Cam conjugate induction hardening equipment

An induction hardening and cam technology, applied in quenching devices, furnaces, heat treatment equipment, etc., can solve the problems of high use cost, large surface quenching depth, overheating of the cam tip, and achieve low use and manufacturing costs, uniform induction hardening, Guaranteed uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

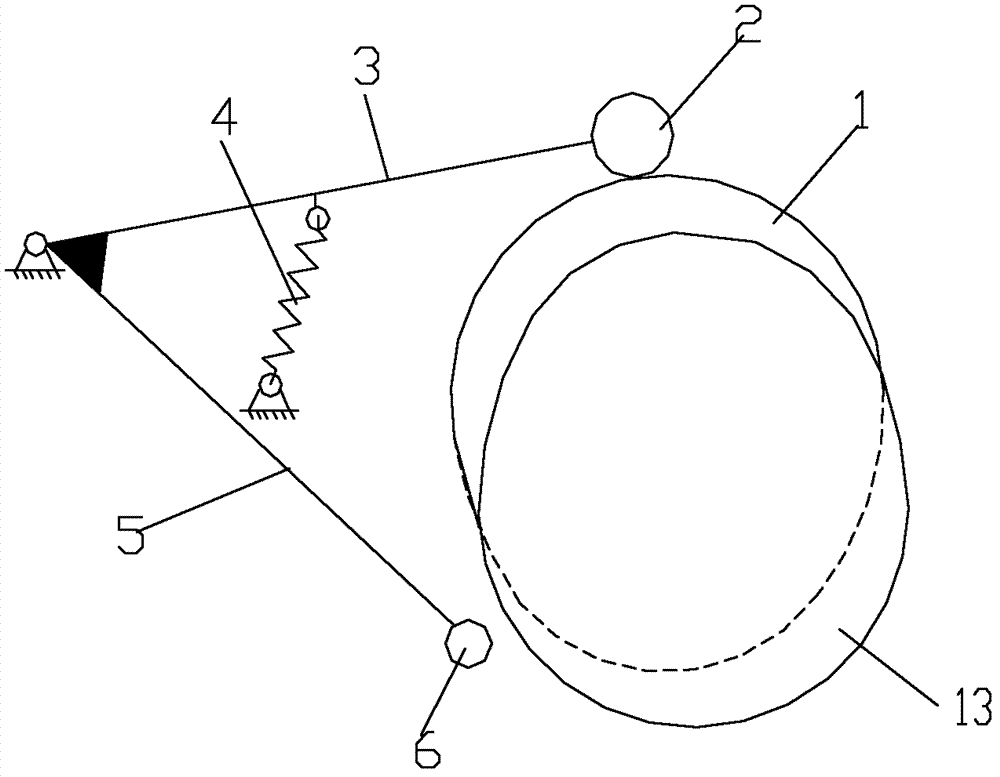

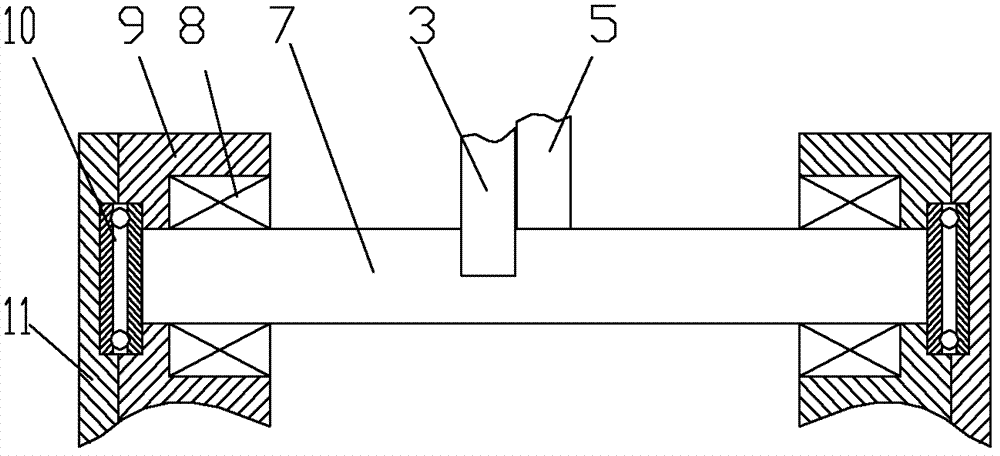

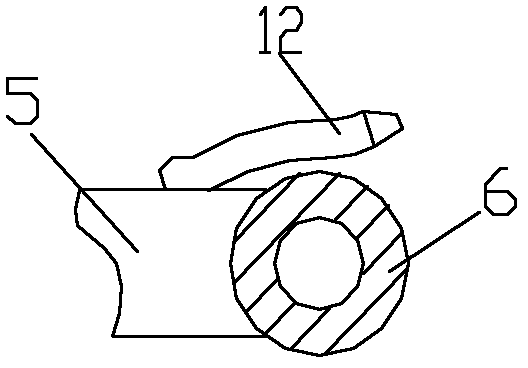

[0020] figure 1 Is a radial sectional view of the present invention, figure 2 Is an axial sectional view of the present invention, image 3 for figure 1 A view, as shown in the figure: the cam conjugate induction hardening device of this embodiment includes a driving rod 3, a follower rod 5, and a driving cam 1 that forms a conjugate cam group with the cam 13 to be quenched. The driving rod 3 It is fixedly connected to the follower lever 5 and hinged in a rotatable manner around a common axis. The end of the driving lever 3 away from the hinge point is provided with a roller 2 for contacting the working surface of the active cam 1, and the end of the follower lever 5 away from the hinge point The part is provided with an inductor 6 for induction hardening the working surface of the cam 13 to be quenched. The part on the working face of the cam 13 to be quenched is conjugated with the part where the active cam 1 is in contact with the roller. The drive rod 5 or The roller 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com