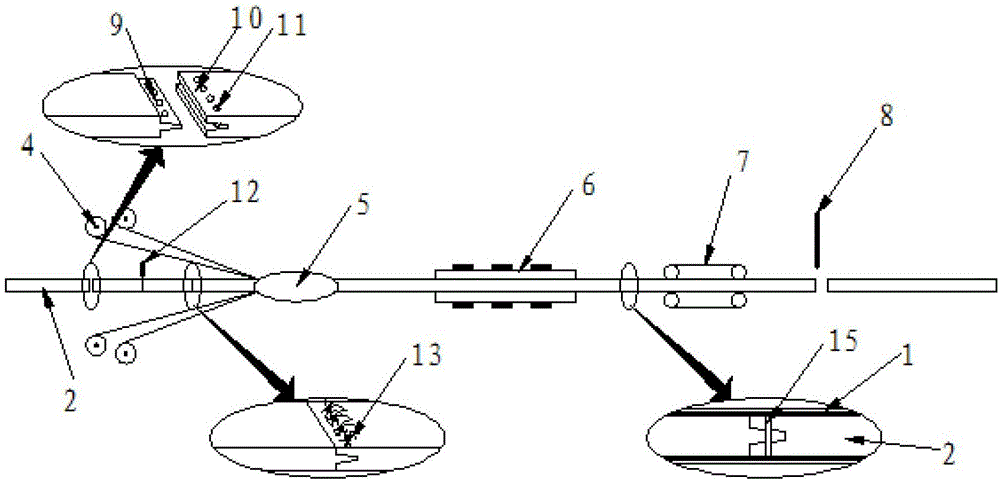

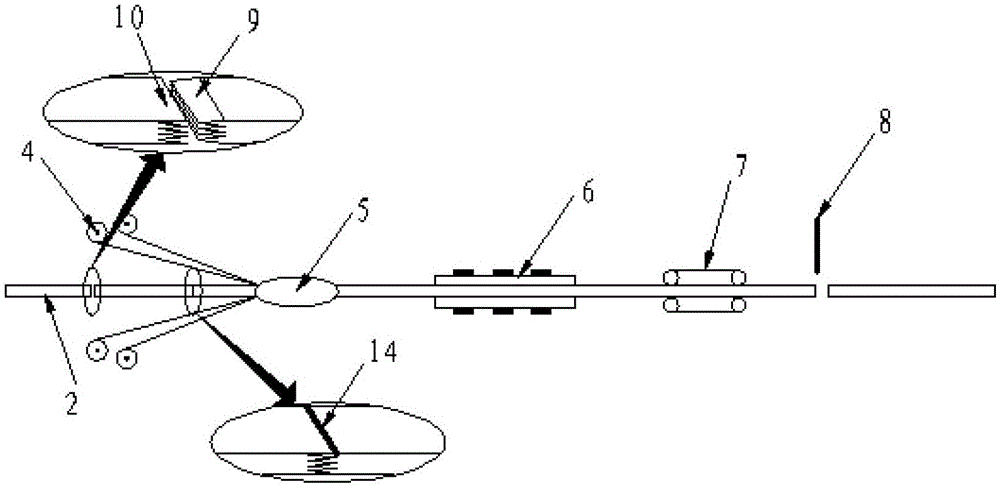

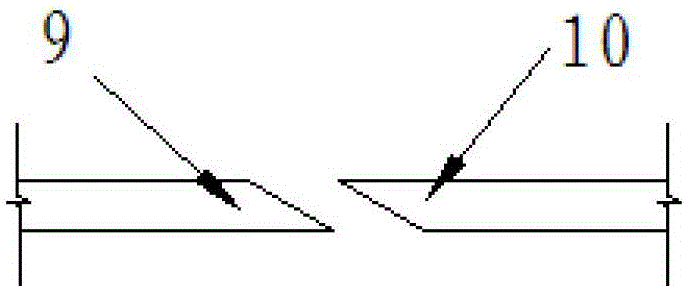

[0034] A pultruded wood core composite sandwich panel. The pultrusion production process is that the glass fiber and paulownia wood core material enter the dipping tank filled with vinyl resin, enter the heating and curing mold through the mold positioning, and pull it through the traction device. Extruded, and finally cut to the required size by cutting equipment. For the core material, the mortise and tenon structure needs to be processed at the joint of the core material. The mortise and tenon structure adopts the oblique alveolar type, which is composed of convex joints and concave joints, and white latex is used for solid wood splicing. At the same time, the upper surface and sides of the core material need to be roughened to strengthen the interface connection with the surface layer. Here, some shallow grooves are used.

Embodiment 2

[0036] A pultruded wooden core composite sandwich panel. The pultruded production process is that the fiber and Balsa wood enter the impregnation tank filled with epoxy resin, enter the heating and curing mold through the mold positioning, and pultrude through the traction equipment. , and finally cut to the required size by cutting equipment. For the core material, the mortise and tenon structure needs to be processed at the joint of the core material. At the same time, the surface needs to be roughened to strengthen the interface connection with the surface layer. Here, some shallow grooves are used. The mortise and tenon structure adopts a combined form, consisting of a convex joint and a concave joint. A row of cylindrical holes is opened at the joint, and the auxiliary joint is a short column of composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com