Method for manufacturing blue brick tiles

A technology for bricks and bricks, which is applied to clay products, other household appliances, household appliances, etc., can solve the problems of increasing production costs and complex production processes, avoiding secondary oxidation, simple production processes, and uniform cooling. easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

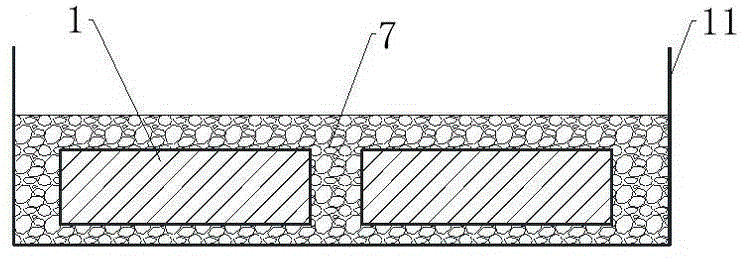

[0032] In this embodiment, the raw materials of brick and tile blanks are clay and 60% coal gangue accounting for 40% of the total mass of raw materials, and the bulk materials are spontaneous combustion coal gangue slag.

[0033] Coal gangue is crushed twice by jaw type, and the maximum particle size after crushing is 5mm; the raw materials are dispersed and mixed, and the amount of water added to the mixture during the mixing process is 11%; the aging time of the mixture is 10 days, and the aging time is 10 days. Add water to the melted mixture to 12% while stirring; the green body is formed by pressing, and the forming pressure is 20MPa; the shaped bricks are naturally air-dried for 20 days.

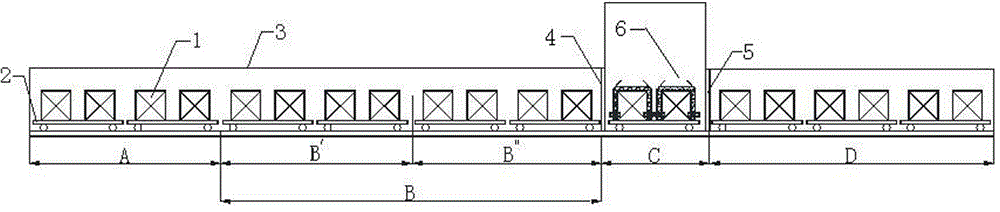

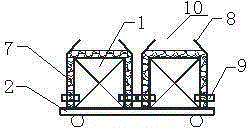

[0034] The dried brick and tile adobe 1 is loaded into the preheating zone A of the tunnel kiln with the kiln car 2 for preheating, and the preheated brick and tile adobe enters the roasting zone B for reduction roasting, and the heating rate of the roasting is 60°C / h. The sintering t...

Embodiment 2

[0038] In this embodiment, the raw materials of brick and tile adobe are clay and 60% coal gangue, which account for 40% of the total mass of raw materials, and iron tailings are used as bulk materials.

[0039] The coal gangue is crushed twice by jaw type, and the maximum particle size after crushing is 5mm; the raw materials are dispersed and mixed, and the water content of the mixture is 11% during the mixing process; the aging time of the mixture is 10 days, and the aging time is 10 days. Add water to the melted mixture to 12% while stirring; the green body is formed by pressing, and the forming pressure is 20MPa; the shaped bricks are naturally air-dried for 20 days.

[0040] The dried brick and tile adobe 1 is loaded into the preheating zone A of the tunnel kiln by the kiln car 2 for preheating, and the preheated brick and tile adobe enters the roasting zone B for roasting, and the roasting zone B is divided into an oxidation roasting zone and reduction roasting belt ...

Embodiment 3

[0044] In this embodiment, the raw materials of brick and tile blanks are clay which accounts for 80% of the total mass of raw materials and coal gangue which accounts for 20%. .

[0045] Coal gangue is crushed twice by jaw type, and the maximum particle size after crushing is 5mm; the raw materials are dispersed and mixed, and the amount of water added to the mixture during the mixing process is 13%; the aging time of the mixture is 10 days, and the aging time is 10 days. Add water to the melted mixture to 14% while stirring; the green body is formed by pressing, and the forming pressure is 20MPa; the shaped bricks are naturally air-dried for 20 days.

[0046] The dried brick and tile adobe 1 is loaded into the preheating zone A of the tunnel kiln by the kiln car 2 for preheating, and the preheated brick and tile adobe enters the roasting zone B for oxidative roasting, and the heating rate of the roasting is 60°C / h. The sintering temperature is 950°C, and the holding time is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com