Patents

Literature

211results about How to "Improve quenching quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

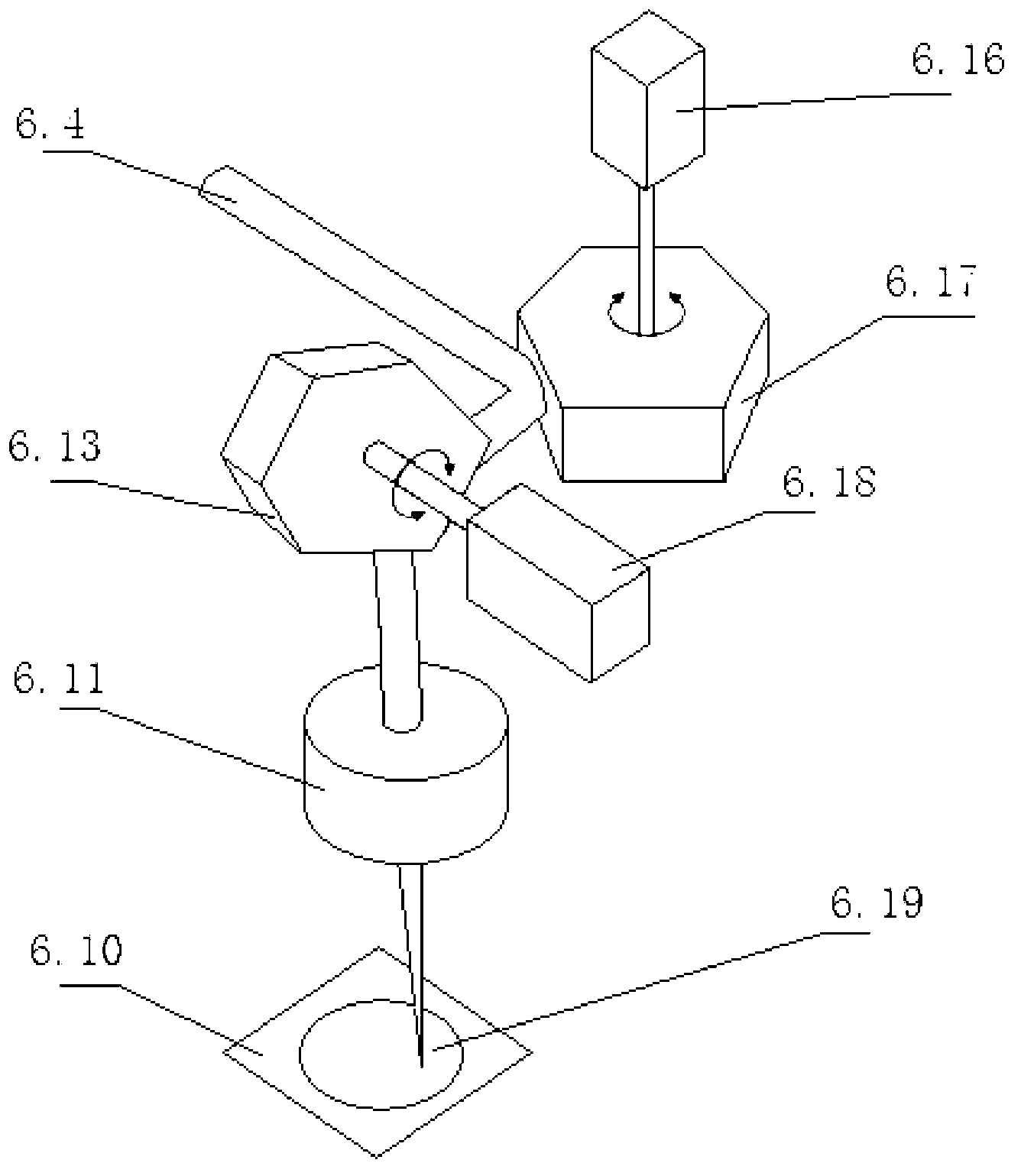

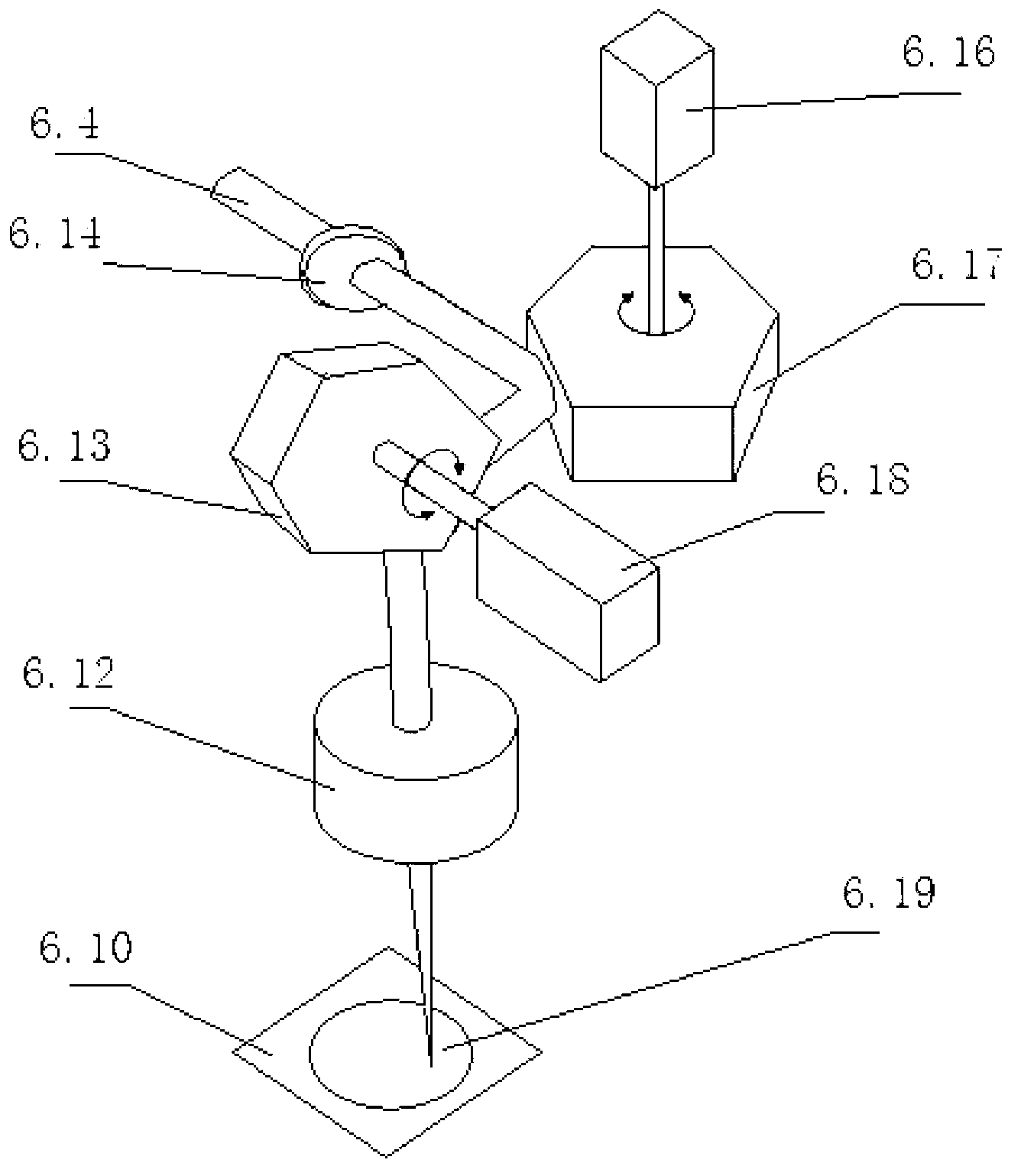

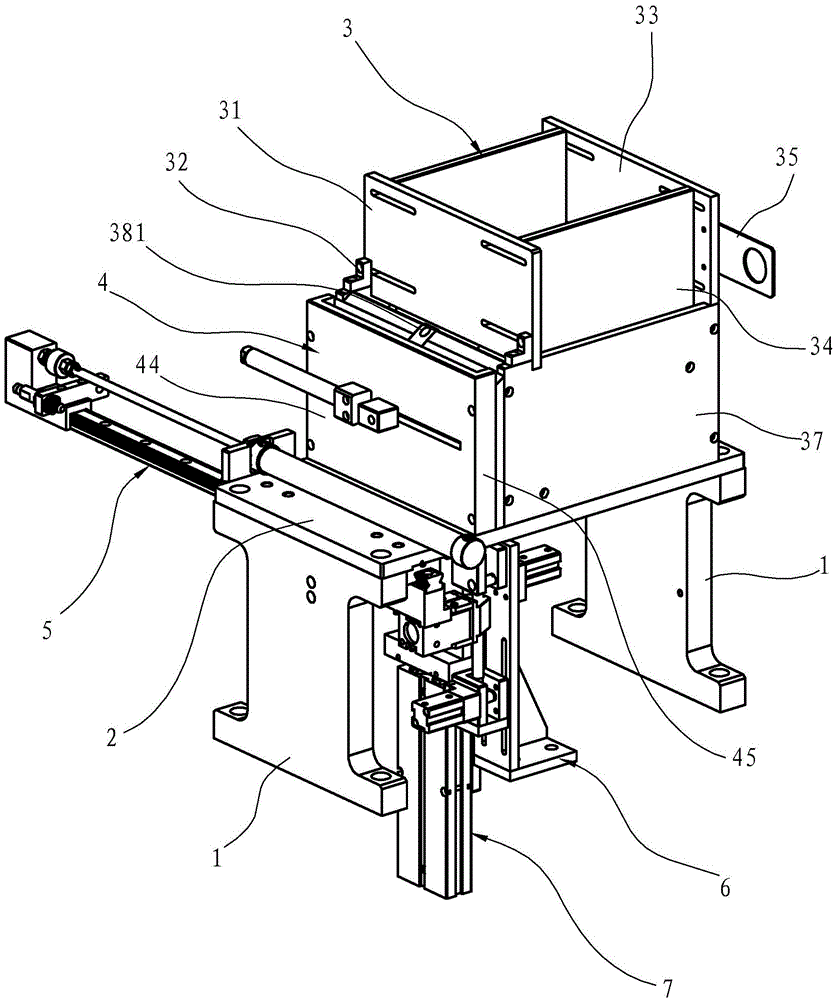

Process method for quenching rotary support gear

ActiveCN102766751AImprove quenching qualityIncreasing energy efficiencyFurnace typesPower flowCoupling

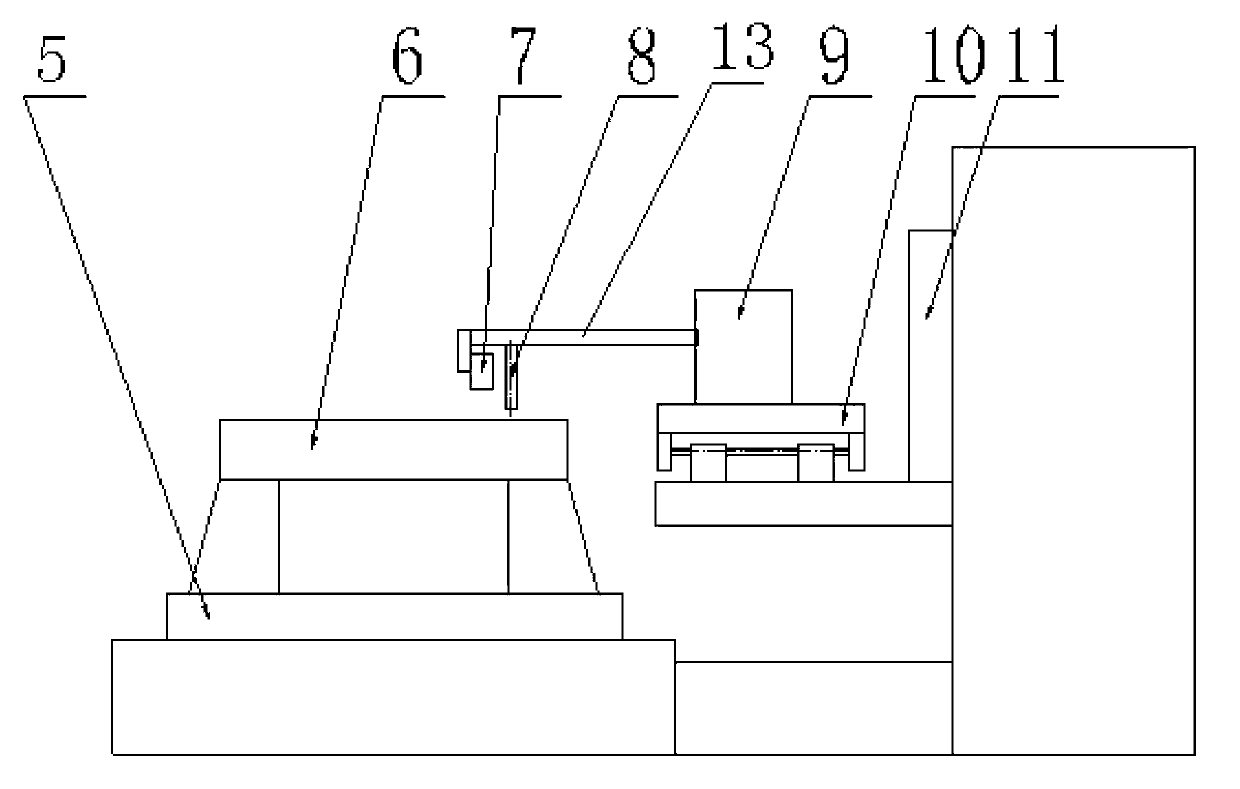

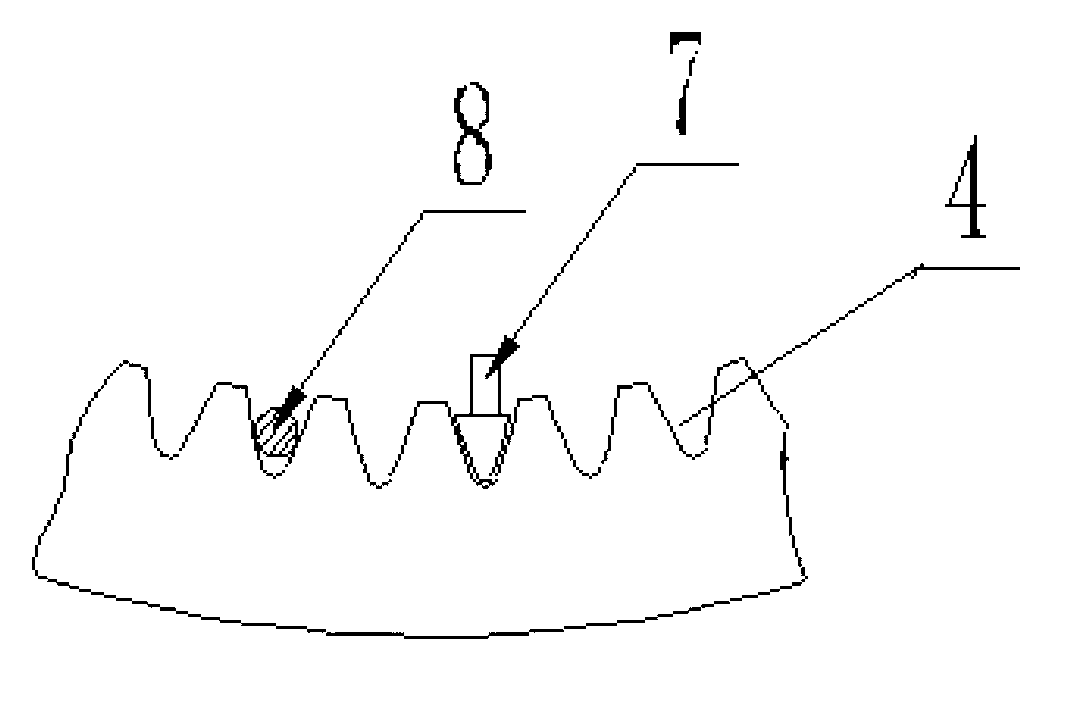

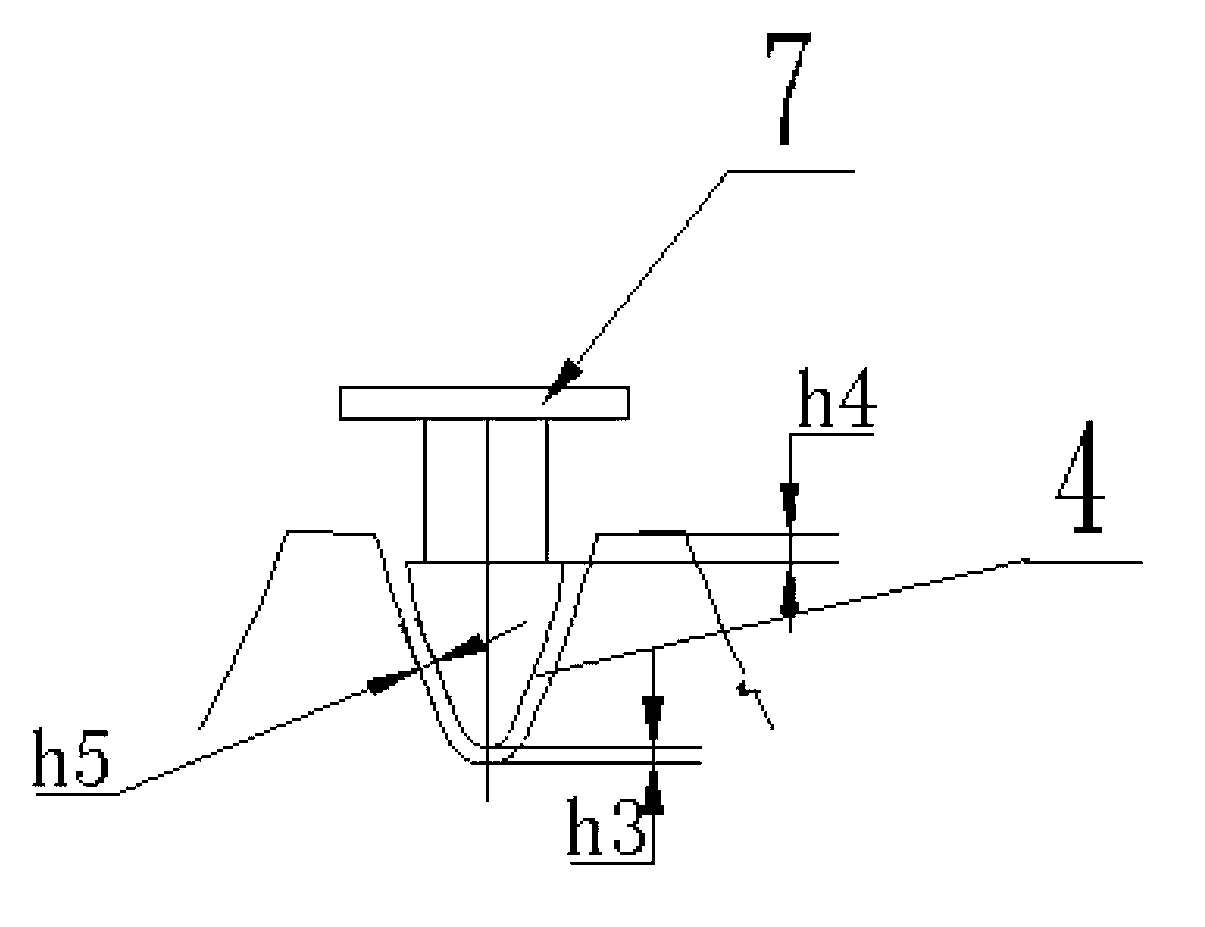

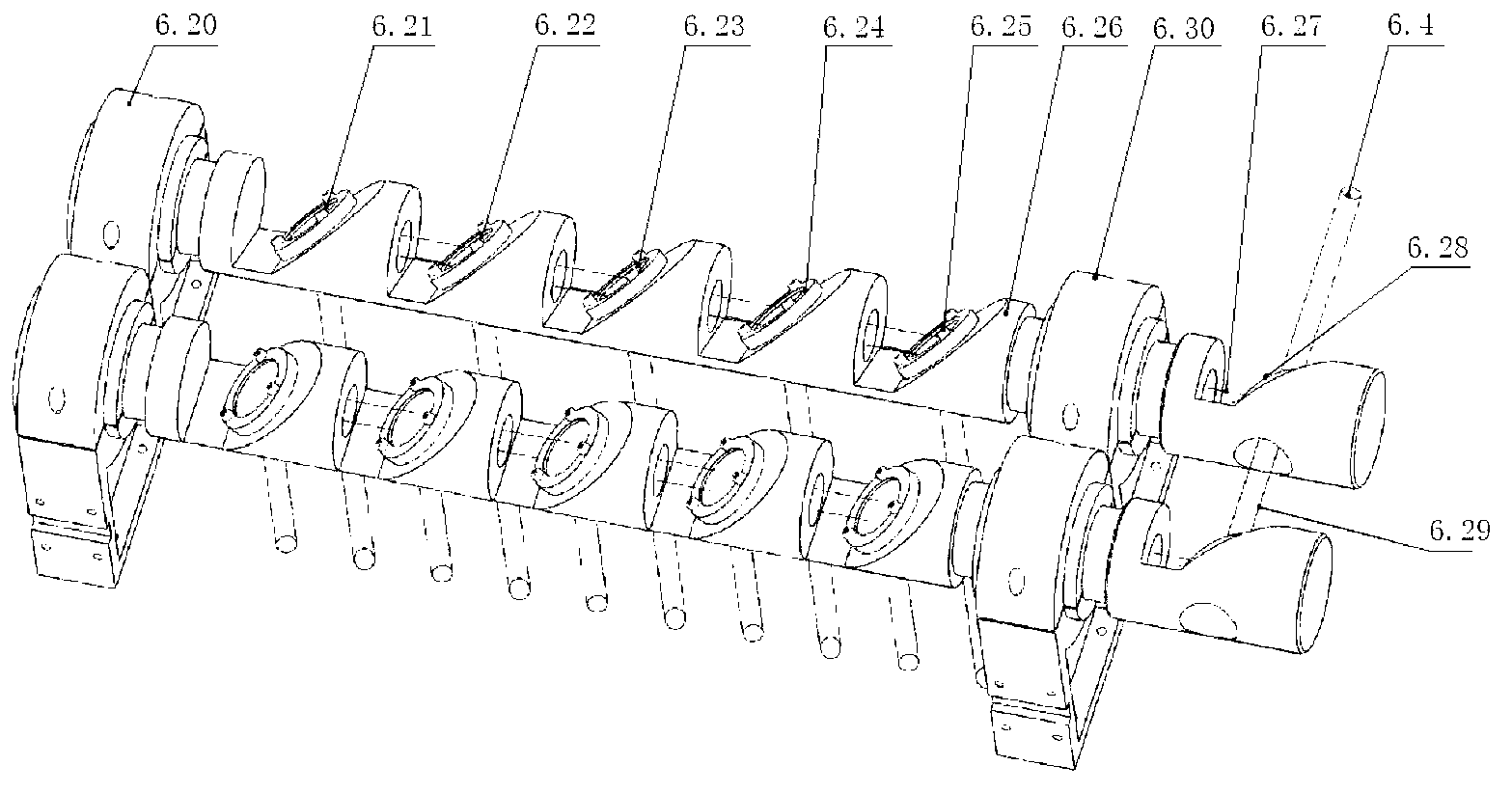

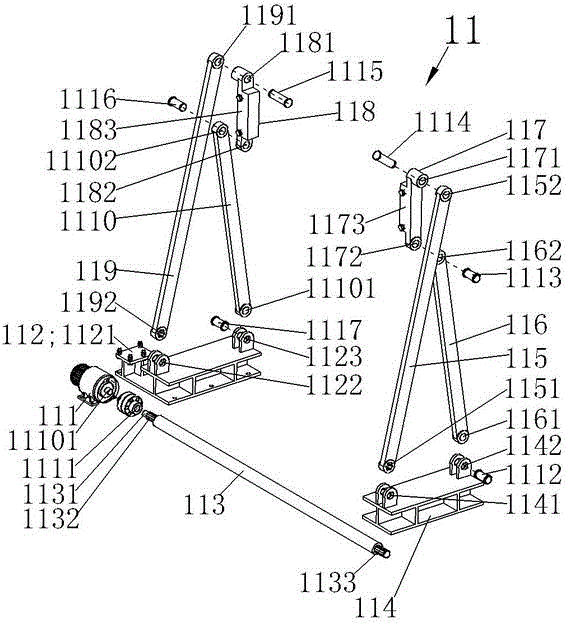

The invention discloses a process method for quenching a rotary support gear. The method comprises the main steps of carrying out rough turning, finishing turning, gear shaping, quenching and tempering on an inner ring and an outer ring of the rotary support gear; an inductor of a quenching device for quenching adopts a medium frequency quenching inductor; the quenching liquid is PGA (polyglycolic acid) quenching liquid; the quenching device comprises a rotary workbench; one side of the rotary workbench is provided with a fixing base capable of vertically moving; a slide base that moves horizontally is erected on a horizontal side plate on one side of the fixing base; the slide base is fixedly provided with a transformer for driving the medium frequency quenching inductor and assisting a localizing guide rod to operate; the induction head on the front end part of the medium frequency quenching inductor is trapezoidal; a coupling gap between the induction head and the dental groove corresponding to the induction head is reserved when the induction head matches with the dental groove corresponding to the induction head; in the quenching process, the process parameters such as the coupling gap between the medium frequency quenching inductor and the dental groove, the entering depth of the current, the speed of the dental groove line, the temperature and the concentration of the quenching liquid are set and regulated; and, the method provided by the invention enhances the quenching quality, and is particularly suitable for the quenching need of the rotary support gear made of the material 50 Mn or the material 42 CrMo and with the module of gear more than 6.

