Patents

Literature

50results about How to "Adjust cooling speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

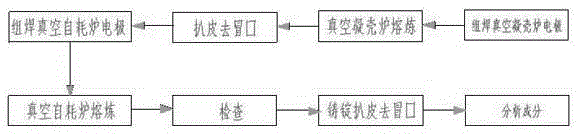

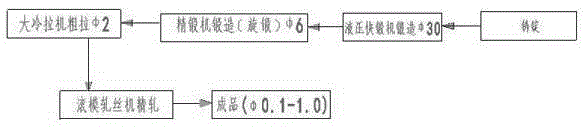

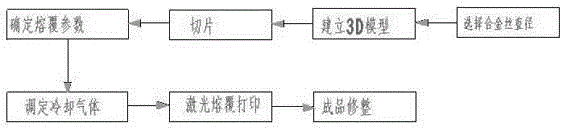

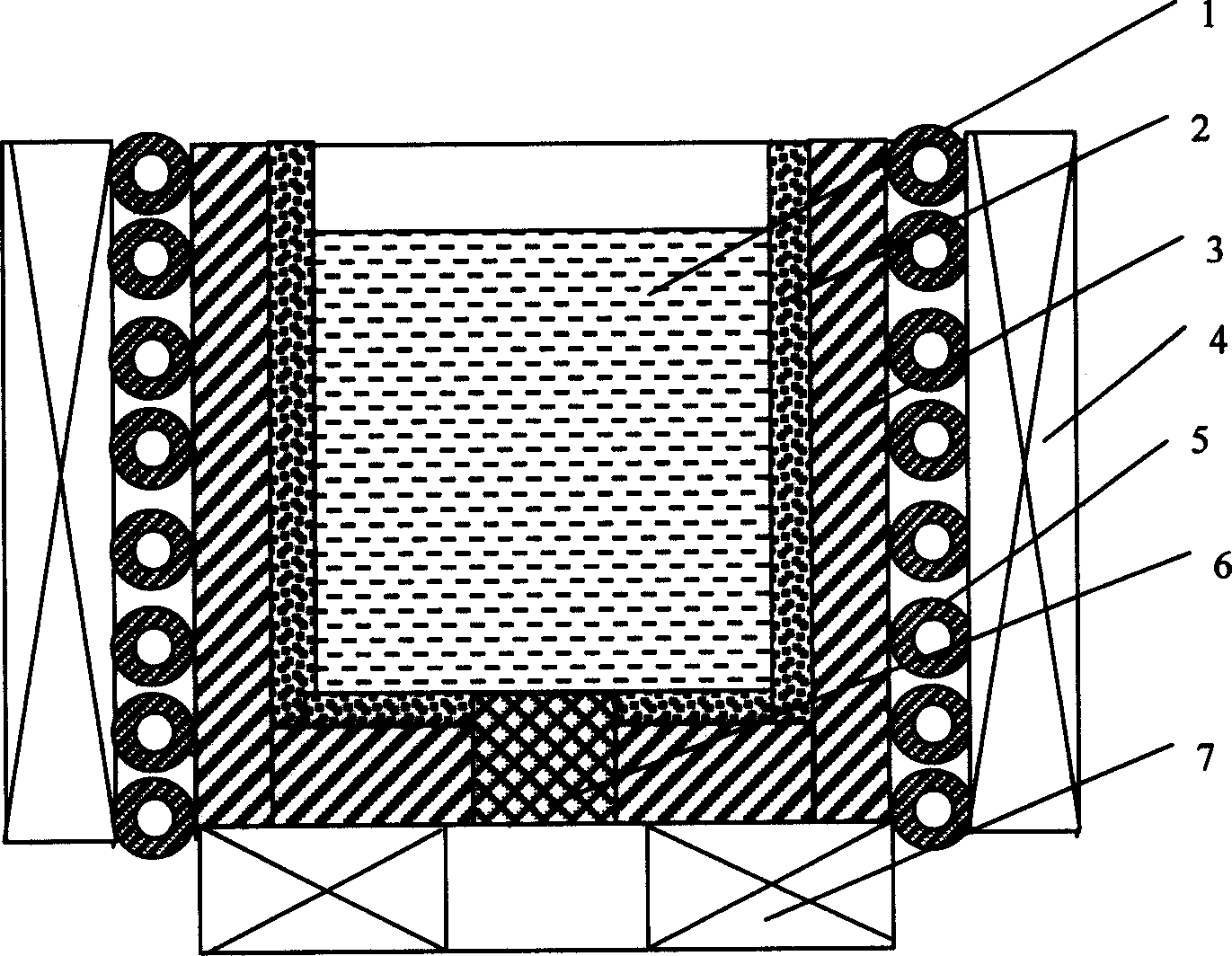

Additive manufacturing method for functional material part based on TiNi memory alloy wire

InactiveCN105268973ALarge molten poolGood for homogenizationAdditive manufacturing apparatusIncreasing energy efficiencyAlloy elementNickel base

The invention belongs to the technical field of forming and manufacturing of metal materials, and particularly relates to an additive manufacturing method for a functional material part based on a TiNi memory alloy wire. The additive manufacturing method comprises the following steps: smelting a titanium-nickel based memory alloy; preparing a titanium-nickel based memory alloy wire; taking the titanium-nickel based memory alloy wire as a raw material; carrying out a laser-cladding additive manufacturing process; and carrying out tissue control and deformation amount control on manufactured parts. A welding pool of a vacuum self-consumption skull furnace is great, and is beneficial for sufficiently homogenizing alloy elements and preventing alloy segregation; and smelting of the vacuum self-consumption skull furnace refers to controlling a cast titanium tissue of a cast ingot, thereby facilitating follow-up cold-hot processing.

Owner:SHENYANG HAINAXIN TECH CO LTD

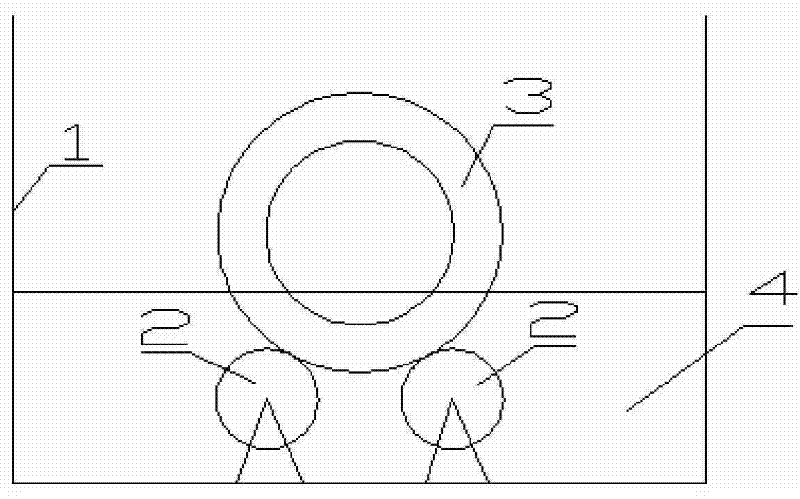

Method and equipment for preparing semisolid fused mass of ferrous material

An apparatus for preparing the semi-solid molten body of iron and steel is composed of a special container for molten iron or steel, temp regulator, stirrer and bottom vibrator. The linear layer of said special container contains nucleation promoter. Its method includes pouring the molten iron or steel at the temp which is 5-10 deg.C, higher than the temp of liquid-phase line into said special container, and stirring or vibrating for 1-10 min.

