Patents

Literature

180results about How to "Solve the bend" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

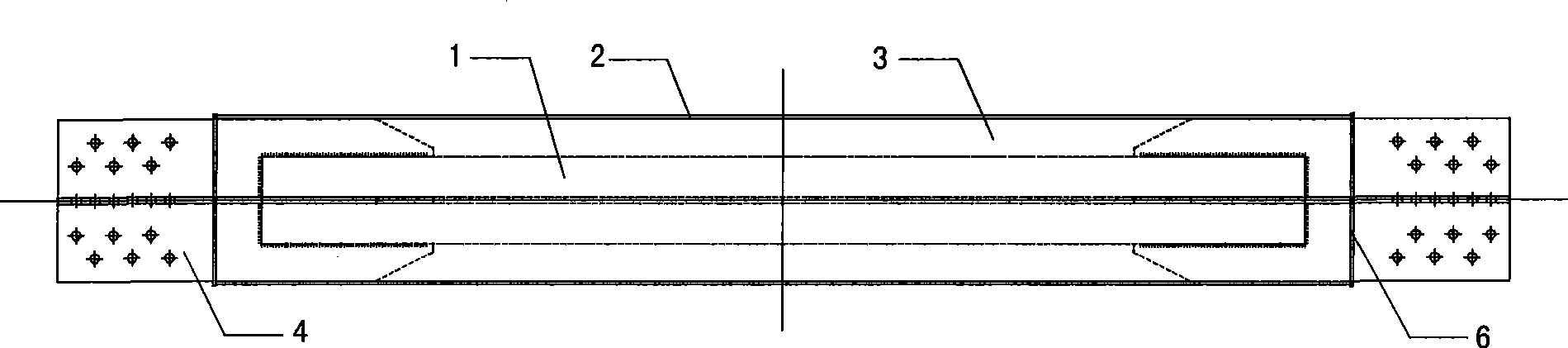

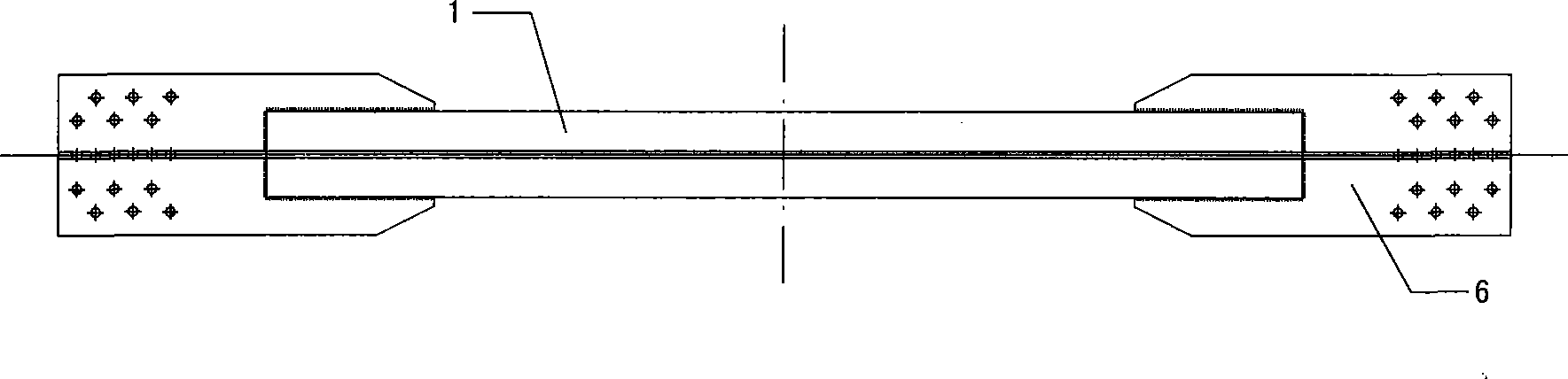

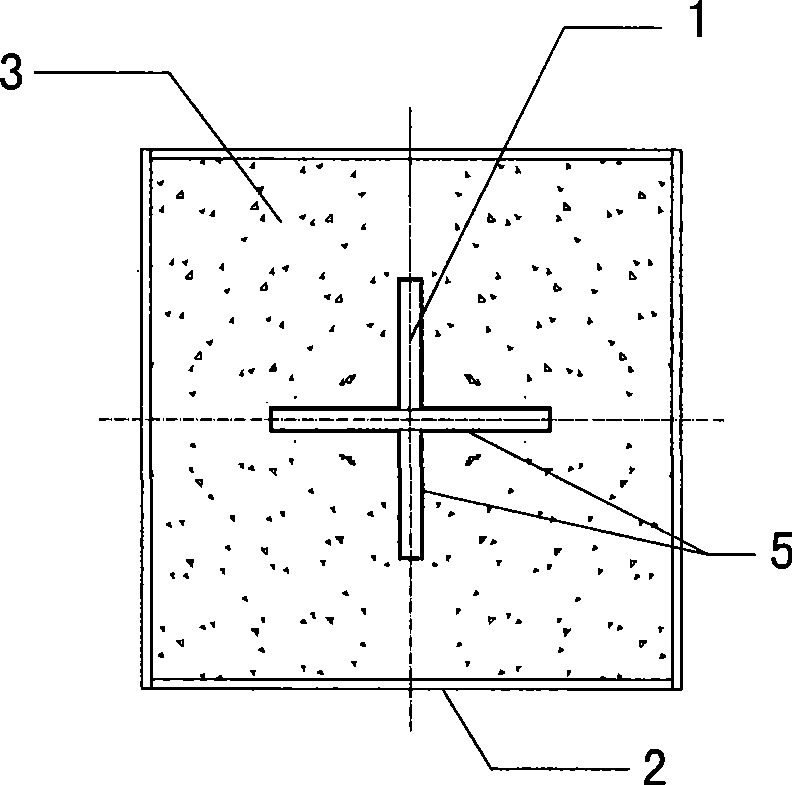

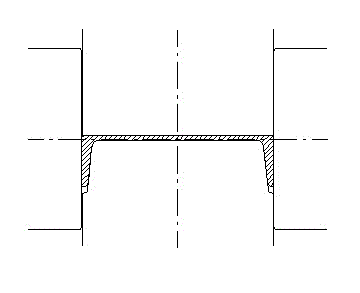

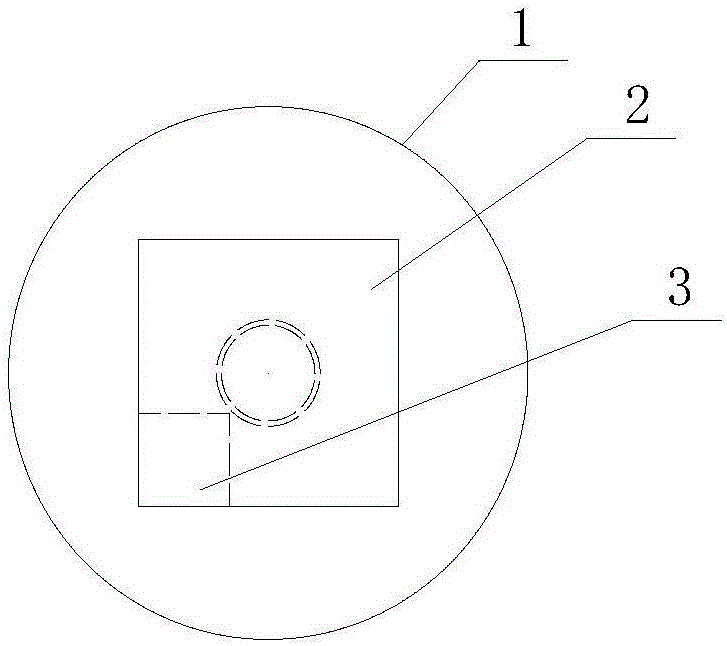

Once variable cross-section cross buckling-restrained bracing member

The invention discloses a cross-shaped buckling constraint support component with a primary variable cross-section. The support component comprises a core material part, a support end node and a sleeve part, wherein, the core material part is formed by welded core plates, the support end node part consists of gusset plates which are directly welded with the core plates, and the sleeve part consists of a square or quadrate steel sleeve and an internal filling material; a delaminating material is arranged between the internal filling material of the steel sleeve and the core plates. The invention also discloses a manufacturing method of the improved buckling constraint support component. The buckling constraint support has very good hysteresis characteristic and energy dissipation performance, is a very effective energy dissipation component, can achieve 1 / 80 deformation to satisfy 1 / 50 floor displacement deformation requirement of an architecture under an infrequent earthquake action and accumulates plastic deformation greater than 200 times of yielding displacement; the buckling constraint support has stable hysteresis characteristic and good low-cycle fatigue characteristic, can greatly improve seismic capability of the architecture, greatly reduce cost of the support and lay a foundation for popularization and application.

Owner:TONGJI UNIV

Technological method for symmetrical paired universal rolling of deformed steel

InactiveCN103143562APromote productionImprove yieldMetal rolling arrangementsInternal stressBar product

The invention discloses a technological method for the symmetrical paired universal rolling of deformed steel. The technological method comprises the following steps of: (1) roughly rolling a raw blank into an intermediate blank of a double-connected rolling piece in a rough rolling unit; (2) cutting off irregular deformed head and tail parts of the intermediate blank by using a sawing and shearing facility; (3) simultaneously carrying out fine rolling on the intermediate blank of the double-connected rolling piece in a fine rolling unit to obtain a double-connected final-section sectional bar; and (4) cooling the rolled double-connected final-section sectional bar to room temperature, and subdividing and straightening the double-connected final-section sectional bar to obtain single final-section sectional bar products through subdividing and straightening facilities. The technological method disclosed by the invention is wide in application range and suitable for rolling various deformed steels, solves the existing problem of post-cooling bending of the single rolled deformed steel, simultaneously optimizes a rolling production line, reduces energy consumption of production, equipment loss and production cost, and improves the production efficiency, and in addition, the rolled piece is good in surface quality, small in internal stress, and good in comprehensive machining quality and mechanical performance.

Owner:CISDI ENG CO LTD

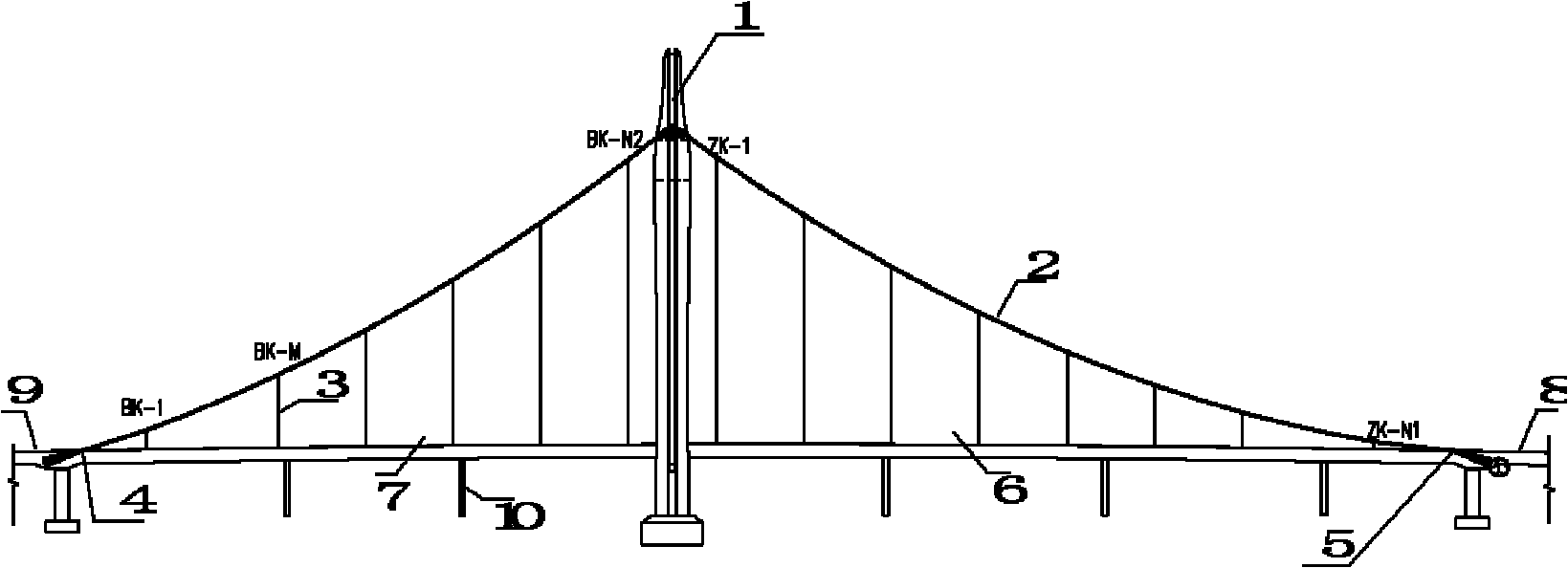

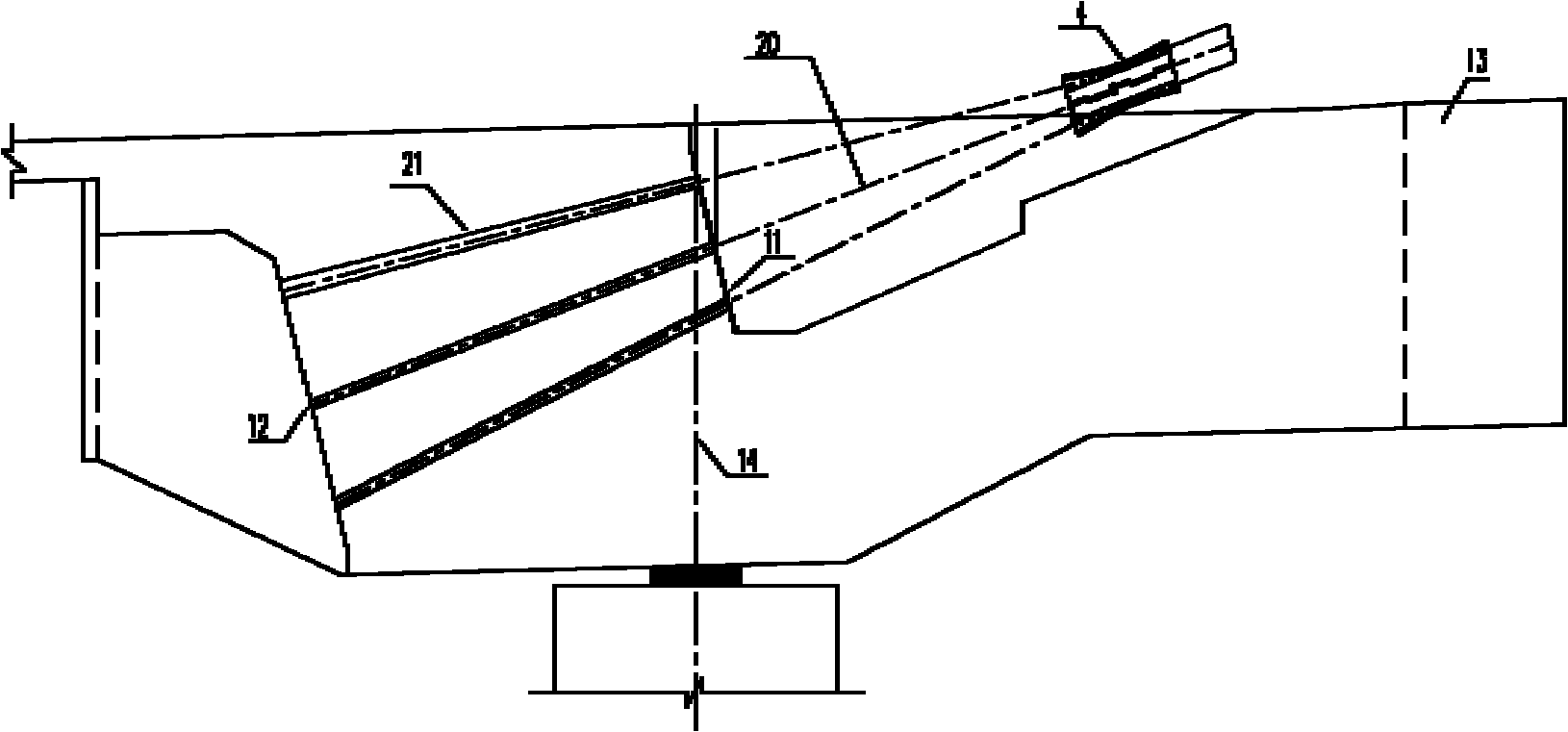

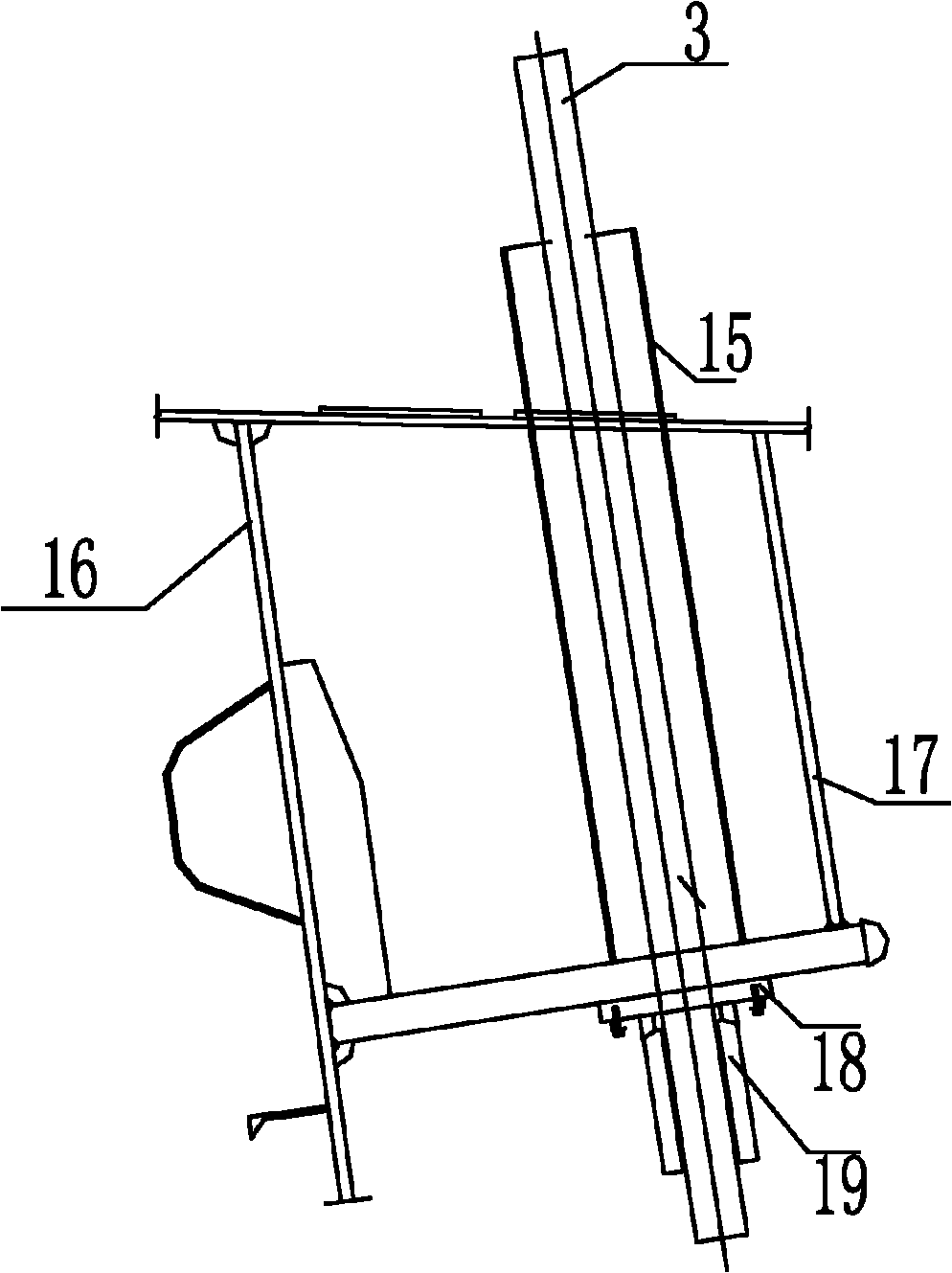

Method for stretching single-tower double-span self-anchored suspension bridge sling of side-span splay cable knot in supportless way

InactiveCN101838969ASolve the bendSolve the costSuspension bridgeBridge structural detailsTowerVertical displacement

The invention discloses a method for stretching a single-tower double-span self-anchored suspension bridge sling of a side-span splay cable knot in a supportless way. The method is characterized by comprising the following steps of: alternately stretching slings at lateral span sides when a main-span sling is gradually stretched from a main tower to a splay cable saddle at a main tower side; firstly stretching a BK-M sling close to a splay cable knot at a lateral span side; then, sequentially and gradually stretching to the side-span splay cable knot; and sequentially and gradually stretching from the BK-M sling to the main tower and upwards pushing a main cable saddle if the deviation of a tower top exceeds a limit in the process. In the method, the characteristic of greater control sling force of a permanent sling close to the side-span splay cable knot is utilized, the vertical displacement of the splay cable knot can be basically controlled after the permanent sling is stretched, the sling force has little increment at a later period, and the whole quantity satisfies the safety requirement. The invention has the advantages of high safety factor, rapidness, convenience, cost saving by saving temporarily fixing facilities, such as a splay cable knot or a temporary sling, and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