Owner:安徽乾坤重工机械有限公司

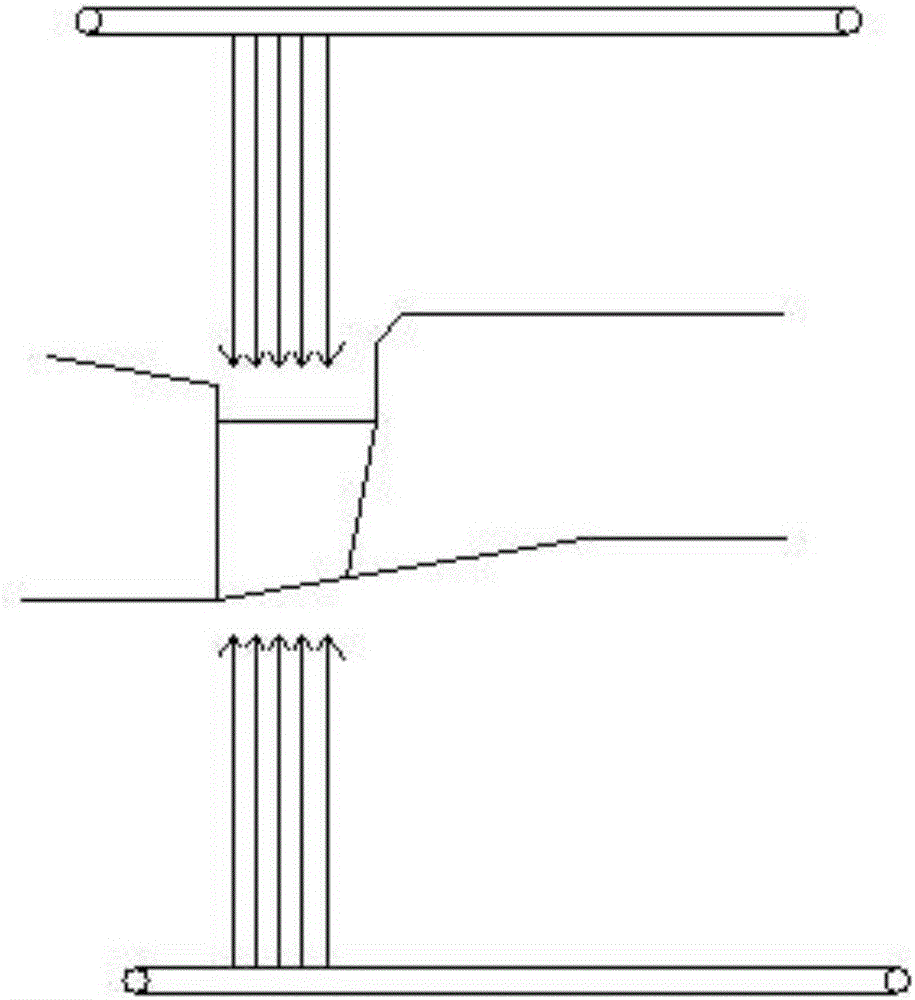

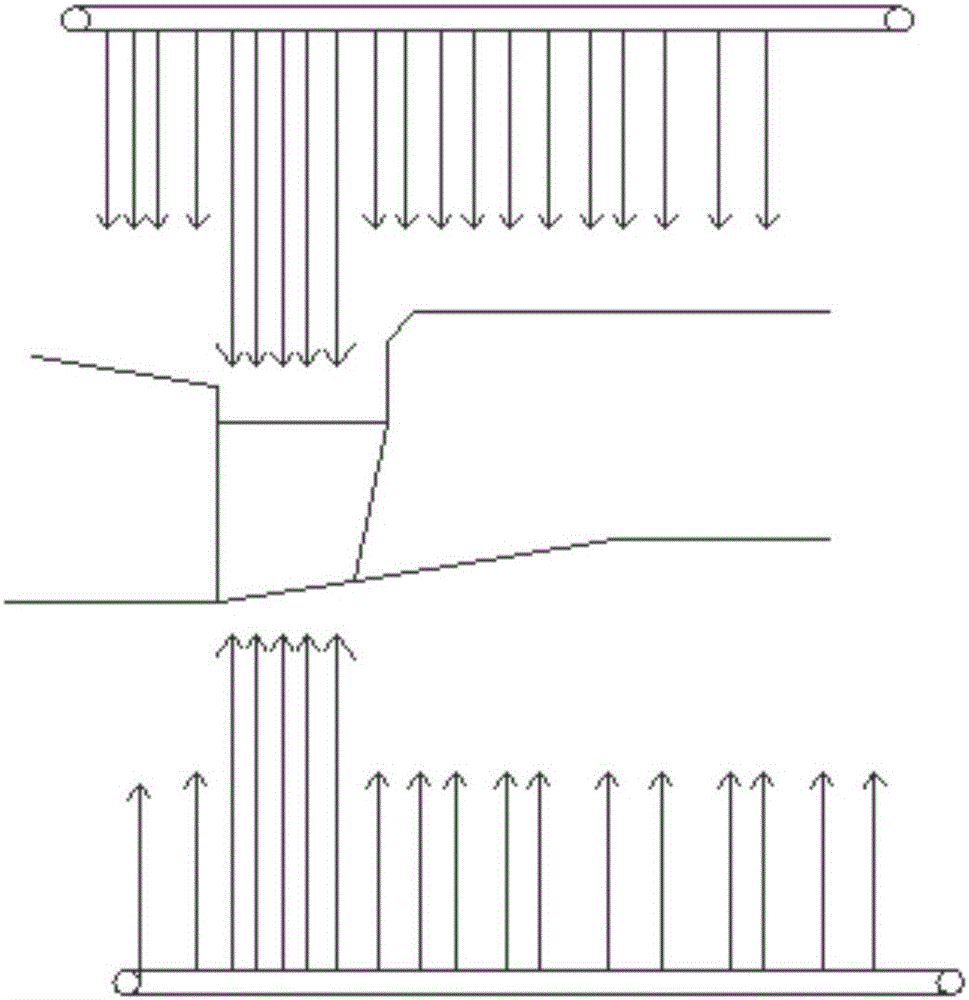

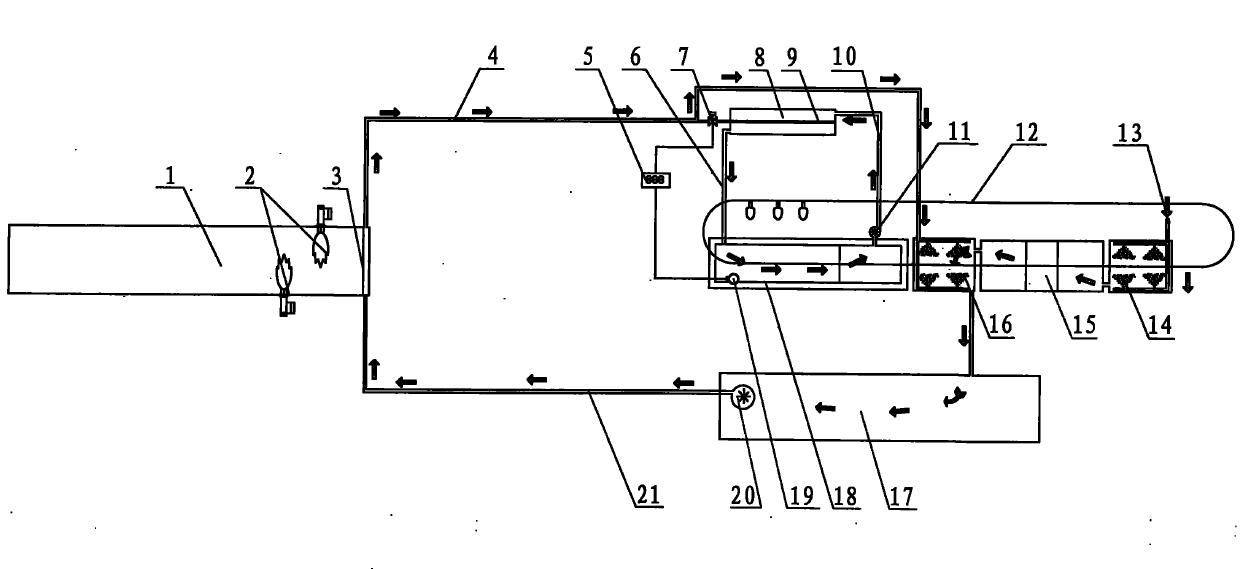

Multi-irradiation laser quenching method and device

The invention discloses a laser quenching method and device. According to the method, single heating in the conventional laser quenching technology is changed into multi-irradiation heating, or even high-frequency multi-irradiation heating by combining multi-irradiation heating with a quick scanning function of a rotating mirror; the heat conduction process caused by input of laser energy is injected into the surface of a workpiece within short heating time in a multi-stacking mode, so that the accumulation of the laser energy absorbed by a metal base body is increased, and the accumulation of the heat conduction depth is also increased. The device comprises a laser device, a control system, a light guide system, a mechanical motion device and a laser processing head. Even if technical parameters adopt high laser power, and when the scanning speed is high, and an irradiation interval exists, the surface temperature of the metal is always controlled to be below a melting point, and heat can be effectively and continuously expanded from the surface of the workpiece into the workpiece; and therefore, on the premise that the surface of the metal is prevented from being melted, the depth of an austenitizing region on the surface of the workpiece is increased, and the laser quenching efficiency is obviously improved.

Owner:WUHAN HIVALUE INTELASER LTD

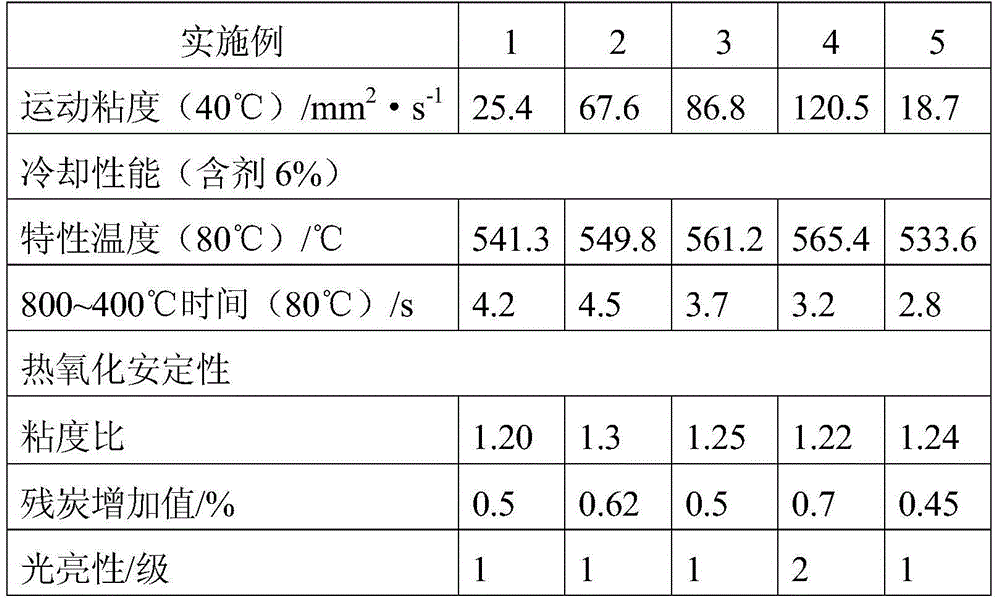

Water-soluble quenching medium

InactiveCN1465722AImprove quenching qualityImprove metallographic structureQuenching agentsQuenchingCarbon steel

The present invention relates to a water-soluble quenching medium. It is formed from proper quantity of polyether high-molecular mixture, surfactant, inorganist salt, sterilizing agent, inorganic alkali and water, and when it is concentration is 4-6%, it can be used for integrally quenching carbon steel, and when its concentration is 8-12%, it can be used for high-frequency quenching carbon steel, and it has the advantages of low use concentration, long service life and stable quenching quality.

Owner:FAW GROUP

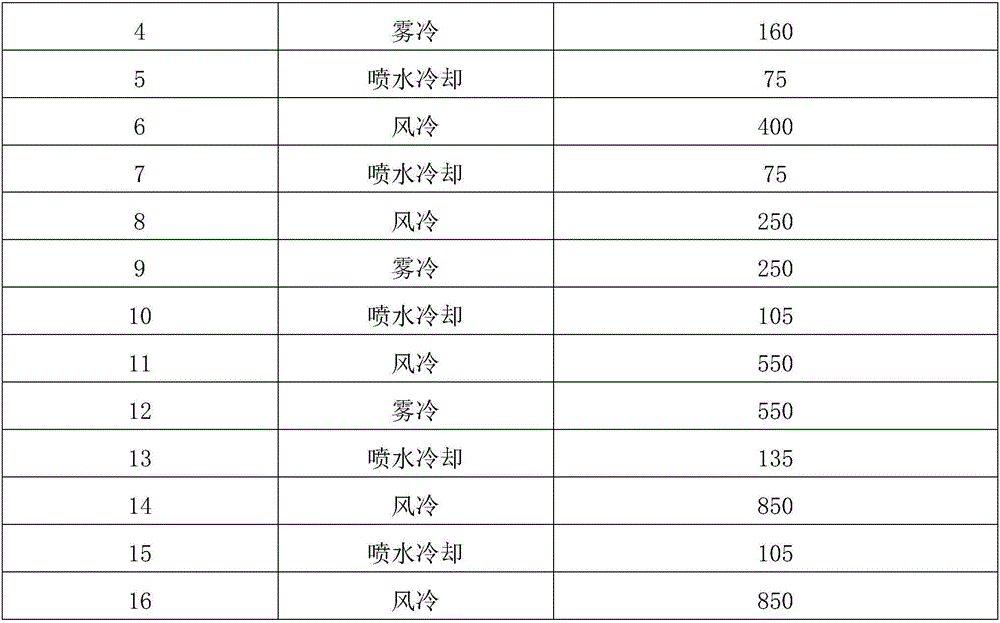

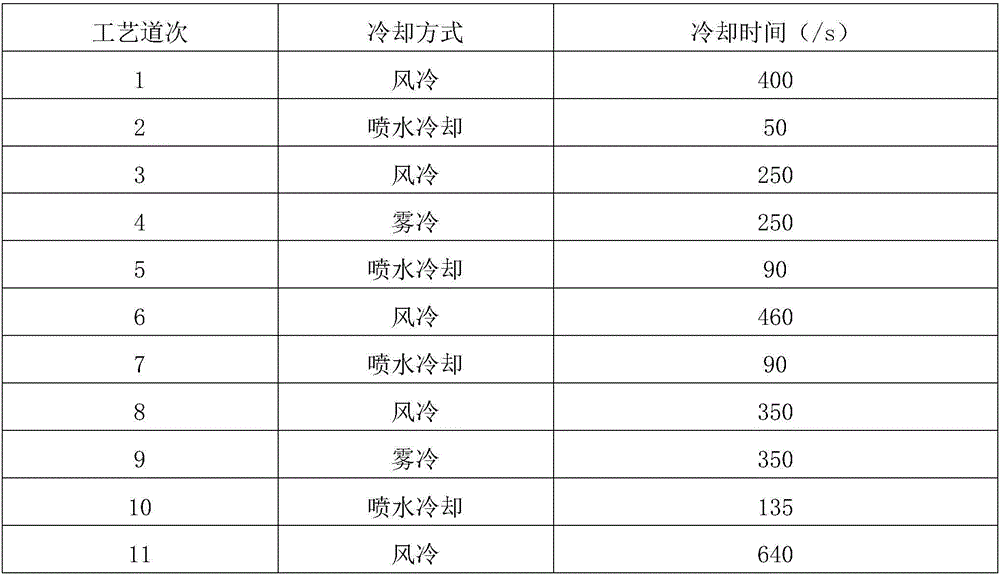

H13 steel vacuum time-control quenching heat treatment technique

InactiveCN101121954AAvoid risk of crackingImprove impact toughnessHeat treatment process controlQuenching agentsSalt waterTime control

The invention discloses a time-controlled sudden cooling vacuum heat treatment process for H13 steel, which includes heating and heat preserving, quenching and tempering; the quenching media for quenching after heating and heat preserving is salt water containing 5 to 10 percent NaC1, and the quenching treatment lasts for 1 to 5 minutes. The invention adopts a special time-controlled sudden cooling process, which not only prevents the danger of cracking during quenching of the salt water, but also greatly improves the quenching quality, so as to effectively improve the impact toughness of the H13 steel after tempering, and thus greatly extends the service life of the mould.

Owner:上海市机械制造工艺研究所有限公司

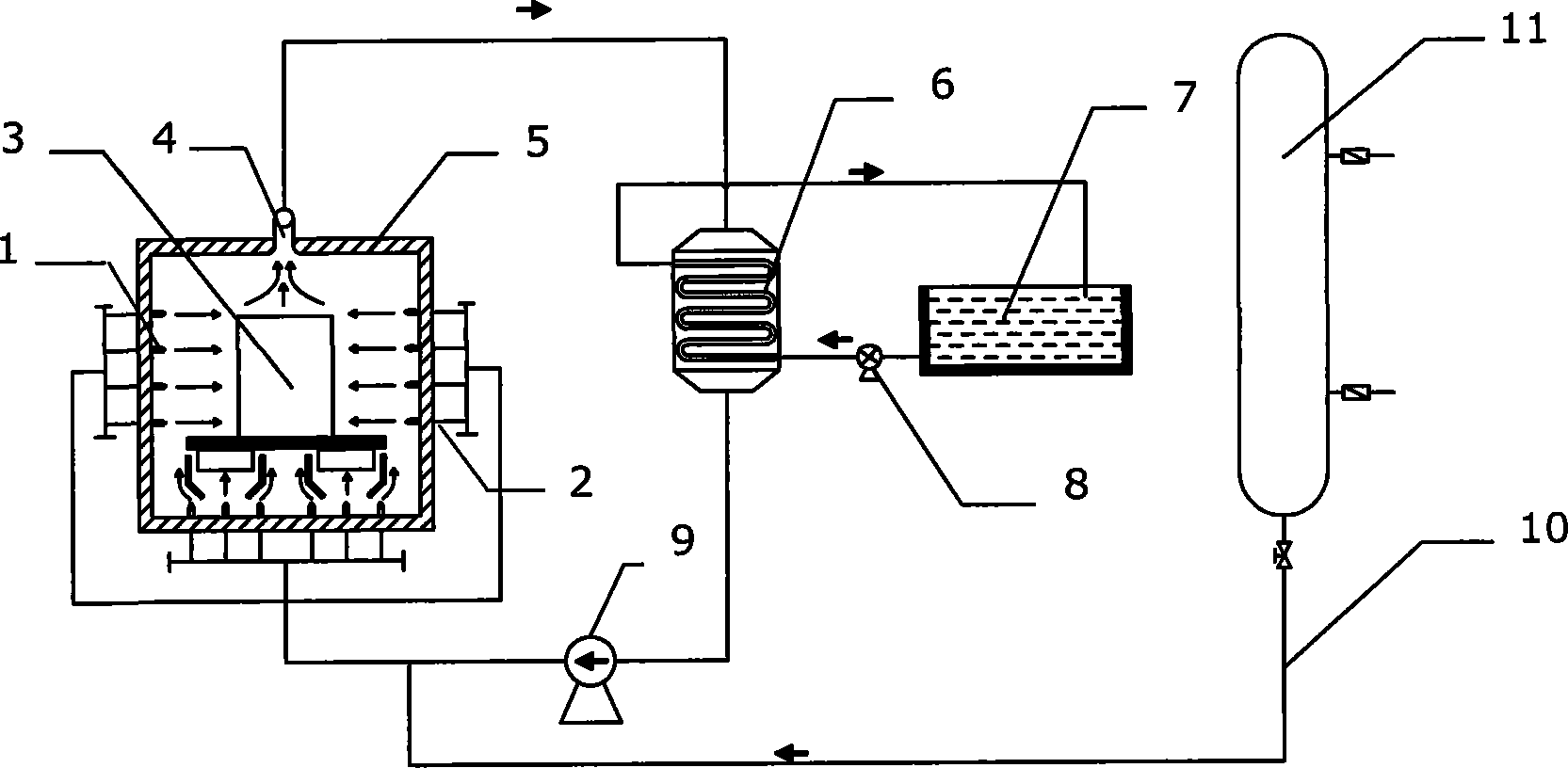

Gas stove outer circulation cooling method of double chamber atmosphere pressure hardening furnace and cooling system thereof

InactiveCN101182593AReduce consumptionEnhanced convective heat transferFurnace typesHeat treatment furnacesCooling chamberNitrogen gas

A gas furnace external circulation cooling method and a cooling system of a double-chamber constant-pressure quenching furnace belongs to the metal quenching field; aiming at the defects of wasting nitrogen with the prior art, the invention provides a method by which the high-temperature nitrogen is discharged from the top of the quenching furnace to be introduced into a heat exchanger out of the furnace for cooling; and then the nitrogen is mixed with the liquid nitrogen from a liquid nitrogen storage tank to participate in the quenching process and the circulation of the gas out of the furnace; the system which implements the method is that the nitrogen outlet at the top of a cooling chamber is connected with the heat exchanger and the outlet of the heat exchanger is connected with the outlet pipe of the liquid nitrogen storage tank in parallel; the main pipe after the parallel connection is connected with the air intake of a convergent divergent channel which is arranged on the cooling chamber; the outlet of the convergent divergent channel is connected with a nozzle to form a gas circulation cooling system; the inlet of a heat exchanging pipe in the heat exchanger is connected with a water pump or a fan and the inlet of the water pump is connected with a water tank; the inlet of the fan is arranged in the atmosphere to form circulation cooling system; the liquid nitrogen storage tank is connected with the parallel main pipe to form a medium supply system. The invention is characterized by saving nitrogen and high-quality quenching.

