Patents

Literature

38results about How to "Control contact area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

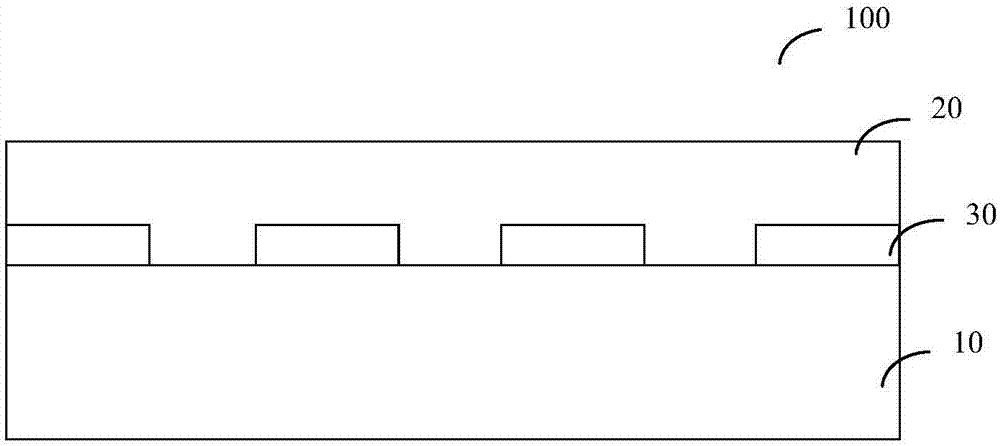

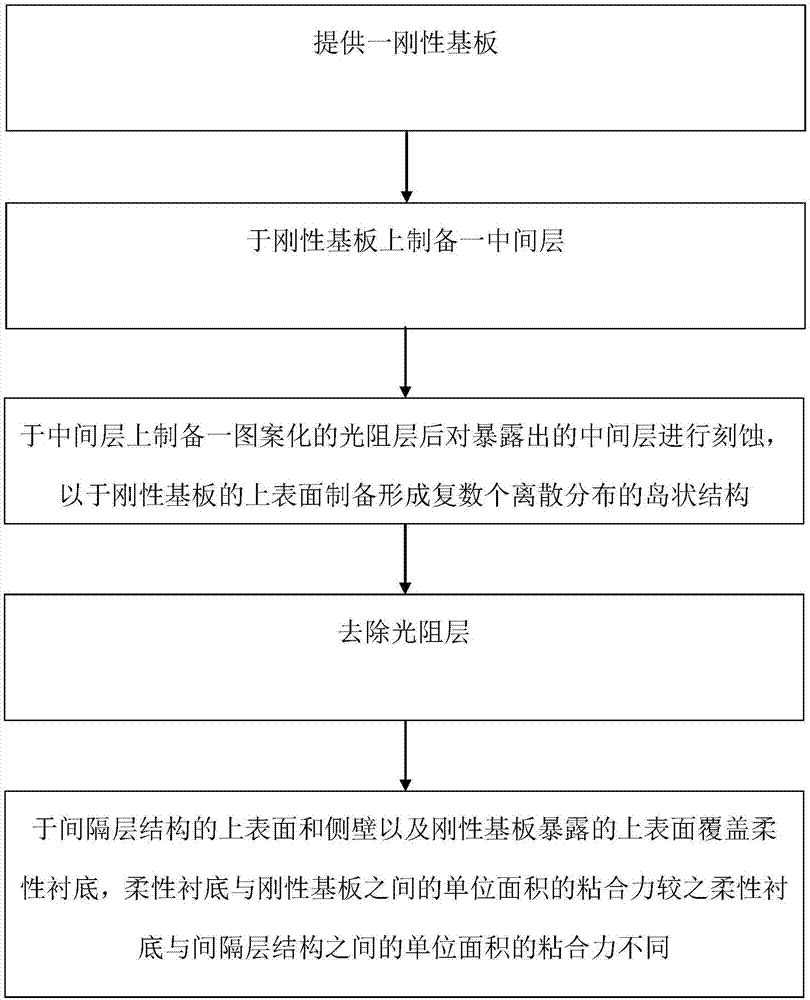

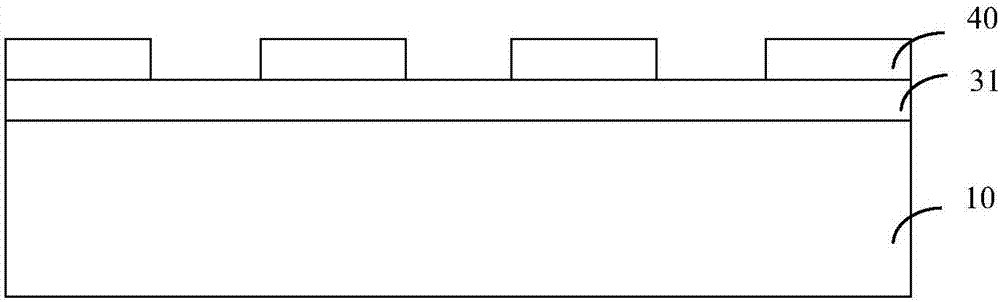

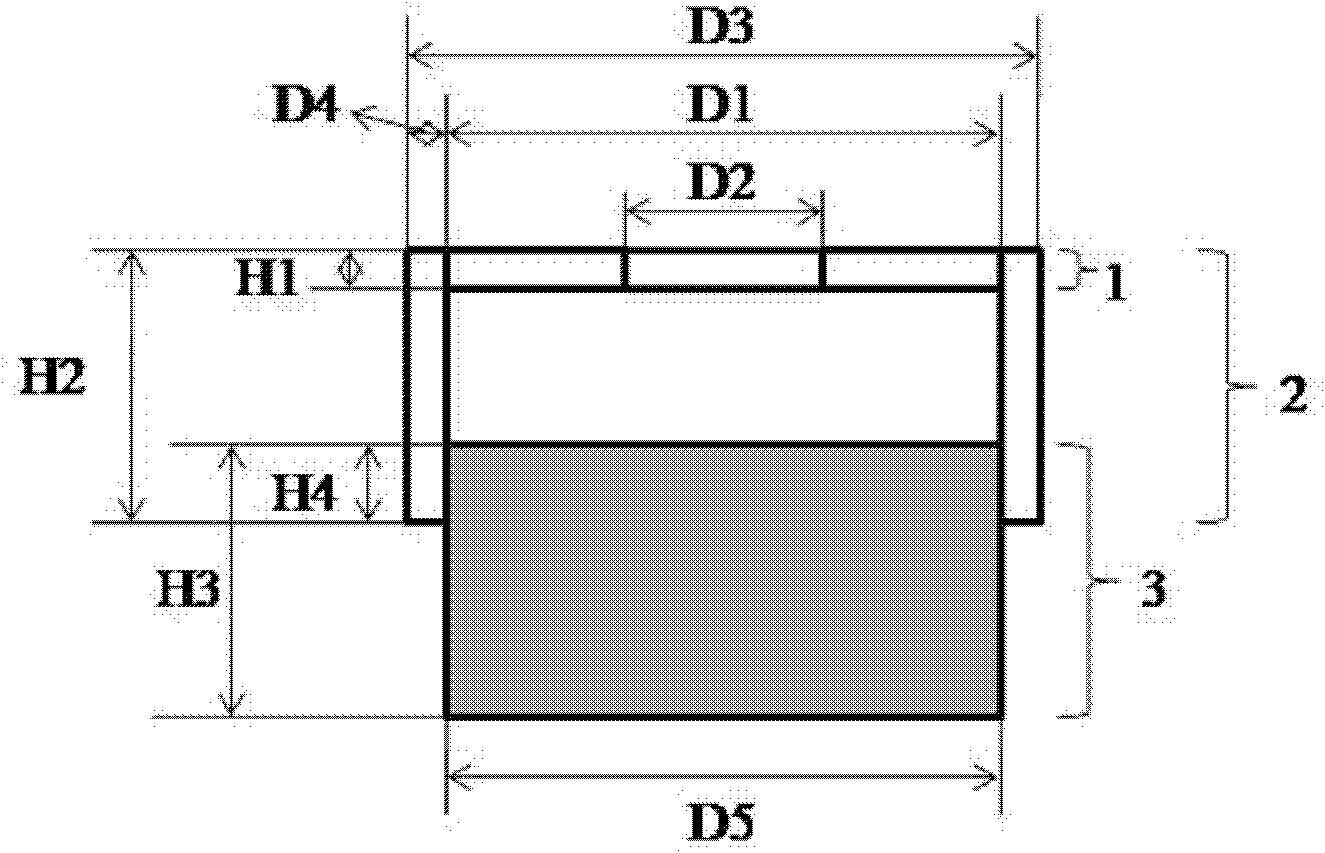

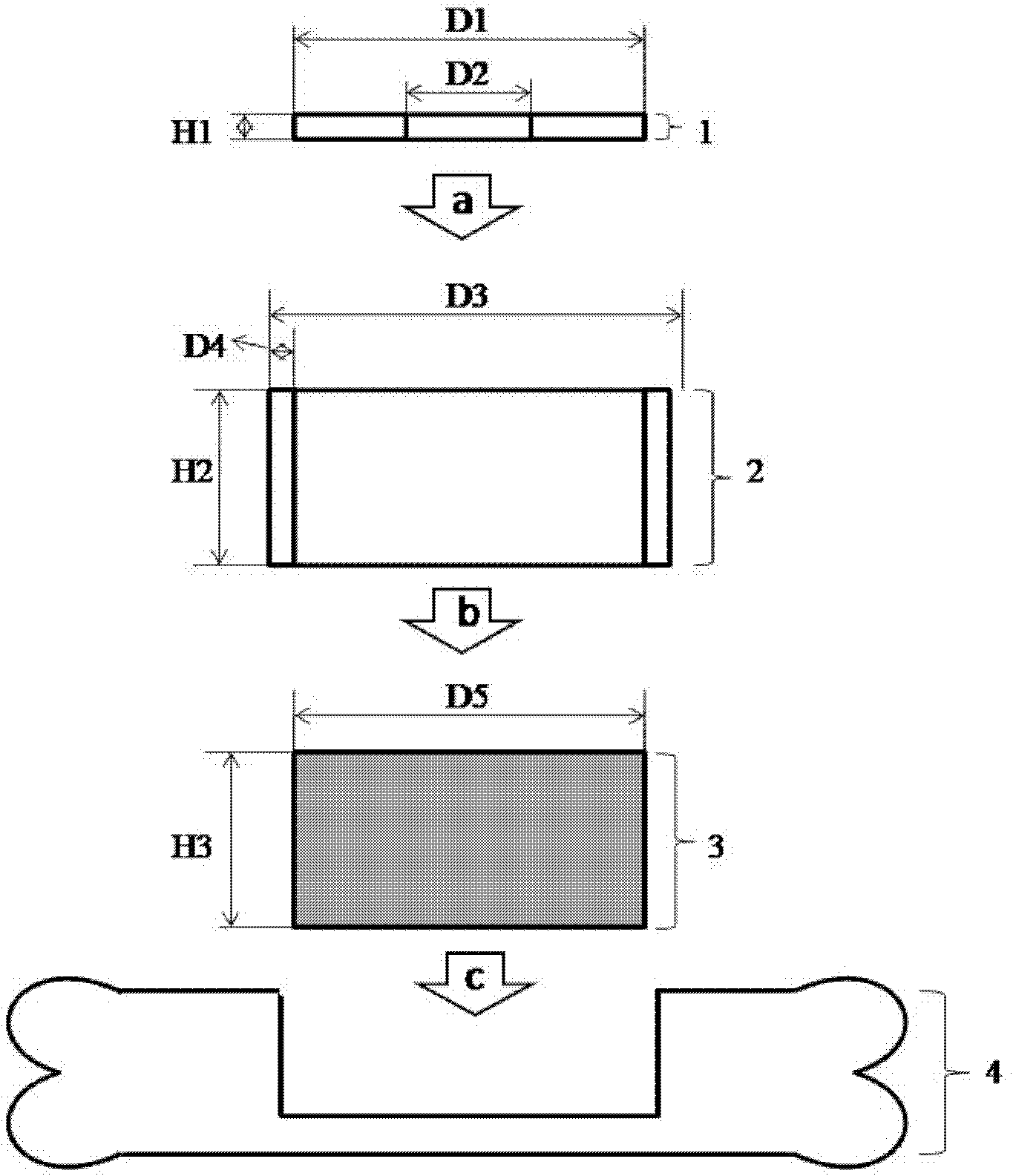

Flexible substrate structure and preparation method thereof

ActiveCN107342305AStrong adhesionControl contact areaSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringFlexible display

The invention discloses a flexible substrate structure, a preparation method of the flexible substrate structure, and a preparation method of a flexible display device. A rigid substrate is provided, a plurality of island structures subjected to discrete distribution are prepared on an upper surface of the rigid substrate, a flexible substrate covers the upper surfaces and side walls of the island structures and the exposed upper surface of the rigid substrate, and the adhesive force of a unit area between the flexible substrate and the rigid substrate is different from the adhesive force of the unit area between the flexible substrate and the island structures; a preparation process of a thin film transistor device structure and an organic light emitting diode device structure is further performed on the basis of the flexible substrate structure to form the flexible display device; and the contact areas of the flexible substrate with the rigid substrate and the island structures can be controlled easily so as to control the total adhesive force of the flexible substrate with the rigid substrate and the island structures, and thus the flexible substrate structure with an ideal adhesive force is prepared.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