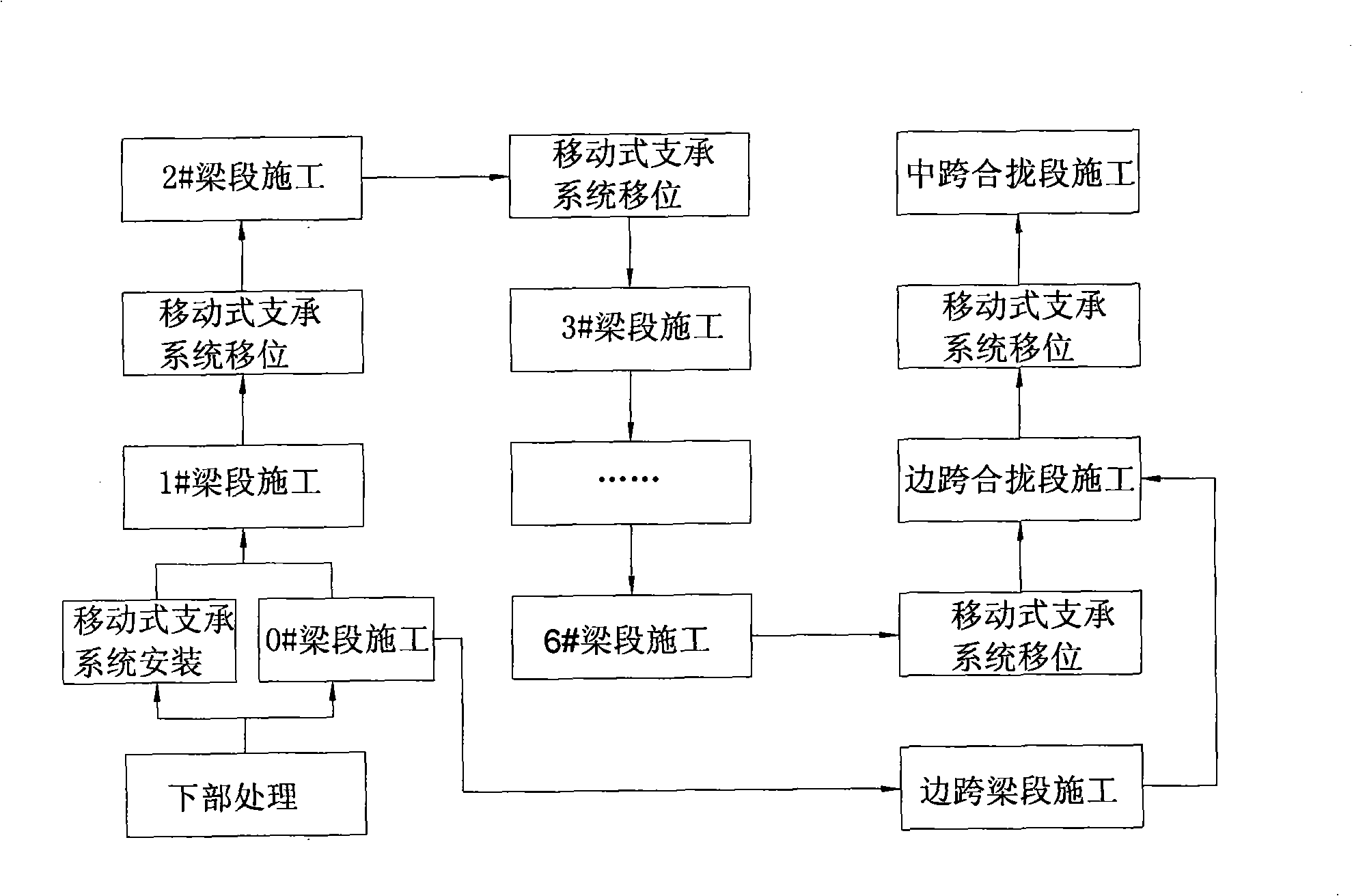

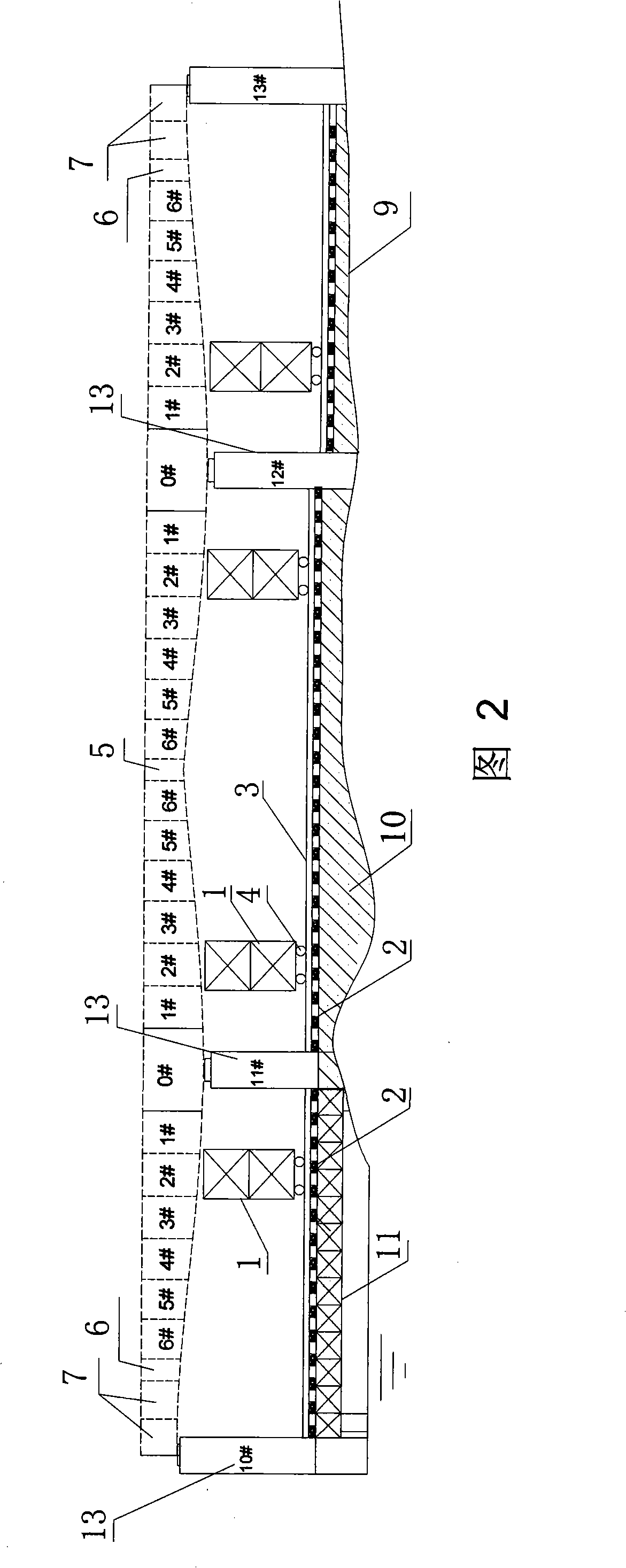

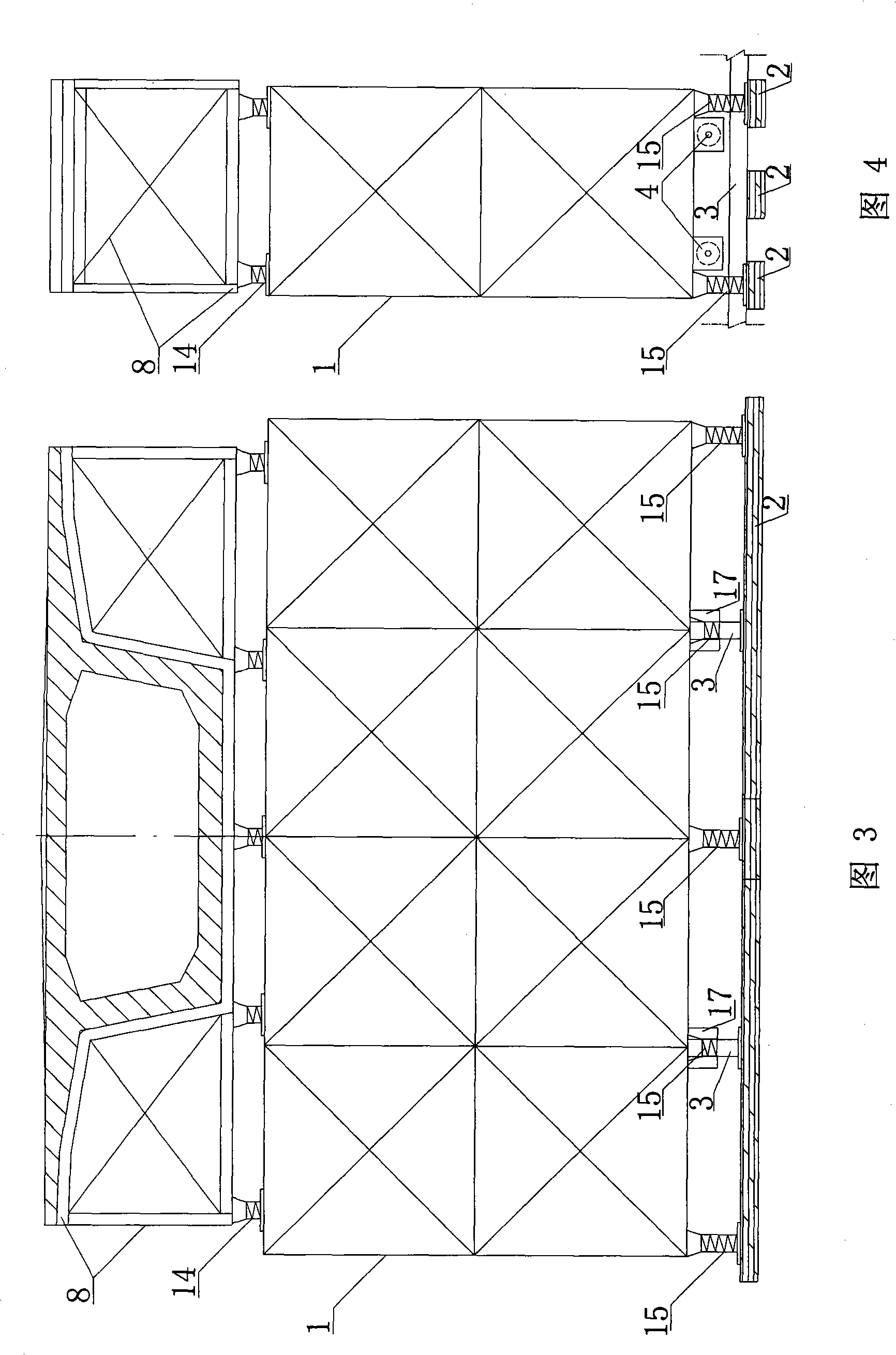

Construction method of mobile type bracket subsection cast-in-situ continuous beam

InactiveCN101280549ASolve the bendSolve the problem of large steel consumptionBridge erection/assemblyBridge materialsSupporting systemEconomic benefits

The invention discloses a construction method of movable support section cast-in-place continuous beam, which comprises the following steps: first perform the treatment for different topography and relief cases under the to-be-constructed continuous beam, and then install movable support system and perform the construction of 0# / SUB> beam section, and then utilize the movable support system to finish the construction of each beam section of the continuous beam body, finally utilize the movable support system to finish the construction of closure section of both side span and middle span, so as to finish the construction of the continuous beam. The construction method provided by the invention has the advantages of strong universality, safety and operability, good economic benefit, less technical difficulty, easy grasp and control, thereby being widely applied in the field of medium-small span continuous beam construction.

Owner:CHINA RAILWAY 12TH BUREAU GROUP 7TH CORPORATION LIMITED +1

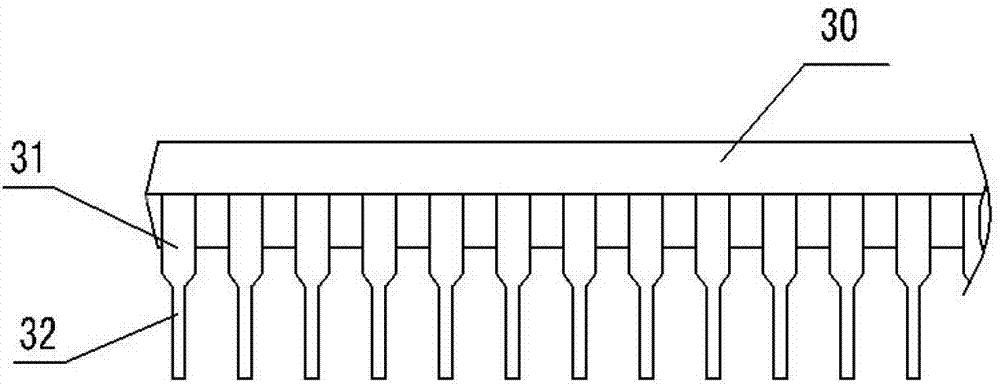

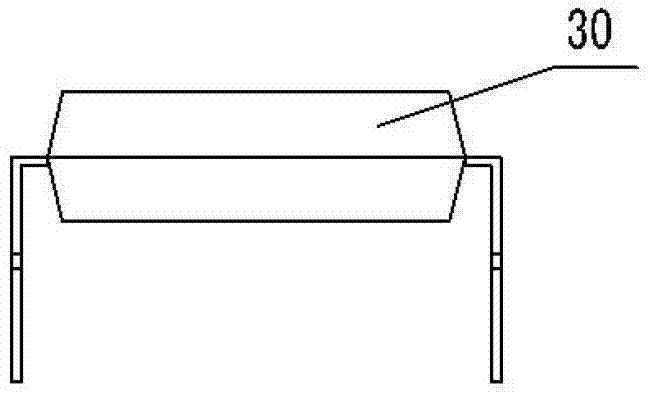

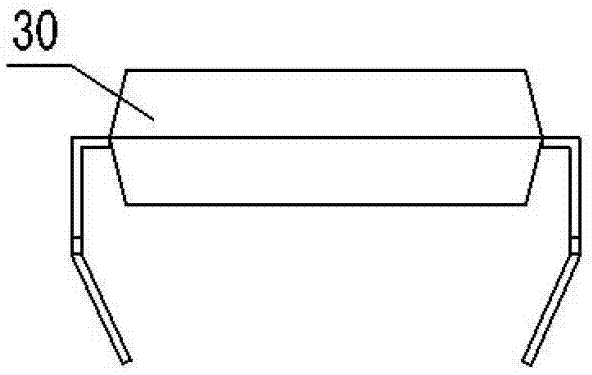

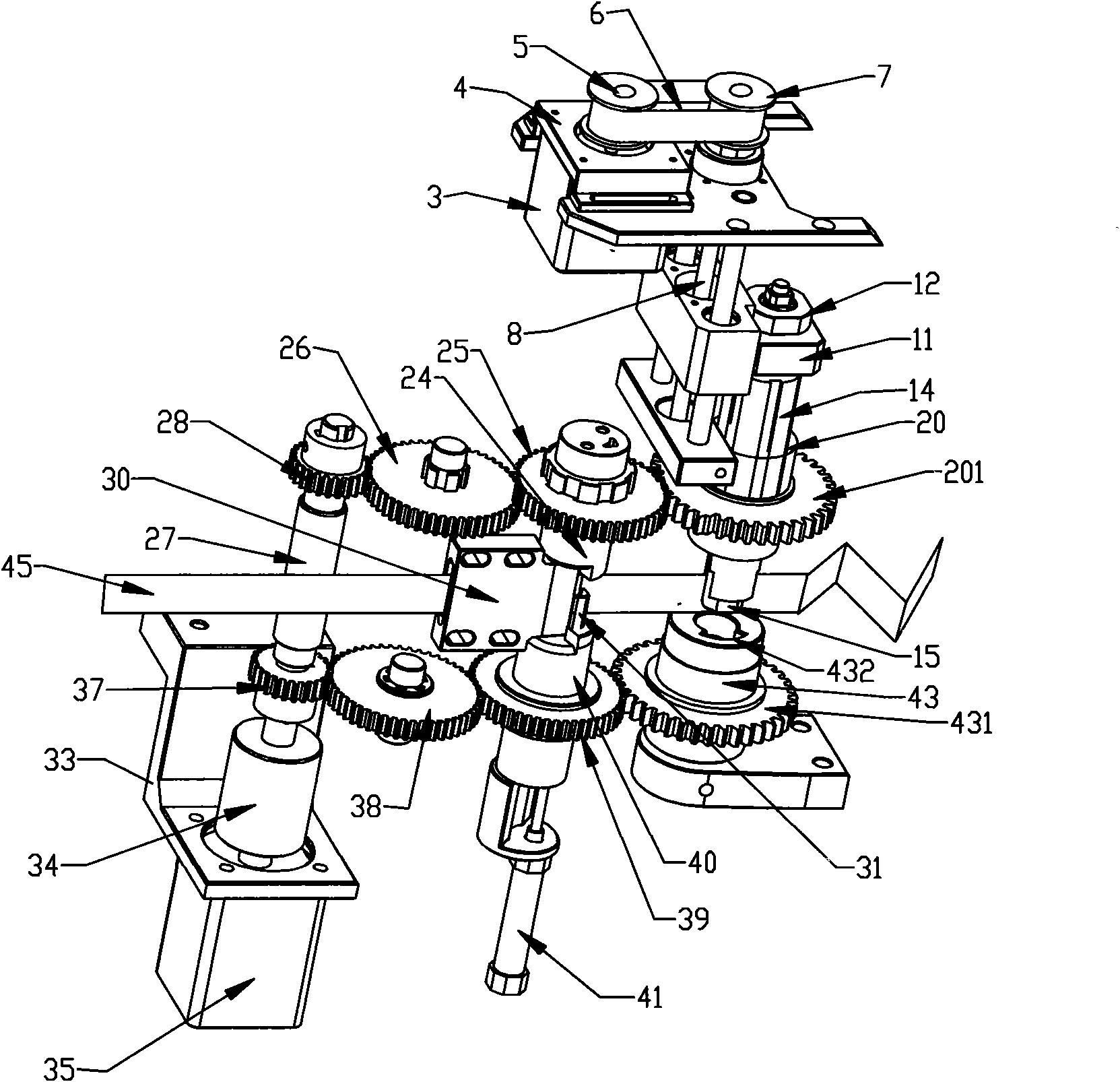

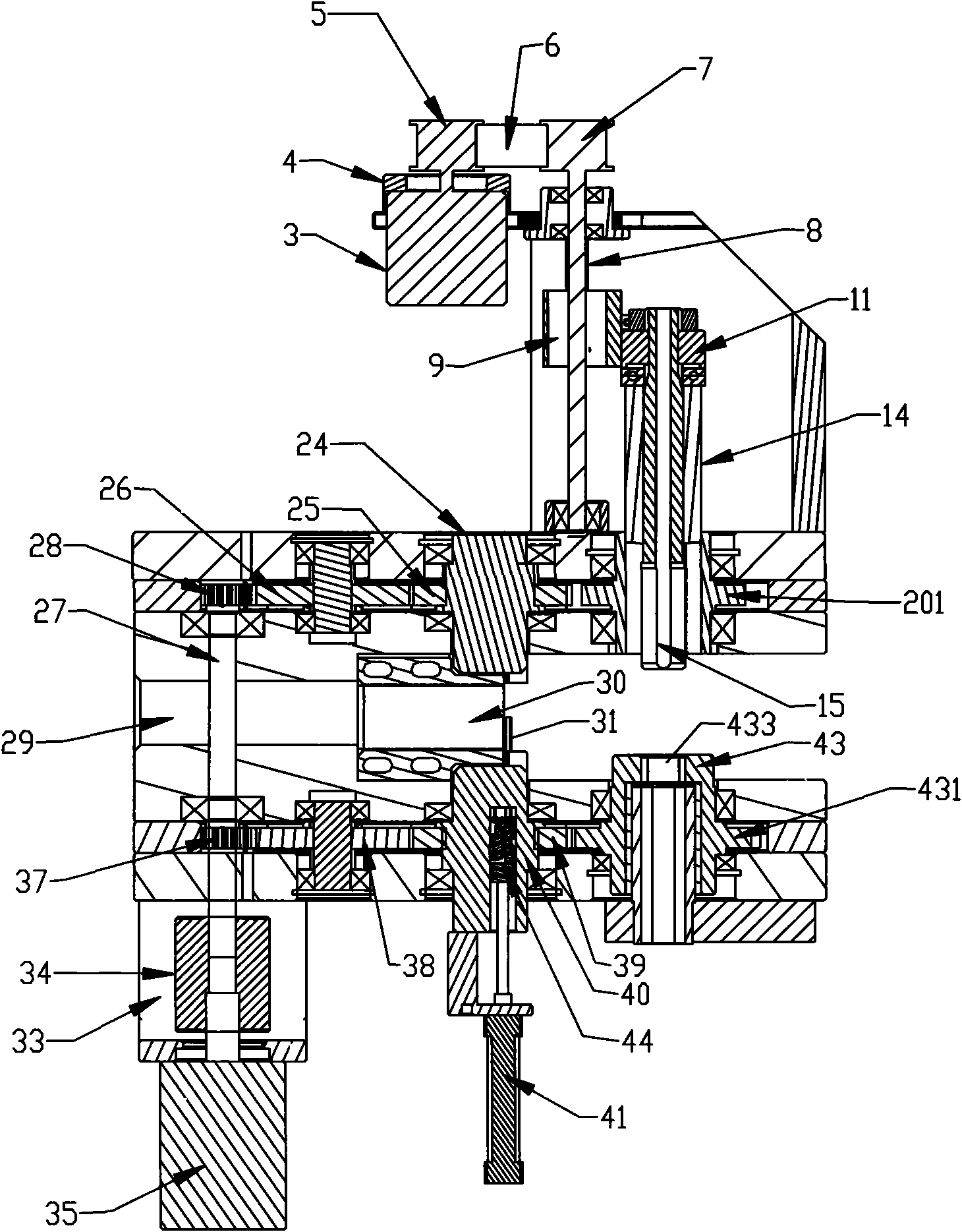

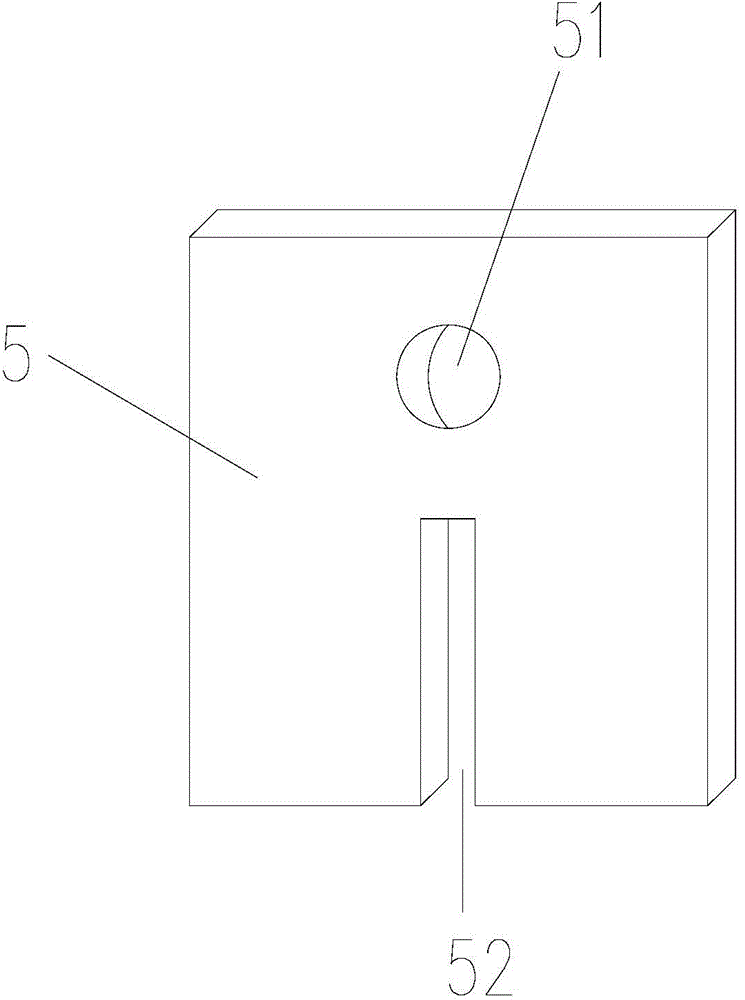

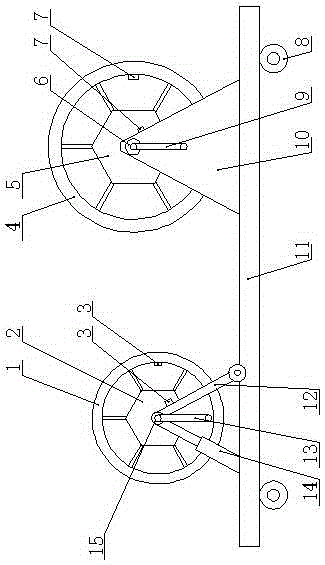

Pin trimming device based on recycled DIP (dual in-line package) type IC (integrated circuit) chip

InactiveCN102856237ASolving Pin Coplanar Trim IssuesSolve the bendSemiconductor/solid-state device manufacturingIntegrated circuit layoutPhotonic integrated circuit

The invention discloses a pin trimming device based on recycled DIP (dual in-line package) type IC (integrated circuit) chip. The pin trimming device is characterized by comprising a pin coplane trimming unit, a pin tooth root trimming unit, a pin prong trimming unit and a pin finishing unit. Based on the device disclosed by the invention, the DIP type IC chip can be efficiently, accurately, economically and practically recycled through the pin coplane trimming, the pin tooth root trimming, the pin prong trimming and the pin finishing in sequence.

