Quenching mechanism of steel ball quenching machine

A quenching machine and steel ball technology, applied in quenching devices, furnaces, heat treatment equipment, etc., can solve the problems of poor physical properties of steel balls, inability to adapt to receive quenching medium separately, easy to deform and replace steel balls, etc., and achieve consistent quenching time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

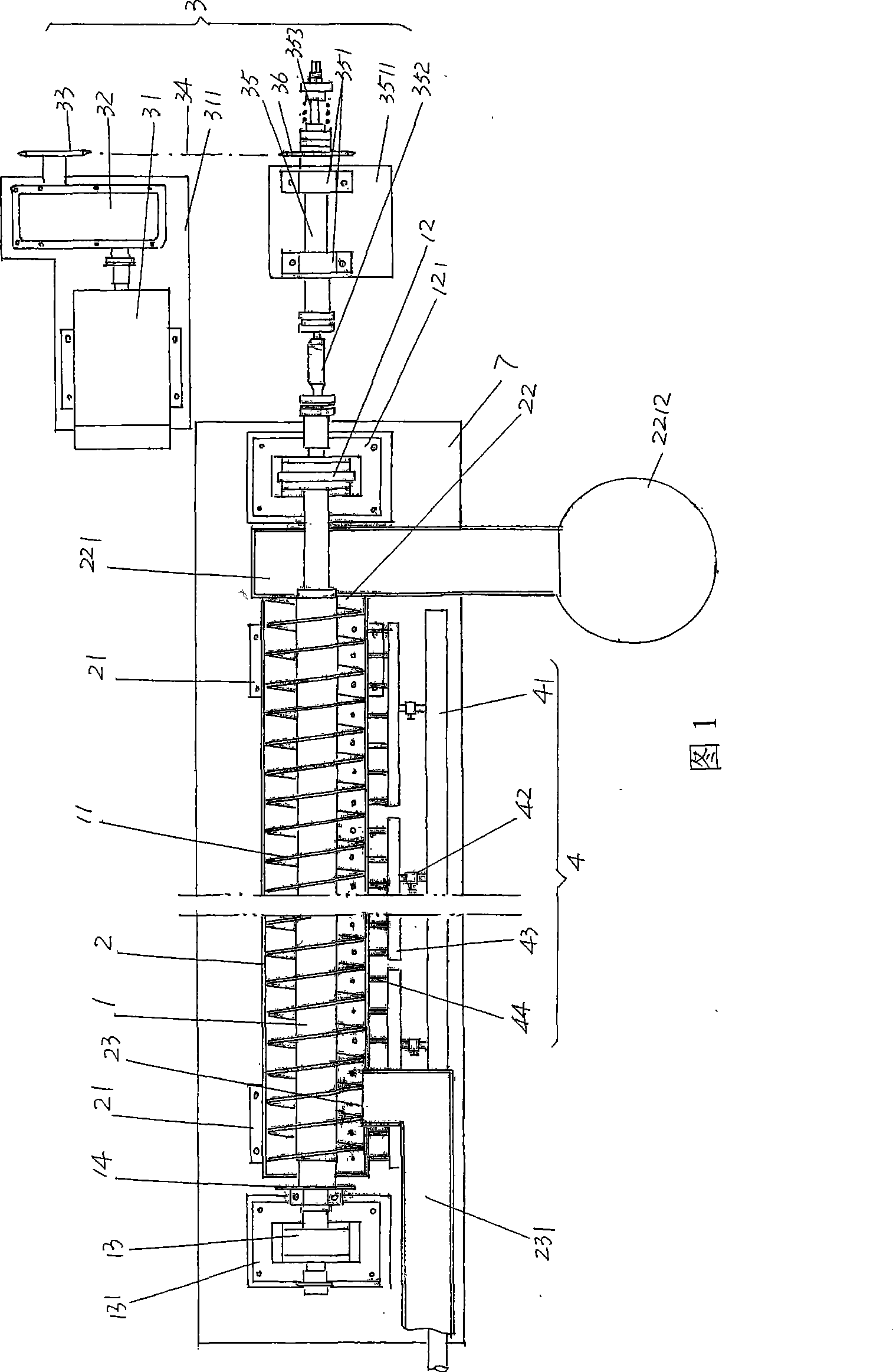

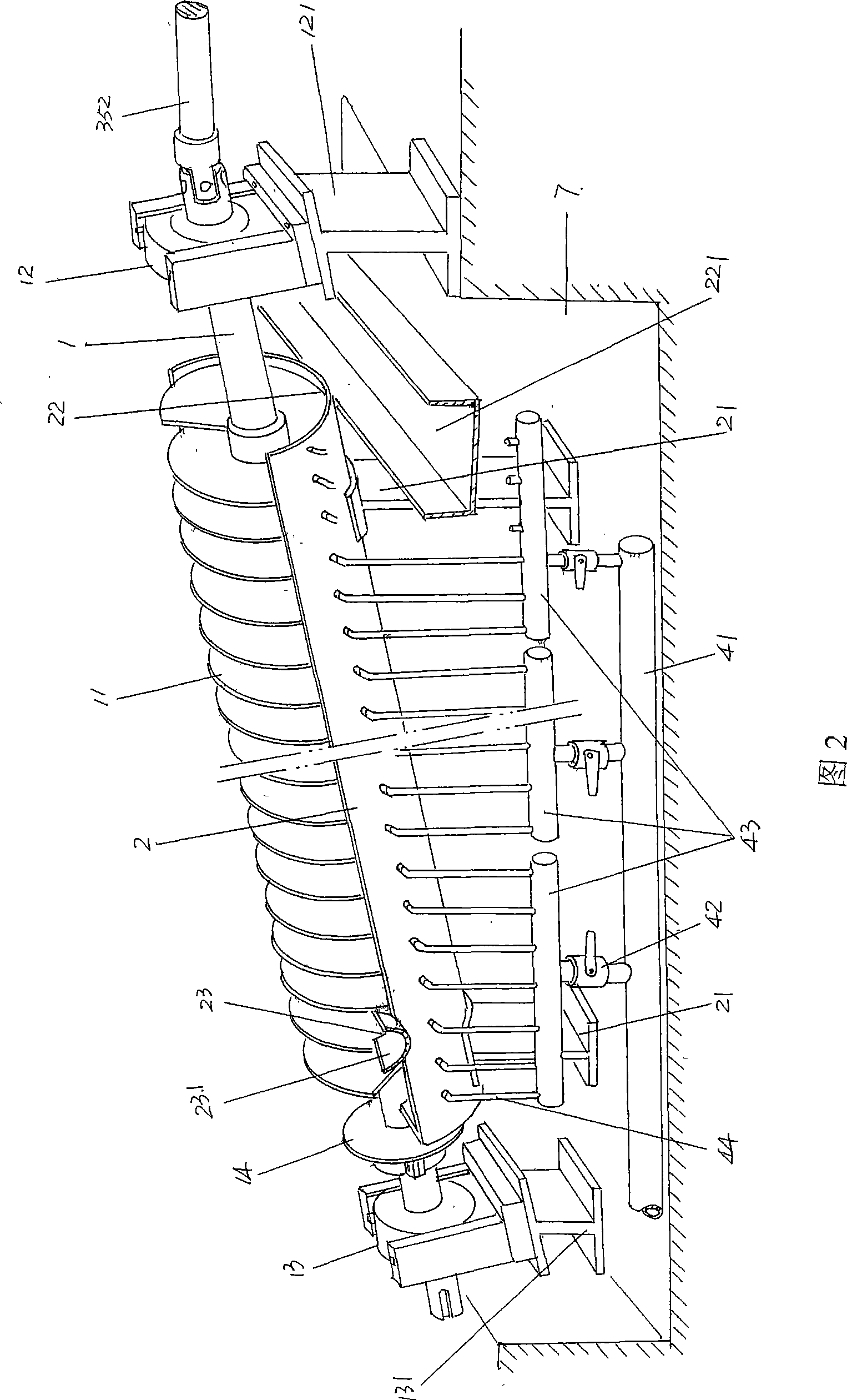

[0025] Please refer to Fig. 1 and Fig. 2, as a preferred example, the middle part of the rod body of the screw rod 1 of the quenching mechanism of the steel ball quenching machine is integrally provided with a spiral piece 11 for separating the steel balls and acting as a drive to drive the steel balls away. The distance between adjacent helical pieces 11 should meet the size (diameter) of the steel balls, so that the steel balls can be movably located therebetween. Taking the current illustrated position state as an example, the two ends of the screw rod 1, that is, the right and left ends are respectively supported on the first and second bearing supports 121, 131 through the first and second bearing supports 12, 13, and the first 1. The second bearing brackets 121 and 131 are fixed on the medium collection tank 7 at the use site of the steel ball quenching machine, and the two keep corresponding, that is, the two are on the same straight line. Among them: the first bearing ...

