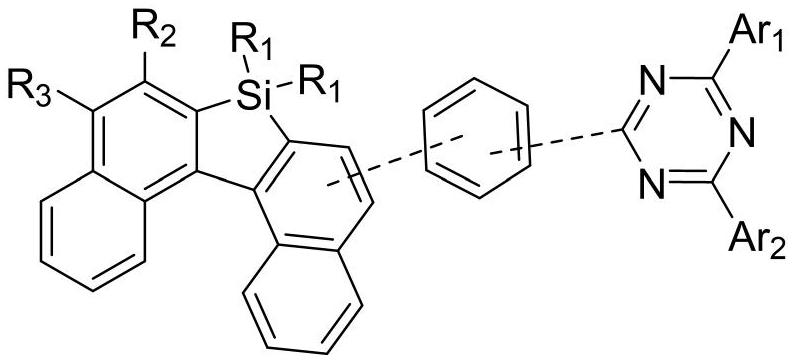

Organic luminescent compound and organic electroluminescent device

A technology for electroluminescent devices and light-emitting compounds, which is applied to silicon organic compounds, electro-solid devices, electrical components, etc., can solve the problems of short lifespan and low light-emitting efficiency of devices, and achieve accelerated quenching, improved light-emitting efficiency, and electron transport. Ability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

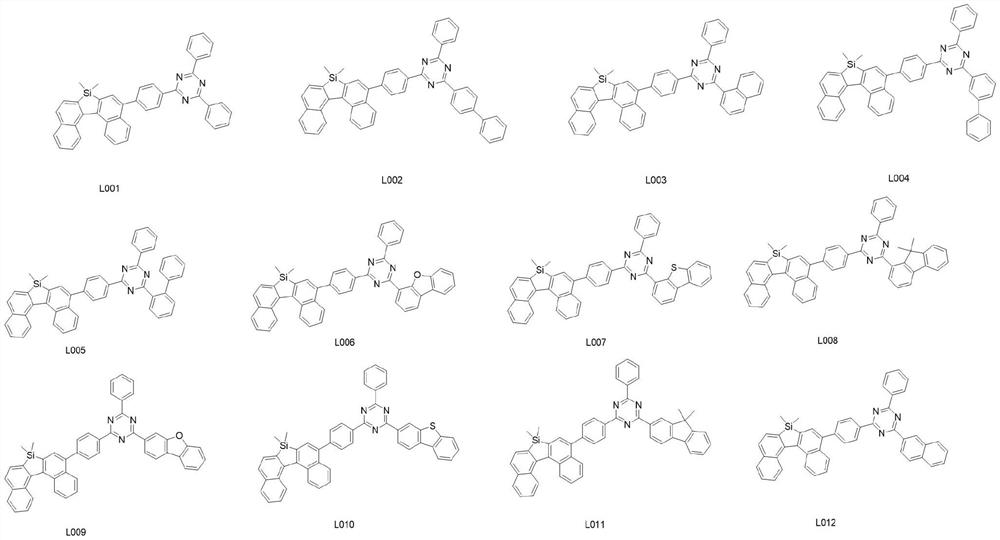

[0029] An organic luminescent material L002, namely the compound numbered L002, the specific synthesis steps are as follows:

[0030] Under nitrogen protection system, weigh A-002 (14.11mmol, 5g), B-002 (12.83mmol15.96g) into the reaction system, add 200ml of toluene, 100ml of absolute ethanol and 100mL of pure water mixed solution, add 4.76 g of anhydrous sodium carbonate and 0.16 g of tetrakis(triphenylphosphine)palladium, heated at 90°C under nitrogen protection and kept stirring for 48 hours, TLC spot plate monitoring raw material B-002 had no residue, then cooled the reaction system to 30°C, and depressurized Filter, rinse the filter cake with 150ml of ethanol and 150ml of petroleum ether in sequence, dry the filter cake in vacuum, add the obtained solid to 150ml of toluene, raise the temperature of the reaction system to 110°C, and keep the After heating and stirring at 110°C for 10 hours, the reaction system was cooled to 30°C, the solution was filtered under reduced pr...