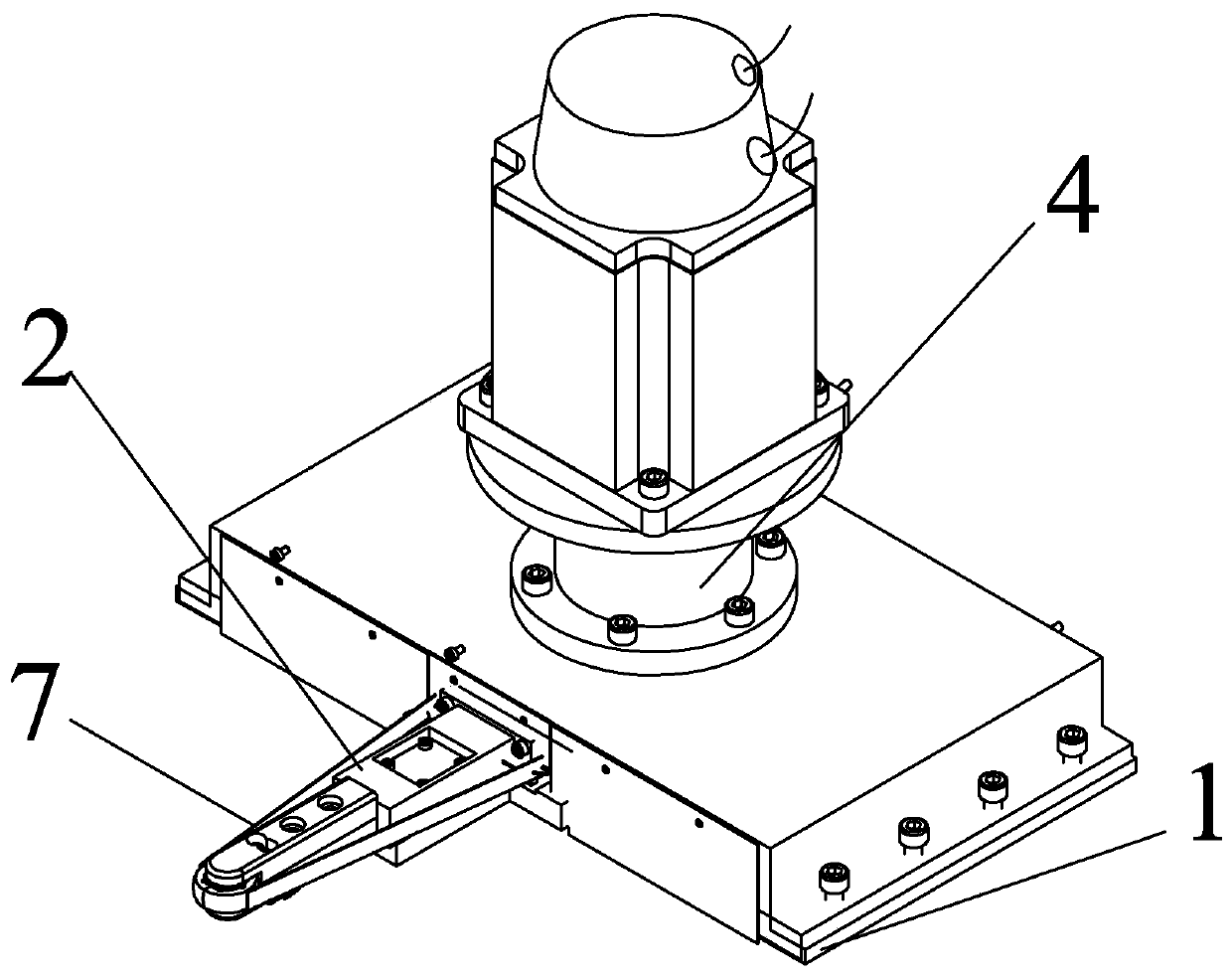

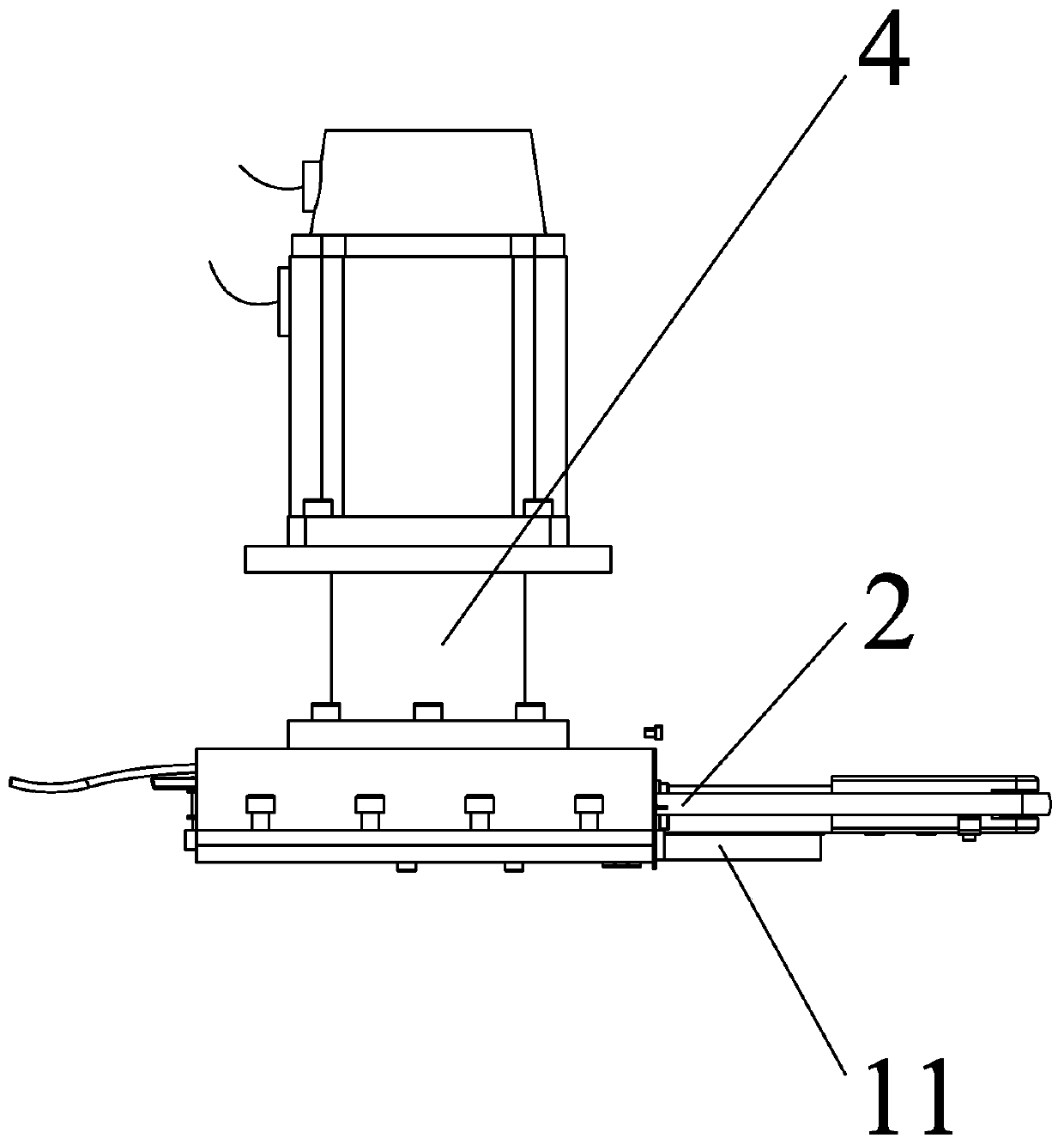

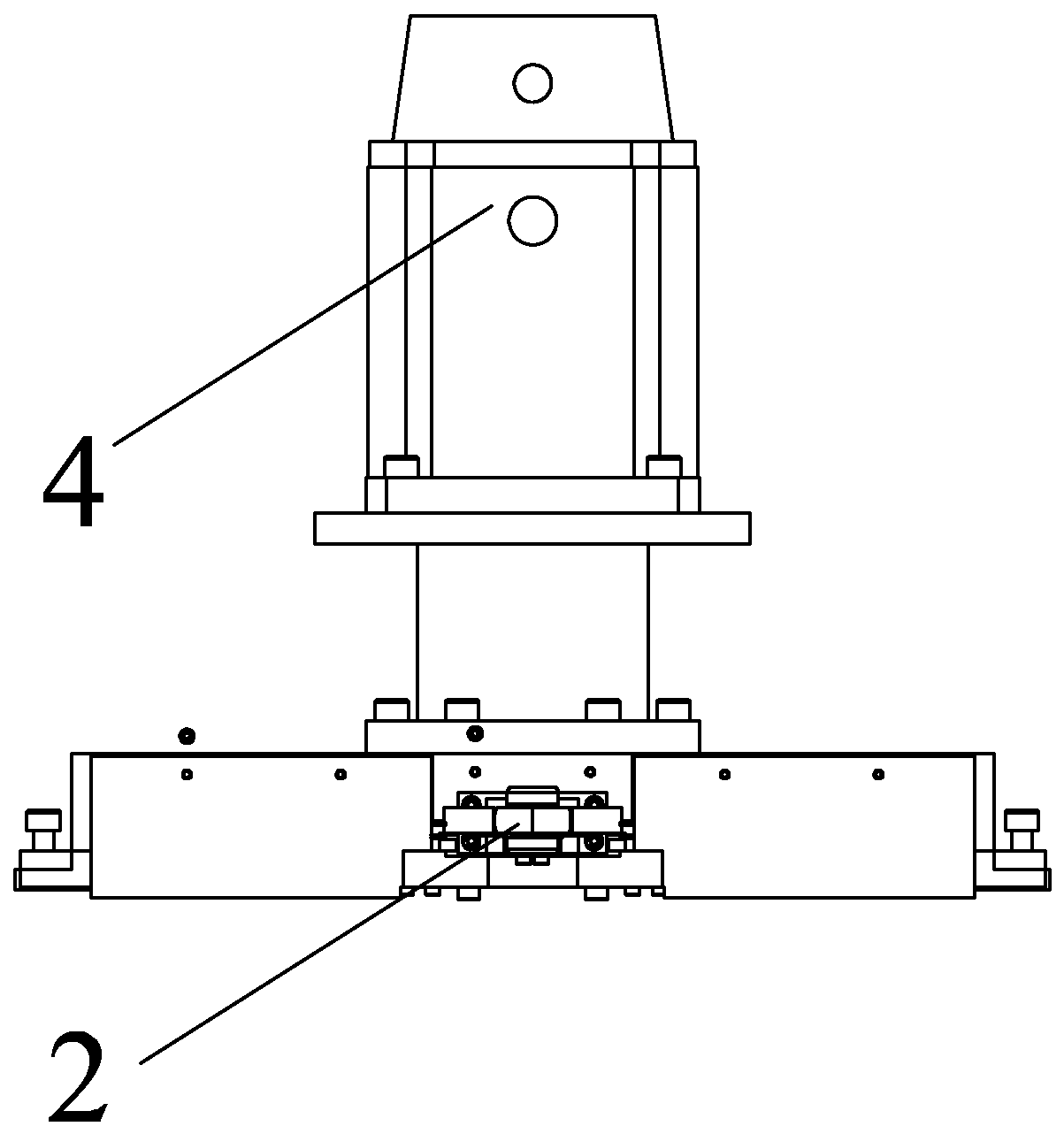

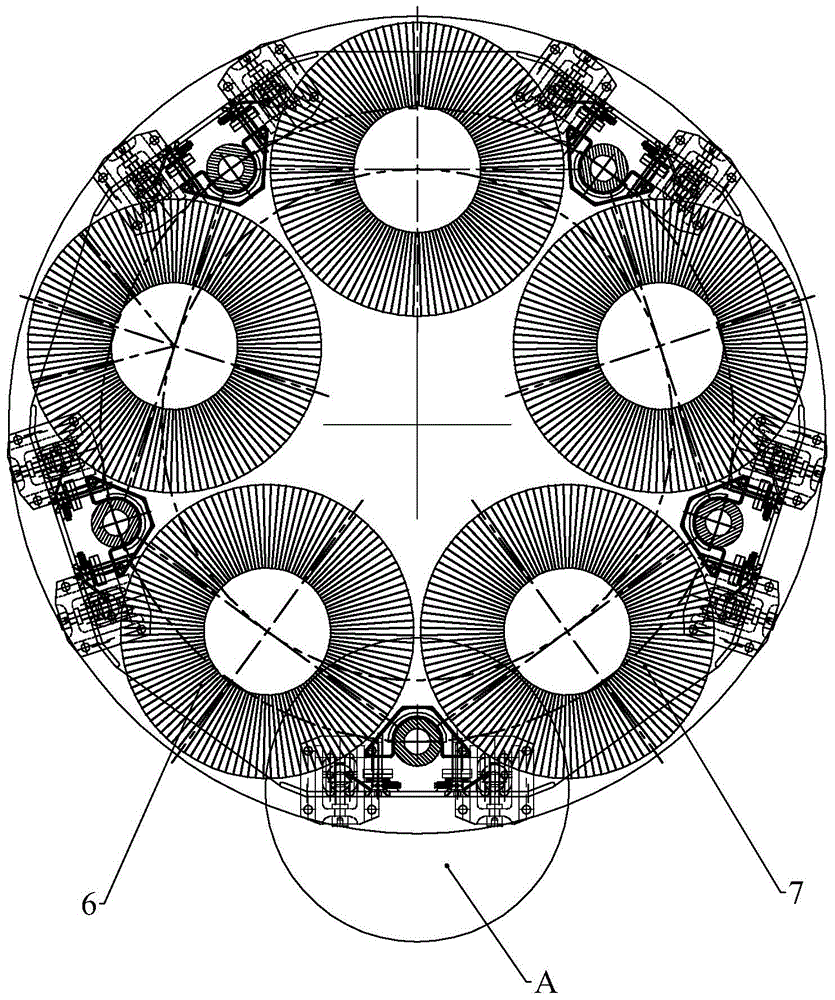

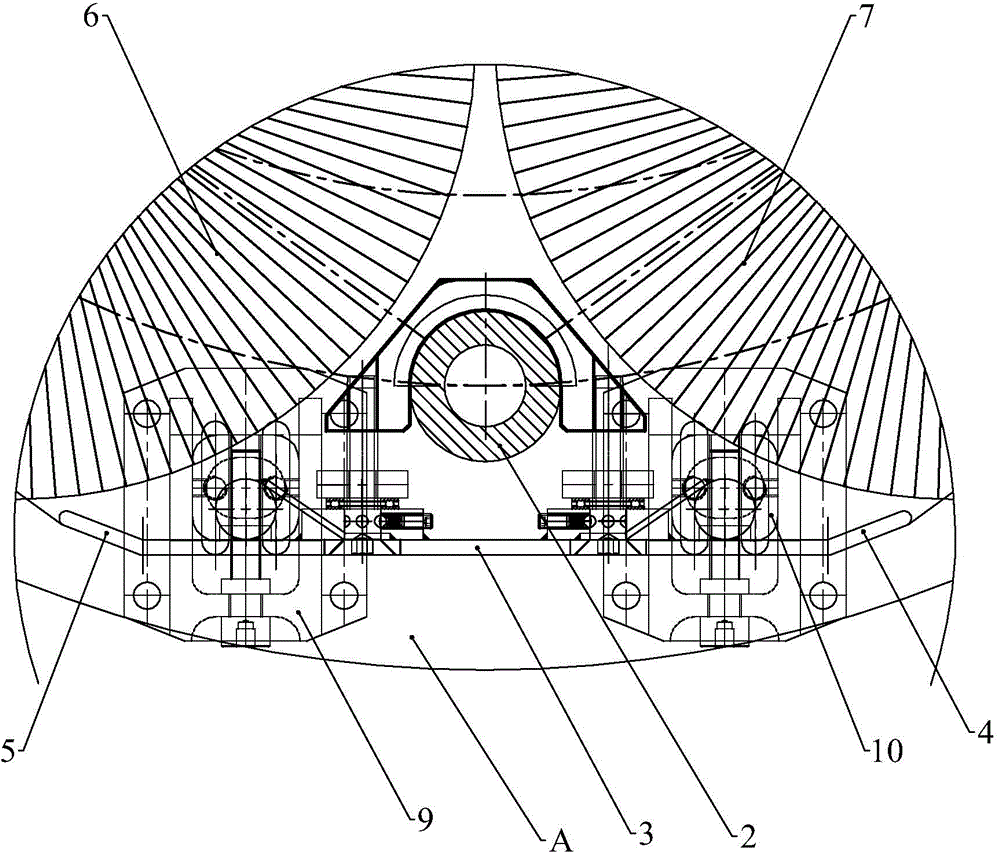

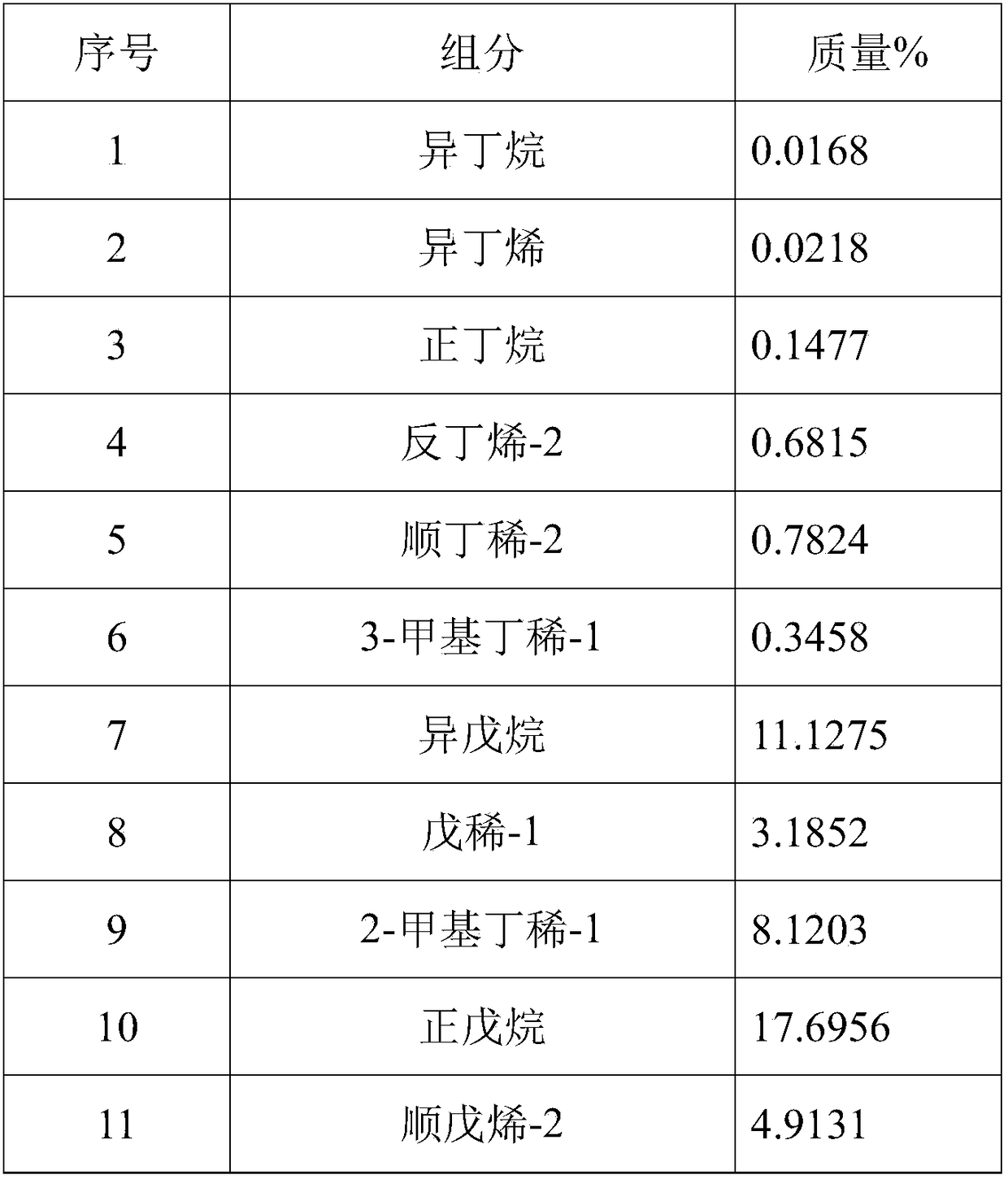

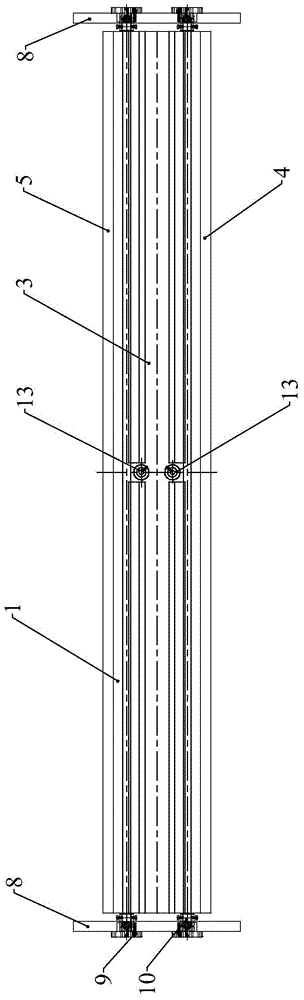

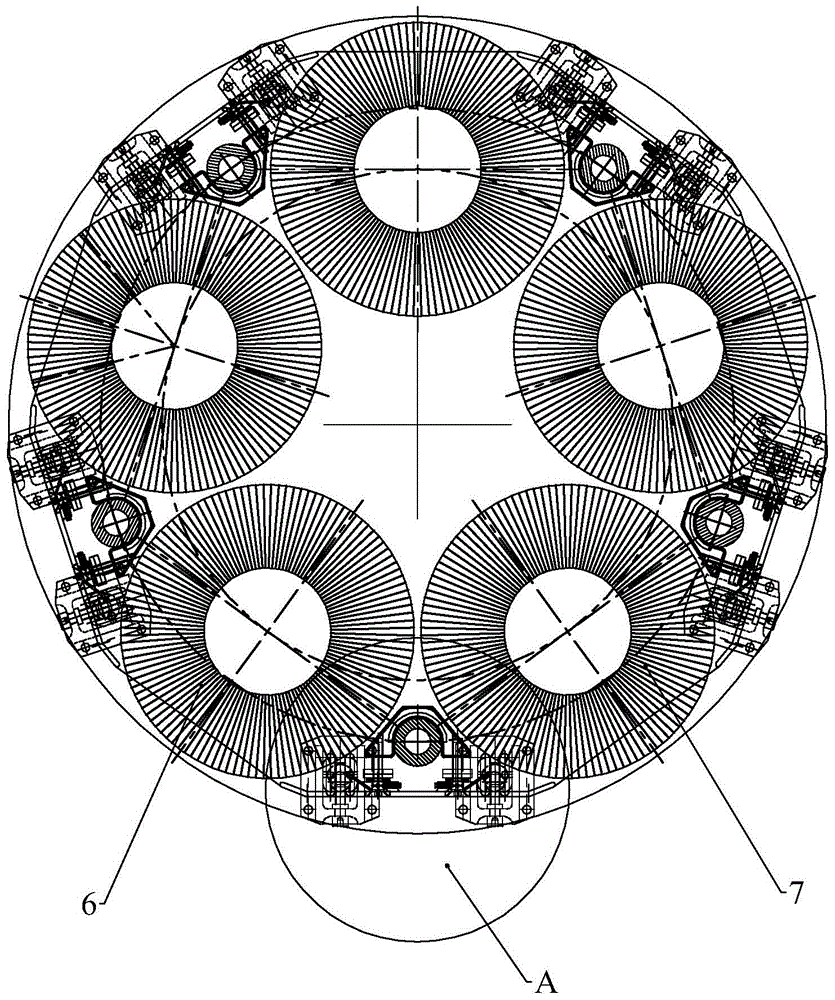

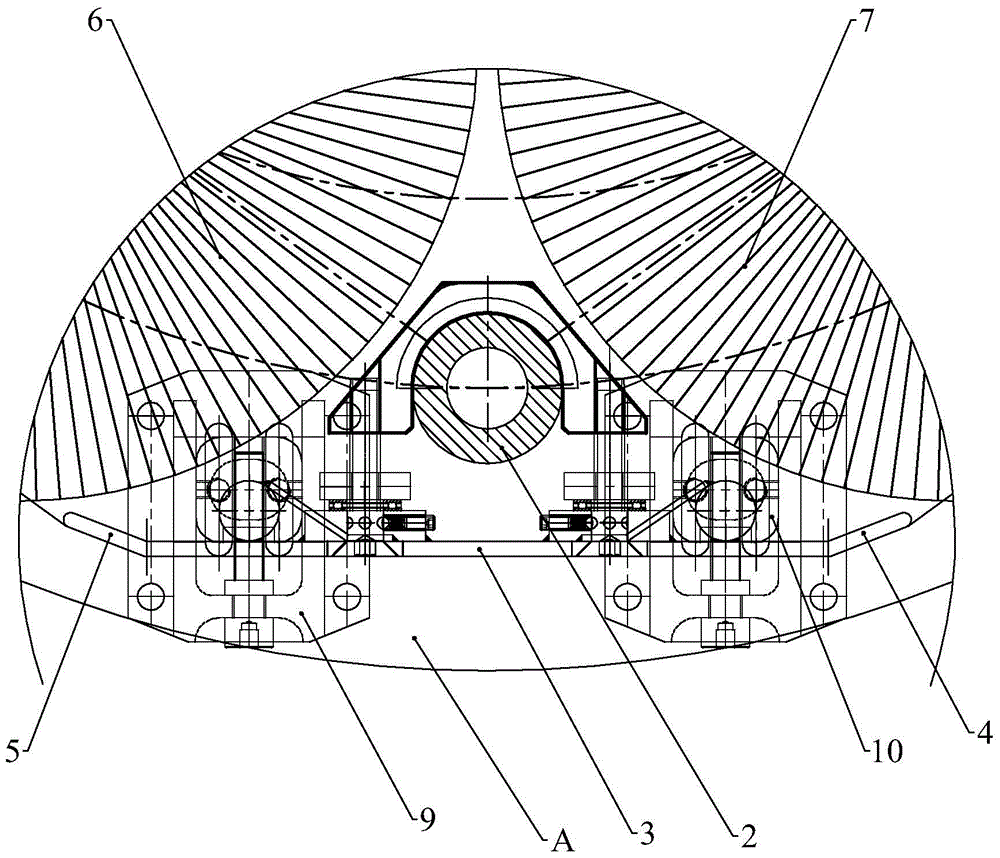

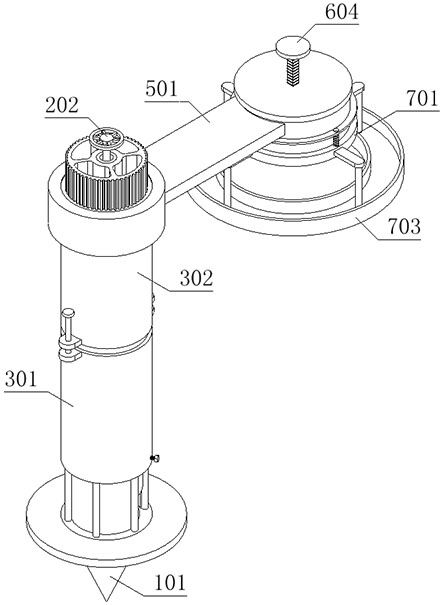

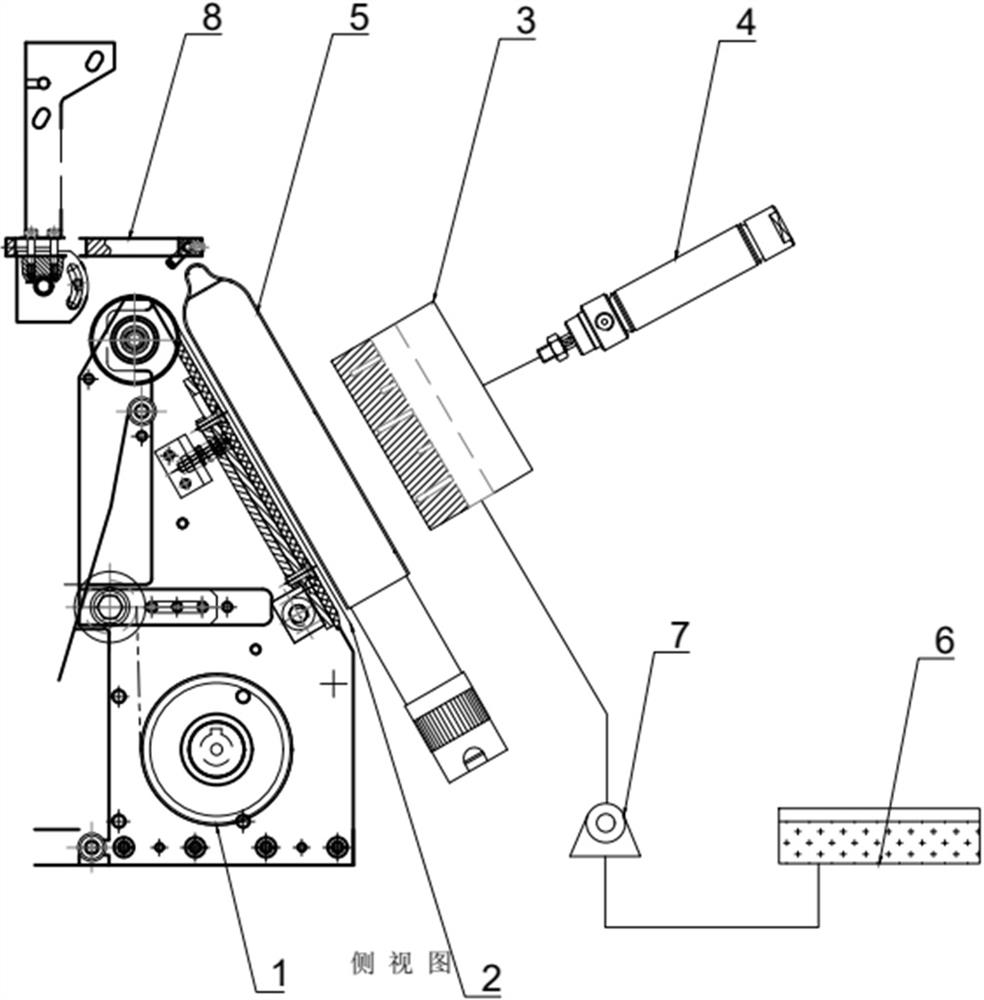

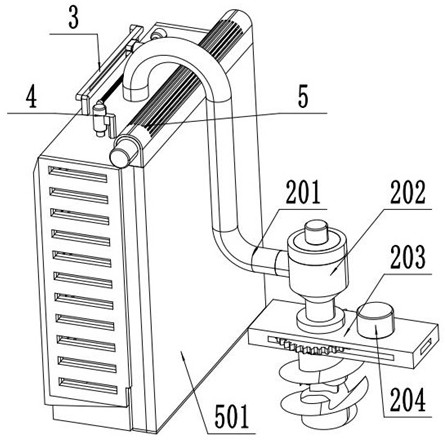

Cantilever wheel belt polishing device with controlled pressure and polishing method

ActiveCN110238729AConstant normal contact pressureControl contact areaOptical surface grinding machinesBelt grinding machinesTarget surfaceContact pressure

The invention provides a cantilever wheel belt polishing device with controlled pressure and a polishing method, belongs to the technical field of ultra-precision processing, and solves the problem that the polishing method in the prior art introduces a certain medium-high frequency error during polishing, so improving the surface precision is difficult, and optical components with large aspect ratio and complex surface cannot be polished effectively, specifically the inner surfaces; meanwhile, the controllable contact pressure polishing device adopts a single contact control method, which cannot effectively polish workpiece with great difference of the target surface. The polishing device provided by the invention comprises a bottom plate, a wheel bar assembly, a drive assembly, a dressing assembly, a polishing belt, a tensioning assembly and a guide idler, is mainly used for ultra-precision machining of optically complex surfaces of hard and brittle materials.

Owner:HARBIN INST OF TECH

Numerical control processing method for corner of groove cavity

InactiveCN102658390AControl contact areaAvoid millingMilling equipment detailsNumerical controlEngineering

The invention discloses a numerical control processing method for a corner of a groove cavity. The method comprises the following steps: firstly, parts of the groove cavity are processed through allowance removal roughing, and allowance for finish is left on the bottom surface and side walls of the groove cavity; secondly, finish machining is carried out on the bottom surface and the side walls of the groove cavity; and finally, when a corner structure of the groove cavity is processed through finish machining, an obvious included angle is formed between a central shaft of a cutter and an axial line of the corner; and the cutter feeds to cut the corner of the groove cavity in the axis direction of the corner, and the track of the cutter is parallel to the axial line of the corner.

Owner:XIAN AIRCRAFT IND GROUP

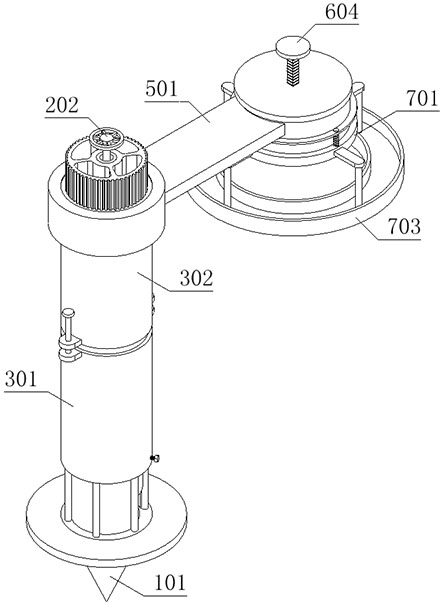

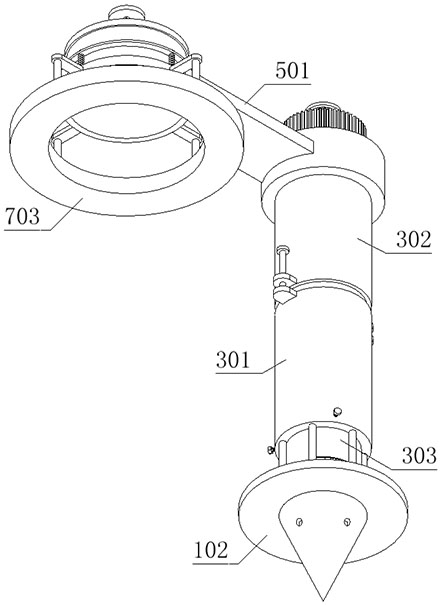

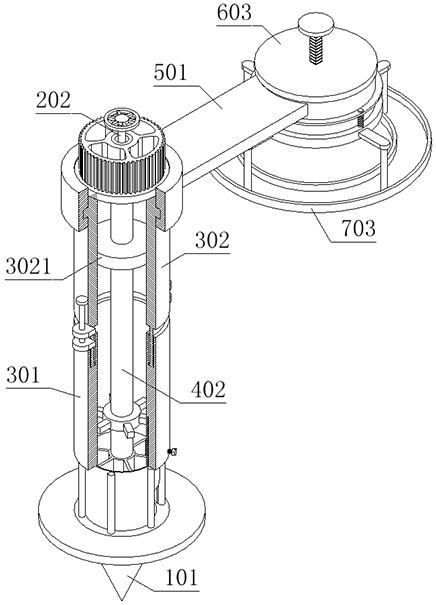

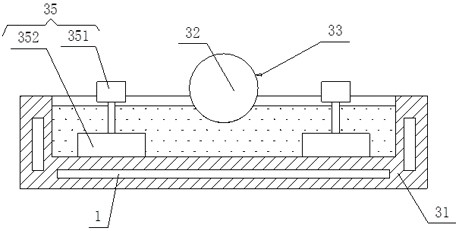

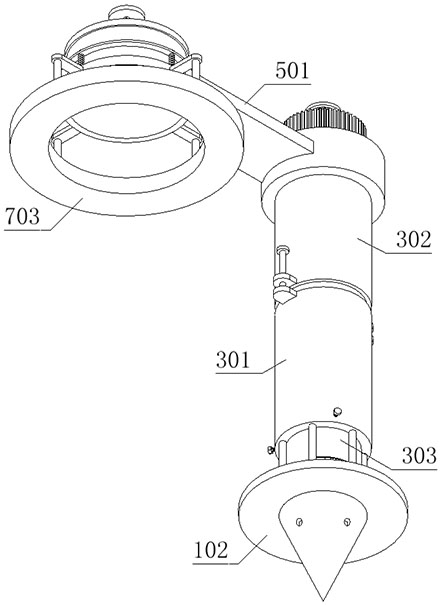

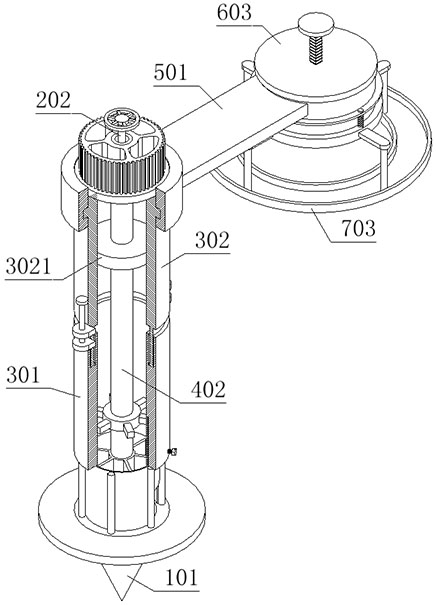

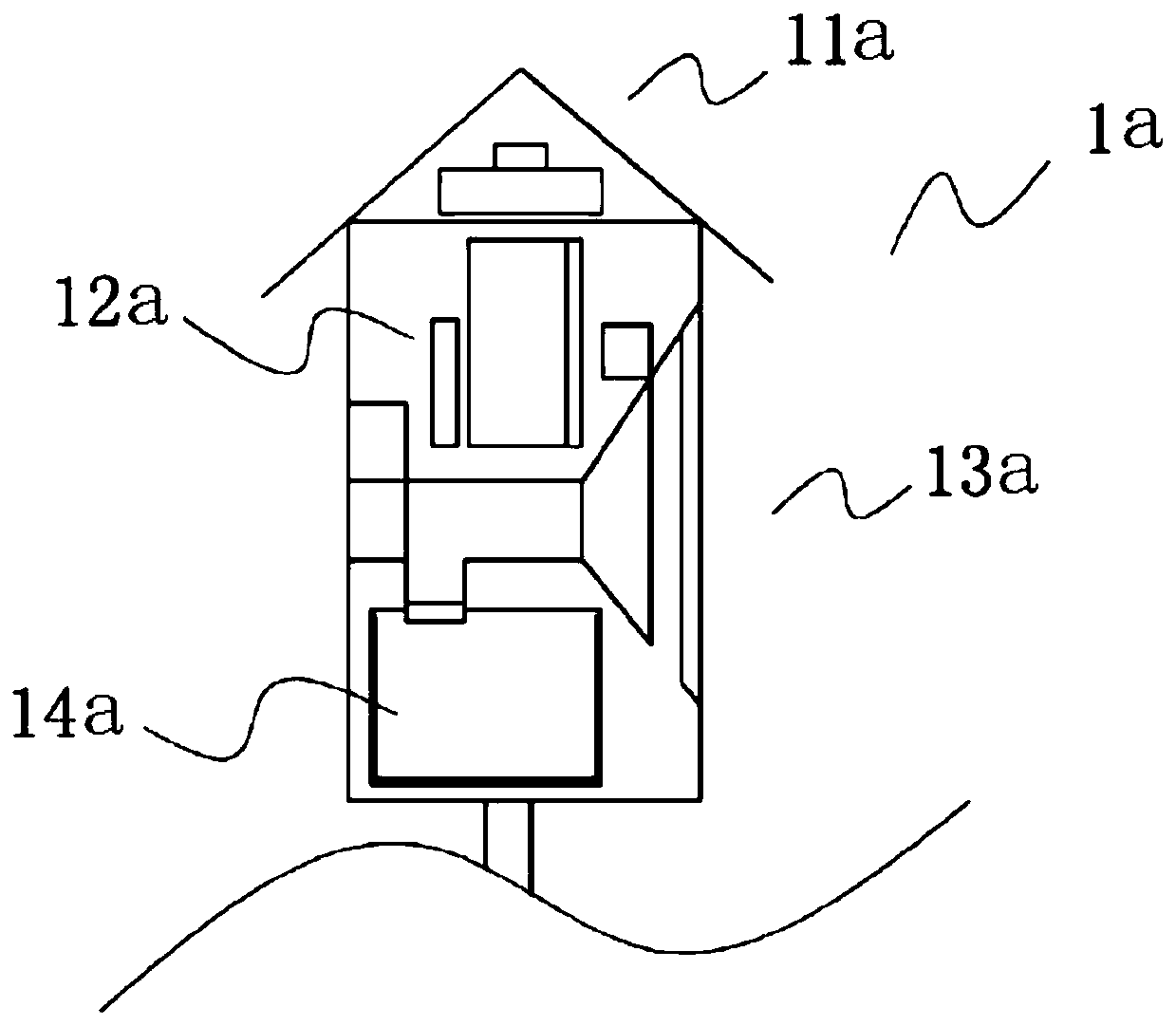

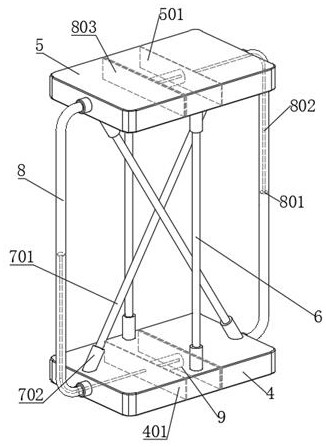

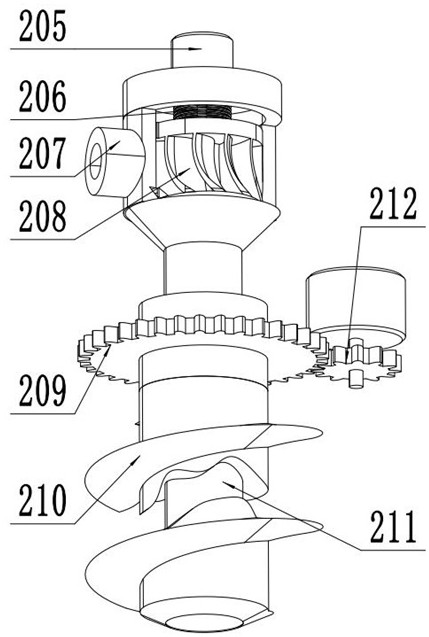

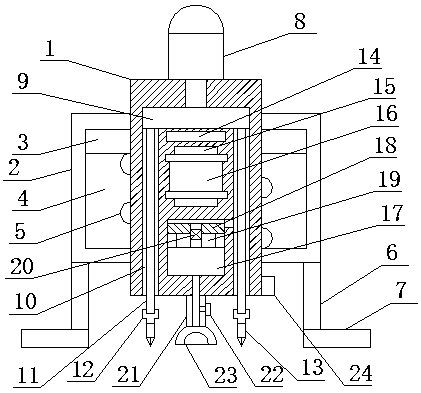

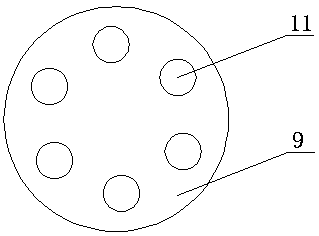

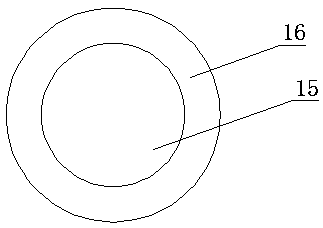

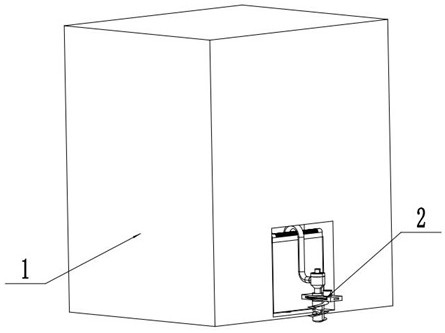

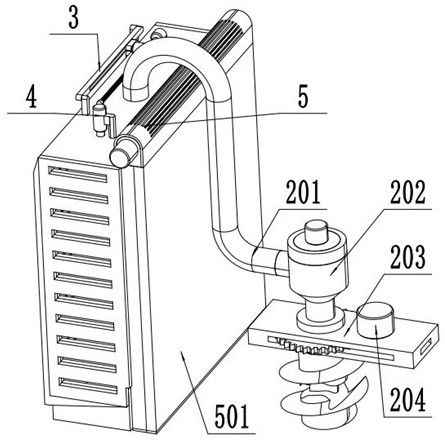

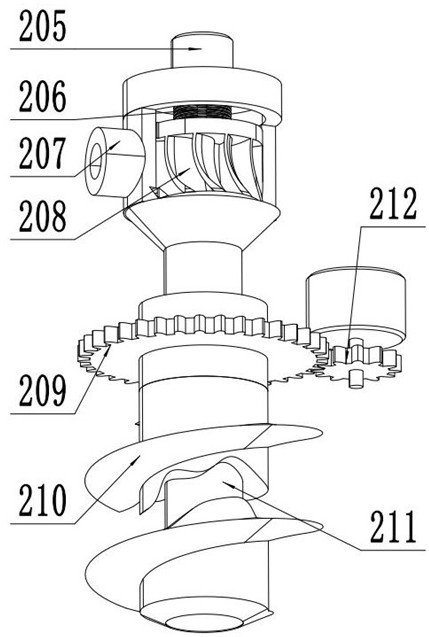

Sewage treatment device adopting microbial technology

ActiveCN113415904AImprove processing qualityImprove delivery accuracyBiological treatment apparatusMicroorganismSewage treatment

The invention provides a sewage treatment device adopting a microbial technology. The sewage treatment device comprises a fixing mechanism; a pushing part is mounted in the fixing mechanism, and an adjusting device is mounted at the top of the fixing mechanism; the driving mechanism is mounted in the adjusting device, a mounting mechanism is mounted on the adjusting device, a storage device is mounted on the right side of the mounting mechanism, and a trigger part is mounted on the storage device. When water waves appear on the surface of a river channel, the sealing frame moves upwards under the impact force of the water waves, so the twelve through holes are separated from the sealing frame, microorganisms in the storage barrel fall into a river channel through the twelve through holes; when water waves are separated from the floating disc, the sealing frame moves downwards under the action of four springs, so intermittent throwing of the microorganisms is realized, full absorption of the river channel is facilitated, and the sewage treatment quality is improved; meanwhile, waste of microorganisms is avoided, and the sewage treatment cost is reduced.