Owner:NORTHEASTERN UNIV

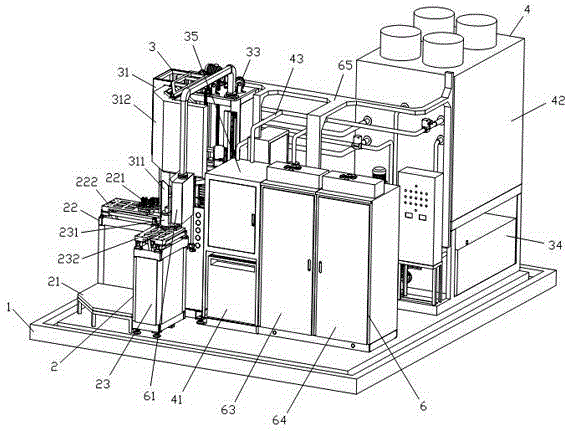

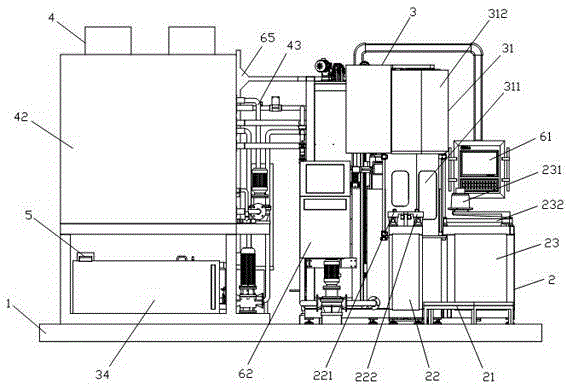

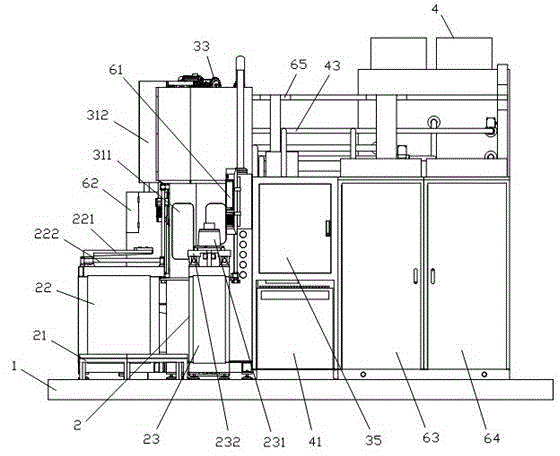

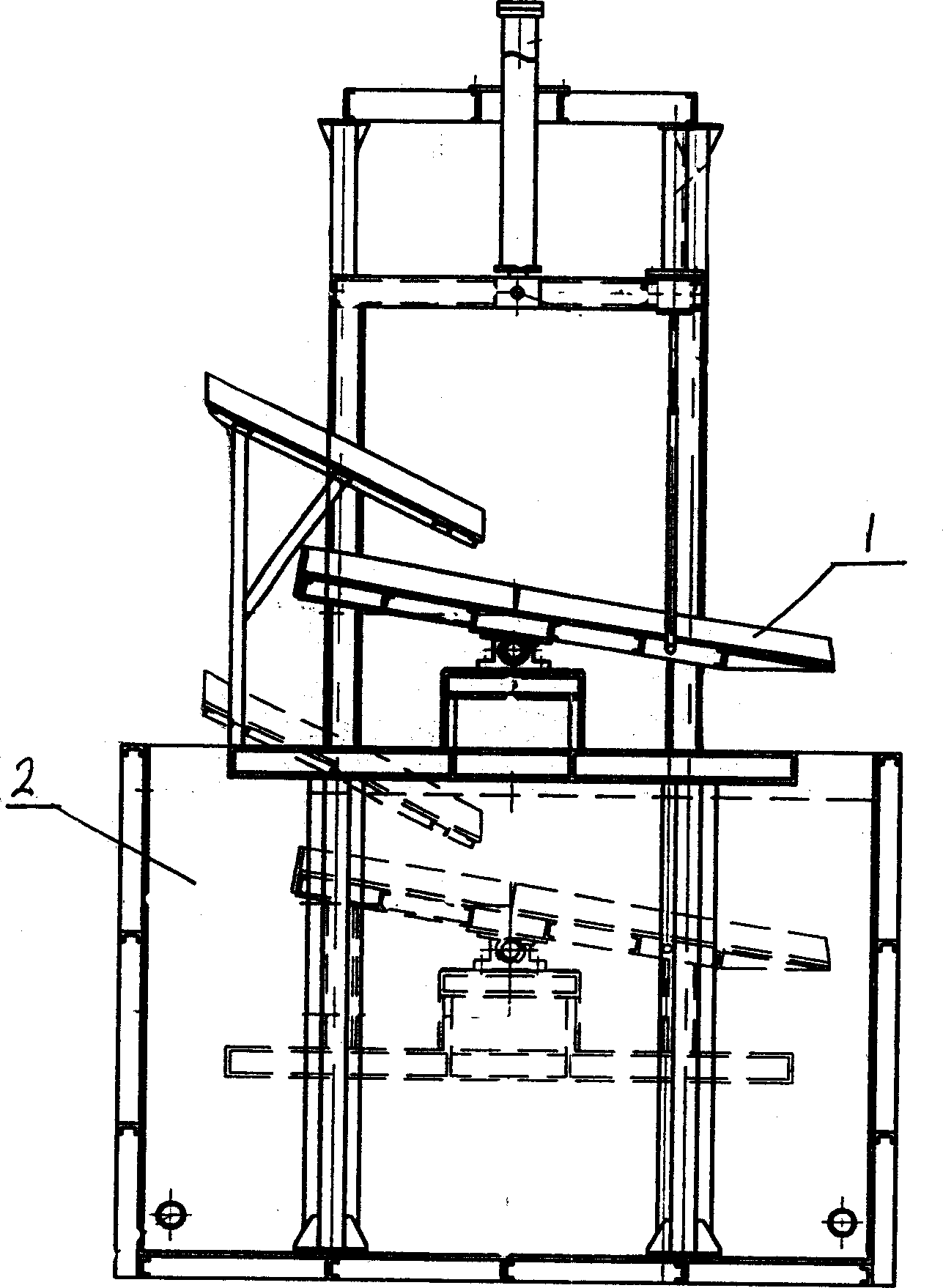

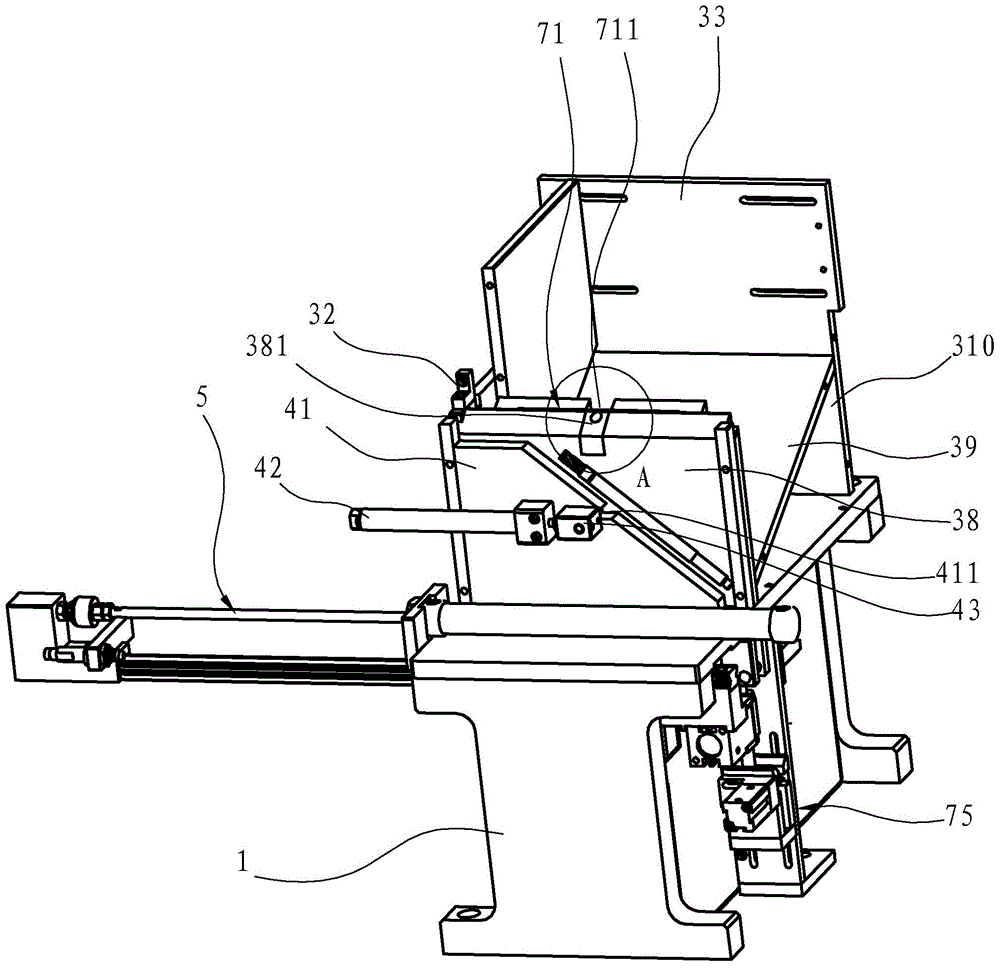

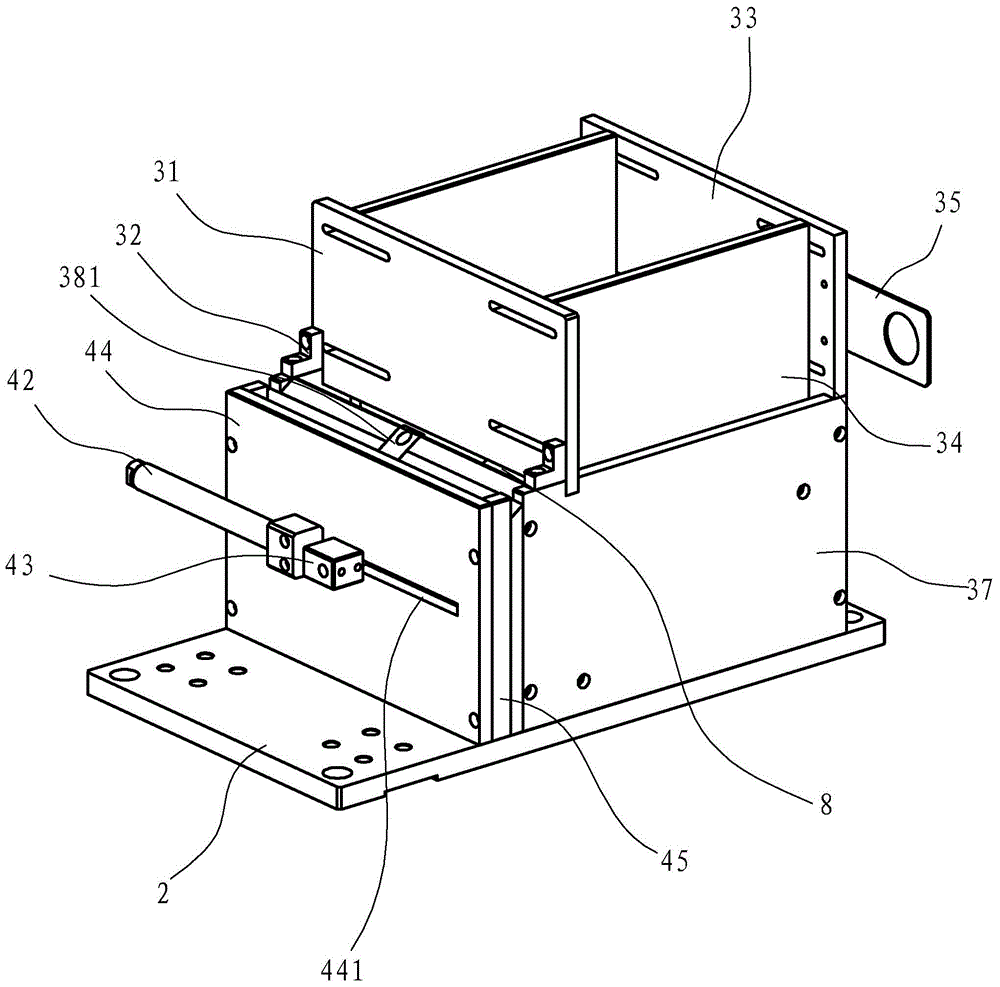

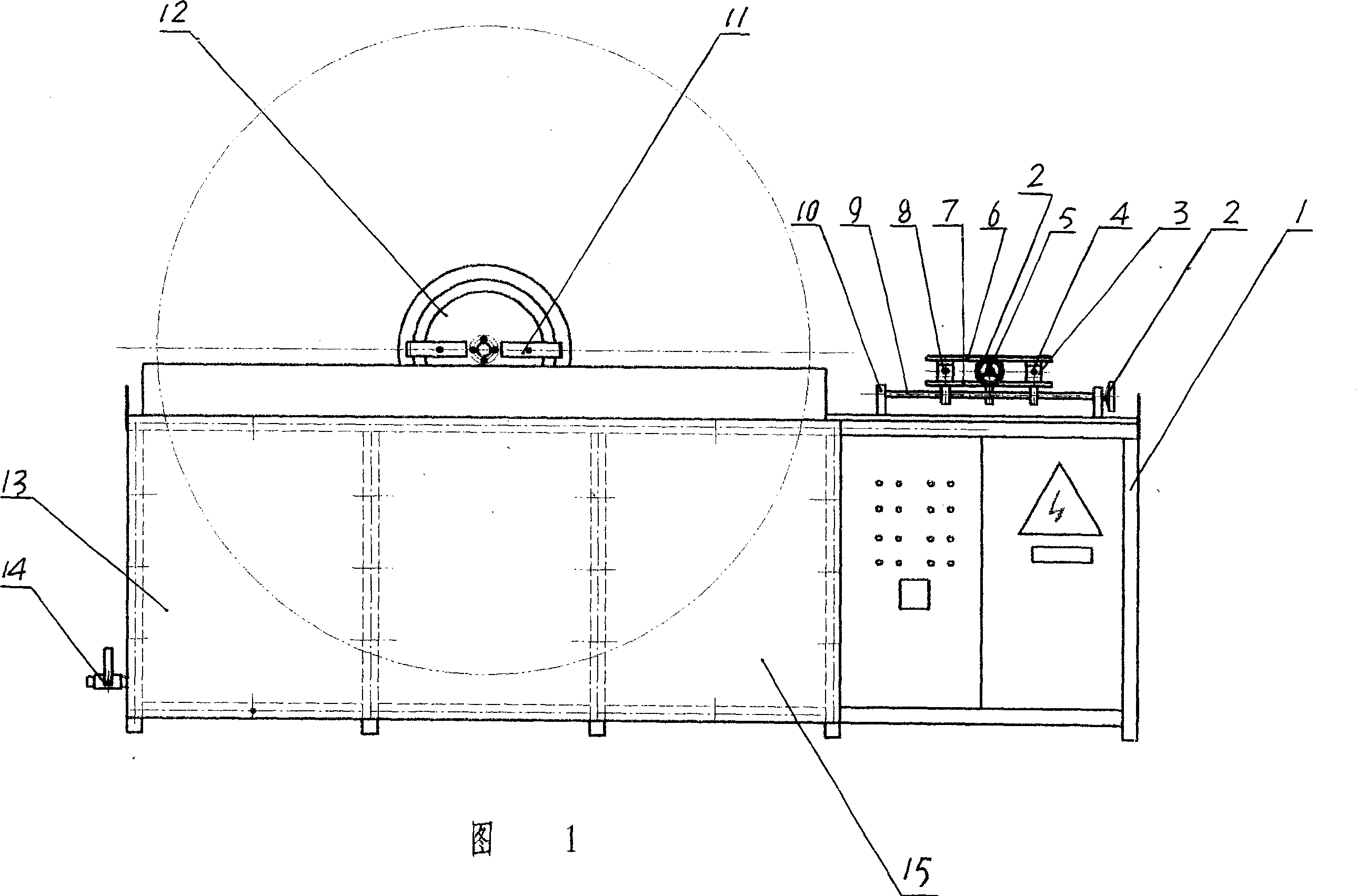

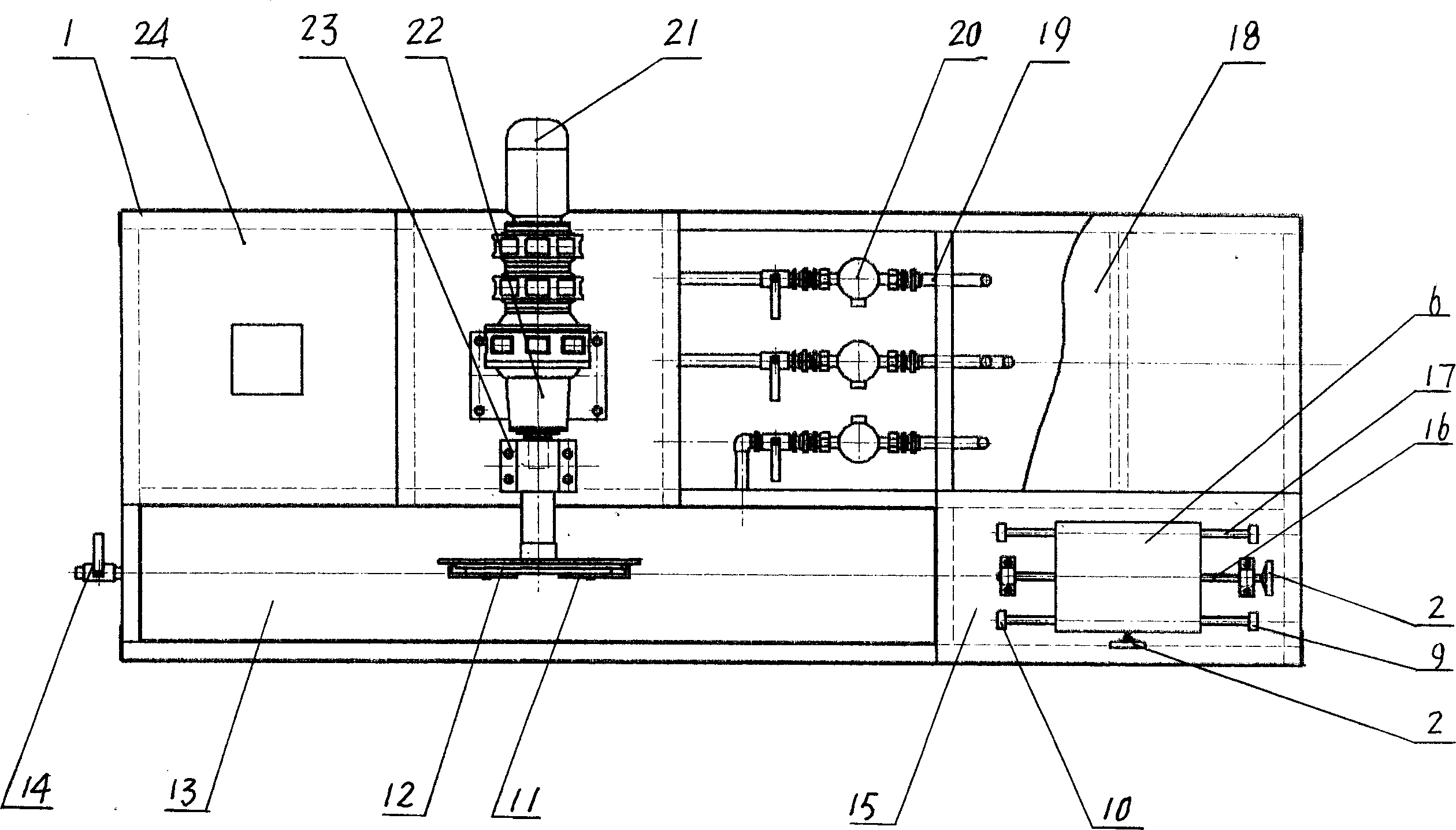

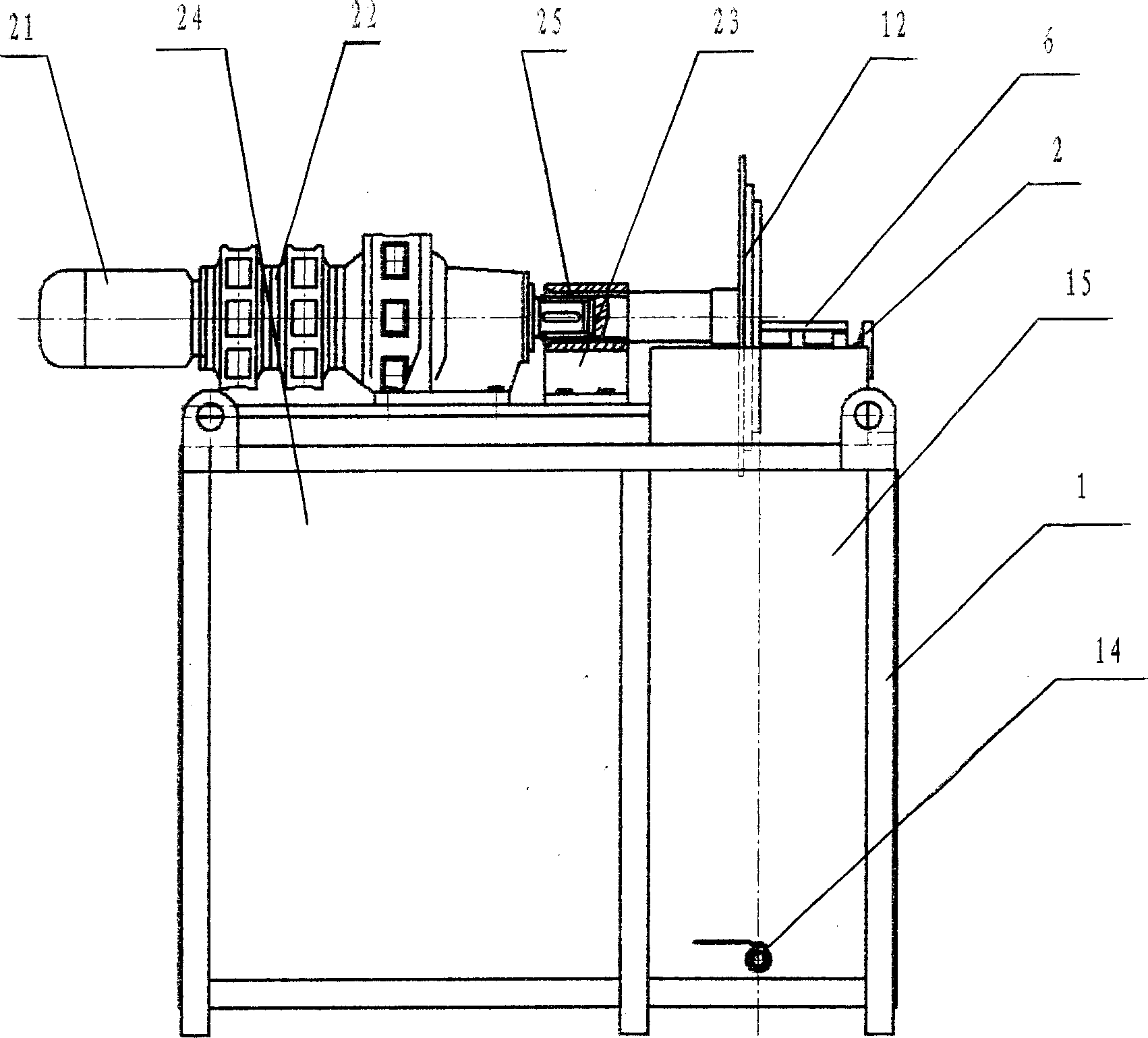

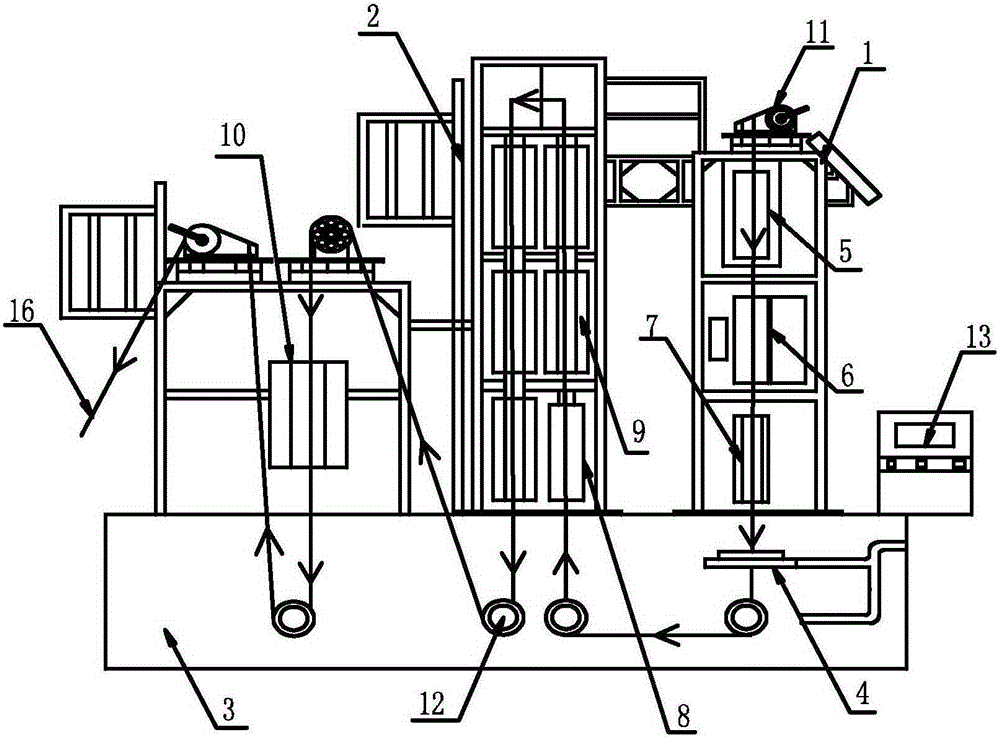

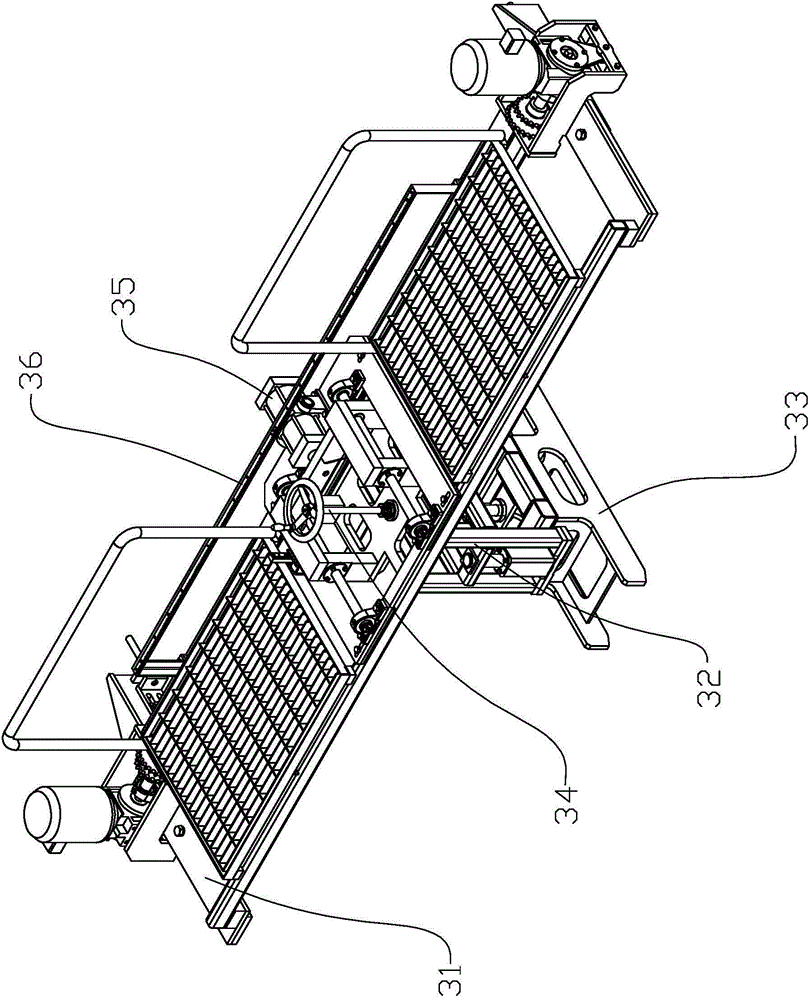

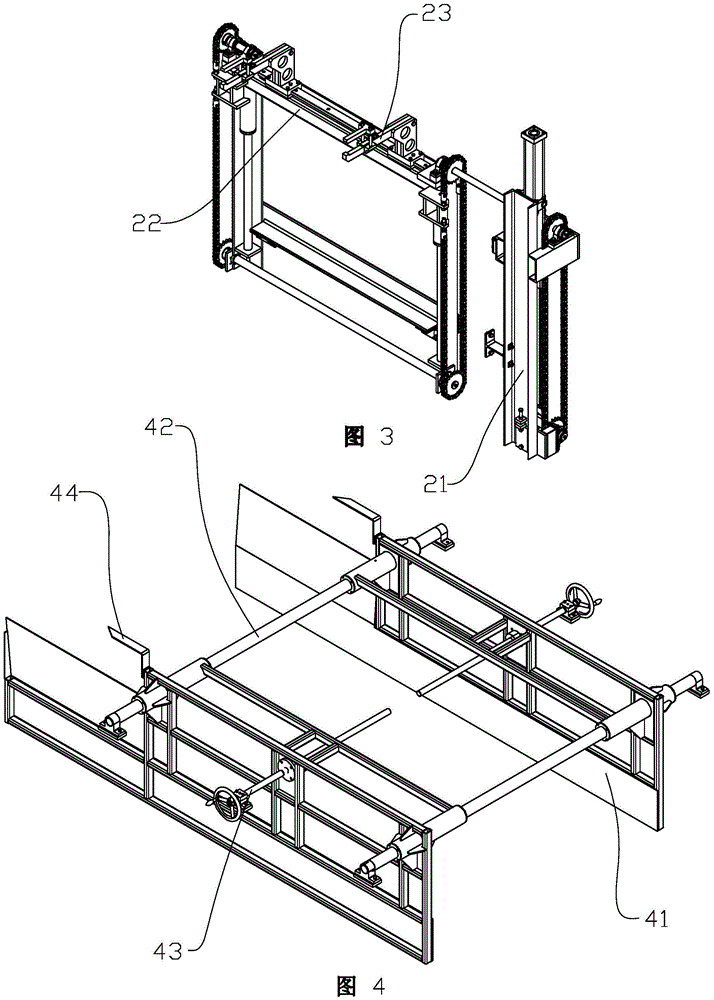

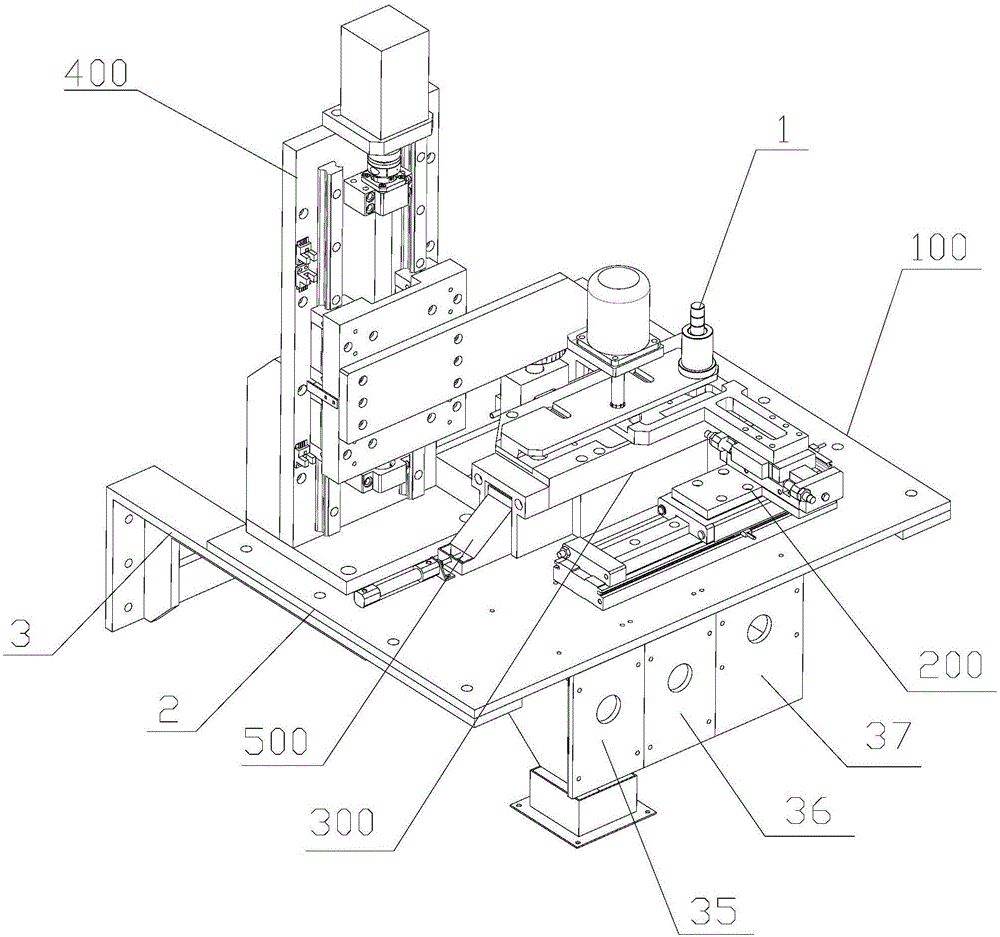

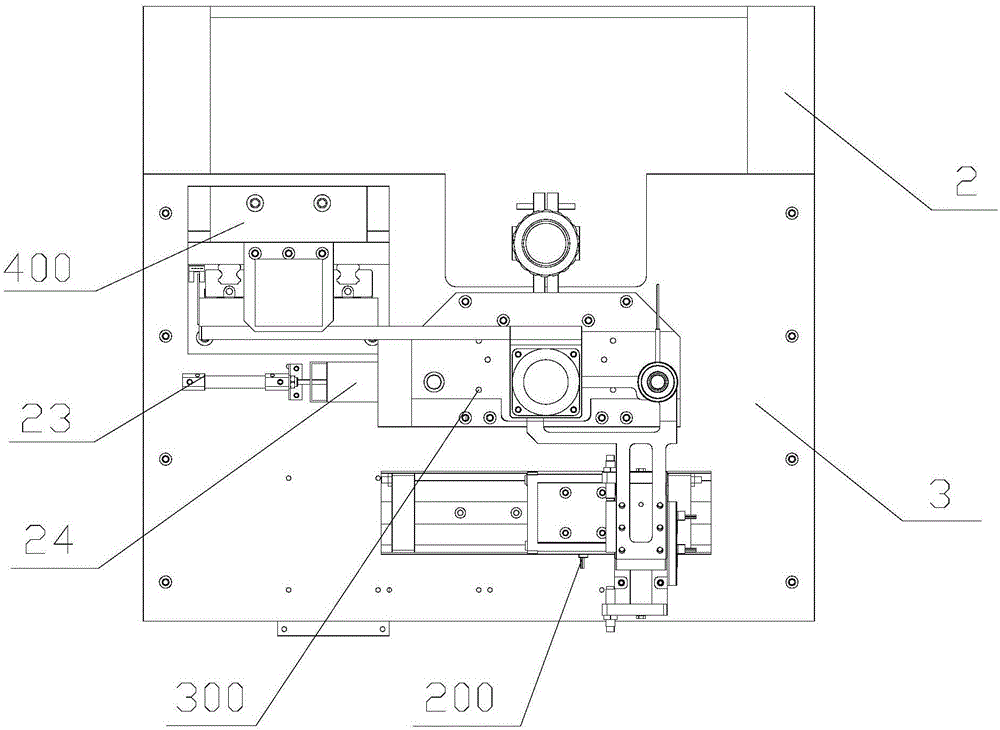

Quench machine tool

ActiveCN102912094ACompact structureReasonable layoutFurnace typesHeat treatment furnacesContinuous productionEngineering

The invention relates to a quench machine tool which comprises a base, a loading and unloading mechanism arranged on the base, a quench mechanism, a cooling mechanism and a control system, wherein the quench mechanism comprises a workpiece sliding platform, a sensor mobile sliding platform and a power switcher; the workpiece sliding platform comprises a machine frame, a ball screw installed on the machine frame, a workpiece top tip and a workpiece top base; the ball screw is driven by a driving device to drive the workpiece sliding platform to linearly move; the workpiece top base is driven to rotate by the driving device; the sensor mobile sliding platform is arranged to match the workpiece sliding platform, is driven by the driving device to shift and comprises a sensor installed on a transition row of the sensor mobile sliding platform and moving along with the sensor mobile sliding platform; and the power switcher is electrically connected with the sensor mobile sliding platform and controls the sensor mobile sliding platform to switch among loads with different frequencies. The quench machine tool not only has high production efficiency, but also has stable workpiece quality and good workpiece consistency, the whole quench process has reasonable actions and high efficiency, and the requirement of massive and continuous production can be satisfied.

Owner:SHIYAN HENGJIN INDUCTION TECH CO LTD

Production process of ultrathin special-shaped aluminum alloy extruded section and product

