Vertical vacuum quenching furnace

A vacuum quenching furnace, vertical technology, applied in quenching devices, heat treatment equipment, manufacturing tools, etc., can solve the problem of large discrete indicators of quenching quality, and achieve the effect of improving quenching quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

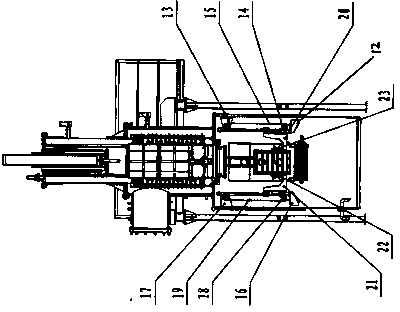

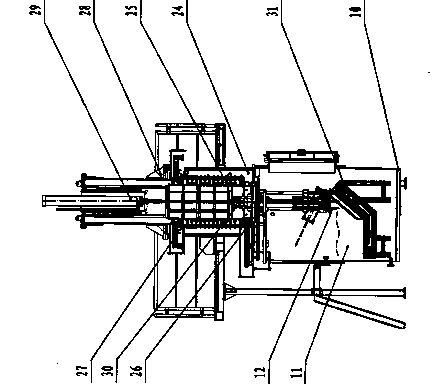

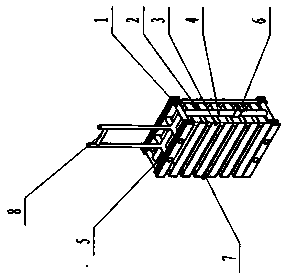

[0013] The present invention is described in detail below in conjunction with accompanying drawing:

[0014] A vertical vacuum quenching furnace, comprising a PLC and a quenching water tank 10, a heating chamber 24 is arranged on the top of the quenching water tank 10, and a lower partition of the heating chamber is arranged between the bottom outlet of the heating chamber 24 and the top entrance of the quenching water tank 10 The hot spot 26 is provided with a lifting cylinder 29 on the top surface of the heating chamber 24, between the lifting cylinder 29 and the top of the heating chamber 24, an insulating door 27 on the heating chamber is provided, and a heating furnace 25 is arranged in the heating chamber 24. The downward protruding output shaft of the lifting cylinder 29 is connected with a mechanical gripper 30, and the lower right inner wall of the quenching water tank 10 is provided with a lower right mounting seat 12 and a lower right sprocket wheel 14 of the lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com