Owner:郯城博化化工科技有限公司

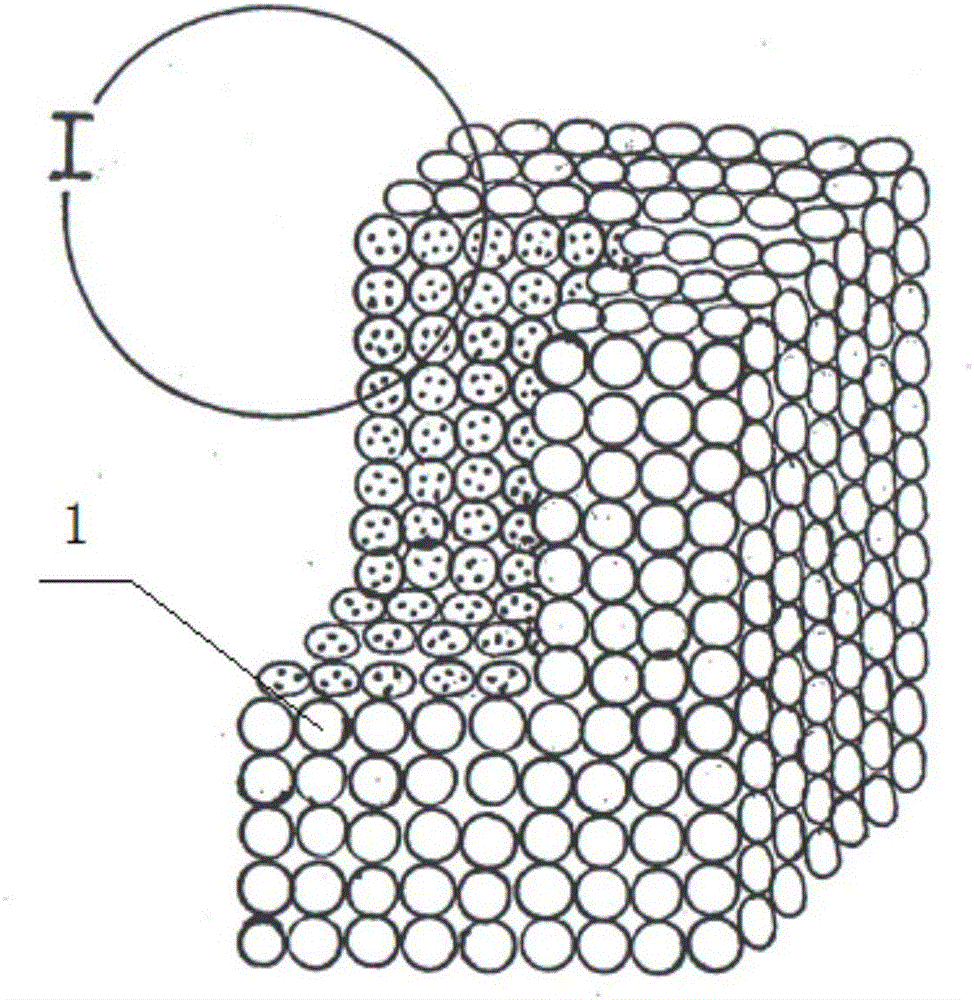

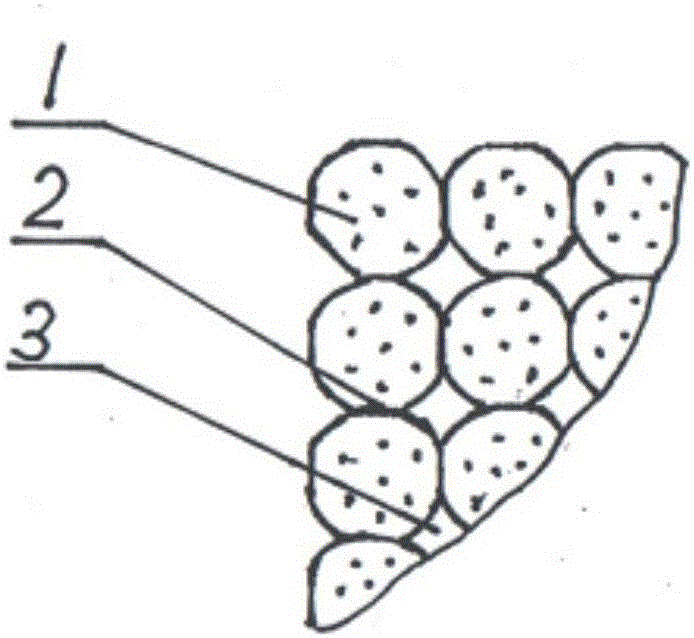

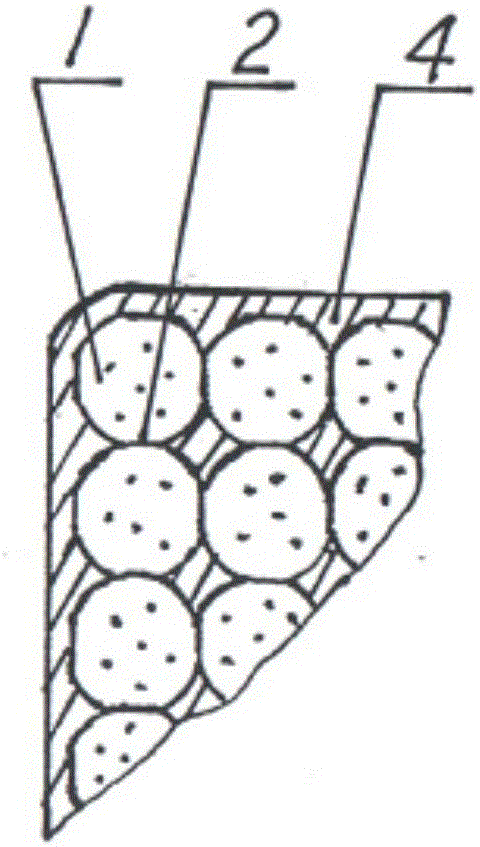

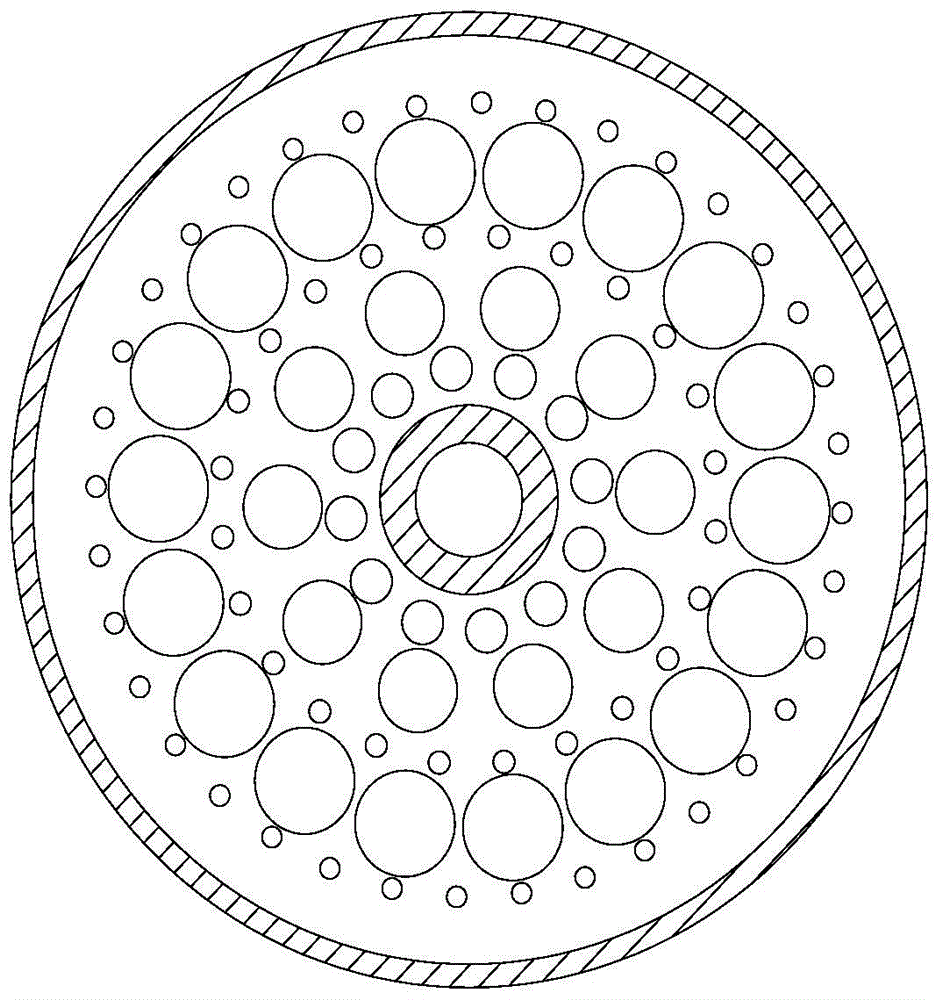

Porous solid material with micro nano-sized circulation pore diameter and preparation method thereof

InactiveCN106086779AControl contact areaGood size consistencyVacuum evaporation coatingSputtering coatingCooking & bakingPrill

The invention discloses a preparation method for a porous solid material with the micro nano-sized circulation pore diameter. The preparation method comprises the following steps that pressure is applied to spherical particles of which the surfaces are coated with binders so that the spherical particles can adhere to one another and be formed, meanwhile, the size of the contact areas between the particles is controlled, or the spherical particles are flat spread in binder thin blocks, then, the binder thin blocks with the spherical particles are inversely placed on a substrate and pressed, the size of the contact areas of the particles and the substrate is controlled, and particle bodies are obtained; then, a material used for a framework is deposited in gaps between the particles through a physical or chemical deposition method, and the framework is generated; and finally, the particles and the binders are removed through a dissolution or baking method, and the porous solid material with the micro nano-sized or nano-sized circulation pore diameter is obtained. The preparation method has the beneficial effects that porous solid materials of different materials can be prepared as required, and the circulation pore diameter of the porous solid material is micro-sized or nano-sized, so that the application range of the porous solid material is wide.

Owner:王华胜

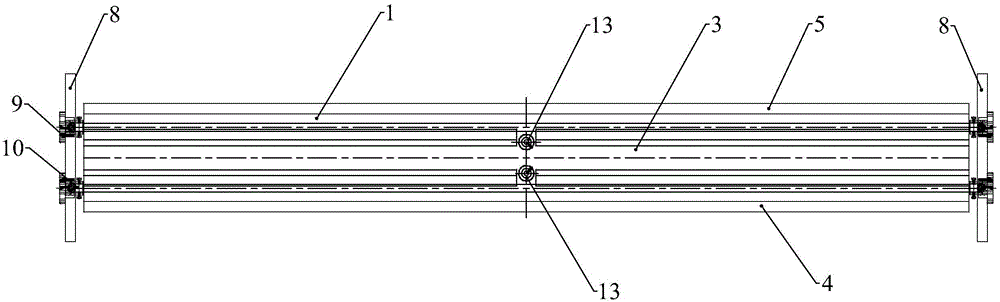

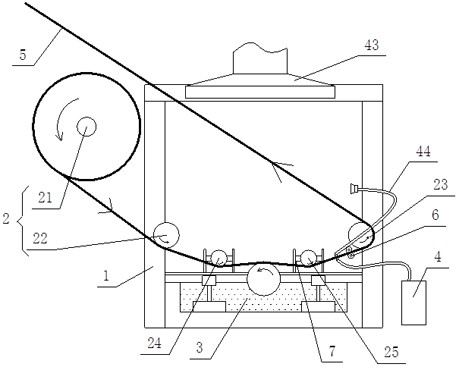

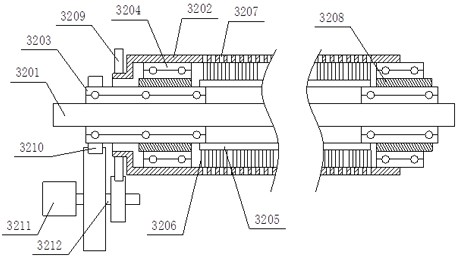

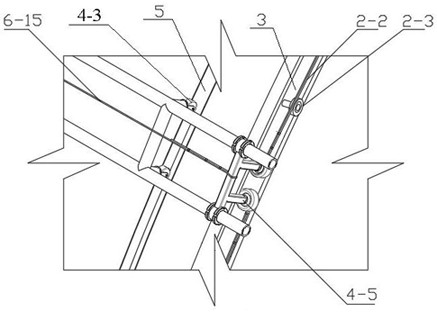

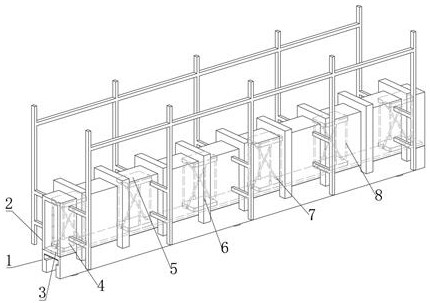

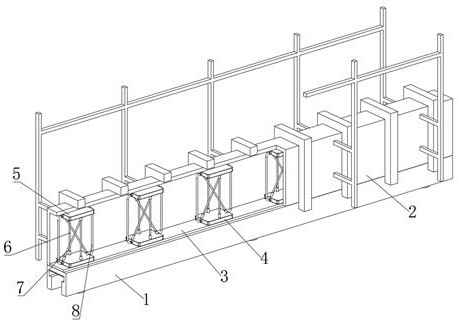

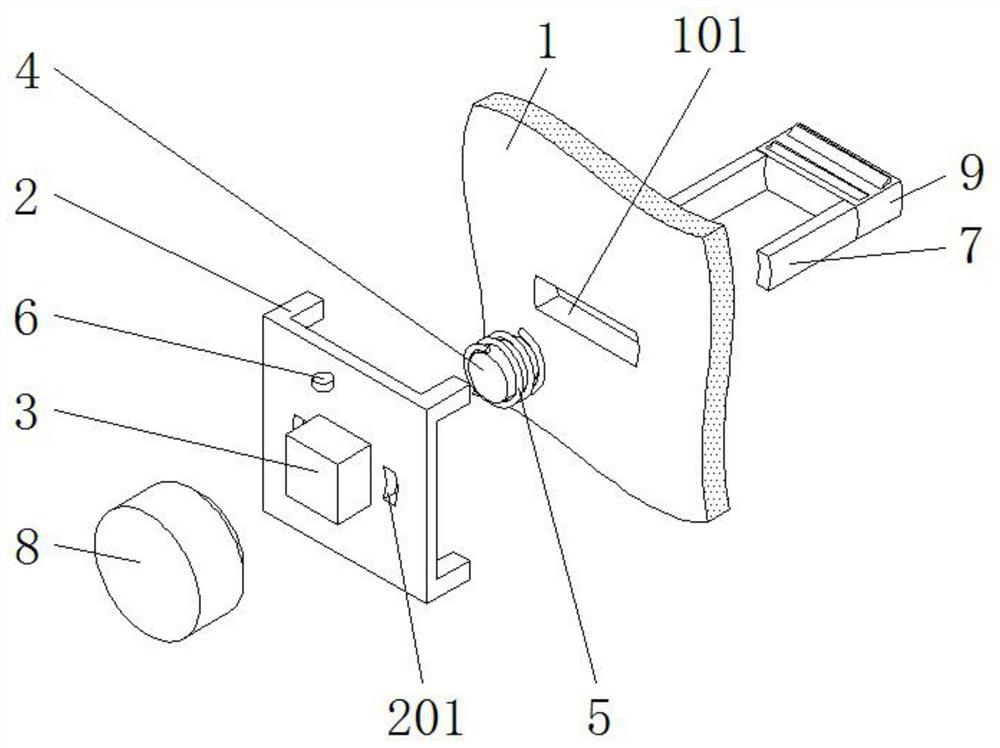

Adjusting plate device for sueding machine brush drum

ActiveCN104911856AGuaranteed parallelismSolve the problem of different diametersRougheningEngineeringMechanical engineering

The invention relates to an adjusting plate device for a sueding machine brush drum, which comprises an adjusting plate, a support rod and support seats at the left and right ends; the adjusting plate has a spreading part, a front guide part and a rear guide part; the front guide part and the rear guide part are both bent inwards, and the bending angles of the front guide part and the rear guide part are respectively consistent with the direction of the tangent line of the adjacent brush roll; the support seat comprises a support disk, an adjusting base plate and an adjusting block; the adjusting base plate is fixed on the support disk, the adjusting block passes through an adjusting bolt and a waist-shaped hole in the vertical direction of the adjusting base plate to form a vertical adjusting mounting structure of the adjusting plate; two bearings at the end part of the adjusting plate are respectively arranged in the waist-shaped holes in the front and back directions of two adjusting blocks by adjusting bolts to form an adjusting plate angle adjusting mounting structure; the adjusting plate is connected with the support rod by adjusting bolts I arranged at the middle front part and the middle rear part to form an adjusting plate bending adjusting mounting structure. The adjusting plate device has the advantages of being capable of adjusting in an omnibearing way, simple in structure and saving in cost.