Owner:HEFEI UNIV OF TECH

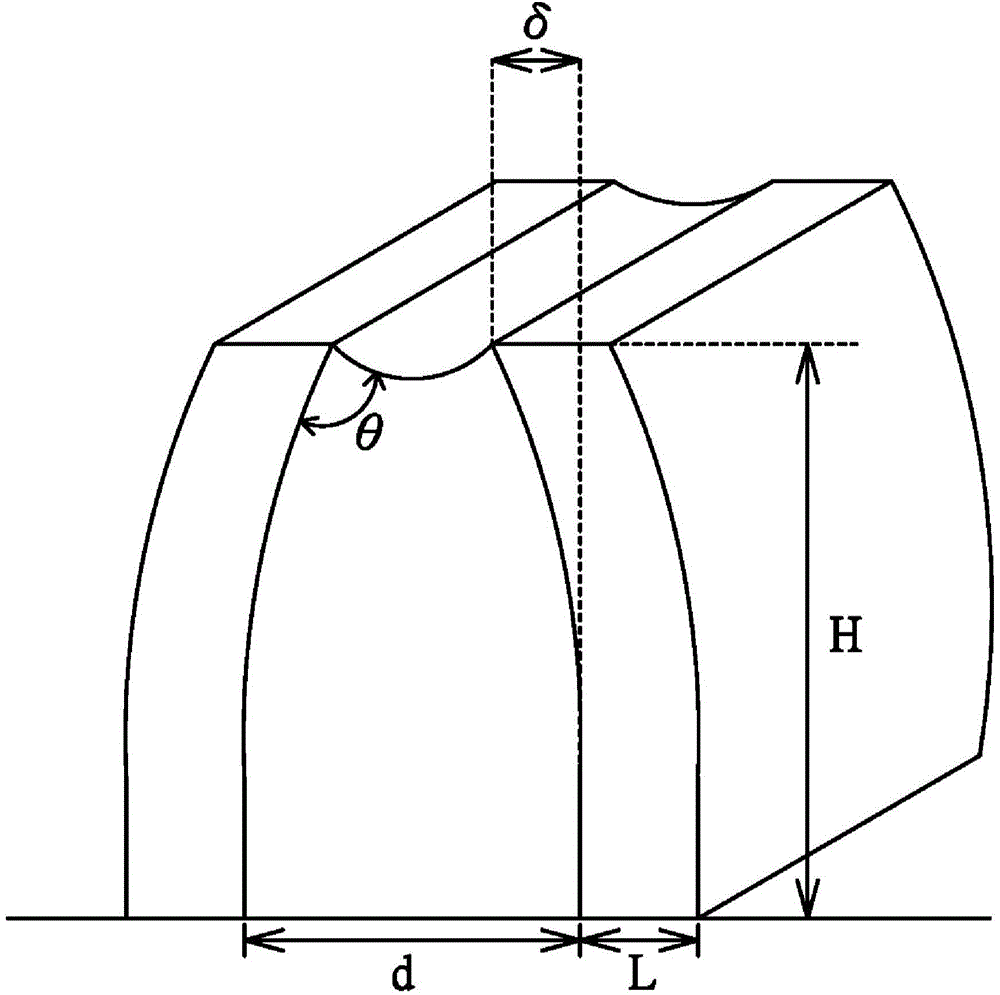

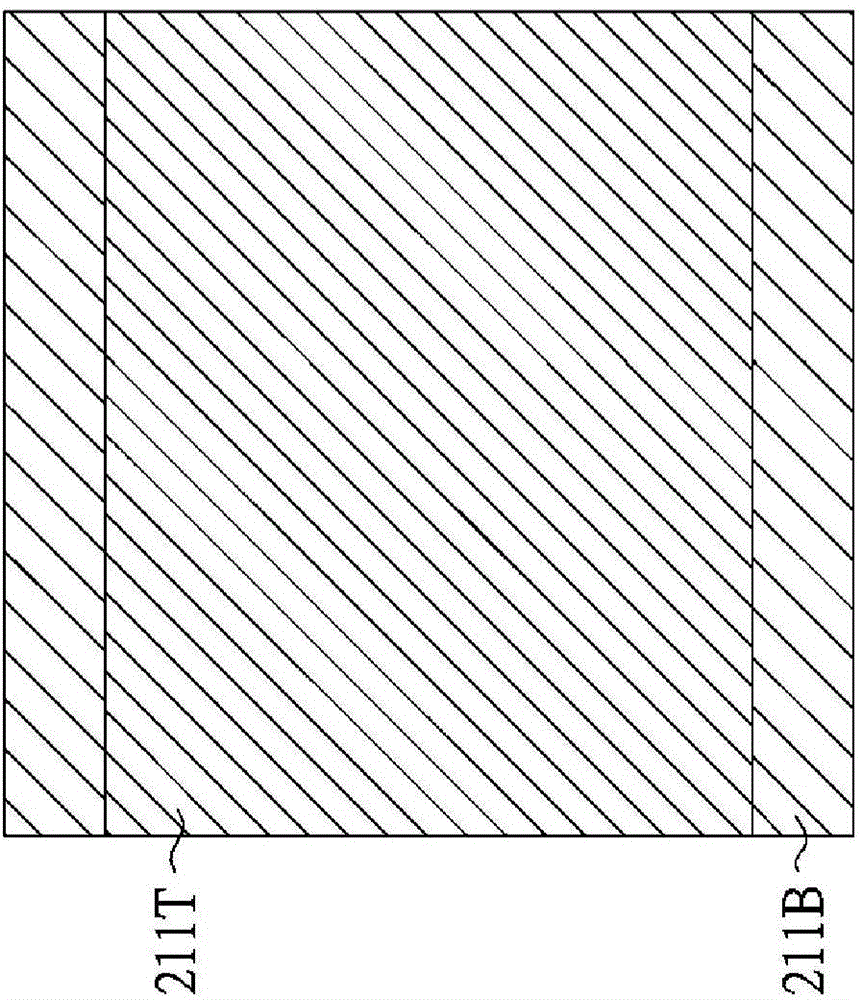

Bending and shearing mechanism

The invention discloses a bending and shearing mechanism, which comprises a body. A bending part and a shearing part are arranged on the body; the bending part comprises a servo motor, a transmission mechanism, a bending shaft, a bending inner die, a bending outer die and a bending outer die lifting mechanism; the bending inner die is arranged on the body and provided with a slotted hole through which a metal cutter material passes; the bending outer die is arranged on the bending shaft and driven by the bending outer die lifting mechanism to lift to attach the positive or negative surface of the bending inner die; the servo motor drives the bending outer die through the transmission mechanism to attach a notch of the bending inner die to rotate positively and negatively so as to press and fold the metal cutter material; the shearing part comprises a shearing inner die, a shearing outer die and a shearing part lifting mechanism; the shearing inner die and the shearing outer die are driven by the lifting mechanism to lift; the shearing inner die is axially fixed and provided with a slotted hole through which the metal cutter material passes; the shearing outer die is externally sleeved on the shearing inner die and attached to the orifice of the slotted hole; the shearing outer die is connected with a shearing shaft; and the shearing shaft is driven by the servo motor through the transmission of the transmission mechanism to rotate so as to drive the shearing outer die to rotate the metal cutter material.

Owner:深圳市华正源数控机电设备有限公司

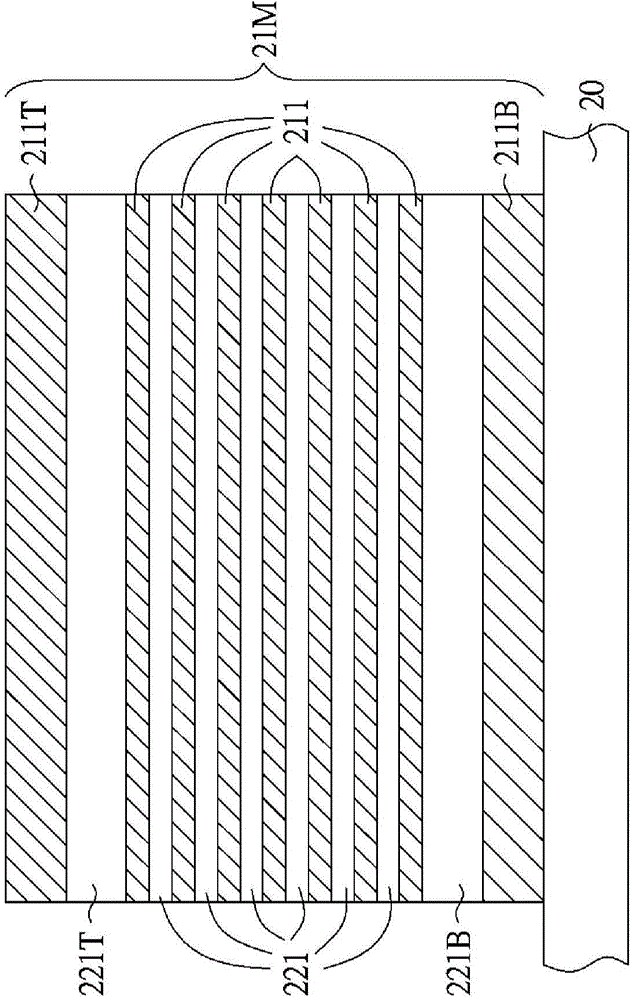

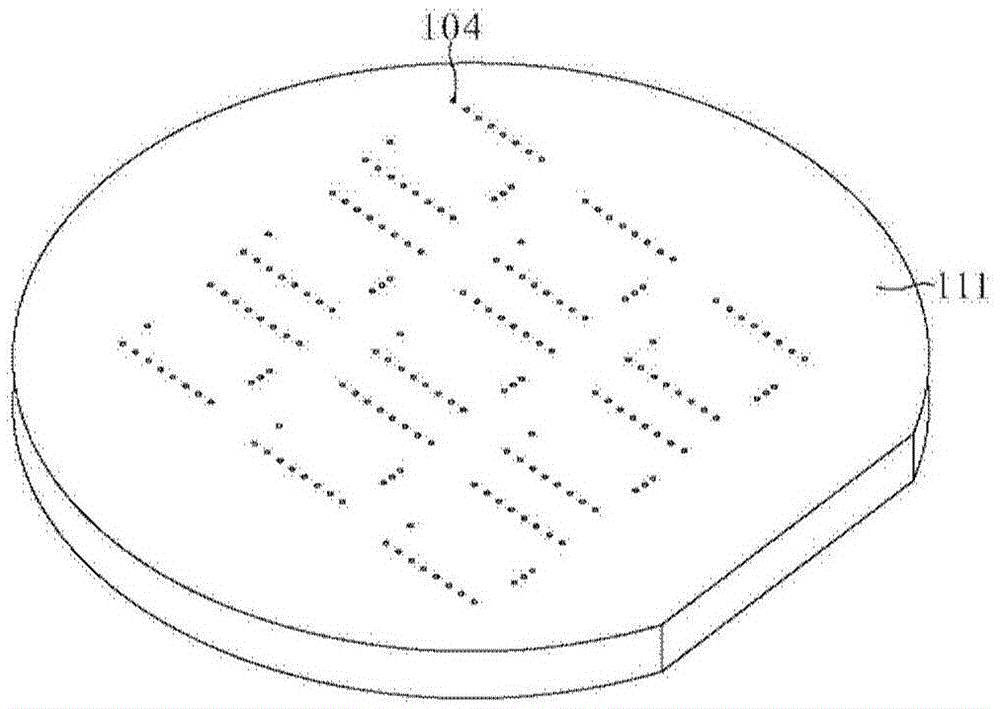

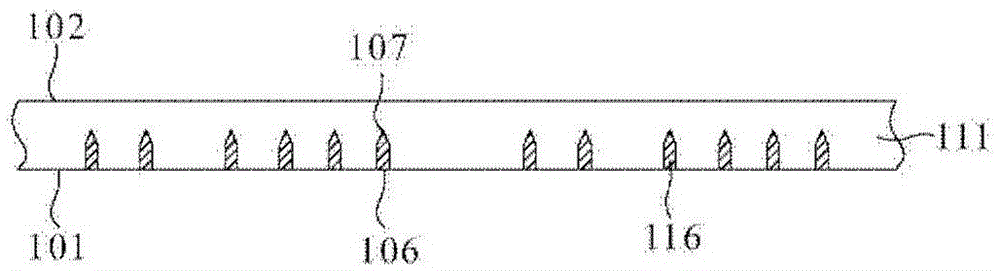

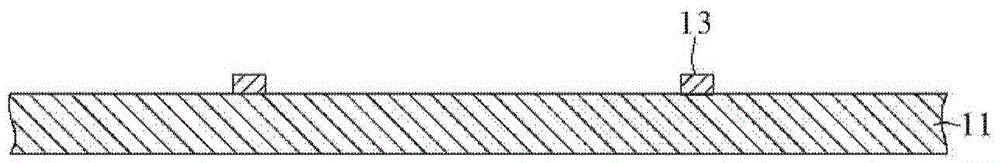

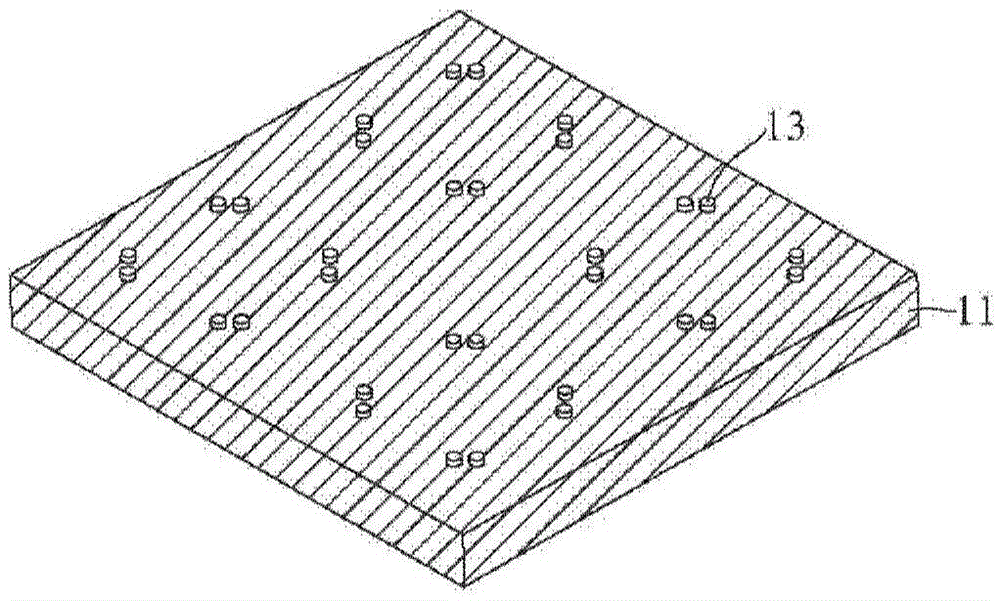

Three-dimensional laminated semiconductor structure and manufacturing method thereof

ActiveCN105097706ASolve the bendHigh strengthSolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorSemiconductor structure

The invention discloses a three-dimensional laminated semiconductor structure and a manufacturing method thereof. In the manufacturing method, a composite layer is formed on a substrate and is formed by alternate lamination of a plurality of first dielectric layer and a plurality of dielectric layers; and afterwards, the composite layer is patterned to form a plurality of first patterned laminates and a plurality of intervals between the first patterned laminates, one of the first patterned laminates has a width F0, and one of the intervals has a width Fs. In an embodiment, the width F0 is equal to or greater than two times of the width Fs. Then, part of the second dielectric layers of one of the first patterned laminates are removed, so that a plurality of first cavities are formed in the first patterned laminate. Afterwards, first conductors are filled in the first cavities of the first patterned laminate.

