Textile conveying cooling alarm device

An alarm device and textile technology, applied in textiles and papermaking, electrical transmission signal system, processing textile material carriers, etc., can solve the problems of no cooling function, unable to stop textile transportation, etc., and achieve the effect of convenient use of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

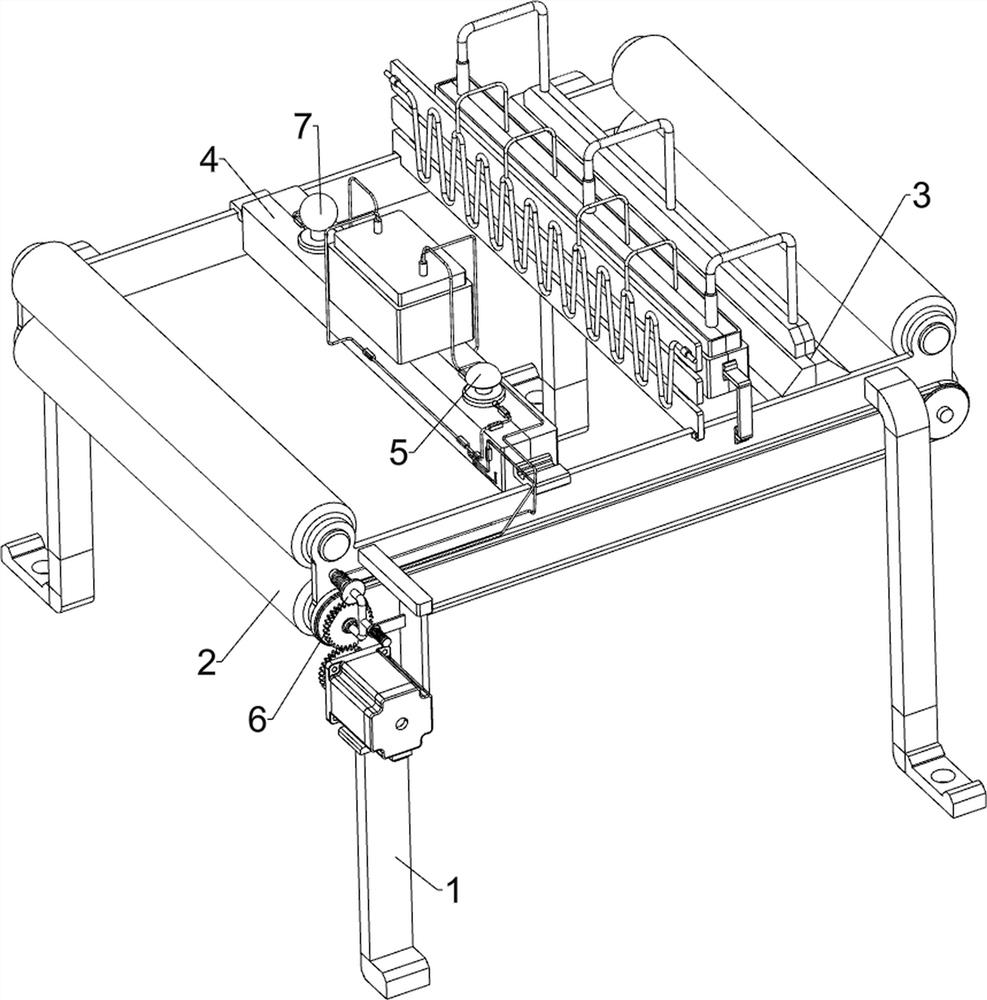

[0027] A textile conveying cooling alarm device, such as Figure 1-Figure 3 As shown, it includes a support 1, a conveying assembly 2 and a cooling mechanism 3. The conveying assembly 2 for textile conveying is installed on the top of the support 1, and the cooling mechanism 3 for cooling by blowing is installed on the right side of the top of the support 1.

[0028] When the textile needs to be conveyed, the textile is first placed between the conveying components 2, and then the conveying component 2 is controlled to start working to convey the textile. During the conveying of the textile, the cooling mechanism 3 is controlled to stop working. The temperature is automatically adjusted to cool down the textiles, and after the textiles are conveyed, the conveying assembly 2 and the cooling mechanism 3 are controlled to stop working.

