Process method for quenching rotary support gear

A technology of slewing bearing and process method, which is applied in the direction of quenching device, process efficiency improvement, and manufacturing tools, etc., can solve the problems of bad stress state of gears, broken gears, etc., and achieve the effect of improving quenching quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

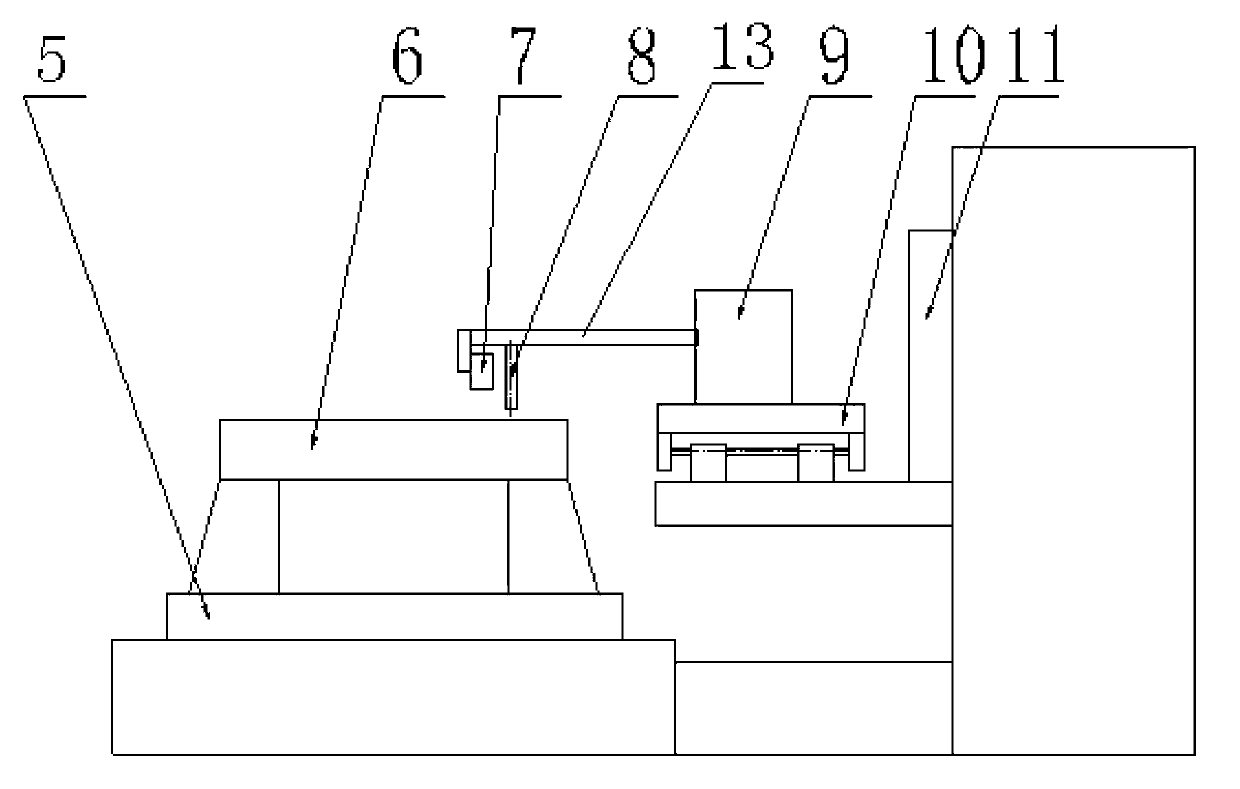

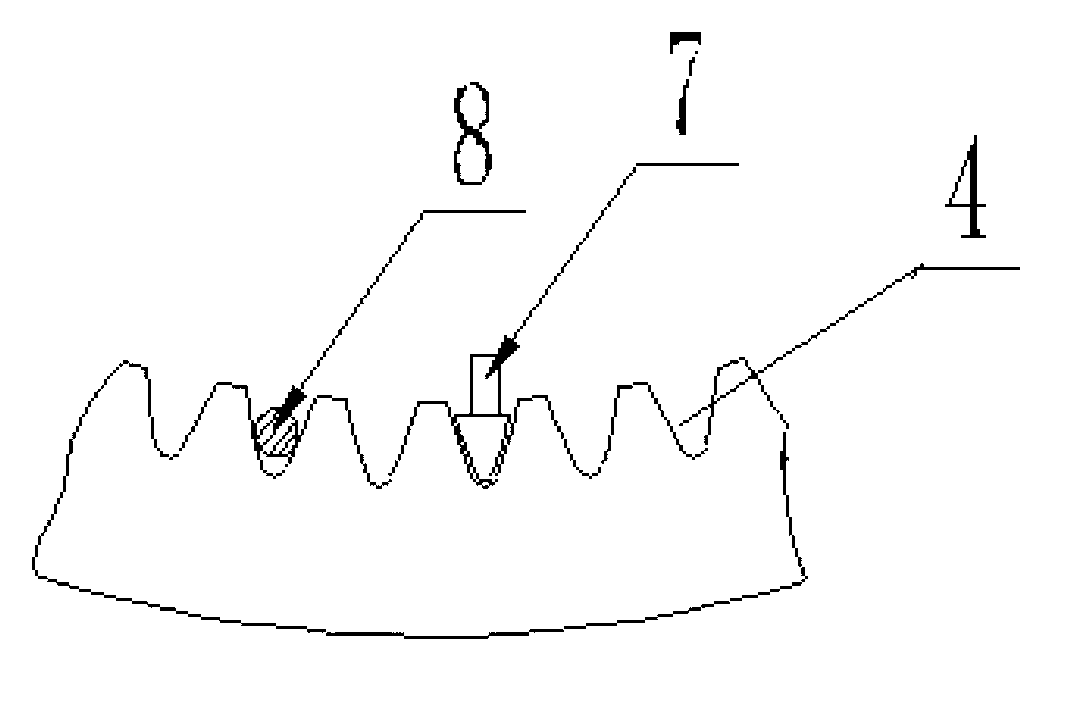

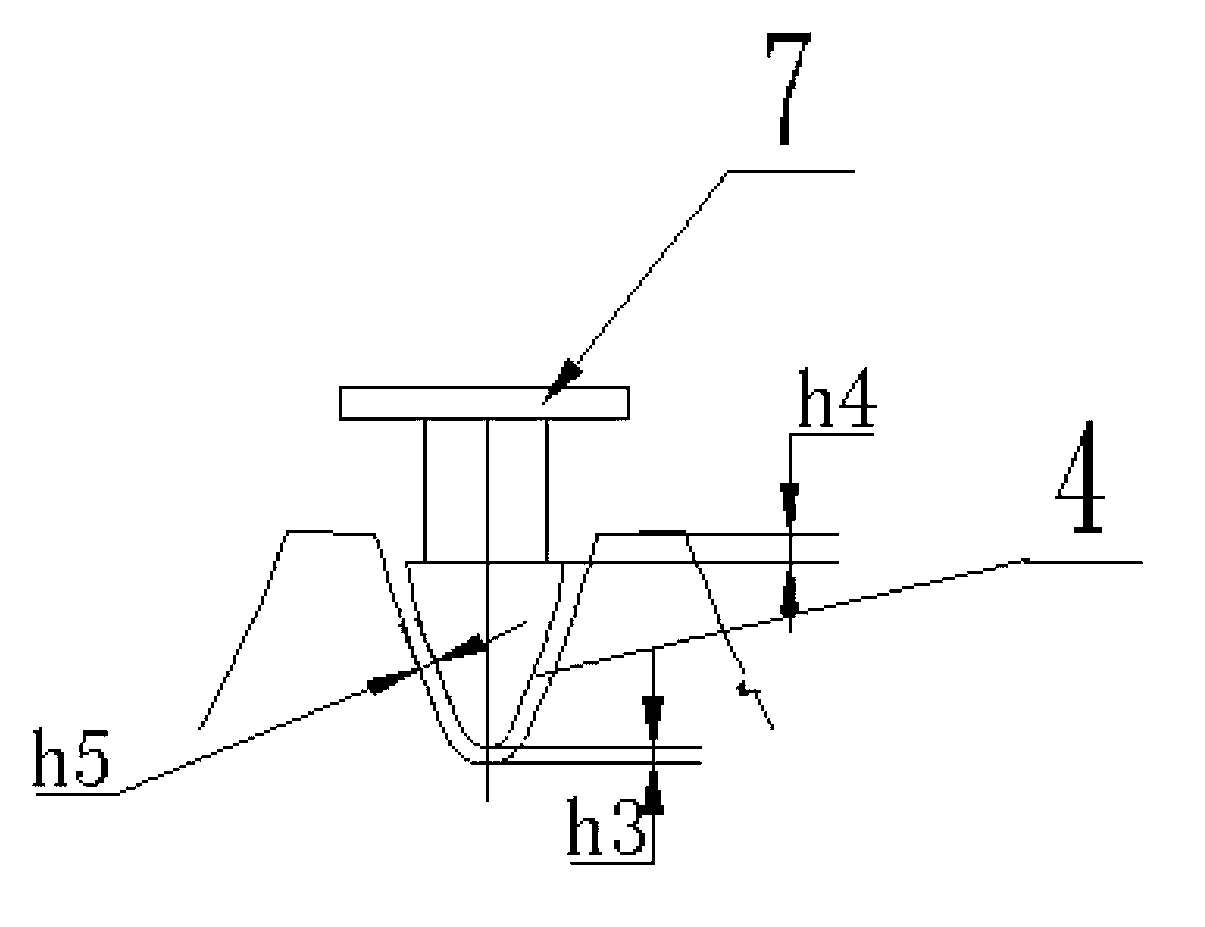

[0029] See the accompanying drawing: a process for quenching gears of slewing rings, the main process of which is to carry out rough turning, finishing turning, gear shaping, quenching and tempering on the inner ring and outer ring of the slewing ring respectively, and the quenching equipment in the quenching process The inductor adopts medium frequency quenching inductor, and the quenching liquid is PAG quenching liquid. The quenching equipment includes a rotary table 5, and a vertically movable fixed seat 11 is provided on one side of the rotary table 5, and the horizontal side of the fixed seat 11 is A sliding seat 10 that moves horizontally is mounted on the board, and a transformer 9 that drives the intermediate frequency quenching sensor 7 and the auxiliary positioning guide rod 8 is fixedly installed on the sliding seat 10. The induction head 12 at the front end of the intermediate frequency quenching sensor 7 is trapezoidal, and the induction When the head 12 cooperates...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com