Owner:GUANGDONG RUITUO ENVIRONMENTAL PROTECTION MACHINERY

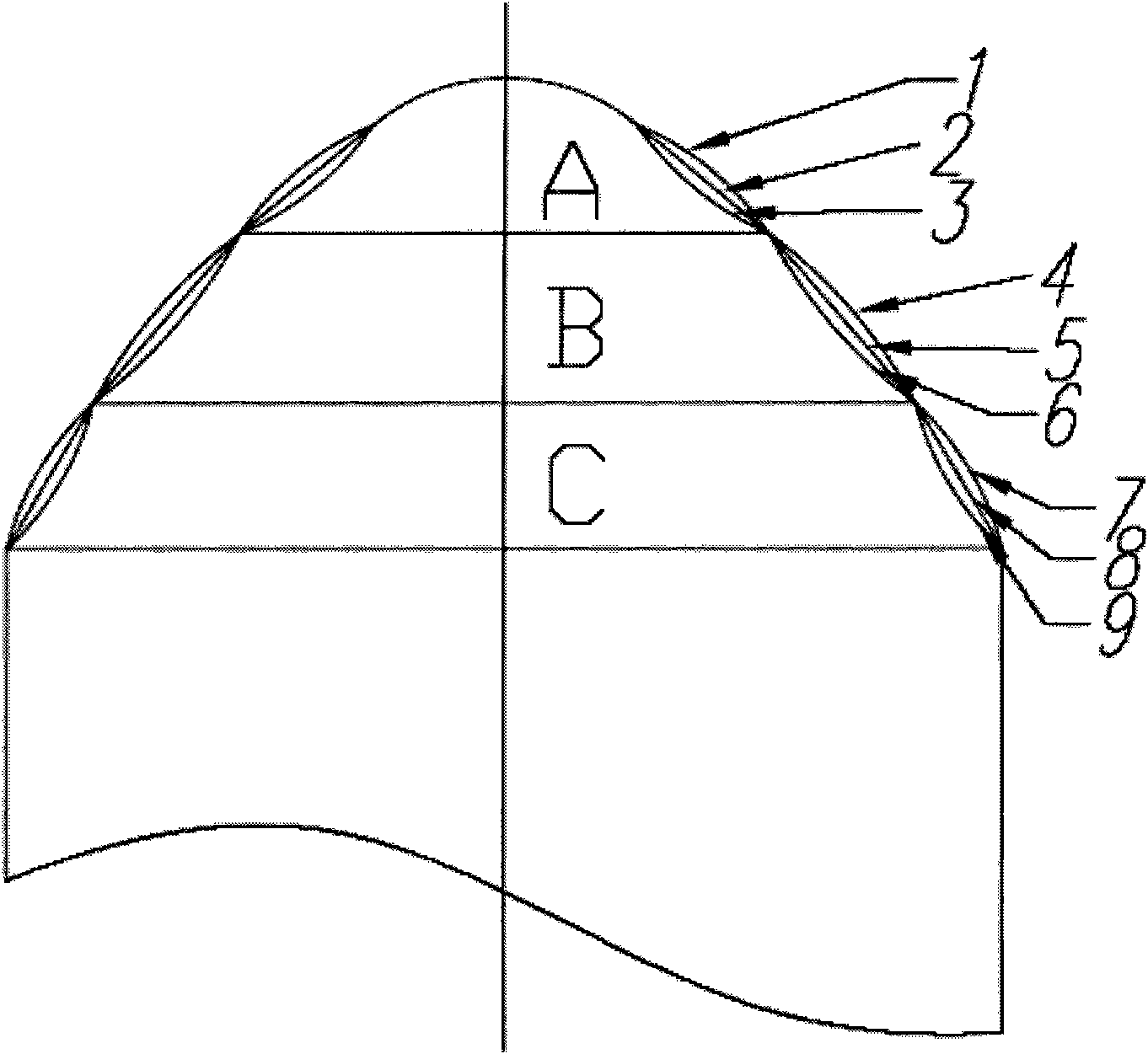

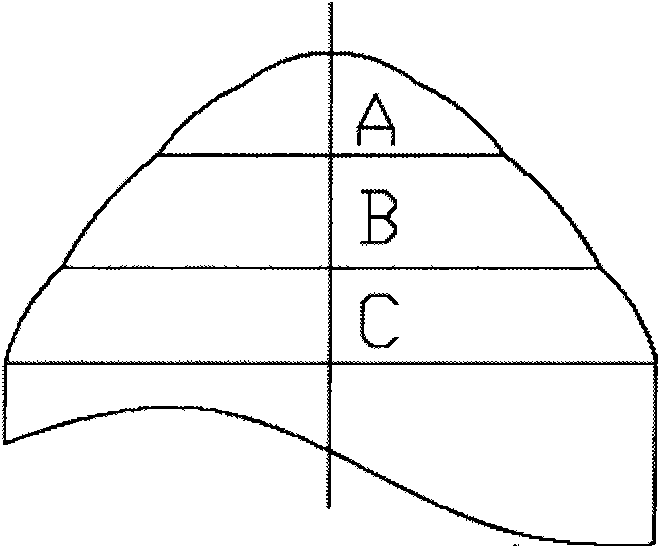

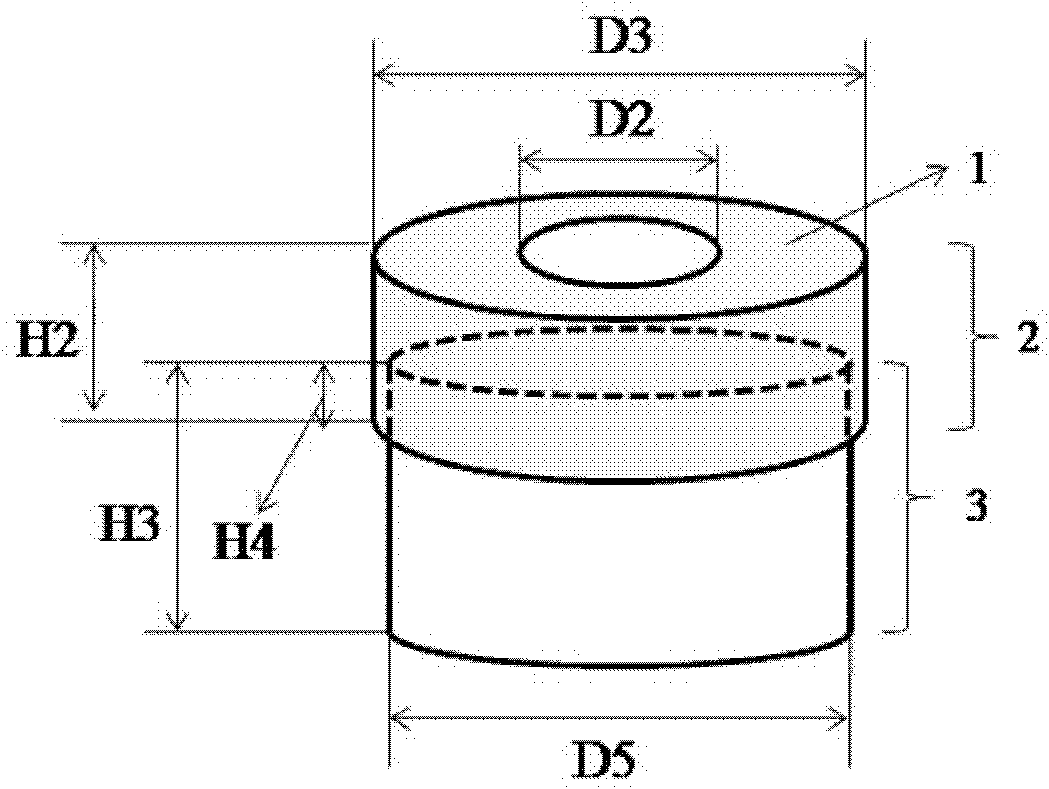

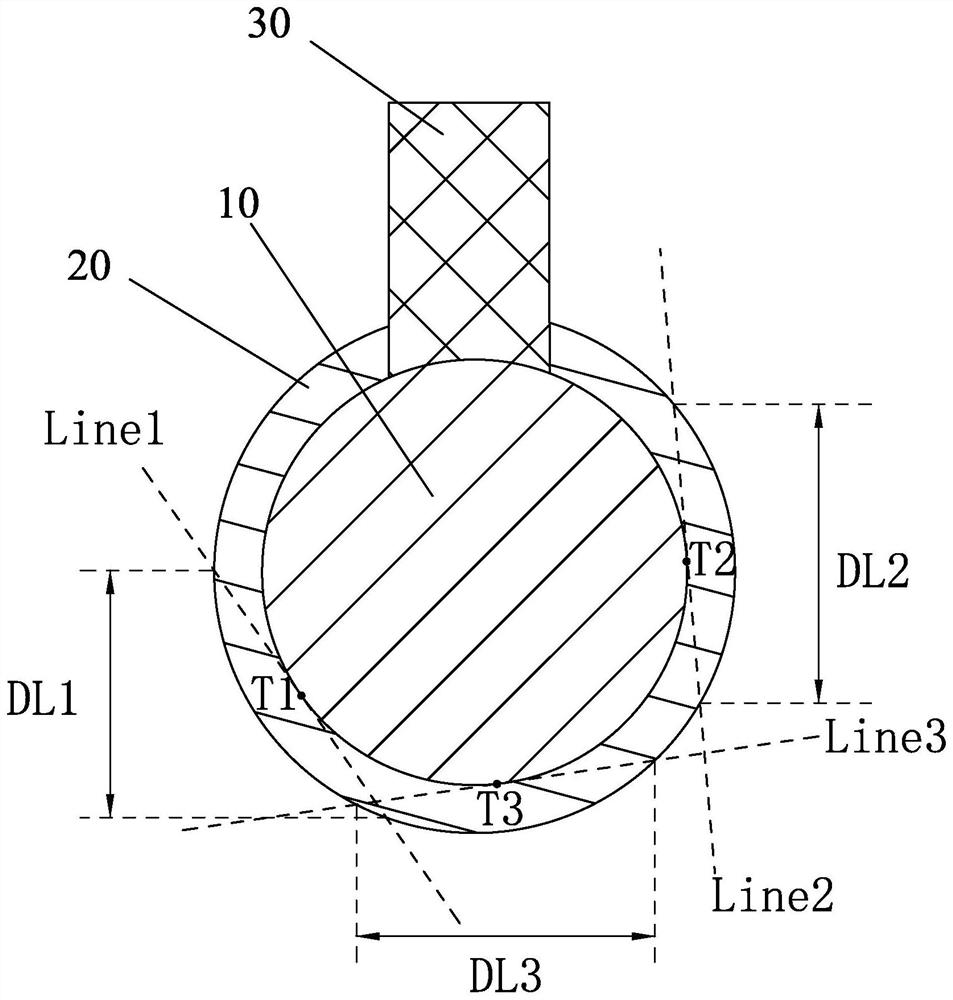

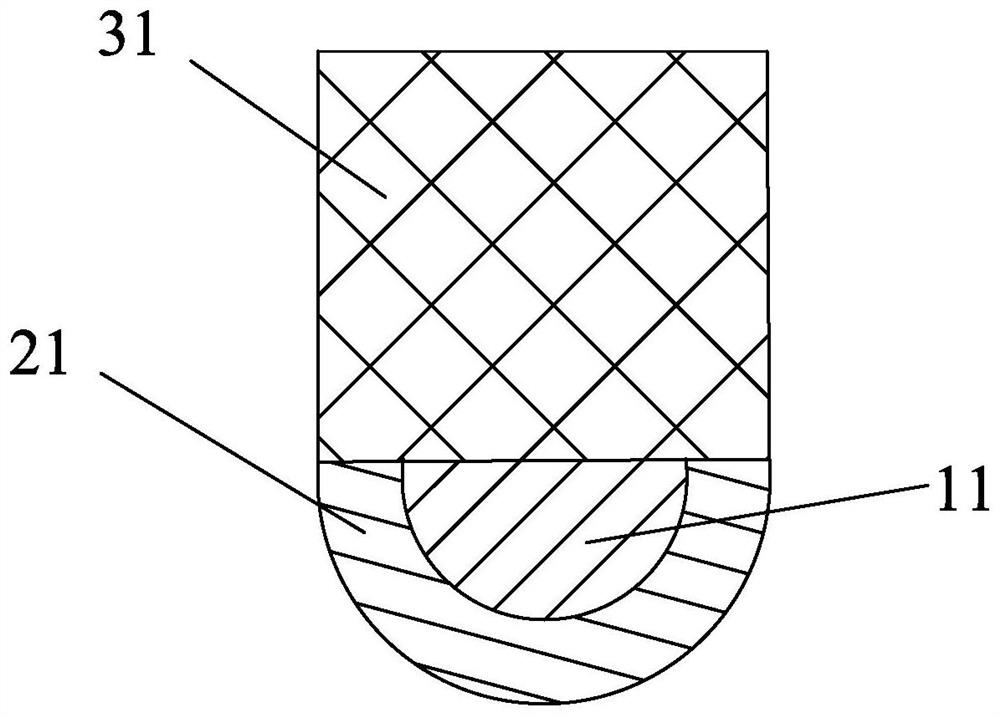

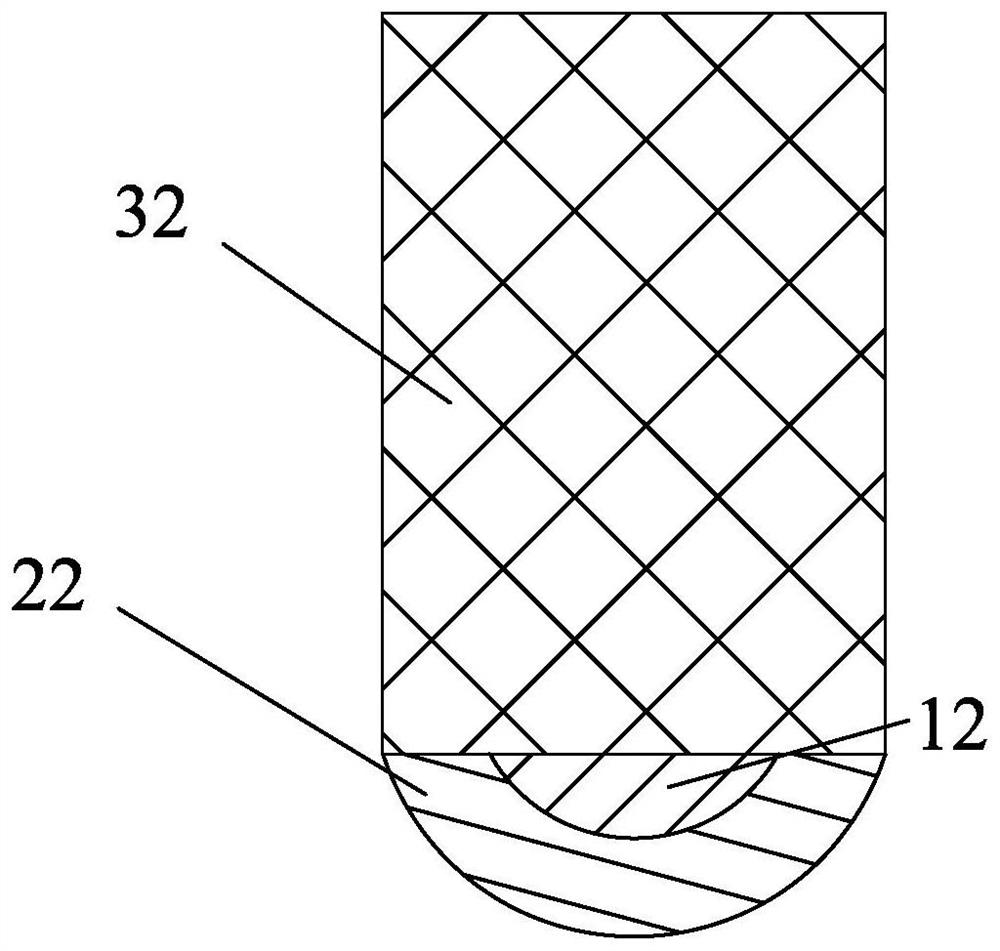

Mine hard alloy tooth

InactiveCN101571032AControl contact areaAvoid the defects of low service lifeDrill bitsAlloyTooth crown

The invention provides a mine hard alloy tooth, which comprises a tooth body and a tooth crown, wherein the tooth crown is arranged on the tooth body and comprises a top and a lateral part, and the outline of the top of the tooth crown has a shape of a convex arc line; the outline of the lateral part of the tooth crown consists of three sections, the first section of the outline has a shape of a straight line, a concave arc line or a convex arc line, the second section of the outline has a shape of a straight line, a concave arc line or a convex arc line, the third section of the outline has a shape of a straight line, a concave arc line or a convex arc line, and the first section of the outline, the second section of the outline and the third section of the outline are in transitional engagement with one another. The multilayer mine hard alloy tooth not only can improve the tooth-revealing height of the hard alloy, but also can conveniently control the contact area of the hard alloy tooth and a broken rock stratum; and the mine hard alloy tooth is widely applied to mines, water wells and geological drilling.

Owner:苏州虹锐管理咨询有限公司

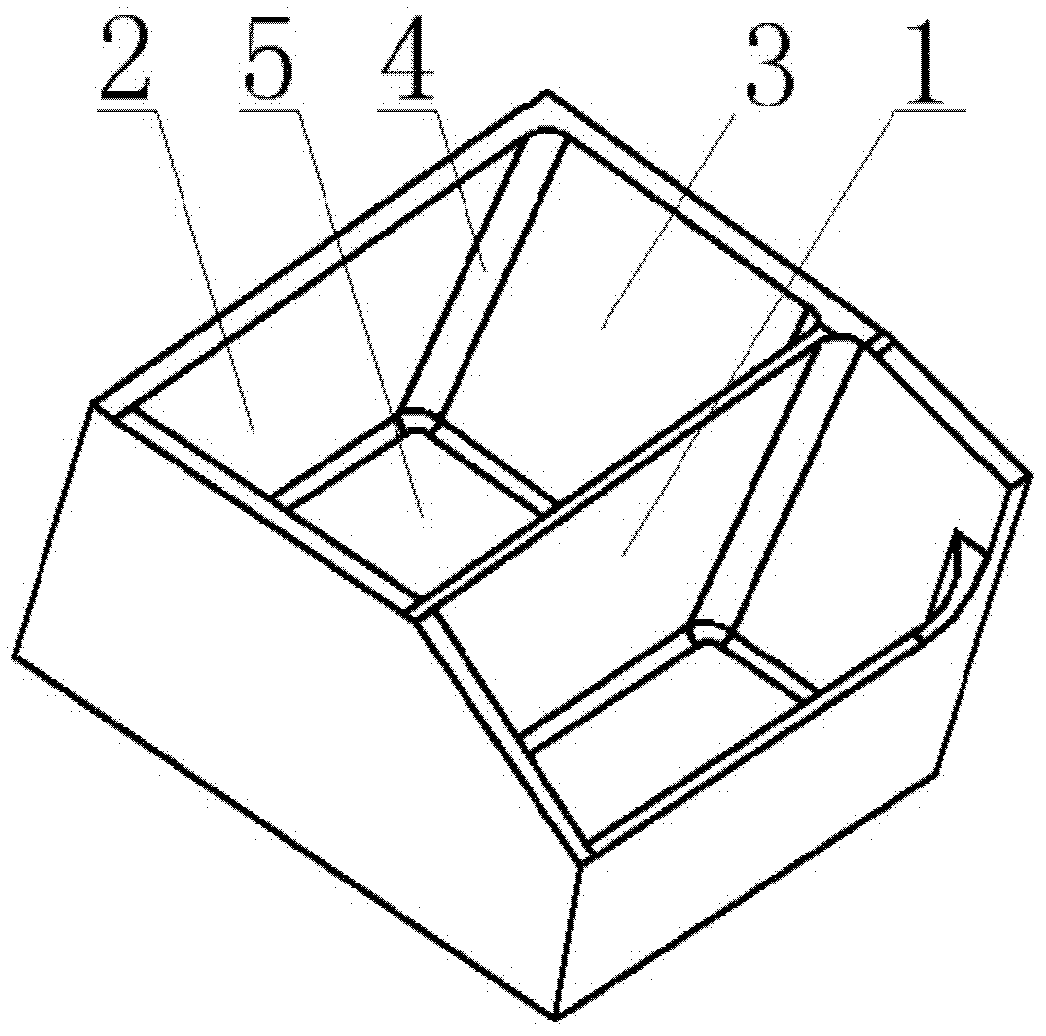

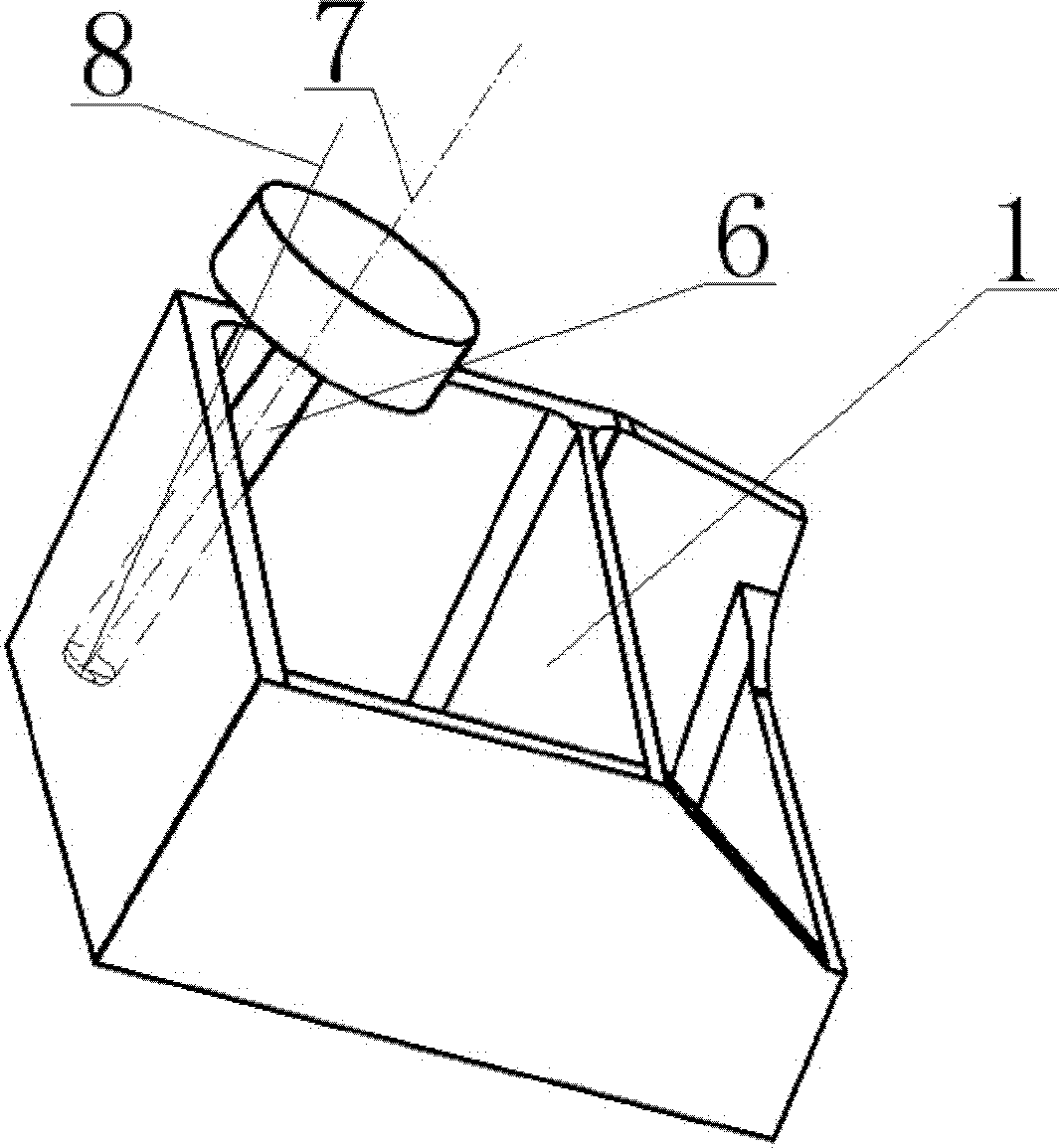

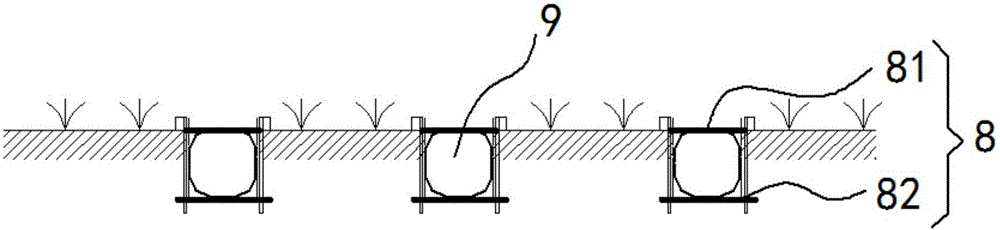

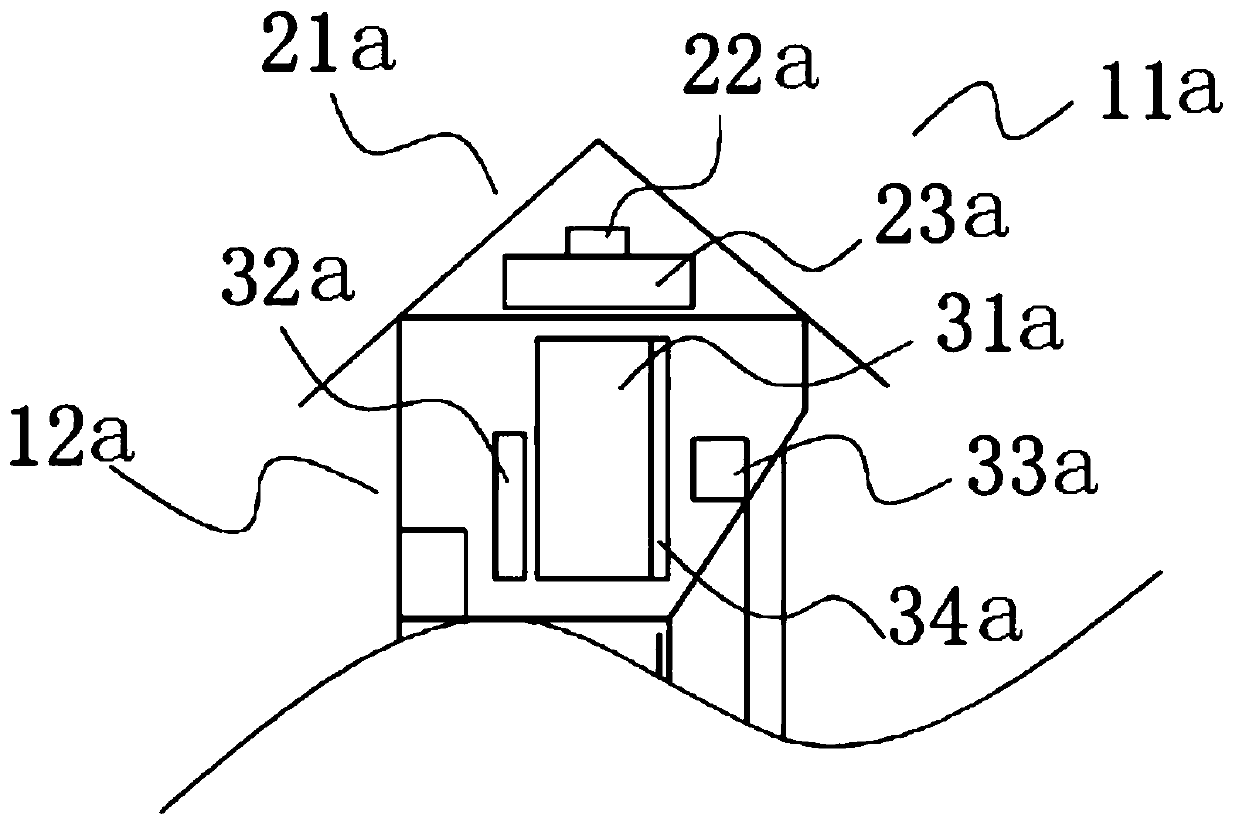

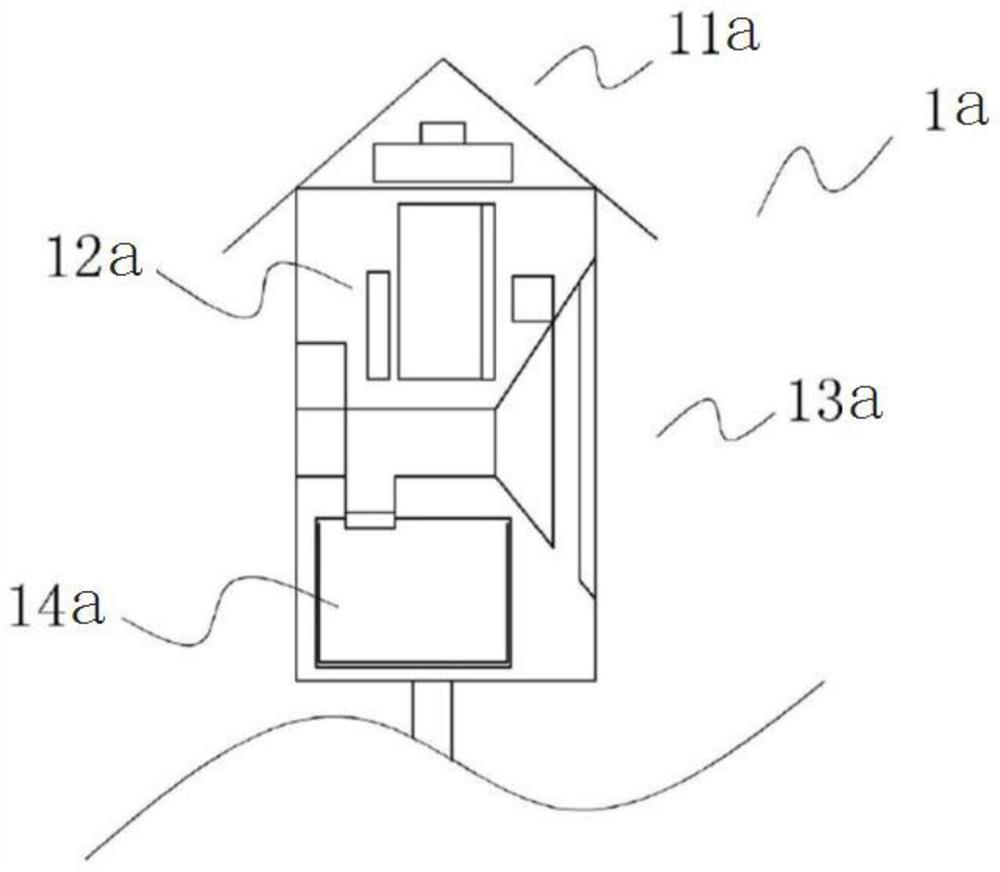

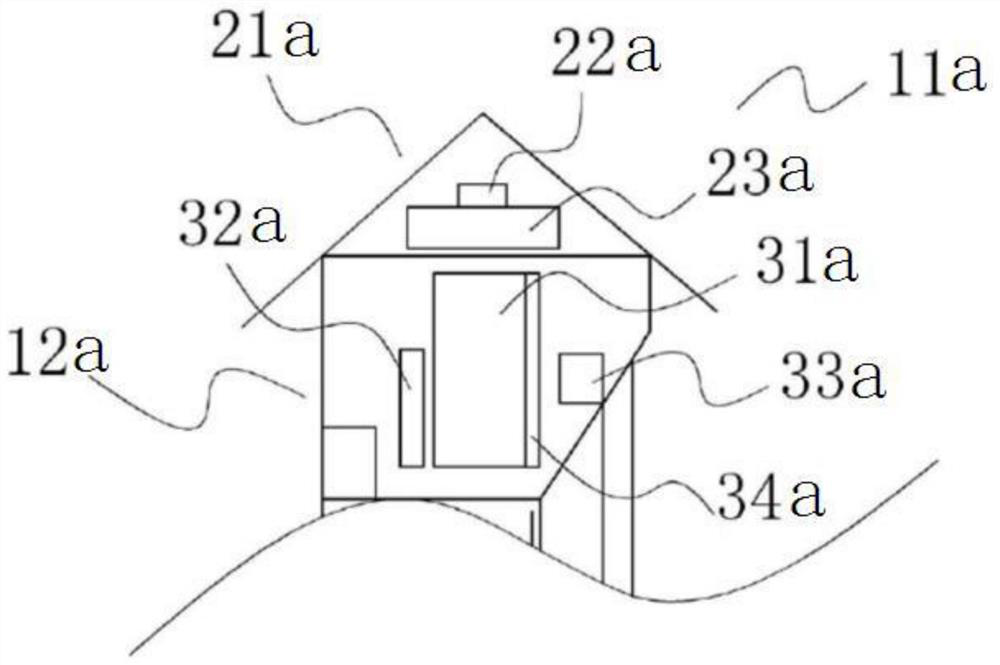

Novel greenhouse with heat storage function

InactiveCN106688707AAffect growthTo achieve the effect of heat preservation and sealingClimate change adaptationRenewable energy machinesGreenhouseUtilization rate

The invention relates to a novel greenhouse with heat storage function, mainly characterized in that an existing greenhouse a heat insulation device and a heat storage device are added to an existing greenhouse and can be combined to provide better input-production ratio for the greenhouse. The novel greenhouse has the advantages that the heat insulation device arranged inside the greenhouse can provide enhanced heat insulation for the greenhouse and higher temperature for a crop planting area; a heat storage system arranged in the greenhouse can collect solar energy and release it in the greenhouse slowly, so that the energy utilization rate is higher and the yield of indoor crops is increased.

Owner:邓新福

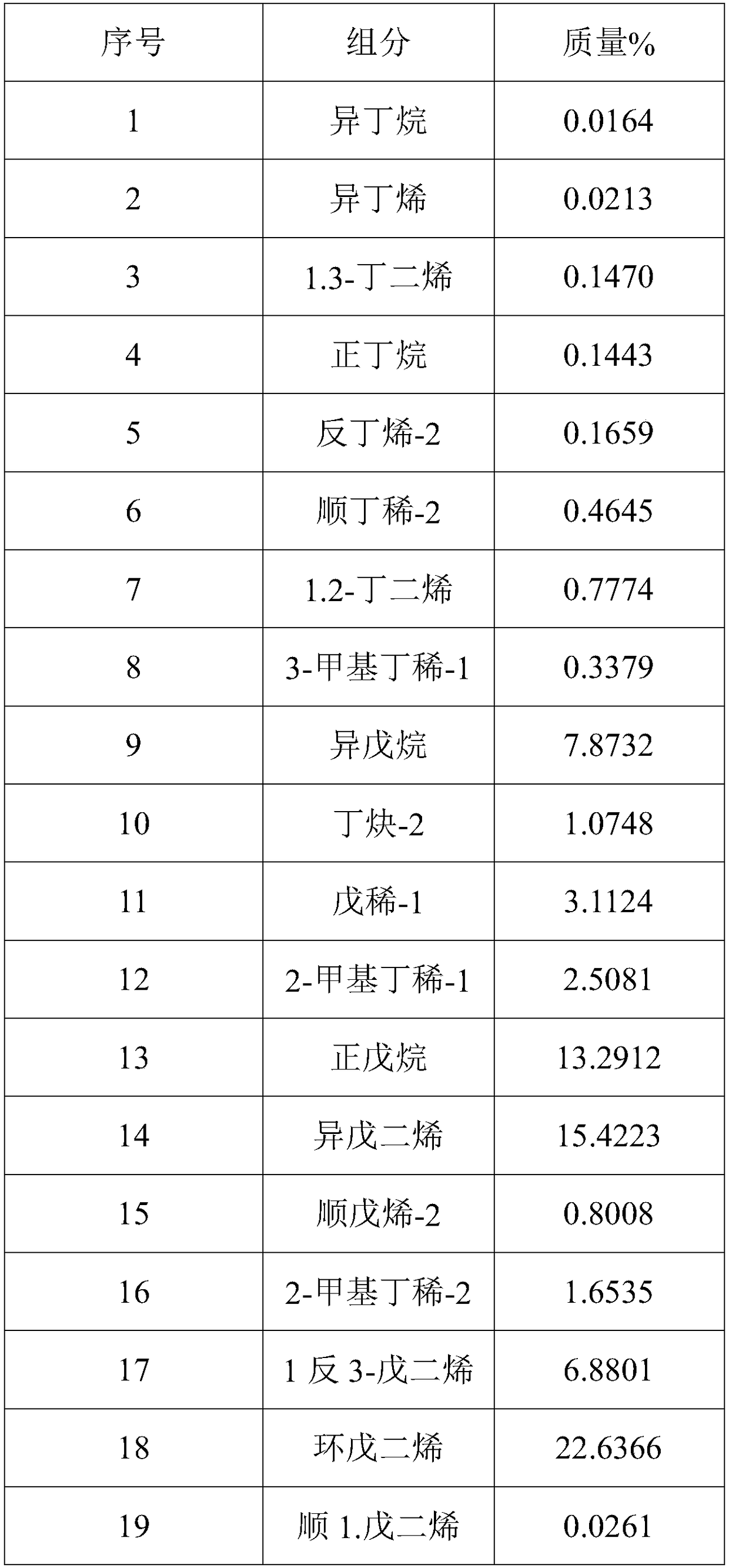

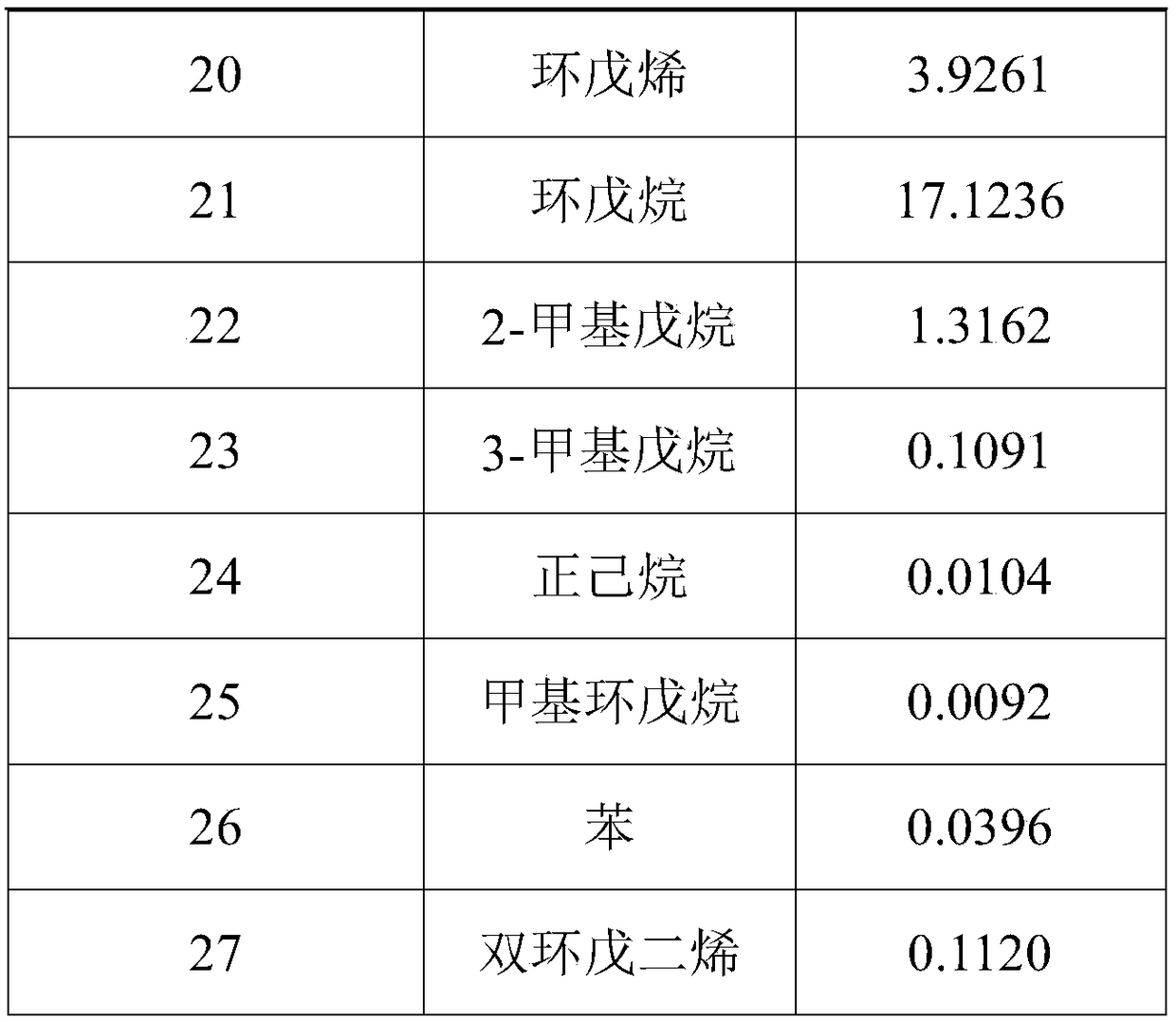

Method for selectively hydrogenating carbon-4 and carbon-5

InactiveCN109438160AControl contact areaConsumption is difficult to controlHydrocarbon by hydrogenationCatalystsHydrogenContact time

The invention belongs to the technical field of light petroleum hydrogenation, and particularly relates to a method for selectively hydrogenating carbon-4 and carbon-5 to convert the carbon-4 and thecarbon-5 into monoolefine. The method for selectively hydrogenating the carbon-4 and the carbon-5 includes that to-be-hydrogenated materials are fed into reactors in feeding modes from bottom to top,selective hydrogenation catalysts are loaded in the reactors, the to-be-hydrogenated materials include C4-C6 diene and alkyne, the content of the carbon-4 is 30%-70%, and the content of the carbon-5 is lower than or equal to 85%; the reactors are simultaneously filled with hydrogen, the temperatures of material inlets of the reactors are 45-60 DEG C, the reaction temperatures are 95-120 DEG C, thereaction pressures are 1.8-2.0 MPa, the reflux ratios are 0, and the differential pressures are 0.02-0.025 MPa when the heights of the catalysts are 1.8 m; the contact time of the to-be-hydrogenatedmaterials and the selective hydrogenation catalysts is longer than or equal to 15 min, reaction products are cooled and then are fed into gas-liquid separation tanks, and separation treatment is carried out.