Owner:MACRONIX INT CO LTD

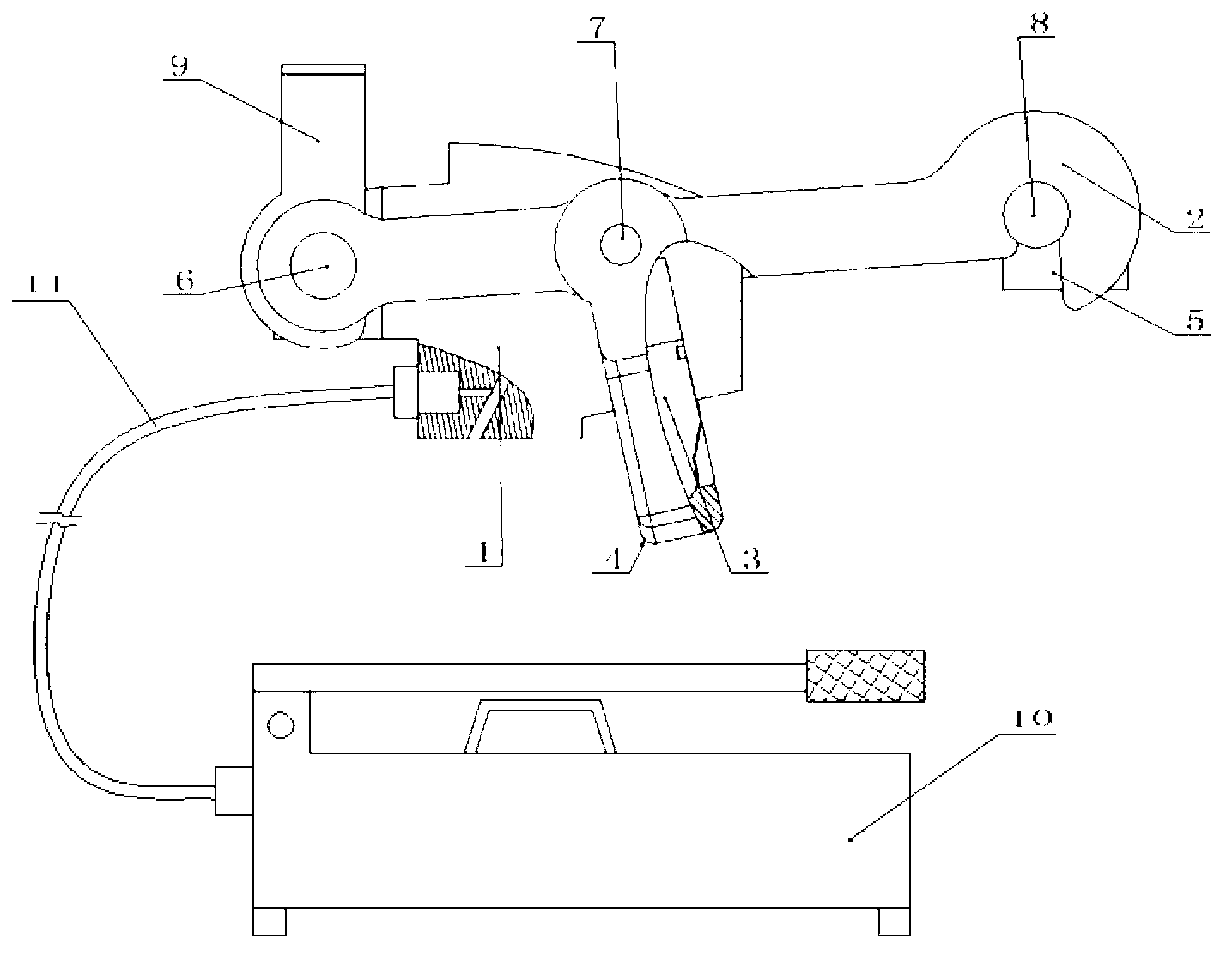

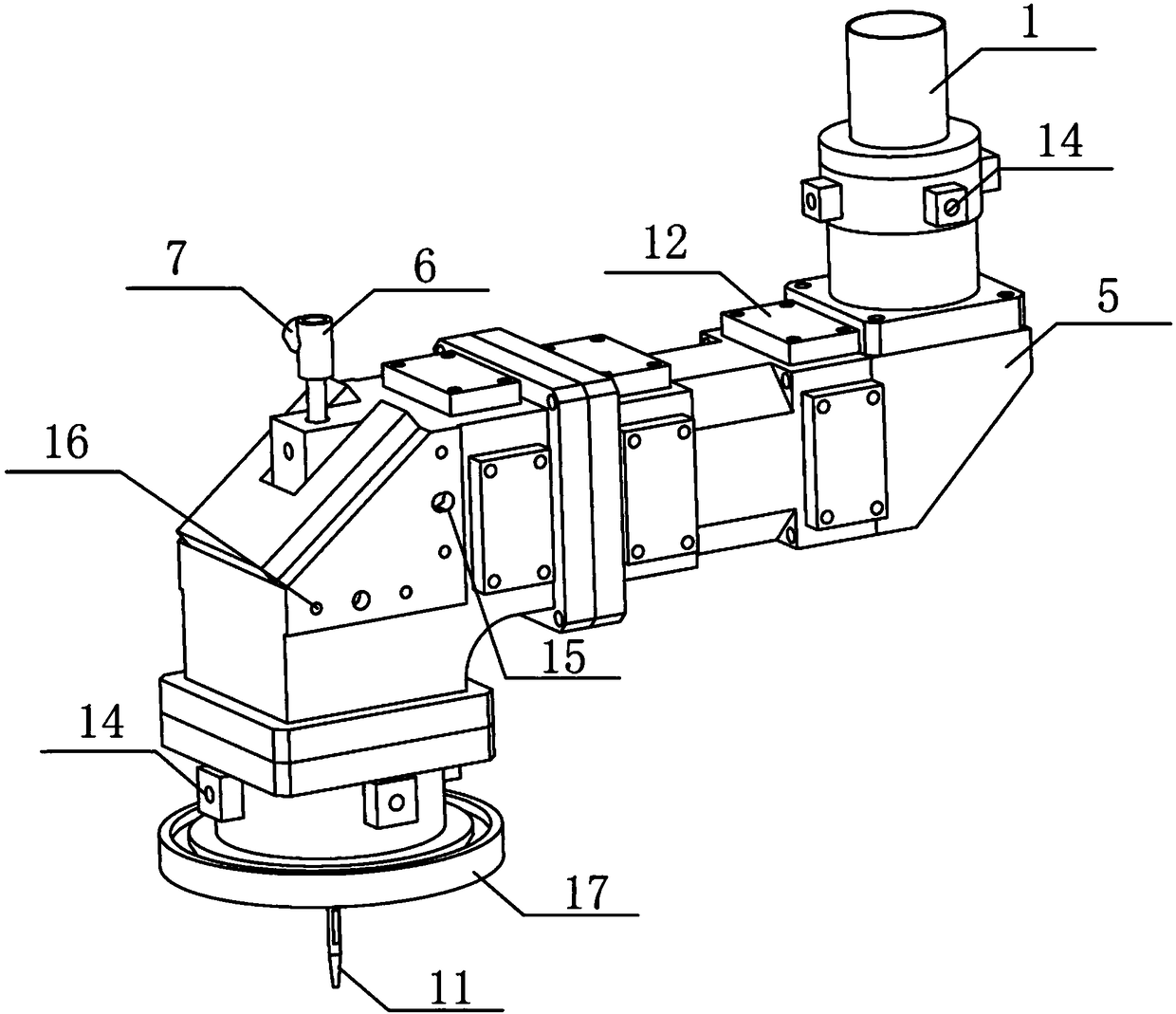

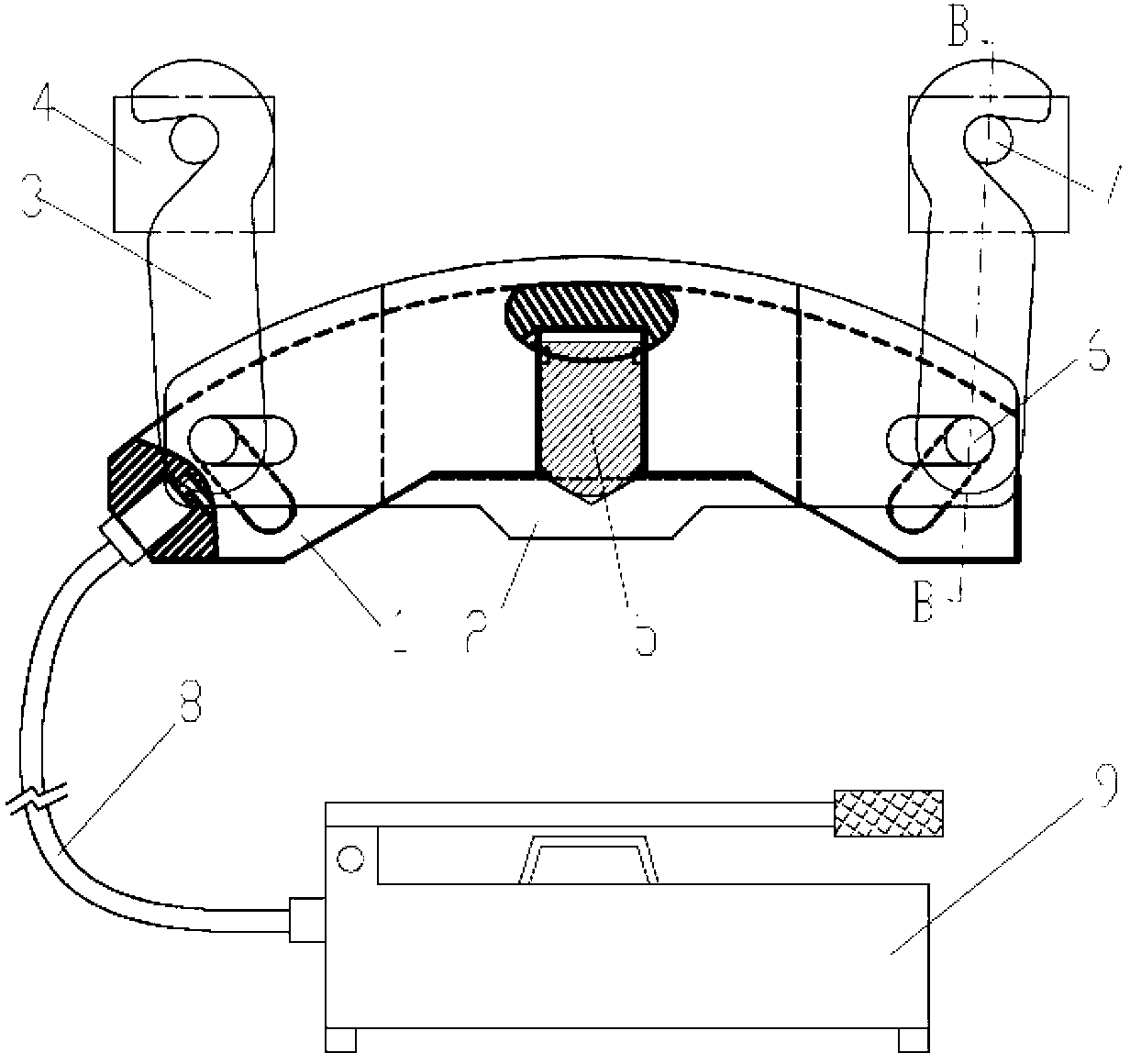

Small portable self-adaptive hydraulic pipe bender

The invention provides a small portable self-adaptive hydraulic pipe bender. The pipe bender comprises a forming die, a compression bar, a pressing bar, a connection bar, a piston, a pipe clamp, a pressing block, a forming die hinge pin, a pressing bar hinge pin, a pressing block hinge pin, a manual hydraulic pump and a high-pressure hose. The forming die is a body structure, and the ends of the pipe clamp and the pressing bar are hinged to the forming die through the forming die hinge pin. The middle of the pressing bar is hinged to the pressing bar hinge pin through the connection bar, the pressing block is hinged to the other end of the pressing bar through the pressing block hinge pin, the piston is disposed in an oil cylinder in the forming die, and the manual hydraulic pump is used for providing oil pressure. During operation, a straight pipe to be bent is attached to the forming die through the pipe clamp and the pressing block, the manual hydraulic pump is pressed repeatedly to generate high-pressure oil to push the piston to move, the connection bar is pushed by the piston and pulls the pressing bar to rotate, and the pressing bar pushes the pressing block to impose bending moment on the pipe to bend the pipe. The pipe bender has the advantages of being portable, compact in structure, large in bending moment, self-adaptive to changes, applicable to pipe bundle bending within limited operation space and capable of preventing producing of defects of pits, indentations and the like on the surfaces of pipes.

Owner:TSINGHUA UNIV

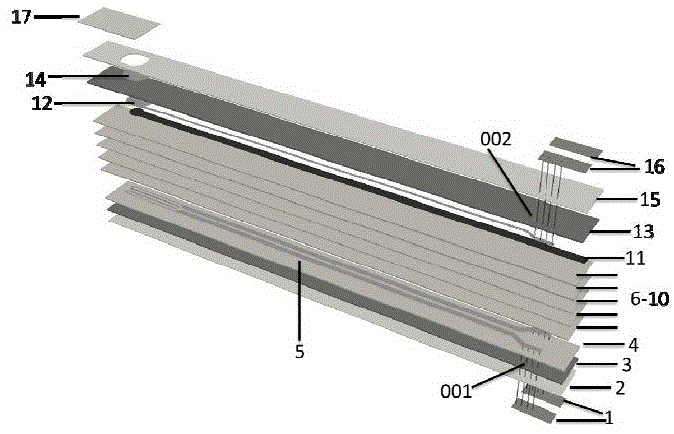

Plate type ceramic oxygen sensor

InactiveCN107525839AAvoid sintering shrinkageImprove flatnessMaterial analysis by electric/magnetic meansAir channelAluminium oxide

The invention provides a plate type ceramic oxygen sensor which comprises electrode pins, a heater, a plurality of aluminum oxide substrate layers, a reference ratio air channel, an internal sensitive electrode, a zirconium oxide functional layer, an external sensitive electrode, a sensitive electrode protection layer as well as a zirconium oxide symmetric layer and aluminum oxide insulating layers, wherein the zirconium oxide symmetric layer is arranged in symmetry with the zirconium oxide functional layer in an overlapping direction; and the aluminum oxide insulating layers are respectively arranged on the upper side and the lower side in the overlapping direction. According to the plate type ceramic oxygen sensor, the problems that an aluminum oxide based oxygen sensor is bent and warped and the like, and power leakage can be caused by electrode pins on a zirconium oxide layer, are solved, and thus the plate type ceramic oxygen sensor which is high in flatness, simple in process and stable in property is provided.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

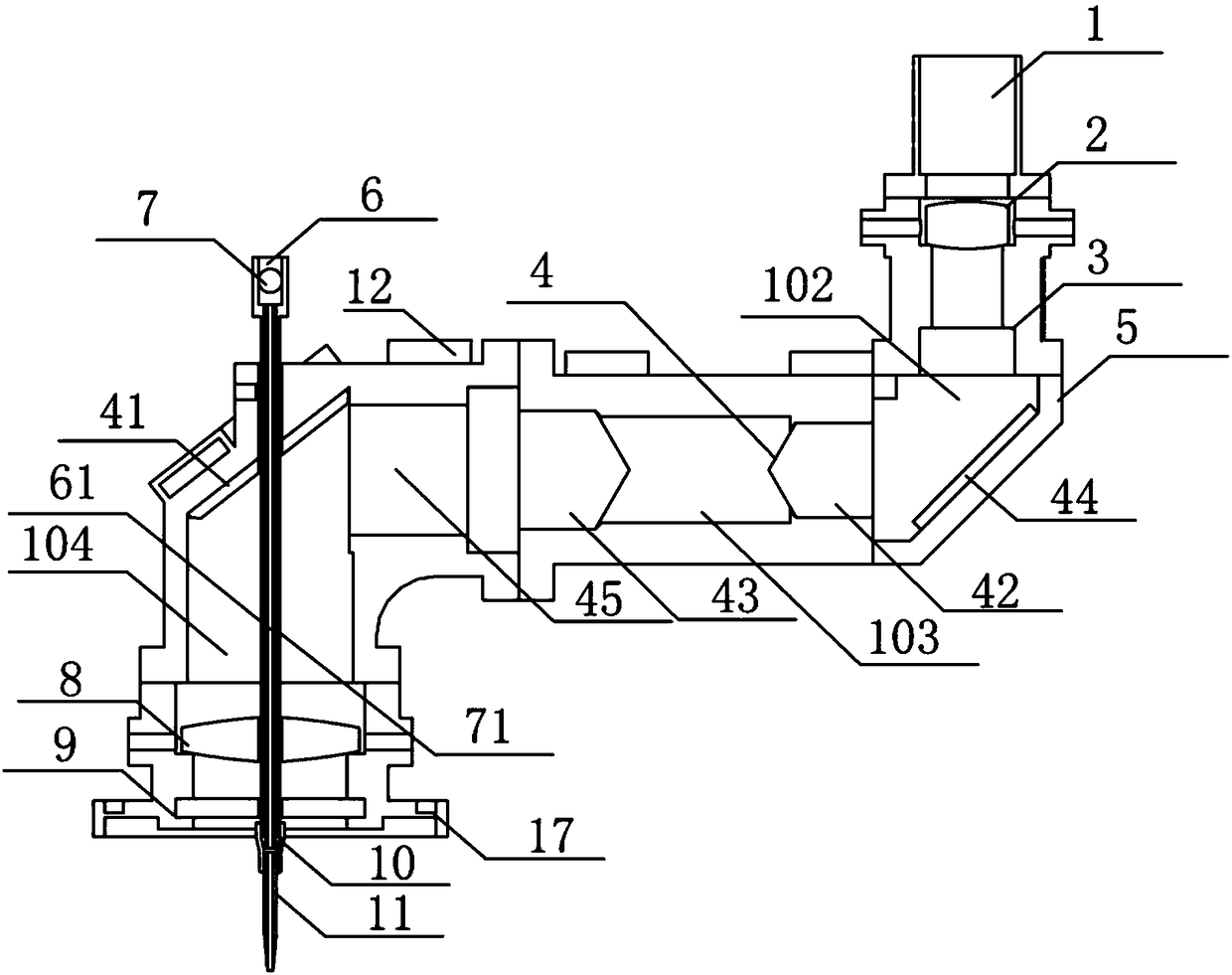

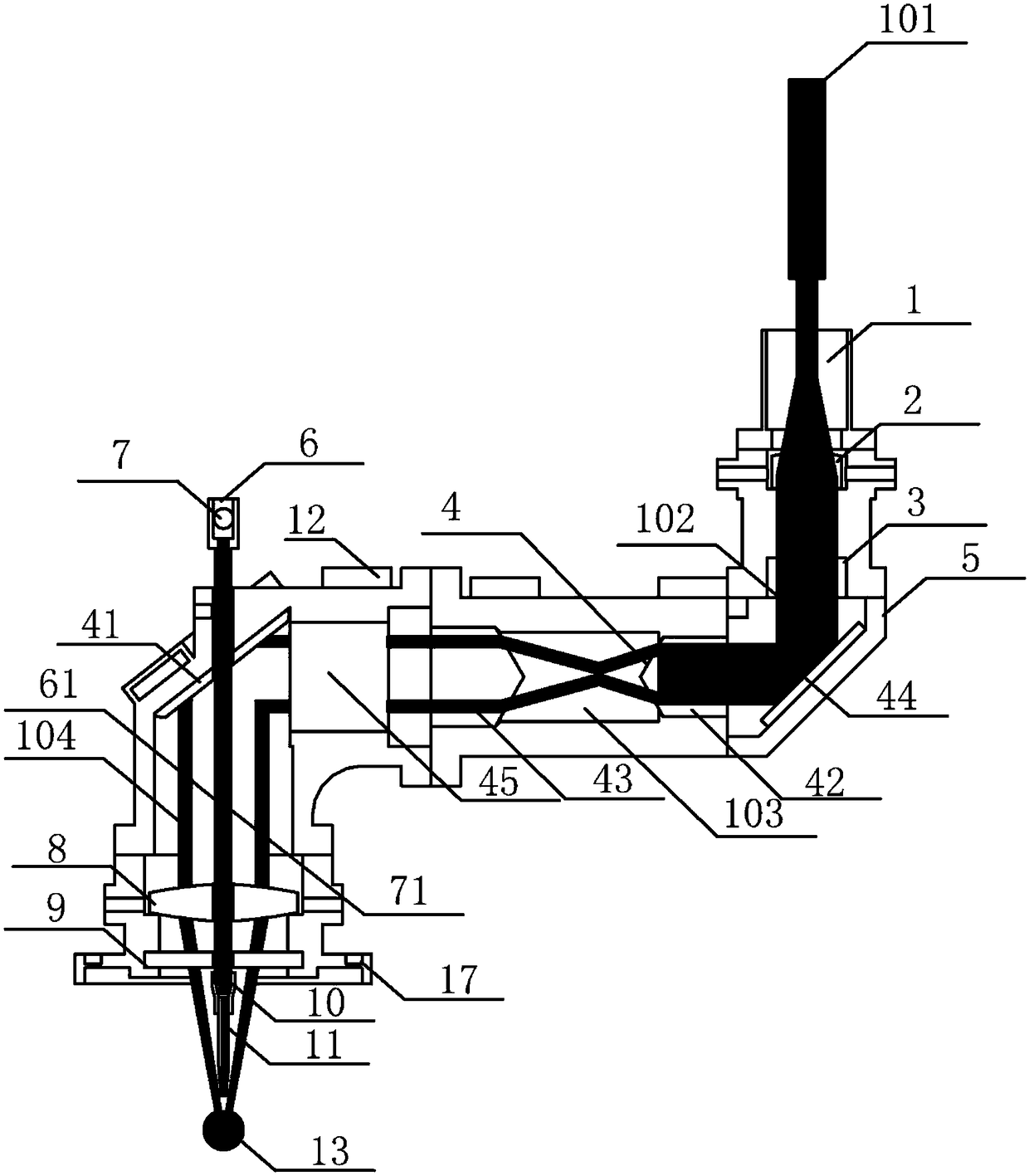

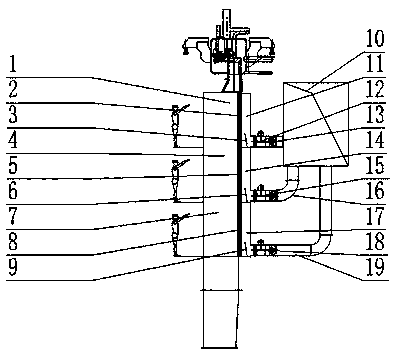

Coaxial wire-feeding cladding head for laser metal printing

PendingCN108544092ASolve the bendImprove stabilityLaser beam welding apparatusTransmission channelLight beam

The invention provides a coaxial wire-feeding cladding head for laser metal printing. The coaxial wire-feeding cladding head for laser metal printing comprises a laser device connector, an annular light beam generation device used for converting a solid laser beam to an annular hollow light beam, a wire-feeding pipe, a focusing mirror and a sealed box body, wherein mutually-communicating transmission channel and output channel are formed in the sealed box body, the transmission channel and the output channel are not located on the same axis, a reflecting mirror is arranged at the junction of the transmission channel and the output channel, the reflecting mirror leads the annular hollow light beam into the output channel, and the focusing mirror is arranged in the output channel; and the wire-feeding pipe is arranged in the output channel along a straight line, and coaxial with the annular hollow light beam. The coaxial wire-feeding cladding head for laser metal printing has the following beneficial effects: a metal wire is transmitted to a cladding position from a position coaxial with the laser beam, so that the coaxiality of the metal wire and the annular laser beam is improved;and the convergence angle of the laser beam during re-focusing is reduced, and the stability of the metal wire in a forming process is improved.

Owner:SHANGHAI IND TECH INST

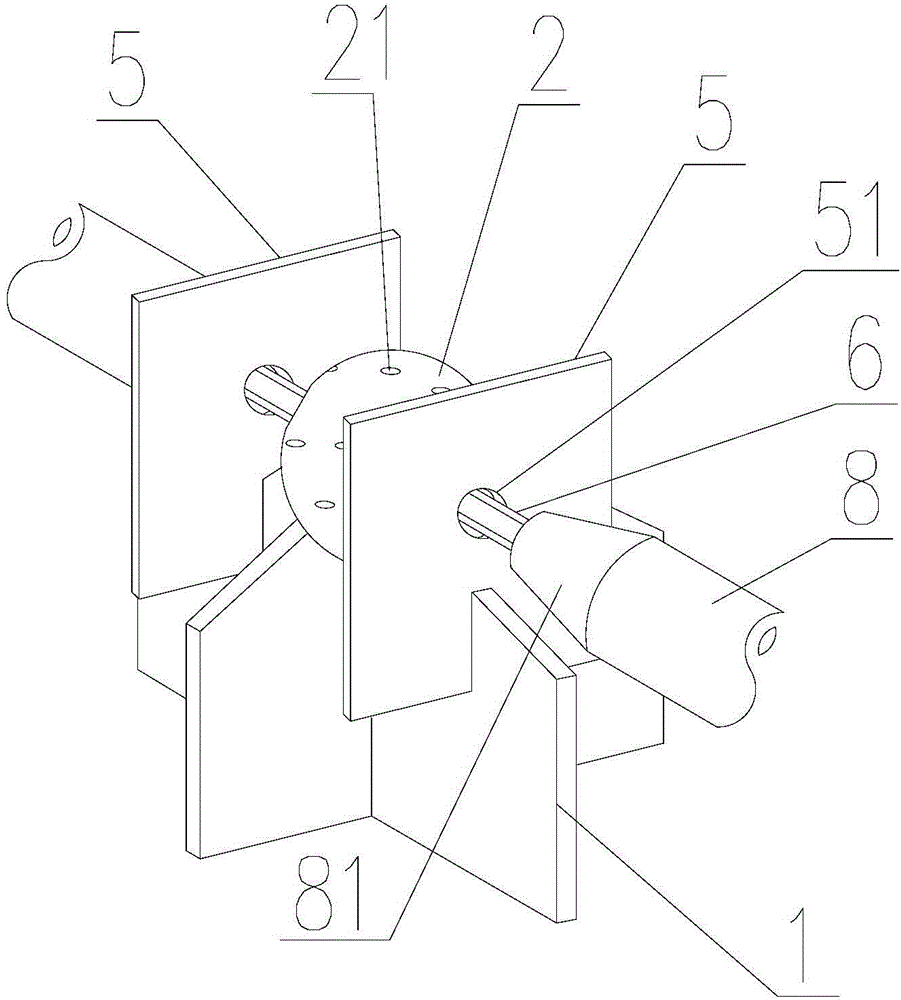

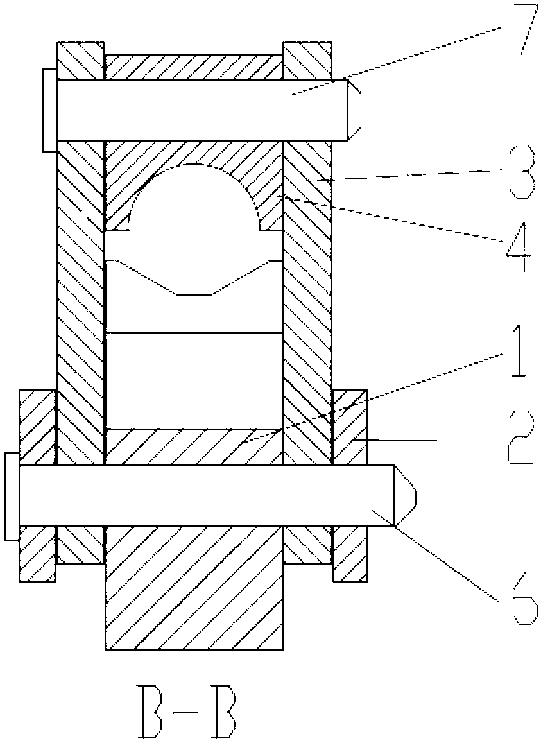

Hinge station plate-type support and mounting method thereof

InactiveCN104963412ASolve the easy instability of assemblySolve the bendBuilding material handlingHinge angleEngineering

The invention discloses a hinge station plate-type support comprising four support arms; round slots are arranged on connecting portions of the four support arms, and bolt balls are placed in the round slots; the bolt ball is provided with a plurality of bolt holes; two opposite support arms are respectively fixed with a clamp plate; a card slot is arranged below the clamp plate, and clamped and fixed on the clamp plate; an upper portion of the clamp plate is provided with a round hole allowing a threadless nut to pass, the center of the round hole is provided with a through hole allowing a bolt to pass, and the bolts are screwed in the bolt holes; the bolts rotate to drive the bolt balls to spin. The invention also discloses a method using the hinge station plate-type support to mount a net rack; the method uses a single crane to adjust the height and angle of the net rack connected with the bolt balls, so the next net rack can be assembled, thus effectively solving the unstable, bending, hard construction and inaccurate positioning problems caused by basic cross-mounting usage of scaffolds and problems in multi-crane hoisting assembling; the hinge station plate-type support is simple in structure, high in safety, simple in operation, economic, and practical.