The invention relates to a production process of an ultrathin special-shaped aluminum alloy extruded section and a product. The process comprises the following steps: (1) preheating: the mould preheating temperature is 490-510 DEG C, the cast ingot preheating temperature is 500-520 DEG C, an extrusion barrel preheating temperature is 455-460 DEG C; (2) extrusion molding: extruding a cast ingot; (3) quenching treatment: firstly performing local online water mist treatment on the extruded aluminum alloy section at an outlet of the extrusion barrel to be set, and then performing integral online waste mist treatment, wherein the temperature of the aluminum alloy section out of a quenching region is 18-35 DEG C; (4) stretch straightening; (5) cutting off to length; and (6) artificial aging. The method provided by the invention can effectively improve the quenching quality of the ultrathin special-shaped aluminum alloy extruded section so as to guarantee the size of the section, and the prepared aluminum alloy extruded section is good in quality, regular in size and high in yield.

Owner:CHINA ZHONGWANG

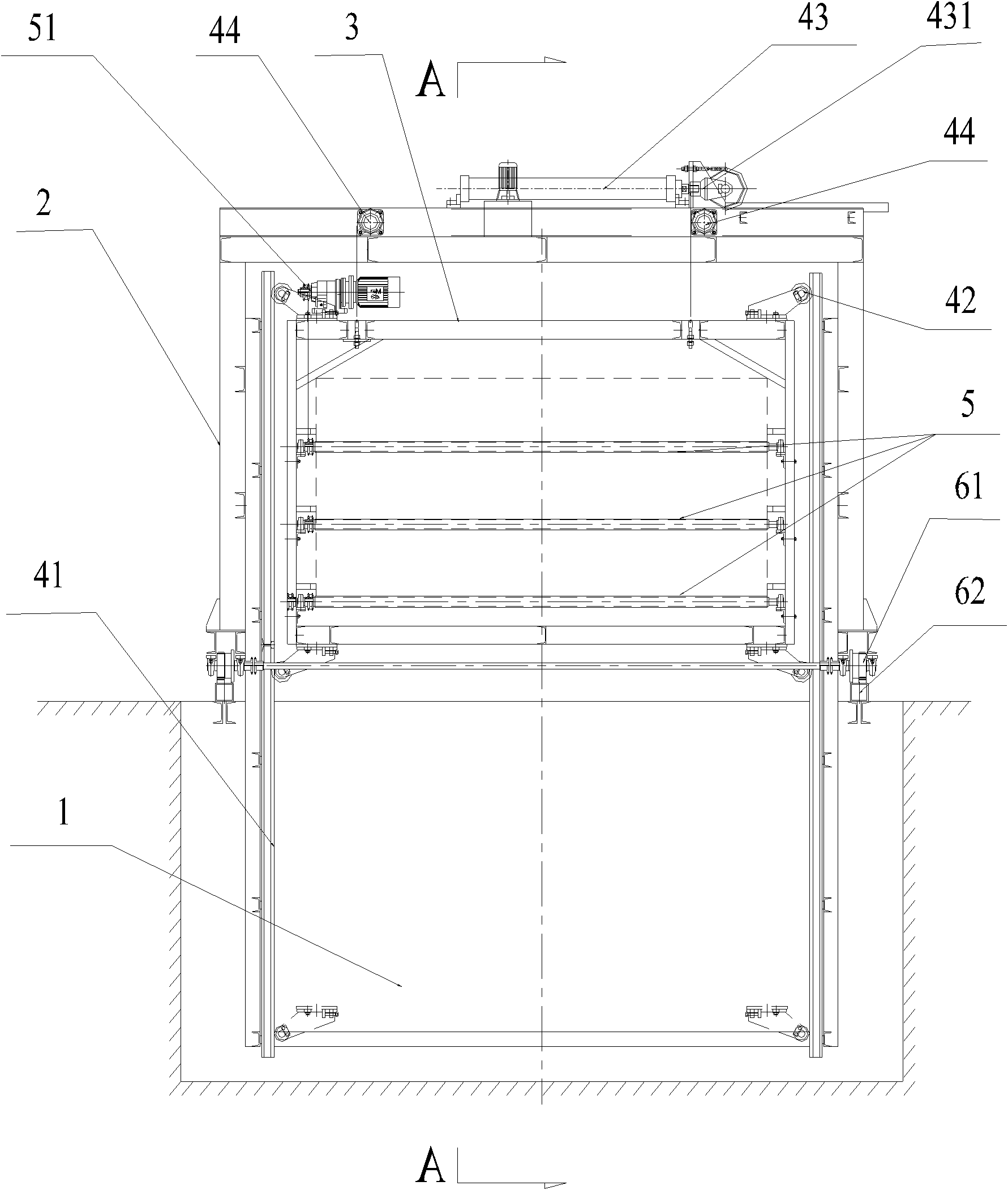

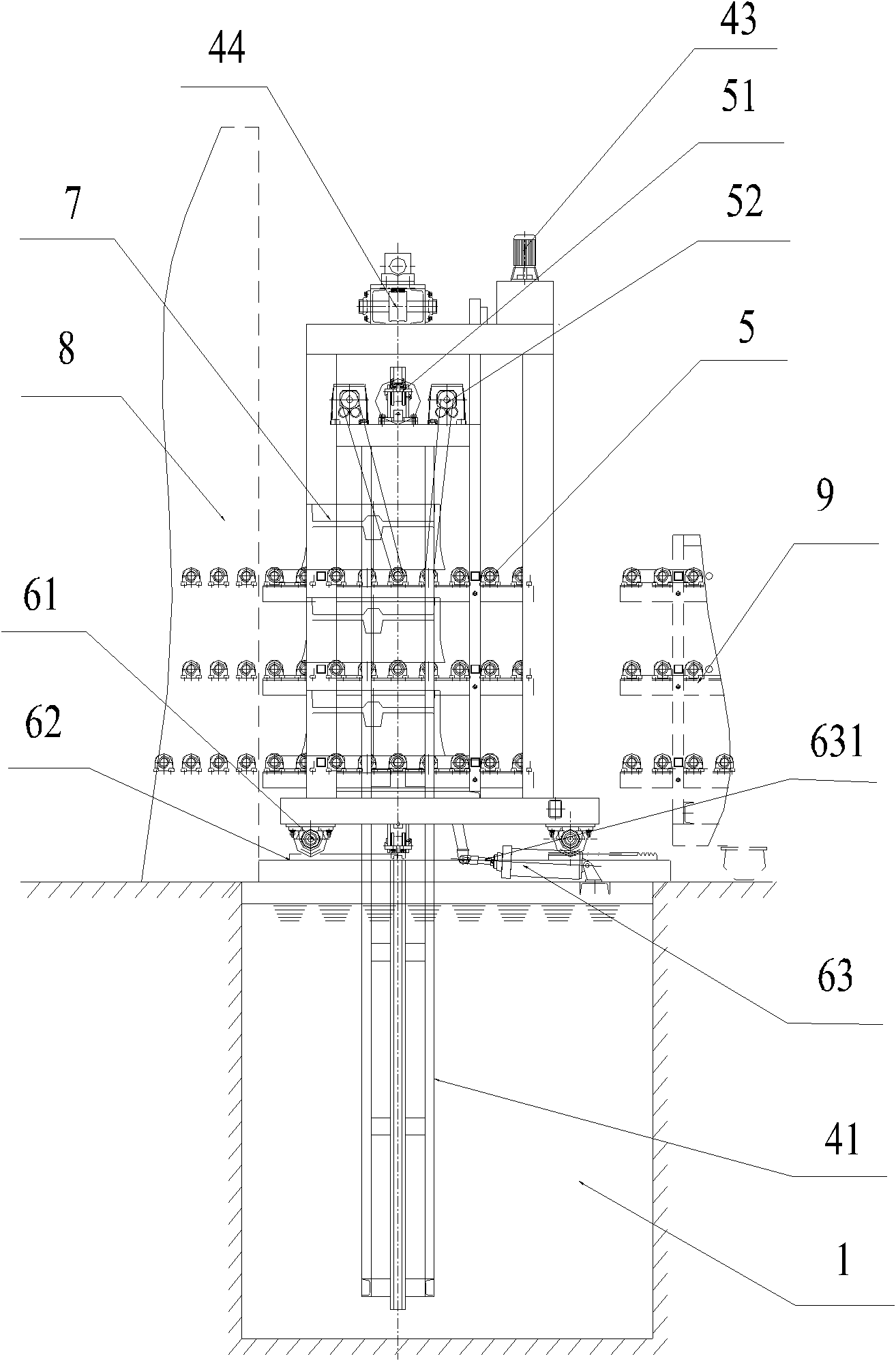

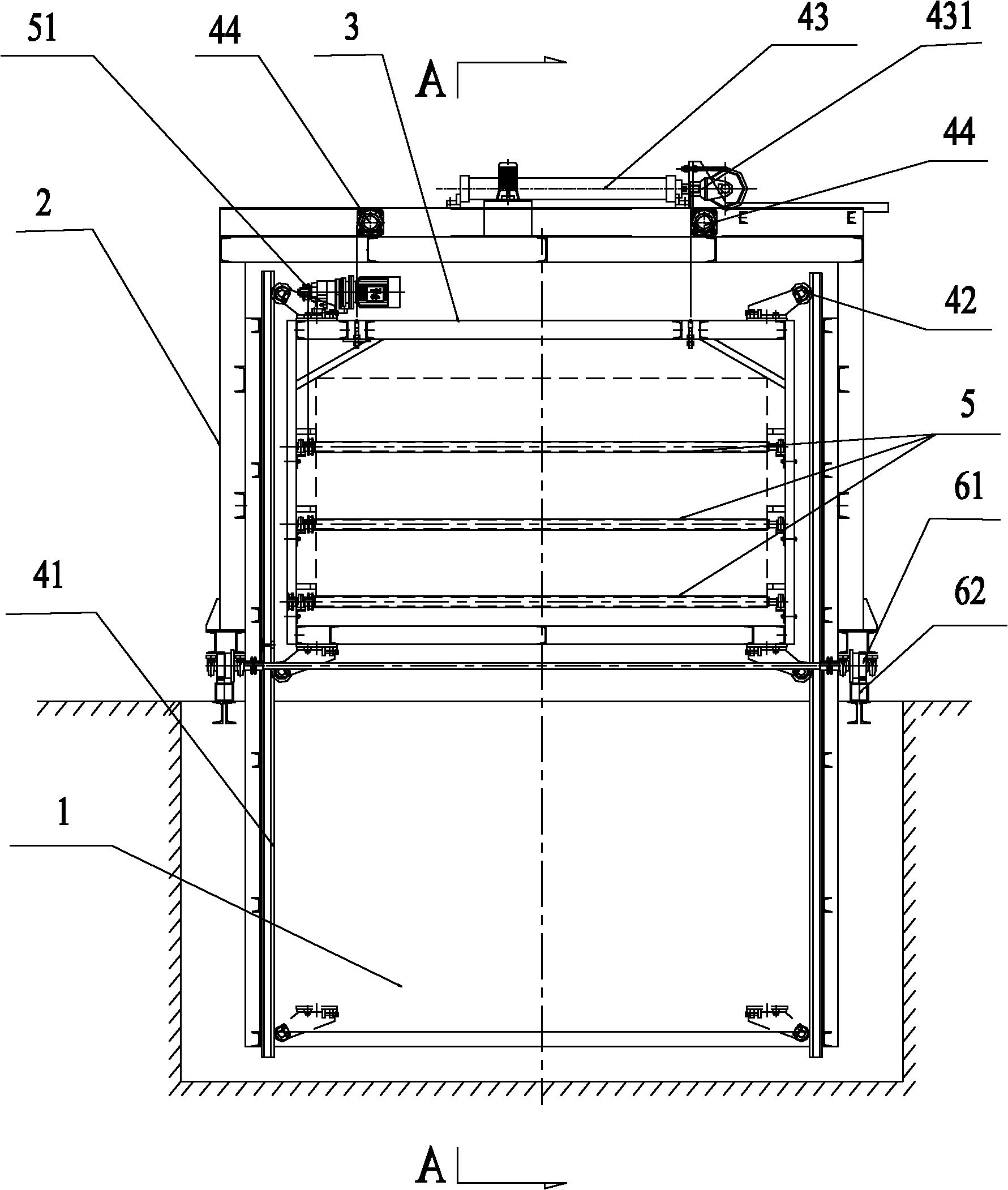

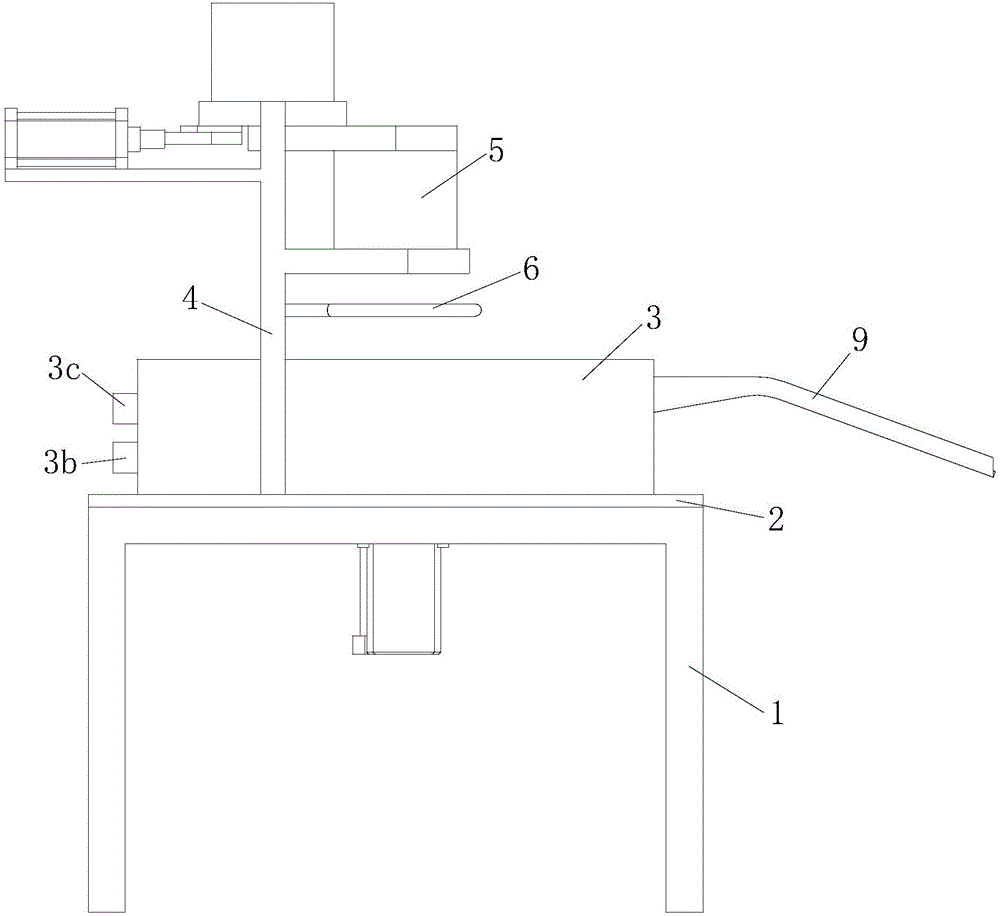

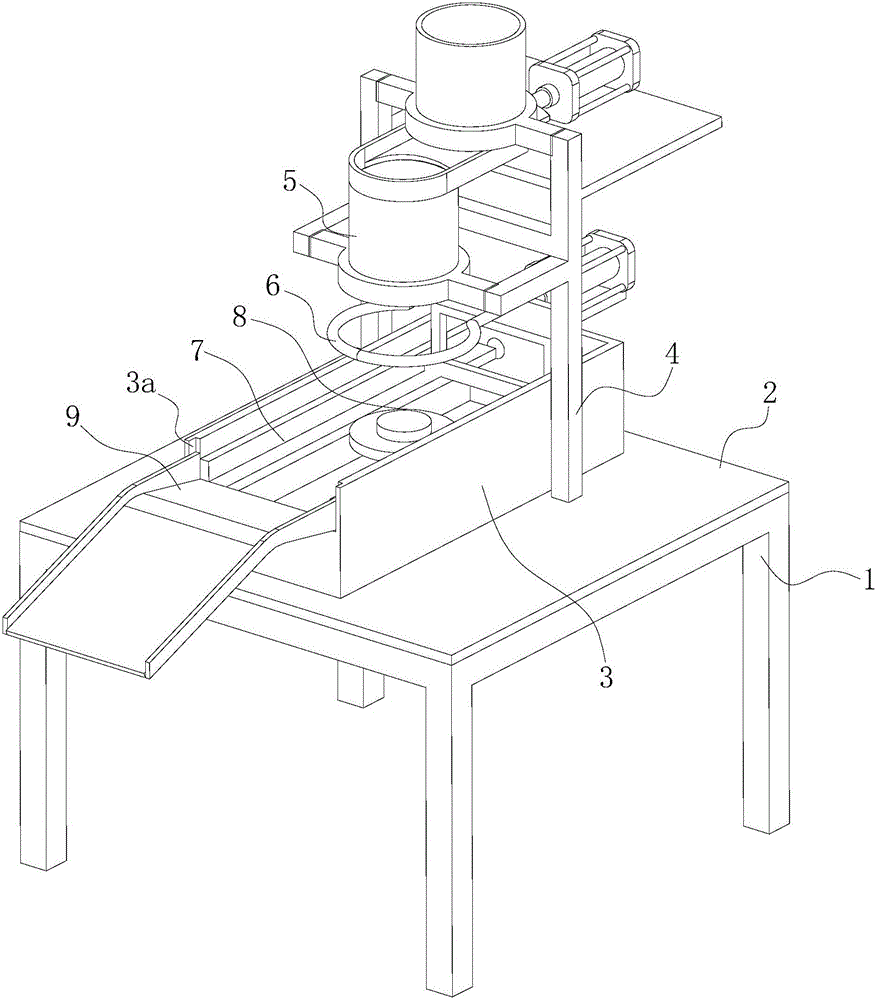

Automatic quenching device

ActiveCN101935748AImprove quenching qualityQuality improvementFurnace typesHeat treatment furnacesQuenchingMaterials science

The invention relates to an automatic quenching device, which comprises a quenching tank, a supporting frame, a quenching frame, a lifting mechanism, and a carrying roller, wherein the supporting frame is arranged above the quenching tank; the quenching frame is positioned inside the supporting frame; the lifting mechanism for making the quenching frame move up and down is arranged between the quenching frame and the supporting frame; and the carrying roller is horizontally arranged inside the quenching frame. The carrying roller is connected to a wheel hub which is quickly carried to a quenching position, and the lifting mechanism lowers the quenching frame to a position below the liquid level of the quenching tank. The automatic quenching device can quickly carry the wheel hub to the quenching position, can control the best quenching moment, and has high wheel hub quenching quality; besides, the automatic quenching device adopts the carrying roller to transfer the wheel hub and avoids local long-time high-temperature operation of a delivery mechanism, so the component damage is small and the later maintenance cost is low.