Owner:BEIJING JIAOTONG UNIV

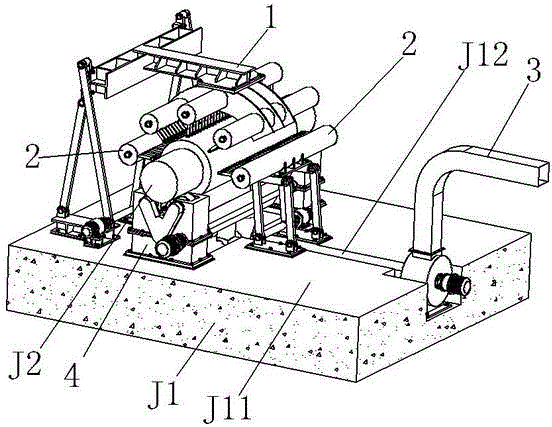

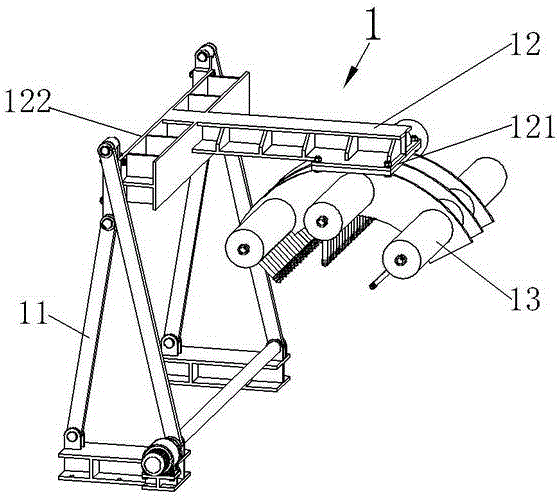

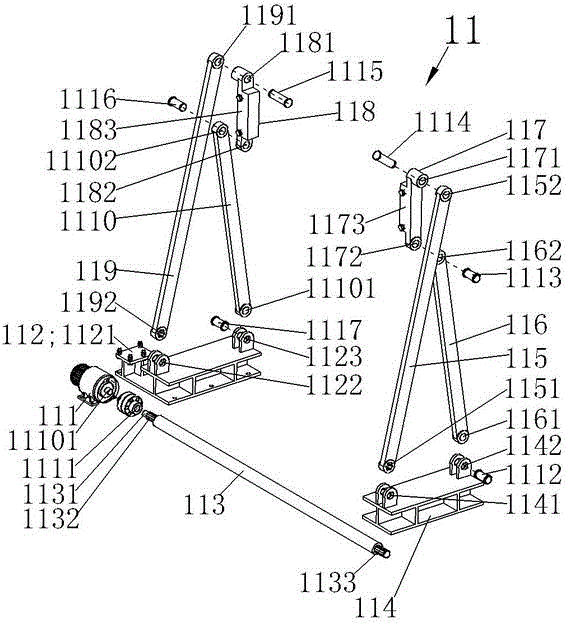

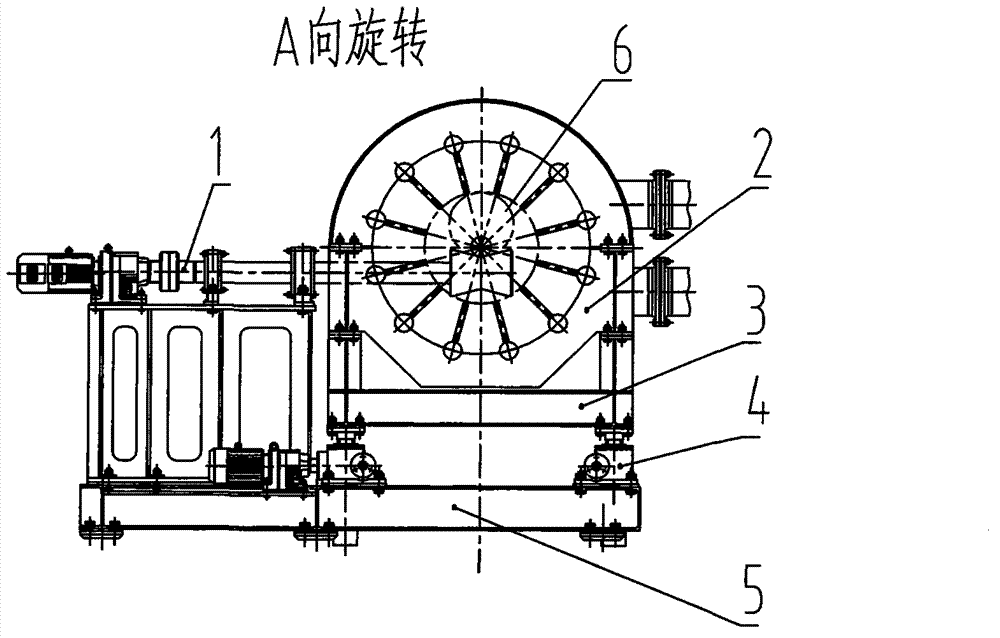

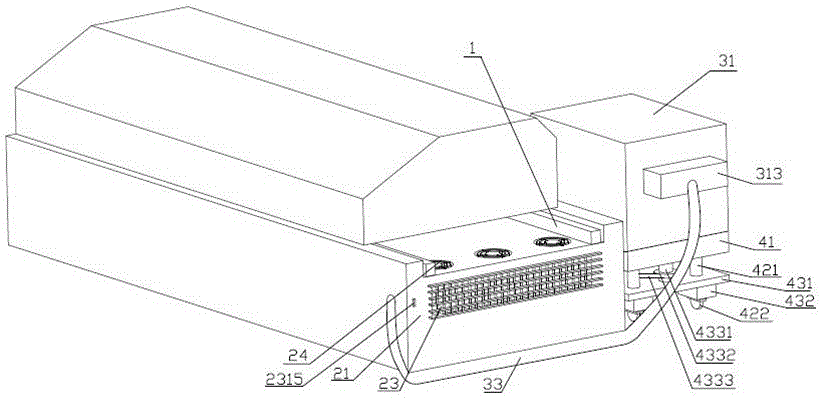

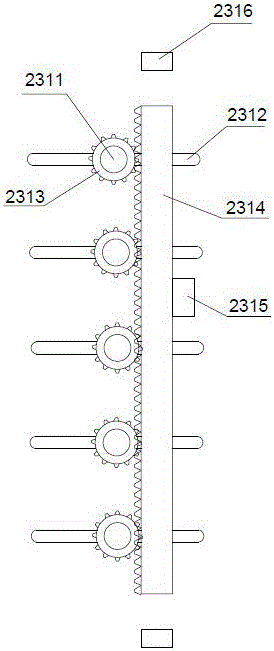

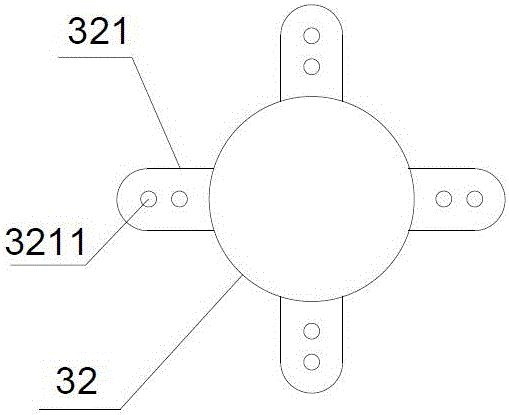

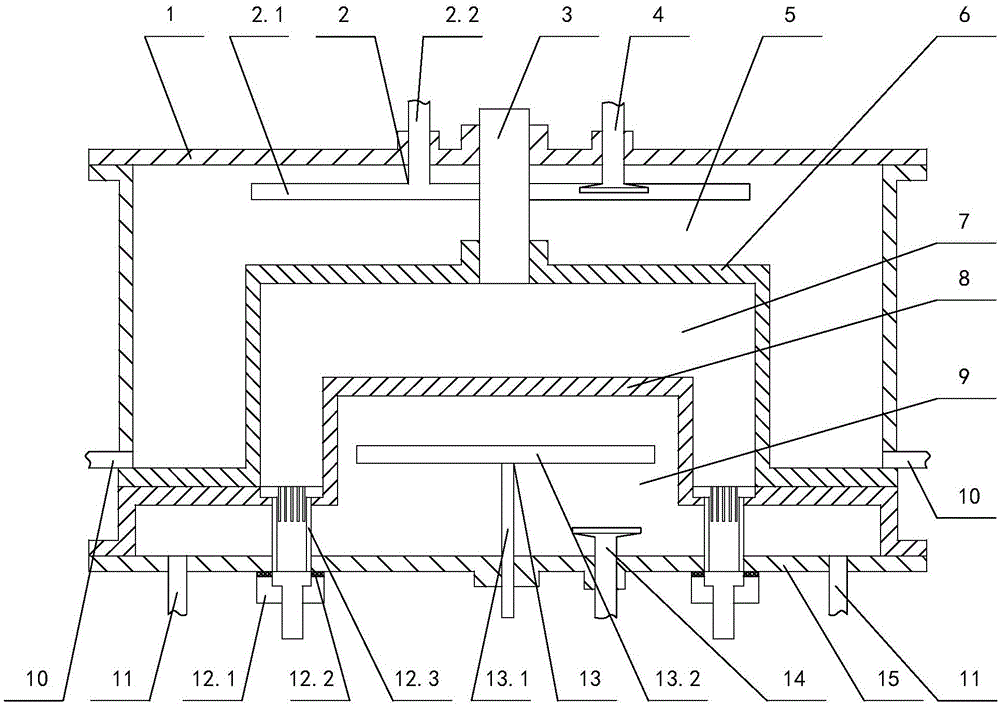

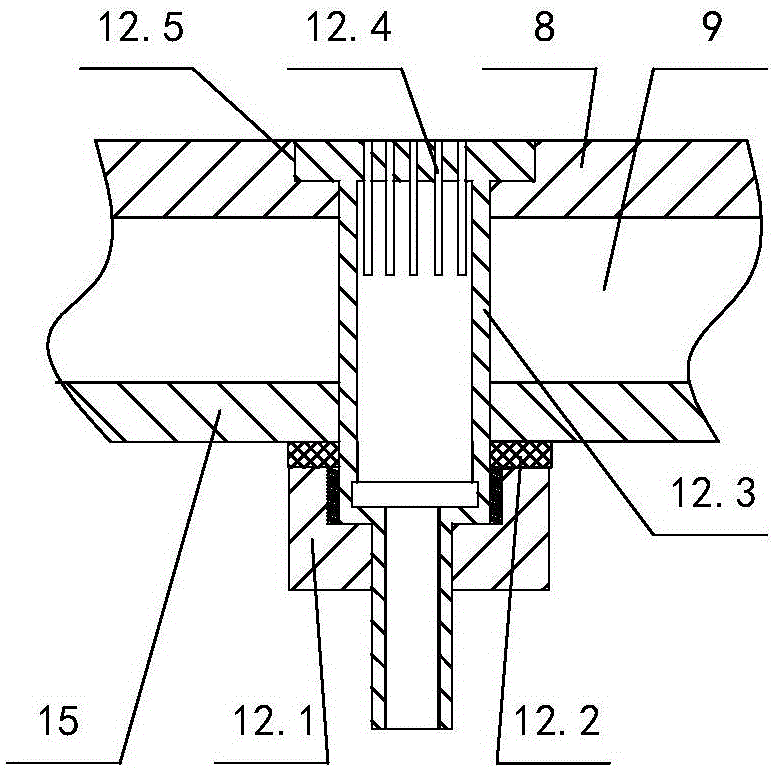

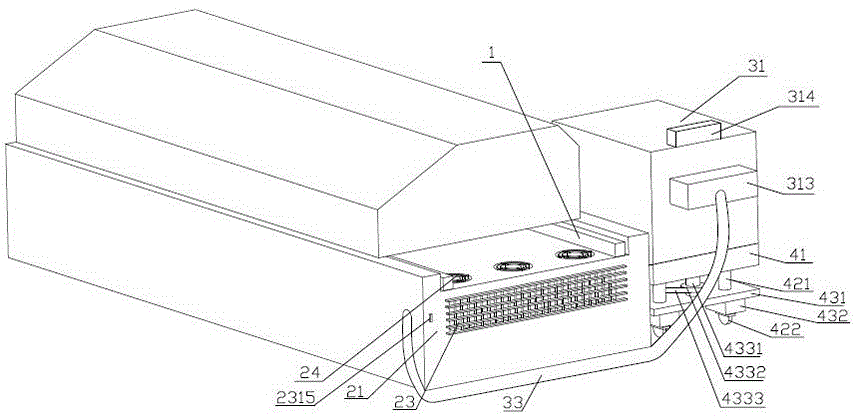

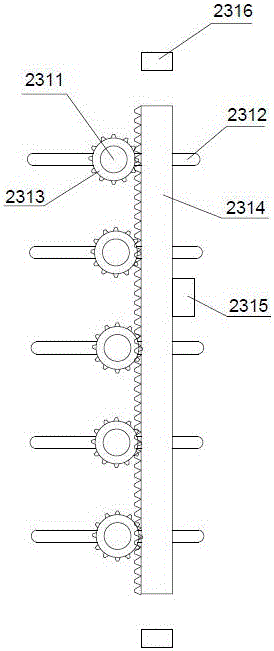

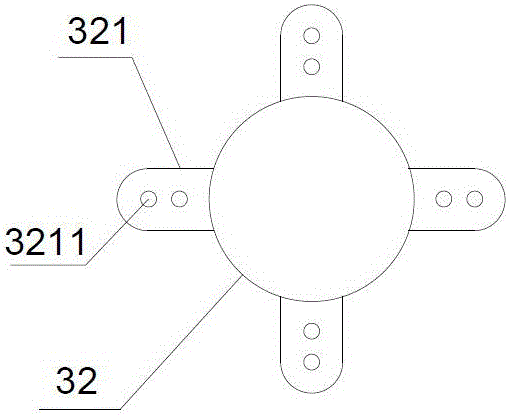

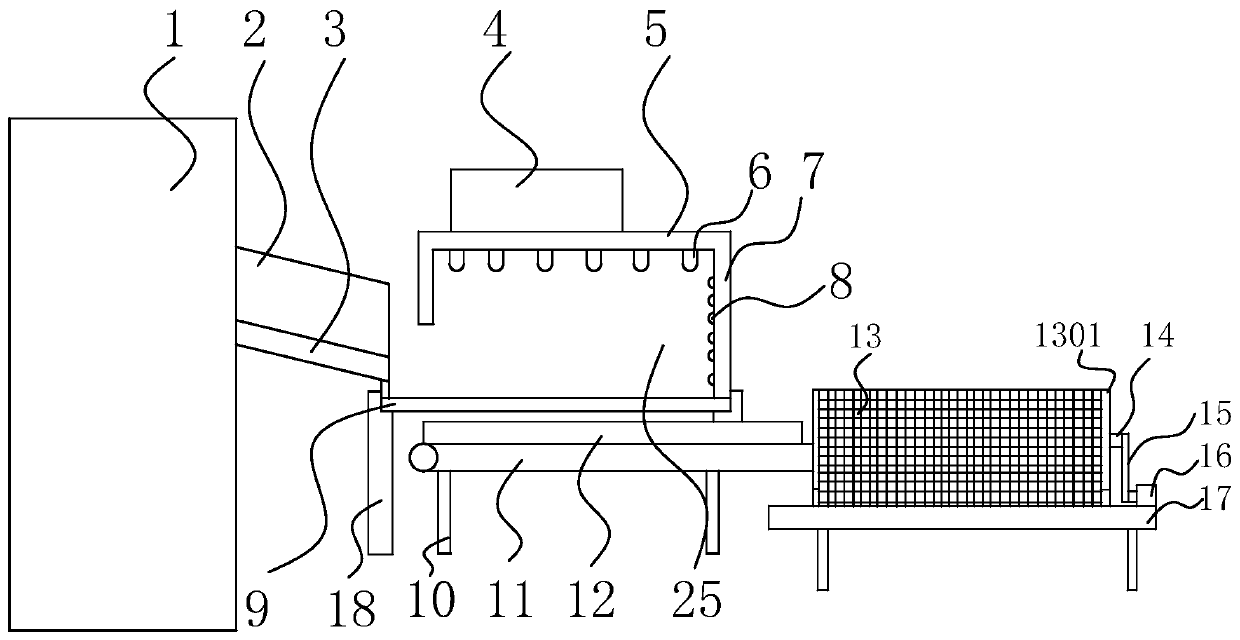

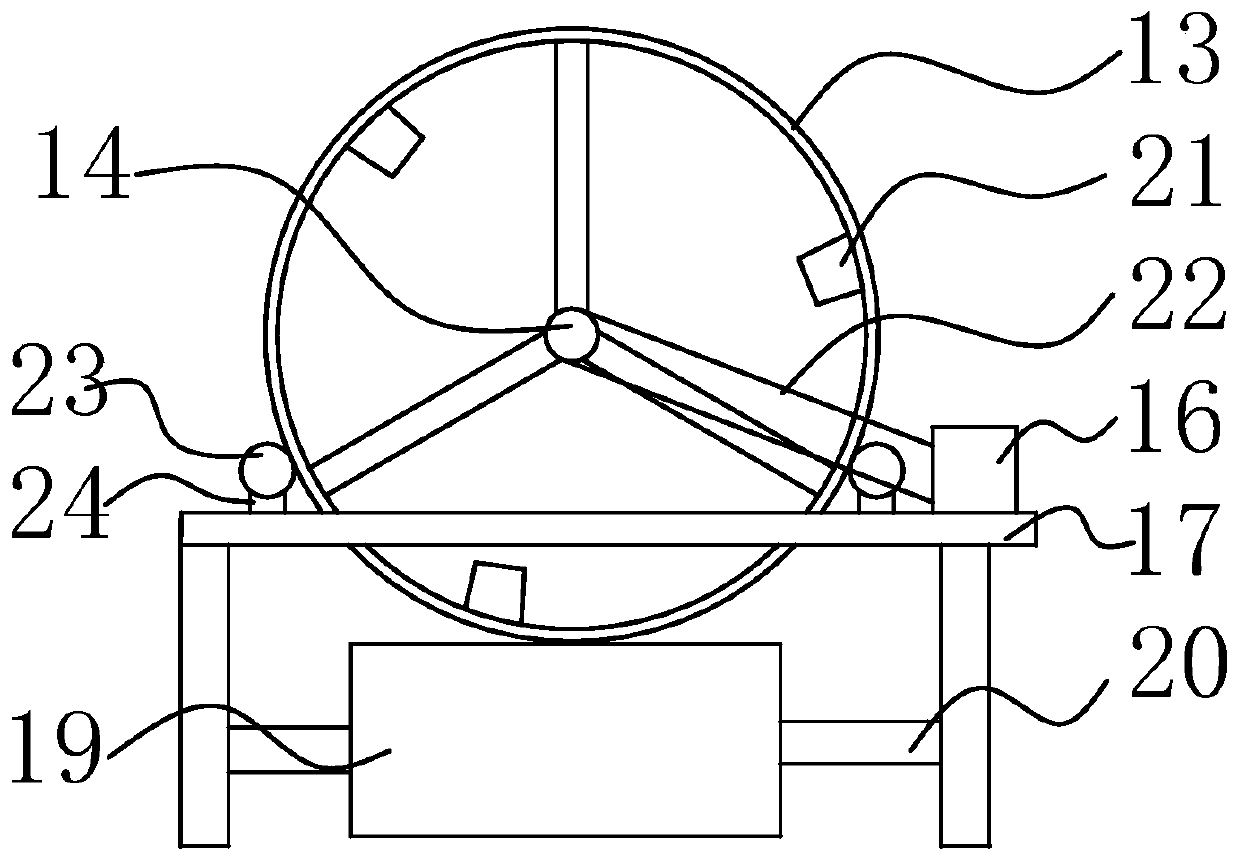

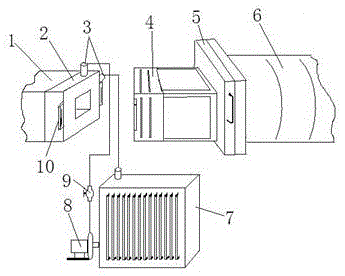

Air blast quenching machine for rollers

InactiveCN105925780AAccurate and reliable rotary motionImprove uniformityFurnace typesHeat treatment furnacesWorking environmentEngineering

The invention relates to mechanical equipment in the field of metal heat treatment, in particular to an air blast quenching machine for rollers. The air blast quenching machine comprises an air spraying device, two heating devices, an air extracting device and a rotation device, wherein the air spraying device, the heating devices and the rotation device are all mounted and fixedly connected to a horizontal surface on a concrete poured foundation base; the air extracting device is mounted and fixedly connected into a groove in the foundation base; the heating devices are arranged on two sides of the rotation device symmetrically; and a workpiece roller is arranged on the rotation device. The air blast quenching machine adopts four-carrier roller synchronous constant-speed mobile rotation, so that the heating uniformity and the quenching quality are improved; due to combined function of the air spraying device and the air extracting device, the cooling speed can be accelerated, and the work environment can be improved; and as both the air spraying device and the heating devices are arranged on and connected with a link mechanism, mobile starting and stopping can be realized, and spray head distances can be adjusted fast.

Owner:KUNMING UNIV

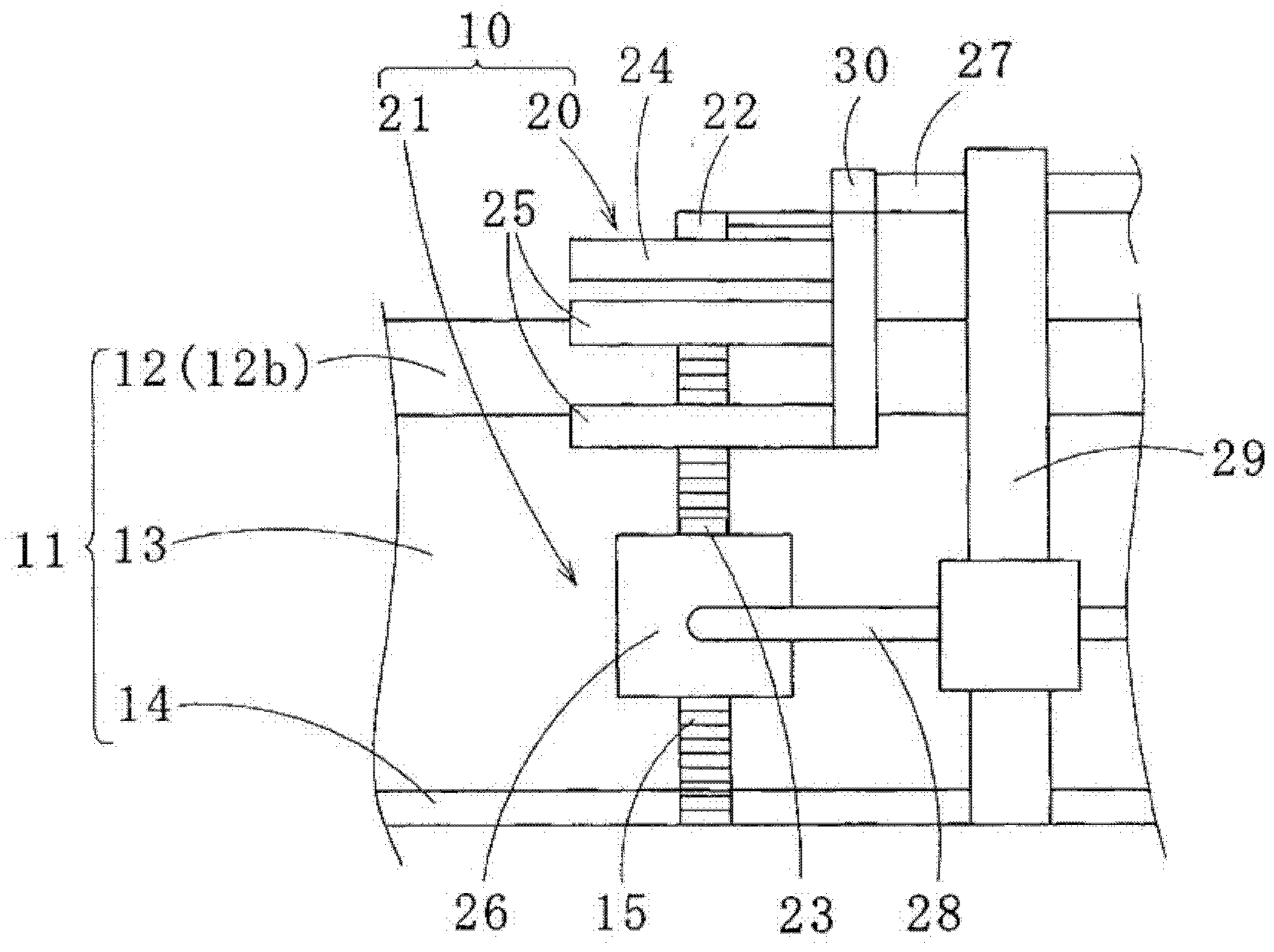

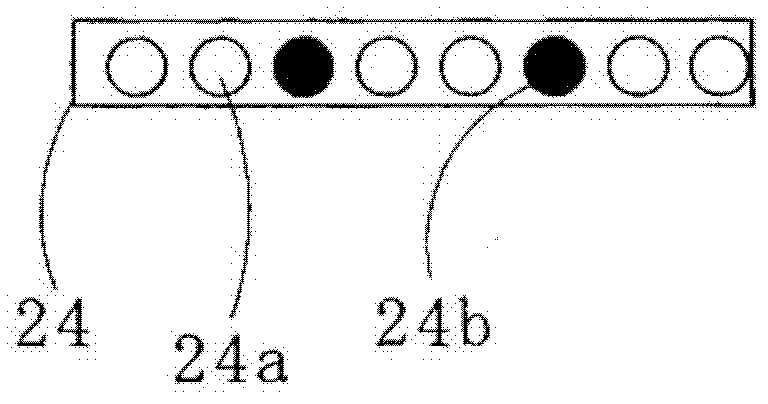

Device and method for cooling welded rail section

InactiveCN102361725AReduce residual stressImprove fatigue strengthRailsFurnace typesCooling fluidControl unit

A device for cooling a welded rail section is provided with a first cooler for cooling a head section of the welded rail section, a second cooler for cooling a column section of the welded rail section, and a control unit for controlling the first cooler and the second cooler. The first cooler is provided with a first temperature detection section for detecting the temperature of the head section, and also with a first discharge section for discharging a first cooling fluid toward the head section. The second cooler is provided with a second temperature detection section for detecting the temperature of the column section, and also with a second discharge section for discharging a second cooling fluid toward the column section. The control section individually changes the kind, amount, and flow speed of the first cooling fluid and the second cooling fluid when the head section and the column section are cooled.

Owner:NIPPON STEEL CORP

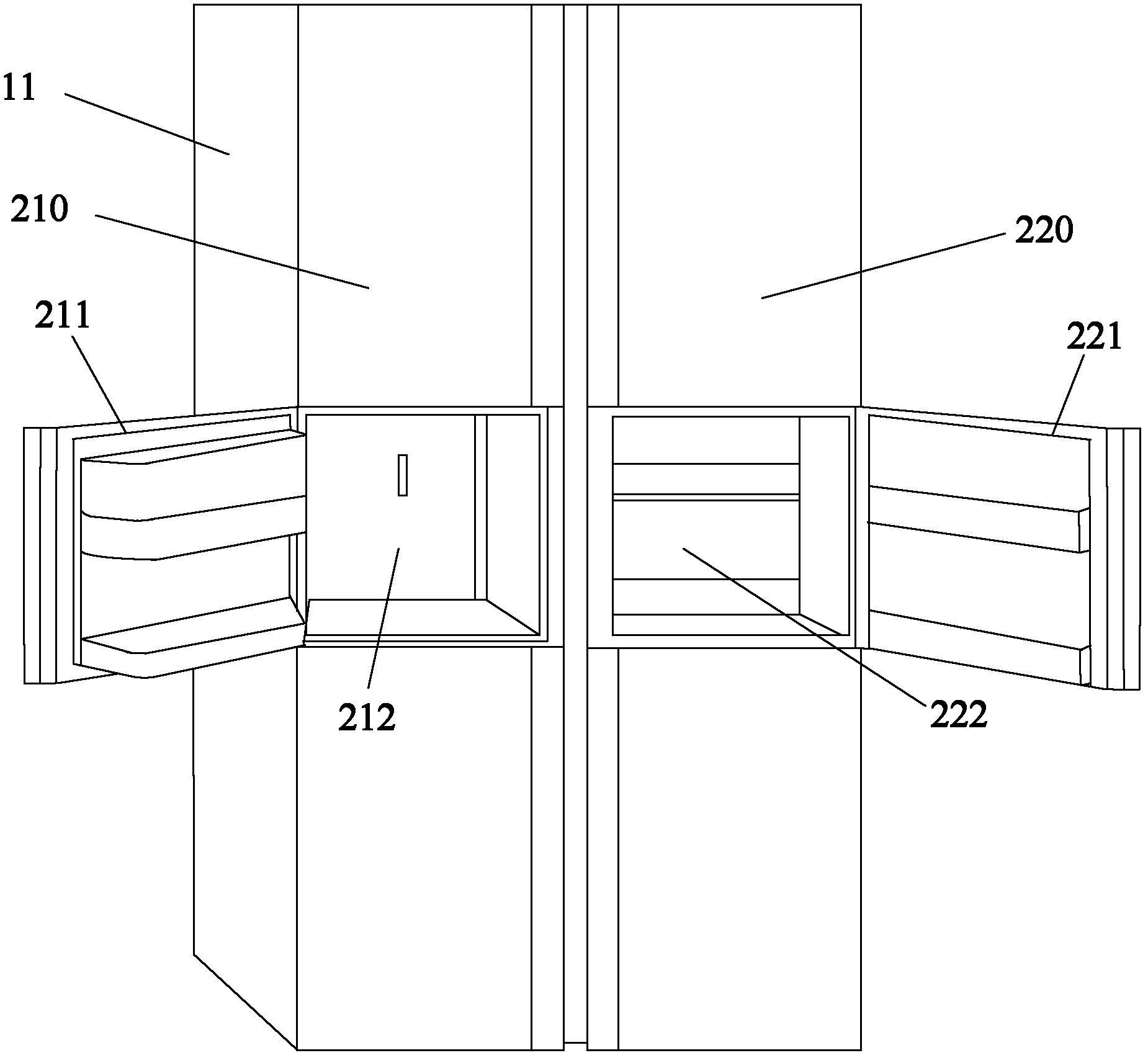

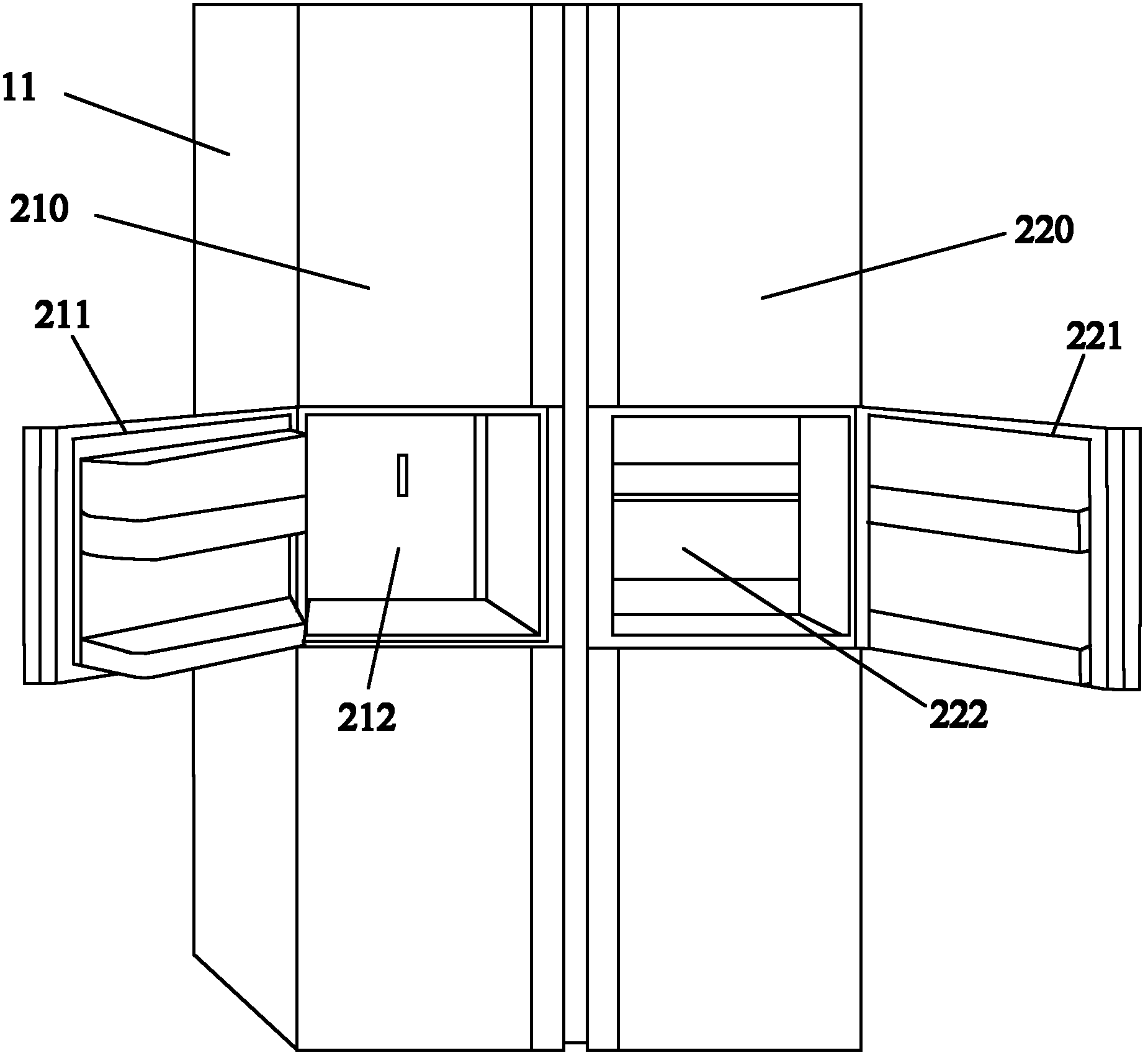

Refrigerator door and refrigerator

ActiveCN102278857AAdjust cooling speedSafe way to openDomestic cooling apparatusLighting and heating apparatusEngineeringCold drinks

The present invention relates to a refrigerator door and a refrigerator, comprising a first door body, characterized in that an inwardly concave cavity and a second door body closing the cavity are arranged on the first door body. By arranging a second door body as a smaller door in the middle of the refrigerator door, and setting an accommodating space on the door body of the smaller refrigerator door, the accommodating space and the above-mentioned chamber can accommodate food that needs to be frequently taken out and put in , for example, milk or cold drinks, etc., which reduces the leakage of cold air caused by the refrigerator door being fully opened, thereby achieving the effect of energy saving and environmental protection.