Owner:ANHUI ZHONGYA STEEL STRUCTURE ENG

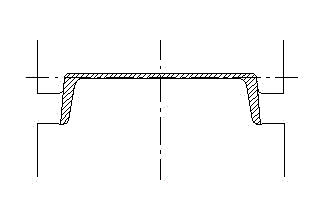

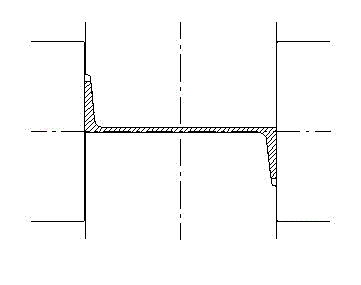

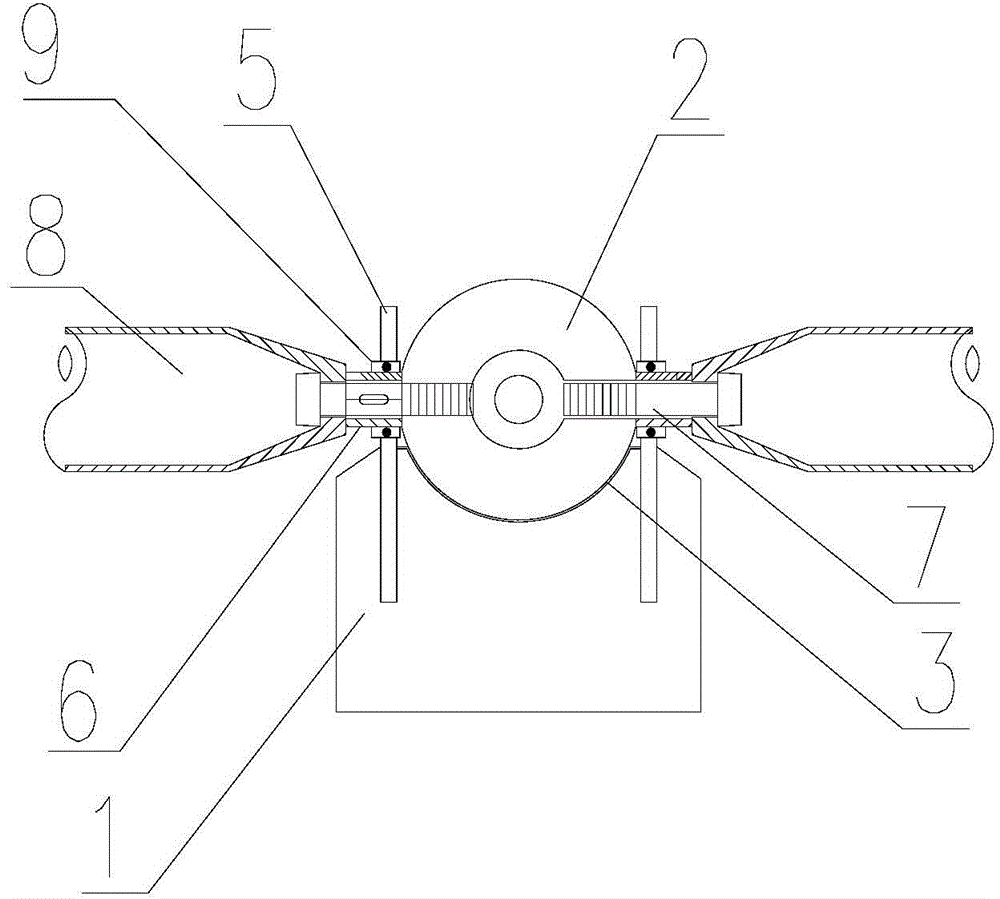

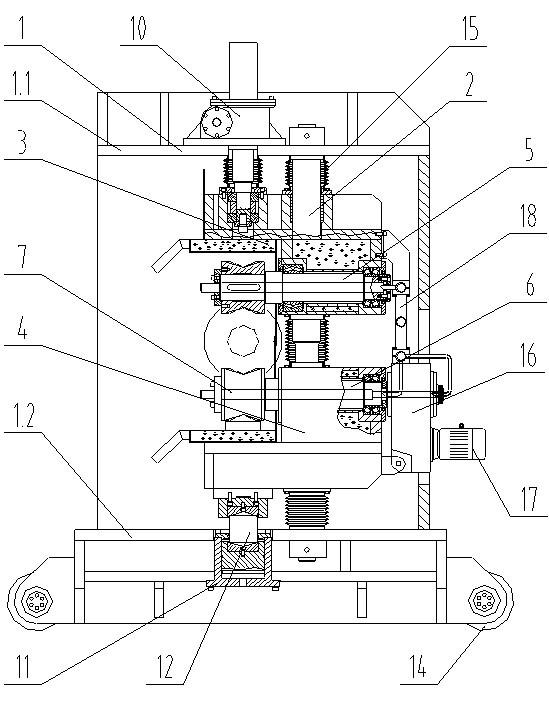

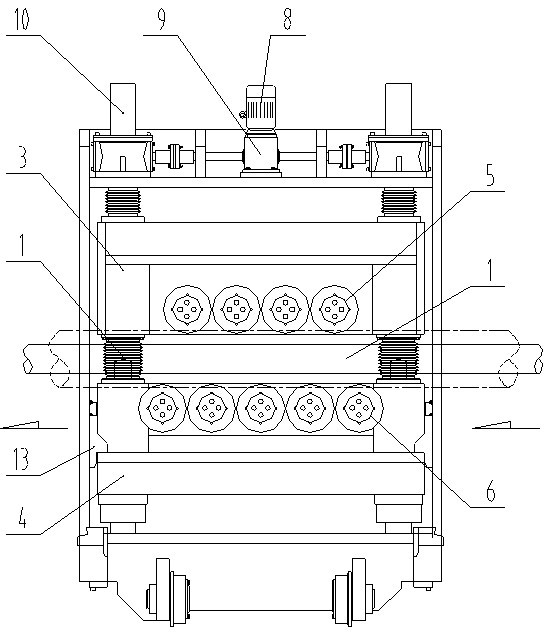

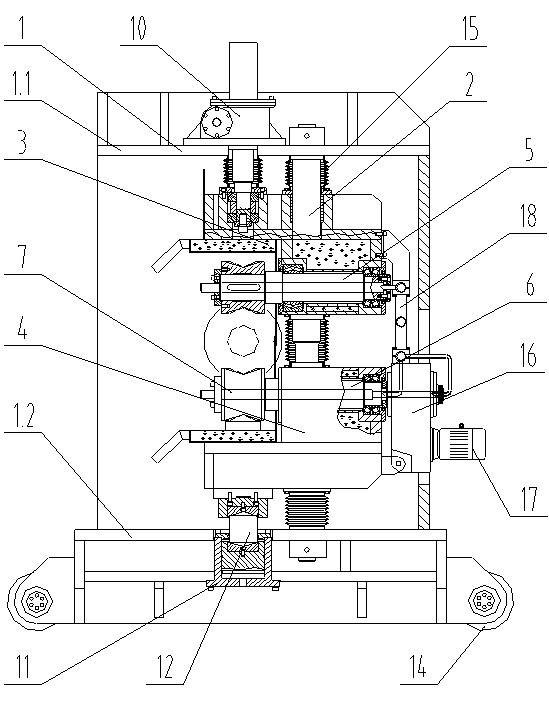

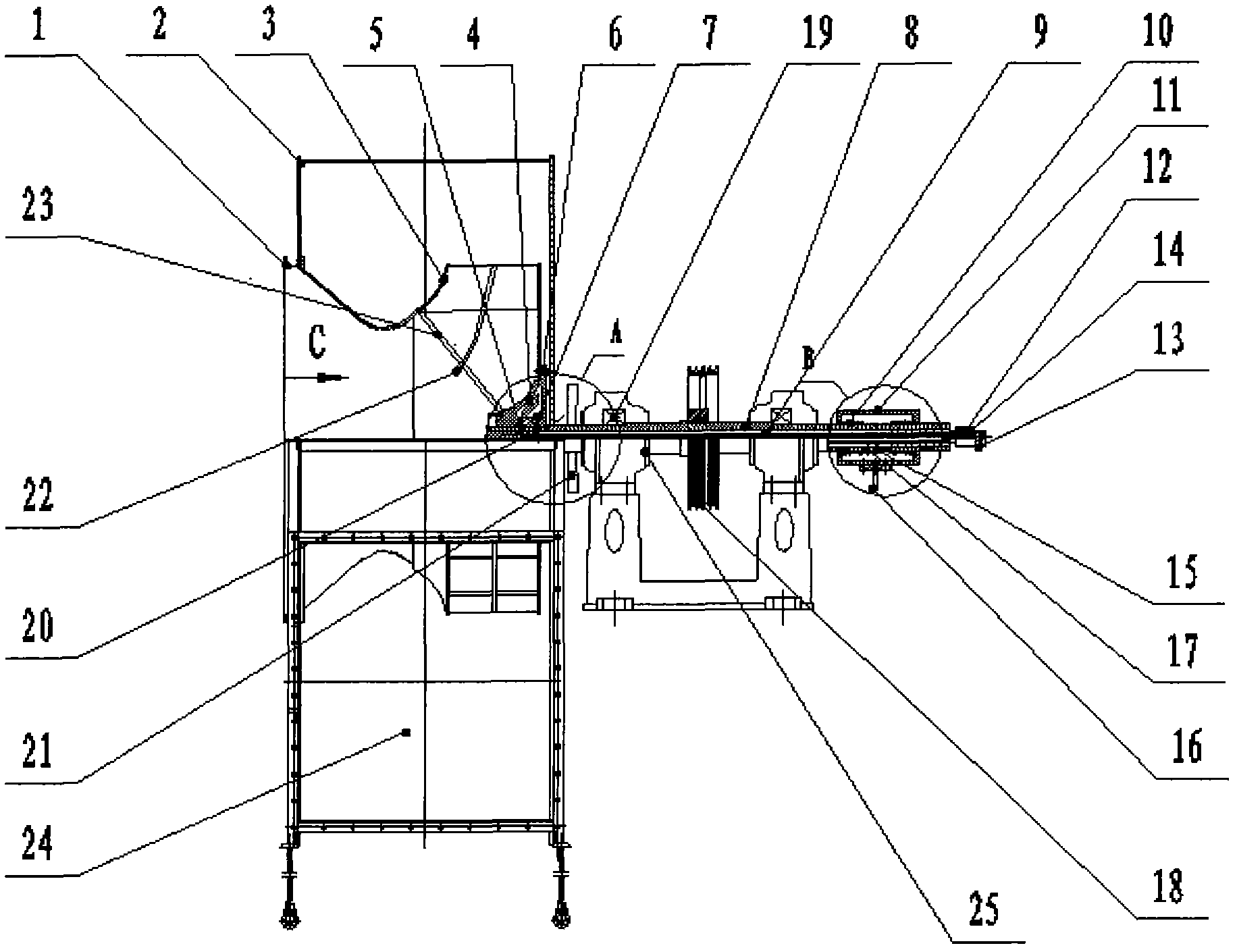

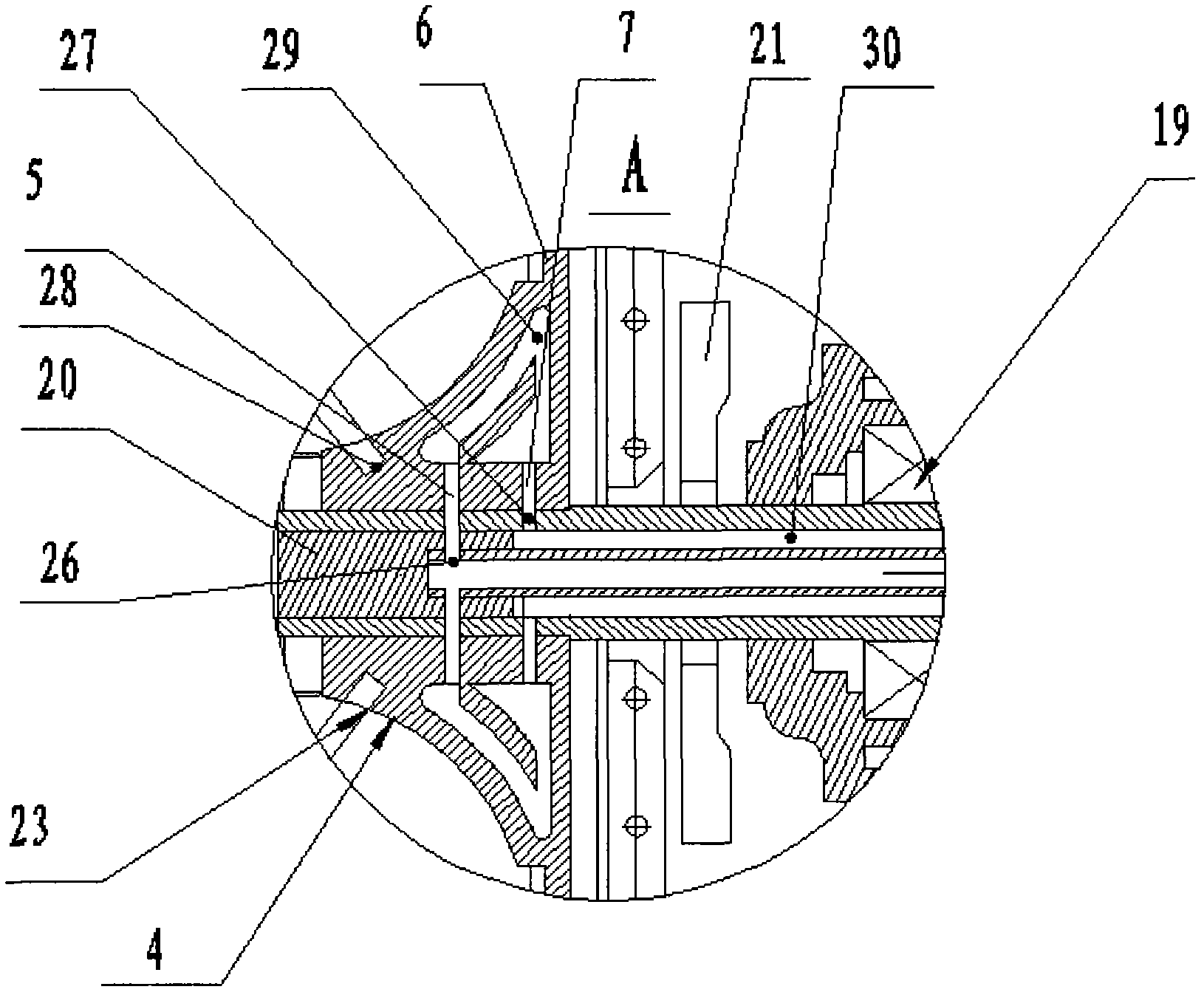

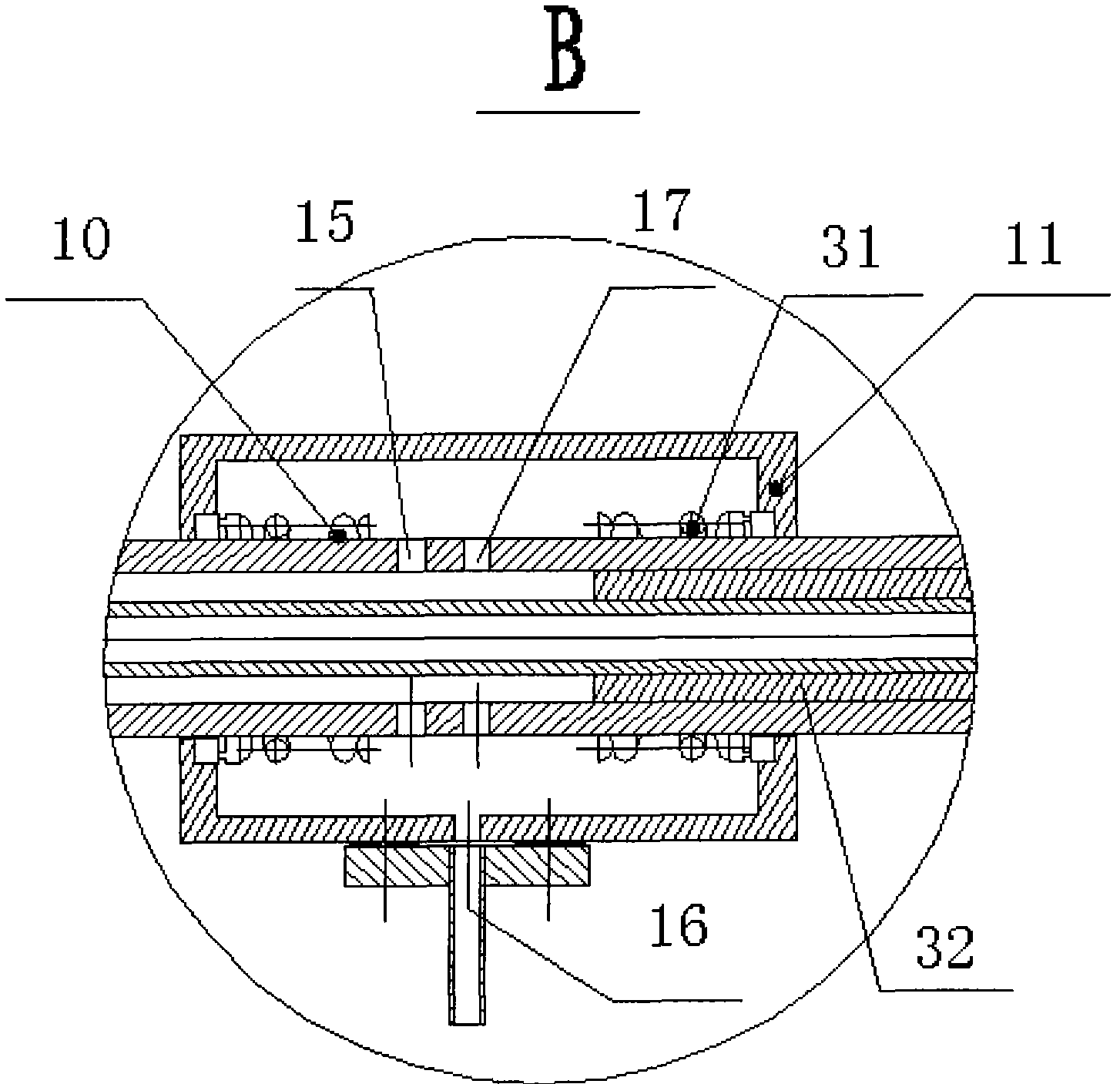

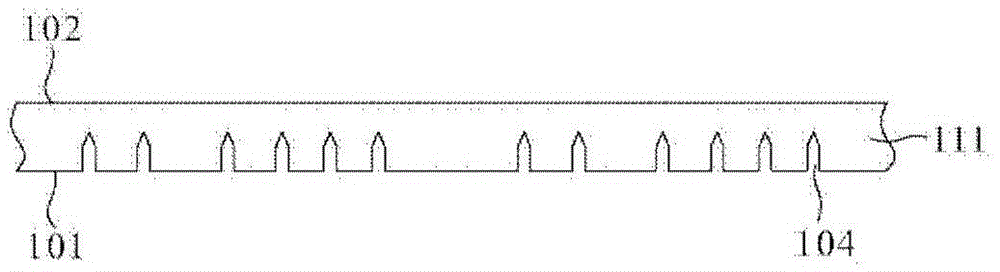

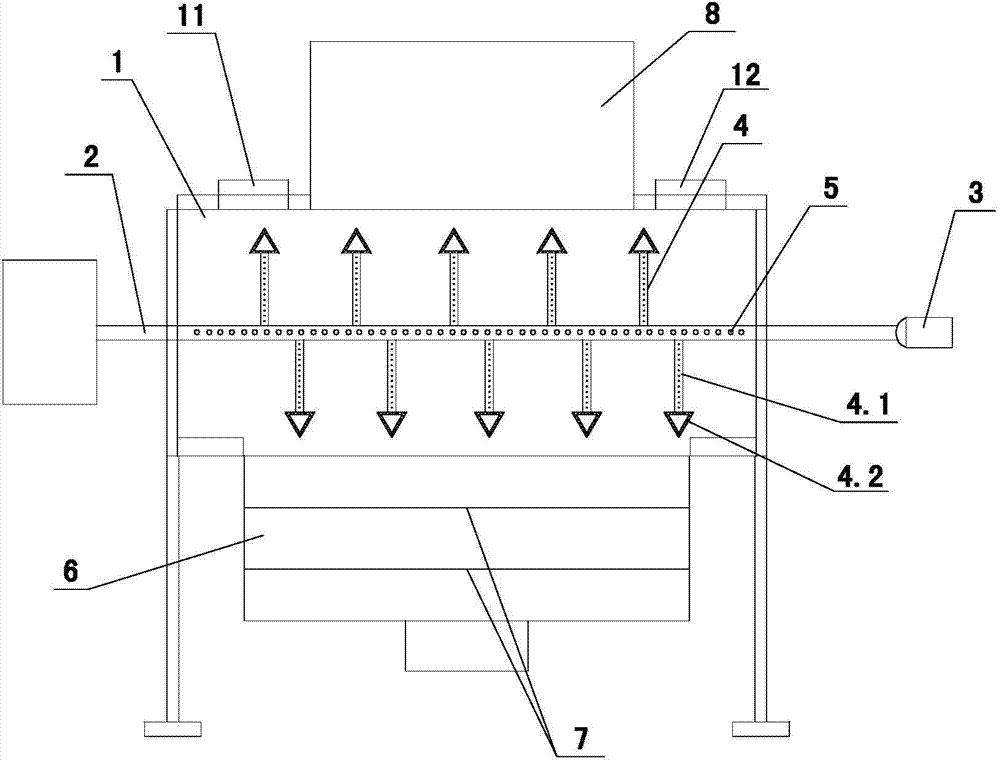

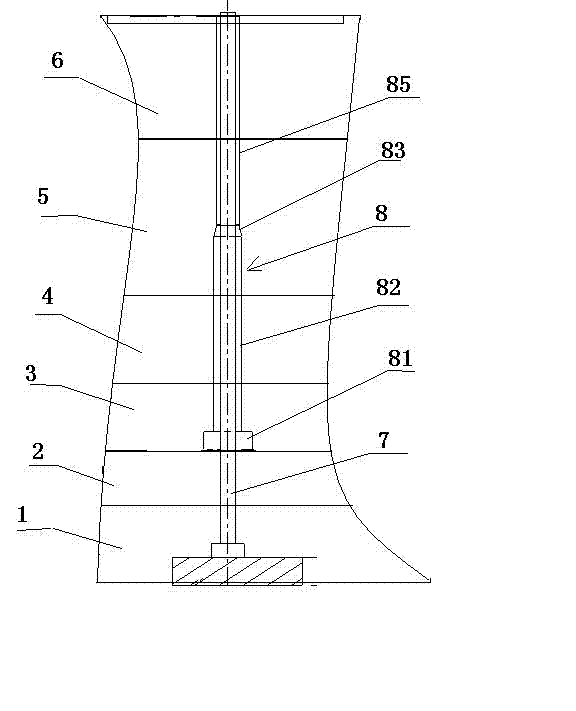

On-line red steel elbow straightener

The invention relates to an on-line red steel elbow straightener which comprises a stander (1) and an upper straightening roller group and a lower straightening roller group which are arranged on the stander (1), wherein each of the upper straightening roller group and the lower straightening roller group consists of a plurality of straightening rollers (7); the central lines of the straighteningrollers (7) of the upper straightening roller group are parallel to one another and positioned on the same horizontal line, and the central lines of the straightening rollers (7) of the lower straightening roller group are parallel to one another and positioned on the same horizontal line; and the straightening rollers (7) of the upper straightening roller group and the straightening rollers (7) of the lower straightening roller group are staggered from each other along the horizontal direction. According to the on-line red steel elbow straightener, the problem that the head of a bar materialwhich is discharged from a rolling machine is bent is solved, the yield is increased, a large amount of time and a large quantity of troubles are saved for the subsequent working procedure, and the logistics of the whole production loop is relatively smooth; and therefore, a phenomenon of repeated reversing is avoided, the production efficiency is improved, the manmade mixed steel risk is reduced, and the burden and the pressure of workers are reduced.