Owner:NANJING CHANGJIANG IND FURNACE TECH GRP CO LTD

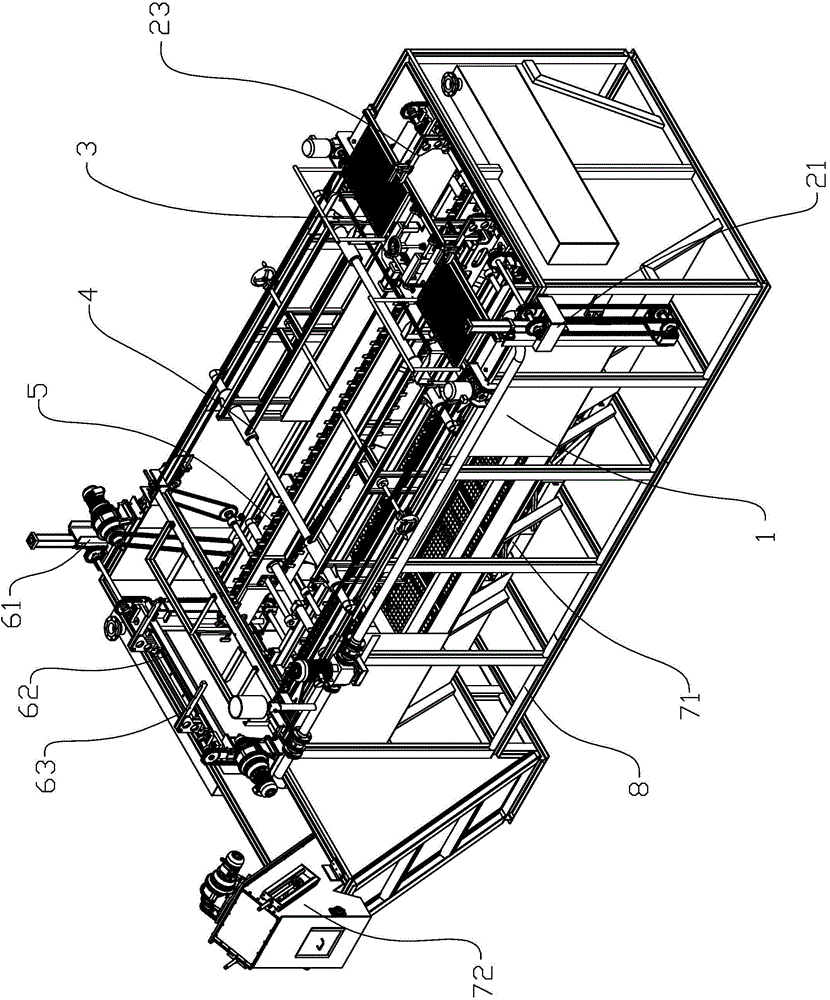

Automatic quenching production line for annular parts

InactiveCN105018709ARealize automatic feeding processReasonable structural designFurnace typesHeat treatment furnacesProduction lineEngineering

The invention discloses an automatic quenching production line for annular parts. The automatic quenching production line for the annular parts comprises a supporting frame. An installing plate is fixed to the upper end of the supporting frame. A cooling pool is fixed to the upper end of the installing plate. Slide ways are fixed to the left end and the right end of the inner wall of the cooling pool. A fixing frame is arranged at the upper end of the cooling pool. A heating ring is fixed to the fixing frame. An automatic feeding device is arranged above the heating ring. A driven gear is installed at the lower end of the installing plate. A telescopic cylinder is fixed to the lower end of the driven gear. A positioning convex block is fixed to the upper end of the telescopic cylinder. A motor installing plate is fixed to the left side of the lower end of the installing plate. A motor is fixed to the motor installing plate. A driving gear is fixed to a shaft of the motor in a key connection manner. The automatic quenching production line has the beneficial effects of being reasonable in structural design, convenient to use and the like, automatic feeding of the parts can be achieved, quenching treatment is performed on the parts, the automation degree is high, the quenching quality is good, the quenching efficiency is improved, and production cost is saved.

Owner:安徽旭虹机械设备有限公司

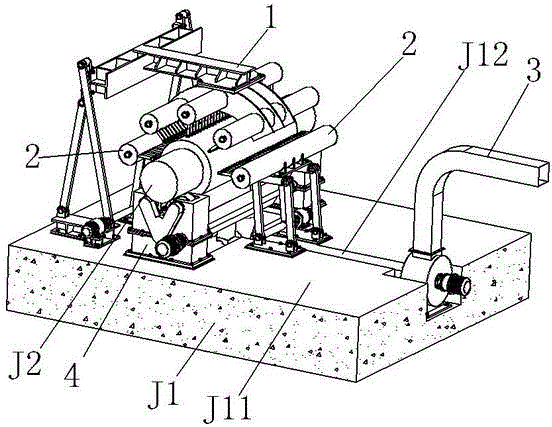

Air blast quenching machine for rollers

InactiveCN105925780AAccurate and reliable rotary motionImprove uniformityFurnace typesHeat treatment furnacesWorking environmentEngineering

The invention relates to mechanical equipment in the field of metal heat treatment, in particular to an air blast quenching machine for rollers. The air blast quenching machine comprises an air spraying device, two heating devices, an air extracting device and a rotation device, wherein the air spraying device, the heating devices and the rotation device are all mounted and fixedly connected to a horizontal surface on a concrete poured foundation base; the air extracting device is mounted and fixedly connected into a groove in the foundation base; the heating devices are arranged on two sides of the rotation device symmetrically; and a workpiece roller is arranged on the rotation device. The air blast quenching machine adopts four-carrier roller synchronous constant-speed mobile rotation, so that the heating uniformity and the quenching quality are improved; due to combined function of the air spraying device and the air extracting device, the cooling speed can be accelerated, and the work environment can be improved; and as both the air spraying device and the heating devices are arranged on and connected with a link mechanism, mobile starting and stopping can be realized, and spray head distances can be adjusted fast.

Owner:KUNMING UNIV

Waste heat hardening and tempering process of motorcycle crank forged piece

InactiveCN101524813AUniform internal and external temperatureImprove quenching qualityOther manufacturing equipments/toolsQuenching agentsMedium frequencyHardness

The invention discloses a waste heat hardening and tempering process of motorcycle crank forged piece, comprising the working procedures like medium-frequency heating, extracting billet, blocking, precise forging, isothermal processing, quenching, tempering and the like. The process can obviously improve hardenability through forging waste heat hardening and tempering, ensure even distribution of tissues and hardness and ensure that the forged piece has the mechanical performance superior to that of the workpieces after conventional hardening and tempering. The workpieces undergoing finish forging adopt short isothermal processing to ensure the temperature of the workpieces to be uniform when entering quenching liquid, thus ensuring stable performance and excellent quality and realizing industrial production. Meanwhile, the short isothermal processing only consumes little electric energy, thus conforming to the requirement of the economical society.

Owner:重庆歇马机械曲轴有限公司

Technique for oil quenching casting sphere made from high chrome alloy

This invention relates to an art for oil-quenching high-chromium alloy cast ball. The high-chromium alloy cast ball and cast-section are heated to quenching temp., then tapped out of the furnace, proceeding oil-quenching, oil temp. being controlled <120 deg.C, when temp. of the product being lowered below 300 deg.C, the cast ball and cast section are taking out of the oil-cell. The wear-resisting high-chromium cast ball and cast section treated by using this method are better than that of prior art treatment in various kinds of technical index, wherein: quenching hardness=60-65 deg.C, difference (between center and surface) of hardness <2.0 RHc, ball falling test >3000 times. This quenching art overcomes prior art defect. The product treated by this method has excellent wear-resisting property and longer service-life.

Owner:ANHUI FENGXING WEAR RESISTANT MATERIALS CO LTD

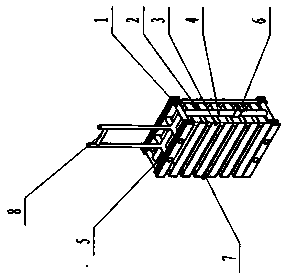

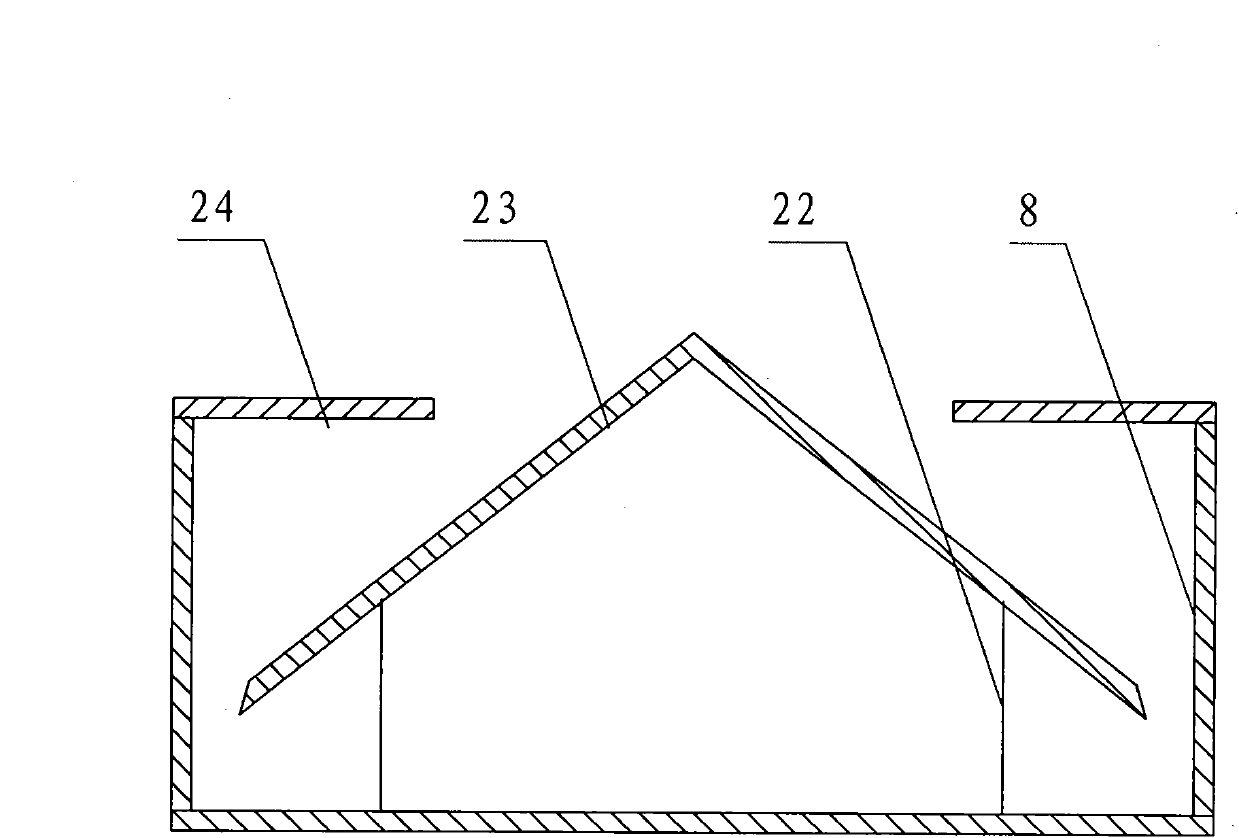

Vertical vacuum quenching furnace

InactiveCN103627863AImprove quenching qualityQuenching devicesProgrammable logic controllerQuenching

The invention discloses a vertical vacuum quenching furnace and solves the problem of high workpiece quenching quality discrete index caused by long workpiece transfer time in a conventional vacuum quenching furnace. The vertical vacuum quenching furnace comprises a PLC (programmable logic controller) and a quenching water tank (10), wherein a heating chamber (24) is arranged at the top end of the quenching water tank; a heating chamber lower heat insulation door (26) is arranged between a bottom outlet of the heating chamber and a top inlet of the quenching water tank; an output shaft of a lifting air cylinder (29), extending downwards is connected with a mechanical paw (30); drawer material boxes (3) and materials to be quenched are arranged in multiple layers of horizontal drawer shelves; a left central supporting shaft (5) is arranged on a central shaft in the longitudinal direction of the left side surface of a cuboid-shaped material basket frame; a right central supporting shaft (4) is arranged on the central shaft in the longitudinal direction of the right side surface of the cuboid-shaped material basket frame; material basket turning support shafts are arranged on the rear sides of the central supporting shafts on the left side surface and the right side surface of the cuboid-shaped material basket frame. A material basket is especially suitable for the vertical vacuum quenching furnace.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 2 RES INST