Owner:濮阳市联众兴业化工有限公司

Coating machine for reverse kiss coating

ActiveCN114798301AControl thicknessGuaranteed coating effectPretreated surfacesCoatingsEngineeringMechanical engineering

The invention discloses a coating machine for reverse kiss coating, which comprises a rack, a cloth releasing device, a gluing device, a drying device and a mesh cloth, the cloth releasing device is arranged in the middle of the rack, the cloth releasing device comprises a cloth winding roller, a first positioning roller, a second positioning roller, a first guide roller and a second guide roller, the cloth winding roller is arranged on one side of the rack, and the first guide roller is arranged on the other side of the rack. A first positioning roller and a second positioning roller which are horizontally arranged are arranged on the machine frame on one side of the cloth winding roller, a first guide roller and a second guide roller are arranged between the first positioning roller and the second positioning roller, a gluing device is installed on the machine frame below the first guide roller and the second guide roller, and a drying device is arranged on the machine frame above the first guide roller and the second guide roller. The screen cloth is installed on the cloth winding roller and wound around the first positioning roller, the first guide roller, the second guide roller and the second positioning roller, and the first guide roller and the second guide roller drive the screen cloth to be connected with the gluing device in an abutting mode. The first guide roller and the second guide roller can move towards the gluing device, the coating thickness can be conveniently controlled, and the coating effect is guaranteed.

Owner:CHENGDU XINGHENGTAI PRINTING

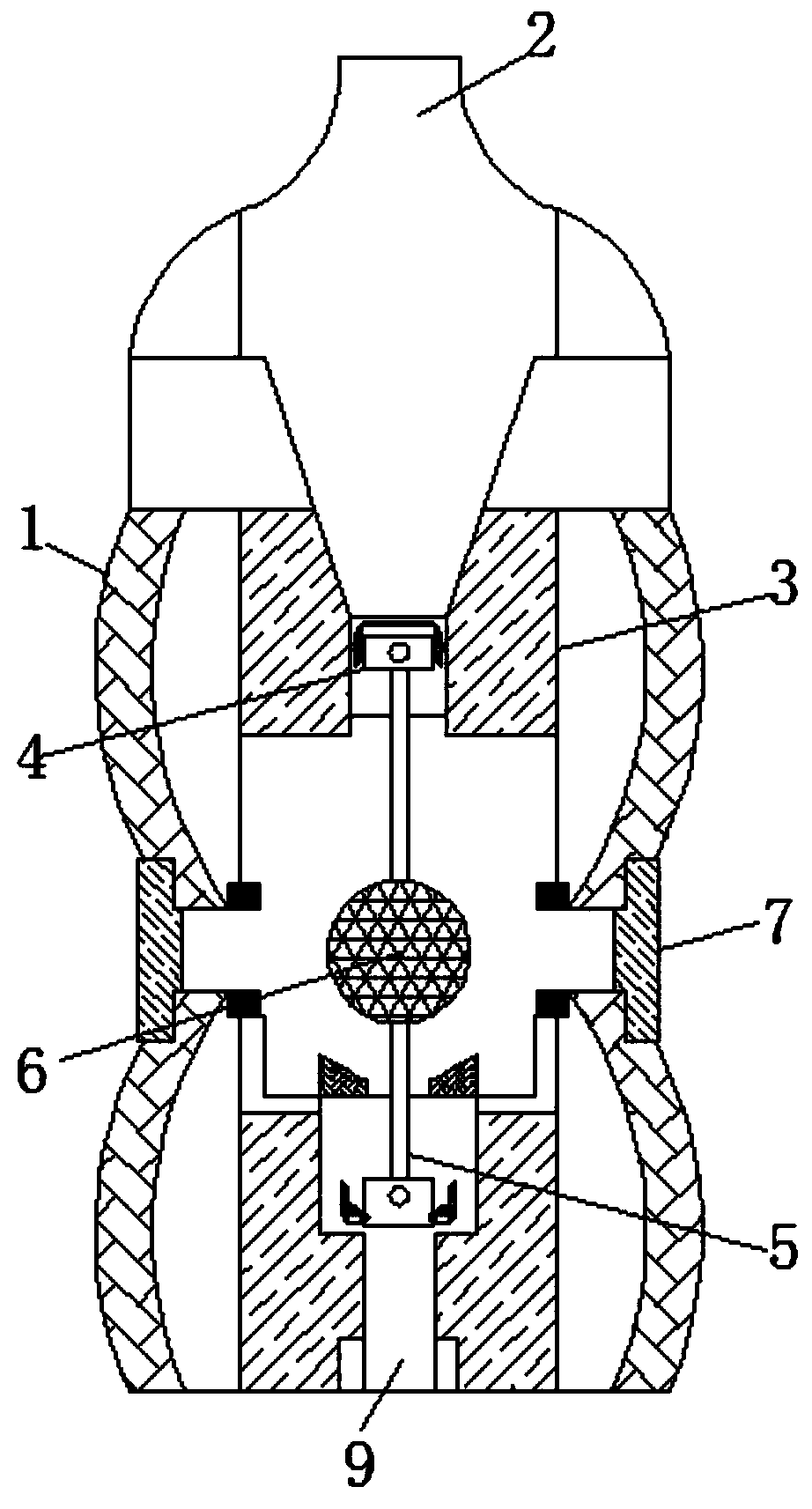

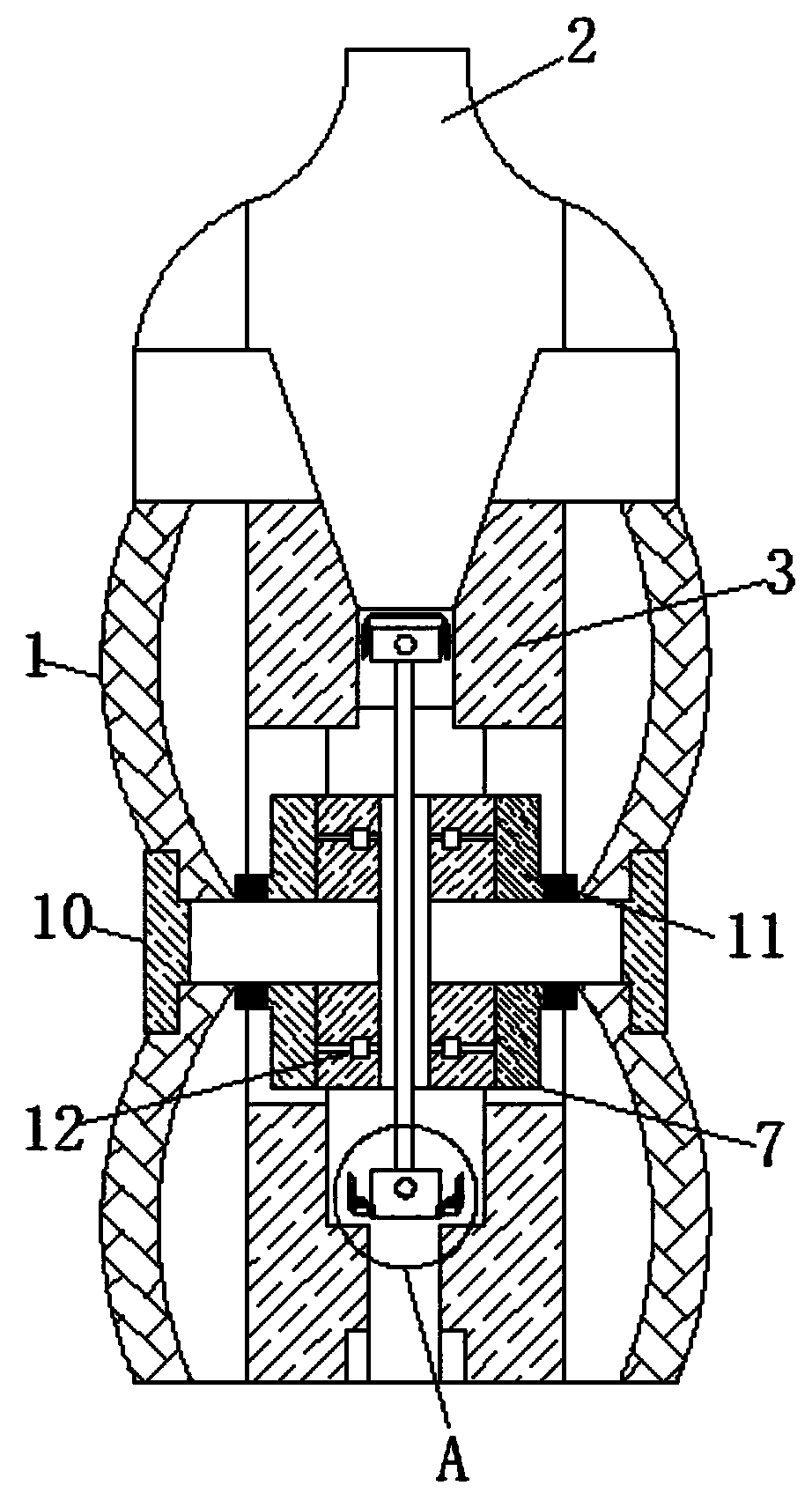

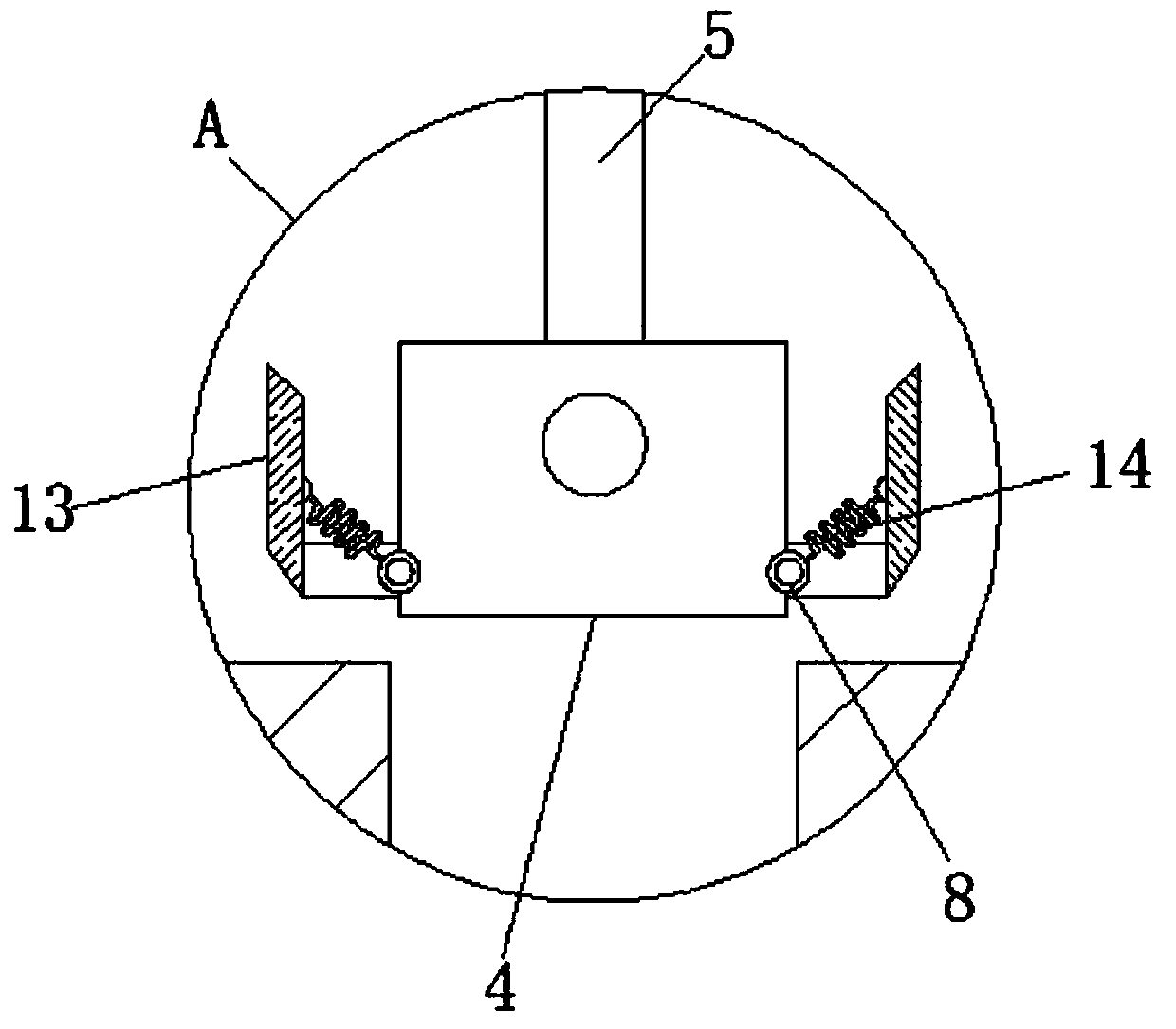

Boiler exhaust valve capable of reducing liquid sloshing by utilizing air elasticity

InactiveCN110805700AEliminate vibrationControl exhaust speedEqualizing valvesSafety valvesExhaust valveEngineering

The invention relates to the technical field of boiler exhaust valves, and discloses a boiler exhaust valve capable of reducing liquid sloshing by utilizing air elasticity. The boiler exhaust valve comprises a valve body, wherein a drain opening is formed in the top of the valve body, retaining blocks are fixedly connected to the interior of the valve body, a piston is movably connected to the surfaces of the retaining blocks, a blocking ball is fixedly connected to one sides, away from the retaining blocks, of the piston through a piston rod, the surface of the blocking ball is movably connected with a compression mechanism, the lower portion of the blocking ball is movably connected with a clamping mechanism, and the lower portion of the clamping mechanism is slidably connected with an inflow opening. According to the boiler exhaust valve, gas is discharged from an exhaust groove in the compression mechanism, at the same time, the condition of liquid oscillation inside the valve bodyis observed, the contact condition of air holes and the blocking ball is controlled by rotating a rotating rod, and the speed of the exhaust gas is indirectly controlled; after the part of air holesare blocked, the vapor outflow speed is slowed to cause the pressure inside the valve body to become large, and the oscillation liquid causes water molecules inside the valve body to be pressed underthe action of high pressure, so that the effect of eliminating the liquid oscillation is achieved.

Owner:楼奇杰

An adjustment plate device for the brush drum of a sanding machine

The invention relates to an adjusting plate device for a sueding machine brush drum, which comprises an adjusting plate, a support rod and support seats at the left and right ends; the adjusting plate has a spreading part, a front guide part and a rear guide part; the front guide part and the rear guide part are both bent inwards, and the bending angles of the front guide part and the rear guide part are respectively consistent with the direction of the tangent line of the adjacent brush roll; the support seat comprises a support disk, an adjusting base plate and an adjusting block; the adjusting base plate is fixed on the support disk, the adjusting block passes through an adjusting bolt and a waist-shaped hole in the vertical direction of the adjusting base plate to form a vertical adjusting mounting structure of the adjusting plate; two bearings at the end part of the adjusting plate are respectively arranged in the waist-shaped holes in the front and back directions of two adjusting blocks by adjusting bolts to form an adjusting plate angle adjusting mounting structure; the adjusting plate is connected with the support rod by adjusting bolts I arranged at the middle front part and the middle rear part to form an adjusting plate bending adjusting mounting structure. The adjusting plate device has the advantages of being capable of adjusting in an omnibearing way, simple in structure and saving in cost.

Owner:GUANGDONG RUITUO ENVIRONMENTAL PROTECTION MACHINERY

Sewage treatment plant using microbial technology

ActiveCN113415904BImprove processing qualityImprove delivery accuracyBiological treatment apparatusMicroorganismWastewater

The invention provides a sewage treatment device using microbial technology, including a fixing mechanism; a pushing part is installed inside the fixing mechanism, and an adjusting device is installed on the top of the fixing mechanism; the driving mechanism is installed inside the adjusting device, and the adjusting device An installation mechanism is installed on the top of the installation mechanism, and a storage device is installed on the right side of the installation mechanism, and a trigger part is installed on the storage device. When water waves appear on the surface of the river, the sealing frame is moved upward under the impact of the water waves in the present invention, so that The twelve through holes are separated from the sealing frame, and the microorganisms inside the storage cylinder fall into the river channel through the twelve through holes. When the water wave is separated from the floating plate, the sealing frame moves downward under the action of four springs, and then The intermittent delivery of microorganisms is realized, which is conducive to the full absorption of the river, improves the quality of sewage treatment, avoids the waste of microorganisms, and reduces the cost of sewage treatment.

Owner:郯城博化化工科技有限公司

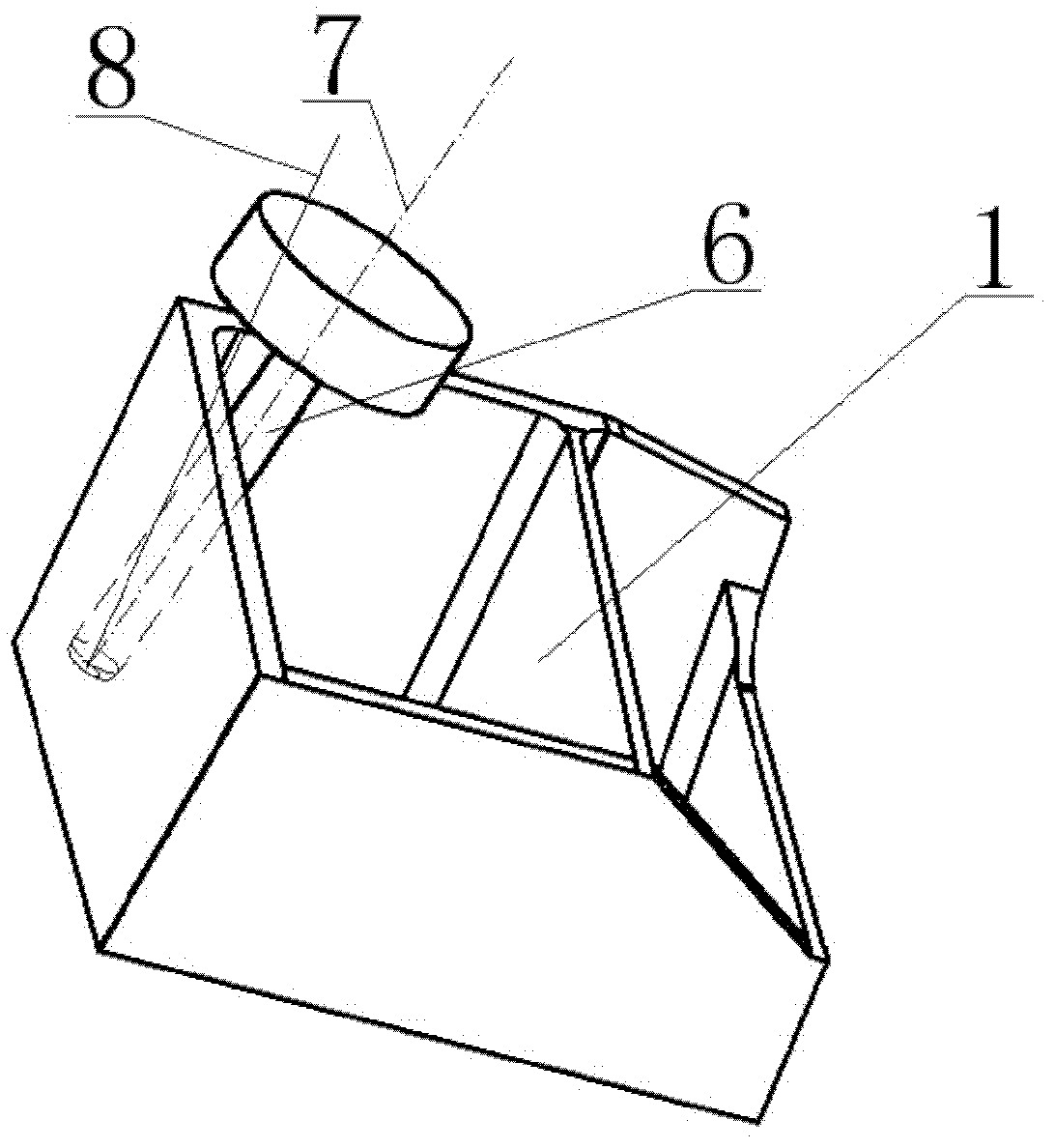

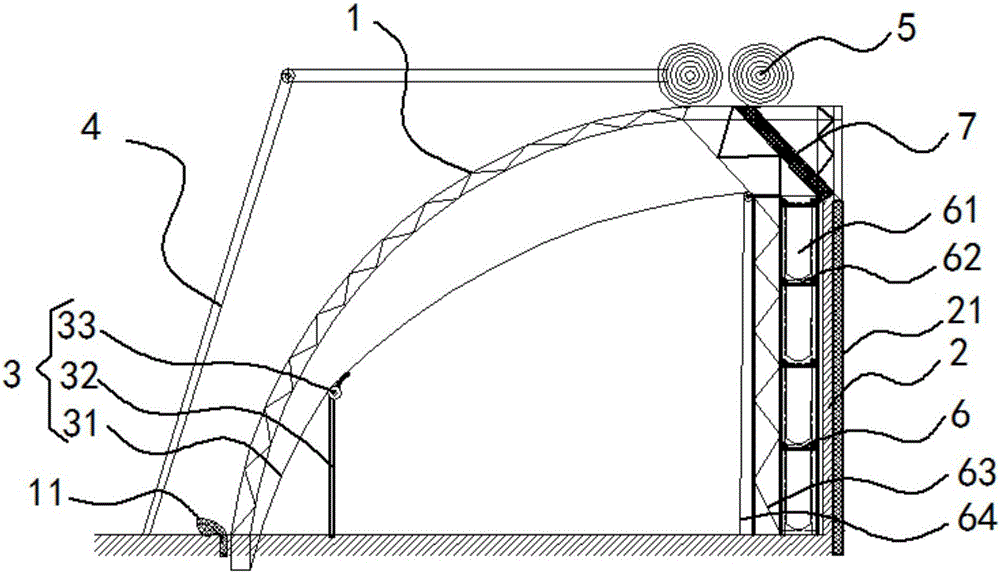

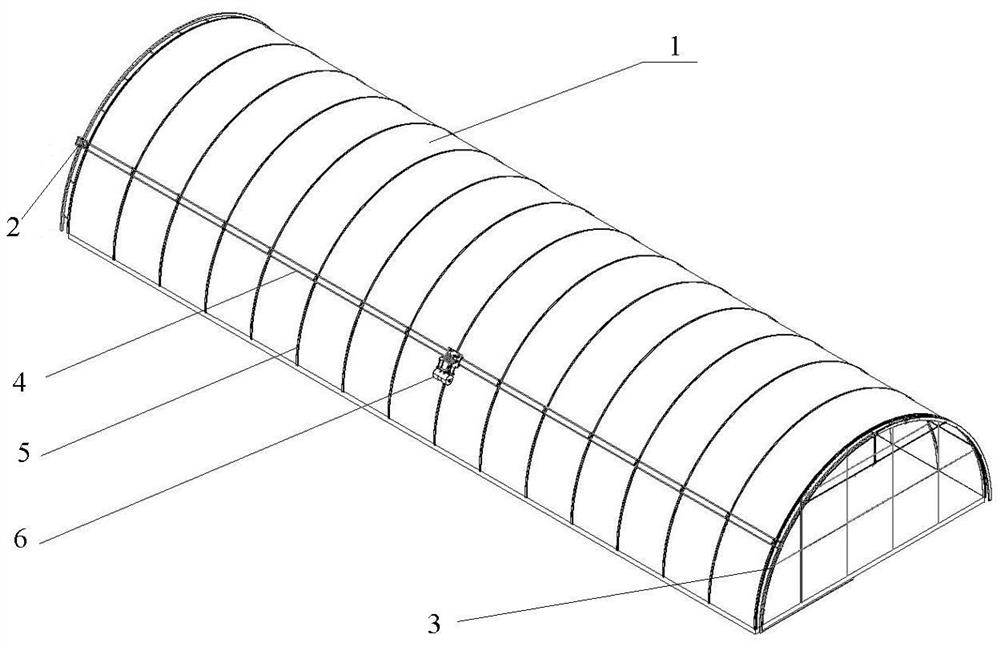

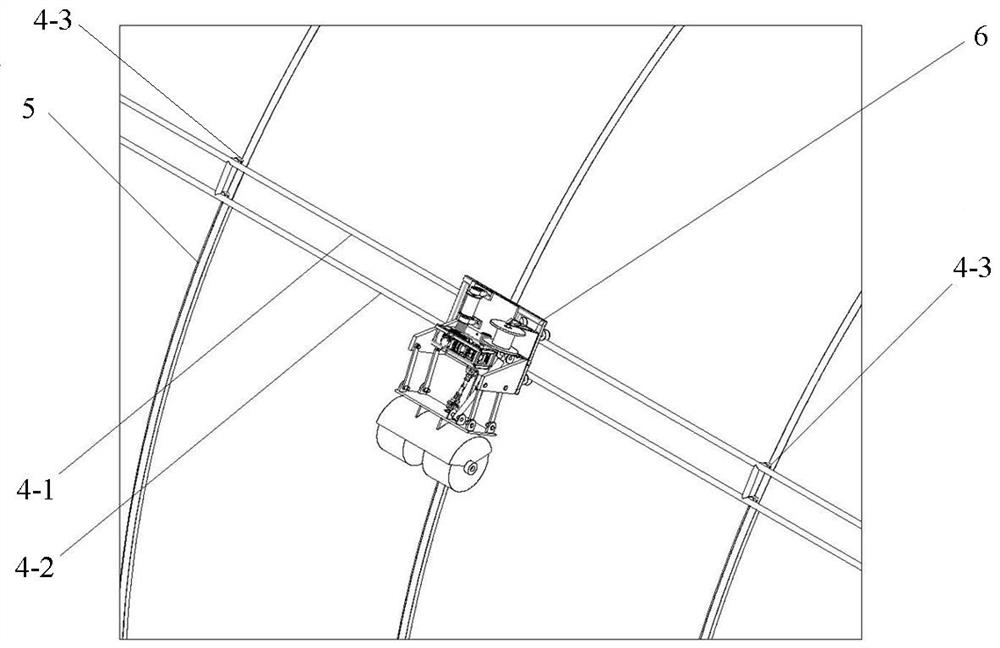

Circular-arch-shaped solar greenhouse snow removing device

PendingCN112470791AEfficient snow removalSolving difficult snow removal problemsClimate change adaptationSnow trapsSnow removalElectric machinery

The invention relates to a circular-arch-shaped solar greenhouse snow removing device which comprises a greenhouse body, a transverse moving frame, traction devices at the two sides of the greenhouseand a snow removing executing device. U-shaped track grooves are formed in the two sides of the arch-shaped greenhouse, and a plurality of outward-turning grooves are formed in the greenhouse body; the bottom of a traction pulley connecting shaft of the transverse moving frame is fixedly connected with a traction steel wire rope; the traction steel wire rope drives the transverse moving frame to move up and down along the slope surface of the greenhouse; the snow removing executing device comprises a snow sweeping brush, a rope winding drum and a driving motor; the driving motor drives the rope winding drum and the snow sweeping brush to rotate, a transverse moving steel wire rope is wound around the rope winding drum, and the two ends of the transverse moving steel wire rope are fixed tothe two ends of the transverse moving frame respectively; and a translation frame is provided with a translation pulley, and the translation pulley is arranged on a rail cross rod of the transverse moving frame and is in sliding connection with a rail cross rod. The device can be suitable for circular-arch-shaped solar greenhouses with different greenhouse lengths and spans, and efficient and rapid snow removal of the greenhouse is achieved.

