Gas stove outer circulation cooling method of double chamber atmosphere pressure hardening furnace and cooling system thereof

A technology of external circulation cooling and gas circulation, applied in the field of metal quenching, can solve the problems of uneven cooling of the workpiece, easy deformation of the workpiece, large consumption of liquid nitrogen, etc. volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

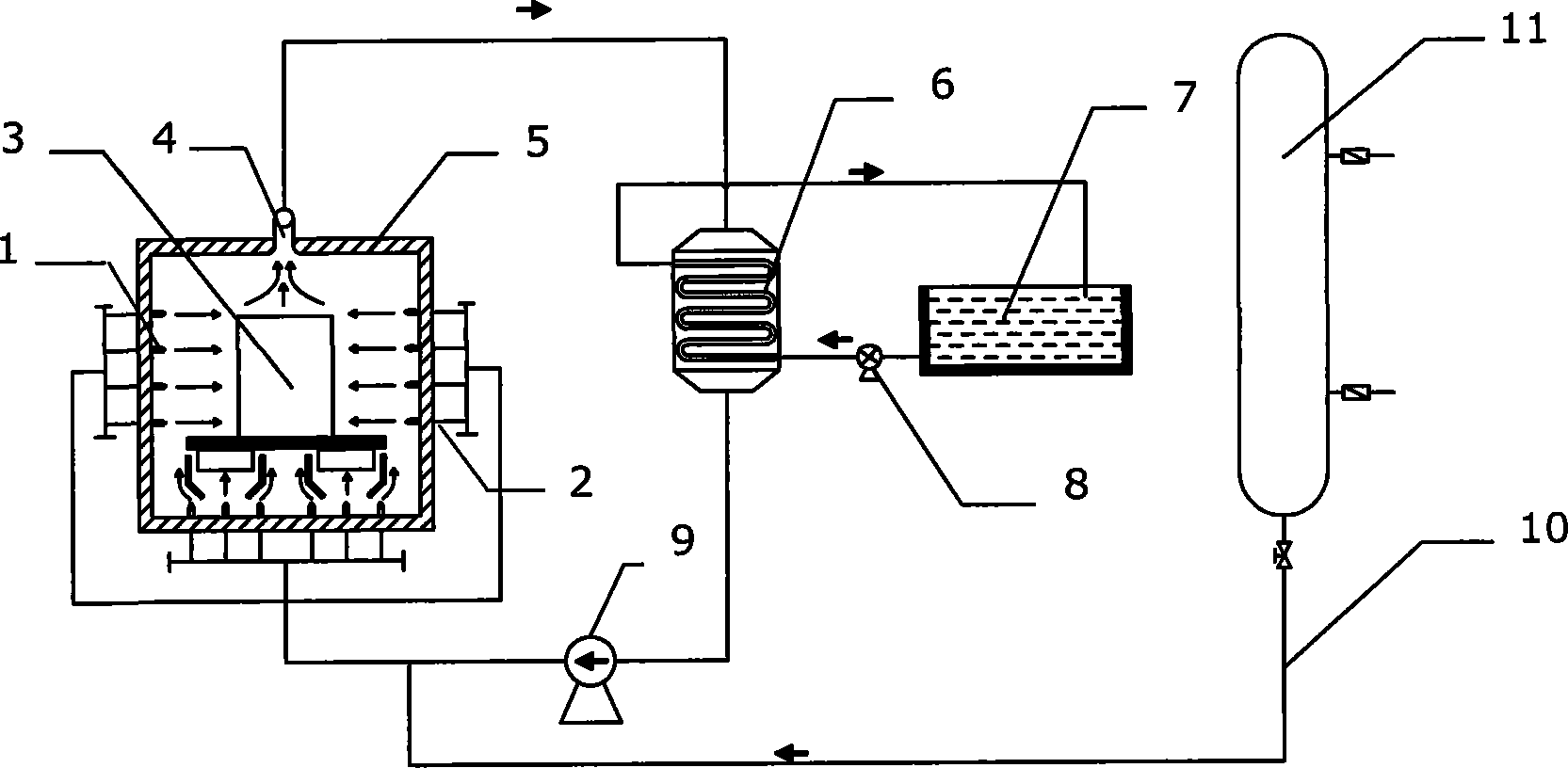

Embodiment 1

[0017] A company mainly produces various high-speed steel knives. The knife body is made of Q235B ordinary carbon structural steel, and the blade is made of W18Cr4V high-speed steel. The two materials are combined by brazing, and the solder is made of brass. The hardness and mechanical properties of the W18Cr4V high-speed steel blade. The quenching equipment adopts a double furnace atmospheric pressure gas quenching furnace. The overall size of the quenching furnace is 6500mm×2800mm×2500mm (length×width×height). Part ξ≤20mm, the workpiece 3 is placed on the bracket made of Q235B structural steel, the loading capacity of each furnace is about 200kg, the quenching temperature is 1260℃~1280℃, and the consumption of liquid nitrogen per furnace is about 700~800L before improvement. The annual cost of liquid nitrogen exceeds 4 million yuan, and the product qualification rate is only about 92%. In order to reduce the consumption of liquid nitrogen and improve the pass rate, on the ba...

Embodiment 2

[0019] A company has newly launched a high-speed steel mechanical tool production line. The tool body is made of Q235B ordinary carbon structural steel or 16Mn low-alloy structure. The tool head is made of W18Cr4V or W9Mo3Cr4V high-speed steel. The two materials are combined by brazing. A good tool needs quenching heat treatment to improve the hardness and mechanical properties of the high-speed steel blade. The quenching equipment adopts a double-furnace atmospheric pressure gas quenching furnace. Placed on a bracket made of Q235B structural steel, the loading capacity of each furnace is about 150kg, and the quenching temperature is 1240℃~1280℃.

[0020] Adopt the cooling system described in the present invention in the design, the nitrogen outlet of the top of the cooling chamber in this system is connected with the heat exchanger, and the outlet of the heat exchanger is connected in parallel with the outlet pipe of the liquid nitrogen storage tank 11, and the main pipe after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com