Owner:HAIER GRP CORP +1

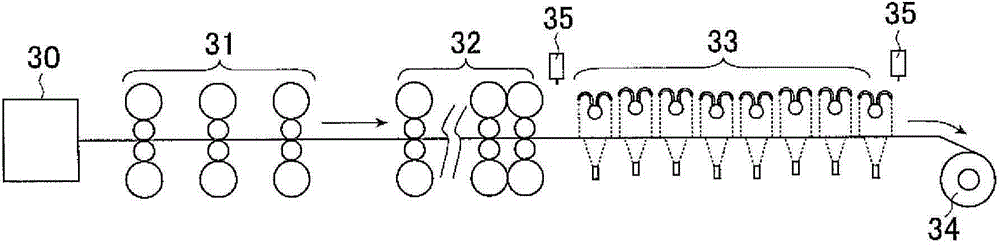

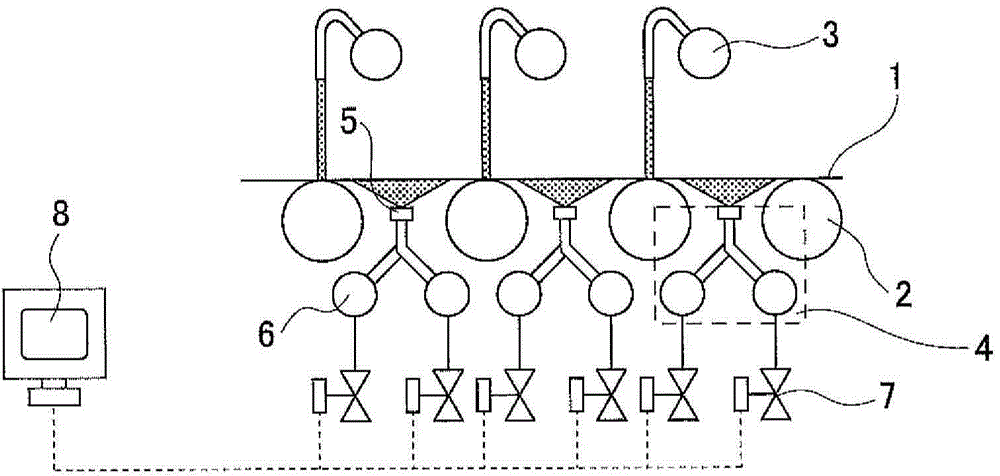

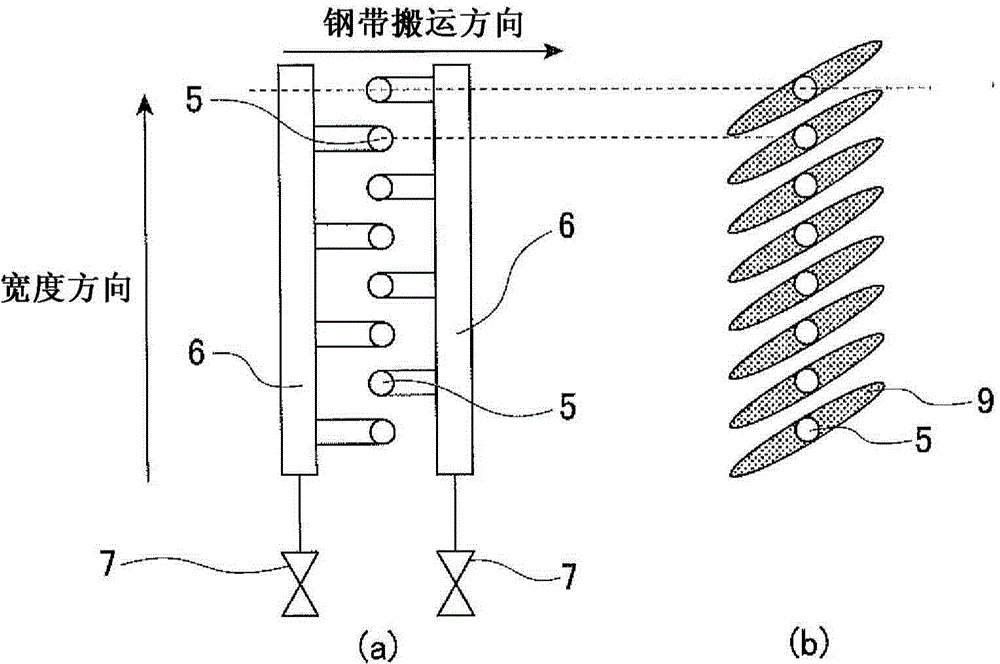

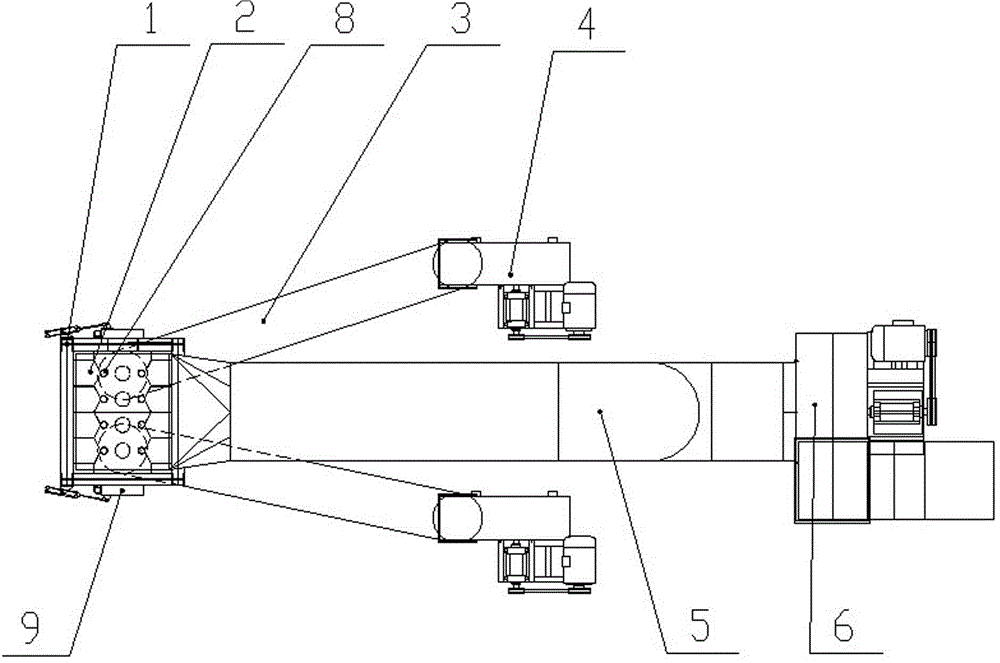

Cooling method and cooling device for hot-rolled steel strip

ActiveCN104884182AChange cooling rateAids in Manufacturing ClassificationWork cooling devicesMetal rolling arrangementsSurface coolingSpray nozzle

Provided are a cooling method and a cooling device for adjusting the volume of cooling water in two levels for each set of width direction headers when cooling a hot-rolled steel strip and for changing the steel strip cooling velocity in multiple levels using a simple method, the method and device being particularly effective for cooling the lower surface of a steel strip in a narrow space. Spray nozzles (5) are disposed in a row at a specified pitch in the width direction of the steel strip. In order that cooling water can be supplied from different piping systems for spray nozzles (5) that are adjacent in the width direction, the cooling headers (6) are configured so that: two systems are disposed per one set; a jetting valve (7) is installed on each; and individual cooling water jetting / stopping is possible.

Owner:JFE STEEL CORP

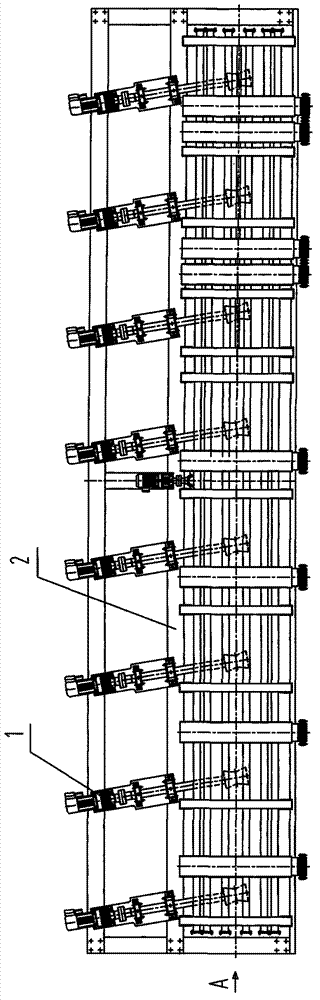

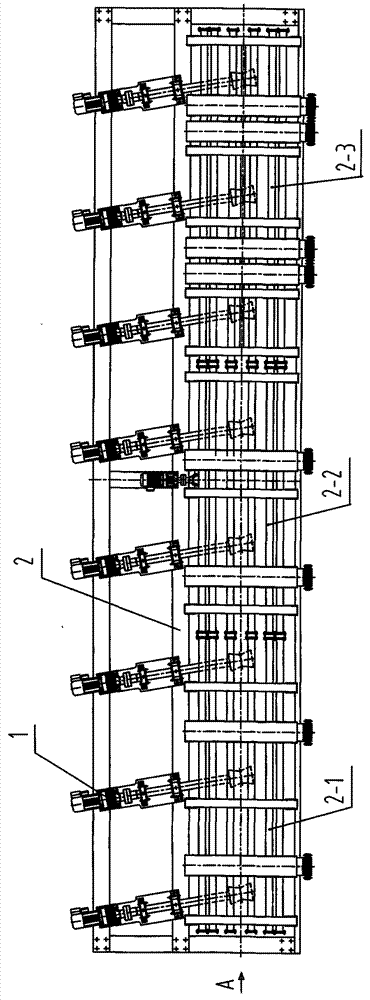

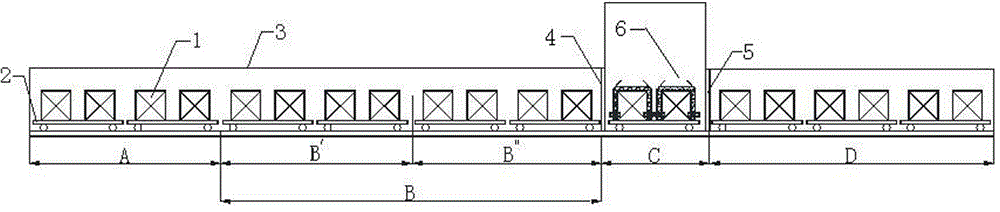

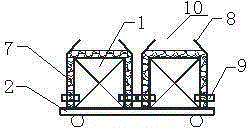

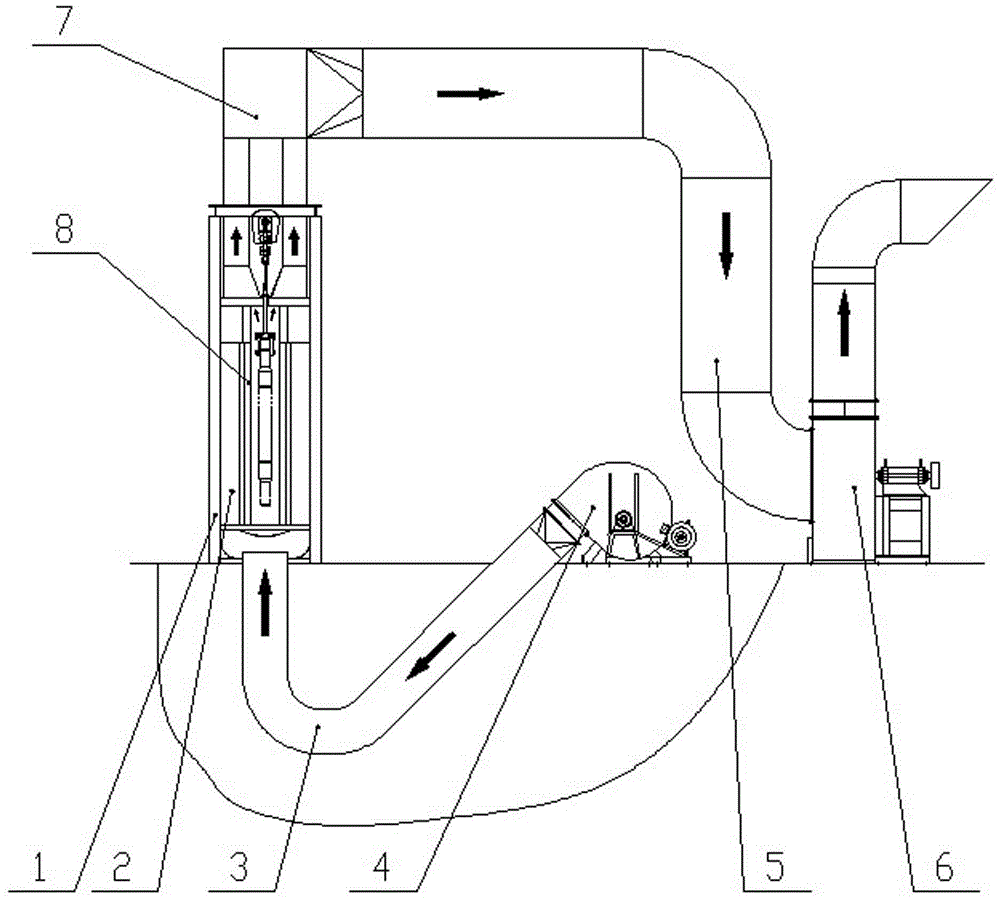

Tunnel steel pipe quenching device and quenching method thereof

InactiveCN102776343AAdjust cooling speedQuality improvementFurnace typesHeat treatment furnacesProduction linePhase change

The invention discloses a tunnel steel pipe quenching device and a tunnel steel pipe quenching method, relating to a seamless steel pipe production device and solving a problem that the current quenching device can not regulate the cooling speed of the steel pipe under different temperatures in the tunnel according to different cooling speeds needed for steel pipe material phase change. The quenching area of a quenching tunnel provided by the invention comprises units, which are independently controlled by a quenching area, a relative slow cooling area and a slow cooling unit respectively. The quenching method comprises the following steps: (1) after a roller drives the steel pipe to enter the quenching area, starting a water pump to carry out large-flow water injection cooling; (2) after the roller drives the steel pipe to enter the relative slow cooling area of the tunnel, starting the water pump to carry out small-flow water injection cooling; (3) after the roller drives the steel pipe to enter the slow cooling area of the tunnel, carrying out gas injection mixed cooling. The quenching device is used for a seamless steel pipe thermal treatment production line so as to precisely adjust the cooling speed at different temperatures of the steel pipe in a quenching process, thereby improving the quality of the steel pipe product.

Owner:TAIYUAN HEAVY IND

Preparing and painting methods of coating of metal mould casting and rising system

ActiveCN104057021AHigh viscosityEasy to sprayMoulding toolsFoundry mouldsSand blastingWorking temperature

The invention relates to preparing and painting methods of a coating of a metal mould casting and rising system. The preparing method comprises the following steps: mixing anhydrous zinc oxide, sodium silicate and anhydrous asbestos powder, after stirring to be uniform, pouring into deionized water with temperature of 65-75 DEG C, and stirring until being completely uniform while pouring. The painting method comprises the following steps: pouring a prepared coating; preheating a mould subjected to sand blasting; painting the mould casting and rising system by using the coating, with thickness of 0.3-0.5 mm; controlling the thickness of the coating of a riser to be 1-3 mm; preheating and fixing, charging the painted metal mould into an insulation furnace for being baked, preheating until the work temperature of the mould is 350-420 DEG C, and keeping for 1-2 hours. According to the coating prepared by adopting the preparing method and the painting method, the casting defects of insufficient casting, cold shut and the like in a production process of the metal mould can be effectively solved. The preparing method and the painting method play a role of well protecting the metal mould, and further ensure that the mould is stable in size and quality.

Owner:广东领创模架科技有限公司

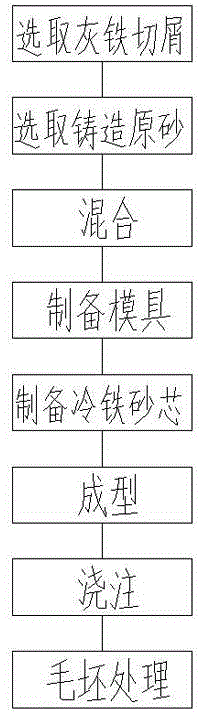

Automobile engine cylinder cover and manufacturing method thereof

ActiveCN103949578AAdjust cooling speedPrevent shrinkageFoundry mouldsMould handling/dressing devicesCrazingMetallurgy

The invention discloses an automobile engine cylinder cover and a manufacturing method thereof. The automobile engine cylinder cover is a product prepared by the following raw materials and the manufacturing method, and comprises the raw material composition by weight: 90% of gray iron cuttings, 10% of casting roughing sand, 5% of a furan resin, and 1.0% of a curing agent. The method has the beneficial effects of effectively preventing generation of defects of casting shrinkage cavities, shrinkage porosity, deformation and cracks.

Owner:FANCHANG COUNTY JINKE CASTING

Rapid exact stable reliable silicon iron sample digestion method

InactiveCN103743617AReduce preprocessing timeAvoid volatile lossChemical analysis using titrationPreparing sample for investigationPotassium nitratePotassium fluoride

The invention discloses a rapid exact stable reliable silicon iron sample digestion method, and belongs to the technical field of test analysis sample pretreatment. The method comprises the steps of firstly placing 0.0800-0.1200g of silicon iron sample into a plastic digestion bottle, successively adding 9-11ml of nitric acid and 4-6ml of hydrofluoric acid, and sealing the digestion bottle; placing the digestion bottle into a heater to heat for 4-6 min under the temperature of 55-65 DEG C after the sample is dissolved, and then cooling the sample to 20-25 DEG C; successively adding 4-6ml of urea solution, 9-11ml of potassium fluoride solution and 2-3g of potassium nitrate, sealing and shaking up, and cooling for 12-18min; filtering a sample solution in a sample bottle, washing the digestion bottle and sedimentation by using the 9-11ml of potassium fluoride solution; shifting the sedimentation and a filter material into a plastic sample bottle, and adding 12-18ml of potassium chloride-ethanol solution. The digestion method provided by the invention has the advantages that various losses in the sample treatment are effectively prevented, the stability, reproducibility and veracity of a testing result are improved, the dissolution is rapid, the sample manufacturing time is shortened, a sample solution is directly used for measuring silicon content, the method is simple and rapid, and the popularization and application value is good.