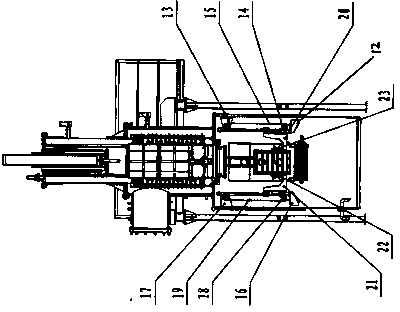

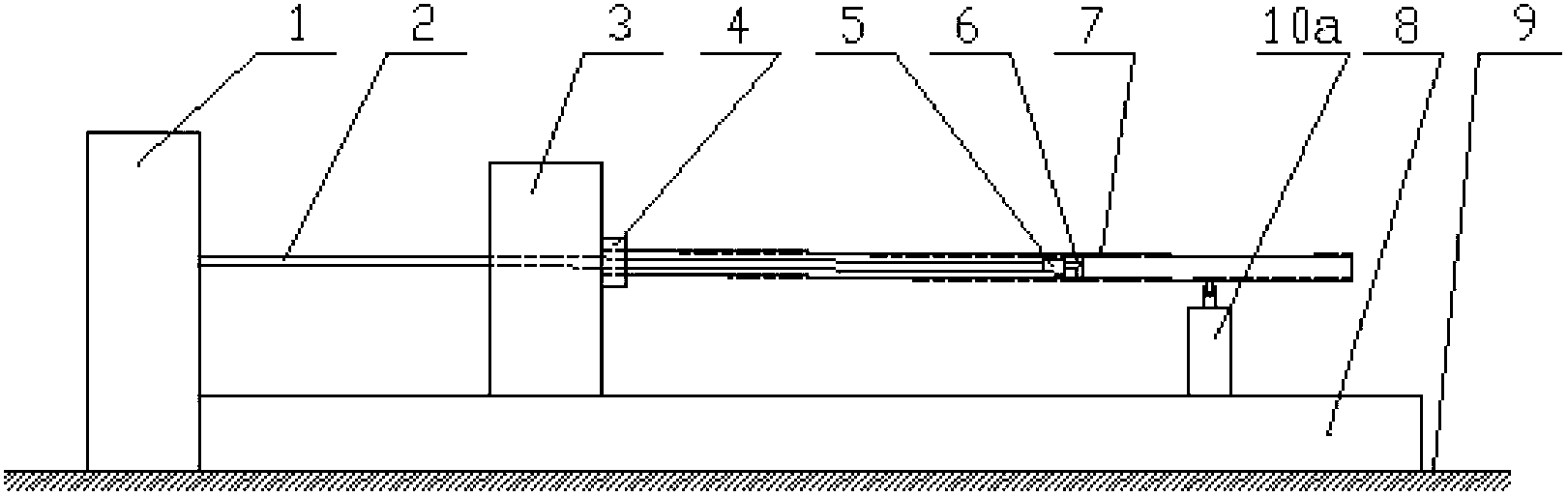

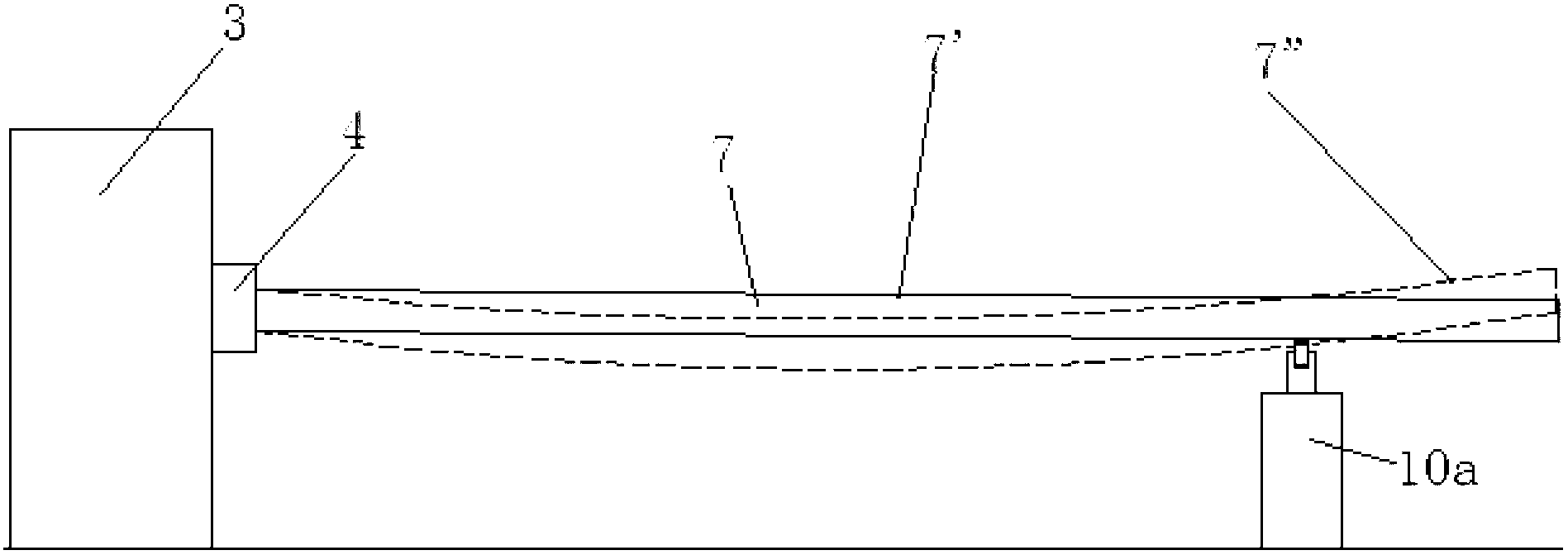

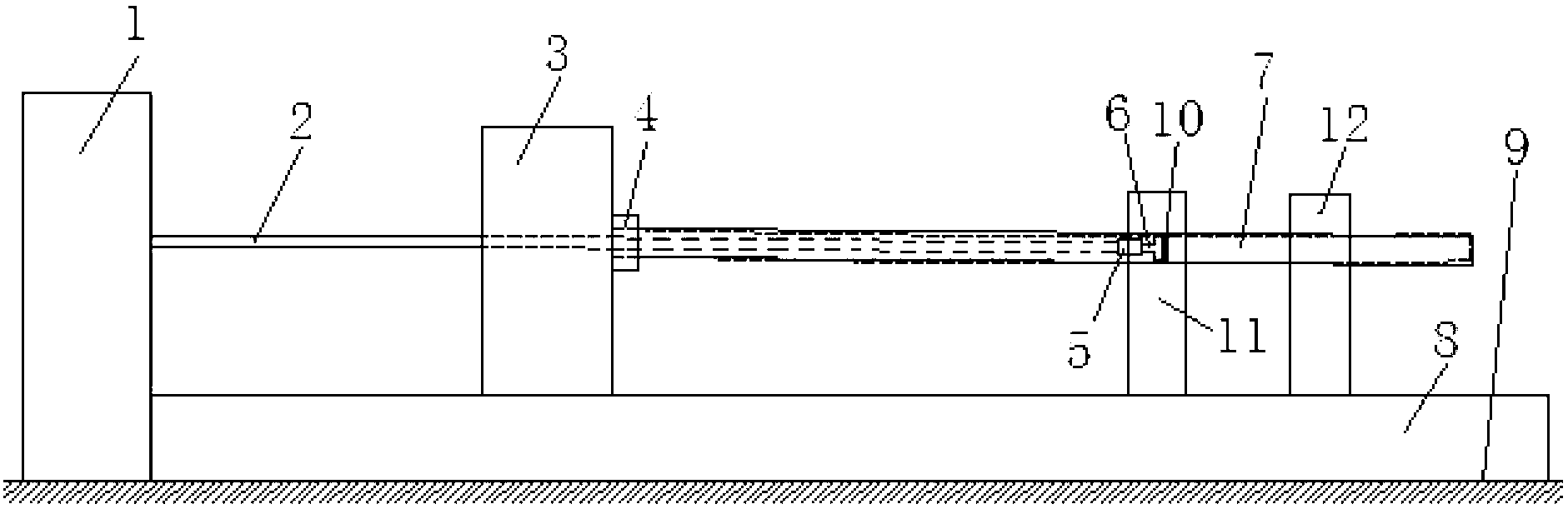

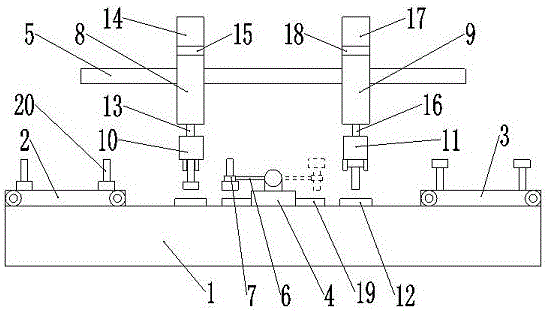

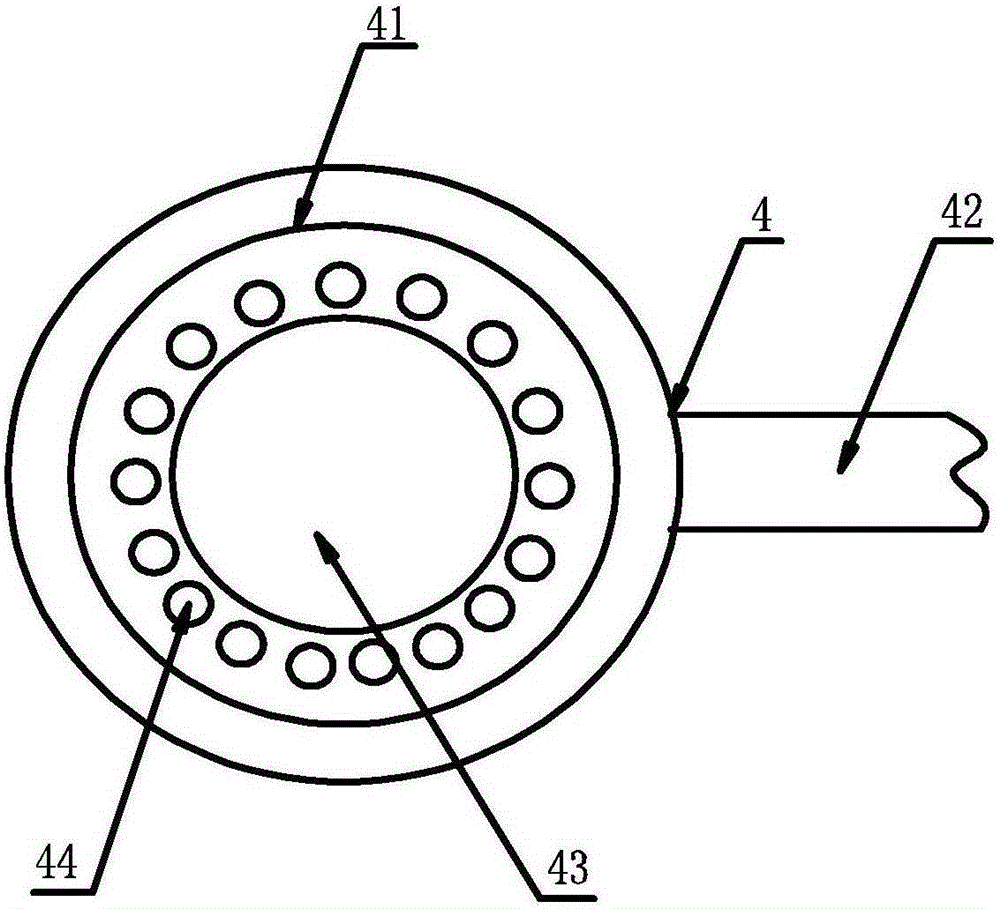

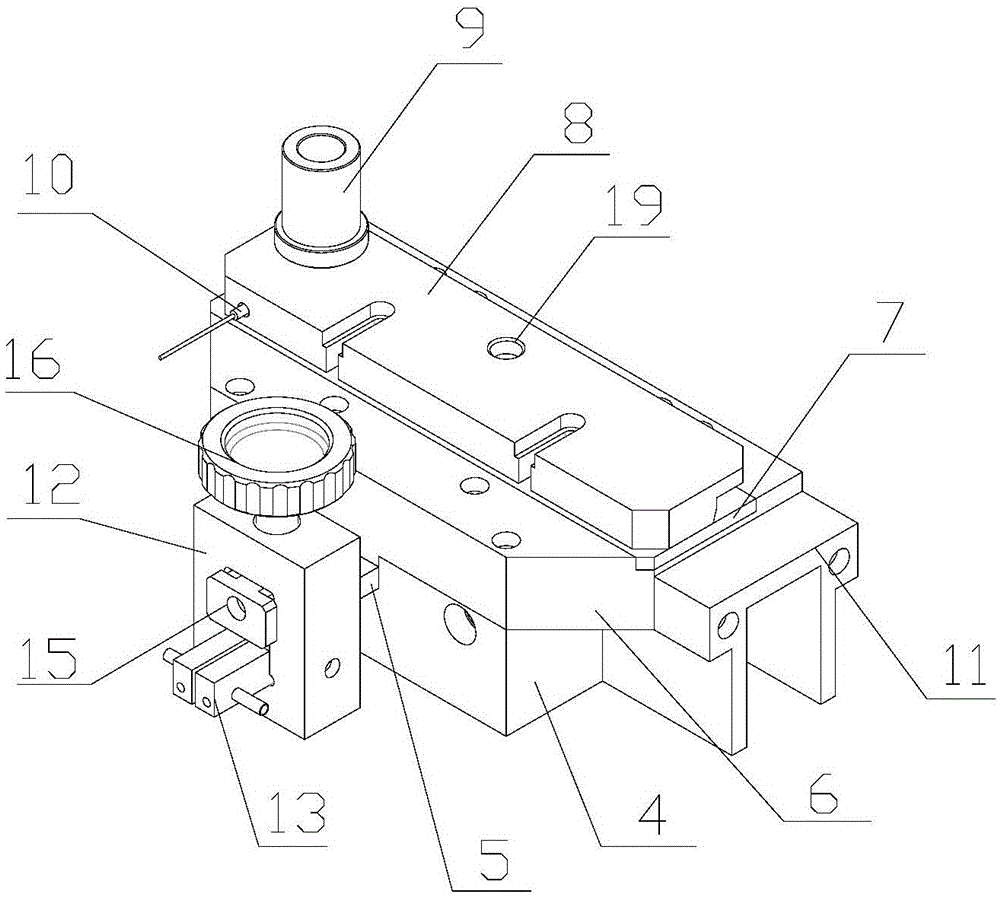

Positioning device and induction hardening equipment for straight round pipe fitting

ActiveCN103014293AReduce volatilityUniform induced currentFurnace typesIncreasing energy efficiencyInductorEngineering

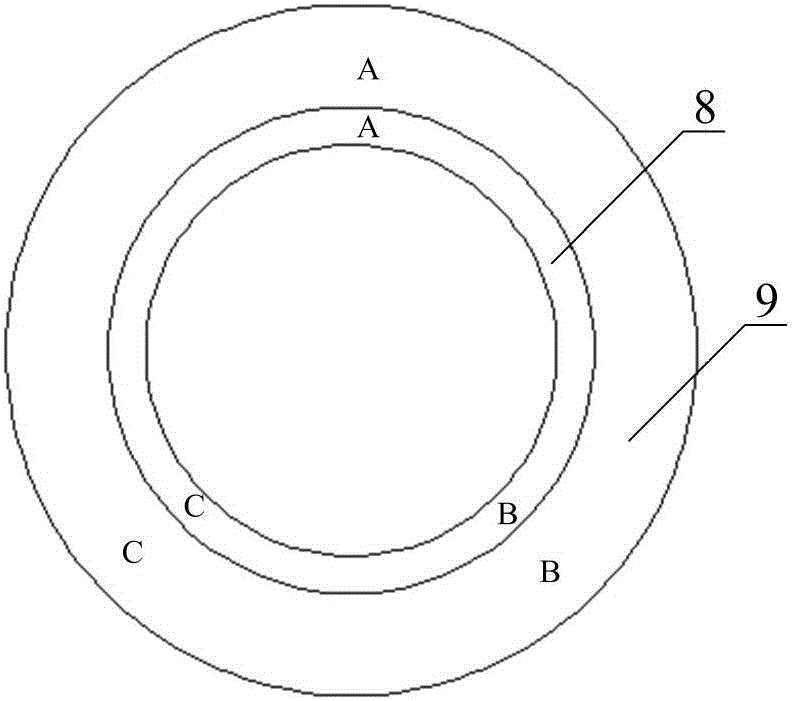

A positioning device for a straight round pipe fitting comprises a positioning device main body provided with a first positioning mechanism, a second positioning mechanism and a third positioning mechanism, wherein respective positioning parts of the first positioning mechanism, the second positioning mechanism and the third positioning mechanism are distributed in the circumferential direction of the same arrangement circumference and can be in contact with the inner peripheral surface or the outer peripheral surface of a straight round pipe fitting (7) in the radial direction of the arrangement circumference; and all the positioning parts can slide and / or roll when the straight round pipe fitting and the positioning device for the straight round pipe fitting move relative to each other. Besides, the invention also provides induction hardening equipment for the straight round pipe fitting, which is equipped with the positioning device for the straight round pipe fitting. The positioning device for the straight round pipe fitting, provided by the invention, can optimally enable the circumferential gap between the wall of the straight round pipe fitting and a hardening inductor to be uniformly the same as much as possible, so that the induced magnetic field intensity in the pipe wall can be uniformly distributed in the circumferential direction, a relatively uniform hardening layer can be effectively formed and the hardening quality is remarkably improved.

Owner:ZOOMLION HEAVY IND CO LTD

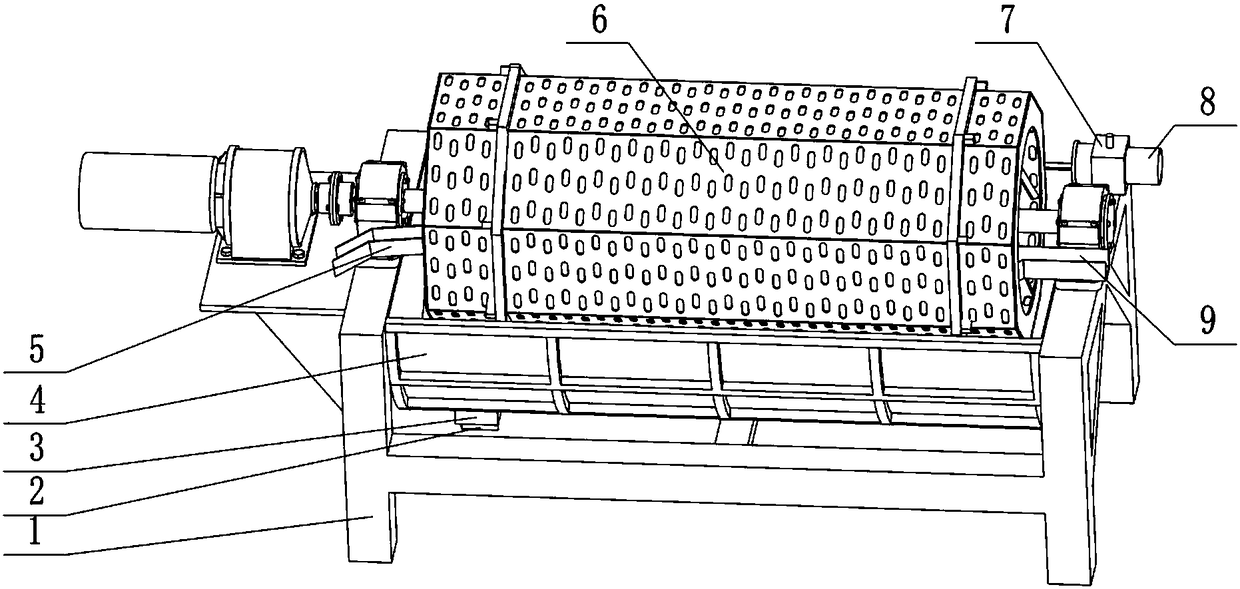

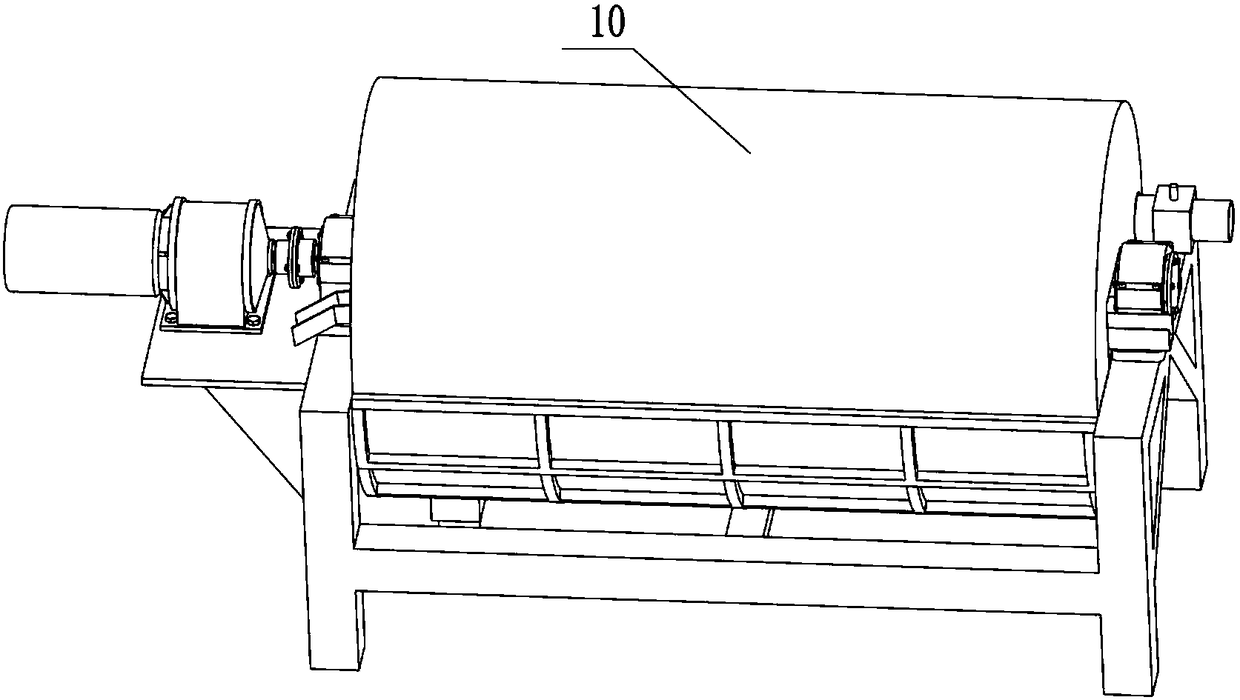

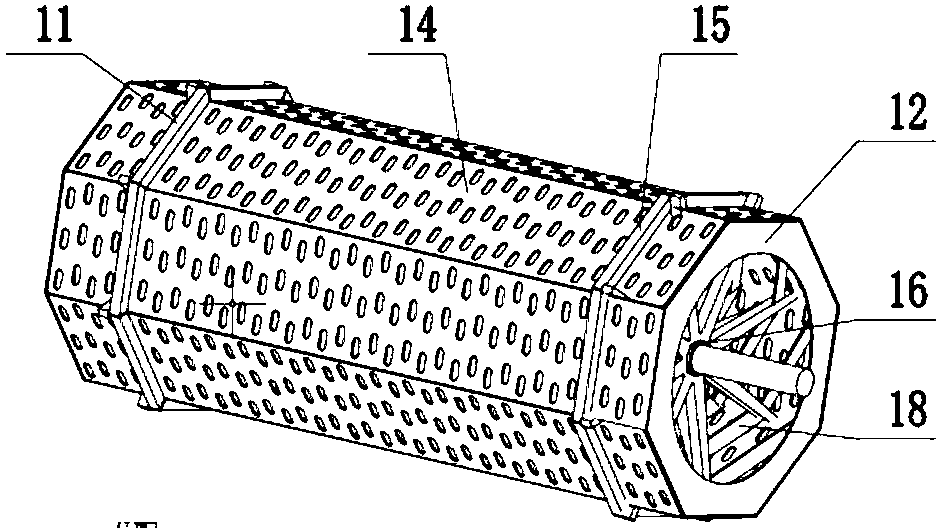

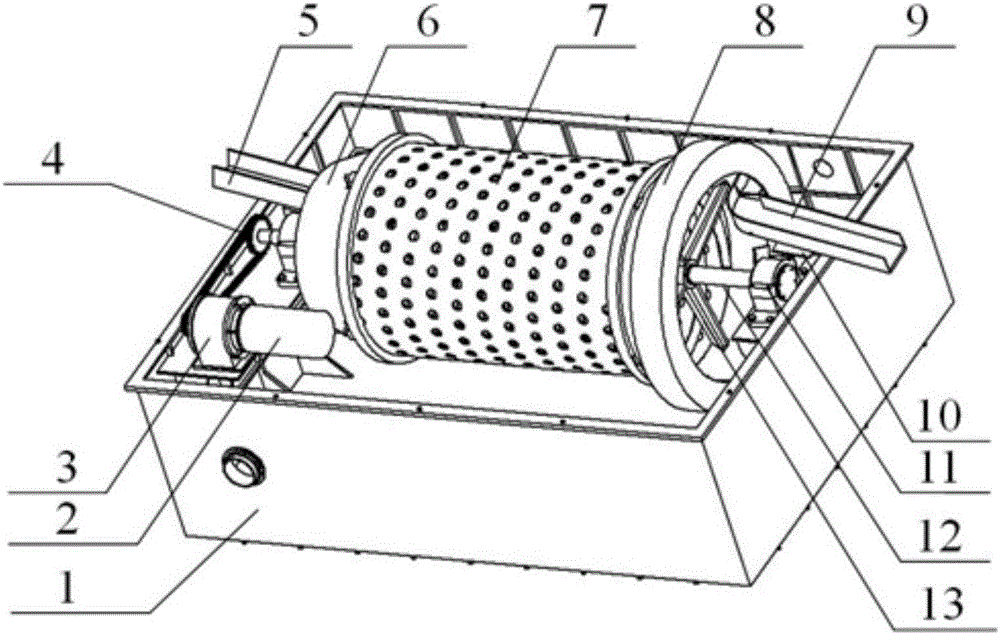

Polygonal drum skew rolling ball-milling steel ball quenching unit

PendingCN108330270AOrderly movementIncrease production capacityFurnace typesHeat treatment furnacesQuenchingInlet channel

The invention provides a polygonal drum skew rolling ball-milling steel ball quenching unit which is used for conducting quenching heat treatment on skew rolling ball-milling steel balls with the diameter phi of 20-80 mm to quickly cool the skew rolling ball-milling steel balls from 800 DEG C-900 DEG C to 100 DEG C-300 DEG C. A quenching drum of the quenching unit is a polygonal drum composed of aplurality of drum flat plates. The inner sides of the drum flat plates are provided with drum partition boards and steel ball lifting plates. The drum partition boards are arranged obliquely. Spiralgrooves are formed between the drum partition boards. The steel balls go into the quenching unit through a ball inlet channel are lifted up by polygonal interior angles through subchannels of the polygonal drum in order and then are subjected to rolling quenching in the spiral grooves. The steel balls at the tail ends of the spiral grooves are lifted up to a certain height by the steel ball lifting plates and then freely fall to a ball outlet channel to be discharged. The drum flat plates are provided with kidney-shaped through holes, the kidney-shaped through holes are used for allowing a quenching medium inside and outside the drum to flow to achieve internal and external heat exchange of the drum and finally complete quenching. The polygonal drum skew rolling ball-milling steel ball quenching unit achieves safe, economical and high-quality quenching of the skew rolling ball-milling steel balls.

Owner:UNIV OF SCI & TECH BEIJING +1

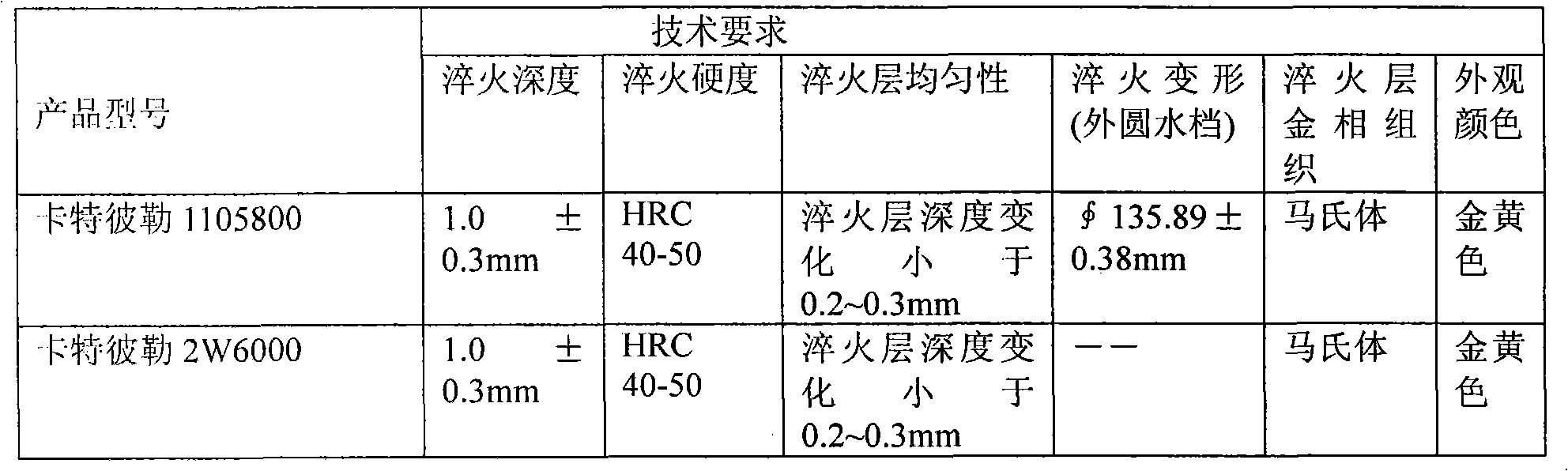

Manufacturing method of quenching cylinder sleeve with micro-deformation of inner holes, golden and high frequency

The invention discloses a manufacturing method of a quenching cylinder sleeve with micro-deformation of inner holes, golden yellow appearance and high frequency. The method comprises the following steps of: (1) selecting alloy gray cast iron containing chromium and copper, carrying out centrifugal casting and processing the cylinder sleeve; (2) adopting high-frequency quenching equipment to quench the cylinder sleeve; (3) spraying quenching cooling medium which is 8 to 12 percent of Houghton Q251 to the heated cylinder sleeve for quick cooling and quenching and adjusting the interval between a sensing ring and an external spraying ring to control and guarantee that the appearance is golden yellow; (4) adopting a car-type low-temperature tempering furnace for tempering with the tempering temperature controlled to be 250 to 280 DEG C and preserving the temperature for 2 hours; (5) carrying out exquisite processing to the tempered cylinder sleeve, saving cutting processing to the peripheral end surfaces and water retaining parts after high frequency quenching, preserving golden yellow appearance and warehousing after being inspected to be qualified. The invention has advanced technique and simple method and by compared with the common high frequency quenching cylinder sleeve, the appearance is beautiful, the hardness and deep uniformity of the quenching layer are good, the wear resistance is good and the service life is long.

Owner:YANGZHOU WUTINGQIAO CYLINDER LINER

Automatic quenching machine tool

ActiveCN105821188AImprove quenching effectImprove quenching qualityFurnace typesHeat treatment furnacesQuenchingManipulator

The invention discloses an automatic quenching machine tool comprising a machine tool main body, wherein the machine tool main body is provided with a servo system. The automatic quenching machine tool is characterized in that a feeding device is arranged at the left side of the machine tool main body; a discharging device is arranged at the right side of the machine tool main body; a turnover seat controlled by the servo system is arranged in the middle of the machine tool main body; a beam is arranged right above the machine tool main body; the turnover seat is provided with a rotating arm by which turnover manipulators are educed; the beam is provided with a left sliding seat and a right sliding seat which are controlled by the servo system; the lower end of the left sliding seat is provided with a left manipulator adapted to the feeding device; the lower end of the right sliding seat is provided with a right manipulator adapted to the discharging device; and the machine tool main body is provided with a quenching system adapted to the left manipulator and the right manipulator. The automatic quenching machine tool has the very remarkable beneficial effects of high work efficiency, automatic double-station quenching of workpieces, good quenching effect and quality and wide application range.