Owner:SHENYANG AGRI UNIV

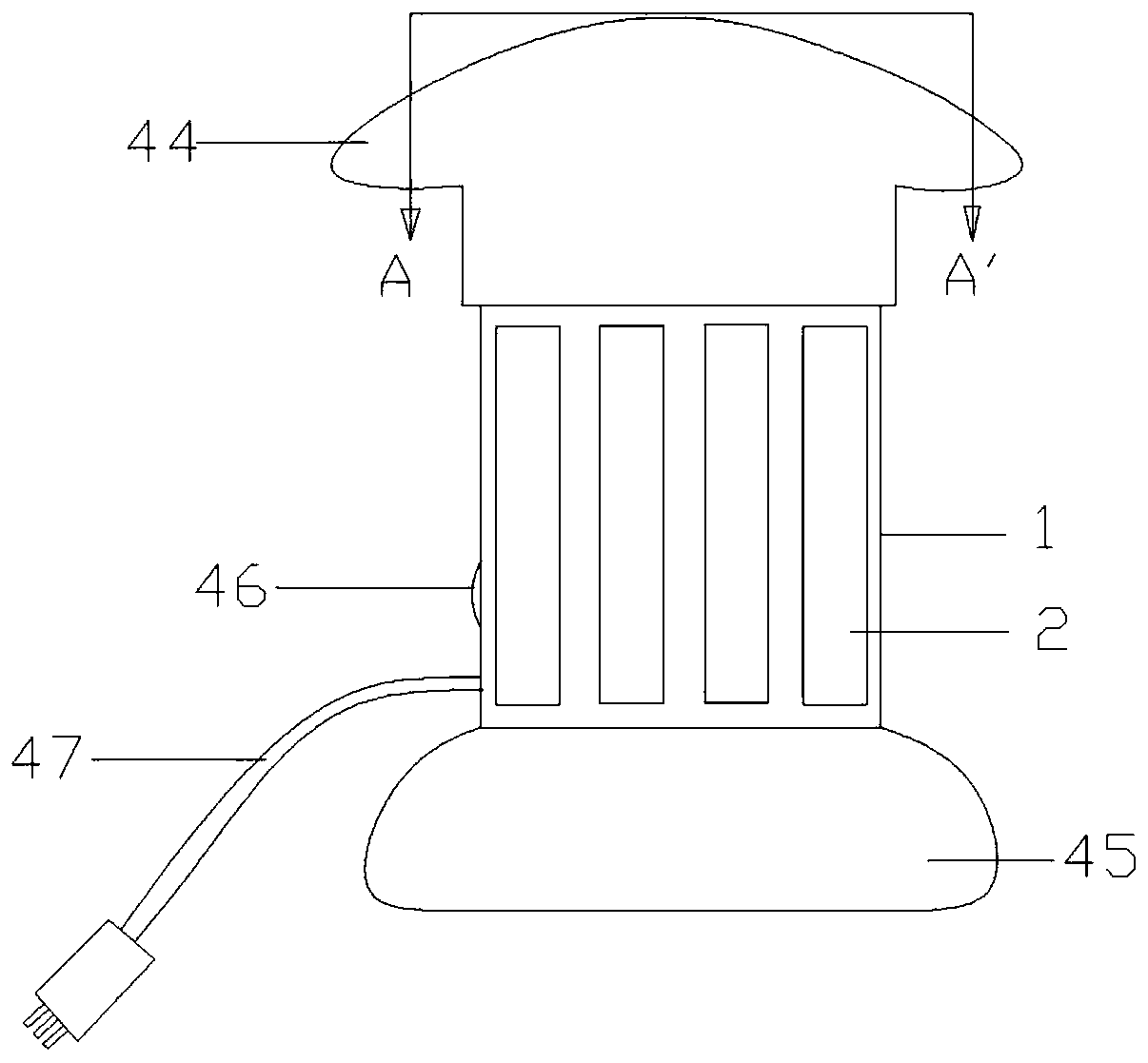

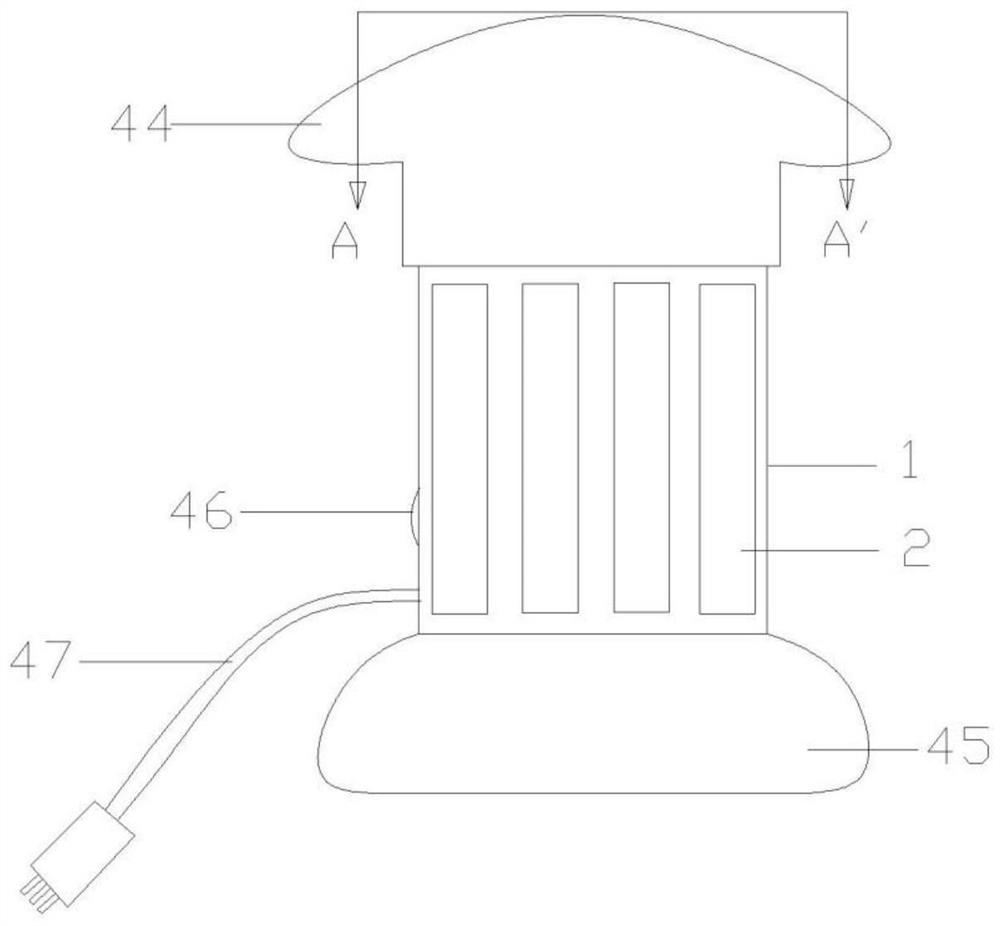

Intelligent ecological bionic mosquito killing device

The invention discloses an intelligent ecological bionic mosquito killing device which comprises a shell, a carbon dioxide gas generator and an artificial sweat feeder, wherein the carbon dioxide gasgenerator and the artificial sweat feeder are arranged in the shell. The intelligent ecological bionic mosquito killing device is characterized by further comprising a gas-liquid mixer and an atomizer, wherein the gas-liquid mixer is arranged in the shell, and the atomizer is arranged in the gas-liquid mixer. A first air outlet pipeline of the carbon dioxide gas generator extends into the gas-liquid mixer through a first air inlet of the gas-liquid mixer, a first liquid outlet pipeline of the artificial sweat feeder is communicated with the atomizer through a first liquid inlet of the gas-liquid mixer, a plurality of first air outlets are formed in the gas-liquid mixer and used for discharging carbon dioxide gas and atomized artificial sweat after mixing, and the first air outlet pipelineand the first liquid outlet pipeline adjust the flow of the carbon dioxide gas and the artificial sweat by equal proportion through a synchronous switch. The intelligent ecological bionic mosquito killing device can uniformly mix and cooperatively control the carbon dioxide gas and the artificial sweat.

Owner:ZHEJIANG WANLI UNIV

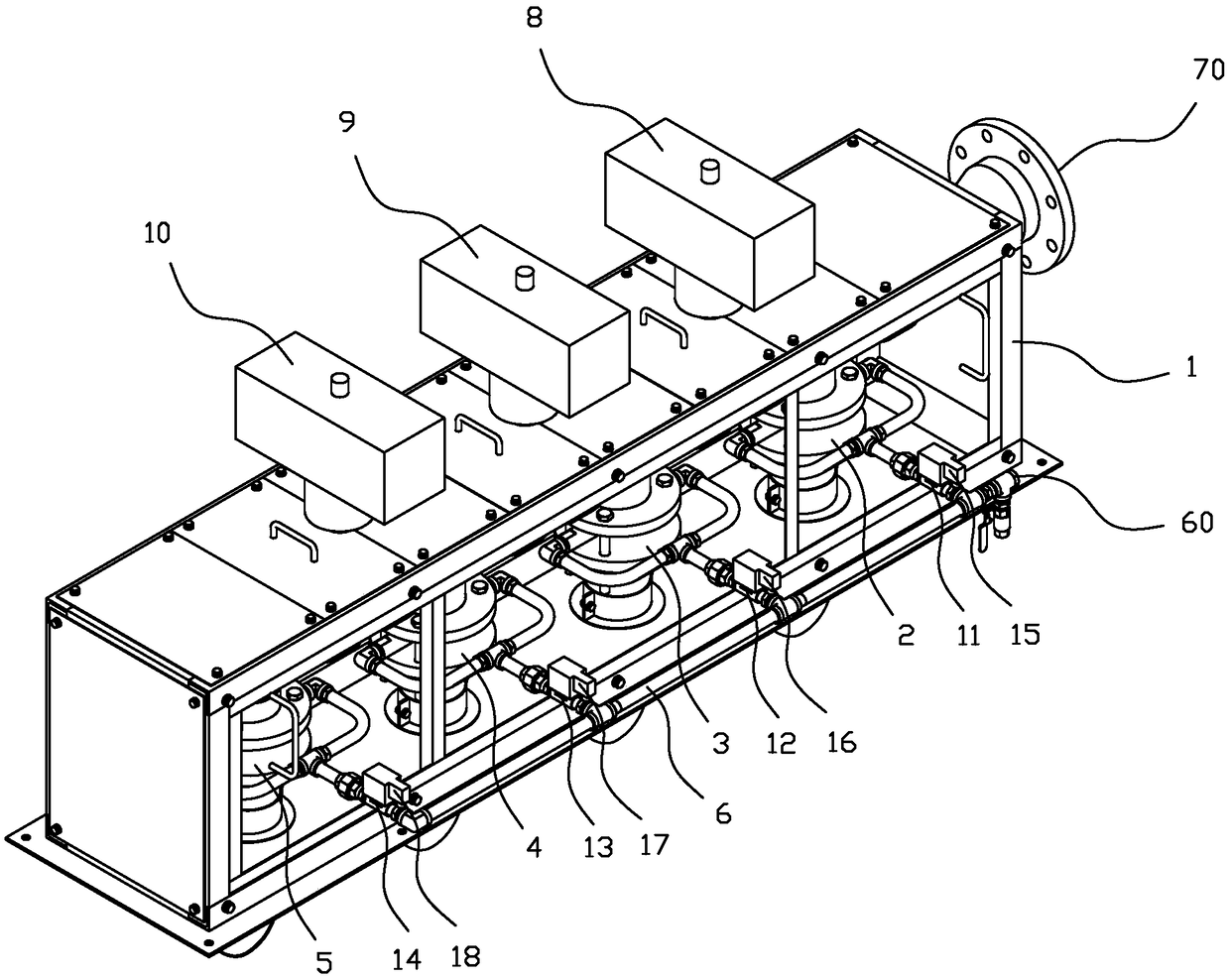

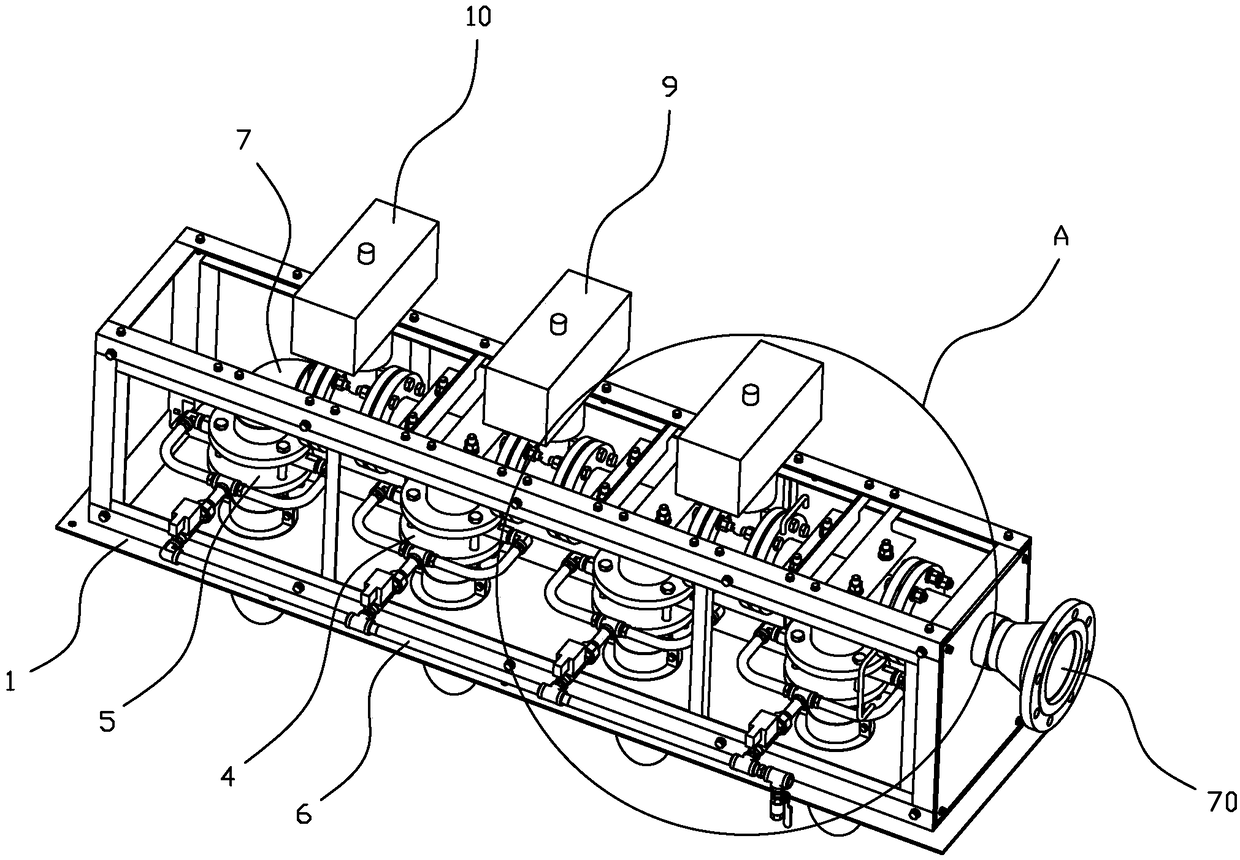

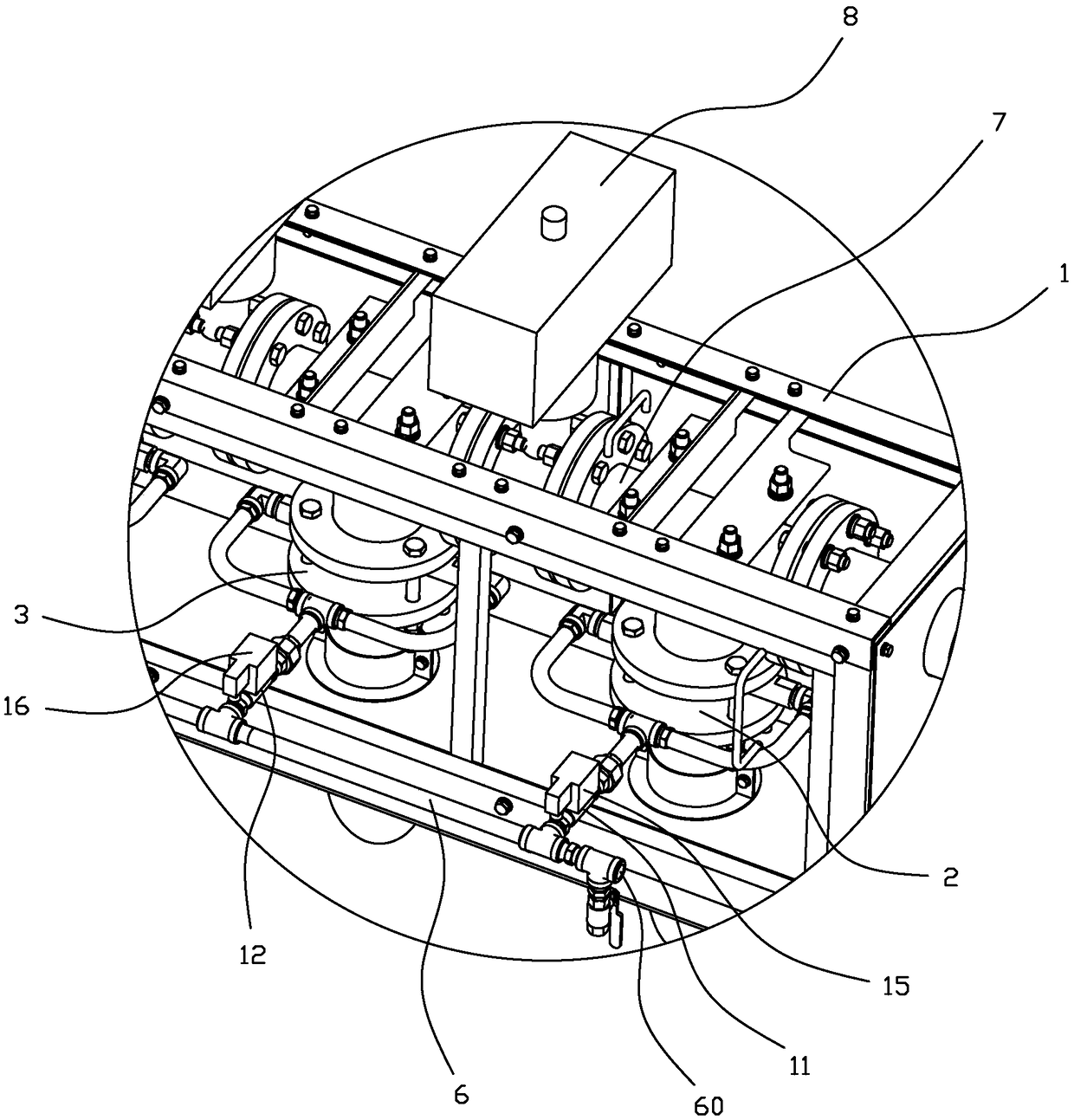

Asphalt foaming device and method

PendingCN109355999AControl contact areaAdjustable contact areaRoads maintainenceEngineeringHigh pressure water

The invention provides an asphalt foaming device and method. The asphalt foaming device comprises a plurality of independent foaming cavities, a high-pressure water conveying pipeline and an asphalt conveying pipeline; the high-pressure water conveying pipeline and the asphalt conveying pipeline are communicated with all the foaming cavities, feeding ports of the high-pressure water conveying pipeline, the asphalt conveying pipeline and all the foaming cavities are sequentially formed and communicated with one another, the portion, between every two adjacent foaming cavities, on the asphalt conveying pipeline is provided with an asphalt valve, and the high-pressure water conveying pipeline is provided with fluid valves for controlling opening and closing of water paths of all the foaming cavities respectively. According to the asphalt foaming device, all the foaming cavities can simultaneously or independently foam, different quantities of foaming cavities can be controlled to foam according to the proportion of asphalt added when an asphalt mixing device is in use, and therefore the asphalt foaming device can be matched with asphalt mixing devices different in yield for use; meanwhile, through the asphalt butterfly valves and electromagnetic flow valves, the flow rate of asphalt and water can be controlled to control the contact area of asphalt foaming, and the foaming amountof asphalt can be adjusted.

Owner:FUJIAN TIETUO MACHINERY

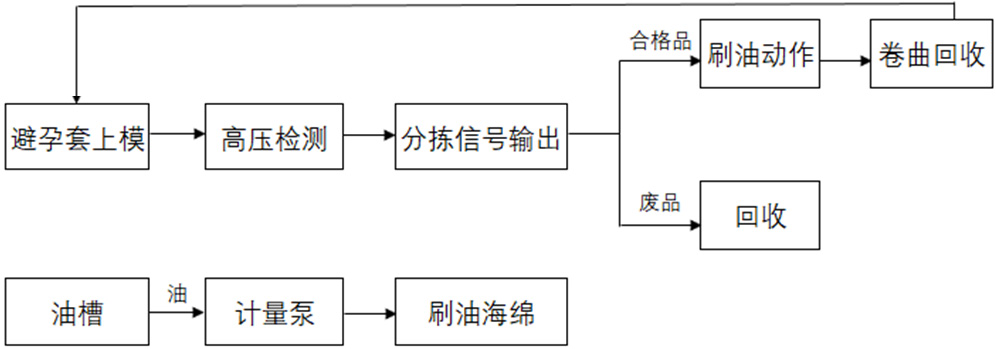

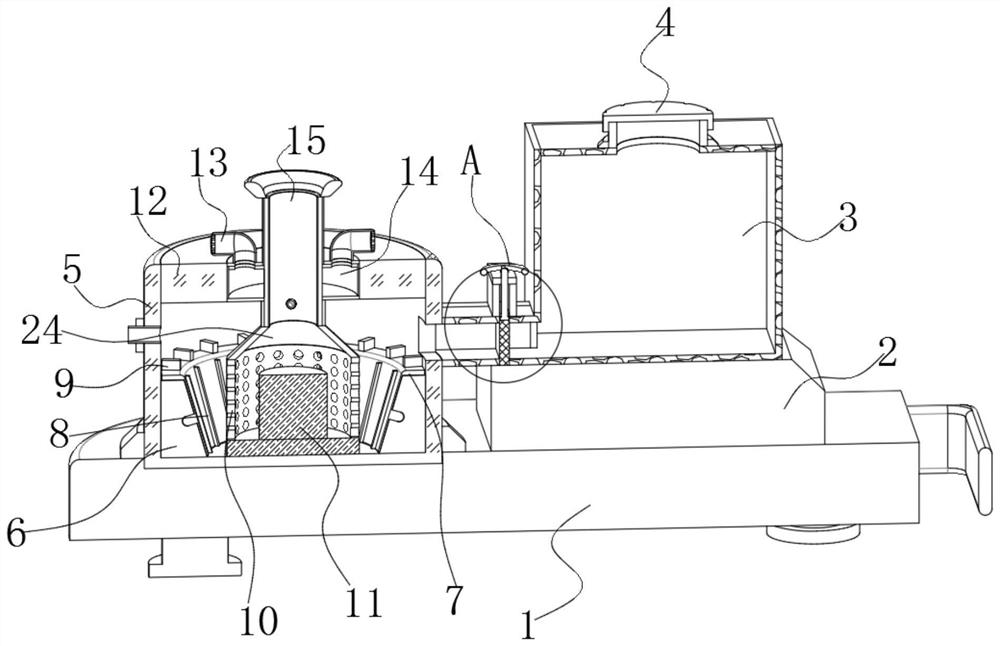

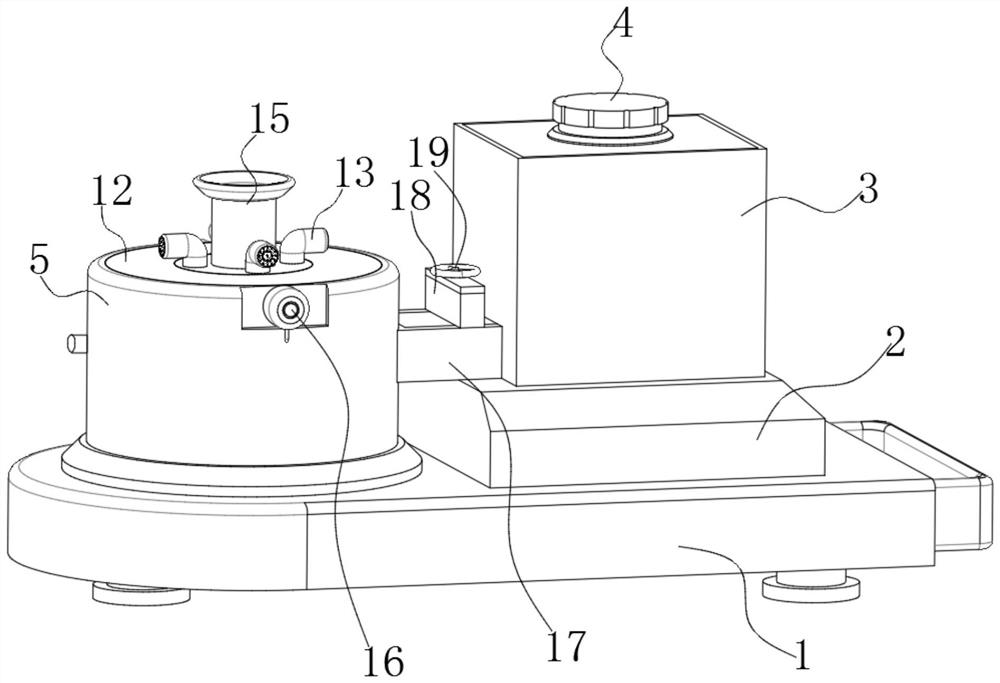

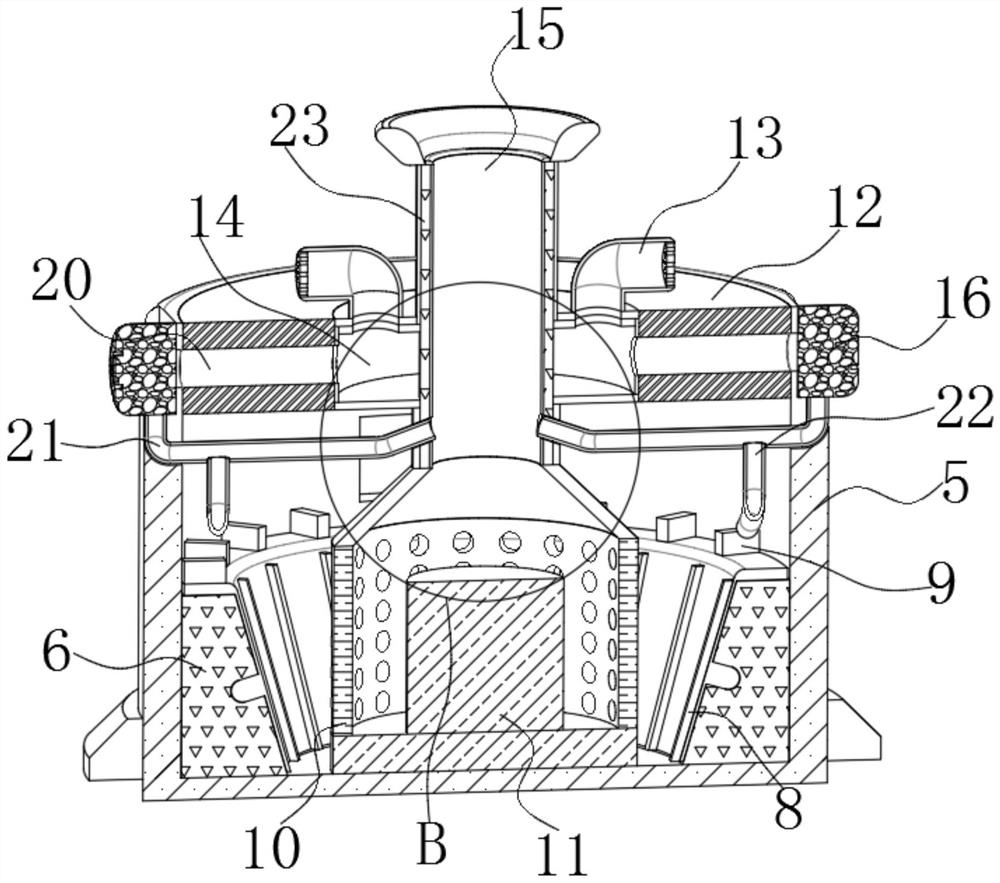

Oil brushing device of full-automatic electronic inspection machine for condoms

PendingCN112844942ACreate pollutionBrush oil evenlyLiquid surface applicatorsCoatingsControl systemStructural engineering

The invention belongs to the technical field of condom production, and particularly relates to an oil brushing device of a full-automatic electronic detection machine for condoms. The device comprises an oil brushing sponge, an action execution element, an oil groove, a metering pump and a control system, wherein the action execution element has a telescopic function and is mounted on the full-automatic electronic detection machine. The oil brushing sponge comprises a rectangular sponge body, a hose evenly provided with oil seepage holes is transversely embedded in the sponge body, the oil brushing sponge is installed at the front end of a connecting rod of the action execution element, and movement of the oil brushing sponge is controlled by the action execution element. The oil groove is used for containing a required condom lubricant. The metering pump is used for conveying the condom lubricant in the oil groove into the oil brushing sponge through the hose. The control system controls work of the whole device. The device is matched with the electronic inspection machine to detect whether the condoms are good or not, then oil brushing and curling are carried out on one side of each condom, the labor cost and the storage cost can be greatly reduced, and pollution to an inspection mold cannot be caused.