Owner:WUKUN STEEL

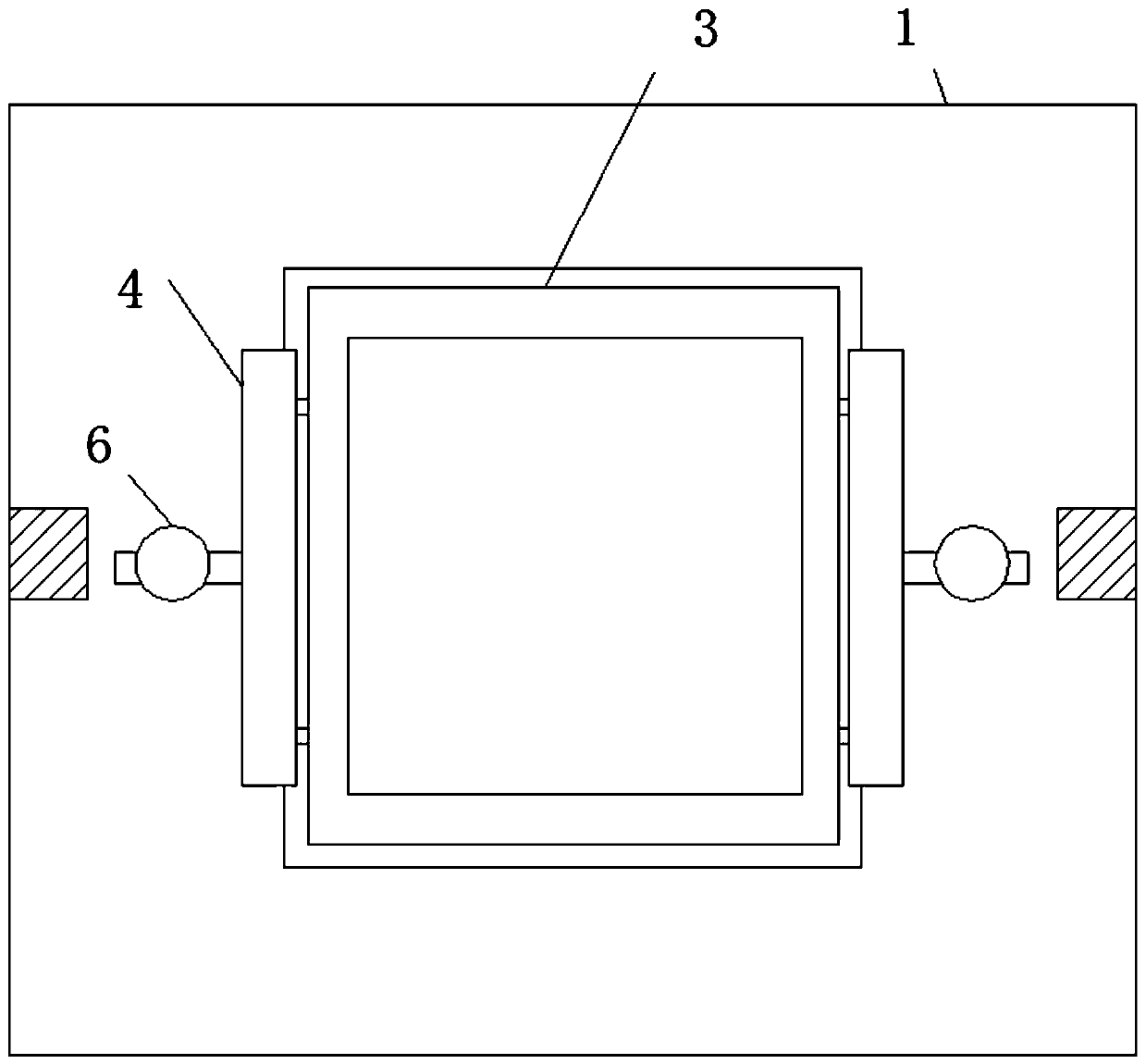

Efficient cooling device for injection mold

The invention relates to the technical field of injection molds, and discloses an efficient cooling device for an injection mold. The efficient cooling device for the injection mold comprises an installing plate, a fixed mold and a movable mold; the upper end of the installing plate is connected with the movable mold through a lifting device and provided with an installing groove matched with thefixed mold, and two adjusting mechanisms are symmetrically connected to the upper end of the installing plate and connected with the left side and the right side of the fixed mold correspondingly; a water outlet pipe is fixedly connected to the left side of the installing groove through a circular hole, and a connecting pipe is fixedly connected to the right side of the installing groove through an installing hole; and a water tank is fixedly connected to the left side of the installing plate, a water pump is fixedly connected to the interior of the water tank, a right-end pipe port of the connecting pipe penetrates through the side wall of the water tank and extends into the water tank, and the left side of the lower end of the water tank communicates with a water inlet pipe. According tothe efficient cooling device for the injection mold, contact cooling can be directly conducted on cooling oil and the mold, cooling is quick and uniform, and the mold cooling speed can be adjusted according to the environment temperature.

Owner:ANHUI ANLAN MOLD

Method for manufacturing blue brick tiles

ActiveCN104098322AAvoid damageReduce production energy consumptionClaywaresTunnel kilnCooking & baking

The invention belongs to the field of building materials, in particular to a method for manufacturing blue brick tiles. According to the invention, dried brick tiles are loaded onto a kiln car and transported into a tunnel kiln for preheating and baking; the kiln car is pulled out and transported to a scattered material placing zone; a kiln car shield is placed onto the kiln car; a scattered material placing opening is formed in the upper part of the kiln car shield; the scattered material is placed inside the kiln car shield through the scattered material placing opening, and covers the periphery of the brick tile blanks; a gas pressurizing nozzle is arranged below the kiln car shield and is used for ejecting non oxidizing gas into the kiln car shield so that the gaps among the brick tile blanks are filled with scattered materials; when coverage using the scattered materials is complete, the kiln car is pulled to a cooling zone, the scattered materials are separated from the brick tile blanks, and the blue brick tile products in caesious appearances are obtained. The scattered materials adopted by the invention is used as a cooling medium, water spraying into the kiln chamber for cooling is not required, the cooling rate and cooling uniformity can be controlled, damage caused by water to the brick tile blanks and the kiln is prevented, and the quality of the blue brick products is improved.

