Metal product quenching medium cyclic utilization device

一种淬火介质、金属制的技术,应用在淬火装置、淬火剂、制造工具等方向,能够解决浪费人力、场地面积大、浪费清水等问题,达到保证淬火质量、场地面积小、不污染环境的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

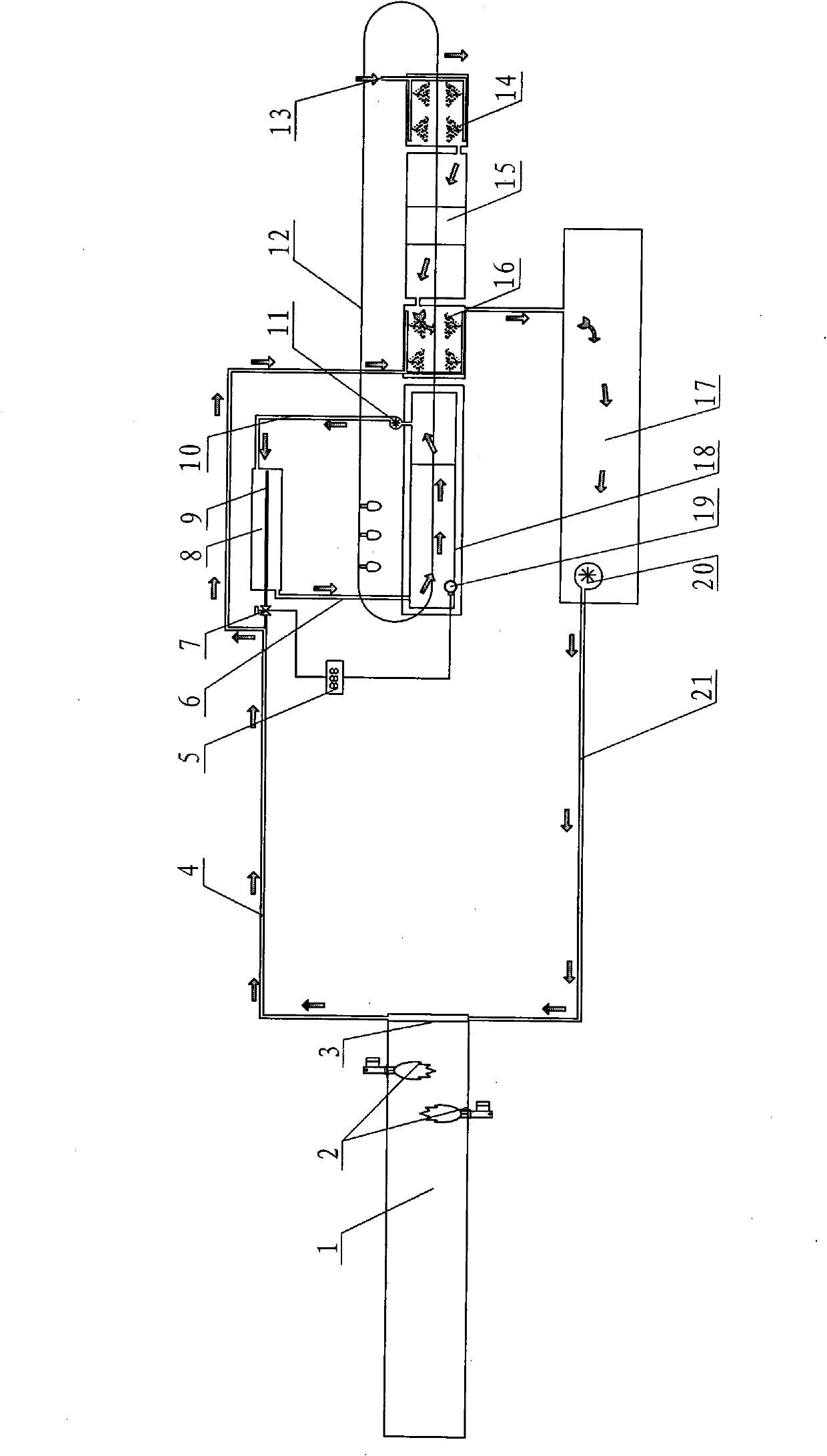

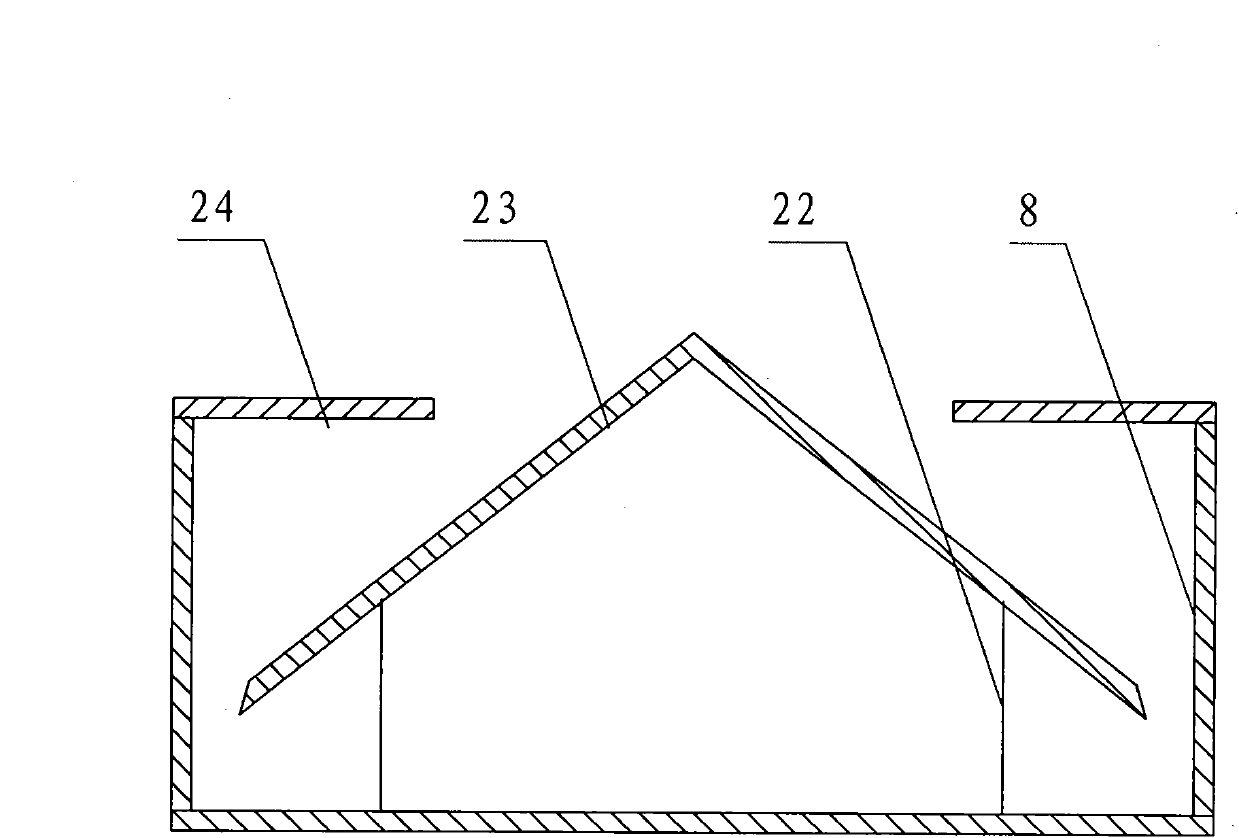

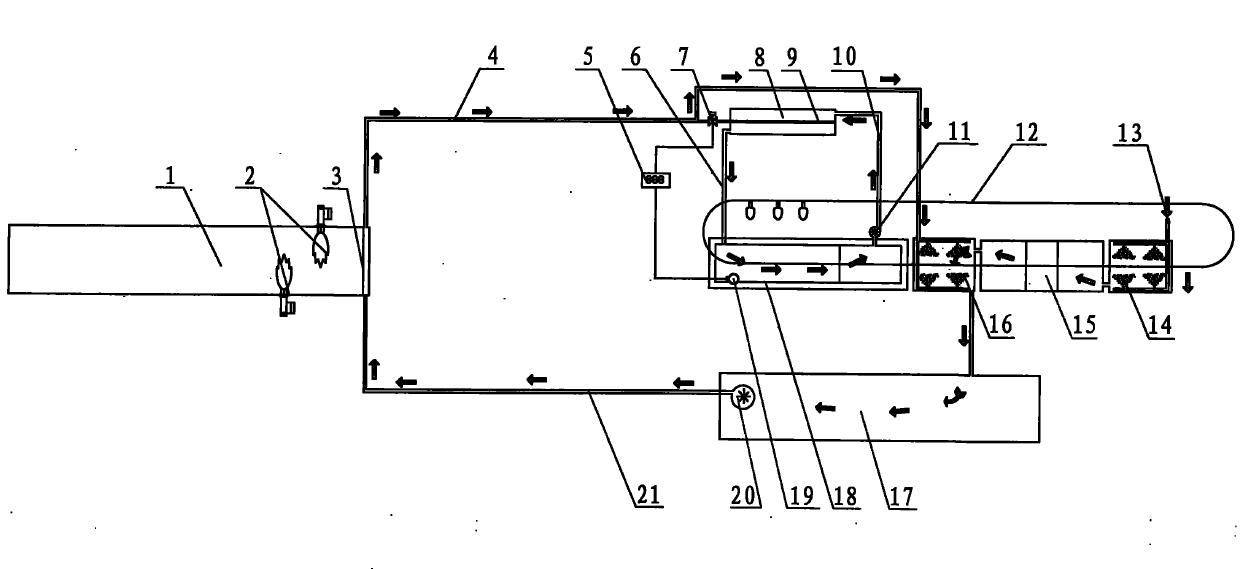

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011] The present invention is a quenching medium recycling device for metal parts. The metal parts in this embodiment refer to steel shovels and metal parts with large quenching capacity suitable for continuous operation. The design idea is: in order to reduce the pollution to the environment and reduce the consumption in the steel shovel quenching process, a melting and confluence tank 8 is designed, and the medium contained in the spraying water is reduced by evaporating the spraying water through the cooling process of the quenching medium. Convergence, the specific method is: the medium melt in the quenching tank 18 is pumped into the medium delivery pipeline 10 through the medium circulation pump 11 and sent to the melting and confluence tank 8, and the solenoid valve 7 of the spray water branch 9 is connected to the temperature control When the signal is turned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com