Owner:SHANGHAI MINGBANG RUBBER PROD +1

Evaporative atomizer for sterilizing germs

PendingCN114288450AEasy to disperseGood demist effectSpraying apparatusLavatory sanitoryMedicineAerosolize

The invention belongs to the technical field of atomizers, and discloses an evaporative atomizer for sterilizing germs.The evaporative atomizer comprises a base and a fan, an atomizing barrel is fixedly mounted at the top of the left end of the base, a top plate is fixedly connected to the interior of the upper end of the atomizing barrel, and an evaporator is fixedly mounted at the bottom of the interior of the atomizing barrel; a protective cover is fixedly connected to the top of the outer side of the lower end of the evaporator, and a gas collecting cover is fixedly installed at the top of the protective cover. Through cooperation of the hot air chamber, the air guiding channel, the air distributing pipe and other structures, the mist exhausting effect is good, liquid is vaporized into mist through high temperature through work of the evaporator, the mist is directly guided into the guiding pipe through the air collecting hood, meanwhile, a heating piece is powered on to generate heat, hot air entering the hot air chamber can be heated, and the heat efficiency is improved. And the fans at the two ends work to guide hot air in the hot air chamber into the air guide pipes at the two ends through the air guide channels at the two ends, so that the aim of good mist exhaust effect can be achieved.

Owner:SHENZHEN YONGHENGFENG INTELLIGENT DEVICE

High-precision rail base for automobile production line

InactiveCN114275477AReduce vibrationAvoid damageSupporting framesMechanical conveyorsProduction lineEngineering

The invention discloses a high-precision automobile production line track base, and belongs to the field of track bases, the high-precision automobile production line track base comprises a conveying track body, the upper end of the conveying track body is fixedly connected with a transfer gasket, and the front side and the rear side of the transfer gasket are fixedly connected with the inner wall of a track base frame; a plurality of flexible buffer bottom blocks are fixedly connected to the upper end of the transfer gasket, and inertia force which is transferred to the track base frame and the transfer gasket and generated in the start and stop process of the conveying track body can be buffered and decomposed through cooperation of the flexible buffer bottom blocks, flexible blocking top blocks, diagonal buffer assemblies and auxiliary flow pipes; continuous transmission of inertia force is effectively avoided, vibration of the conveying track body and the track base frame is reduced, damage of the inertia force to the conveying track body and the track base frame is effectively reduced, the stability of the conveying track body is improved, and then the control precision of the conveying track body is effectively guaranteed.

Owner:江苏密特科智能装备制造有限公司

An intelligent ecological bionic mosquito killing device

ActiveCN109845710BWell mixedEco-bionic effect is goodInsect catchers and killersControl mosquitoEnvironmental engineering

An intelligent ecological bionic mosquito killing device, including a housing, and a carbon dioxide gas generator and an artificial sweat supplier arranged in the housing, is characterized in that it also includes a gas-liquid mixer arranged in the housing, and a gas-liquid mixer arranged in the housing. The atomizer in the mixer, the first outlet pipeline of the carbon dioxide gas generator extends into the gas-liquid mixer through the first air inlet of the gas-liquid mixer, the first outlet pipeline of the artificial sweat supplier The liquid pipeline communicates with the atomizer through the first liquid inlet of the gas-liquid mixer, and the gas-liquid mixer is also provided with a plurality of first gas outlets for mixing the carbon dioxide gas with the atomized artificial sweat After discharge, the first air outlet pipeline and the first liquid outlet pipeline also adjust the flow of carbon dioxide gas and artificial sweat in equal proportions through a synchronous switch. The intelligent ecological bionic mosquito killing device can evenly mix carbon dioxide and artificial sweat, and control the two synergistically.

Owner:ZHEJIANG WANLI UNIV

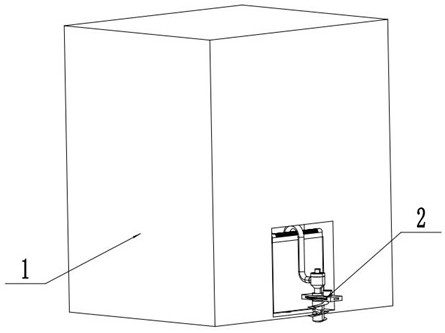

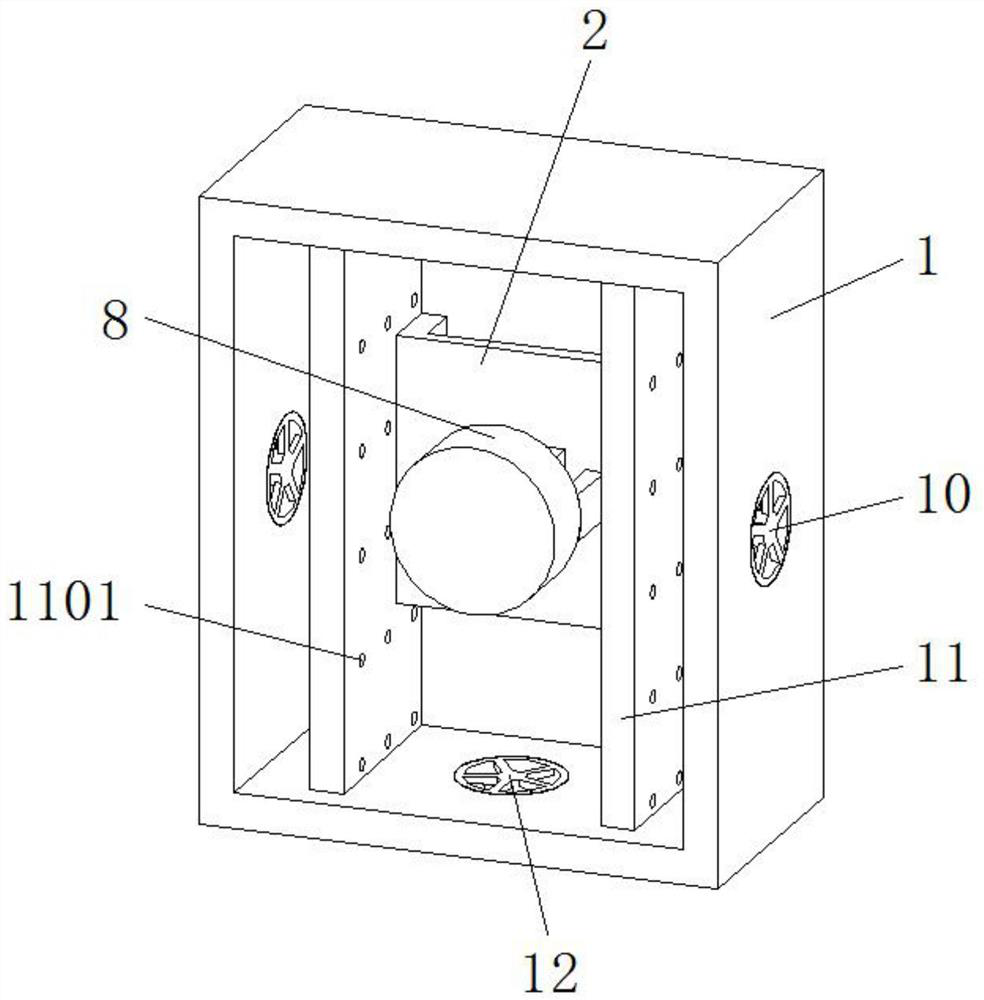

A kind of refrigeration equipment suitable for electrical cabinets under high temperature conditions

ActiveCN113518548BChange sizeControl contact areaConstructionsPump installationsWind runCooling effect

The invention discloses a refrigeration device suitable for electrical cabinets under high-temperature conditions, which relates to the technical field of refrigeration, and includes a water supply mechanism, a diffuser mechanism, a cooling mechanism, and an air supply mechanism installed in the electrical cabinet, and the diffuser mechanism makes the airflow flow, The cooling mechanism includes a number of water guide plates arranged in the refrigeration box, two adjacent water guide plates are arranged alternately and every two water guide plates are rotatably connected by cooling connecting rods, and one end of the lowermost water guide plate is set There are counterweights to guide the flow of water, and the air supply mechanism realizes multi-angle air supply. The invention uses underground cold water, controls the contact area between air flow and cold water flow, and adjusts the wind direction and speed to cool down the electrical cabinet. It is energy-saving and environmentally friendly, and has a good cooling effect. , high cooling efficiency.