Owner:LIAONING TECHNICAL UNIVERSITY

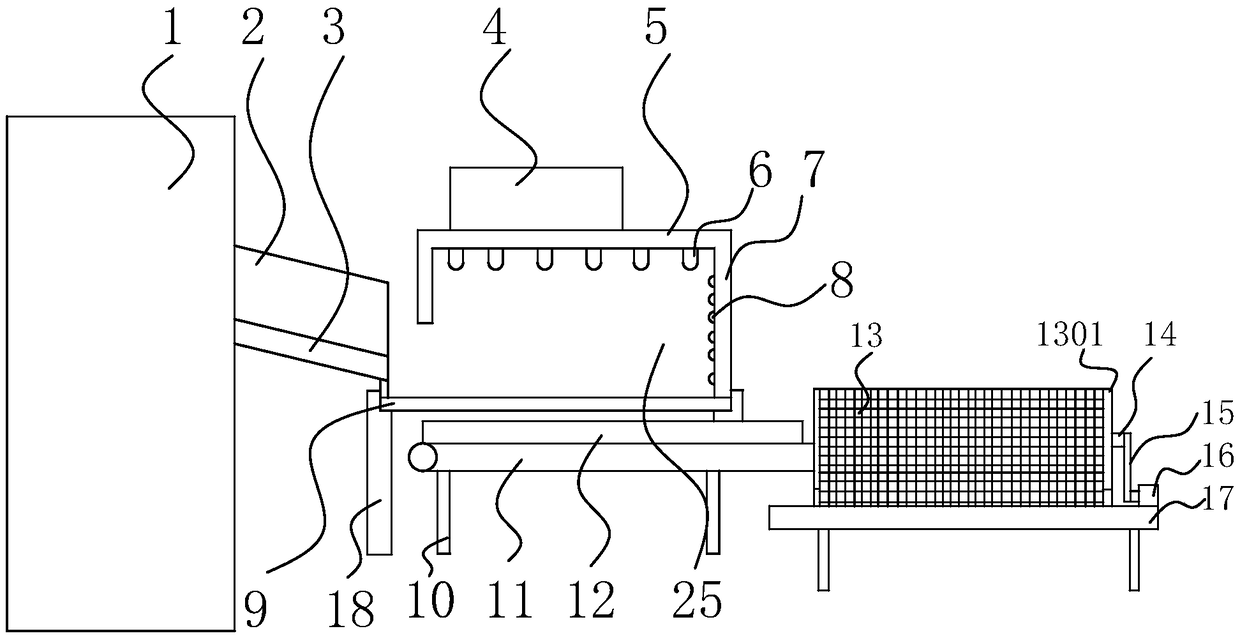

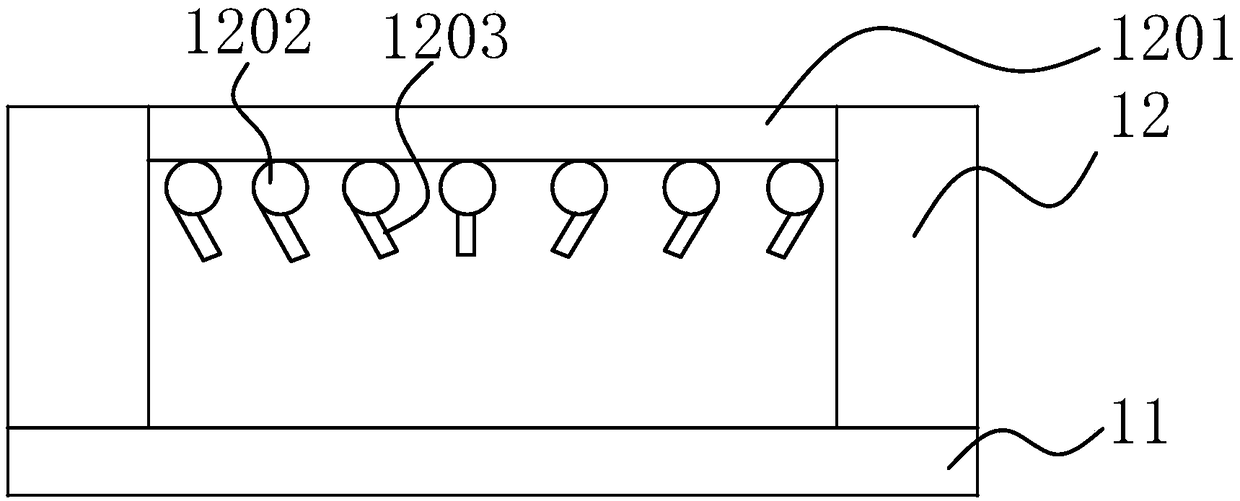

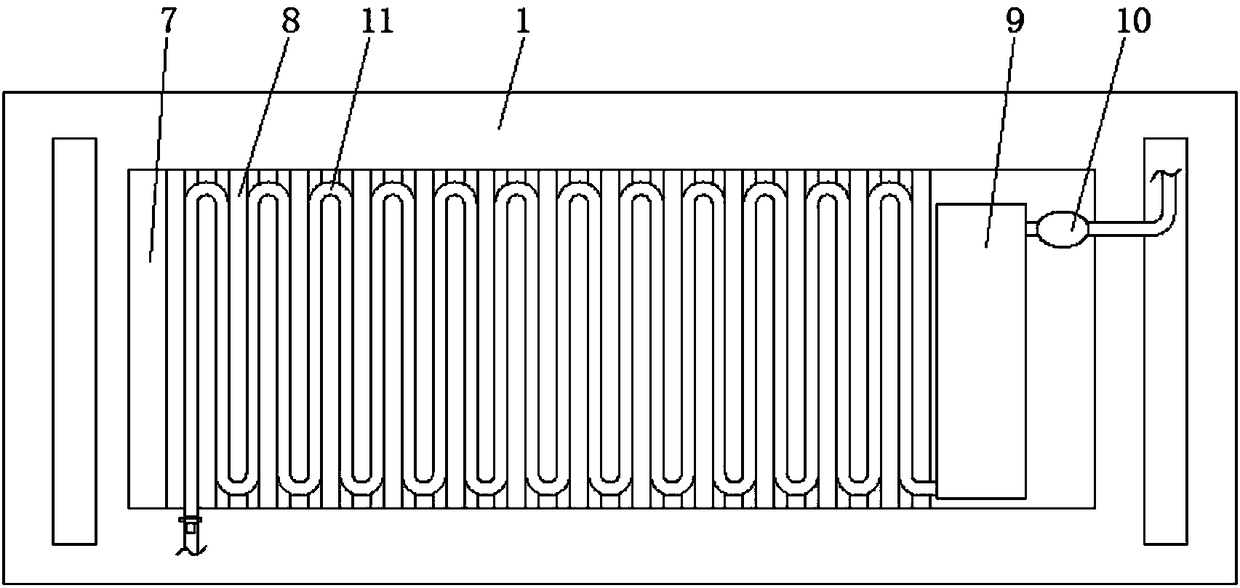

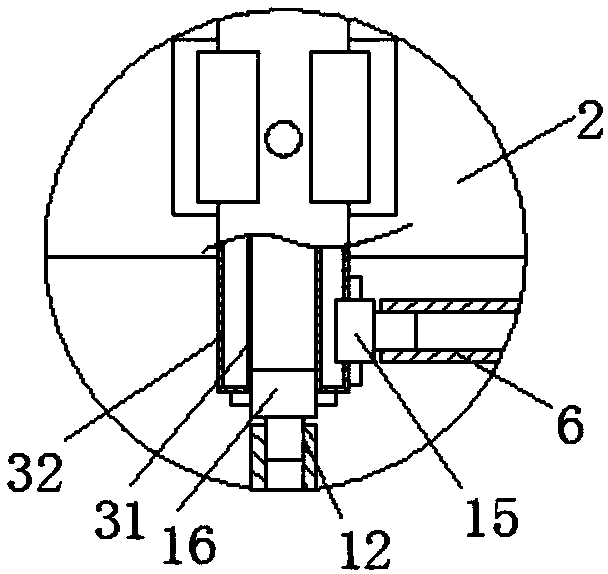

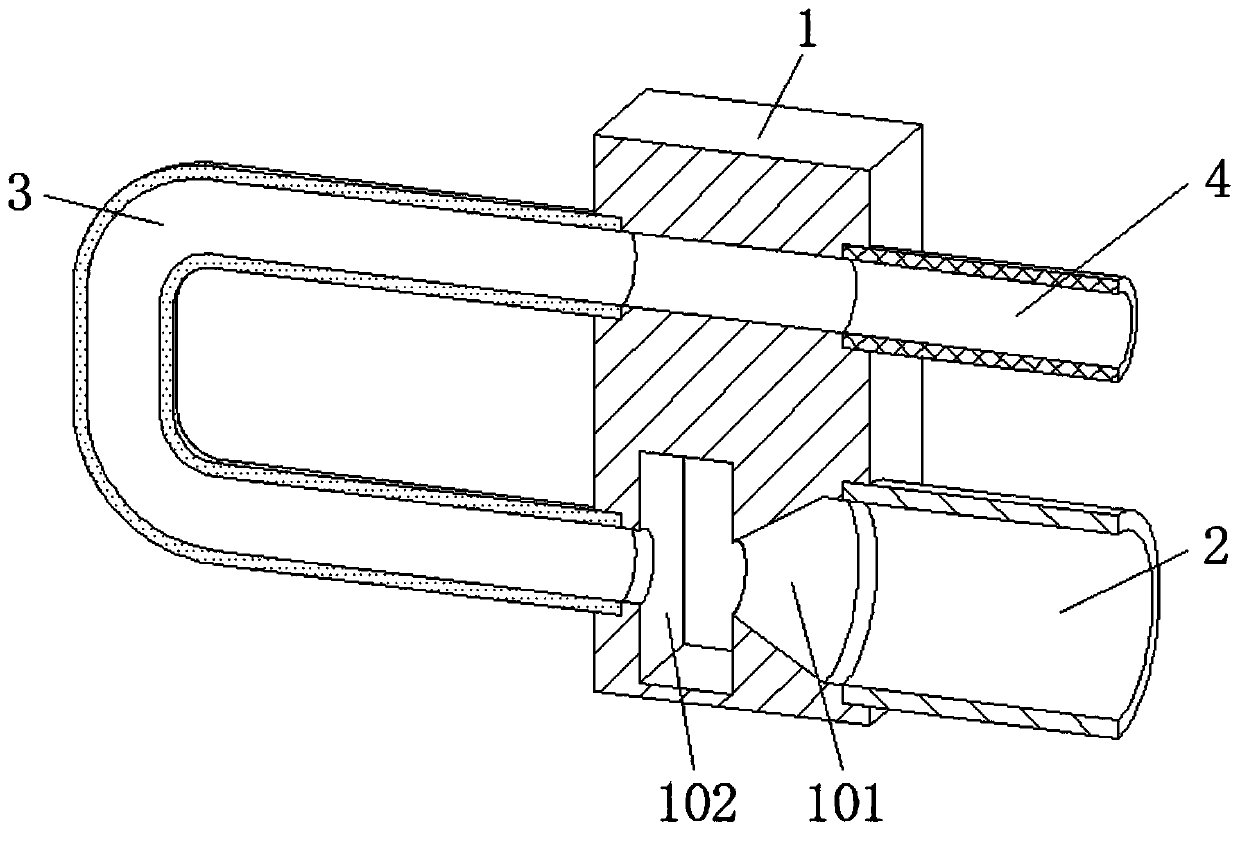

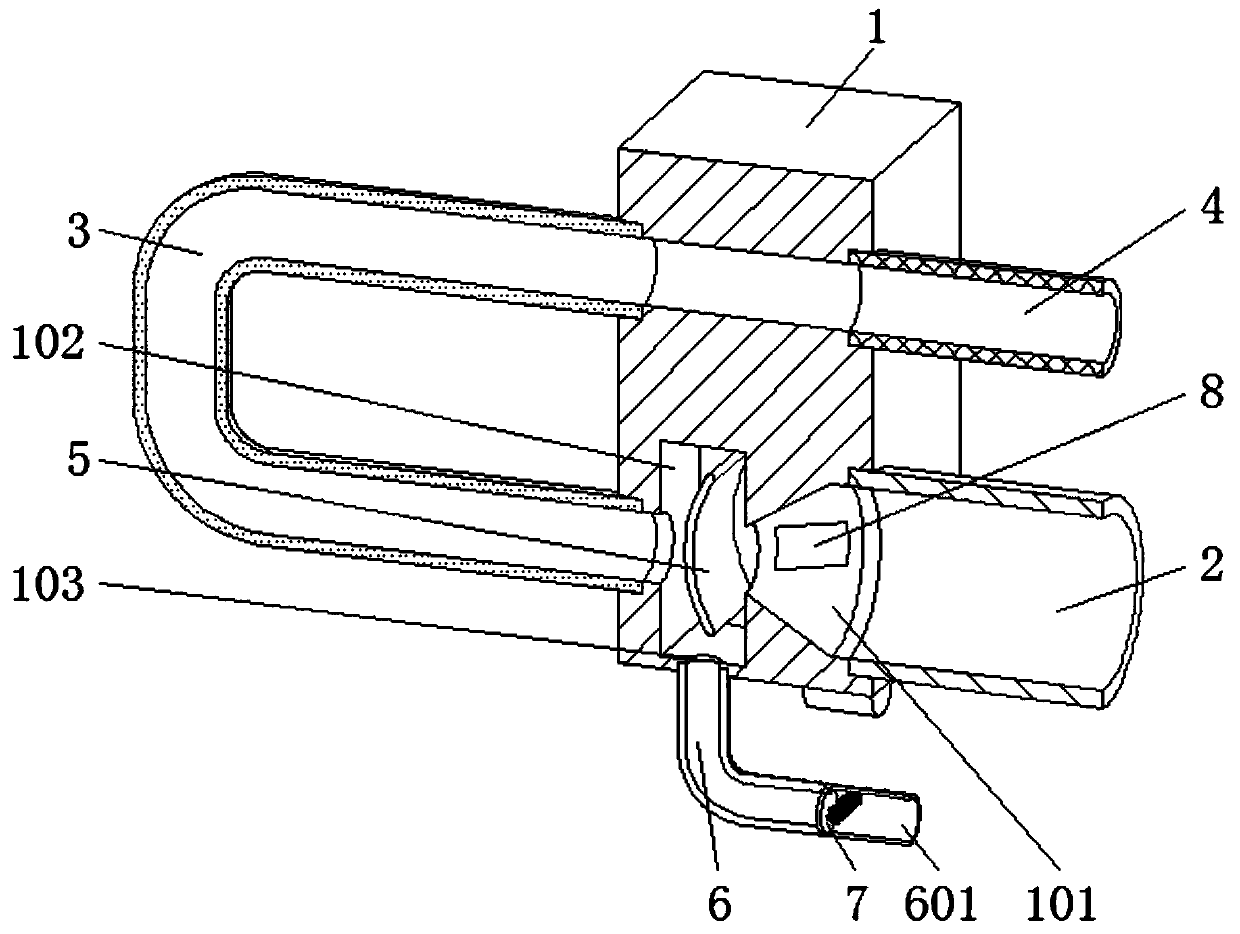

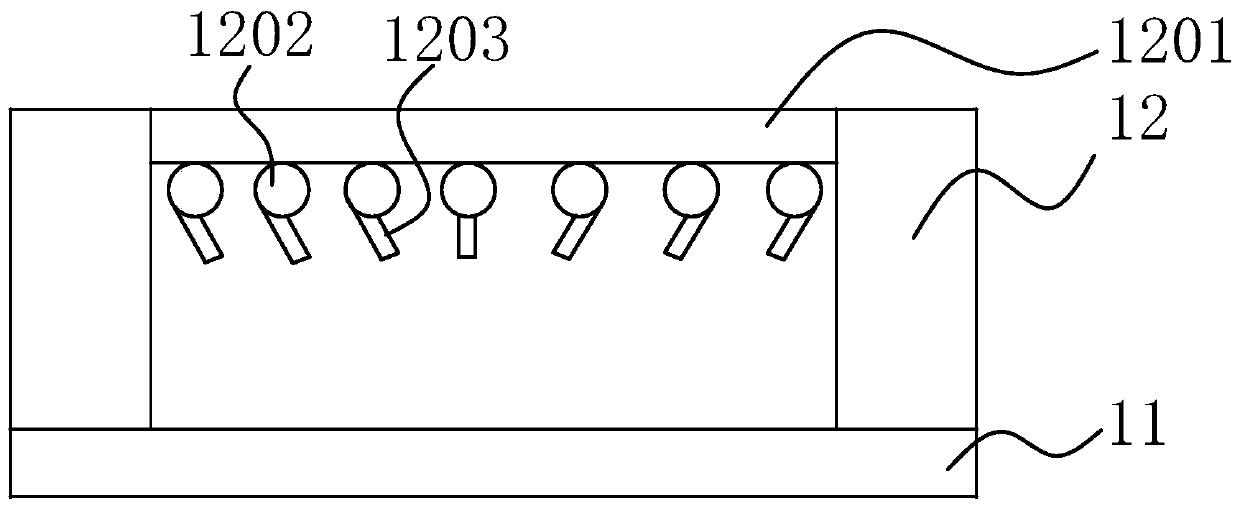

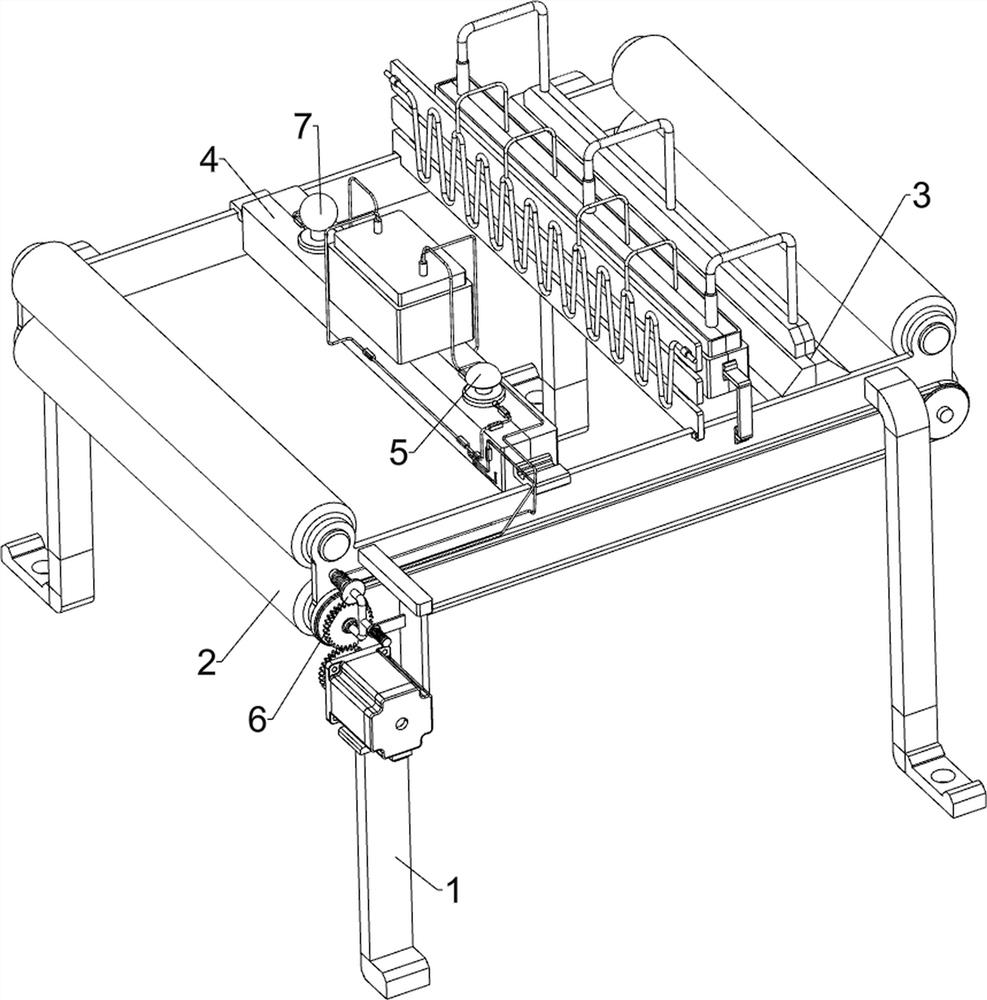

Adjustable type reflow soldering machine

ActiveCN106112169AGood cooling effectEasy to usePrinted circuitsMetal working apparatusHeat sinkReflow soldering

The invention discloses an adjustable type reflow soldering machine, and belongs to the technical field of reflow soldering machines. The adjustable type reflow soldering machine comprises a conveying rail, an air cooling device arranged below the conveying rail and a water cooling mechanism connected with the air cooling device, wherein the air cooling device comprises a wind box, a plurality of fans, an air inlet and an air outlet; the multiple fans are arranged at the air outlet; a flow adjustment device is arranged at the air inlet; the water cooling mechanism comprises a water storage tank, a plurality of cooling pipes, a backflow pipe and a backflow pump; the water storage tank is arranged at one side of the reflow soldering machine, and is provided with a water inlet and a water outlet; a heat dissipation device is arranged at the water inlet; the multiple cooling pipes are arranged in the wind box; one end of each cooling pipe is connected with the water outlet, and the other end of each cooling pipe is connected with the backflow pipe; the backflow pipe is connected with the cooling pipes and the water inlet; the heat dissipation device comprises a heat dissipation groove, a rotating shaft arranged at a notch of the heat dissipation groove and a plurality of heat dissipation fins arranged on the rotating shaft; and heat dissipation strips are arranged at two side surfaces of each heat dissipation sheet. The adjustable type reflow soldering machine can adapt to the environment temperature and guarantee a proper cooling speed after a PCB is soldered so as to guarantee the soldering quality.

Owner:安徽广晟德自动化设备有限公司

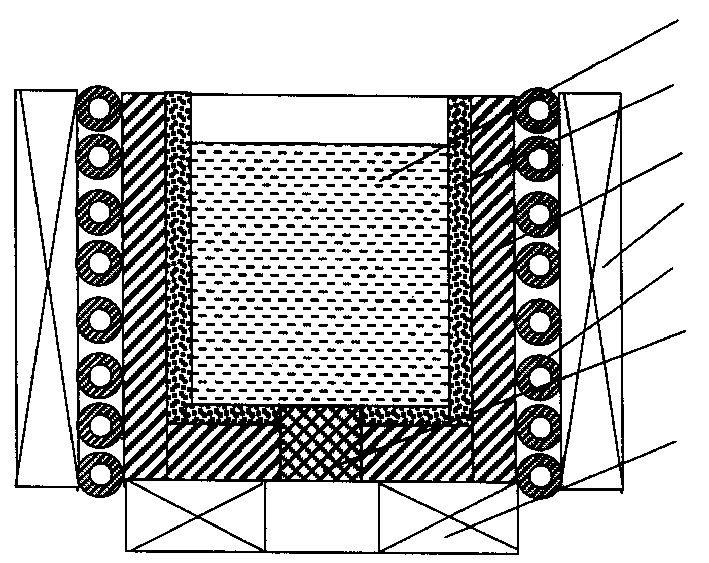

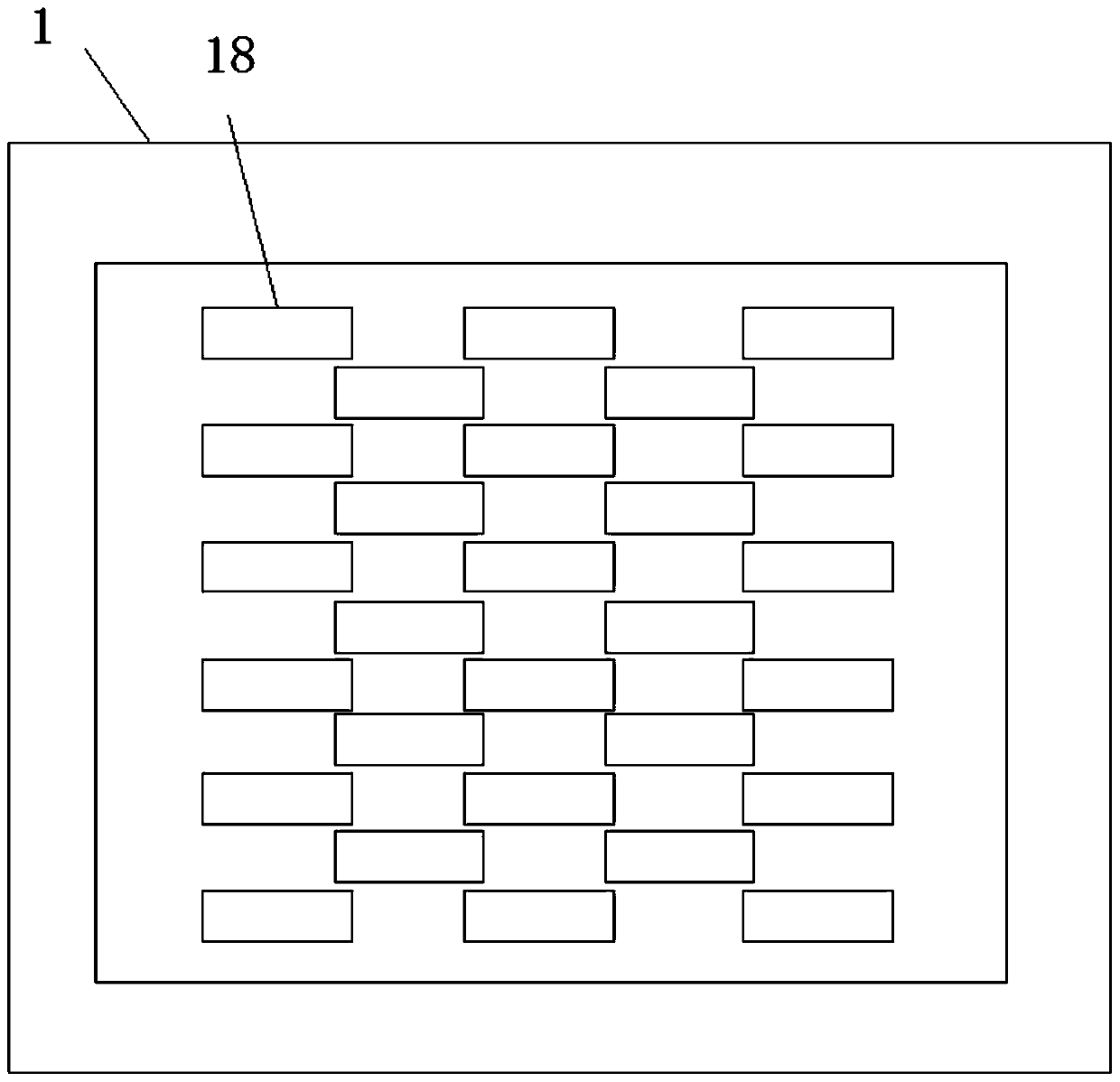

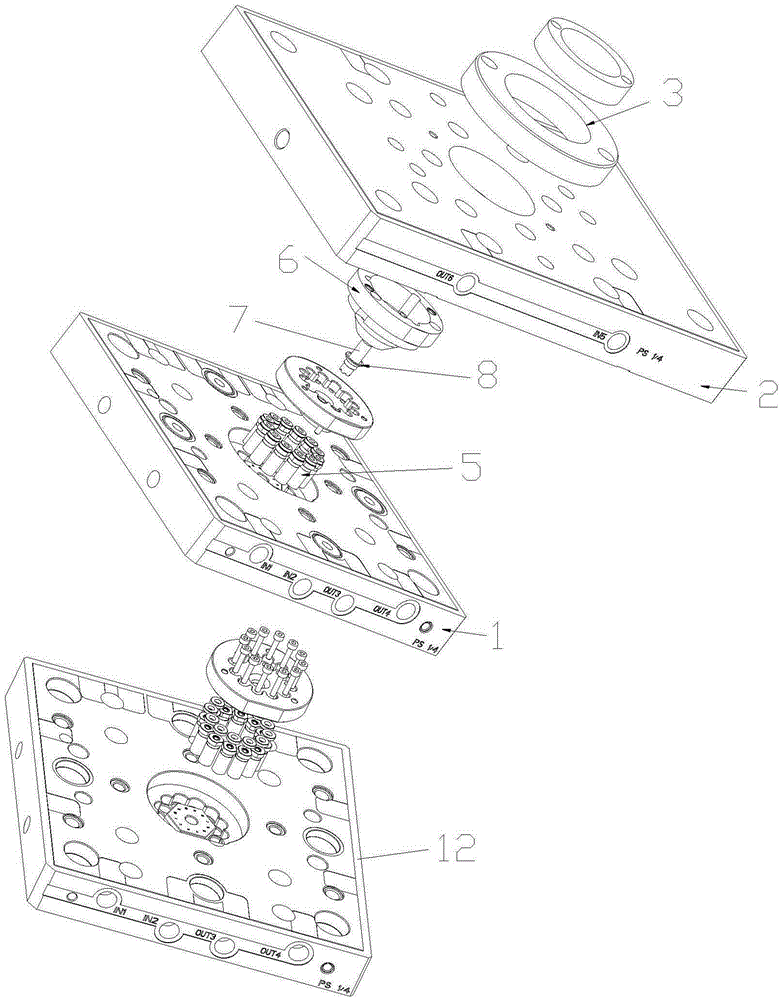

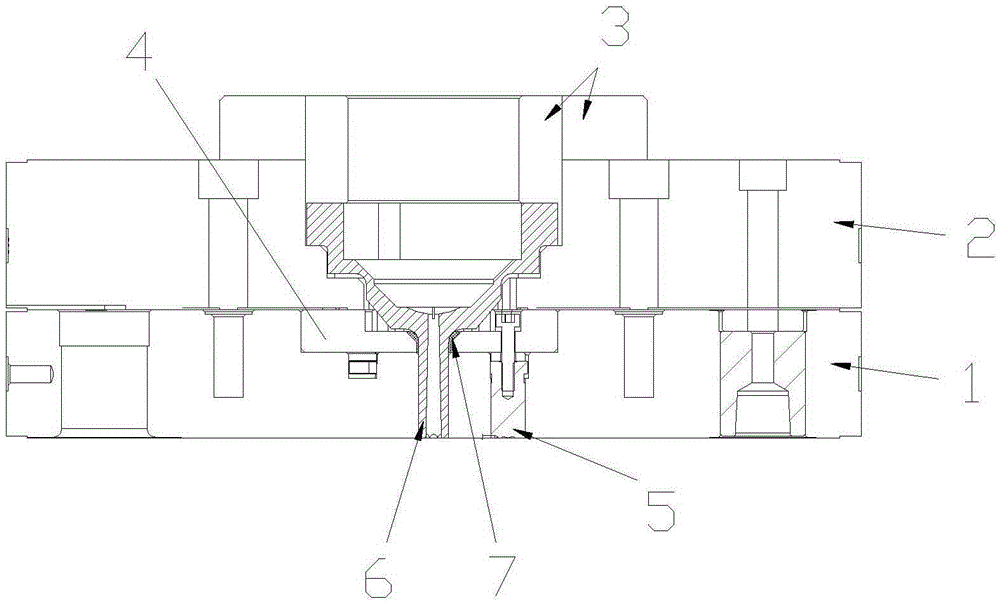

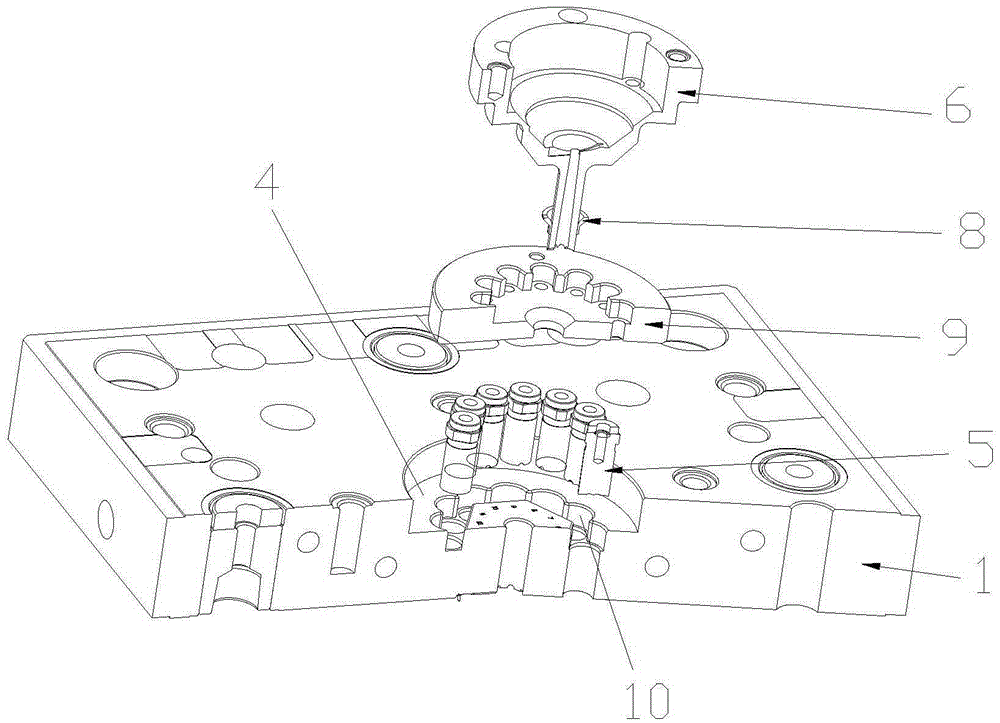

Expandable polystyrene secondary foaming molding die for LED lampshade

The invention discloses an expandable polystyrene secondary foaming molding die for an LED lampshade. An upper die frame (1) is provided with a feeding pipe (3), and the feeding pipe (3) penetrates the upper die frame (1) and an upper die plate (6) to be communicated with a cavity (7). A discharging opening in the bottom end of the feeding pipe (3) is located in the top face of the cavity (7). A first cooling system is further arranged on the upper die frame (1). A second cooling system is arranged on a lower die frame (15). A first steam heating system is arranged in the upper die frame (1). A second steam heating system is arranged in the lower die frame (15). The lower die frame (15) and a lower die plate (8) are further provided with an ejection mechanism which is driven by an air cylinder and used for ejecting the molded LED lampshade. Due to the fact that the cooling systems and the heating systems are arranged on the molding die, the upper die frame and the lower die frame can be cooled and heated rapidly; and furthermore, the die structure is simple through the air pressure ejection mechanism.