Owner:JIANGYIN DONGCHEN MACHINERY MFG

High-temperature resistant centrifugal fan

ActiveCN102230478AGuaranteed operational reliabilityReliable coolingPump componentsPumpsImpellerCentrifugal fan

The invention discloses a high-temperature resistant centrifugal fan, comprising a fan body, a driving group, a rotary joint and a cooling medium collector, wherein the fan body comprises an enclosure, a wind inlet, an impeller, a hub, a wheel disc and a wind outlet; the driving group comprises a main shaft and a belt wheel; the rotary joint is provided with a cooling medium inlet and a rotary joint seal; the main shaft is in a hollow structure, one end of the main shaft is connected with the hub of the impeller, and the other end of the main shaft is connected with the rotary joint; a core pipe is arranged inside the main shaft; an annular cavity is formed between the main shaft and the core pipe; the hub is in a hollow structure, and a hollow cavity is formed in the hub; the joint between the main shaft and the hub is provided with a cooling medium path; and the cooling medium enters the core pipe from a cooling medium inlet positioned on the rotary joint and is introduced into the hub via the cooling medium path to be cooled. According to the high-temperature resistant centrifugal fan disclosed by the invention, the fan can bear 1000-DEG C high-temperature gas delivery due to the hollow structures of the main shaft and the hub and the cooling of the cooling medium.

Owner:SHANDONG LINFENG TECH

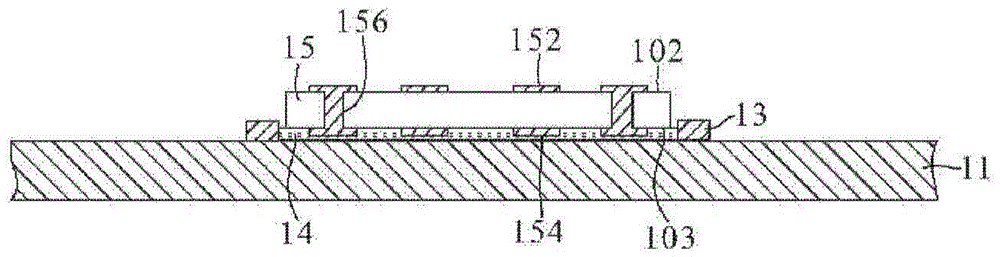

Wiring board with embedded interposer integrated with stiffener and method of making the same

InactiveCN105789058ASolve the bendSemiconductor/solid-state device detailsSolid-state devicesInterposerHemt circuits

A wiring board with embedded interposer is characterized in that the embedded interposer is integrated with a stiffener and a build-up circuitry is deposited on the stiffener, so that the mechanical robustness of the stiffener can prevent the entire wiring board from warping. The interposer provides primary fan-out routing whereas the build-up circuitry provides further fan-out routing and can further enlarge the pad size and pitch of the interposer.

Owner:BRIDGE SEMICON

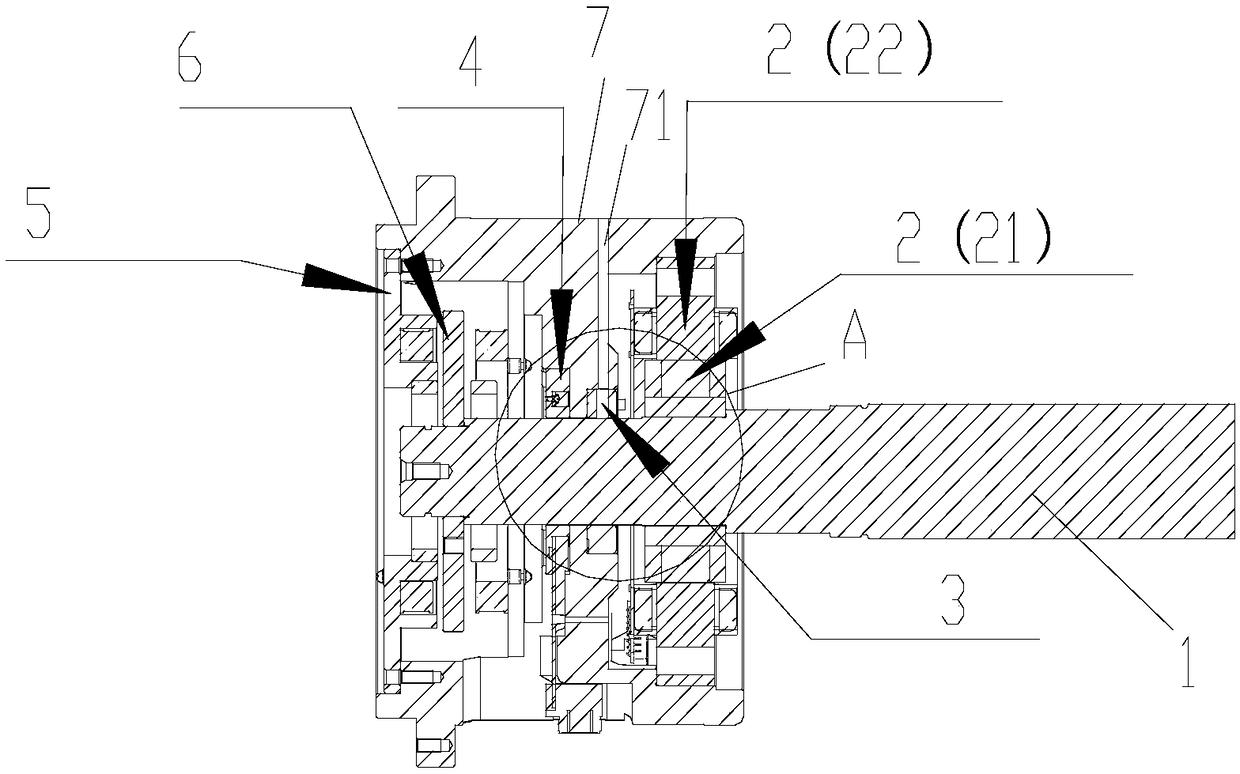

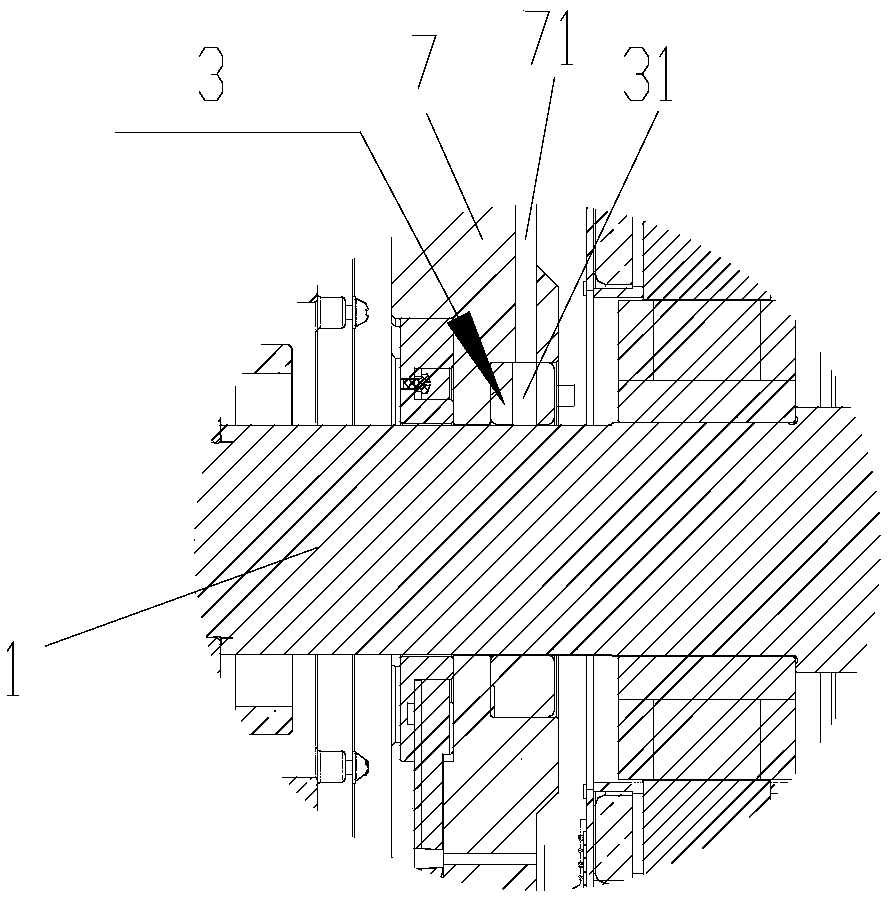

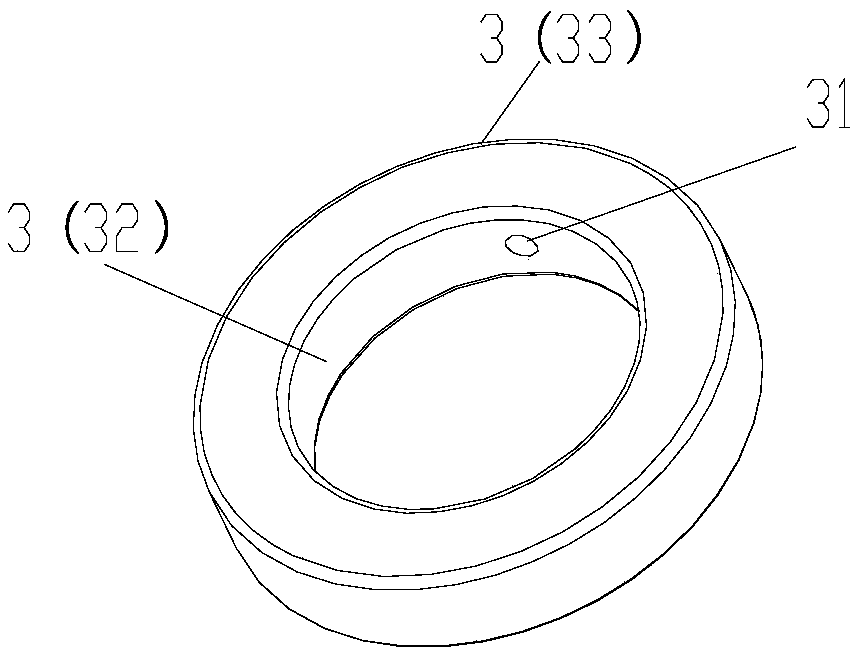

Rotating shaft bearing structure and motor

The invention provides a rotating shaft bearing structure and a motor. The rotating shaft bearing structure comprises a rotating shaft (1), a magnetic suspension radial bearing (2) and a static pressure bearing (3); the magnetic suspension radial bearing (2) sleeves the rotating shaft (1); the static pressure bearing (3) sleeves the rotating shaft (1), and the static pressure bearing (3) and the magnetic suspension radial bearing (2) are located at different positions in the axial direction of the rotating shaft (1); and the static pressure bearing (3) is provided with vent holes (31), one ends of the vent holes (31) are in communication with the radial inner wall of the static pressure bearing, the other ends of the vent holes (31) are in communication with the radial outer wall of the static pressure bearing (3), so that gas with certain pressure is introduced into a gap between the radial inner wall of the static pressure bearing (3) and the rotating shaft (1) from the outside of the static pressure bearing (3). According to the rotating shaft bearing structure, the side, close to the static pressure bearing, of the rotating shaft can bear larger gas pressure, so that the rotating shaft is pressed back into a designed gas gap, so that the rotating shaft is prevented from deviating from the designed gas gap, and the operation reliability of the motor is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Wiring board with dual wiring structures integrated together and method of making the same

InactiveCN105702649AAvoid problems with unconnected contact padsSolve the bendFinal product manufactureSemiconductor/solid-state device detailsEngineeringUltimate tensile strength

Owner:BRIDGE SEMICON

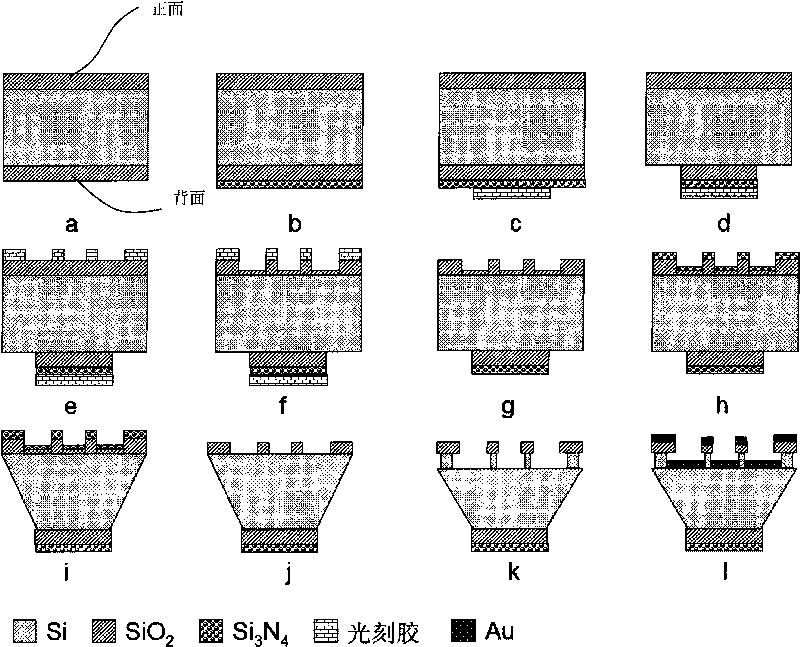

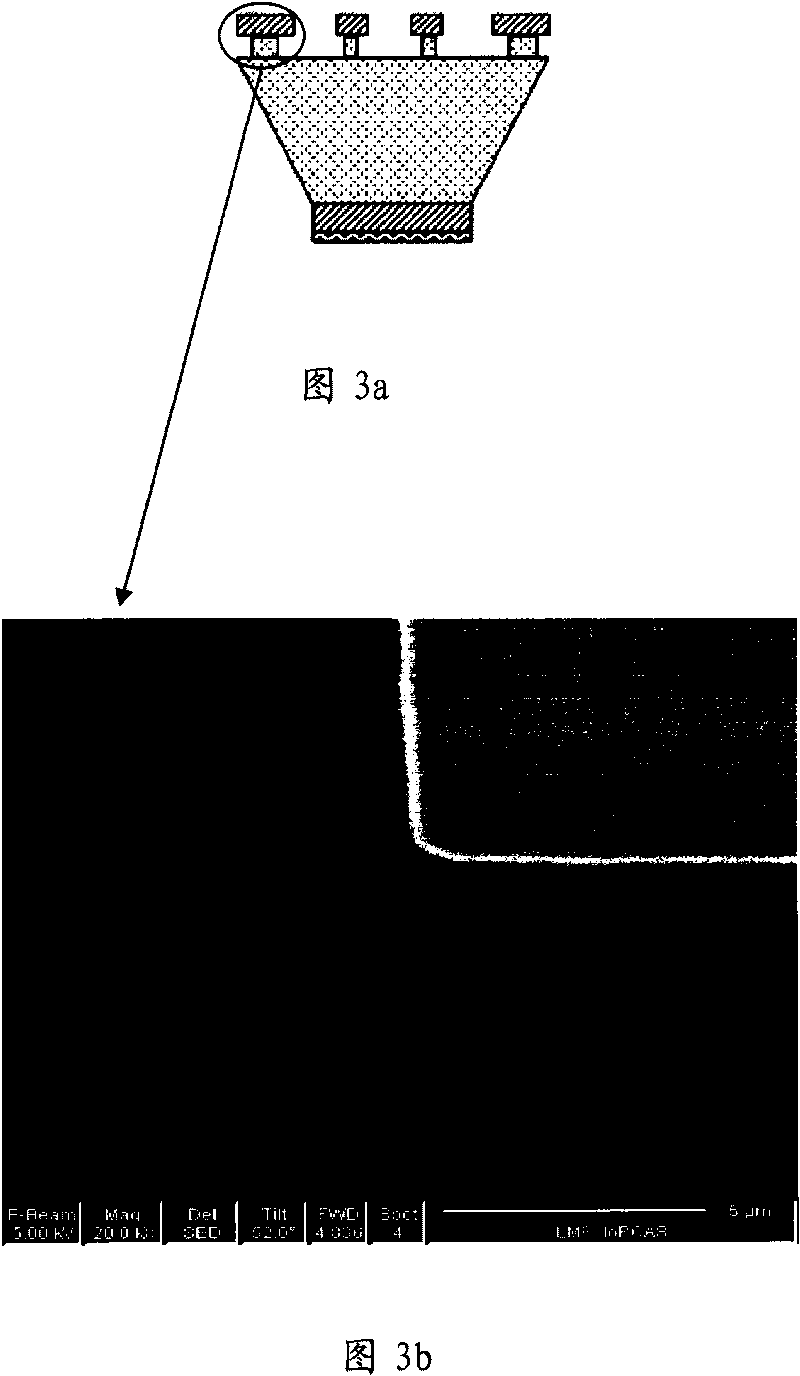

Method for manufacturing integrated micro four-point probe chip based on nano-processing technology

InactiveCN101738541ASolve the bendCorrosion resistanceNanostructure manufactureResistance/reactance/impedenceResistSilicon oxide

The invention discloses a method for manufacturing an integrated micro four-point probe based on nano-processing technology, which comprises the following steps: a, growing a first silicon nitride layer on the back face of a double-face oxidized silicon slice and manufacturing a first photo-resist mask, and performing etching according to the mask pattern to expose silicon; b, manufacturing a second photo-resist mask on the front face of the silicon slice, removing the silicon oxide layer not covered by the second photo-resist mask on the front face of the silicon slice, but at least remaining a part, and growing a second silicon nitride layer on the front face after the removal of the photo-resist; and c, etching the sample obtained by the step b) in KOH solution, removing the second silicon nitride layer and the silicon oxide layer on the front face to expose the silicon, etching out an undercut structure, and finally growing a conductive layer on the front face. The manufacturing method has the advantage that: the thermal expansion coefficient of the mask is consistent with that of the silicon, the manufacturing process is simplified, and the yield is improved by remaining a silicon dioxide thin film on the surface of the silicon slice and then growing a silicon nitride thin film to realize a double-layer mask.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

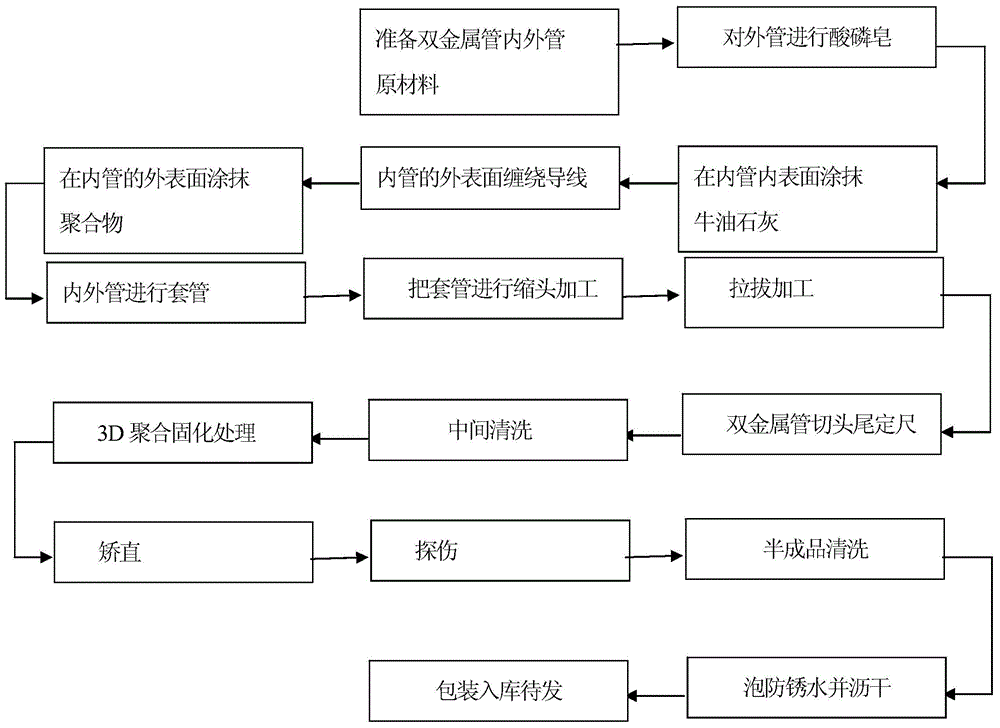

Manufacturing method of carbon steel stainless steel double-metal polymerization pipe

InactiveCN105299335ASolve the problem of poor thermal conductivitySolve the bendRigid pipesBeef TallowBond Force

The invention relates to a manufacturing process of a double-metal steel pipe (a carbon steel stainless steel polymerization pipe); the process is combined with a 3D printing technology principle to form a layer of 2-25 microns of polymers on the surface of an inner pipe of the double-metal steel pipe; and then, the inner pipe is put in an outer pipe to perform the drawing polymerization molding for two steel pipes. The process comprises the steps of: preparation of raw materials of the inner and outer pipes-acid phosphorus soap for the outer pipe-coating of beef tallow lime on the inner surface of the inner pipe-winding of a lead on the outer surface of the inner pipe-coating of a polymer on the outer surface of the inner pipe-sleeving of the inner and outer pipes-head shrinkage-drawing-size determination through head and tail cutting-cleaning of the raw materials of the double-metal steel pipe-3D polymerization curing-straightening-flaw detection-cleaning of a finished product-preparation of antirust water and draining-packaging and warehousing for future delivery. The process applies a3D polymerization process to solve the problems of low bonding force of the inner and outer pipes and low heat conductivity in general double-metal pipes, obviously reduces the use level of heat exchanger stainless steel pipes in three industries, reduces the cost, and is green, environment-friendly and energy-saved.

