Flame retardant piece for modular internal concave type anti-explosion valve

An explosion-proof valve, modular technology, applied in the direction of fire rescue, etc., can solve the problems of bulky flame retardant, low efficiency of quenching and flame extinguishing, etc., and achieve the effect of compact structure, modular design, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

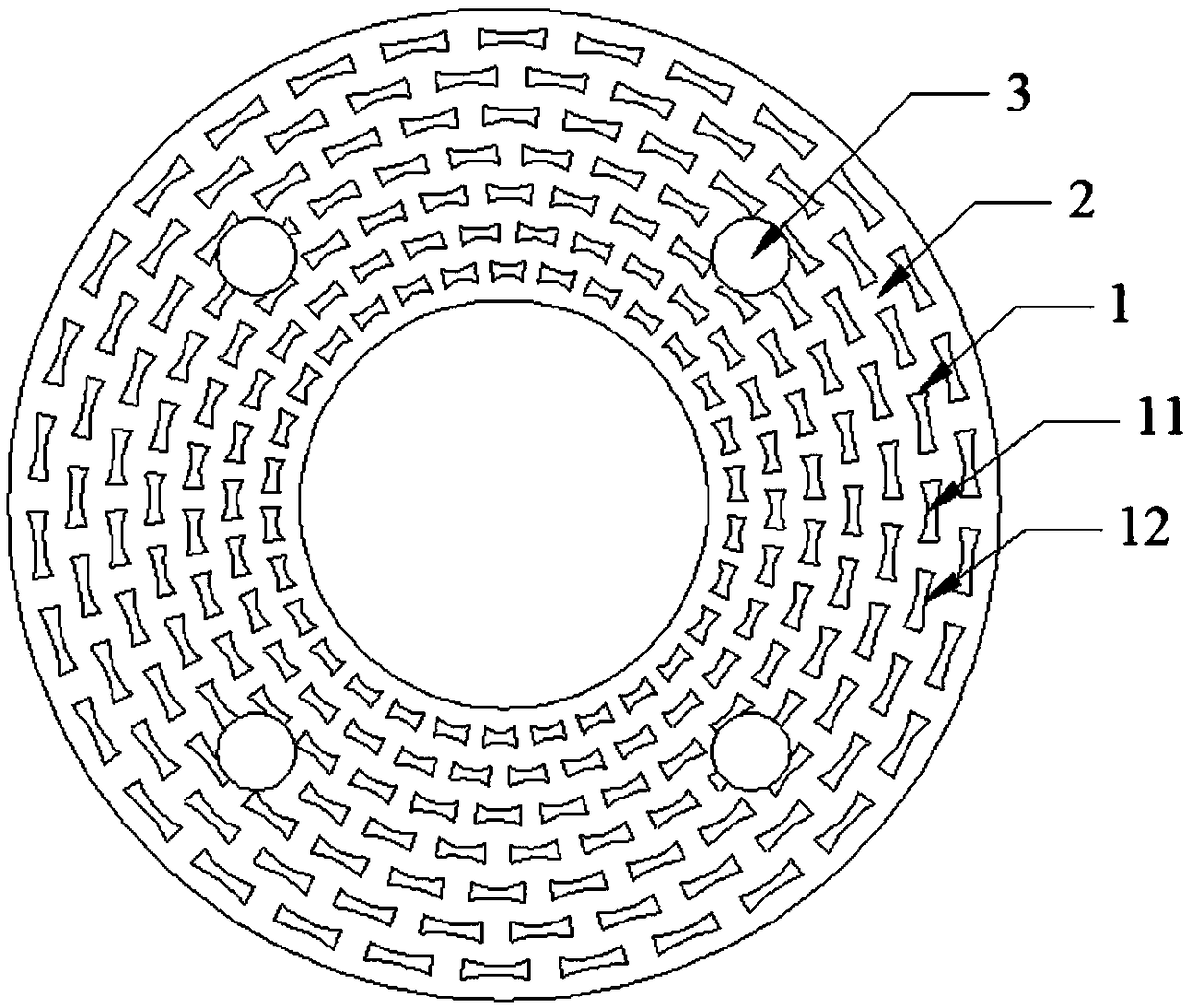

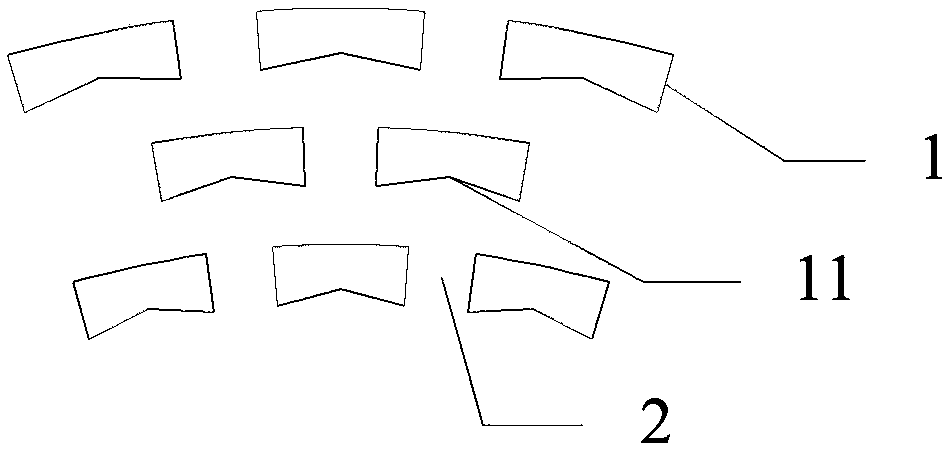

[0025] As shown in Embodiment 1-4, a flame retardant sheet for a modular concave explosion-proof valve of this embodiment, the flame retardant sheet is circular, and more than one spoiler is provided on the flame retardant sheet Column 1, the spoiler column 1 includes a windward side 11 and a leeward side 12; the windward side 11 of the spoiler column 1 is a concave structure, and the spoiler column 1 of the first row is located in the rear The front center of the gap 2 between two adjacent spoiler posts 1 in a row, and the gap between two adjacent spoiler posts 1 in the rear row is smaller than the width of the spoiler posts 1 in the previous row. Four mounting holes 3 are opened on the flame retardant sheet.

[0026] The concave structure is a triangular concave (such as figure 2 shown), or trapezoidal concave (such as image 3 shown), or arc concave (such as Figure 4 shown).

[0027] The gap 2 of the two spoiler columns 1 forms the flow path of the deflagration flame,...

Embodiment 2

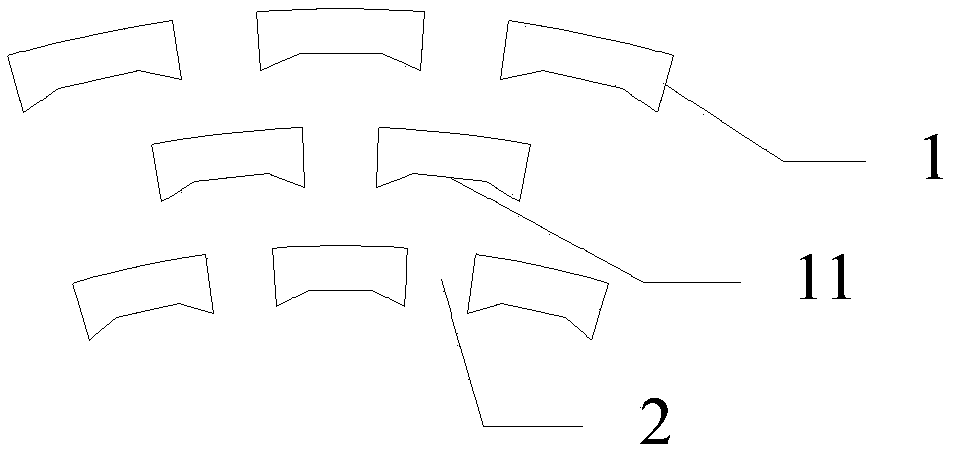