Owner:俞雄飞

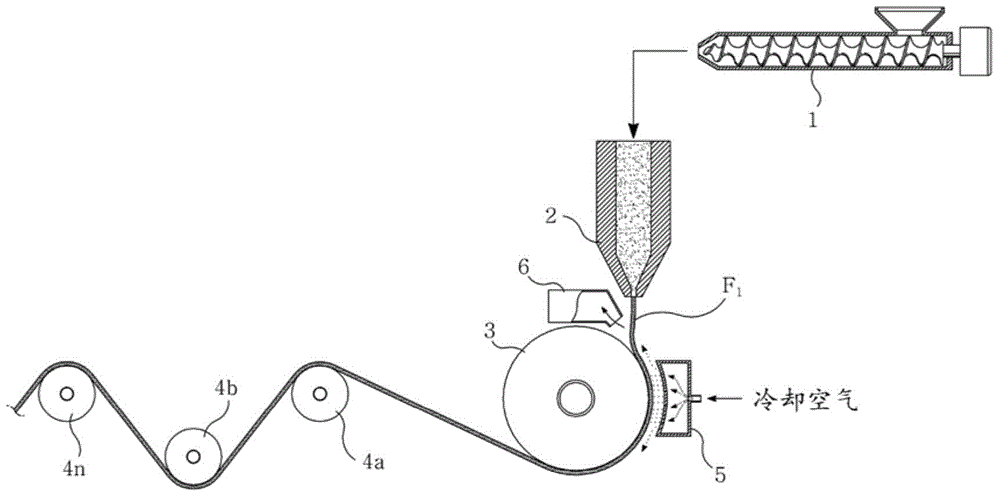

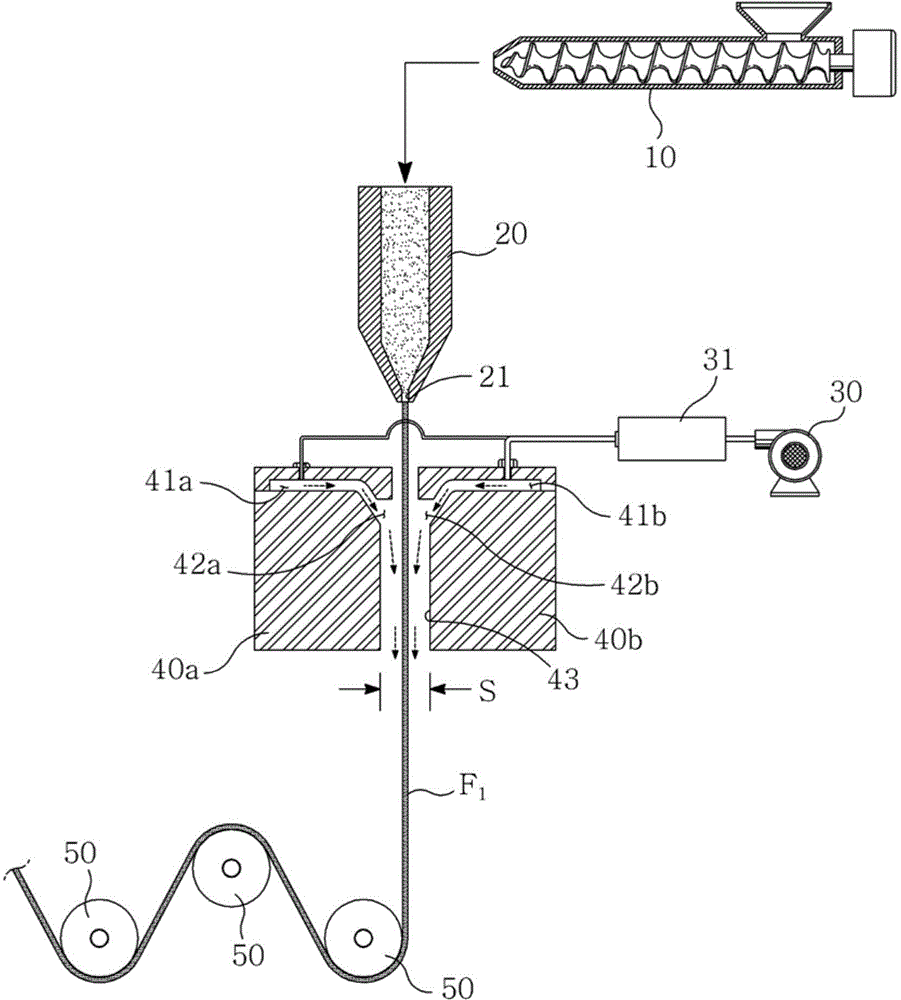

Apparatus for manufacturing a fine porous film for a separation film of a battery and method for manufacturing a film using same

InactiveCN103563127ASimple structureLow costCell seperators/membranes/diaphragms/spacersFinal product manufactureEngineeringDual axis

Owner:伊赛尔科技有限公司

Lipstick tube extrusion cooling device

The invention discloses a lipstick tube extrusion cooling device, which comprises an atomization device, an air drying device and a discharging device, wherein the atomization device is arranged on the outlet end of an extruder; the air drying device and the discharging device are arranged on the lower end of the atomization device; the outlet end of the extruder is aslant provided with a discharging plate; the atomization device comprises a longitudinal conveying belt, a supporting seat and a top plate, wherein the longitudinal conveying belt is arranged on the bottom of the discharging plate; the supporting seat supports the longitudinal conveying belt; the top plate is arranged on the upper end of the longitudinal conveying belt; the top plate and a supporting plate are enclosed to forman atomization chamber; the outer side of the top of the top plate is provided with a water tank; the inner side of the top of the top plate is provided with atomization shower nozzles communicated with the water tank; the air drying device comprises a lateral conveying belt arranged on the lower part of the discharging end of the longitudinal conveying belt, and supporting legs used for supporting the lateral conveying belt; the outlet end of the lateral conveying belt is provided with the discharging device. The lipstick tube extrusion cooling device has the advantage of simple structure, an instantaneous cooling effect is realized, and the problem of low cooling efficient of a traditional cooling device is solved.

Owner:安徽裕佳铝塑科技有限公司

Novel optical mold

The invention discloses a novel optical mold. The novel optical mold comprises a female mold plate and a male mold plate. Holes are formed in the bottoms of the centers of the female mold plate and the male mold plate. Cushion blocks are arranged inside the holes, mold cavities are formed in the parts, below the holes, of the female mold plate and the male mold plate respectively, mold cores are arranged inside the female mold plate and the male mold plate, and a pouring nozzle is arranged inside the female mold plate. The optical mold can keep machining precision of the mold cavities high, the pouring nozzle can effectively lower material consumption, and cooling speed is kept high and balanced.

Owner:DONGGUAN HARMONY COOPERATION PLASTIC & HARDWARE TECH CO LTD

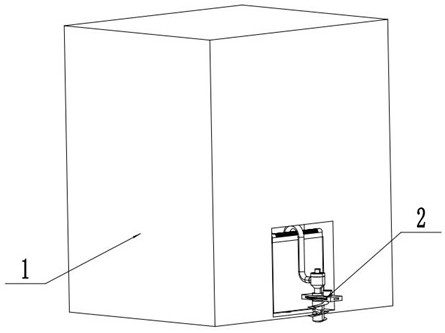

Computer for information system integration convenient for heat dissipation

InactiveCN108415526AAvoid cooling dead zoneImprove cooling effectDigital processing power distributionSoftware engineeringLiquid tank

The invention discloses a computer for information system integration convenient for heat dissipation. The computer comprises a shell body, wherein the inner wall of the shell body is rotationally connected with an oscillating deck, one end of the oscillating deck is movably connected with an eccentric wheel connecting rod mechanism fixed on the inner wall of the shell body, the side face of the oscillating deck is provided with a sleeve, one side wall of the shell body is provided with an air inlet, the outer side of the air inlet is provided with a negative pressure blower connected to the outer wall of the shell body, the air inlet is internally provided with a wind collection plate, the side face, located in the shell body, of the wind collection plate is connected with a first flexible pipe, the top face of the shell body is provided with a mounting plate, the top face of the mounting plate is connected with a heat dissipation plate, a cooling liquid tank, a water pump and a controller, and a cooling pipeline is embedded in the top face of the heat dissipation plate. The computer for the information system integration convenient for heat dissipation has the advantages that thestructure is reasonable, the installation is convenient, a cooling mode can be automatically switched, the cooling speed can be automatically adjusted, dead angles of the heat dissipation are avoided, and the heat dissipation efficiency is high.

Owner:广州骏驿信息科技有限公司

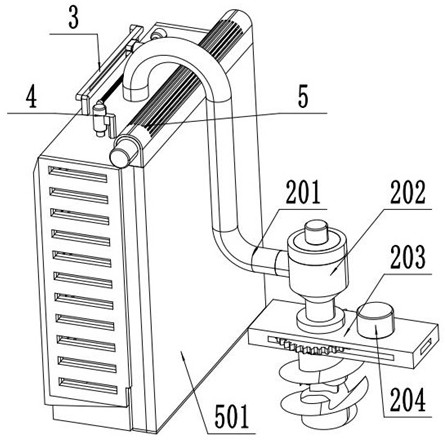

New energy automobile battery cooler

InactiveCN110224200AFully atomizedExtend the atomization timeElectric propulsion mountingSecondary cellsElectrical batteryNew energy

The invention relates to the technical field of battery coolers, and discloses a new energy automobile battery cooler. The new energy automobile battery cooler comprises a base, a conical hole, a cavity, a liquid inlet pipe, a heat exchange pipe and a liquid outlet pipe; a flow baffle is fixedly mounted between the front side surface and the rear side surface of the interior of the cavity; a liquid discharge hole is formed in the bottom surface of the cavity; and a backflow pipe I is fixedly connected to the interior of the liquid discharge hole in a sleeving mode. According to the new energyautomobile battery cooler, cooling liquid enters the cavity after being atomized through the conical hole; on one hand, the fog-state cooling liquid impacts the flow baffle inside the cavity, liquid droplets of the cooling liquid which is not completely atomized are attached to the concave surface of the flow baffle and are accumulated inside the backflow pipe I, and when a certain amount of the liquid droplets is accumulated, the baffle is pressed to be opened, so that the cooling liquid flows back to a cooling liquid tank; and on the other hand, the fog-state cooling liquid is blocked by theflow baffle, so that a path of reaching the heat exchange pipe by the fog-state cooling liquid is prolonged, the atomizing time of the fog-state cooling liquid is further prolonged, the atomization of the cooling liquid is more sufficient, and the cooling efficiency is improved.

Owner:钟家明

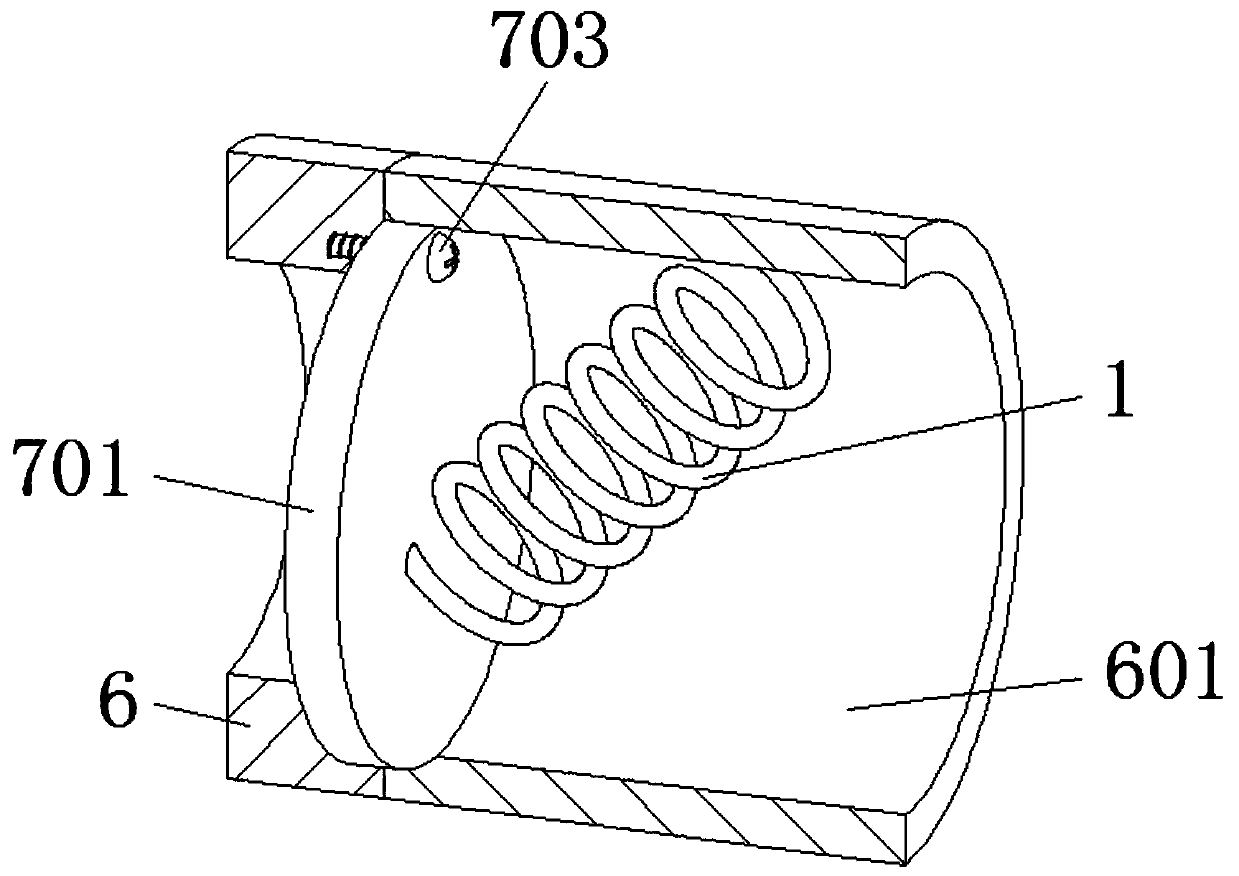

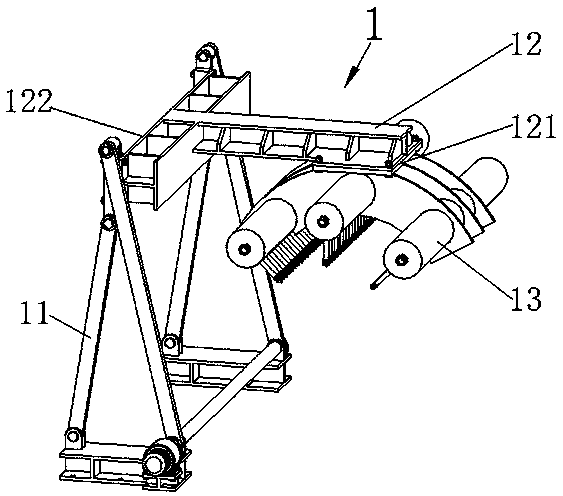

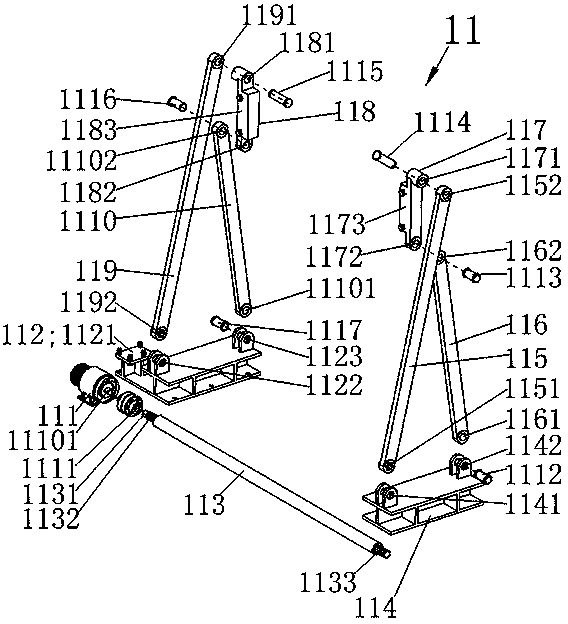

Suspension type workpiece air cooling device

A suspension type workpiece air cooling device comprises blowing fans and a cooling chamber. Workpiece entrances and exits are arranged on the front face and the back face of the cooling chamber respectively. Blowing boxes are arranged in the cooling chamber left and the right in pairs. The inner side of each blowing box is connected with an air collection pipe with spray holes. The blowing fans are provided with blowing pipelines. Air outlets of the blowing pipelines are connected with the lower ends of the blowing boxes. An air-induced box is arranged on the upper portion of the cooling chamber. An air outlet of the air-induced box is connected with an air-induced pipeline. An air outlet of the air-induced pipeline is provided with an air-induced fan. The suspension type workpiece air cooling device is especially suitable for continuous and fast air cooling processes of large suspension type workpieces, especially shaft rod workpieces and workpieces treated through normalizing and tempering heating, all points, in the axial direction, of the workpieces are cooled evenly, and guarantees are provided for improving the structure property of the workpieces, especially hardness evenness, after heat treatment is finished.

Owner:QINHUANGDAO DEV ZONE CHUNGUANG CASTING MACHINERY

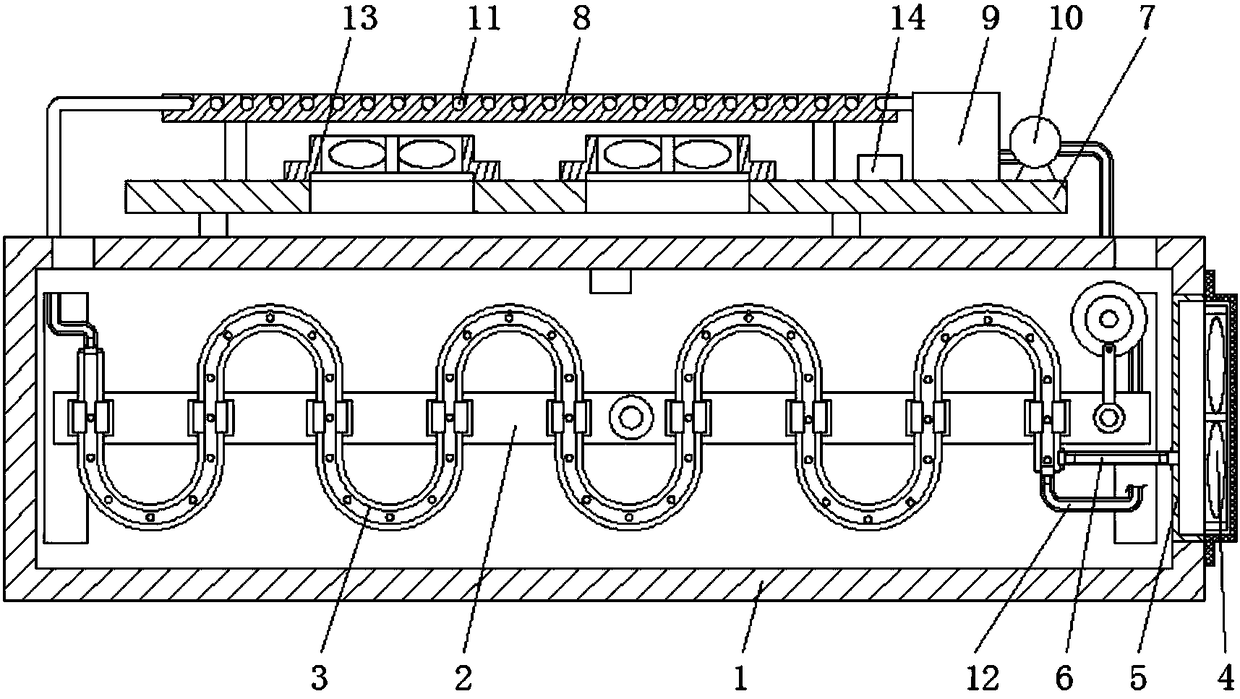

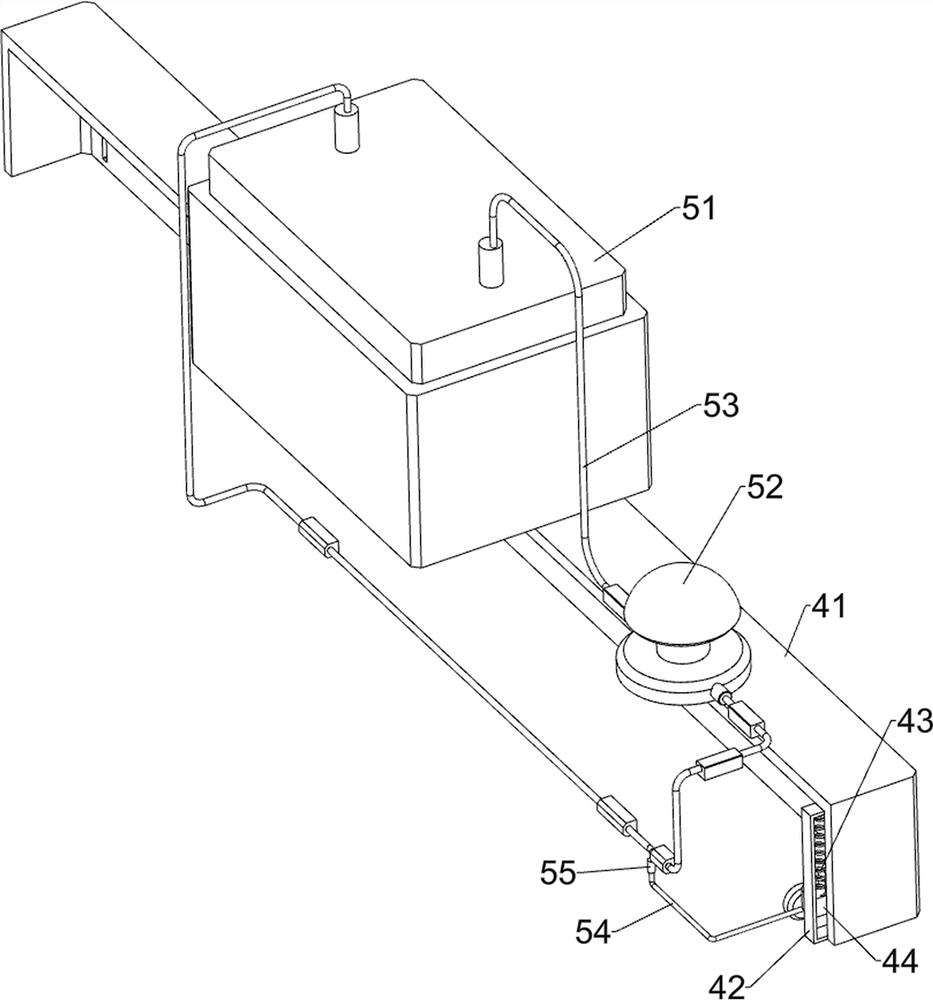

Reflow soldering machine

InactiveCN106001841AImprove cooling effectSimple structurePrinted circuit assemblingMetal working apparatusWater storage tankEngineering

A reflow soldering machine belongs to the technical field of the reflow soldering machine. The reflow soldering machine comprises a conveying rail, an air-cooling device which is arranged below the conveying rail and a water-cooling mechanism which is connected with the air-cooling device. The air-cooling device comprises an air bellow, a plurality of fans, an air inlet port and air outlet ports. The plurality of fans are arranged at the air outlet ports and a flow adjusting device is arranged at the air inlet port. The water-cooling mechanism comprises a water storage tank, a plurality of cooling pipes, a return pipe and a return pump. The water storage tank is arranged on one side of the reflow soldering machine and provided with a water inlet port and a water outlet port. A heat dissipating device is arranged at the water inlet port. The plurality of cooling pipes are arranged in the air bellow. One end of each cooling pipe is connected with the water outlet port and the other end of each cooling pipe is connected with the return pipe. The return pipe is connected with the cooling pipes and the water inlet port. The heat dissipating device comprises a heat dissipating groove, a rotary shaft which is arranged at the groove opening of the heat dissipating groove and a plurality of heat dissipating sheets which are arranged at the rotary shaft. Heat dissipating strips are arranged on both two side surfaces of each heat dissipating sheet. The water storage tank is further provided with an ice-cooling device. The machine is capable of adapting to the environment temperature and ensuring a suitable cooling speed after PCB welding, so that the welding quality can be guaranteed.

