Adjusting plate device for sueding machine brush drum

A technology for adjusting the plate and the brush drum, which is applied in the directions of textile and paper making, roughening, and fabric surface trimming, etc., can solve the problems of brush wear, wear of the middle position of the brush roller, uneven grinding, etc., and achieves simple structure, Cost saving, guaranteeing the effect of parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

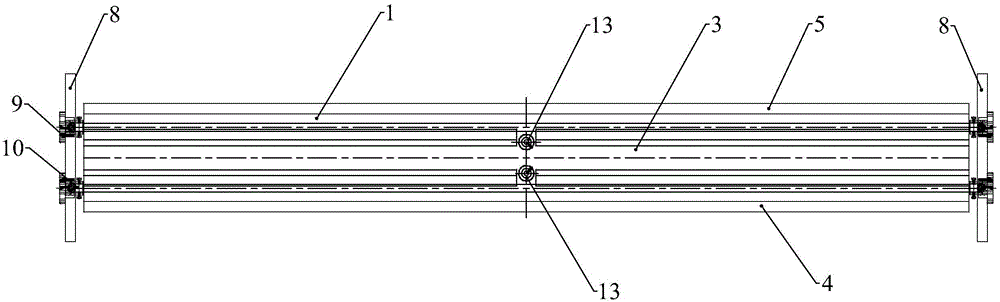

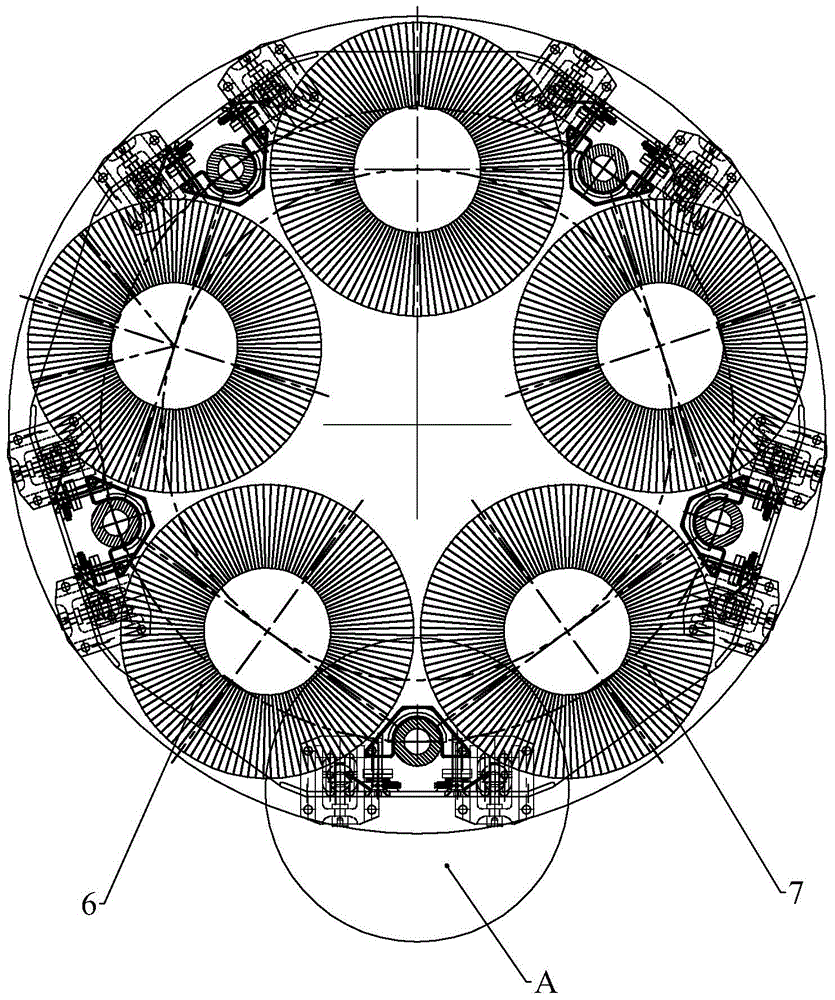

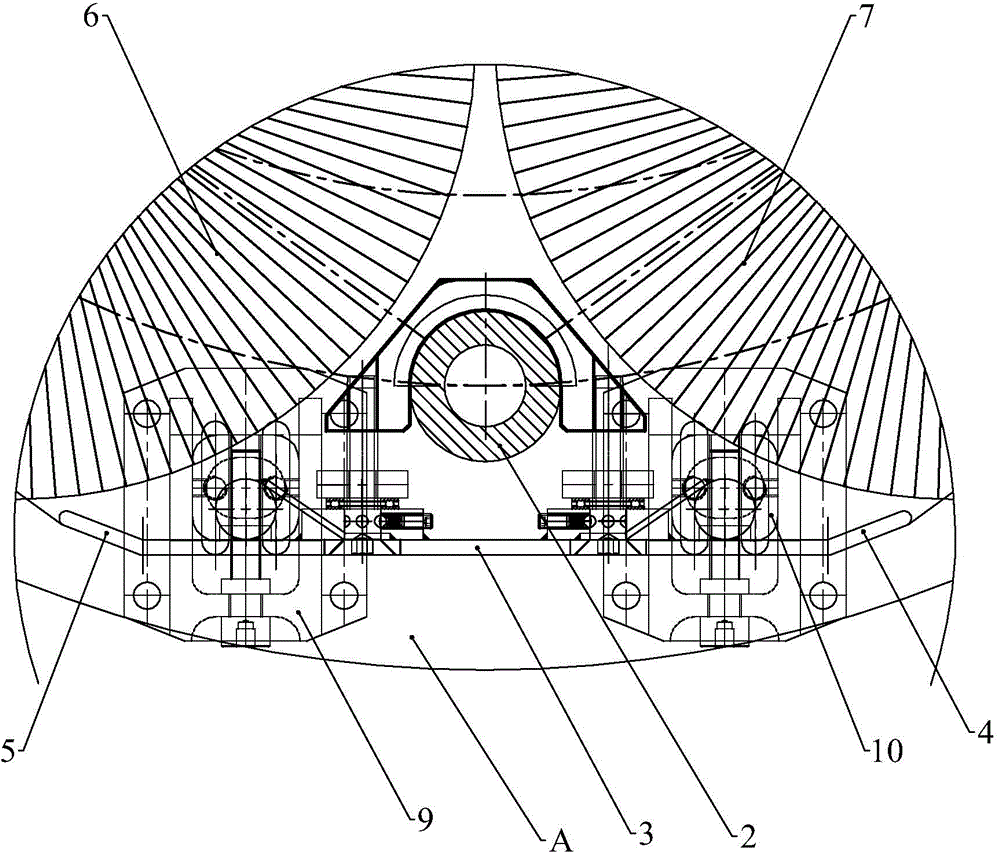

[0024] refer to Figure 1 to Figure 7 , this embodiment includes an adjustment plate 1, a support rod 2, and support seats at left and right ends; the adjustment plate has an opening portion 3, a front guide portion 4 and a rear guide portion 5, and the front guide portion and the rear guide portion are all bent inward and its bending angle is consistent with the tangent angle direction of the adjacent brush rollers 6 and 7; the support seat includes a support plate 8, an adjustment base plate 9 and an adjustment block 10; the adjustment base plate is fixed on the support plate, and the adjustment base plate There are waist-shaped holes 11 in the upper and lower directions, and the adjustment block forms the adjustment installation structure of the adjustment plate up and down through the adjustment bolts and the waist-shaped holes of the adjustment base plate; the adjustment block has waist-shaped holes 12 in the front and rear directions, and the two ends of the adjustment pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com