Embodiment 2

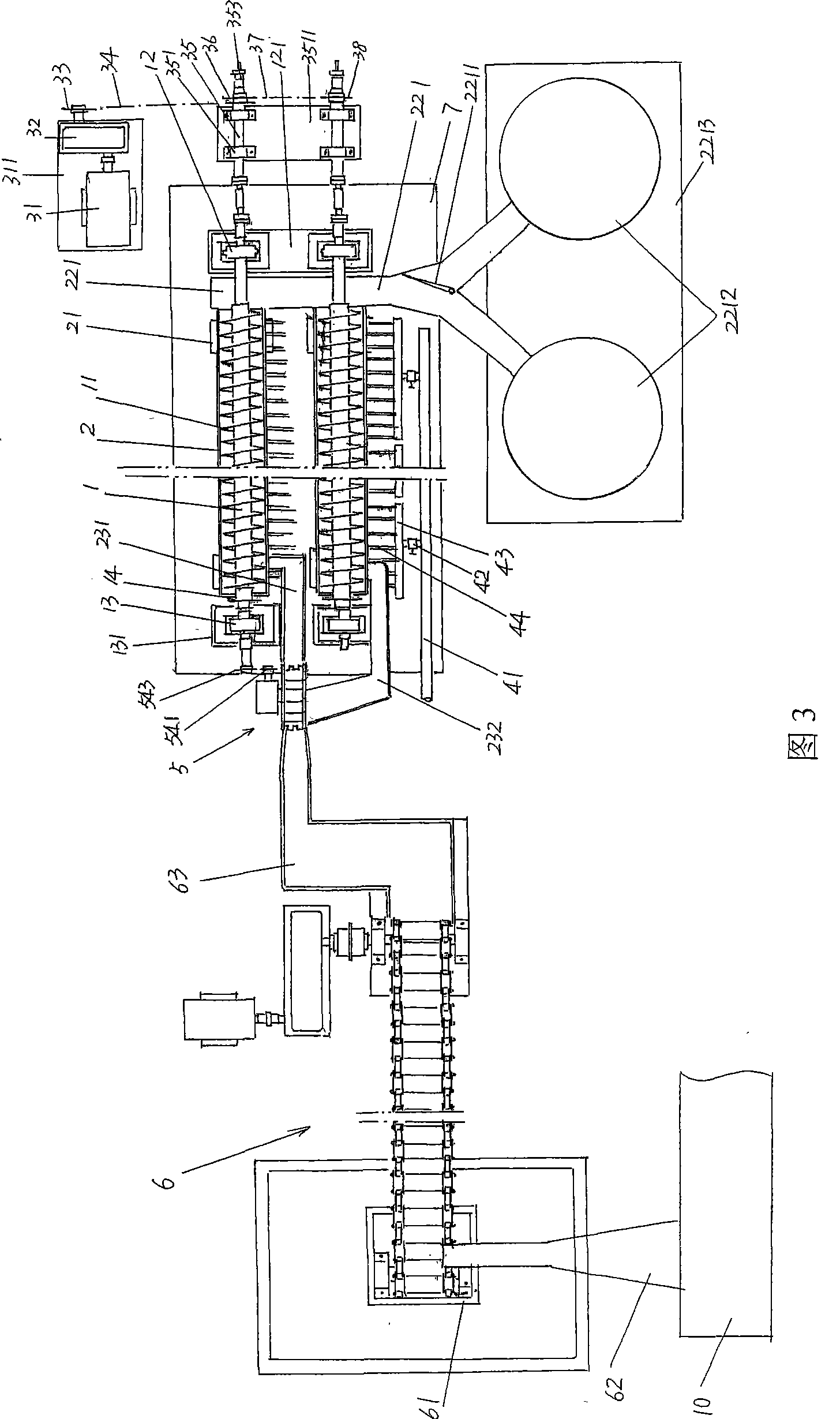

[0029] Please refer to Figure 3. Compared with Embodiment 1, the quenching mechanism of the steel ball quenching machine has two sets of the same structure and the same way. The medium conveying mechanism 4 just increases to two sets, and increases one and is used to provide the goal raceway 232 of steel ball to the medium groove 2 of a set of quenching mechanism in the front of the illustrated position state, and, second sprocket wheel 36 changes With double sprockets, increase the second chain 37 and the third sprocket 38, the second chain 37 takes on the transmission connection between a pair of main shafts 35 of two sets of quenching mechanisms. Because it is two sets of quenching mechanisms, the quenching effect will be significantly improved. Therefore, a guide door 2211 is pivotally arranged on the channel of the ball-out raceway 221 fixed on the first bearing bracket 121. When one of the pair of ball-collecting containers 2212 After a container is full of steel balls, ...

Embodiment 3

[0031] Please refer to Fig. 4 and in conjunction with Fig. 3, the structure of the ball feeding mechanism 5 suitable for the situation of embodiment 2 has been provided, the ball feeding mechanism 5 includes a first frame 51, a second speed reducer 52, a ball feeding plate 53, The power transition device 54, the second speed reducer 52 is fixed on the first frame 51, the ball feeding disc 53 is fixed on the power output shaft of the second speed reducer 52, and there is at least an intermediate spacer on the edge of the ball feeding disc 53. In response to the ball storage cavity 531 in the middle of the steel ball from the steel ball lifting mechanism 6 of the steel ball quenching machine, the power transition device 54 includes the fourth and fifth sprockets 541, 543 and the third chain 542, the fourth sprocket 541 is fixed on the shaft end of the power input shaft of the second reducer 52 , while the fifth sprocket 543 is fixed on the end of the screw rod 1 , and the third c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com