Ohmic heating method and ohmic heating device

A heating method and power supply technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of inability to quench the tooth surface, difficult to guarantee the quality of quenching or annealing, and low operating efficiency, and achieve the effect of high-efficiency quenching or annealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The best mode adopted for carrying out the present invention will be described in detail below based on the drawings.

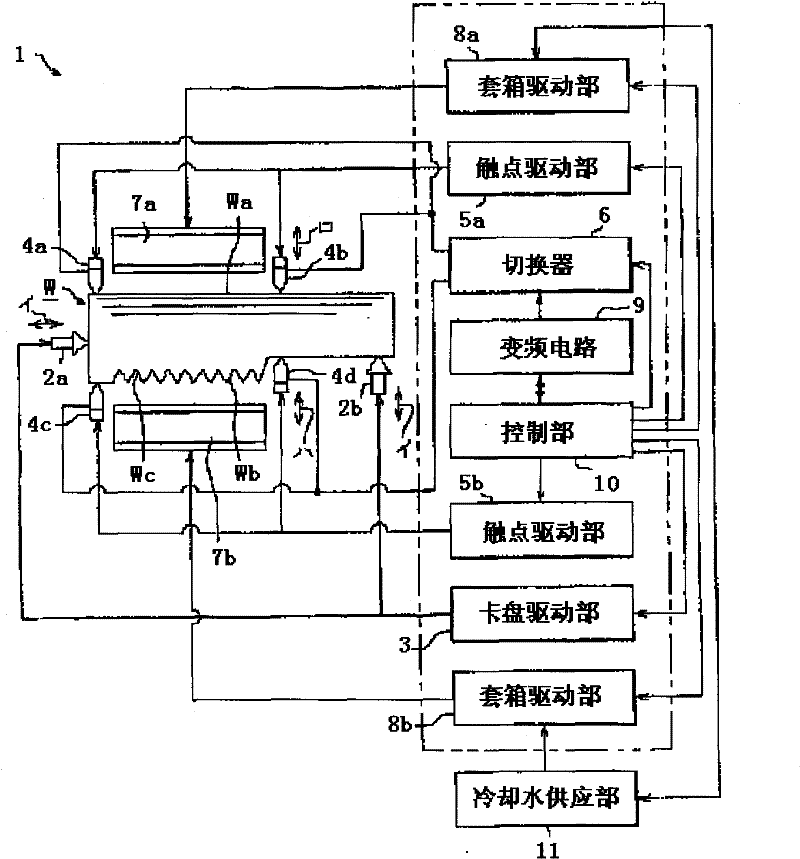

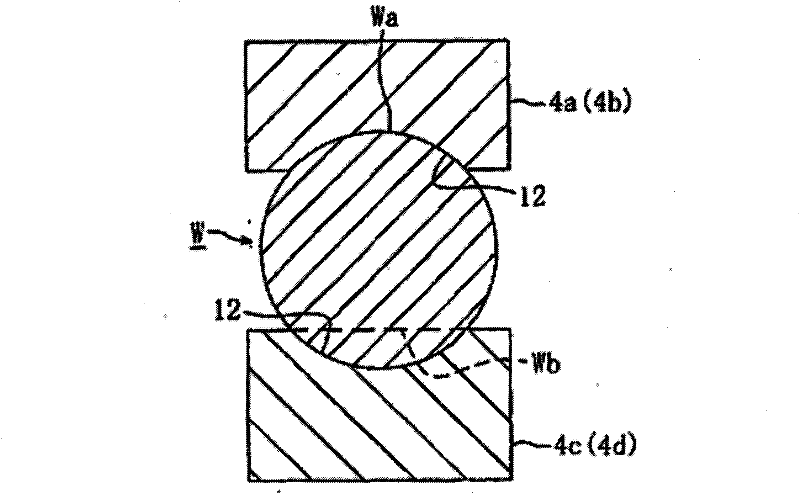

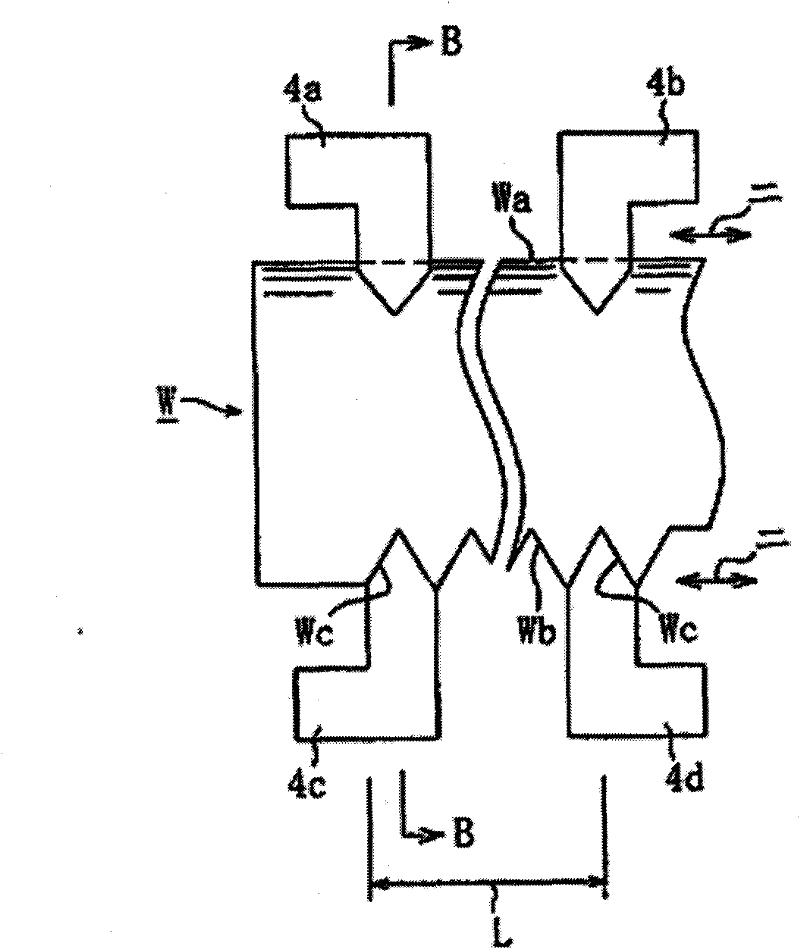

[0026] Figure 1 ~ Figure 7 This shows an embodiment when the energization heating device according to the present invention is used for rack quenching. Such as figure 1 As shown, the rack (hereinafter referred to as the workpiece W) to which the energization heating device 1 of the present invention is applied is composed of a tooth surface Wb having a relative axis of helical teeth at a predetermined angle, and a semicircular arc on the opposite side of the tooth surface Wb The backside Wa structure of the surface composition.

[0027] Then, the energized heating device 1 is equipped with the following devices: left and right chucks 2a, 2b supporting both ends of the workpiece W as supporting means, and the chucks 2a, 2b are moved in the direction indicated by the arrow ii and clamped or loosened The chuck drive unit 3 composed of the click of the workp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com