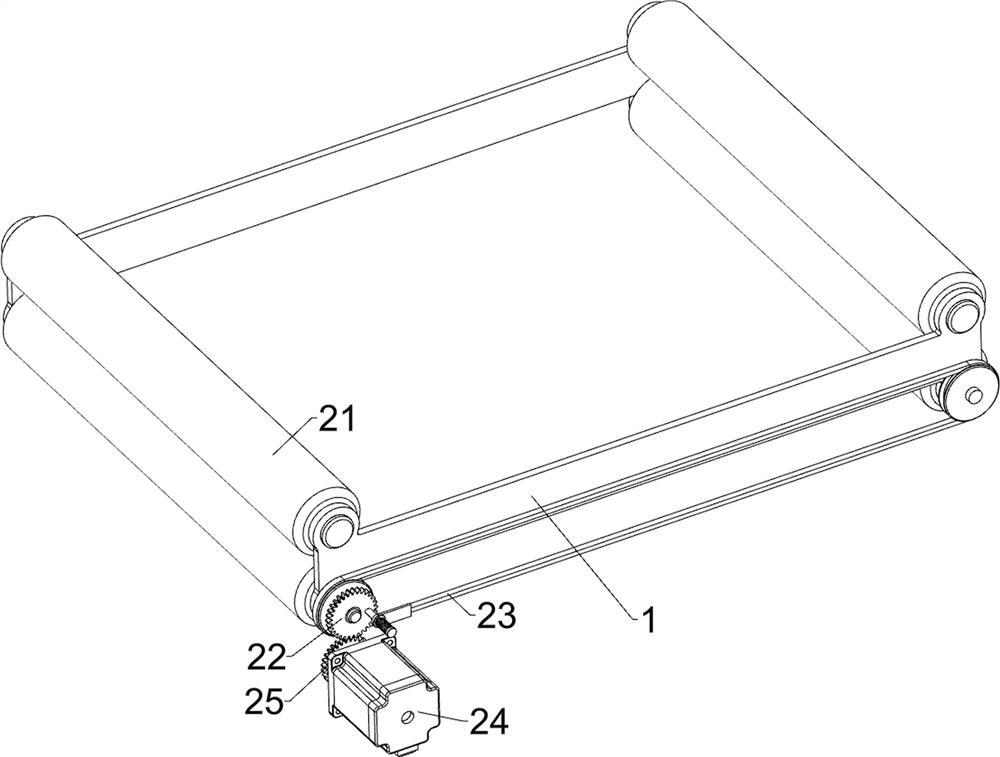

[0029] The conveying assembly 2 includes a drum 21, a first gear 22, a drive pulley set 23, a reduction motor 24 and a second gear 25, and the u...

Embodiment 2

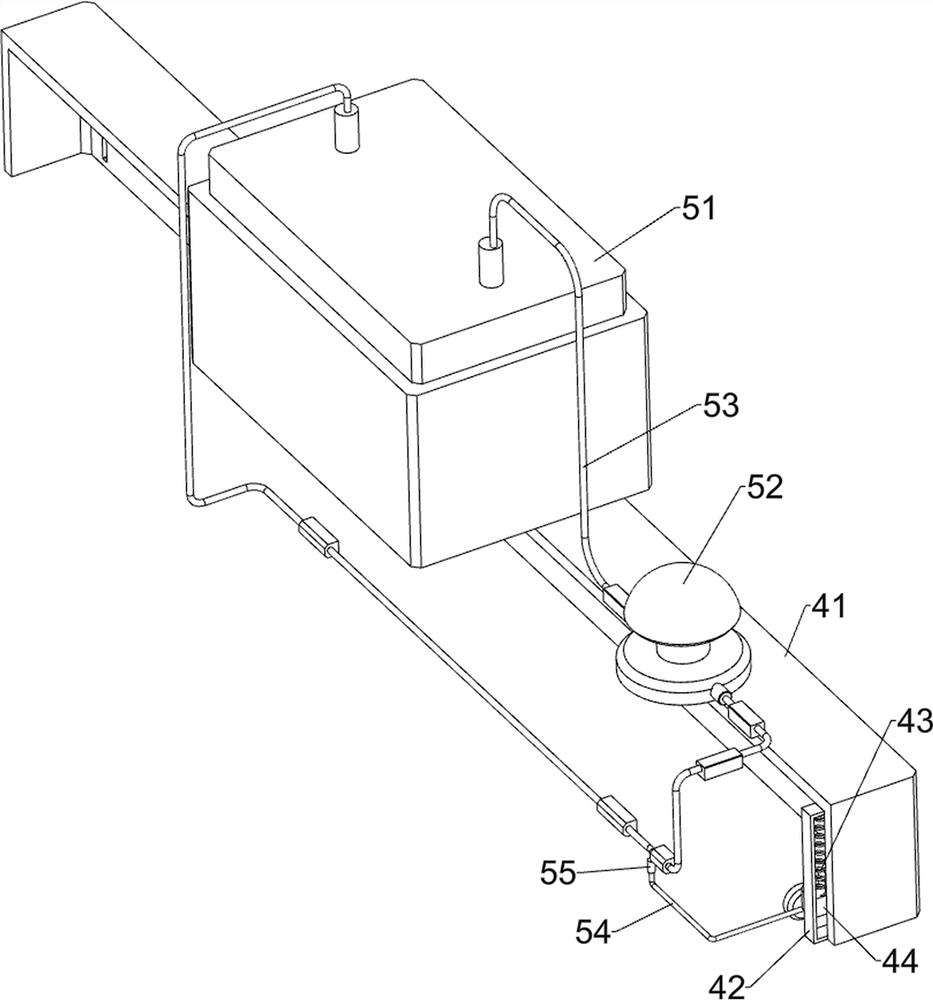

[0034]On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a reaction mechanism 4 is also included. A reaction mechanism 4 is installed on the left side of the top of the support 1. The reaction mechanism 4 includes a mounting frame 41, a slide rail 42, a first spring 43, a slider 44 and an air bag 45. The top left side of the support 1 The side is fixedly connected with the installation frame 41 by bolts, and the front and rear sides of the installation frame 41 are provided with slide rails 42, and the slide rails 42 are all slidably provided with sliders 44, and a first An air bag 45 is connected between the spring 43 and the slider 44, and an inert gas is housed in the air bag 45.

[0035] After the textile is cooled down, when passing through the airbag 45, if the temperature of the textile is still too high, the airbag 45 will expand, and the diameter of the airbag 45 becomes larger, the first spring 43 is compressed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com