Owner:徐州金宸制冷设备有限公司

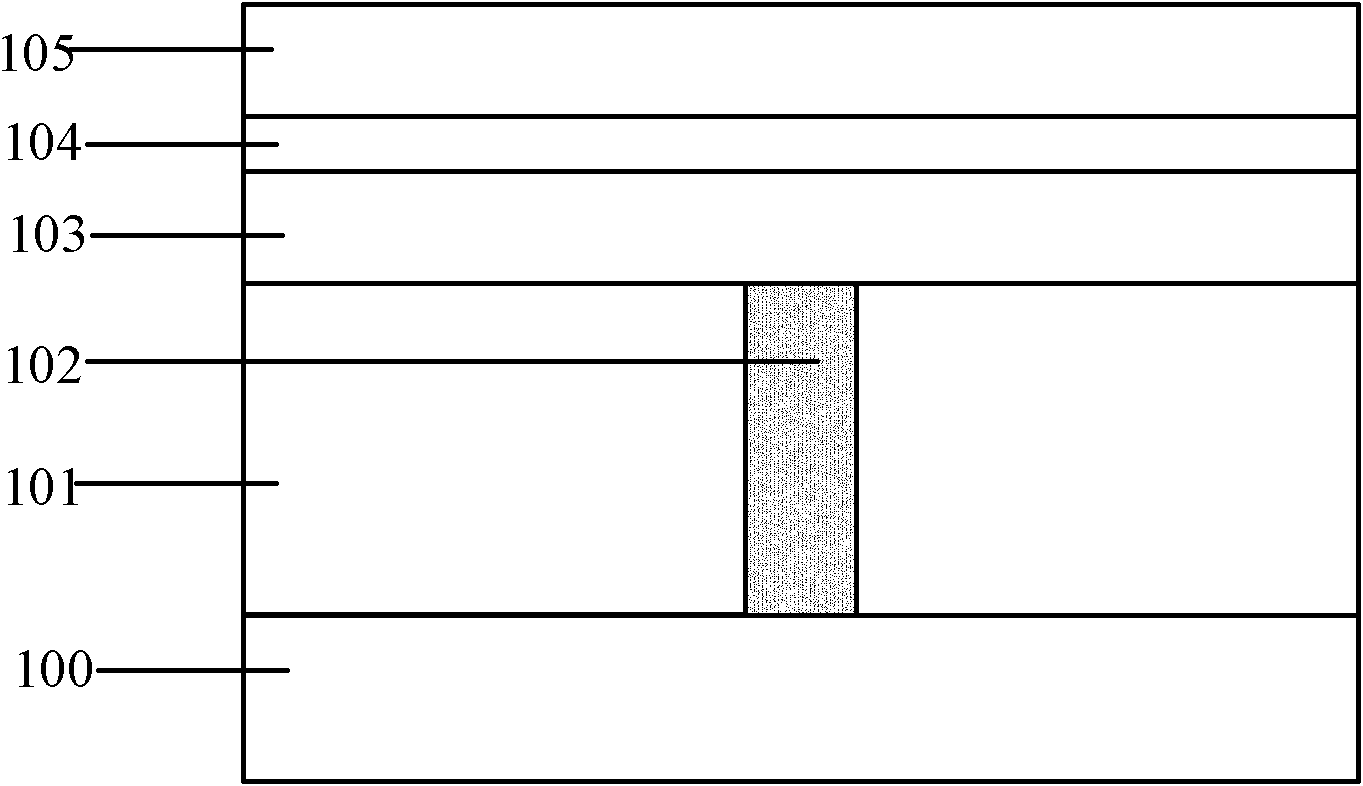

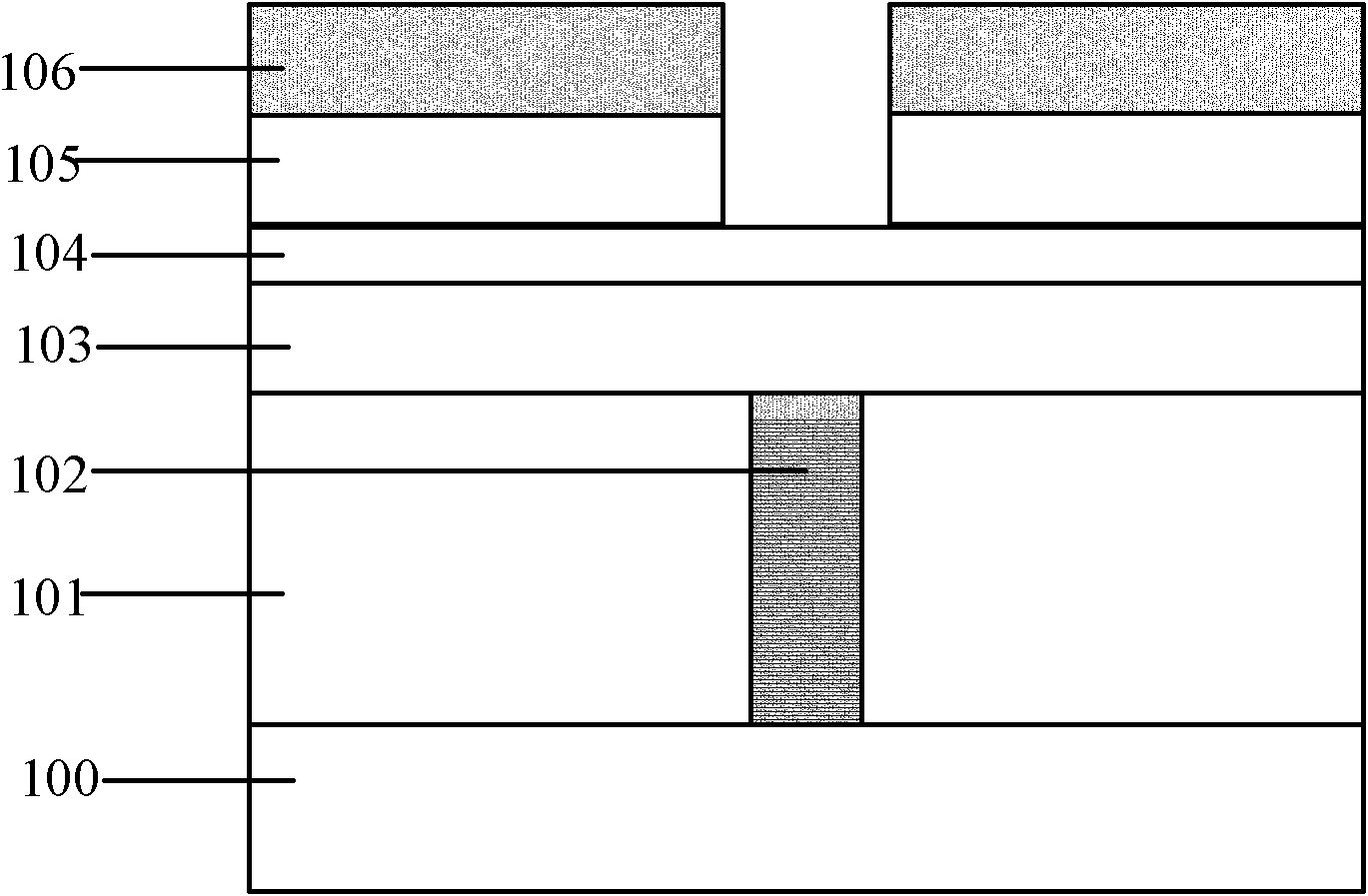

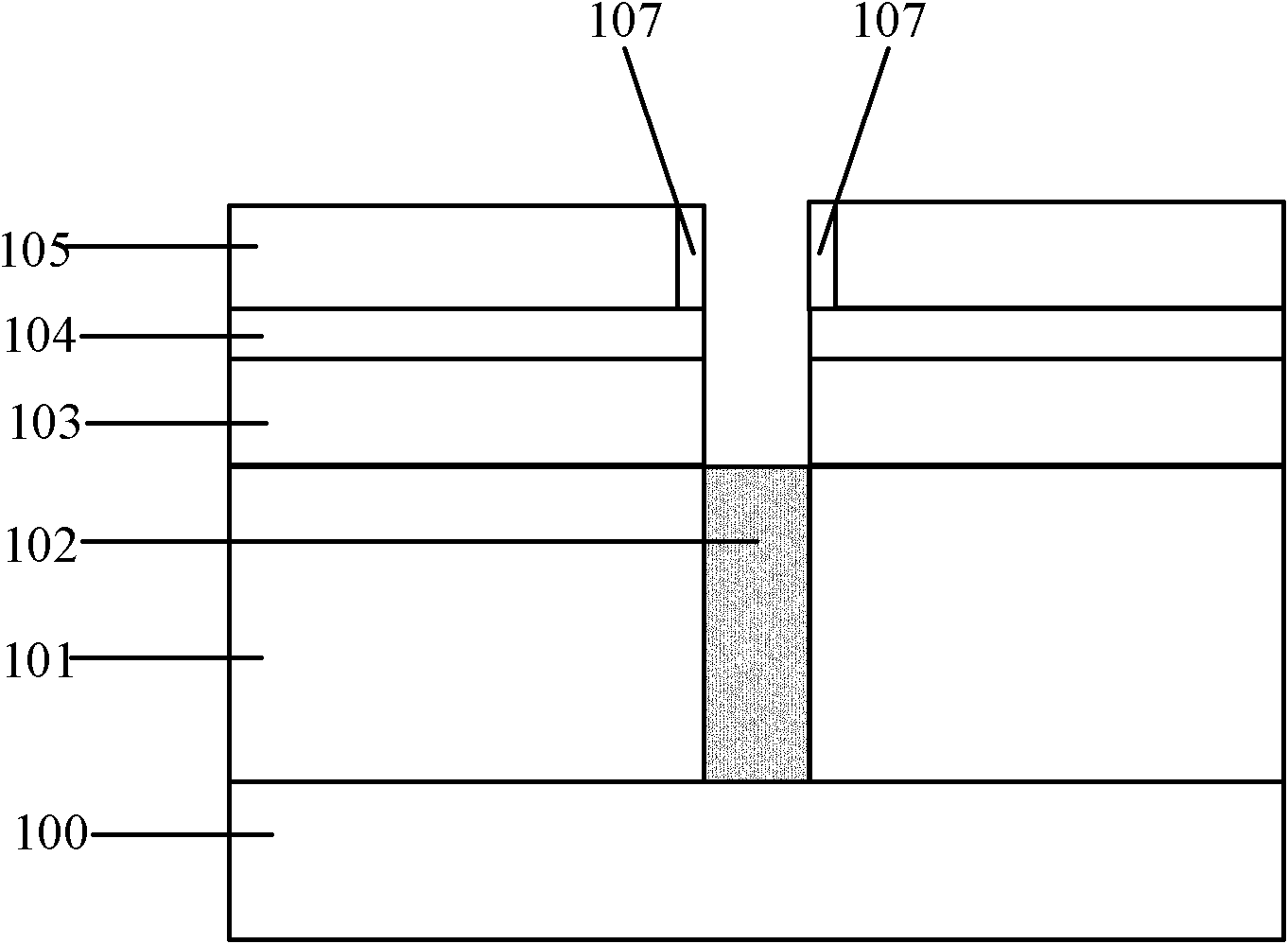

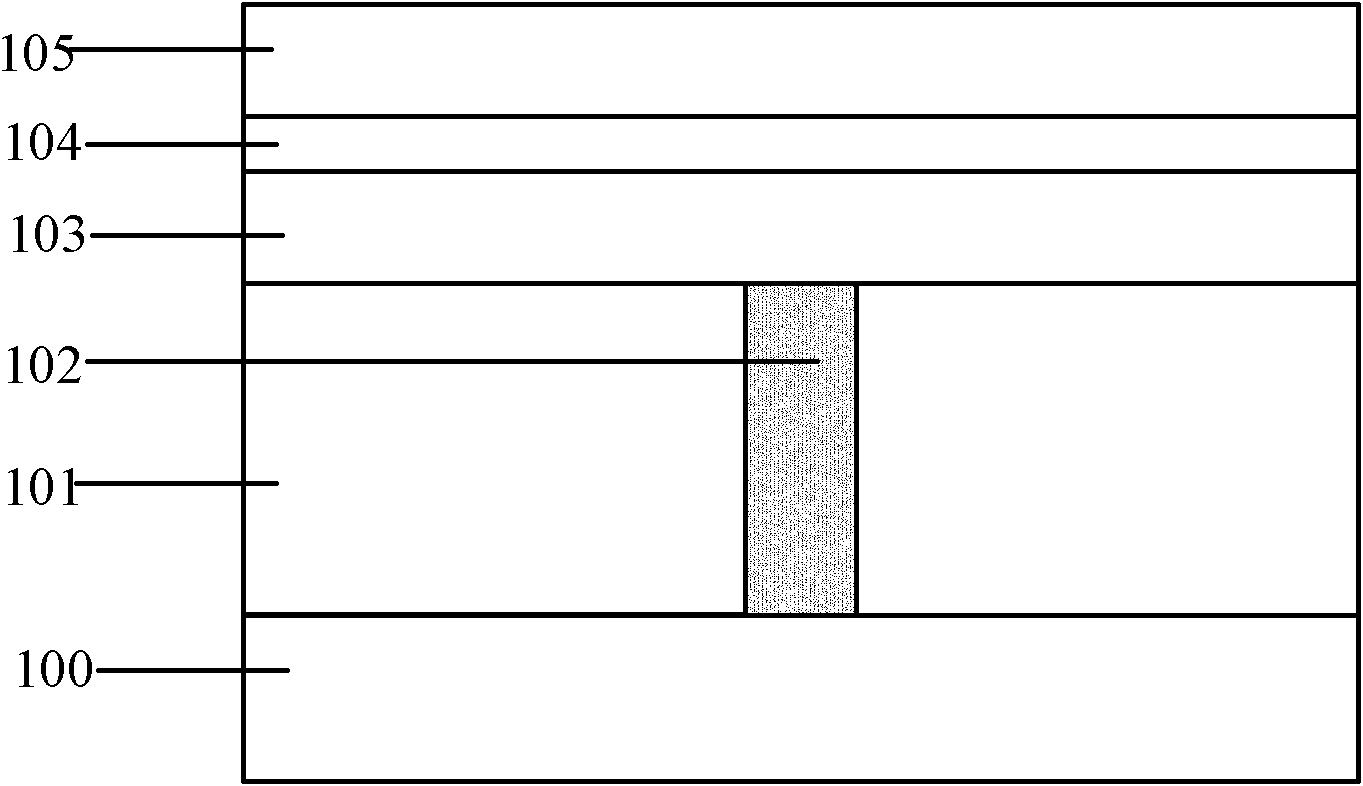

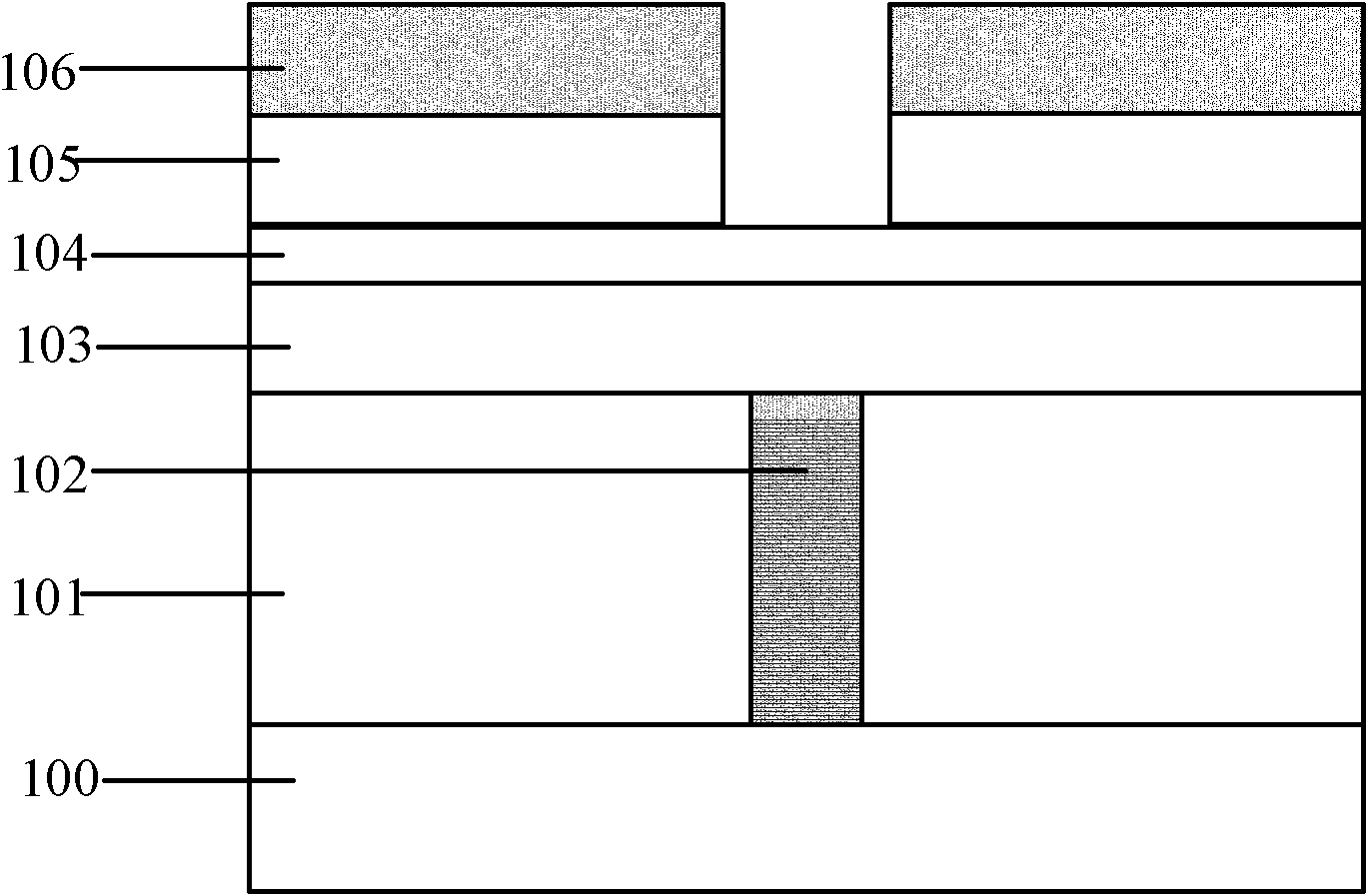

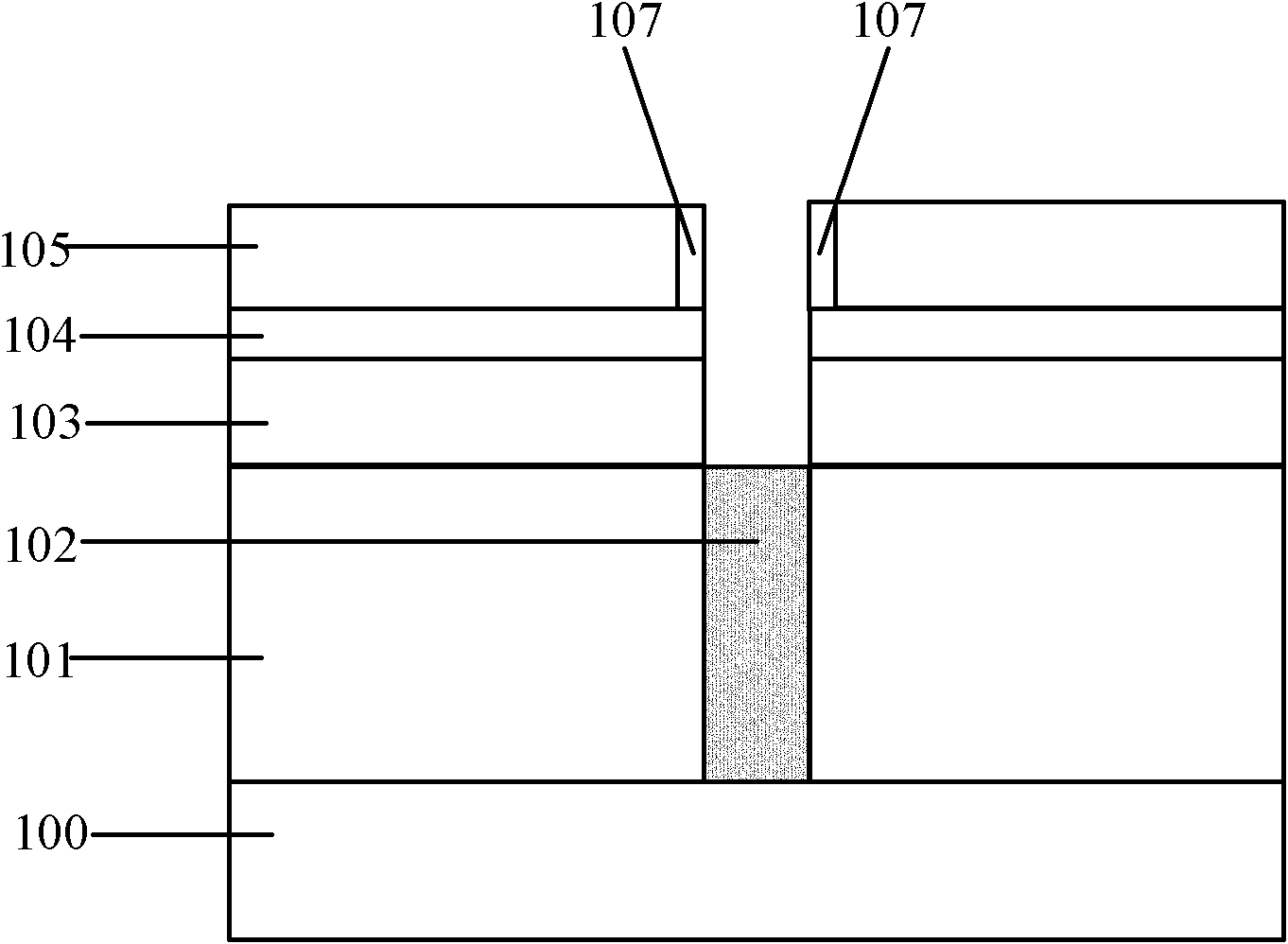

Phase change memory and manufacturing method thereof

The invention provides a phase change memory and a manufacturing method thereof. The method comprises the following steps of: providing a semiconductor substrate, wherein an interlayer medium layer and a contact jack plug positioned in the interlayer medium layer are formed on the semiconductor substrate; forming an insulating medium layer covering the contact jack plug on the interlayer medium layer; forming a bowl-shaped opening in the insulating medium layer, wherein the contact jack plug is exposed out of the bottom of the bowl-shaped opening; and forming a phase change layer in the bowl-shaped opening. The phase change memory formed by using the method disclosed by the invention has small phase change current and low power consumption.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

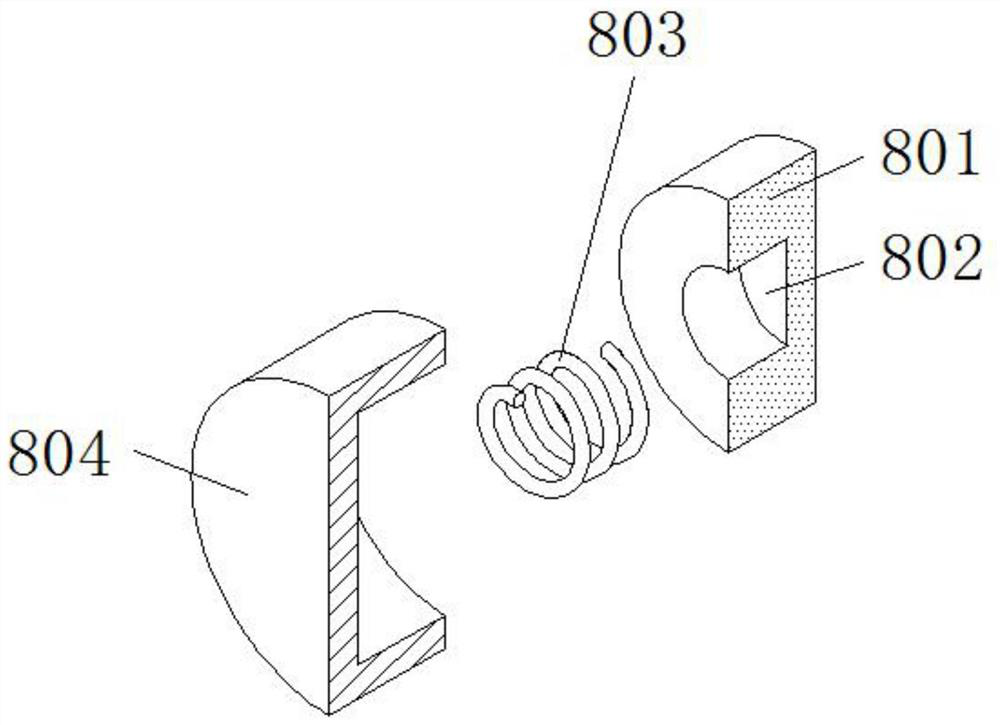

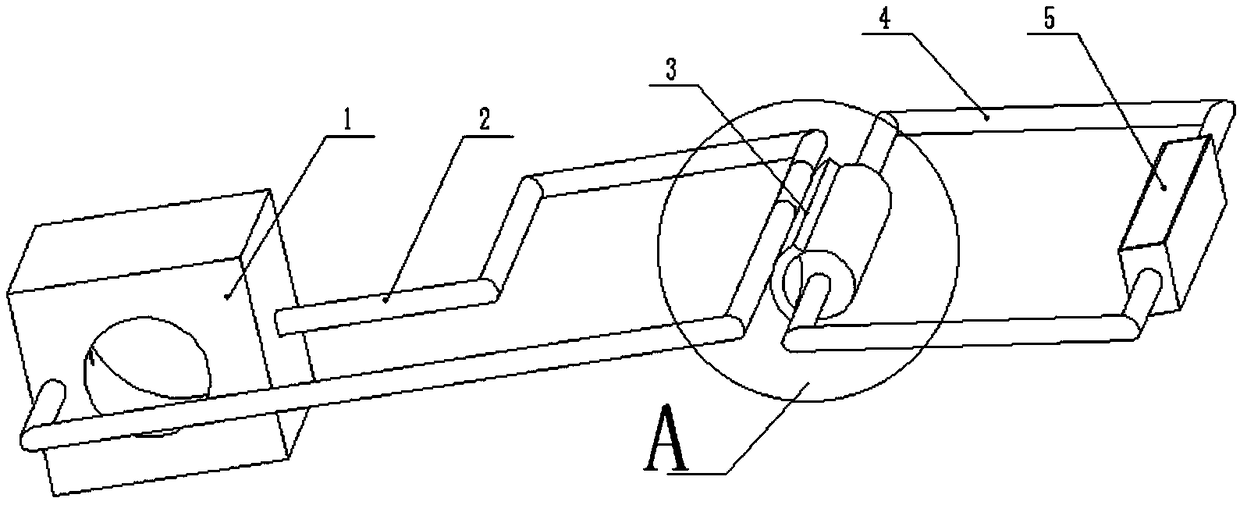

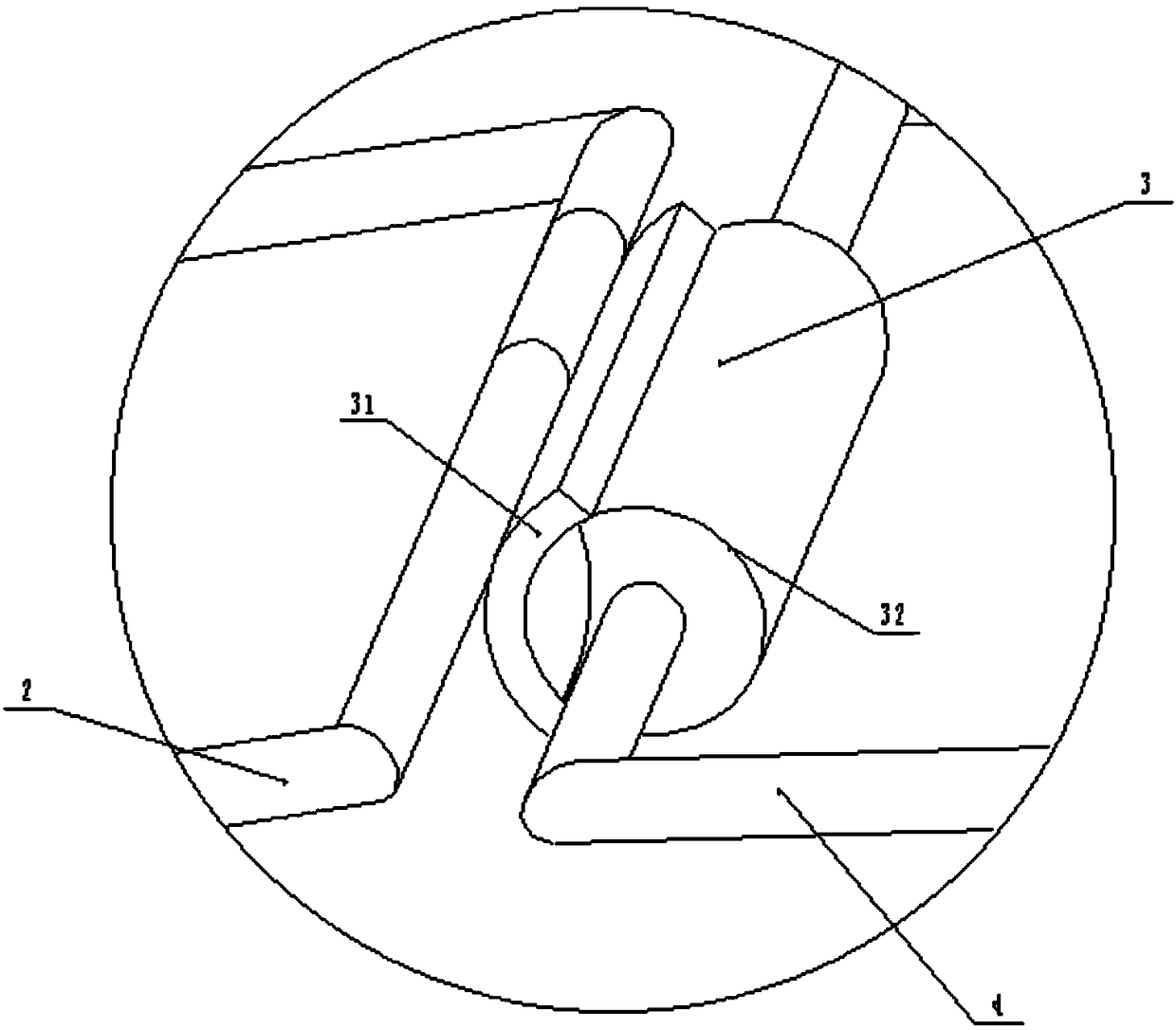

A lake ice breaker

The invention discloses a lake surface ice breaker. The lake surface ice breaker comprises a cylindrical shell and a supporting shell, a limiting ring is fixed to the side face of the cylindrical shell, a hollow structure is formed in the supporting shell, the portion, located on the limiting ring, of the cylindrical shell is sleeved with the hollow structure, the portion, located in the hollow structure, of the cylindrical shell is sleeved with a spiral spring, the top of the spiral spring is fixed to the bottom face of the limiting ring, and multiple supporting legs are fixed to the bottom of the supporting shell. An ice layer is broken through cutting, as the contact area between the cutting portion and the ice layer is small, large-area breakage of the ice surface is avoided, and accidents caused by ice surface breakage are reduced. In addition, the spiral spring serves as a buffering element during force application, the contact area between a cutting component and the ice surface can be controlled, it is avoided that the cutting component gets stuck and then is broken, and the service life of the component is prolonged.

Owner:周旻洋

Controllable vascularized artificial bone graft

InactiveCN102415922BRapid vascularizationWell vascularizedBone implantClinical efficacyVascular fibrosis

The invention discloses a controllable vascularized artificial bone graft in which a soft tissue window, a soft tissue window anchor bearing and a cell-stent complex match with each other to be integrated, wherein the cell-stent complex is made of porous medical alloy compounded with osteoblasts; and the soft tissue window and the soft tissue window anchor bearing are both made of medical absorbable materials, and the contact area of the artificial bone graft and a host soft tissue is controlled through adjusting the aperture of the soft tissue window so as to further realize the controllability of graft vascularization. The controllable vascularized artificial bone graft can realize the controllable vascularization after grafting, provides a good nutrition supply and metabolism environment for grafting cells, and simultaneously avoids local excessive vascular fibration of the graft, promotes osteogenic ability after artificial bone grafting, and effectively improves the clinical effect.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

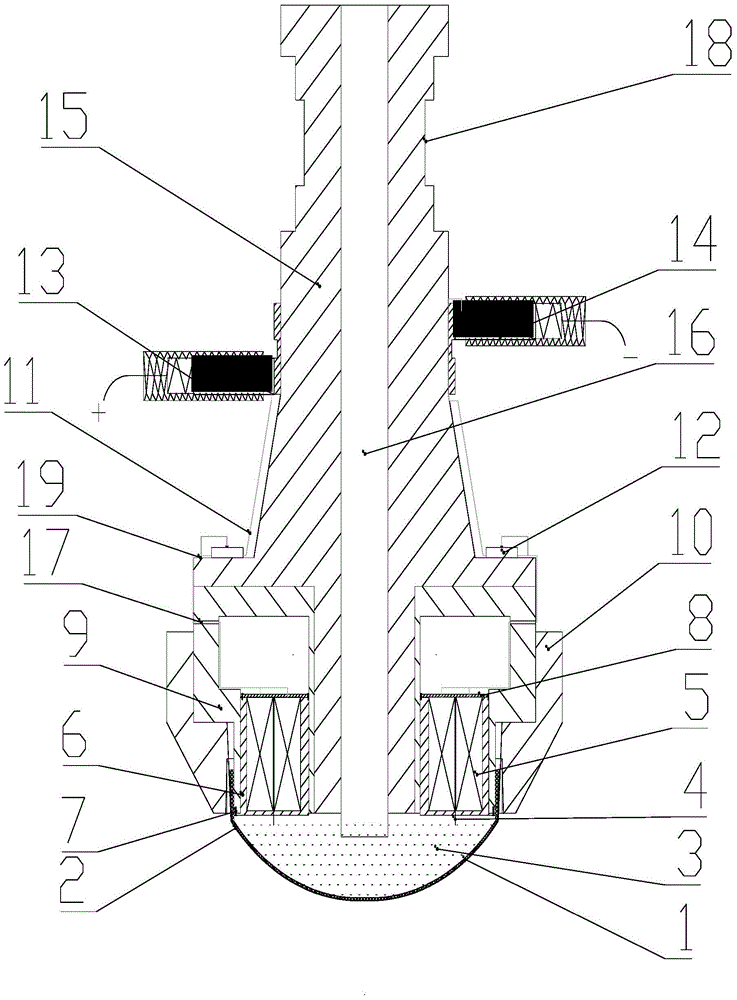

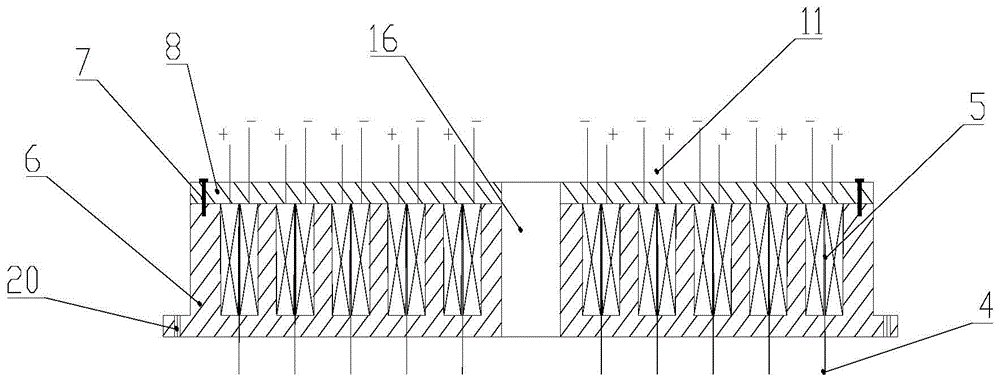

An electronically controlled magnetic field flexible capsule liquid-filled polishing device

InactiveCN104097142BEnsure stabilityImprove surface accuracyGrinding machine componentsOptical surface grinding machinesPower flowEngineering

The invention relates to an electrically controlled magnetic field flexible ballonet fluid-filled polishing device and belongs to the field of flexible machining tools for ultraprecise optical surfaces. The device comprises a flexible ballonet, rheological fluid, electromagnets, variable resistors, a circular carbon brush, a rotating shaft, clamping grooves and the like. During work, each variable resistor is adjusted to acquire the required current, power is supplied to each group of electromagnets, an electric power conductor is connected with the outside through the circular carbon brush; under the action of a comprehensive magnetic field formed by the multiple electromagnets, the rheological fluid in the flexible ballonet becomes thick or approaches a solid state, a working surface is in copying contact with a workpiece, and the flexibility of the ballonet can be controlled through the magnitude of the current; the clamping grooves in the rotating shaft are used for fixing the device onto a power head of a common machine tool to obtain driving power, so that the device rotates at high speed for polishing. The polishing device has the advantages of adjustable flexibility of a tool head, controllable magnetic field and high adaptability to surface curvature change, and can meet the requirement for quickly polishing ultra smooth free curved surfaces.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Phase change memory and manufacturing method thereof

The invention provides a phase change memory and a manufacturing method thereof. The method comprises the following steps of: providing a semiconductor substrate, wherein an interlayer medium layer and a contact jack plug positioned in the interlayer medium layer are formed on the semiconductor substrate; forming an insulating medium layer covering the contact jack plug on the interlayer medium layer; forming a bowl-shaped opening in the insulating medium layer, wherein the contact jack plug is exposed out of the bottom of the bowl-shaped opening; and forming a phase change layer in the bowl-shaped opening. The phase change memory formed by using the method disclosed by the invention has small phase change current and low power consumption.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Electric appliance cabinet refrigeration equipment suitable for high-temperature condition

ActiveCN113518548AChange sizeControl contact areaConstructionsPump installationsAir velocityWater flow

The invention discloses electric appliance cabinet refrigeration equipment suitable for a high temperature condition, and relates to the technical field of refrigeration. The electric appliance cabinet refrigeration equipment comprises a water supply mechanism, an air dispersion mechanism and a cooling mechanism which are installed in an electric appliance cabinet, the air supply mechanism and the air dispersion mechanism enable air flow to flow, and the cooling mechanism comprises a plurality of water guide plates arranged in a refrigeration box; two adjacent water guide plates are arranged in a staggered mode, every two water guide plates are rotationally connected through a cooling connecting rod, a balancing weight is arranged at one end of the lowermost water guide plate, water flow is guided to flow, and the air supply mechanism achieves multi-angle air supply. According to the invention, underground cold water is used in a cycled way, the contact area between the air flow and the cold water flow is controlled, and the wind direction and speed are adjusted to cool the electric appliance cabinet; and thus, the energy is saved, the environment is protected, the refrigeration effect is good, and the refrigeration efficiency is high.

Owner:徐州金宸制冷设备有限公司

Virtual power plant load optimization scheduling device based on virtual unit subgroup

InactiveCN113435643AControl contact areaCooling Rate AdjustmentDigital data processing detailsForecastingThermodynamicsLoad optimization

The invention relates to the technical field of virtual power plant load optimization scheduling devices, and discloses a virtual power plant load optimization scheduling device based on a virtual unit subgroup. The virtual power plant load optimization scheduling device comprises a box body, a circuit board and an electrical module, the electrical module is fixedly installed on the front surface of the circuit board, and a temperature sensor is fixedly installed on the top surface of the electrical module. A third through hole is formed in the front face of the circuit board and located on one side of the electrical module, a through groove is formed in the front face of the interior of the box body, and a sliding rod is movably connected into the third through hole and the through groove in a sleeved mode. According to the virtual power plant load optimization scheduling device based on the virtual unit subgroup, adjusting mechanisms and temperature sensors are installed in front of and behind an electrical module, when the heating value of the electrical module is changed, a cylinder is controlled to stretch out and draw back, so that a stretching mechanism is controlled to stretch out and draw back, and then the contact area between a heat dissipation end and external air is controlled; and thus, the heat dissipation rate is adjusted.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

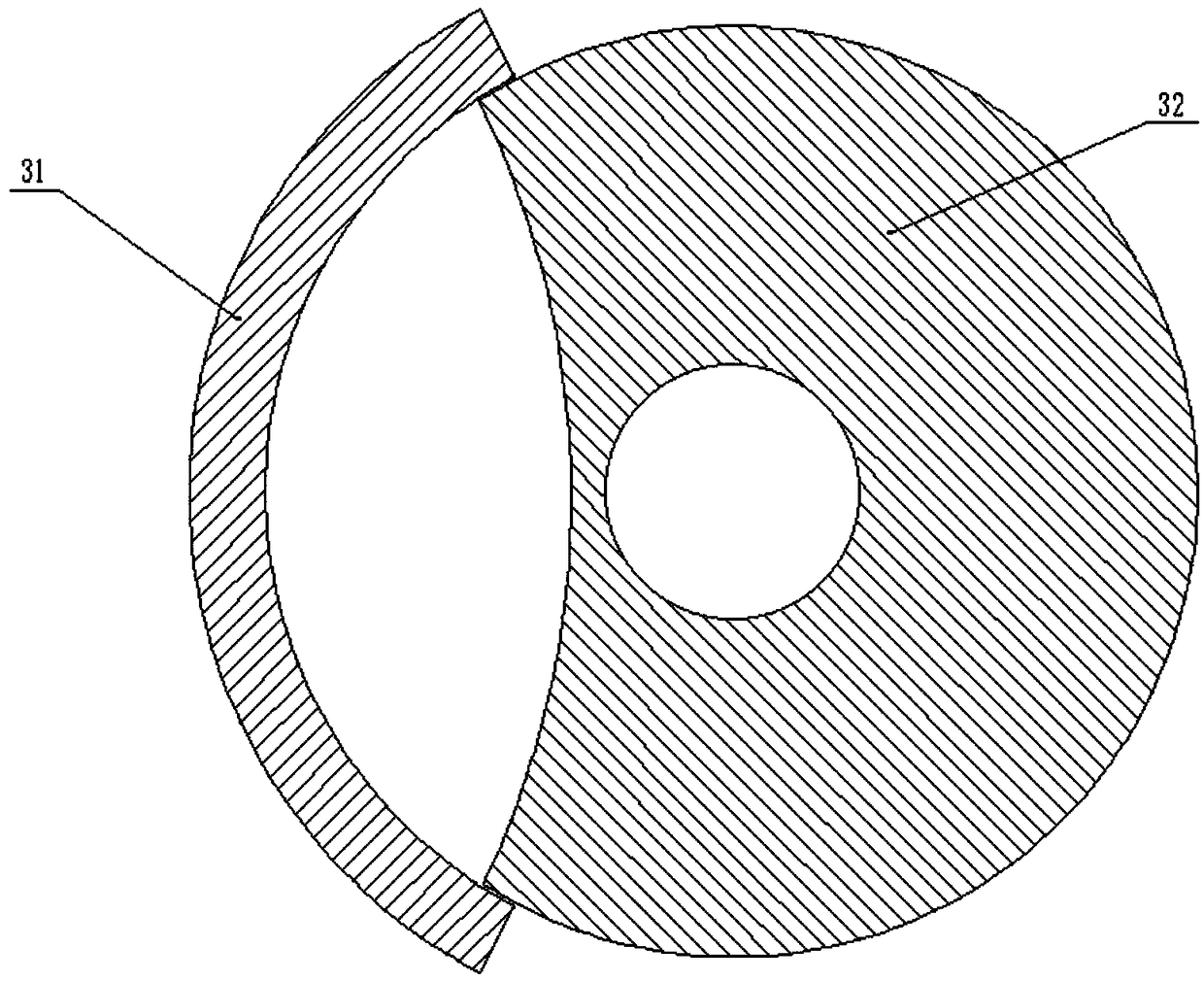

Reutilizing device for ship low-grade heat source

PendingCN109373796AReduce friendlinessCompact structureRecuperative heat exchangersLeft halfThermal insulation

The invention discloses a reutilizing device for a ship low-grade heat source. The reutilizing device comprises a heat exchanger as well as a hot oil pipeline and a thermal insulation pipeline which are connected with the heat exchanger, wherein the heat exchanger comprises a left half body and a right half body which can rotate relative to the left half body; the left half body is in the shape ofa curved plate; the right half body is in the shape of a cylinder; the cylinder is cut in a length direction to form a crescent moon shaped pit; the centre of the curved plate is superposed with thatof the cylinder; the hot oil pipeline is fixedly arranged on the wall surface of one side of the left half body; the thermal insulation pipeline is fixedly arranged on the middle part of the right half body, and can simultaneously rotate along with the right half body; the hot oil pipeline communicates with an external low-grade heat source; the thermal-insulation pipeline communicates with external thermal insulation equipment; and the heat exchanger is divided into a fixed left half body and a right half body which rotate relative to the left half body. Contact between the surface of the left half body and the surface of the right half body is realized through rotation, so that low-grade heat energy flows to the thermal insulation equipment from the low-grade heat source through the heat exchanger. The reutilizing device is compact in structure and is reasonable in design.

Owner:ZHEJIANG OCEAN UNIV

Touch pen point and touch pen

PendingCN114138127AControl deformationControl contact areaInput/output processes for data processingComputer graphics (images)Engineering

The invention relates to a stylus nib and a stylus. The touch pen point comprises a soft conductive material layer and an inner core, wherein the soft conductive material layer is used for being in contact with a touch panel to form a contact area, and the inner core is used for pressing the soft conductive material layer towards the touch panel when force is applied and is made of a hard material; the inner core is used for pressing a pressing part of the soft conductive material layer, and the pressing part of the inner core is substantially in a sphere shape, a hemisphere shape or a segment shape; and the soft conductive material layer is tightly covered on the pressing part of the inner core with substantially the same thickness. The invention further provides a corresponding touch pen. According to the stylus point and the stylus, the deformation of the stylus point can be controlled, the contact area between the stylus point and the touch panel can be controlled, and the stylus can be used by holding the stylus in an inclined mode.

Owner:深圳市精源宇科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com