Multistage quenching process and equipment for NdFeB (neodymium iron boron) magnetic powder production

A quenching equipment and NdFeB technology are applied in the field of quenching devices, which can solve the problems of wasting water resources and energy, easy to freeze transportation pipelines, and high production costs, and achieve the effects of thorough quenching, improving quenching efficiency and saving rare earth metals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

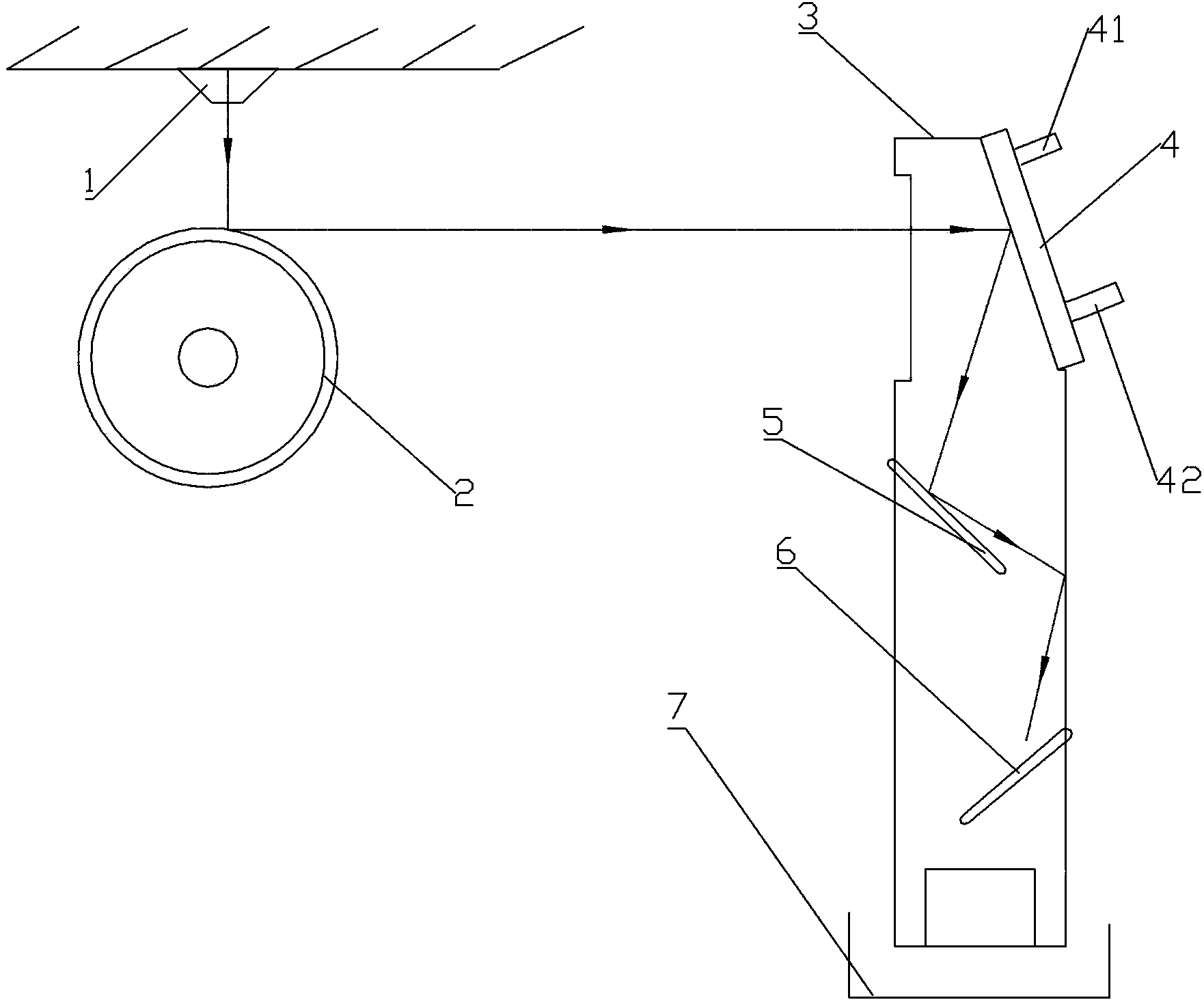

[0023] Embodiment 1, the nozzle 1 of the present invention sprays the incoming material to the molybdenum wheel 2. The incoming material is generally molten steel at 1300 ° C. The rotating molybdenum wheel 2 continuously throws off the incoming material sprayed from above. A small amount of molybdenum Mo will be infiltrated during the process. Adding molybdenum to the material can improve the elastic limit, corrosion resistance and maintain permanent magnetism. The temperature of the tape is about 800°C, and the high-temperature strip is thrown into the barrel 3. The side of the molybdenum wheel 2 in the direction of throwing and throwing is provided with a barrel 3 corresponding to the inlet, and the upper part of the barrel 3 corresponds to the inlet. The other side of the feed port is provided with a downward-sloping primary cooling plate 4. After being thrown into the barrel 3, the high-temperature strip is blocked by the primary cooling plate 4 and folded obliquely downwar...

Embodiment 2

[0024]Embodiment 2, the present invention comprises nozzle 1, molybdenum wheel 2, feed barrel 3, primary cooling plate 4, secondary cooling plate 5, tertiary cooling plate 6, after the incoming material enters material barrel 3, the first cooling plate 4, The flow between the secondary cooling plate 5, the tertiary cooling plate 6 and the barrel wall of the barrel 3, the molybdenum wheel 2 is installed under the nozzle 1, and the incoming material is sprayed downward from the nozzle 1 to the molybdenum wheel 2, and the incoming material is generally 1300°C The rotating molybdenum wheel 2 continuously throws the incoming material sprayed from above, and the incoming material will infiltrate a small amount of molybdenum Mo when it comes into contact with the molybdenum wheel 2. Adding molybdenum to the material can improve the elastic limit, corrosion resistance and maintain Permanent magnetism, the incoming material is initially cooled down during this process to form a high-tem...

