Surface hardening treatment method for large-power low-speed diesel engine piston bar

A hardening treatment and piston rod technology, which is applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve the problems of uneven heating in induction hardening, large deformation in flame quenching, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

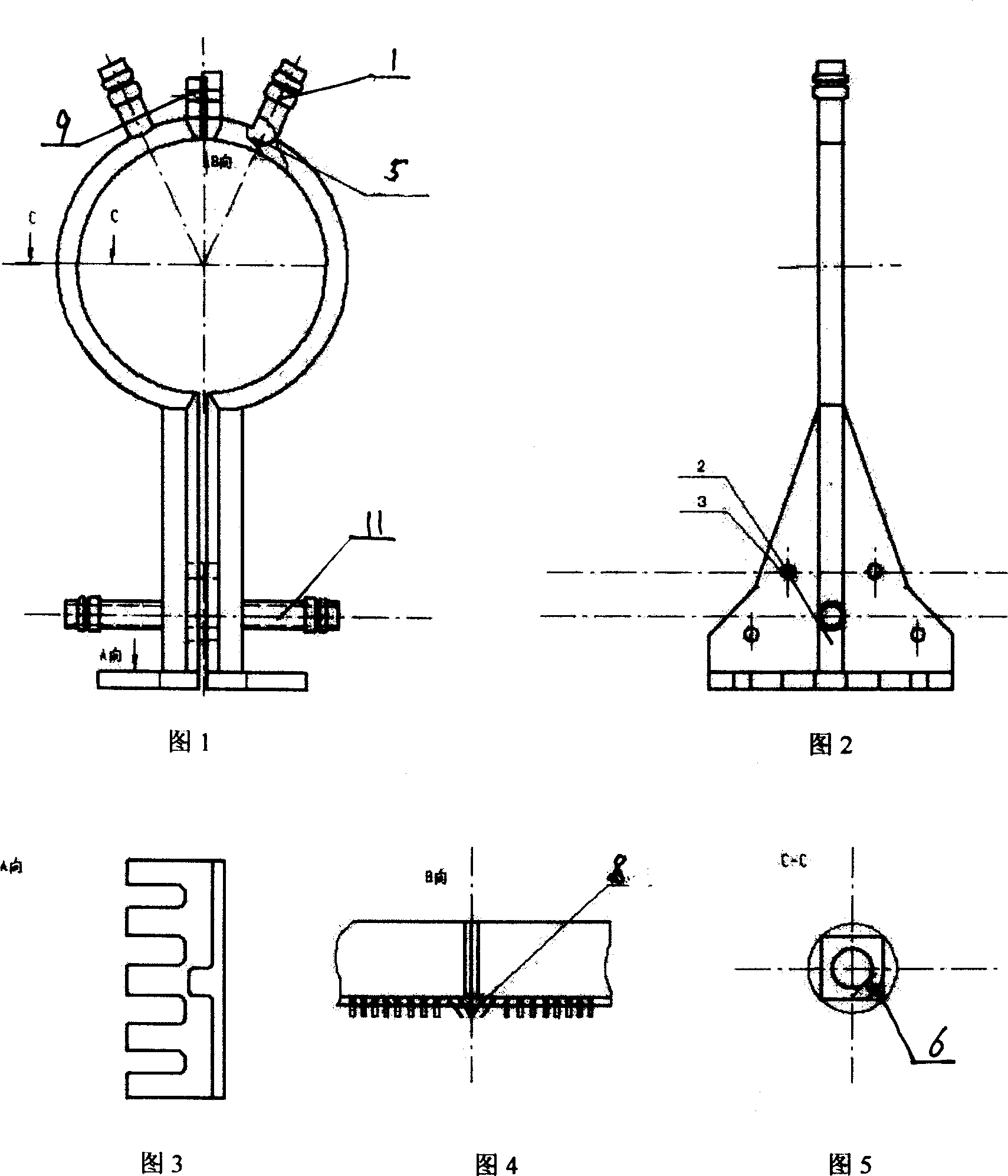

[0006] Embodiment 1, a surface hardening treatment method and inductor of a high-power low-speed diesel engine piston rod of the present invention are specifically realized through the following technical solutions:

[0007] 1. Production of the sensor:

[0008] The sensor adopts Φ30 red copper rod, which is composed of two semicircular parts on the left and right. The inside is a hollow channel connected with the water inlet pipe 1 and the water outlet pipe 11. A decompression distribution baffle 5 is installed on the two water inlet pipes of the sensor to spray water. The position of the hole 6 is set at the lower edge of the inner side of the sensor and drilled at a position 45° inward to form a continuous distribution of water spray holes. The diameter of the water spray holes is Φ1.5mm and the spacing is 4mm. Simultaneously, the front parts of the two half inductors are drilled at 45° incline to the joint site near the water spray hole 8 at the joint site to ensure that t...

Embodiment 2

[0014] A surface hardening treatment method for a piston rod of a high-power low-speed diesel engine of the present invention, taking the external diameter of a low-speed marine diesel engine 50MC as an example of a piston rod of 200 mm, (1) continuous heating: the piston rod is vertically arranged on a rotatable chassis of the base , the upper center positioning hole is set under the top cone of the frame; the sensor is installed around the lower end of the piston rod. up to 920°C; (2) Cooling: use circulating water as the cooling medium, when the heating temperature of the piston rod reaches 920°C, the cooling water in the sensor is continuously sprayed to the surface of the heated piston rod through the water spray hole for cooling and quenching (3) Tempering: put the piston rod into the tempering furnace for tempering heating, the tempering temperature is 240°C for 4 hours, and then air-cooled. Whether it is the hardness of the surface, the depth of the hardened layer, or ...

Embodiment 3

[0016] A kind of surface hardening treatment method of piston rod of high-power low-speed diesel engine of the present invention, take the piston rod of 70MC of low-speed marine diesel engine as an example, (1) continuous heating: install inductor, inductor walking speed 140mm / min , the piston rod rotates at a speed of 50rad / min, and the temperature of the piston rod is continuously heated to 930°C; (2) Cooling: using circulating water as the cooling medium, when the heating temperature of the piston rod reaches 930°C, it is continuously sprayed for cooling; (3) Tempering: Tempering temperature is 230°C, time is 4 hours, air cooling. Whether it is the hardness of the surface, the depth of the hardened layer, or the structure, it can fully meet the requirements of the drawing and process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com