Owner:WONH IND

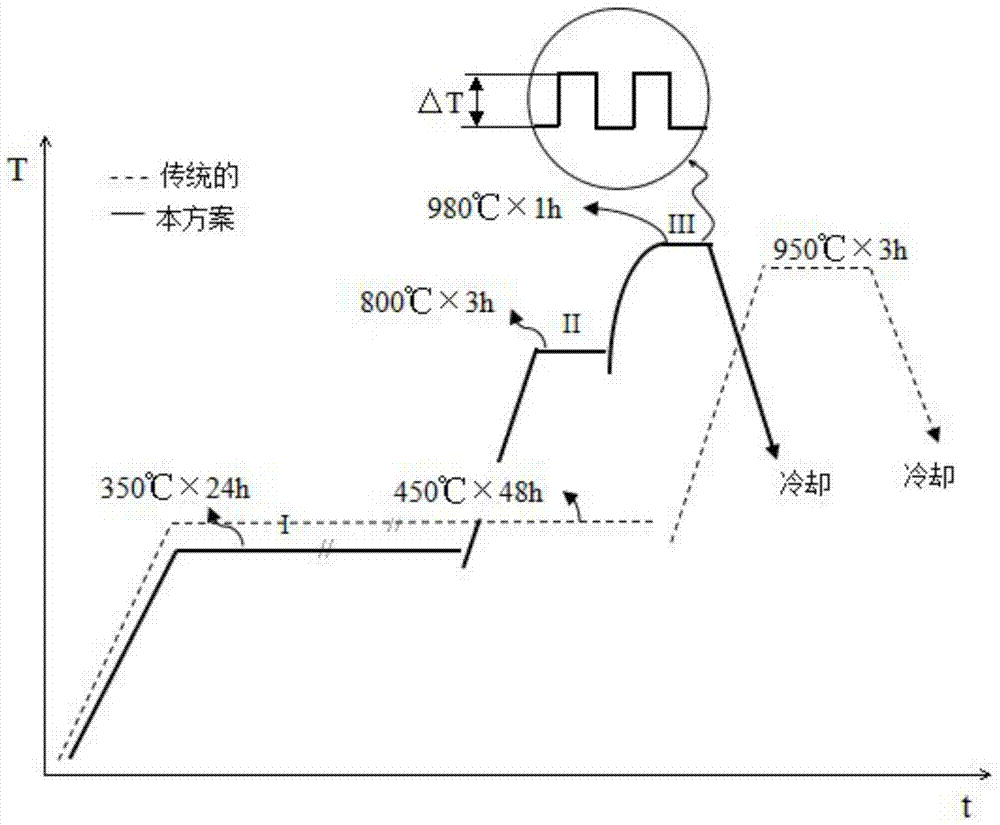

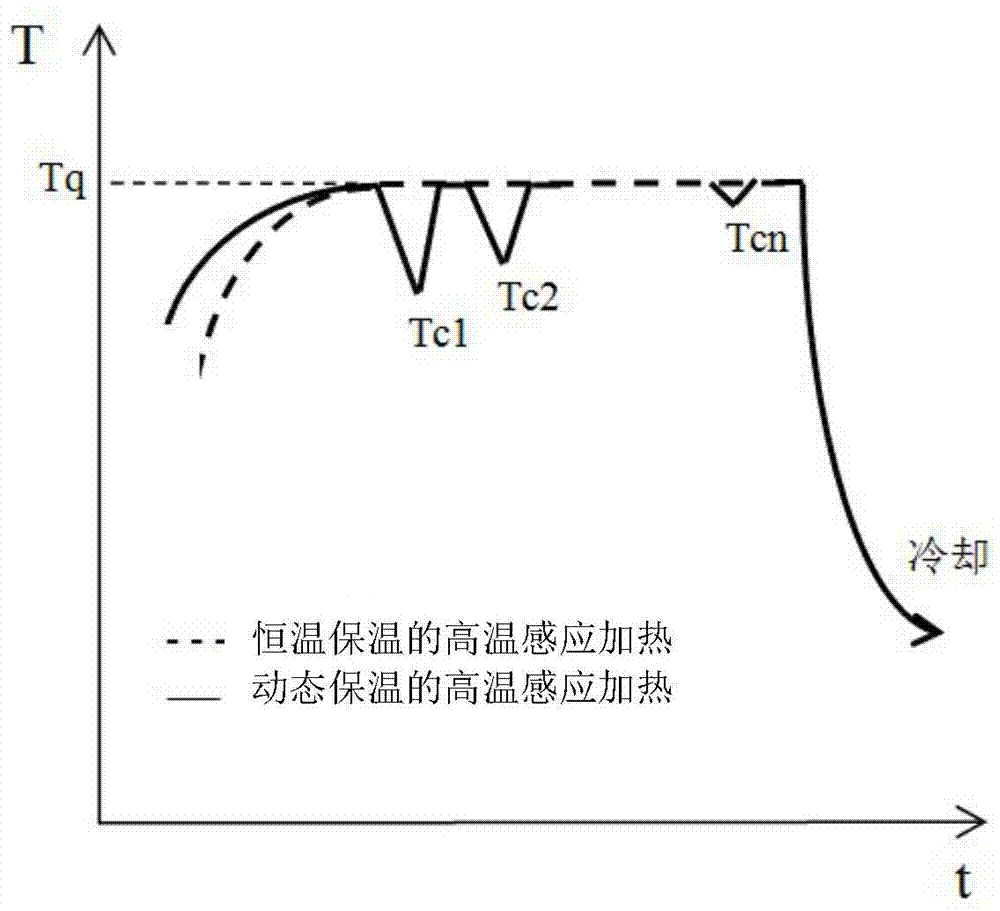

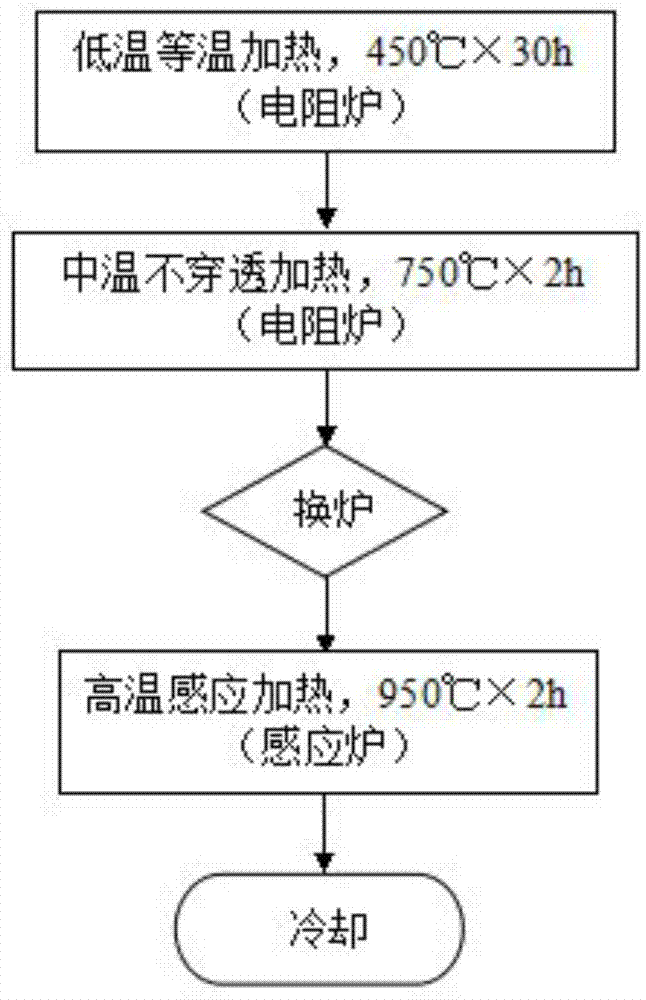

Heating method during quenching of large supporting roller

InactiveCN104775009AImprove quenching qualityAvoid deficienciesFurnace typesHeat treatment furnacesThree stageQuenching

The invention relates to a heating method during quenching of a large supporting roller, wherein the heating method comprises three stages of (I) low-temperature isothermal heating, (II) middle-temperature non-penetration heating and (III) high-temperature induction heating; in the stage (III), a high-temperature induction heating process of 'heating-cooling-heating' dynamic heat preservation also can be adopted, and thus the heating quality and the quenching quality of the supporting roller are improved. The heating method has the advantages of high heating depth, uniform heating temperature, microstructure refinement and the like, is suitable for deep quenching heat treatment of large rollers, shafts, rods and other workpieces, and has broad popularization and application prospects.

Owner:BAOSHAN IRON & STEEL CO LTD

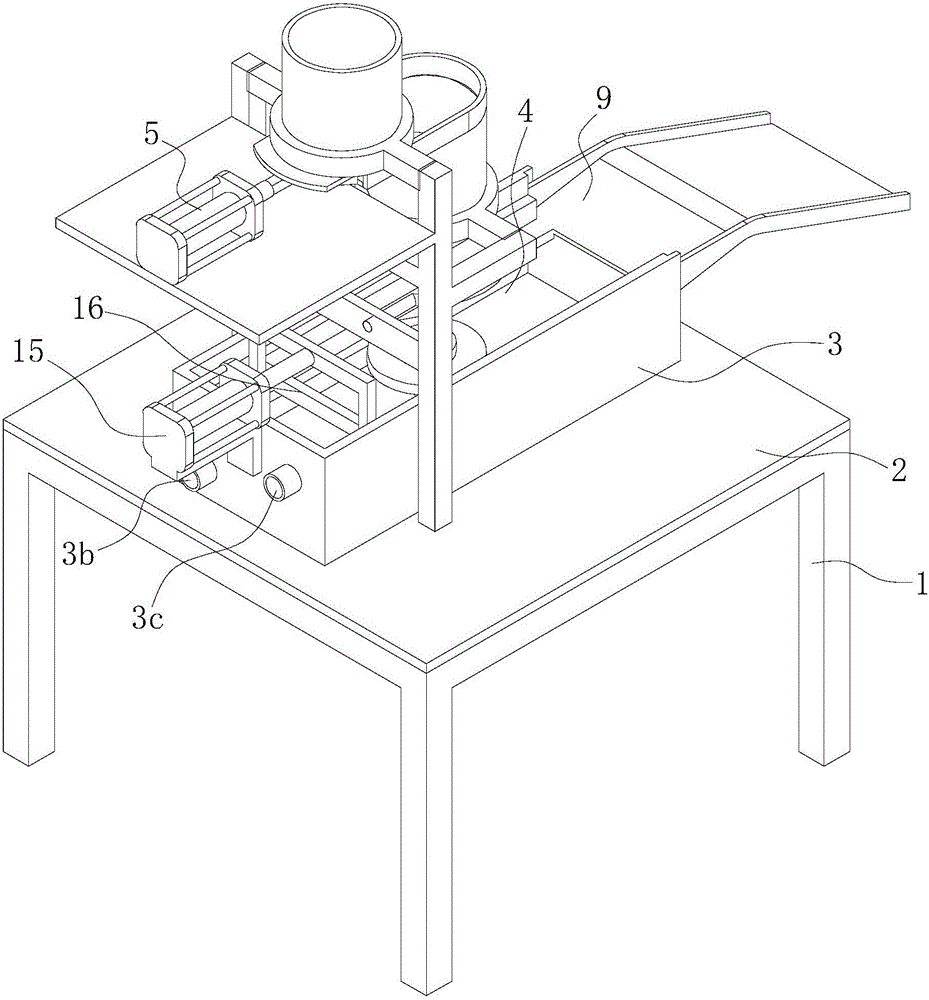

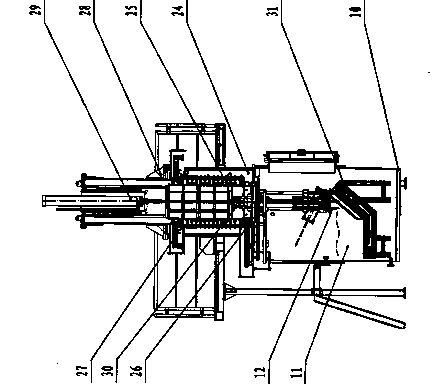

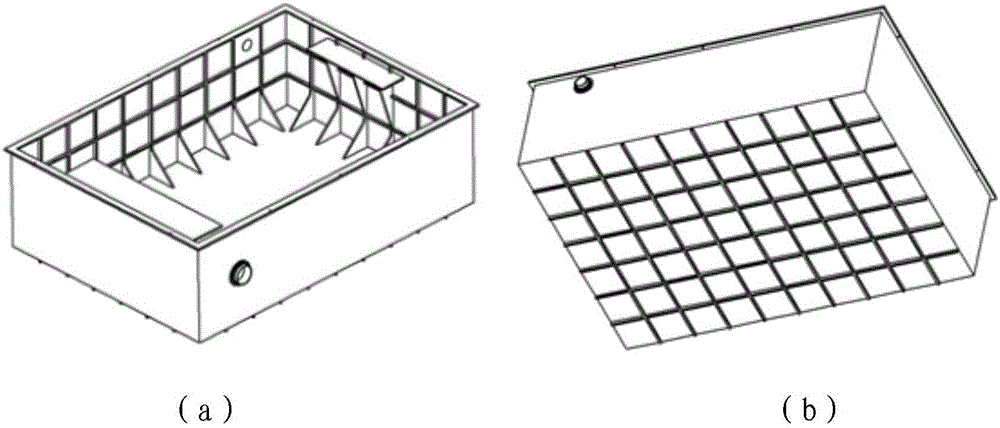

An automatic feeding mechanism used for quenching of shaft type workpieces

ActiveCN104831031ARealize automatic feeding functionIncrease the level of automationFurnace typesHeat treatment furnacesEngineeringMechanical engineering

An automatic feeding mechanism used for quenching of shaft type workpieces is disclosed. The automatic feeding mechanism is characterized in that the automatic feeding mechanism comprises a material layout box allowing shaft type workpieces to be disposed transversely, a material arrangement box adjacent to the material layout box, and a conveying assembly for conveying the shaft type workpieces to a quenching station; the top of the material arrangement box is open; a material jacking plate passing through the bottom plate of the material layout box and jacking the shaft type workpieces in the material layout box up into the material arrangement box is disposed longitudinally in the material layout box; a material receiving inclined plate one side of which is inclined is disposed in the material arrangement box so that the shaft type workpieces jacked up into the material arrangement box are in an inclined state; an erecting pushing element for converting the shaft type workpieces in the inclined state into longitudinally erect shaft type workpieces is disposed at the material arrangement box; the bottom of the material arrangement box is provided with an opening through which the longitudinally erect shaft type workpieces can pass; the conveying assembly comprises a conveying pushing element, a clamping jaw pushed by the conveying pushing element and used for clamping the longitudinally erect shaft type workpieces; and trace bending deflection caused by traditional transverse quenching is avoided, thus improving quenching quality and increasing the quenching efficiency of the shaft type workpieces.

Owner:NINGBO HAWK ELECTRICAL APPLIANCE CO LTD

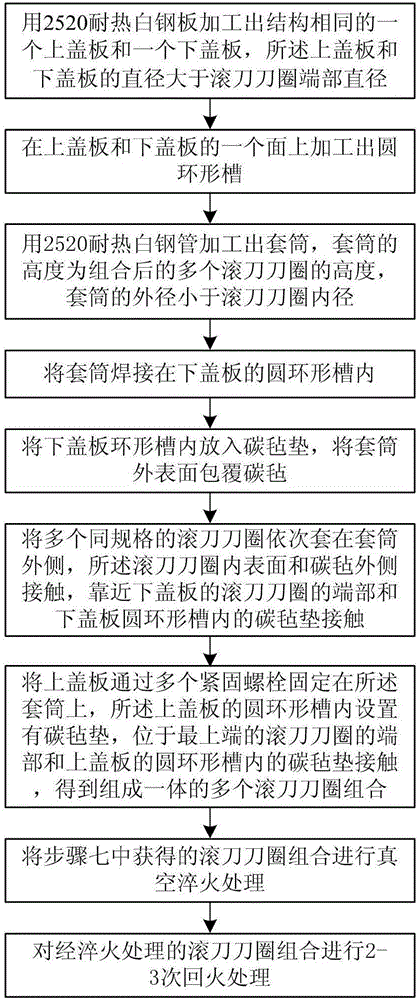

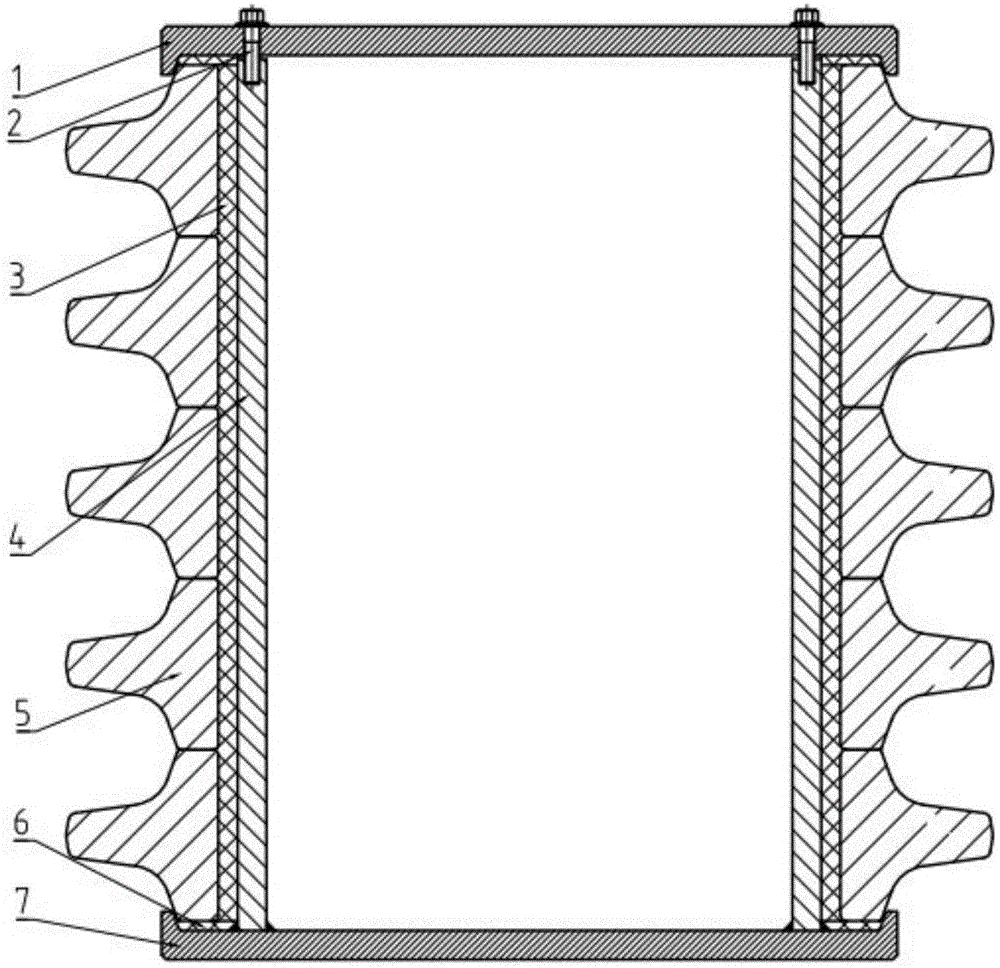

A gradient hardness heat treatment method for hob cutter rings of a full-section tunnel boring machine

ActiveCN106498144AGuaranteed Gradient HardnessSpeed up coolingFurnace typesHeat treatment furnacesTunnel boring machineHardness

A gradient hardness heat treatment method for hob cutter rings of a full-section tunnel boring machine belongs to the technical field of vacuum heat treatment. The objective of the invention is to overcome problems that processes at present are complex and a production efficiency is low. The method includes assembling a plurality of the hob cutter rings of the same size to obtain an integrated assembly of the plurality of hob cutter rings, subjecting the obtained assembly of the hob cutter rings to vacuum quenching treatment, and subjecting the assembly subjected to quenching treatment to 2-3 times of tempering so as to allow the hardness of the hob cutter rings to reach process requirements and to complete heat treatment. The gradient hardness of the hob cutter rings subjected to vacuum oil quenching is achieved by adjusting the quenching process. An auxiliary structure used is simple and the production efficiency is increased.

Owner:凌远科技股份有限公司

Saw blade quenching machine

InactiveCN1912151AReasonable structureEasy to useFurnace typesHeat treatment furnacesAgricultural engineeringWater resources

The invention relates to a saw disc movable quenching machine which belongs to saw blade heat-treating mechanism. Its features are that the integral combination type engine base has tank structure which is made up of main water tank, quenching water tank, circulating water tank and electric cabinet; the middle of upper cover plate of the main water tank is orderly set electromotor, cycloidal-pin gear speed reducer, plain bearing housing, and saw blade dead plate from the back to front; the upper cover plate of the electric cabinet is zoom type spaying frame whose mounting plate is set cooling water nozzle, flame thrower nozzle, and high pressure air nozzle; the circulating water circuit is set between the quenching water tank and the circulating water tank, main water tank and circulating tank; the electric cabinet is set computer plate to control the corresponding operation. Thus it has the advantages of safe, saving water resource, and lowering the cost.

Owner:权岚

Synthetic quenching liquid and using method thereof

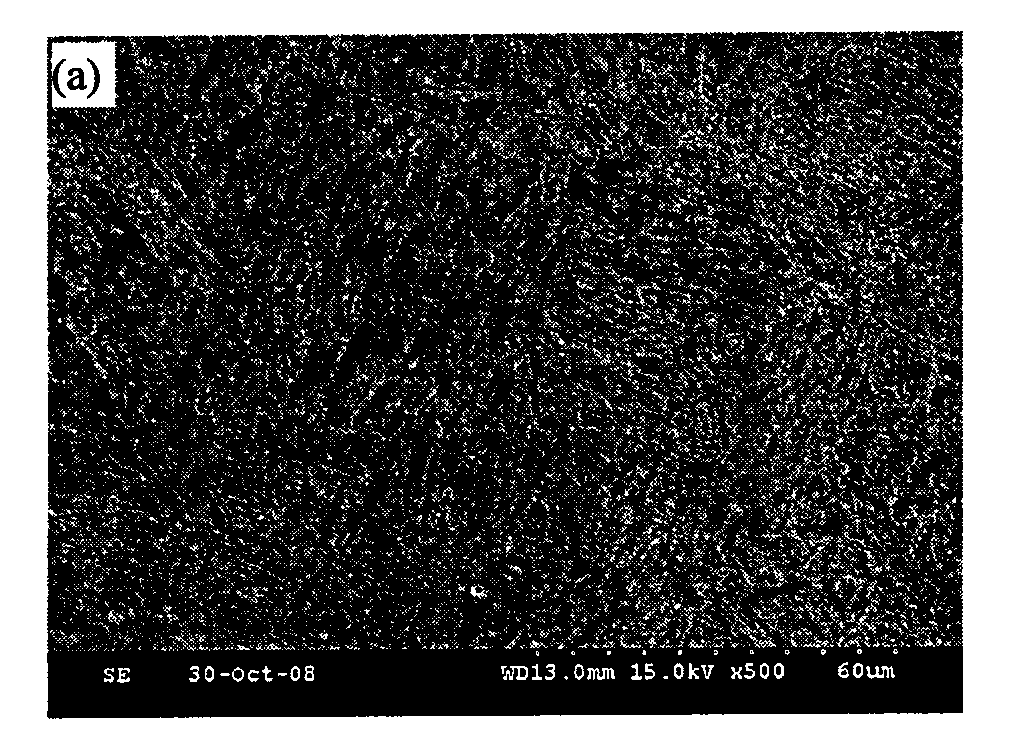

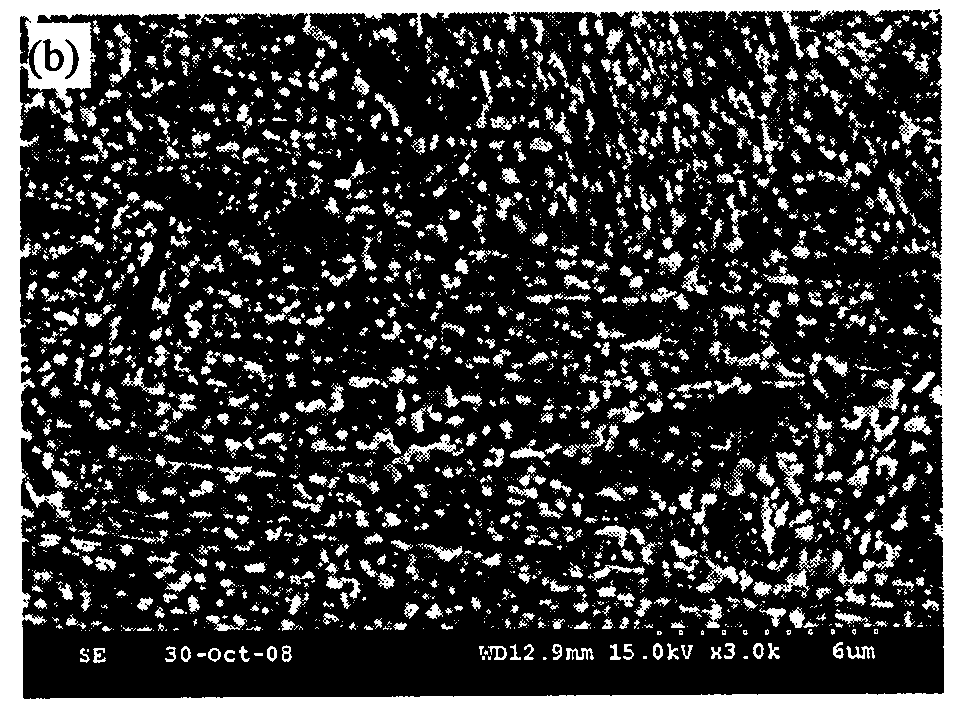

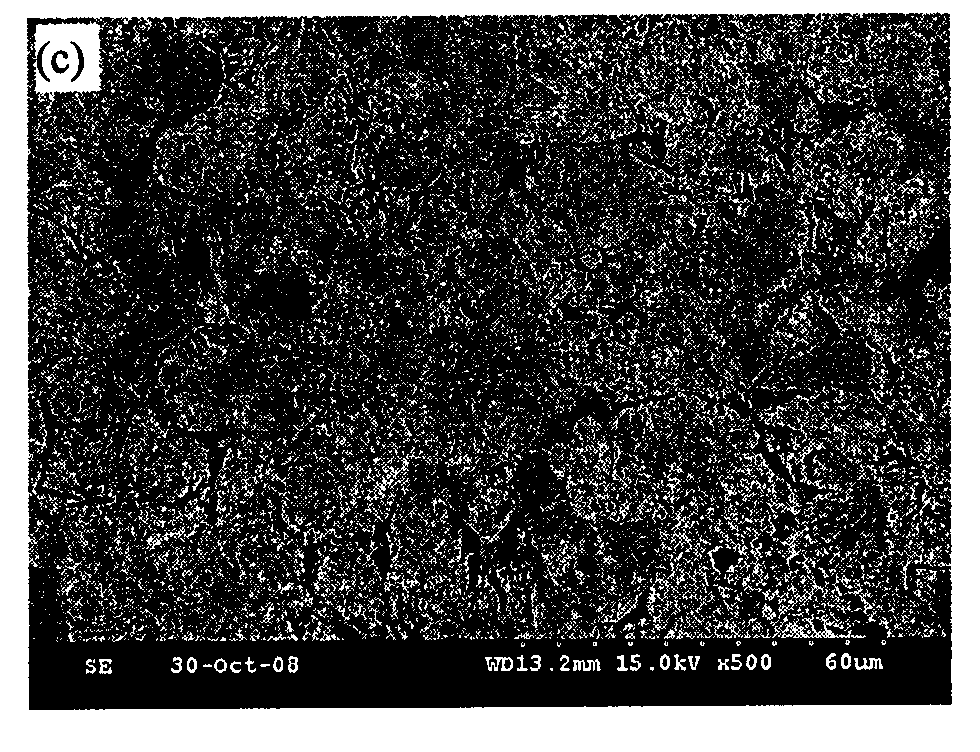

InactiveCN106435113AImprove quenching qualityReduce manufacturing costQuenching agentsNonferrous metalWorking environment

The invention discloses a synthetic quenching liquid and a using method thereof. The synthetic quenching liquid comprises the following raw materials in percentage by weight: 83-88% of compound PAG, 10-15% of a cooling accelerant, 1.5-2% of an antioxidant and 0.5-1.5% of a defoaming agent. Through the adoption of the synthetic quenching liquid and the using method thereof, the requirement of high-difficulty heat treatment of quenching can be met, and the hardness HRC can be adjusted optionally within the range of 35-63; the synthetic quenching liquid saves oil compared with traditional quenching oil; and magnetic flaw detection shows that no quenching crack is caused and the hardness is moderate, and the metallographic structure is qualified and meets the requirement. The synthetic quenching liquid has the effects of deep hardening zone, uniform quenching hardness and no soft spot, greatly reduces the tendency of quenching deformation and cracking, cannot corrode ferrous metals or nonferrous metals, makes a quenched workpiece bright, has a short-term antirust effect, cannot age or go bad easily, has a long service life, is incombustible, is safe to use, improves the working environment, causes no environment pollution, greatly improves the processing quality of quenched surfaces and the production efficiency and reduces the production costs of enterprises.