Owner:安徽广晟德自动化设备有限公司

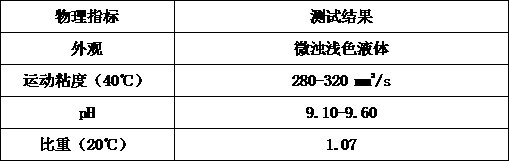

Environment-friendly water-soluble quenching liquid and preparation method thereof

InactiveCN111074046AAvoid water quenching cracking and quenching soft spotsSolve the problem of oil quenchingQuenching agentsAntifoam agentAqueous solubility

The invention discloses an environment-friendly water-soluble quenching liquid, which comprises the following components in percentage by mass: 25-45% of polyalkylene glycol, 5-10% of compound amine,1-3% of polybasic carboxylic acid, 0-1% of defoaming agent, 0-2% of antioxidant, 0-1% of corrosion inhibitor and the balance of deionized water; dissolving the composite amine, adding carboxylic acid,stirring for reaction, then sequentially adding antioxidant and corrosion inhibitor, stirring uniformly, then adding polyalkylene glycol polymer for reaction, finally adding the defoaming agent, andstirring uniformly. The cooling performance of the environment-friendly water-soluble quenching liquid provided by the invention is between water and oil, so the quenching liquid can not only avoid water quenching cracking and quenching soft spots, but also solve the defects that oil cannot be hardened and quenched thoroughly, the cooling speed can be adjusted by changing the concentration so as to be suitable for workpieces with different hardenability materials and different sizes, and the quenching liquid is a non-nitrite system, so the quenching liquid is safe and environment-friendly.

Owner:沙索(广州)工业介质科技有限公司

A lipstick tube extrusion cooling device

The invention discloses a lipstick tube extrusion cooling device, which comprises an atomization device, an air drying device and a discharging device, wherein the atomization device is arranged on the outlet end of an extruder; the air drying device and the discharging device are arranged on the lower end of the atomization device; the outlet end of the extruder is aslant provided with a discharging plate; the atomization device comprises a longitudinal conveying belt, a supporting seat and a top plate, wherein the longitudinal conveying belt is arranged on the bottom of the discharging plate; the supporting seat supports the longitudinal conveying belt; the top plate is arranged on the upper end of the longitudinal conveying belt; the top plate and a supporting plate are enclosed to forman atomization chamber; the outer side of the top of the top plate is provided with a water tank; the inner side of the top of the top plate is provided with atomization shower nozzles communicated with the water tank; the air drying device comprises a lateral conveying belt arranged on the lower part of the discharging end of the longitudinal conveying belt, and supporting legs used for supporting the lateral conveying belt; the outlet end of the lateral conveying belt is provided with the discharging device. The lipstick tube extrusion cooling device has the advantage of simple structure, an instantaneous cooling effect is realized, and the problem of low cooling efficient of a traditional cooling device is solved.

Owner:安徽裕佳铝塑科技有限公司

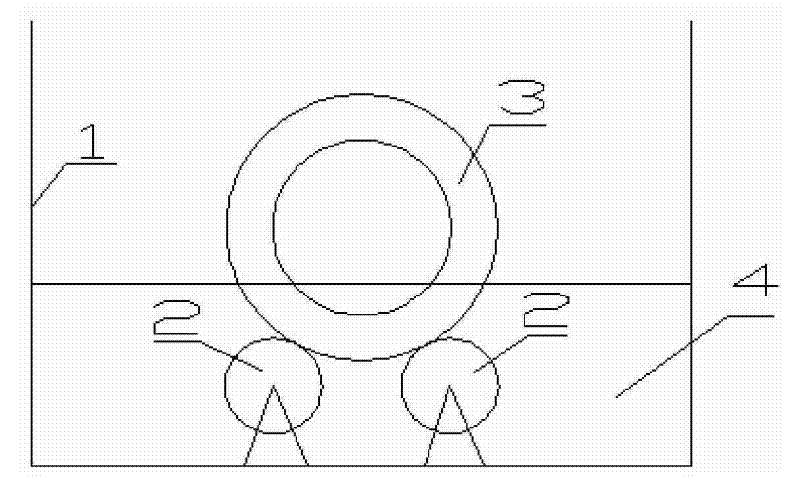

Method for cooling steel pipe

InactiveCN101423887BAdjust cooling speedCool evenlyFurnace typesHeat treatment furnacesThick wallProblem solve

The invention relates to a steel pipe cooling method, which belongs to the field of steel pipe heat treatment. The technical problem solved by the invention is to provide the steel pipe cooling method which can satisfy the demand for cooling medium and thick-wall steel pipes. The steel pipe cooling method comprises the following steps of placing a steel pipe to be parallel to the liquid level of a liquid cooling medium, dipping part of the steel pipe in the liquid cooling medium, rotating the steel pipe and cooling the steel pipe. The method has the advantages of simple process, simple equipment, low cost and broad application prospects.

Owner:攀钢集团成都钢铁有限责任公司

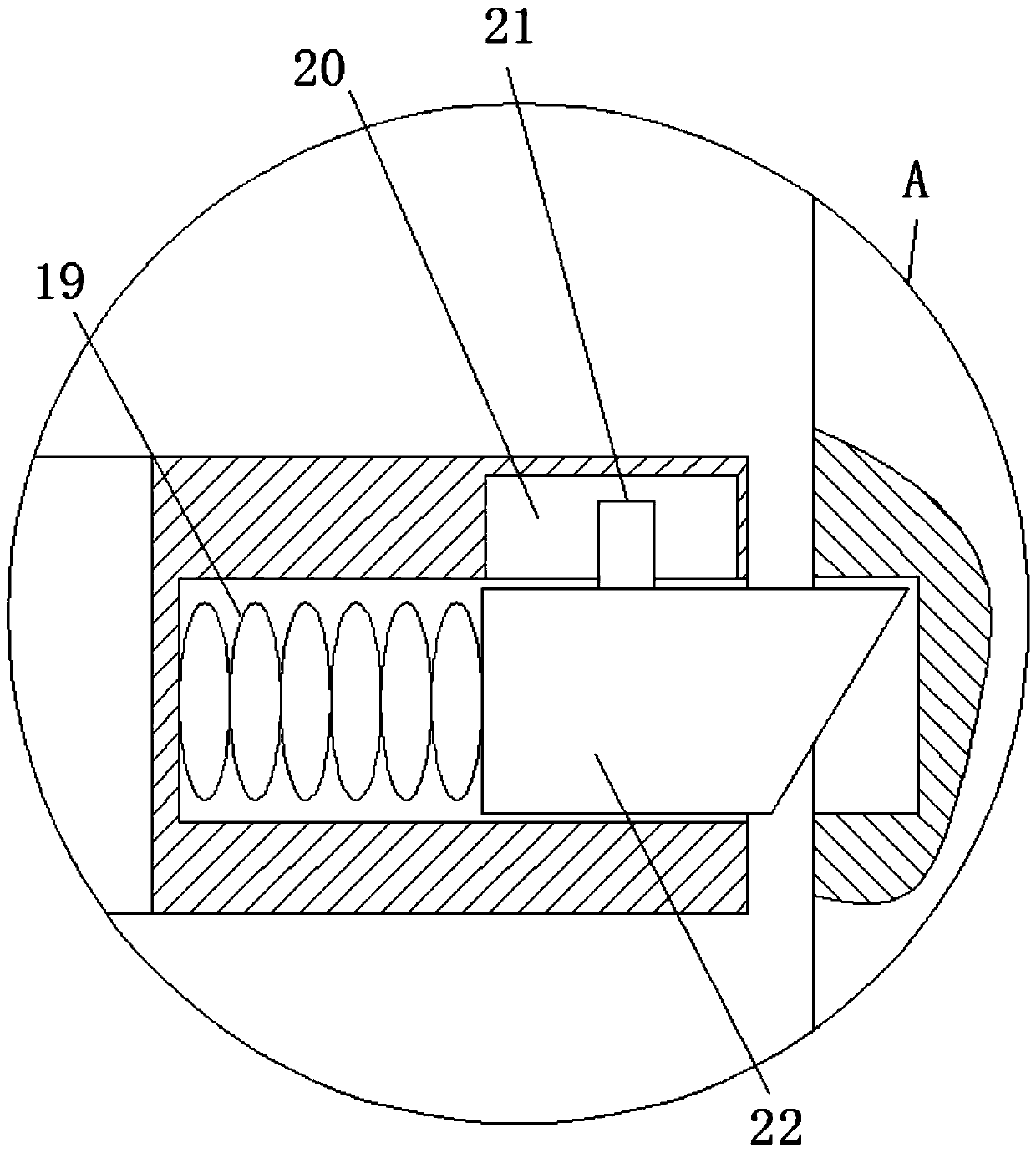

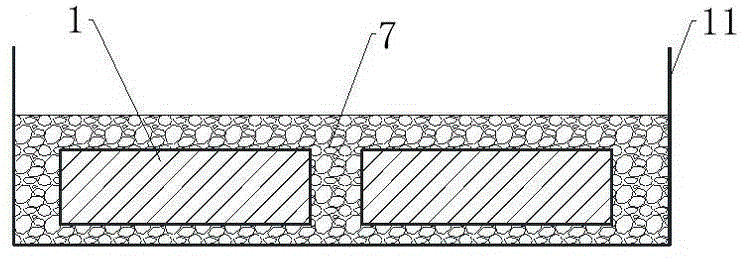

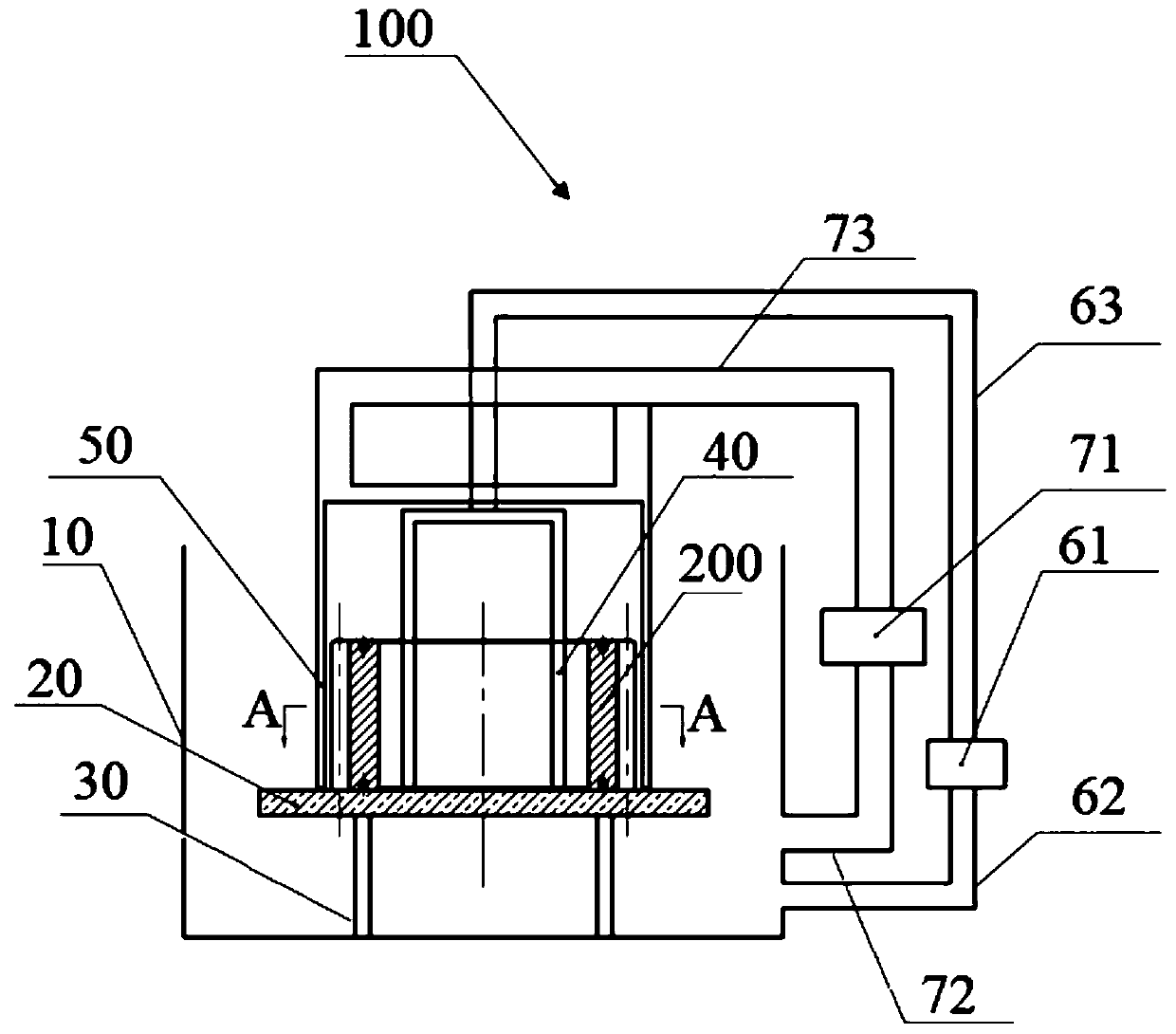

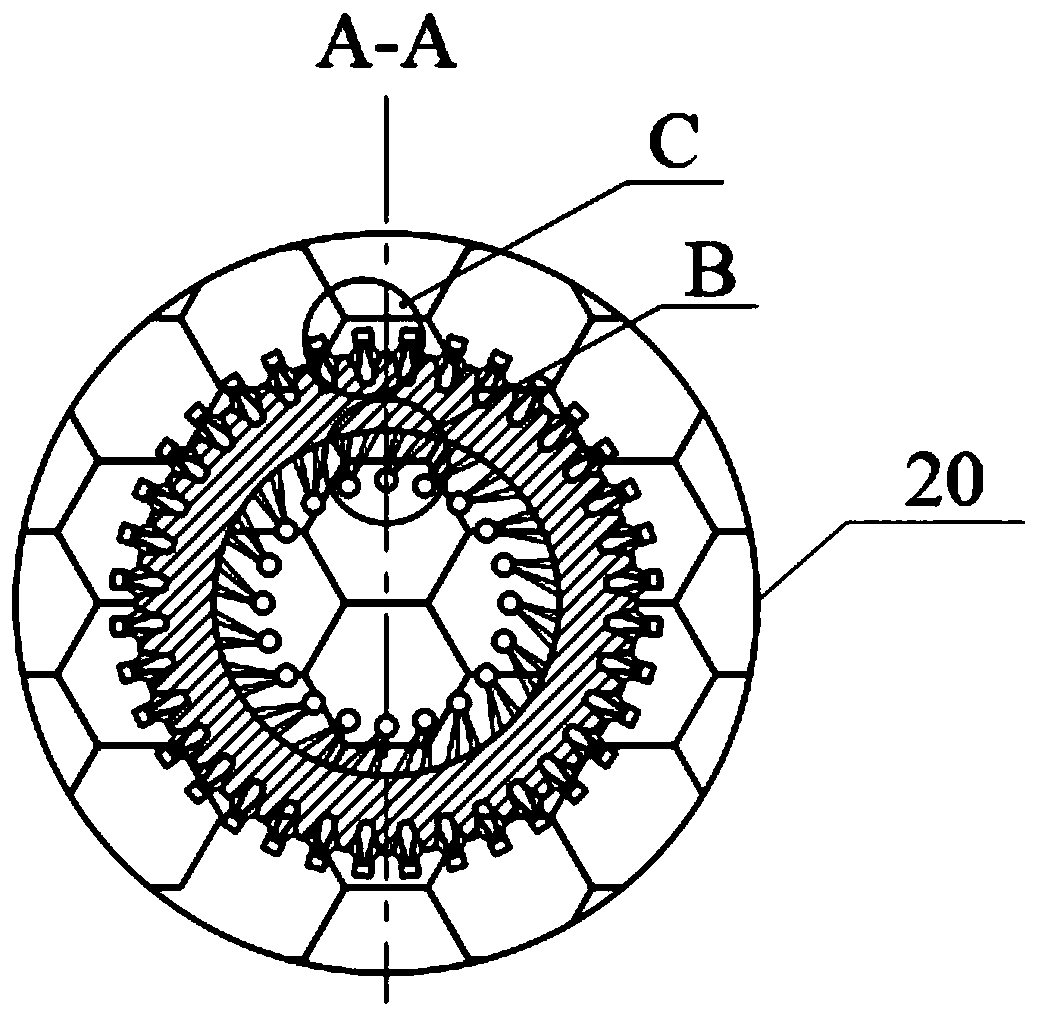

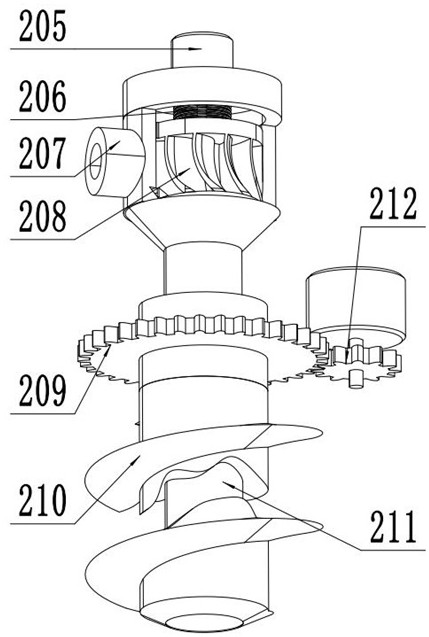

Buried liquid quenching and spraying device

PendingCN110157874AAdjust cooling speedImprove performanceFurnace typesHeat treatment furnacesEngineeringHardness

The invention discloses a buried liquid quenching and spraying device. The device comprises an outer groove for accommodating quenching mediums, a lifting platform for bearing parts, and a lifting device for driving the lifting platform to lift. The buried liquid quenching and spraying device suitable for parts with inner holes further comprises an inner spraying device for spraying the inner holes of the parts, an outer spraying device for spraying the outer side surfaces of the parts, a first circulating device for extracting the quenching mediums in the outer groove to spray by the inner spraying device, and a second circulating device for extracting the quenching mediums in the outer groove to spray by the outer spraying device. The buried liquid quenching and spraying device effectively guarantees the internal and external hardness of the parts, and controls the consistency of different batches of parts.

