Air blast quenching machine for rollers

A quenching machine and air-cooling technology, which is applied in the field of mechanical equipment and roll air-cooling quenching machines, can solve the problems of unfavorable heat treatment quality of roll parts, small fluctuation range of blast cooling speed, and poor control of energy consumption in the process. Accurate and reliable rotary motion, improved working environment, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

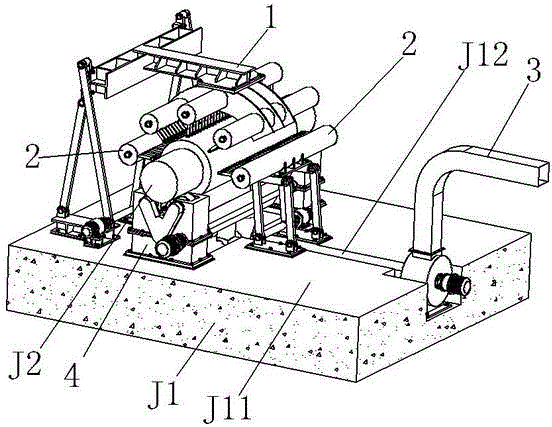

[0035] see figure 1 , Figure 15 , Figure 16 As shown, the present invention is composed of a blasting device 1, a heating device 2, an exhausting device 3 and a rotating device 4, and the blasting device 1, the heating device 2, and the rotating device 4 are all placed and fixedly connected to the concrete foundation J1 On the set horizontal plane J11, the exhaust device 3 is placed and fixed in the groove J12 provided on the foundation base J1; The heating device 2 is arranged symmetrically on both sides of the rotating device 4 , and the workpiece roll J2 is arranged on the rotating device 4 .

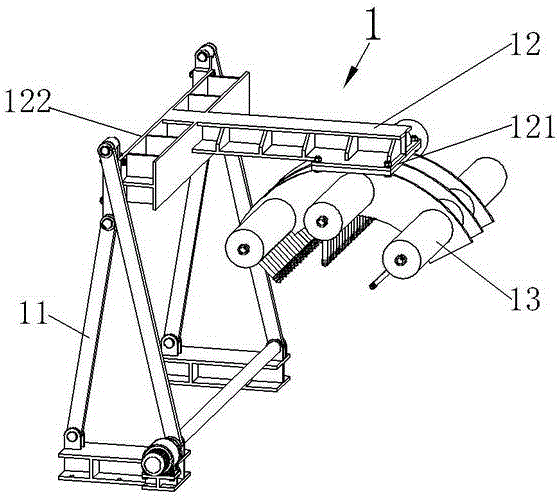

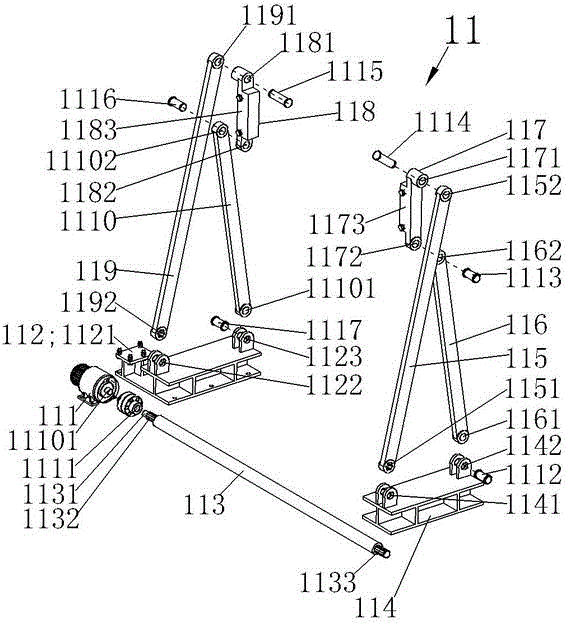

[0036] see figure 1 , figure 2 , image 3 , Figure 4 As shown, the blasting device 1 is composed of a connecting rod device 11, a bracket 12, and a blower 13; On the plane 1173 set on 117 and the plane 1183 set on the second connecting rod 118, the second plane 121 set on the bracket 12 is placed and fixedly connected to the joint plane 1331 set on the connecting plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com