Embodiment 2

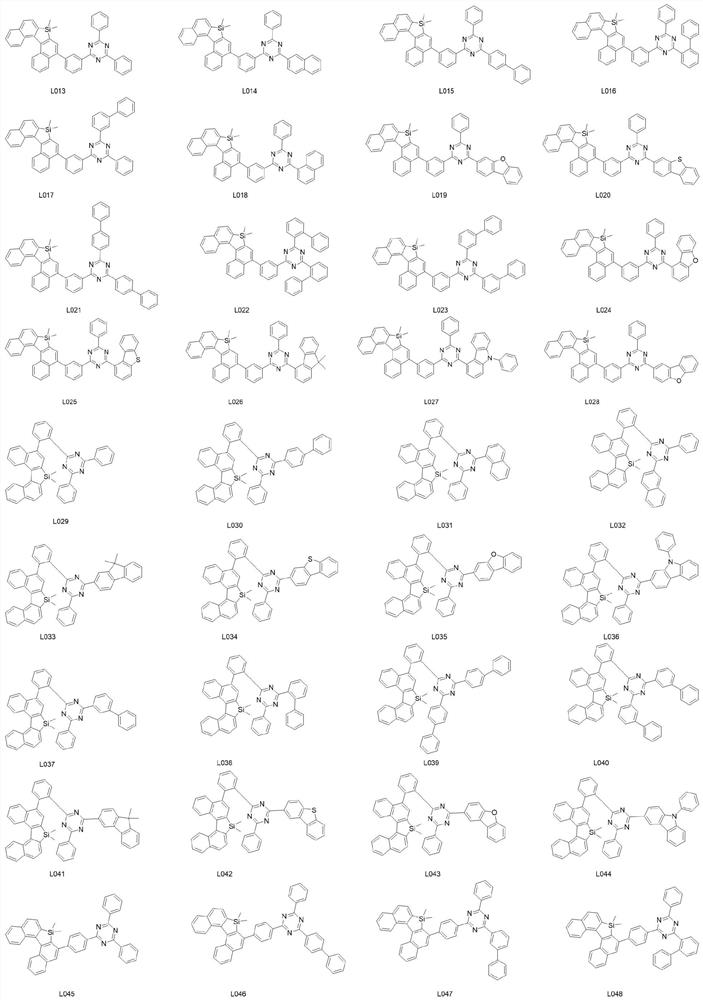

[0038] An organic luminescent material L019, namely the compound numbered L019, the specific synthesis steps are as follows:

[0039] Under nitrogen protection system, weigh A-019 (14.11mmol, 5g), B-019 (12.83mmol16.14g) into the reaction system, add 200ml of toluene, 100ml of absolute ethanol and 100mL of pure water mixed solution, add 4.80 g of anhydrous sodium carbonate and 0.20 g of tetrakis(triphenylphosphine)palladium, heated at 90°C under the protection of nitrogen and kept stirring for 48 hours, TLC spot plate monitoring raw material B-019 had no residue, then cooled the reaction system to 30°C, and depressurized Filter, rinse the filter cake with 150ml of ethanol and 150ml of petroleum ether in sequence, dry the filter cake in vacuum, add the obtained solid to 150ml of toluene, raise the temperature of the reaction system to 110°C, and keep the After heating and stirring at 110°C for 10 hours, the reaction system was cooled to 30°C, the solution was filtered under red...

Embodiment 3

[0047] An organic luminescent material L043, namely the compound numbered L043, the specific synthesis steps are as follows:

[0048] Under a nitrogen protection system, weigh A-043 (14.11mmol, 5g), and add B-043 (11.76mmol15.63g) into the reaction system, add a mixed solution of 200ml toluene, 100ml absolute ethanol and 100mL pure water, add 4.36 g of anhydrous sodium carbonate and 0.14 g of tetrakis(triphenylphosphine)palladium, heated at 90°C under nitrogen protection and kept stirring for 48 hours, TLC spot plate monitoring raw material B-043 had no residue, then cooled the reaction system to 30°C, and depressurized Filter, rinse the filter cake with 130ml of ethanol and 130ml of petroleum ether in sequence, dry the filter cake in vacuum, add the obtained solid to 120ml of toluene, raise the temperature of the reaction system to 110°C, and keep the After heating and stirring at 110°C for 10 hours, the reaction system was cooled to 30°C, the solution was filtered under reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com