Embodiment 3

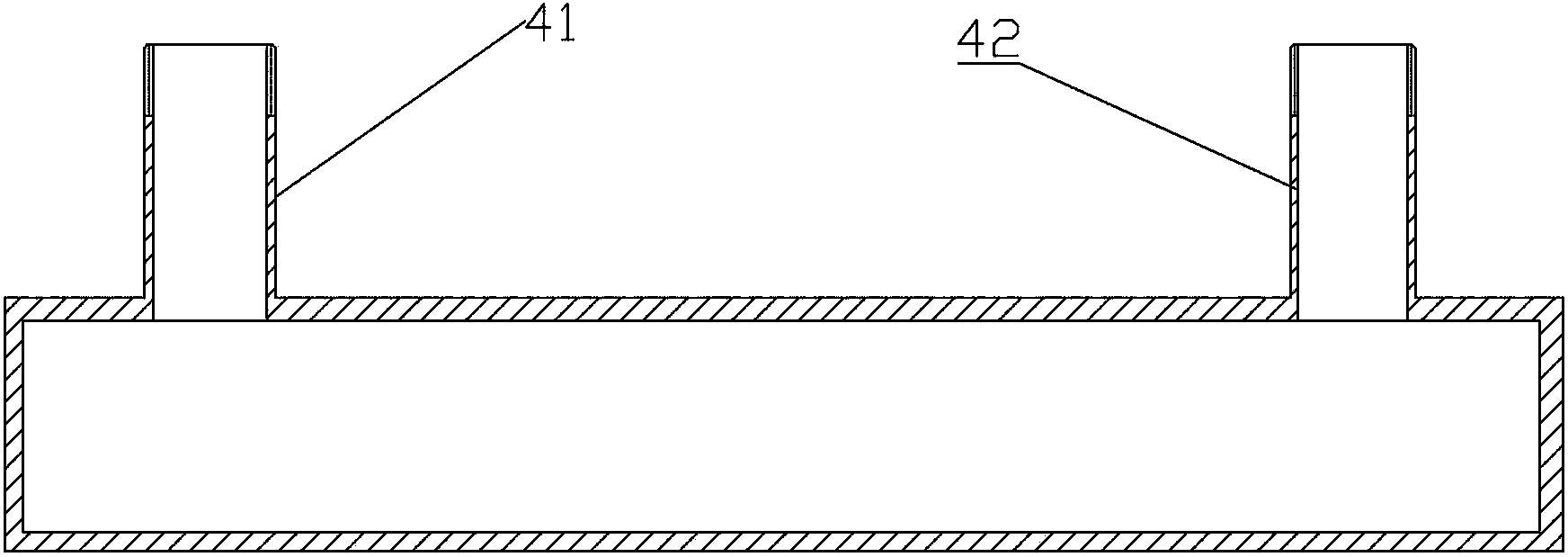

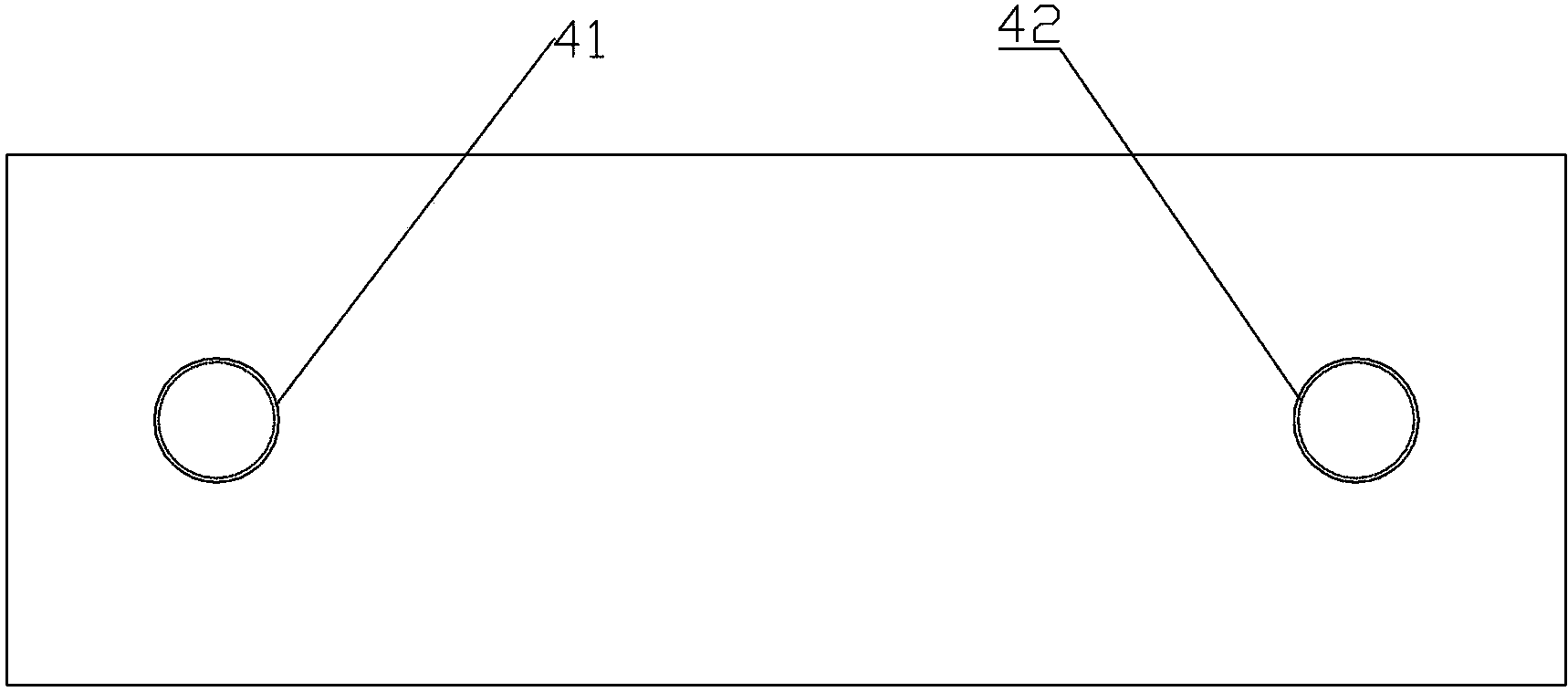

[0025] Embodiment 3, the inside of the first-stage cooling plate 4 is provided with a cavity for heat exchange and a cooling plate water outlet 41 and a cooling plate water inlet 42 communicating with the cavity, and continuously circulates and injects cooling water for heat exchange. The cooling plate 4 is maintained at a lower temperature. refer to Figure 1 to Figure 7 , and the rest are the same as the above-mentioned embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com