[0031] As shown in Embodiment 1, 5-7, a flame retardant sheet for a modular concave explosion-proof valve of this embodiment, the flame retardant sheet is circular, and more than one The spoiler column 1, the spoiler column 1 includes a windward side 11 and a leeward side 12; the leeward side 12 of the spoiler column 1 is a concave structure; the spoiler column 1 in the previous row is located The front center of the gap 2 between two adjacent spoiler posts 1 in the latter row, and the gap between the two adjacent spoiler posts 1 in the latter row is smaller than the width of the spoiler posts 1 in the previous row; Four mounting holes 3 are opened on the flame retardant sheet.

[0032] The concave structure is a triangular concave (such as Figure 5 shown), or trapezoidal concave (such as Image 6 shown), or arc concave (such as Figure 7 shown).

[0033] The gap 2 of the two spoiler columns 1 forms the flow path of the deflagration flame, and the annular flame retardant ...

Embodiment 3

[0037] As shown in Embodiment 1, 8-10, a flame retardant sheet for a modular concave explosion-proof valve of this embodiment, the flame retardant sheet is circular, and more than one The spoiler column 1, the spoiler column 1 includes a windward side 11 and a leeward side 12; the windward side 11 and the leeward side 12 of the spoiler column 1 are both concave structures; the front row of The spoiler column 1 is located in the front center of the gap 2 between two adjacent spoiler columns 1 in the rear row, and the gap between the two adjacent spoiler columns 1 in the rear row is smaller than the spoiler in the previous row The width of the column 1; four installation holes 3 are opened on the flame retardant sheet.

[0038] The concave structure is a triangular concave (such as Figure 8 shown), or trapezoidal concave (such as Figure 9 shown), or arc concave (such as Figure 10 shown).

[0039] The gap 2 of the two spoiler columns 1 forms the flow path of the deflagrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com