Owner:SHANGHAI TIAN YANG STEEL TUBE

Preparation device of calcium 2-hydroxy-4-methylthio-butyrate

ActiveCN104725290AIncrease touch pointsIncrease contact surfaceOrganic compound preparationRotary stirring mixersAgricultural engineeringN-Butyrate

The invention discloses a preparation device of calcium 2-hydroxy-4-methylthio-butyrate, which comprises a drying device, a mixing device with a liquid spray device, a screening device and a control device, wherein the mixing device is arranged in the drying device; the liquid spray device is connected to the mixing device; the screening device is arranged on the lower side of the drying device; and the control device controls the operation of the drying device, liquid spray device, mixing device and screening device. The preparation device has the advantages of quick and thorough reaction, high product yield, high drying speed and efficiency, low energy consumption, fewer product impurities, high purity, low waste / exhaust emission, high safety and environment friendliness, is convenient and easy to operate, and shortens the technical process.

Owner:宁波它世界生物科技有限公司

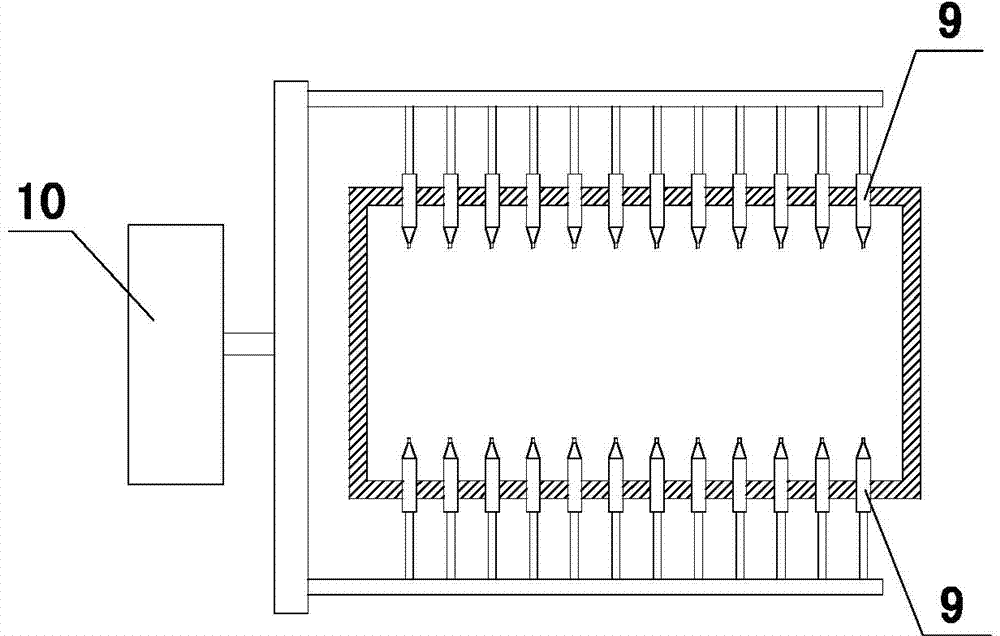

Multi-section side-blowing device for spinning

InactiveCN109355719AAddress technical deficiencies beyond our controlEliminate hidden dangers prone to personal safety accidentsFilament/thread formingInlet valveIndustrial engineering

The invention provides a multi-section side-blowing device for spinning. The multi-section side-blowing device for spinning comprises a side-blowing box, multiple side-blowing rectifying devices and an air-blowing channel. A side-blowing pipe is fixed in the side-blowing box. The side-blowing rectifying device comprises an air inlet pipe, an air inlet valve, an air distributing cavity, an air baffle and an air distributing plate. The air inlet pipe is provided with an air inlet and an air outlet. The air inlet is connected with the side-blowing pipe. The air outlet is connected with the air distributing cavity. The air inlet pipe is further provided with the air inlet valve. The air outlet of the air inlet pipe is provided with the air baffle. The air-blowing channel is separated from theside-blowing rectifying device through the air distributing plate. Side-blowing of the multi-section side-blowing device adopts multi-section inlet air, and each section of an air quantity can be independently controlled, so a technical defect that the air quantity of each point of the side-blowing cannot be controlled is solved.

Owner:WUJIANG JINGMEIFENG IND

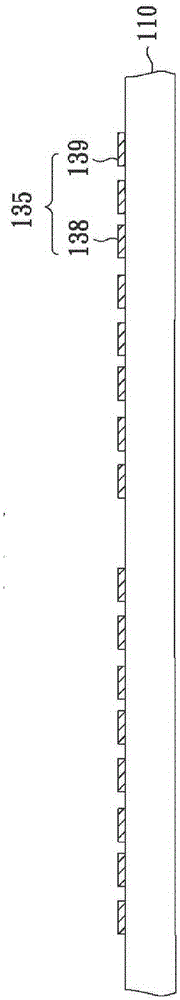

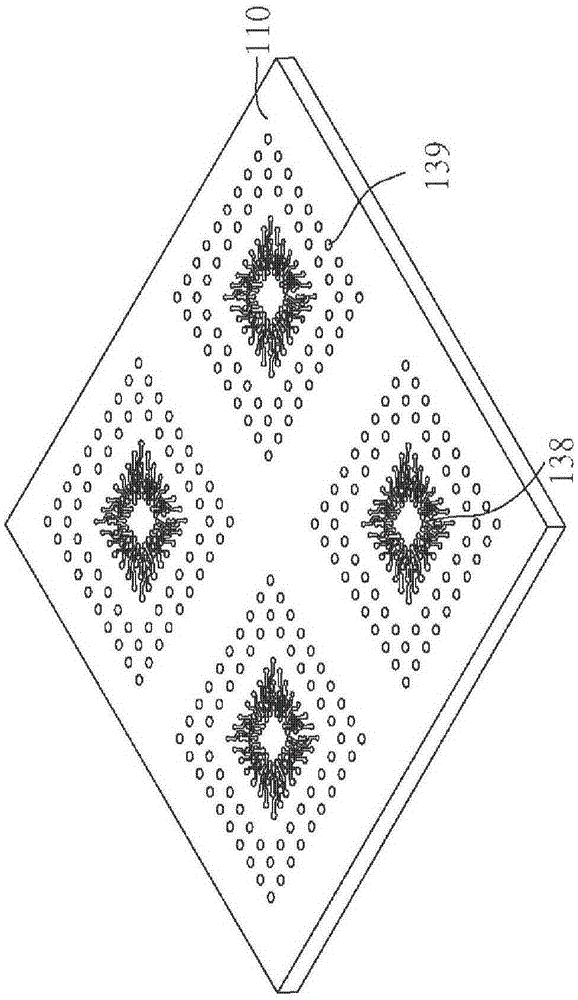

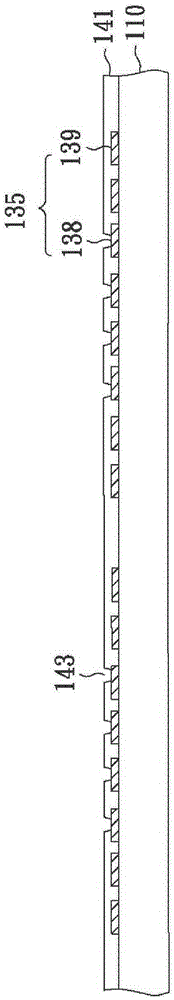

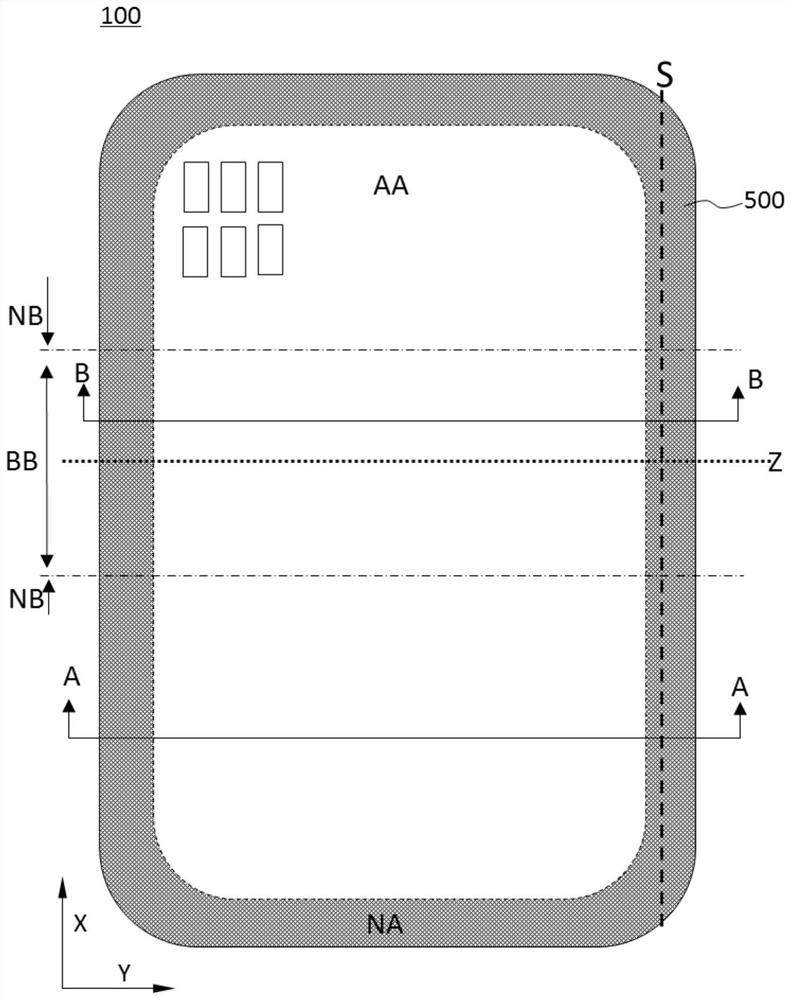

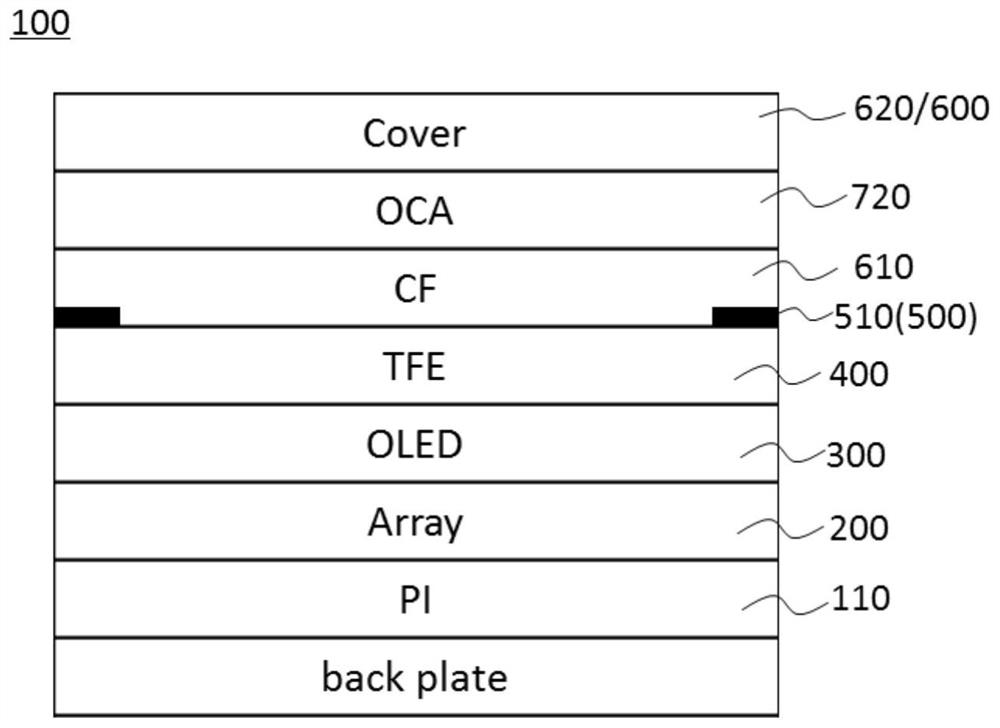

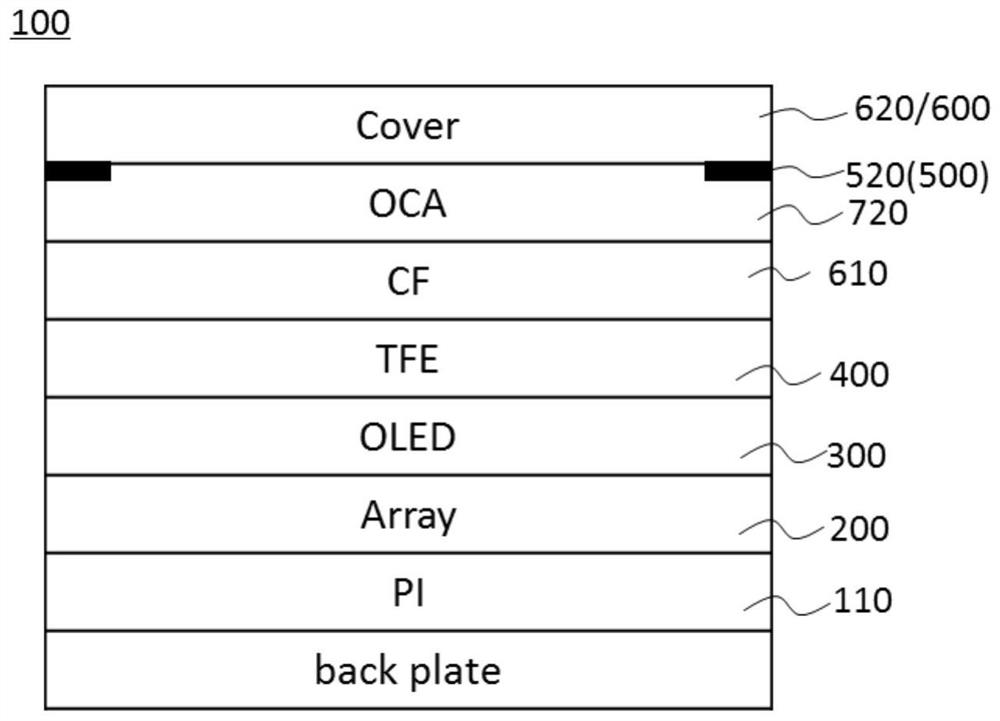

Display panel, display device and manufacturing method of display panel

ActiveCN111740030ASolve warpingSolve the bendSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses a display panel, a display device and a manufacturing method of the display panel. The display panel is divided into a display area and a non-display area surrounding the display area; the display panel comprises a substrate, an array layer, a display layer and a packaging layer which are arranged in sequence, the display panel further comprises an ink layer which is located in the non-display area and surrounds the display area. The ink layer at least comprises a first ink layer and a second ink layer which are positioned on different layers; the orthographic projection of the first ink layer on the substrate is a non-closed pattern surrounding the display area; the orthographic projection of the second ink layer on the substrate is a non-closed pattern surroundingthe display area. The invention further provides a manufacturing method of the display panel and a display device comprising the display panel. The warping or bending problem of the flexible displaypanel can be solved while the non-display area is shielded from light.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Artificial stone wood combined colorful environment friendly stone furniture table-board and method of producing the same

InactiveCN101508554ASolve delaminationSolve warpingSynthetic resin layered productsLaminationTechnical standardFirming agent

The invention discloses a man-made colored and environment-friendly stone furniture table-board combining stone and wood and a manufacturing method thereof. Ethyl methyl ketone is taken as a firming agent, cobalt naphthenate solution is taken as an accelerator, unsaturated polyester resin and talc powder are taken as binders and waste slabs are taken as basal layers and the table-board is manufactured by certain processes. The table-board successfully solves the technical problems of delamination, upwarping, bending and deformation of the existing man-made stone and saves over 60% of chemical raw materials, thereby greatly lowering the cost of the product, and the surface hardness and lustrousness meet the national relevant technical standards. The table-board is free from delamination, upwarping, bending and deformation and has the advantages of beautiful design, bright color, durability, low cost, light weight, high strength, bending resistance, changing waste into valuable and environment protection. Various flower patterns can be designed based on the requirements. The luxurious rate and decorative effect of the table-board is superior to the natural stone and is a super top-quality building decoration material.

Owner:江孟东

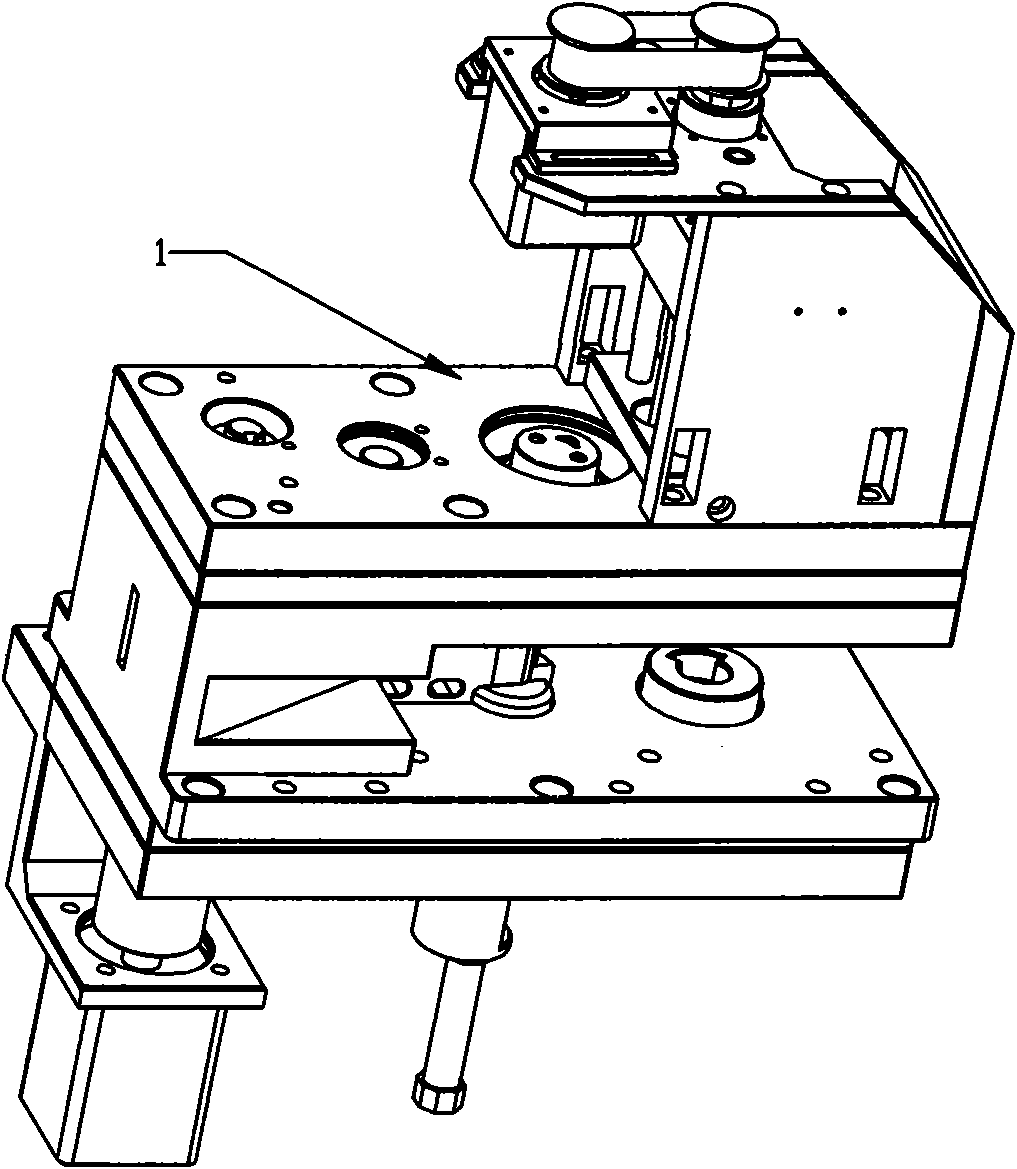

Ejection mechanism for injection molding mold

The invention discloses an ejection mechanism for an injection molding mold, wherein the ejection mechanism comprises a sleeve pedestal installed on a male mold ejection plate and a sleeve body arranged on the sleeve pedestal, an axle hole used for mounting a pin shaft is arranged in the sleeve body, the sleeve body is a double-joint sleeve body, the double-joint sleeve body comprises a movable sleeve body connected with the pedestal and an ejection sleeve body, a conical connecting body with a gradually decreasing outside diameter is arranged at the crossing site of the ejection sleeve body and the movable sleeve body, the movable sleeve body is arranged in a male template, the outside diameter of the ejection sleeve body is smaller than that of the movable sleeve body, and the inside diameter of the ejection sleeve body is equal to that of the movable sleeve body. The double-joint sleeve body with outside diameter difference is utilized in the invention, so that the sleeve end face is used for ejecting the formed product during the ejection process, the double-joint sleeve body applies a uniform ejection force on the formed product to guarantee the demolding, reduce the breakage of the formed product and generate no ejection mark on the outline of the formed product, and the ejection mechanism is simple and reasonable in structure, high in stability and is capable of avoiding such demolding failures of the formed product as breakage, scratch, etc.

