Spray quenching medium

A technology of quenching medium and mass ratio, applied in the direction of quenching agent, heat treatment equipment, manufacturing tools, etc., can solve the problems of high rapid quenching efficiency, low production efficiency, small deformation, etc., achieve efficiency improvement, cost saving, and increase convection The effect of thermal velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

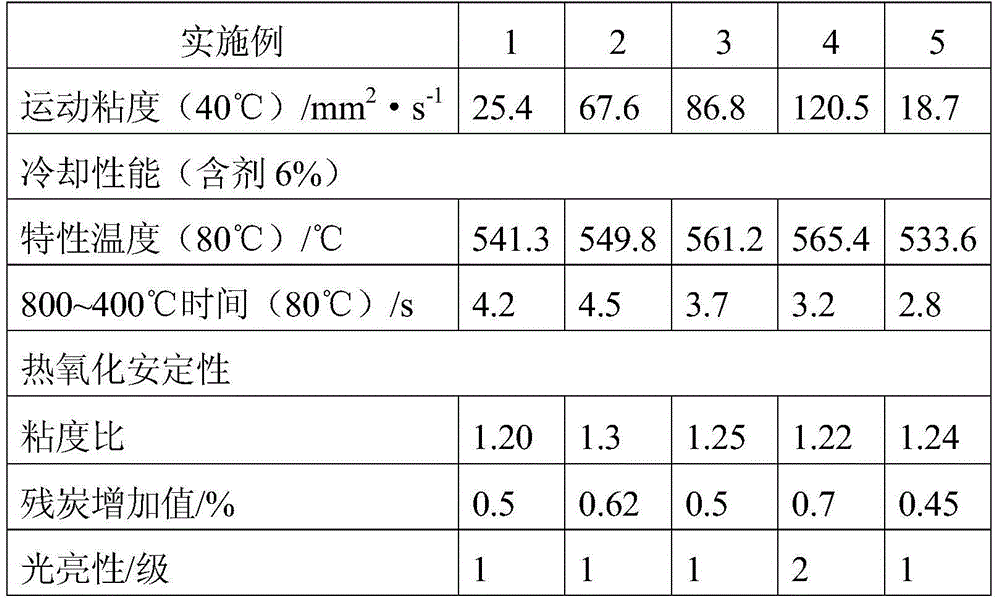

Examples

Embodiment 1

[0023] Preparation of spray quenching medium 1: first dissolve 3kg of antioxidant and 2kg of brightener in 650kg of No. 32 mechanical oil, then add 300kg of No. 100 mechanical oil, and finally add 45kg of refrigerant, and stir evenly. Wherein the antioxidant is composed of p-phenylenediamine, 6-tertiary butyl-4-methylphenol, thiodipropionate diester with a mass ratio of 1:1:2, p-phenylenediamine is 1.5kg, 6 - 1.5 kg of tertiary butyl-4-methylphenol and 3 kg of diester thiodipropionate. The brightener is composed of sodium benzoate, nicotinic acid, nonylphenol polyoxyethylene ether and benzylidene acetone with a mass ratio of 3:1:1:1.

[0024] Add the spray quenching medium 1 into the spray oil tank on the spray quenching furnace, open the pressurization equipment to pressurize the spray quenching medium; set the quenching temperature to 850°C and the fuel injection time to 12s according to the quenching material 65Mn. The flow rate of spray quenching medium is 30L / s; heat the...

Embodiment 2

[0027] Preparation of spray quenching medium 2: first dissolve 5kg of antioxidant and 3kg of brightener in 700kg of No. 32 mechanical oil, then add 250 kg of No. 100 mechanical oil, and finally add 42 kg of refrigerant, and stir evenly. Wherein the antioxidant is composed of p-phenylenediamine and 2,6-tertiary butyl-4-methyl-2 with a mass ratio of 1:1, and the brightener is composed of sodium benzoate and benzylidene acetone with a mass ratio of 1:1 .

[0028] Add the spray quenching medium 2 into the spray oil tank on the spray quenching furnace, open the pressurization equipment to pressurize the spray quenching medium; The flow rate of spray quenching medium is 20L / s; heat the workpiece to be quenched and perform quenching treatment.

[0029] The surface of the obtained quenched workpiece is quickly hardened, and there are individual soft spots after complete hardening, and the energy consumption is small.

Embodiment 3

[0031] Preparation of spray quenching medium 3: first dissolve 2kg of antioxidant and 3kg of brightener in 750kg of No. 32 mechanical oil, then add 200kg of No. 100 mechanical oil, and finally add 45kg of refrigerant, and stir evenly. The antioxidant is composed of p-phenylenediamine, 6-tertiary butyl-4-methylphenol and thiodipropionate diester with a mass ratio of 1:1:1. The brightener is composed of sodium benzoate, nicotinic acid, nonylphenol polyoxyethylene ether and benzylidene acetone with a mass ratio of 1:1:1:1.

[0032] Add the spray quenching medium 3 into the spray oil tank on the spray quenching furnace, open the pressurization equipment to pressurize the spray quenching medium; set the quenching temperature to 850°C and the fuel injection time to 18s according to the quenching material 30CrMo The flow rate of spray quenching medium is 25L / s; heat the workpiece to be quenched and perform quenching treatment.

[0033] The resulting quenched workpiece is quickly har...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com