Owner:NANJING HIGH SPEED GEAR MFG

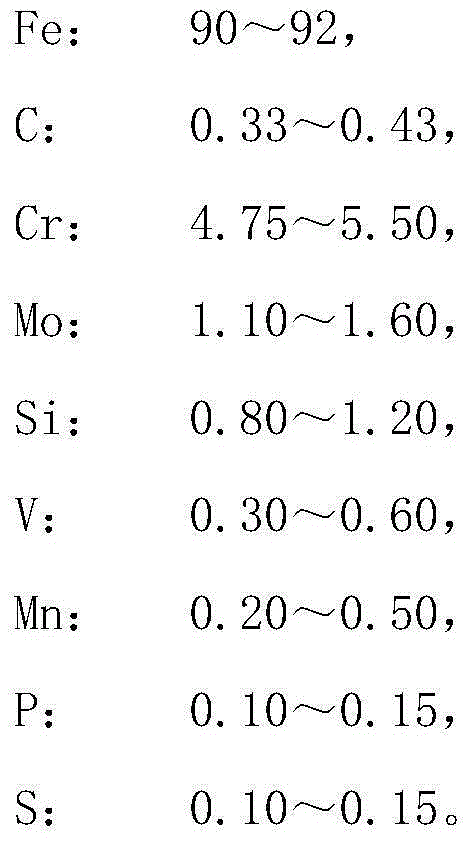

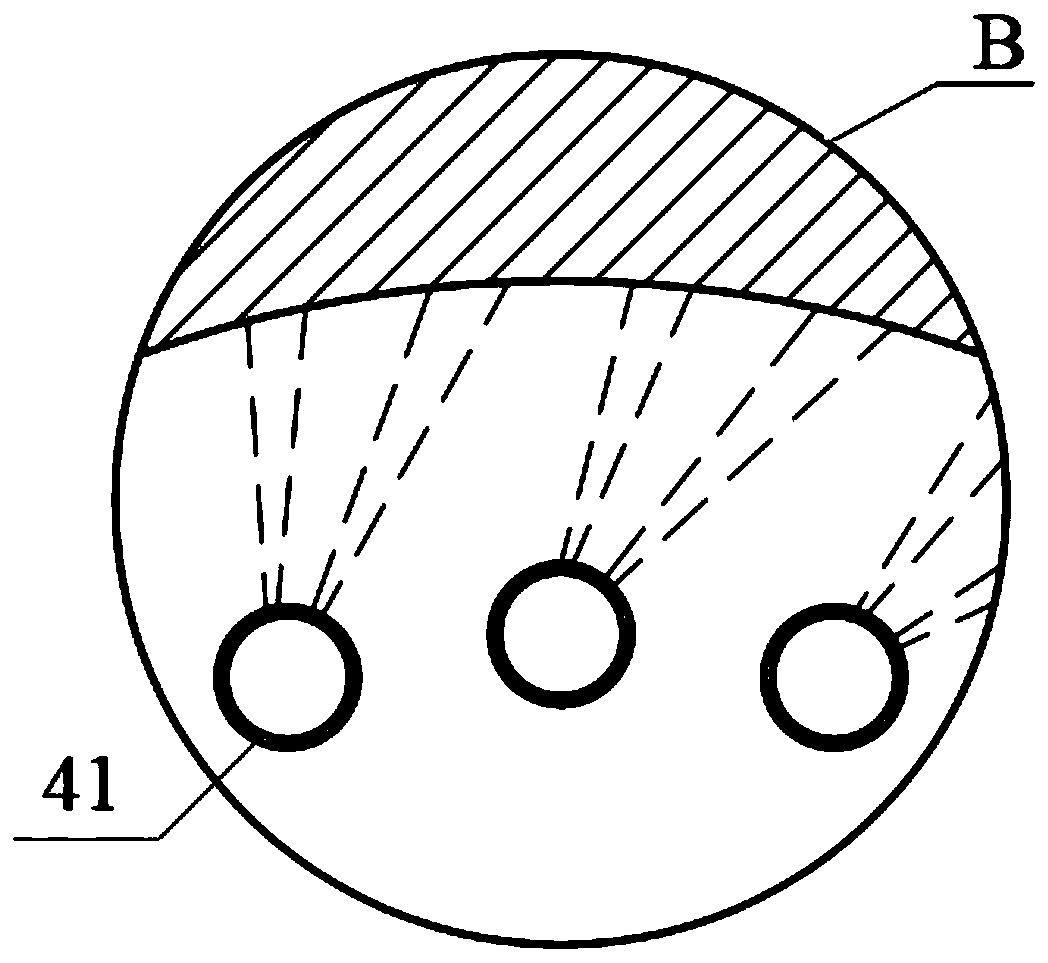

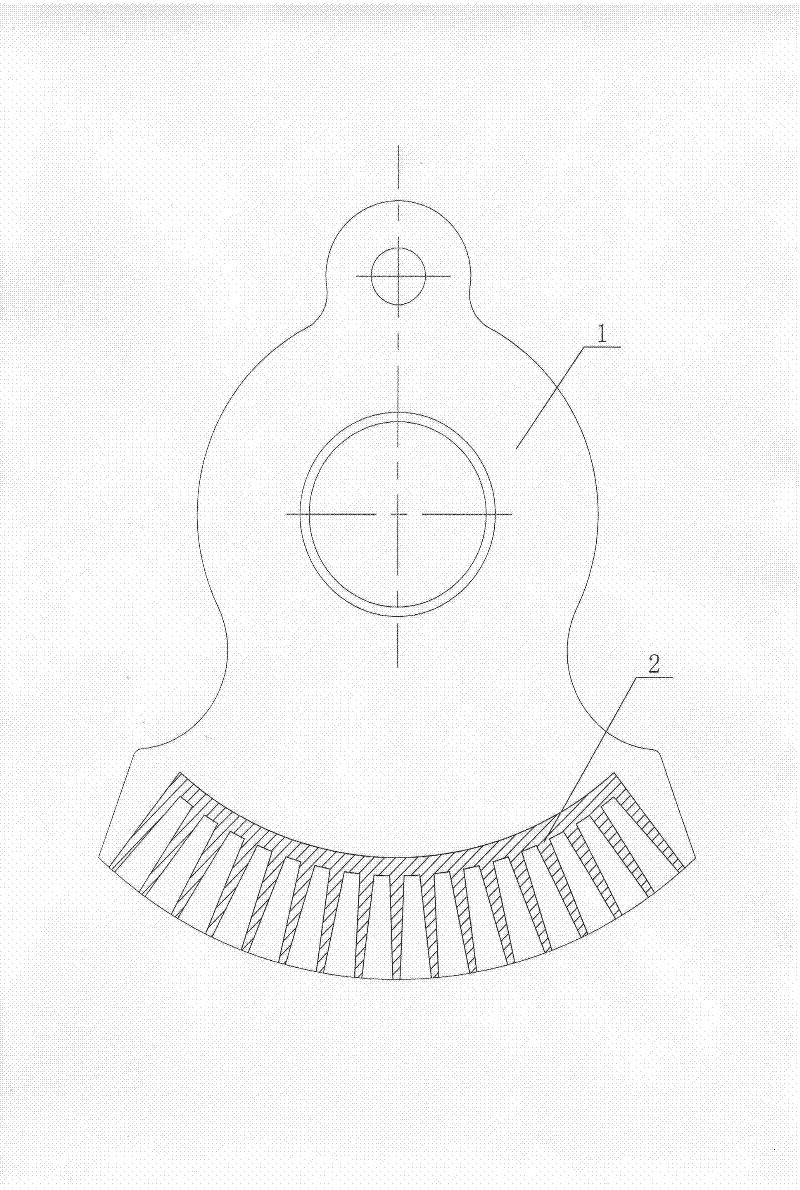

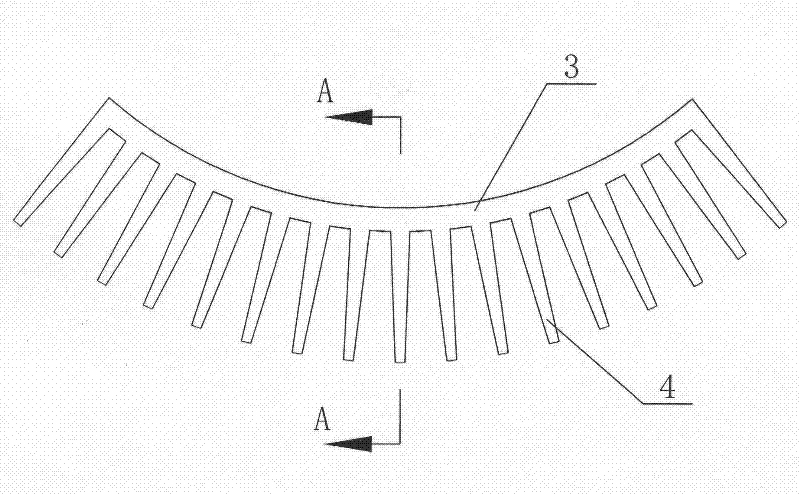

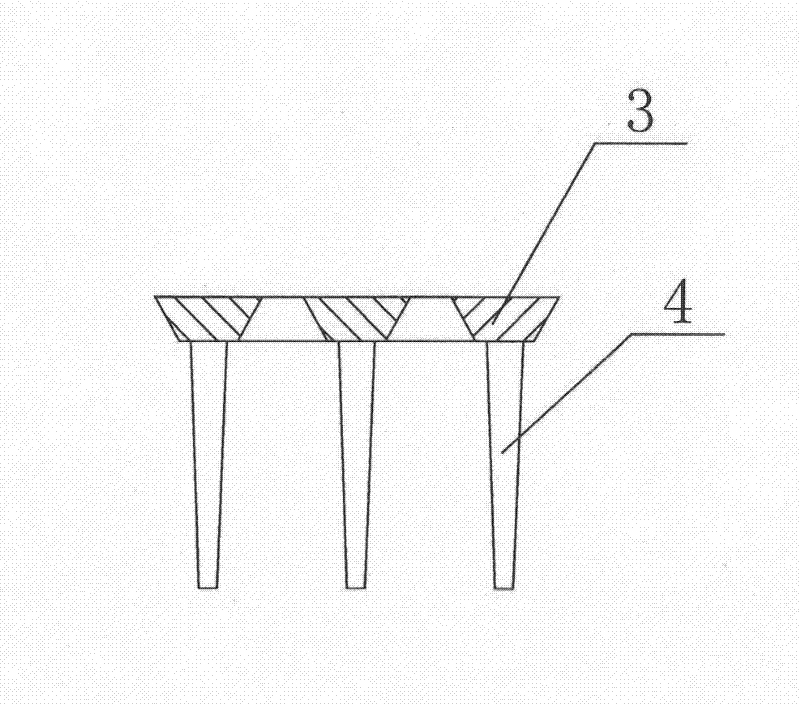

Combined hammer head and manufacturing process thereof

ActiveCN101934242BHigh strengthImprove impact toughnessGrain treatmentsManufacturing technologyEconomic benefits

The invention belongs to the technical field of preparation of hammer heads widely used in the fields of crushing, pulverizing and the like, in particular to a combined hammer head and a manufacturing process thereof. The combined hammer head comprises a framework and a hammer block, wherein the framework is arranged in the hammer block, and is adjacent to the front end of the hammer block; the framework is a high-chromium iron framework and comprises a frame; the frame is in a circular arc shape and is provided with conical rods; the conical rods are distributed on the circular-arc bottom surface of the frame at equal intervals; and the hammer block is a low-carbon multivariant low alloy steel hammer block. The invention is characterized in that the framework is arranged in the hammer block and is obtained by carrying out integral casting on hypereutectic high-chromium iron; the framework and the hammer block are subject to composite casting; the hammer block adopts low-carbon multivariant low alloy steel, and has higher strength and favorable impact toughness; the abrasion resistant framework has excellent abrasive resistance; and the invention gives full play to the advantages of the two materials, thereby obviously prolonging the service life of the hammer head of a crusher and reducing the equipment maintenance rate; and the process is simple, the production efficiency ishigh, and the economic benefits are considerable.

Owner:ZHENGZHOU HI TECH MECHANICAL IND

A kind of refrigeration equipment suitable for electrical cabinets under high temperature conditions

ActiveCN113518548BChange sizeControl contact areaConstructionsPump installationsWind runCooling effect

The invention discloses a refrigeration device suitable for electrical cabinets under high-temperature conditions, which relates to the technical field of refrigeration, and includes a water supply mechanism, a diffuser mechanism, a cooling mechanism, and an air supply mechanism installed in the electrical cabinet, and the diffuser mechanism makes the airflow flow, The cooling mechanism includes a number of water guide plates arranged in the refrigeration box, two adjacent water guide plates are arranged alternately and every two water guide plates are rotatably connected by cooling connecting rods, and one end of the lowermost water guide plate is set There are counterweights to guide the flow of water, and the air supply mechanism realizes multi-angle air supply. The invention uses underground cold water, controls the contact area between air flow and cold water flow, and adjusts the wind direction and speed to cool down the electrical cabinet. It is energy-saving and environmentally friendly, and has a good cooling effect. , high cooling efficiency.

Owner:徐州金宸制冷设备有限公司

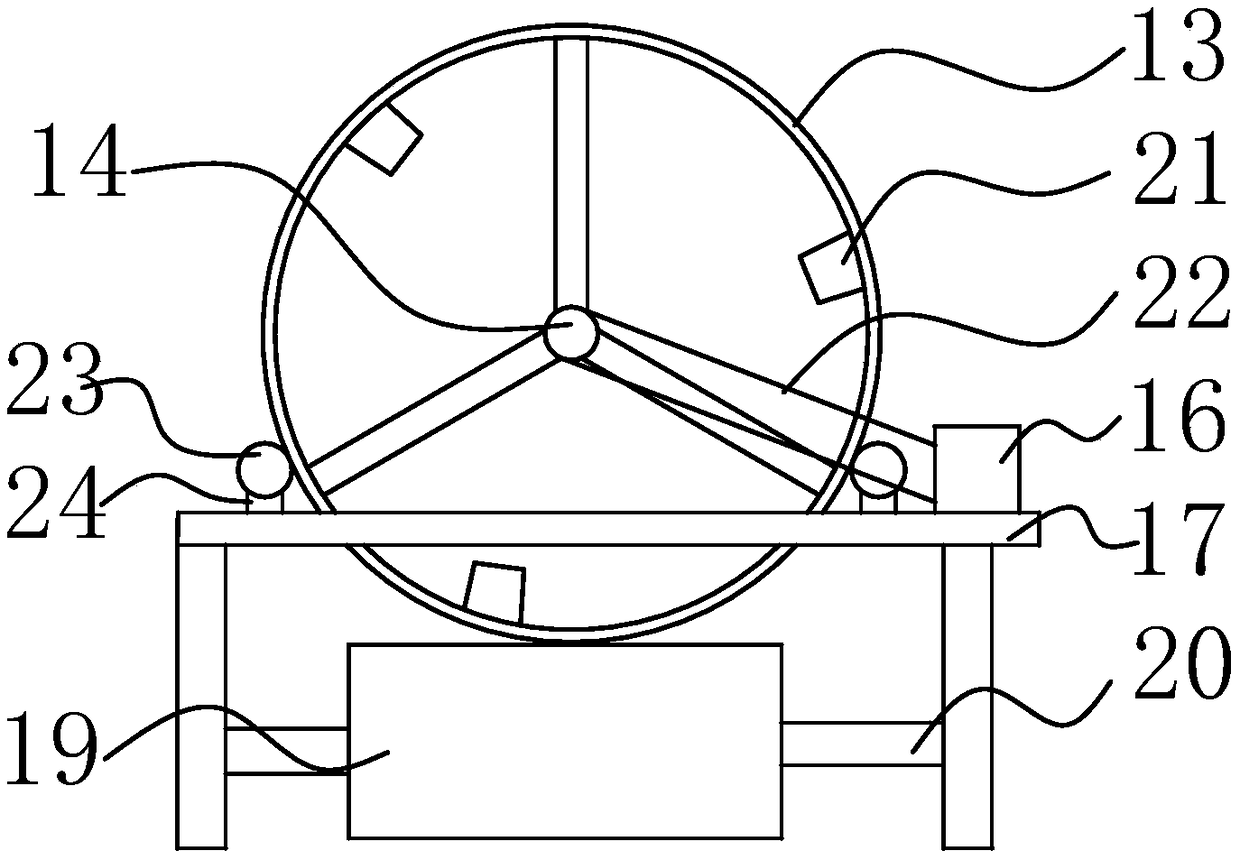

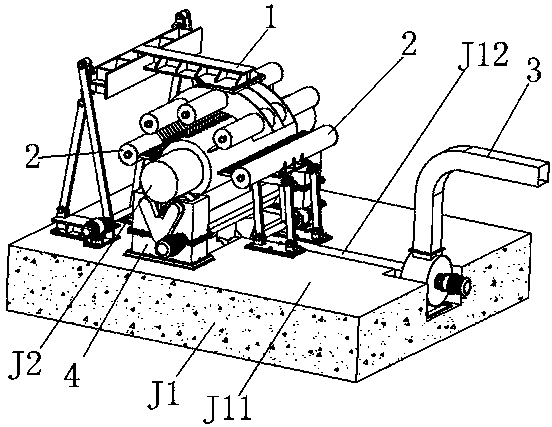

Roll air-cooled quenching machine

InactiveCN105925780BHigh-efficiency air-cooled quenchingAccurate and reliable rotary motionFurnace typesHeat treatment furnacesWorking environmentMechanical equipment

The invention relates to mechanical equipment in the field of metal heat treatment, in particular to an air blast quenching machine for rollers. The air blast quenching machine comprises an air spraying device, two heating devices, an air extracting device and a rotation device, wherein the air spraying device, the heating devices and the rotation device are all mounted and fixedly connected to a horizontal surface on a concrete poured foundation base; the air extracting device is mounted and fixedly connected into a groove in the foundation base; the heating devices are arranged on two sides of the rotation device symmetrically; and a workpiece roller is arranged on the rotation device. The air blast quenching machine adopts four-carrier roller synchronous constant-speed mobile rotation, so that the heating uniformity and the quenching quality are improved; due to combined function of the air spraying device and the air extracting device, the cooling speed can be accelerated, and the work environment can be improved; and as both the air spraying device and the heating devices are arranged on and connected with a link mechanism, mobile starting and stopping can be realized, and spray head distances can be adjusted fast.

Owner:KUNMING UNIV

Water circulation device for plastic extruder stock mould

The invention discloses a water circulation device for a plastic extruder stock mould and belongs to the field of plastic processing machines. The water circulating device is arranged between a forming mould connected with an extruding cylinder and the stock mould, wherein the shape of the section of the water circulation device is the same as that of the forming mould and the shape of the stock mould, and a hollow shell of an inner cavity of the water circulation device is provided with a water input and output opening. Water circulation is formed in the inner cavity of the water circulation device through a water input and output pipe. The water circulation device weakens intensity of transmitting heat from the forming mould to the stock mould, the heat is taken away by means of water circulation, cooling speed of the stock mould and plastic profiles is increased, and the stock mould is controlled to reach ideal cooling speed, so that product quality is ensured.

Owner:XINJIANG HUATING IND & TRADE

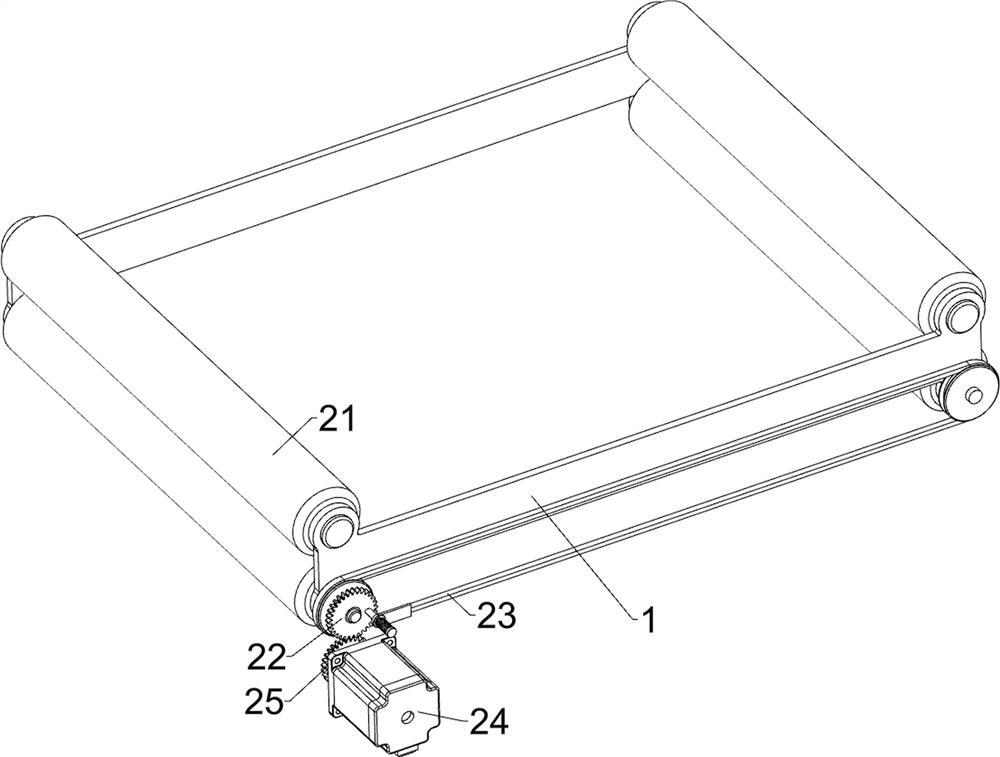

Textile conveying cooling alarm device

ActiveCN113403786AAdjust cooling speedEasy to useHeating/cooling textile fabricsElectric transmission signalling systemsMechanical engineeringAlarm device

The invention relates to an alarm device, in particular to a textile conveying cooling alarm device. The textile conveying cooling alarm device has an alarm function, can cool conveyed textiles and automatically stops conveying when the temperature of the textiles is too high. The textile conveying cooling alarm device is characterized by comprising a support, a conveying assembly and a cooling mechanism; the conveying assembly is installed on the support and conveys the textiles in a rotating mode; and the cooling mechanism is mounted on the support and is used for cooling in an air blowing manner. Through the characteristics of inert gas, the textile cooling speed can be automatically adjusted, and the equipment is very convenient to use; through a sound reminding mechanism and a visual reminding mechanism, sound and light are matched for reminding, and higher safety can be achieved; and when the temperature of the textile is too high, a second gear and a first gear are disconnected, the equipment can automatically stop working, and the conveyed textile can be better protected.

Owner:临沂临港国有资产运营集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com