Owner:ANSHUN HONGYI SPECIAL STEEL BALL MFG

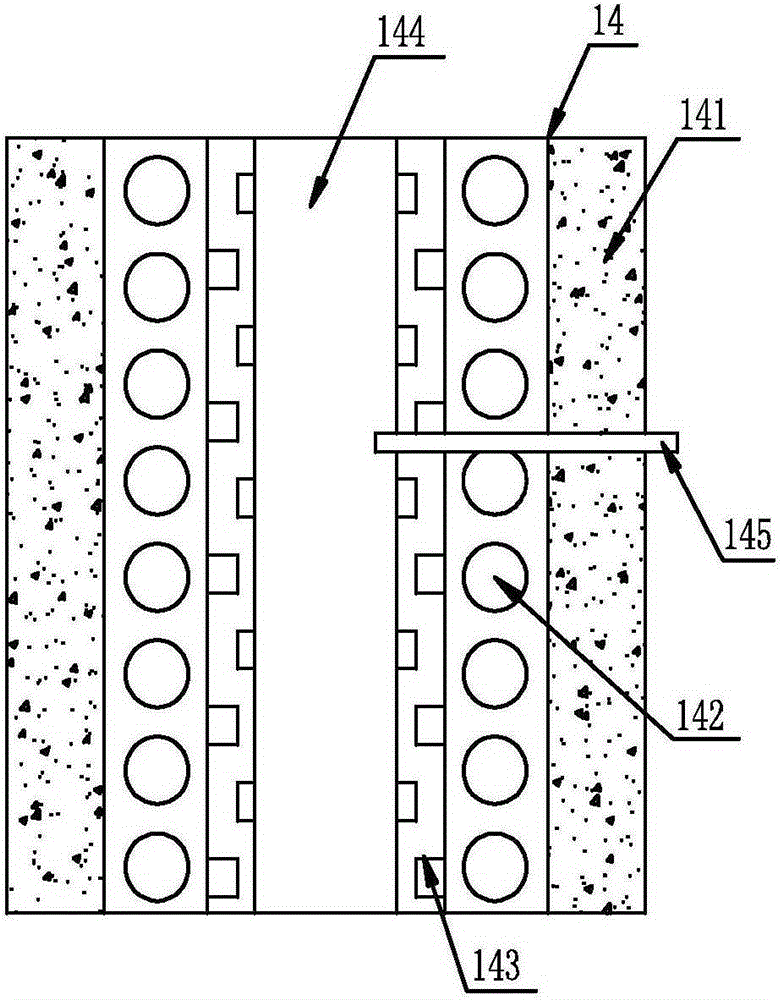

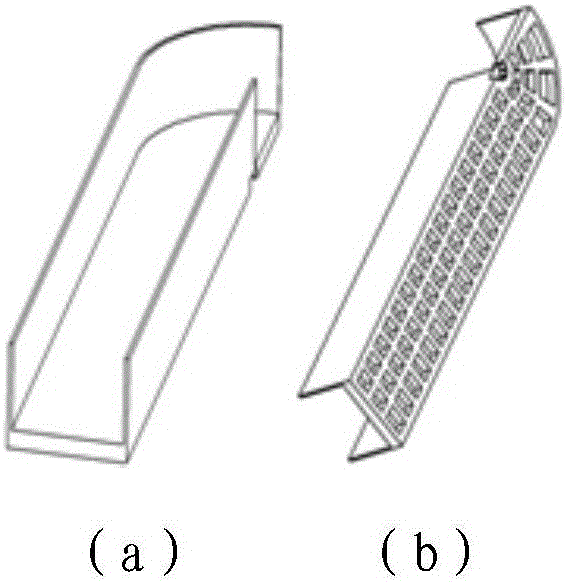

Heat treatment device for round-link chain and application method thereof

ActiveCN105349757AHigh degree of integrationImprove work efficiencyFurnace typesHeat treatment furnacesHardnessLath

The invention discloses a heat treatment device for a round-link chain and an application method thereof. The device comprises a quenching part and a tempering part which are sequentially arranged, wherein first cooling parts are arranged at the quenching part and the tempering part; the quenching part is provided with a quenching temperature regulating box; the tempering part is sequentially provided with an uniform-temperature tempering heating box, at least one tempering temperature regulating box and a differential-temperature tempering heating box; the quenching temperature regulating box is provided with a second cooling part. The device has the characteristics of being high in integration degree and high in working efficiency; after the round-link chain is quenched, an uniform and small low-carbon lath martensite structure can be obtained; the quenching quality is high; the second cooling part and the first cooling parts are correspondingly connected to a cooling source, so that the cooling quality can be improved, and the requirements of each part of the round-link chain on hardness and toughness can be met.

Owner:SHANDONG LUNAN GRP ENERGY EQUIP MFG

Automatic quenching oil tank

ActiveCN104928450AImprove quenching qualityAccurate feedingFurnace typesProcess efficiency improvementQuenchingDrive motor

An automatic quenching oil tank comprises a feeding device, a discharging device, a quenching conveying chain and an antiskid machine. The antiskid machine comprises an antiskid rack, a vertical sliding seat and a cylinder fixed on the antiskid rack, chain rails are arranged on the left side and the right side of the upper end of an oil tank frame, the left end and the right end of the antiskid rack are matched with the left side and the right side of the oil tank frame through a sliding rail structure, a rotating shaft extending in left-right direction is arranged on the antiskid rack, chain wheels corresponding to the chain rails arranged on the oil tank frame are arranged on the rotating shaft, the rotating shaft is connected with a driving motor, a push rod of the cylinder is arranged in front-rear direction, the end of cylinder is connected with the vertical sliding seat, a vertical screw is arranged at the upper end of the vertical sliding seat, and a press plate is arranged at the lower end of the vertical screw and assembled at the lower end of the vertical sliding seat through a line rail which is arranged in a vertically-extending manner. By the automatic quenching oil tank, large deformation of a plate spring in the process of quenching can be prevented, quenching quality is improved, realization of automated quenching is facilitated, quenching efficiency is improved, and quenching labor intensity is reduced.

Owner:山东森德数控机械有限公司

Spray quenching medium

A spray quenching medium comprises, by mass, 20-35% of No.100 machine oil, 60-75% of No.32 machine oil, 0.2-0.5% of an antioxidant, 0.2-0.3% of a brightener and 2-5% of a cooling accelerant. The spray quenching medium can be used in spray quenching of metal heat treatment, and can be normally used in a range from normal temperature to 150DEG C without heating or cooling; the spray quenching medium can be sprayed on a workpiece to greatly increase the convection heat transfer speed, the cooling time is 10-20s only, and the efficiency increases 3-5 times; and the oil spraying time and the oil spraying amount can be conveniently adjusted, so the best cooling performance and the best quenching quality are guaranteed.

Owner:武汉永正科技发展有限公司

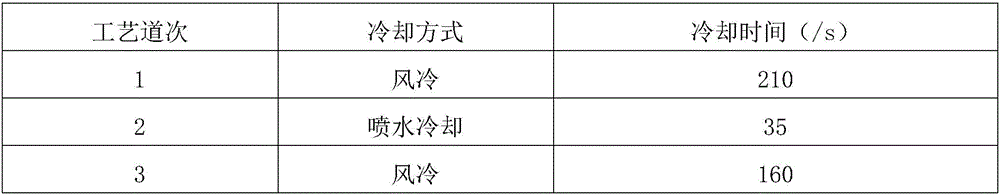

Thermal treatment method for thick die steel

The invention belongs to the technical field of die steel and particularly relates to a thermal treatment method for thick die steel. The thermal treatment method for thick die steel comprises the steps that steel ingots are subjected to quenching heating, the tapping temperature is 800-900 DEG C, and the hoisting time is 2-4 min; air cooling is conducted during hoisting; and the quenching process is conducted after completion of hoisting. According to the thermal treatment method for thick die steel, the problem of hardenability of die steel of 700-900 mm is mainly involved. The quenching quality is improved by making the reasonable field quenching thermal treatment process.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

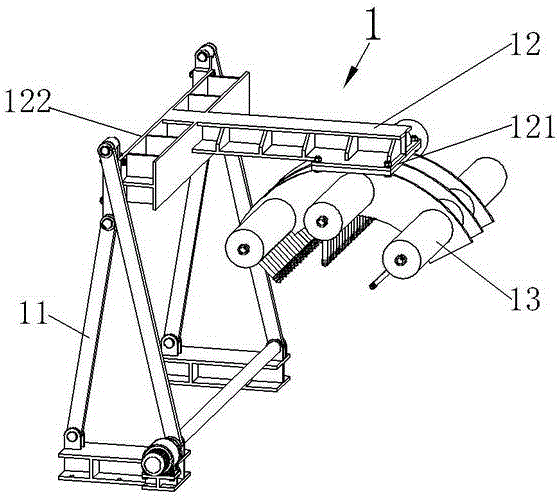

High-frequency induction heating and spray quenching device and method thereof

ActiveCN105018684AReduce loading and unloadingShorten the overall cycleIncreasing energy efficiencyQuenching devicesInductorMaterial distribution

The invention provides a high-frequency induction heating and spray quenching device. The high-frequency induction heating and spray quenching device comprises a workbench, a loading and unloading mechanism for loading and unloading workpieces from a feeding hopper, an inductor assembly for heating and quenching, a heat monitoring assembly for monitoring heating capacity, a servo sliding table for entering and retreating from the inductor assembly and a falling material distribution mechanism. The workbench comprises a platen. The loading and unloading mechanism, the inductor assembly and the servo sliding table are sequentially arranged on the platen. The heat monitoring assembly is arranged in the inductor assembly and corresponds to the workpieces. The falling material distribution mechanism is arranged on the discharge side of a heating and quenching mechanism. The invention further provides a high-frequency induction heating and spray quenching method adopting the high-frequency induction heating and spray quenching device. The manners of single-end magnetic suction rotary heating and quenching, servo positioning, heating capacity monitoring, falling material distribution mechanism and the like are adopted; the device and the method have the beneficial effects of being short in loading and unloading period, high in positioning accuracy and capable of achieving automatic distribution; and therefore quality and efficiency are improved, and the production cost is reduced.

Owner:JIANG SU NAN FANG BEARING CO LTD

Drum device for online continuous quenching of inclined rolled steel balls

ActiveCN105671294AEnergy savingIncrease productivityFurnace typesHeat treatment furnacesQuenchingVariable frequency control

The invention discloses a drum device for online continuous quenching of inclined rolled steel balls. The drum device comprises a water tank, a variable frequency control motor, a speed reducer, a chain wheel mechanism, a ball inlet chute, a conical ball inlet drum, a columnar quenching drum, a conical ball outlet drum, a ball outlet chute, a chute bracket, a bearing base, a rotating shaft and a four-jaw spoke; the conical ball inlet drum is used for smoothly leading large-diameter steel balls, introduced by the ball inlet chute, into the columnar quenching drum; the columnar quenching drum is used for realizing spiral feeding and quenching functions of the steel balls; and the conical ball outlet drum is driven by the rotating shaft to rotate to realize the purposes of fishing the quenched steel balls and pouring the steel balls in the ball outlet chute. The drum device has the following beneficial effects: for the steel balls, with diameters of 50-65 mm, molded through high-temperature inclined rolling, the online continuous quenching is performed, so that the energy is saved, the quenching time is precisely controlled, and the quality of the steel balls is improved; and the drum device is high in quenching efficiency, stable in process, low in noise and high in automation degree, and can satisfy the large-batch continuous quenching requirement of the steel balls.

Owner:UNIV OF SCI & TECH BEIJING

Ohmic heating method and ohmic heating device

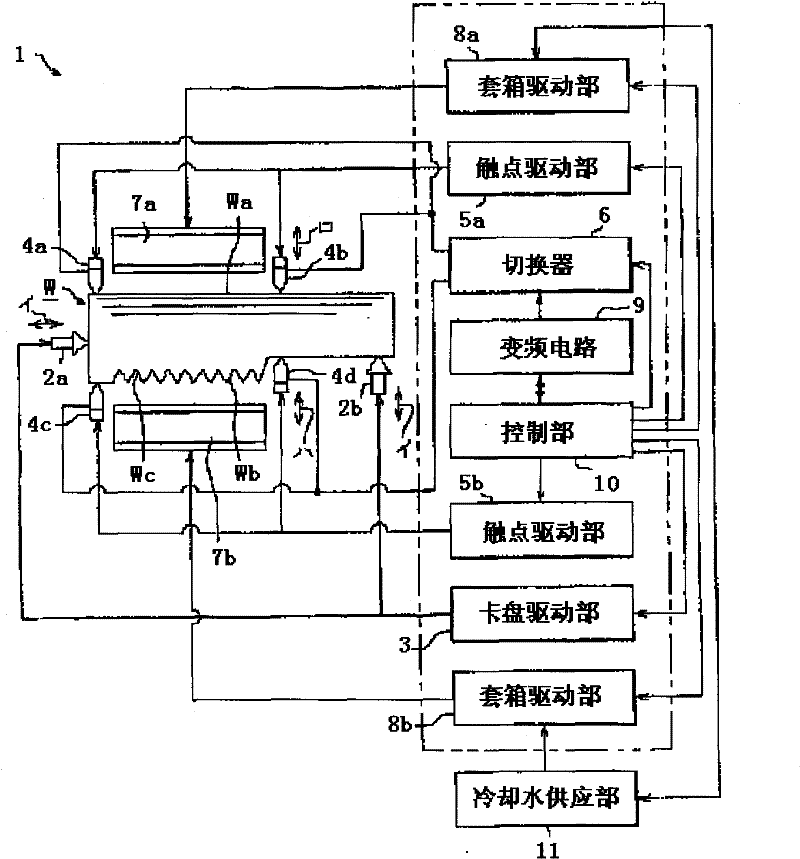

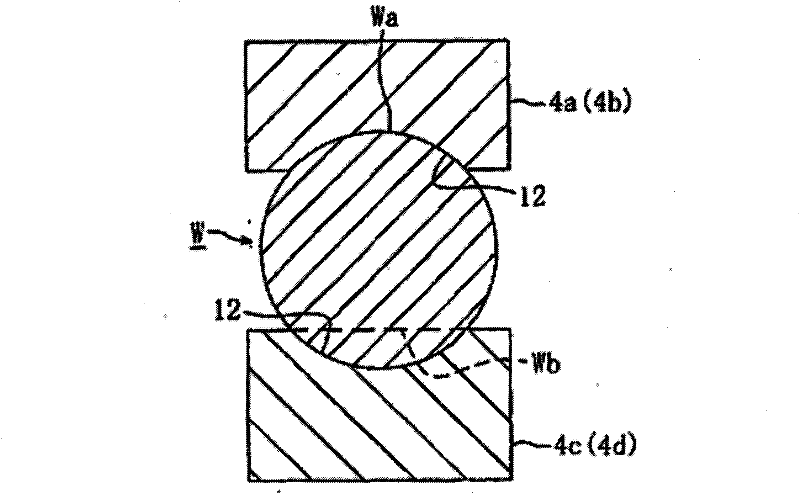

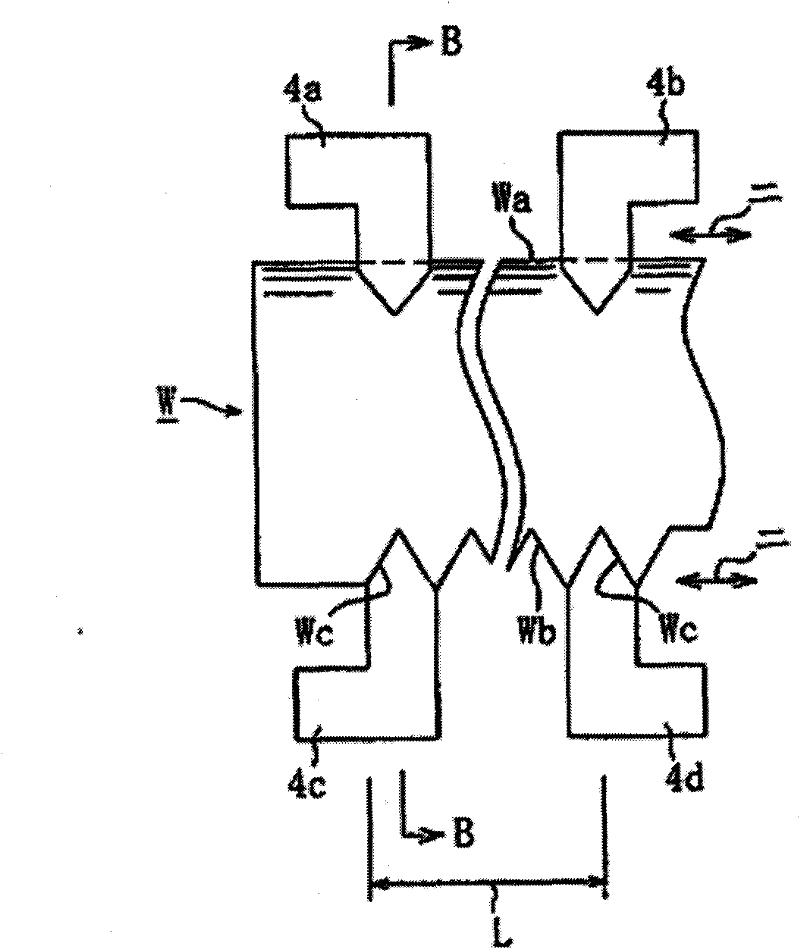

ActiveCN102234710AAccelerated quenchingImprove efficiencyFurnace typesHeat treatment furnacesPower flowContinuous operation

The invention relates to an ohmic heating method and an ohmic heating device. Through the ohmic heating method and the ohmic heating device, the quenching or annealing of the back surface and tooth surface of a workpiece can be carried out in a roughly continuous operation period, and the high-precise quenching or annealing quality is easily obtained on the back surface or tooth surface while striving to improve the efficiencies of quenching or annealing. The ohmic heating method is characterized by comprising the following steps that a switching device is switched to a back surface side, so that one pair of first touch points contact the two ends of the heating range in the length direction of the back surface of the workpiece supported by a support device, the regulated frequency and output current for the back surface are supplied to the touch points from a power supply device, and then ohmic heating is carried out on the back surface; and after the step, the switching device is switched to a tooth surface side, so that one pair of second touch points contact the two ends of the heating range in the length direction of the tooth surface of the workpiece, the regulated frequency and output current for the tooth surface are supplied to the touch points from the power supply device, and then the ohmic heating is carried out on the tooth surface.

Owner:宫电高周波设备(上海)有限公司

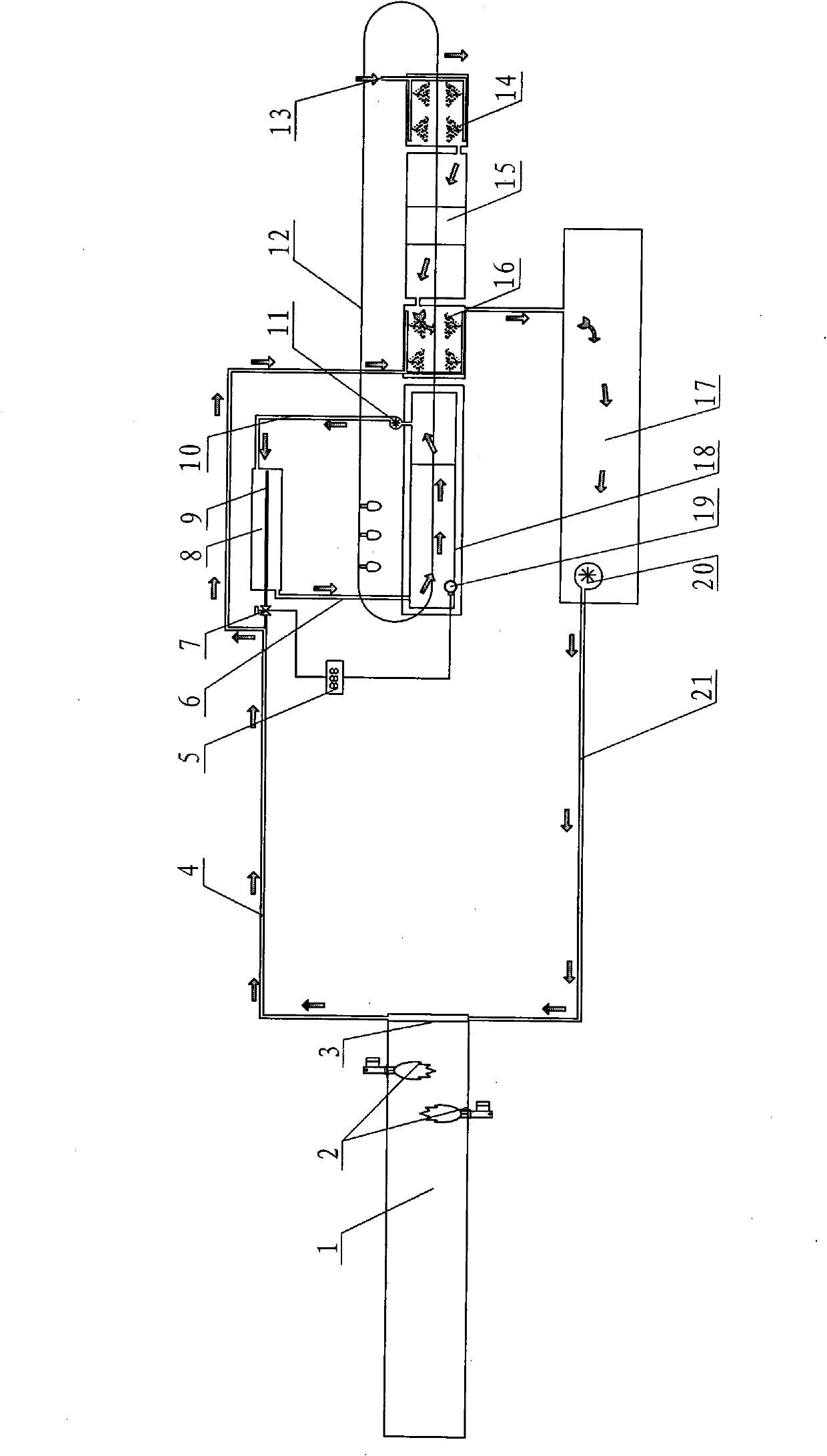

Metal product quenching medium cyclic utilization device

InactiveCN101906516ANo churnAchieve coolingRecuperative heat exchangersDirect contact heat exchangersElutionLiquid storage tank

The invention relates to a metal product quenching medium cyclic utilization device. The device comprises a heating furnace, a spray chamber, an infiltration groove, an elution chamber, a liquid storage tank, a quenching groove and a melting convergence groove, wherein a liquid conveying pipeline is arranged between one end of the insulating furnace door of the heating furnace and a water pump in the liquid storage tank; a spray water conveying pipeline is arranged between the other end of the insulating furnace door and the spray chamber; the melting convergence groove is arranged above the quenching groove; a spray water splash guard is covered in the melting convergence groove; the spray water splash guard is provided with a splash-proof cover plate; a spray water branch is divided from the spray water conveying pipeline at the position of the melting convergence groove; the branch is communicated with the melting convergence groove; an electromagnetic valve is added on the spray water branch; a temperature controller is connected with the quenching groove; and a medium conveying pipeline, a medium reflux pipeline, the melting convergence groove and the quenching groove constitute a medium circulation circuit. By using the device of the invention, the recovery and cyclic utilization of the medium are both performed in the melting convergence groove automatically, the procedures of medium recovery are reduced to the minimum, the operation is safe; and the medium can not be wasted and the environment can not be polluted.

Owner:TANGSHAN CHANGZHI AGRI TOOLS DESIGNING & MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com