Quench machine tool

A quenching machine tool and cooling mechanism technology, applied in the field of quenching machine tools, can solve the problems of low use efficiency, poor applicability, low productivity, etc., and achieve the effects of high workpiece quenching quality, compact structure and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

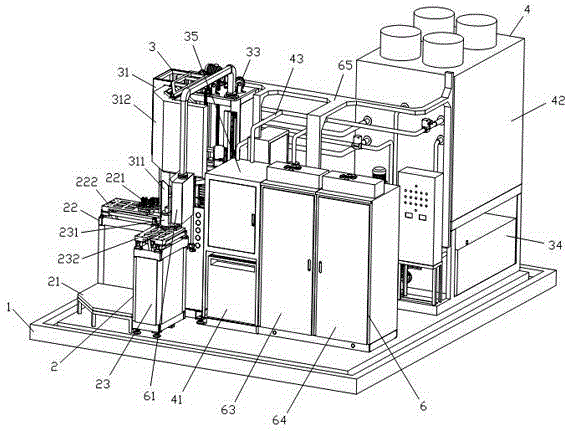

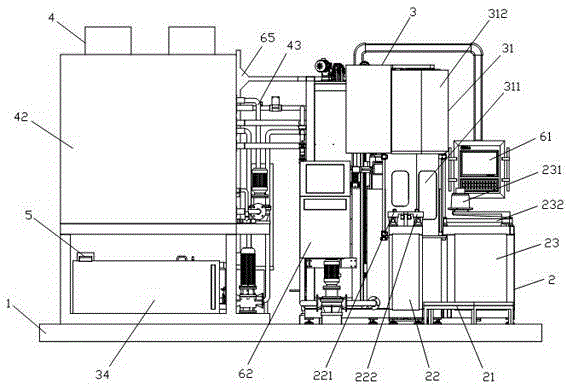

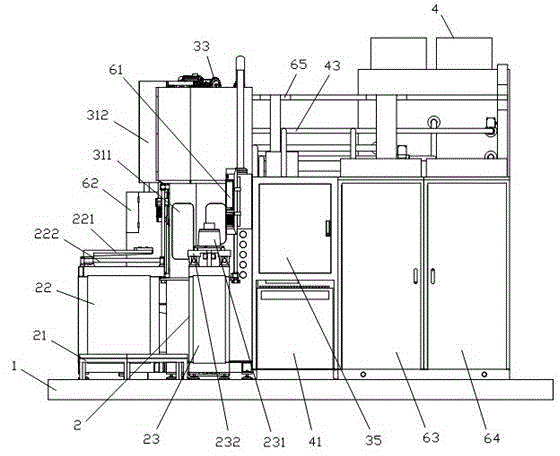

[0031] Such as Figures 1 to 9 As shown, the quenching machine tool of the present invention is a vertical induction hardening machine tool, including a substantially square base 1 and a loading and unloading mechanism 2, a quenching mechanism 3, a cooling mechanism 4, an oil-water separator 5 and a control system 6 arranged on the base 1 .

[0032] The loading and unloading mechanism 2 is located on one side of the quenching mechanism 3, including a pedal 21, a first loading and unloading station 22 and a second loading and unloading station 23; the pedal 21 is located at a corner of the base 1, and its height is the same as that of the first loading and unloading station 22 and the second loading and unloading station 23 are compatible; the first loading and unloading station 22 includes the first positioning fixture 221 and the first positioning fixture slide table 222 fixedly assembled with the first positioning fixture 221; the second loading and unloading station 23 Inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com