Owner:SHENGYANG PRECISION MOLD KUSN

Wiring board with interposer and dual wiring structures integrated together and method of making the same

InactiveCN105789173AAvoid the problem of not connectingSolve the bendSemiconductor/solid-state device detailsSolid-state devicesInterposerEngineering

Owner:BRIDGE SEMICON

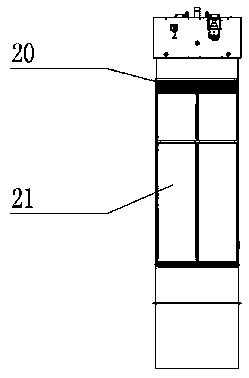

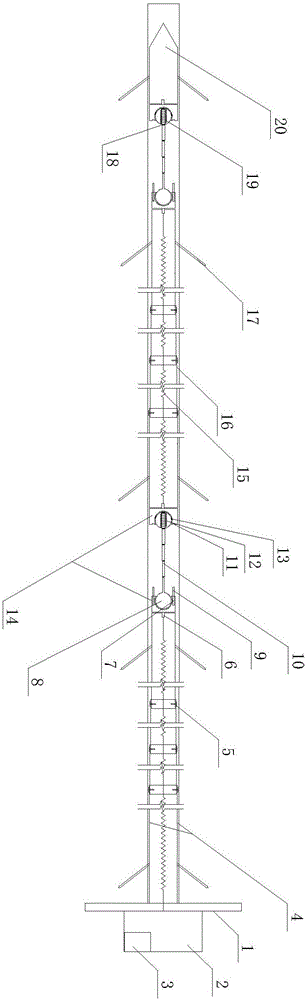

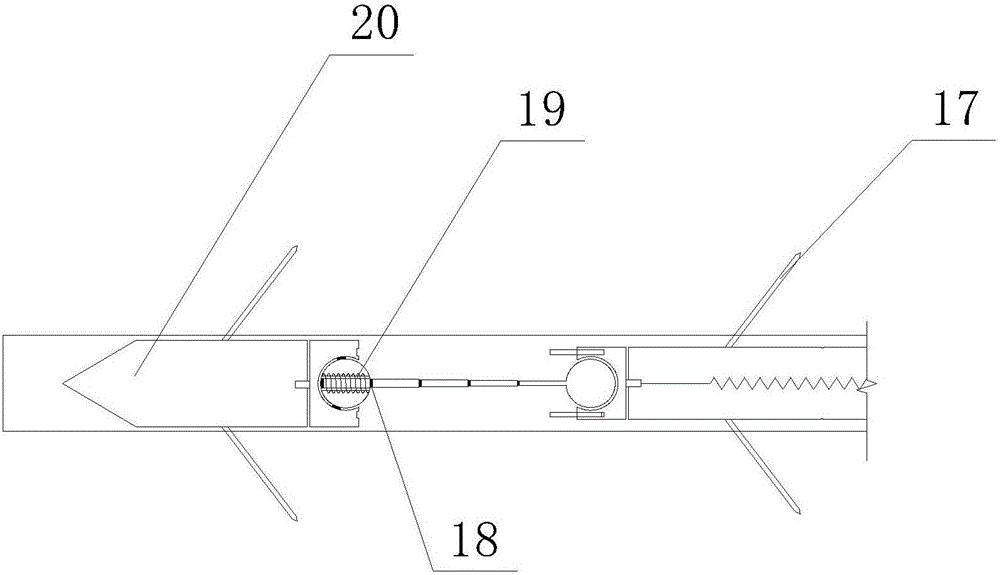

Multi-point displacement meter capable of automatically measuring space displacement

ActiveCN106482624ASolve the entanglementSolve the bendUsing electrical meansCombined useData acquisition

The invention provides a multi-point displacement meter capable of automatically measuring space displacement. The multi-point displacement meter comprises an anti-explosion online monitoring terminal, an anti-explosion Bluetooth emitter, a space displacement sensor, a wire, a drilling rod, a fixed ratchet and an end drilling rod. According to a to-be-measured rock stratum separation layer, an offset position and depth of a drilling hole, length of the drilling rod is adjusted. Then, the drilling rod part is completely inserted into the drilling hole, and a reference plate tightly clings to surrounding rock. When a separation layer and offset occur in each rock stratum, a rotation small ball in the space displacement sensor rotates, a displacement telescopic rod is extended, and the space displacement sensor transmits a signal to the anti-explosion online monitoring terminal for processing and then stores the data. During data acquisition, the data is transmitted into a collector through the anti-explosion Bluetooth emitter. By combining the space displacement sensor, the drilling rod, the anti-explosion online monitoring terminal and the Bluetooth device, the movement rule of surrounding rock in the space can be precisely and properly researched, measurement is real and installation is easy.

Owner:SHANDONG UNIV OF SCI & TECH

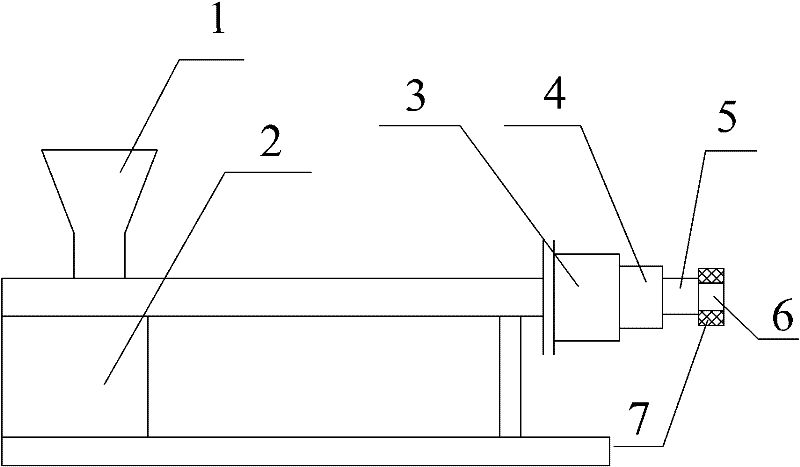

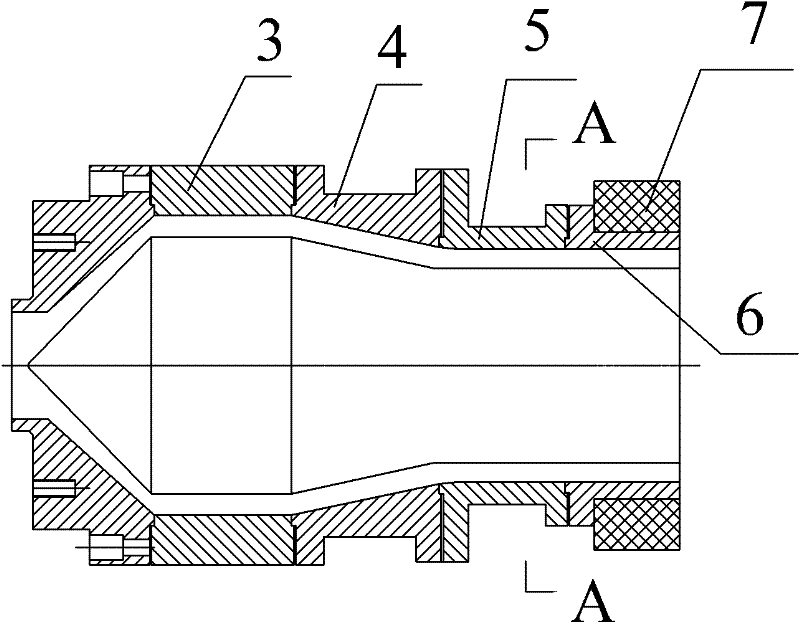

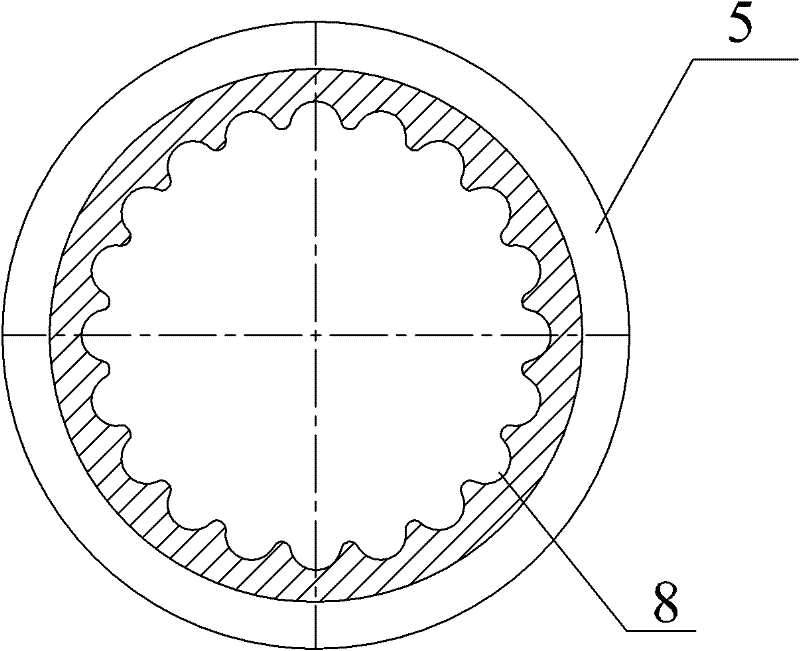

Super-high molecular weight polyethylene reinforced pipe and preparation method and production equipment thereof

The invention relates to a super-high molecular weight polyethylene reinforced pipe and a preparation method and production equipment thereof. The polyethylene reinforced pipe is characterized in that: a plurality of longitudinal reinforcing ribs are arranged on an outer wall of a pipe body. The super-high molecular weight polyethylene reinforced pipe comprises the following components in part by mass: 100 parts of super-high molecular weight polyethylene, 3 to 6 parts of talcpowder, 0 to 1.0 part of graphite and 0 to 25 parts of flame retardant antistatic material. A plastic reinforced pipe is directly extruded and molded; and the polyethylene reinforced pipe has the characteristics of low investment, is easy and convenient to produce and is practicable. The problem that the super-high molecular weight polyethylene reinforced pipe bends or hangs downwards during use is solved, and a super-high molecular weight polyethylene large-caliber ultra-thin wall pipe is extruded and molded. Because the talcpowder serves as a lubricating agent, the production loss of raw materials can be reduced by 2 percent; and due to the design of the reinforcing ribs, compared with a common super-high molecular weight polyethylene pipe, the reinforced pipe has a wall thickness which can be reduced by over 20 percent under the conditions of the same pressure and the same caliber.

Owner:SHANDONG DIHAO WEAR RESISTING PIPE

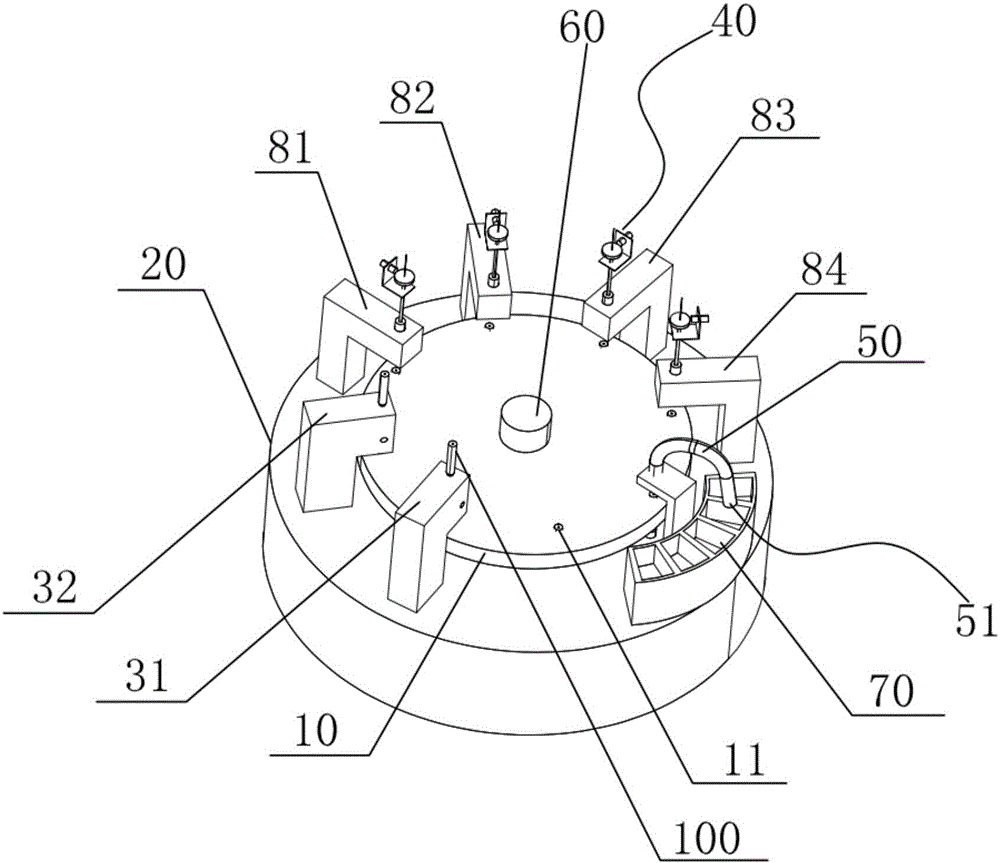

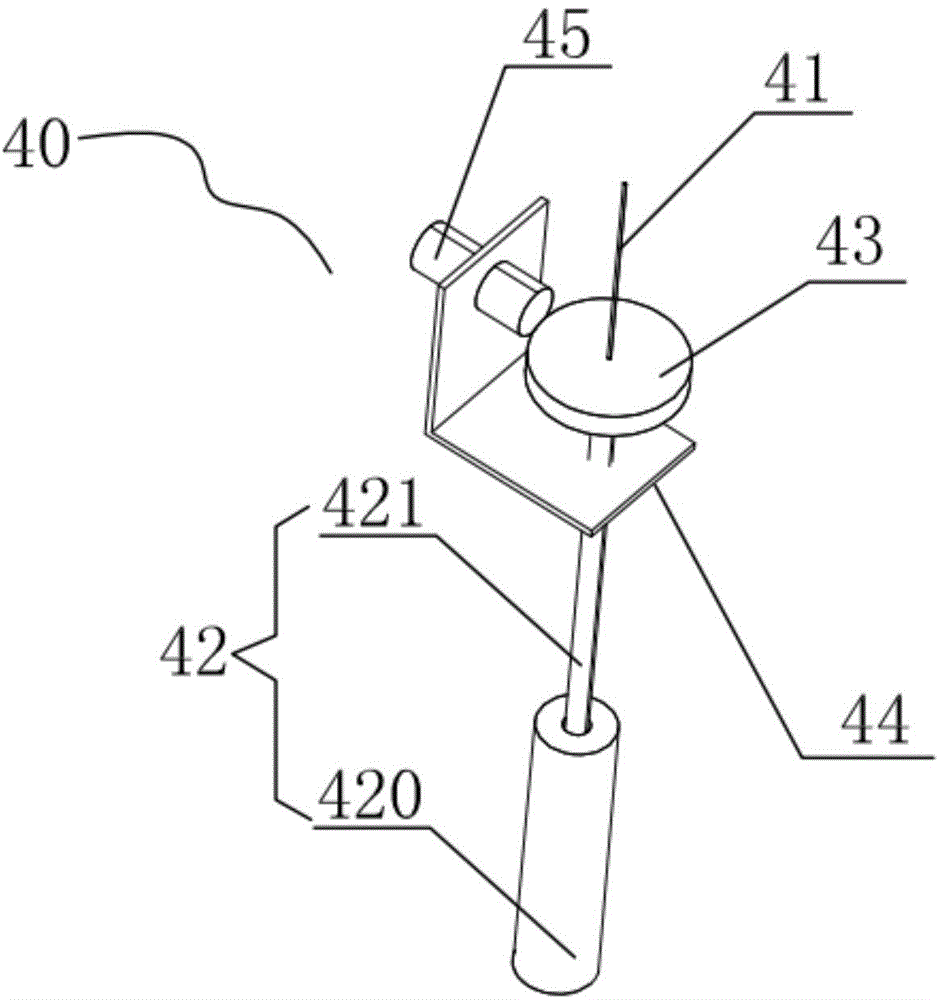

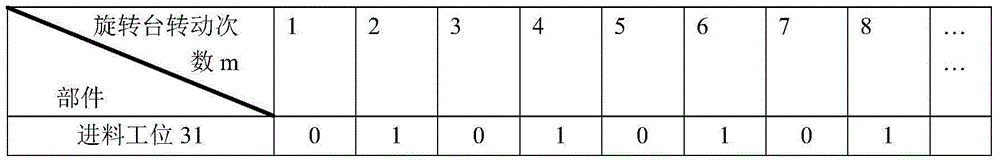

Micropore detecting device and rotating detecting device

ActiveCN104457510ASolve the bendResolve detectionMechanical diameter measurementsSortingProtection mechanismEngineering

The invention discloses a micropore detecting device and a rotating detecting device. The micropore detecting device comprises detecting needles, detecting needle protection mechanisms, weights, movable supports and optical fibers. Each detecting needle protection mechanism comprises a fixed sleeve and a sliding sleeve. The detecting needles penetrate through the sliding sleeves and the fixed sleeves. The movable supports drive the sliding sleeves to move up and down. The weights are fixed to the detecting needles and are pressed on the sliding sleeves, the weights can move up and down along with the sliding sleeves, and the detecting needles can move downwards through the weights. When the movable supports drive the sliding sleeves to move downwards in the fixed sleeves, the detecting needles located in the fixed sleeves move downwards to penetrate through holes of workpieces to be detected. When the movable supports move upwards, the sliding sleeves move upwards in the fixed sleeves and eject the weights upwards so that the detecting needles can be drawn out of the workpieces to be detected. The optical fibers are fixed to the movable supports and used for inducting whether the detecting needles move upwards or not, and therefore whether the detecting needles penetrate through the inner holes of the workpieces to be detected or not can be judged. The rotating detecting system comprises the micropore detecting device used for detecting the inner holes of the workpieces.

Owner:深圳市特思路精密科技有限公司

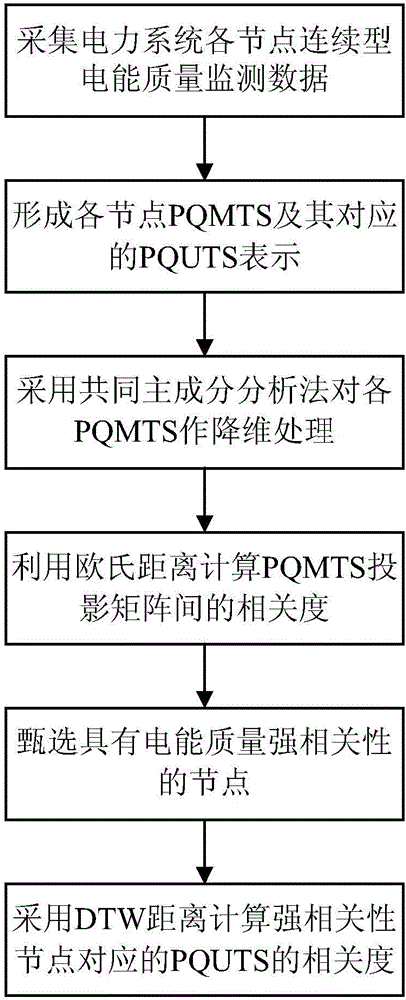

Power quality time sequence correlation assessment method

InactiveCN106447537ADoes not destroy isomorphismEasy to measure distance in spaceData processing applicationsPower qualityPrincipal component analysis

The invention discloses a power quality time sequence correlation assessment method. Continuous electric energy quality index monitoring data is represented by unitary time sequences, and the whole electric energy quality situation is represented by multivariate time sequences; a common principal component analysis method is adopted to conduct dimension reduction processing on the electric energy quality multivariate time sequences of nodes, and projections of the multivariate time sequences in common characteristic subspaces are obtained; an Euclidean distance is utilized to calculate the relevance of the multivariate time sequences after dimension reduction; electric energy quality strong-correlation nodes are selected, and a DTW distance is adopted to calculate the relevance of the unitary time sequences of indexes corresponding to the nodes. By the adoption of the method, the correlation assessment between the electric energy quality multivariate time sequences and the unitary time sequences of corresponding indexes is achieved, the operation law and propagation characteristics of electric energy quality pollution are embodied, and the mutual influence of the electric energy quality of the indexes is quantified.

Owner:QINHUANGDAO POWER SUPPLY COMPANY OF STATE GRID JIBEI ELECTRIC POWER COMPANY +3

Portable hydraulic pipe bending machine

The invention provides a portable hydraulic pipe bending machine. The portable hydraulic pipe bending machine comprises a molding bed, movable beams, pulling rods, pressure blocks, a piston, pin shafts, small pins, a manual hydraulic pump and a high pressure hosepipe; the molding bed is hinged to the pulling rods and the movable rods through the pin shafts; the pressure blocks are hinged to one ends of the pulling rods through the small pins; the piston is arranged in an oil cylinder which is arranged inside the molding bed; the manual hydraulic pump is used for providing oil pressure. A straight pipe is leaned on the molding bed through the two pressure blocks during operation, the manual hydraulic pump is repeatedly pressed to generate high pressure oil to drive the piston to move, the piston drives the movable beams to move, the movable beams drives the pulling rods which drive the pressure blocks to impose bending moments on the pipe to enable the pipe to be bent. The portable hydraulic pipe bending machine has the advantages of being portable, compact in structure, large in bending moment, applied to pipe bundle bending which has operational space constraint, not easy to generate defects such as pressuring marks, scratches and hollows on the pipe surface.

Owner:TSINGHUA UNIV

Paying-off and taking-up device with counting function

Owner:STATE GRID CORP OF CHINA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com