Micropore detecting device and rotating detecting device

A detection device and a technology of rotation detection, applied in the direction of mechanical diameter measurement, sorting, etc., can solve problems such as difficult operation, easy bending of flexible inspection tools, and detection deviations, etc., to achieve accurate detection data, high detection efficiency, and solve the problems of measurement The effect of needle bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

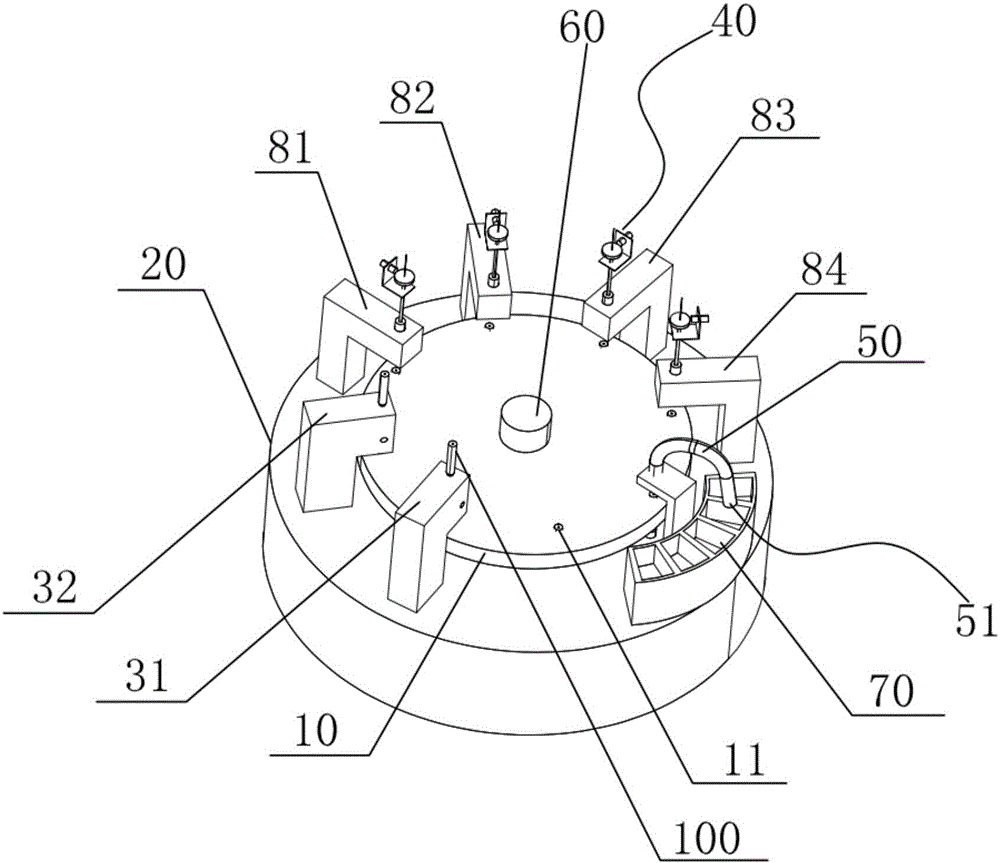

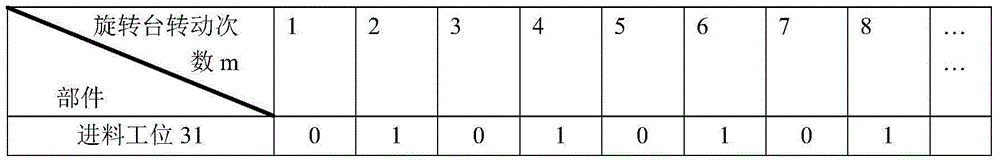

[0020] A specific embodiment of the present invention provides a rotation detection system, which can be used for automatic detection of precision micro-holes (referred to as through-holes) of superhard material workpieces, such as detection of inner holes of ceramic ferrules. Such as figure 1 As shown, the rotation detection system includes a rotary table 10, a support table 20, a feeder, a micropore detection device 40, a discharger 50 and a control system.

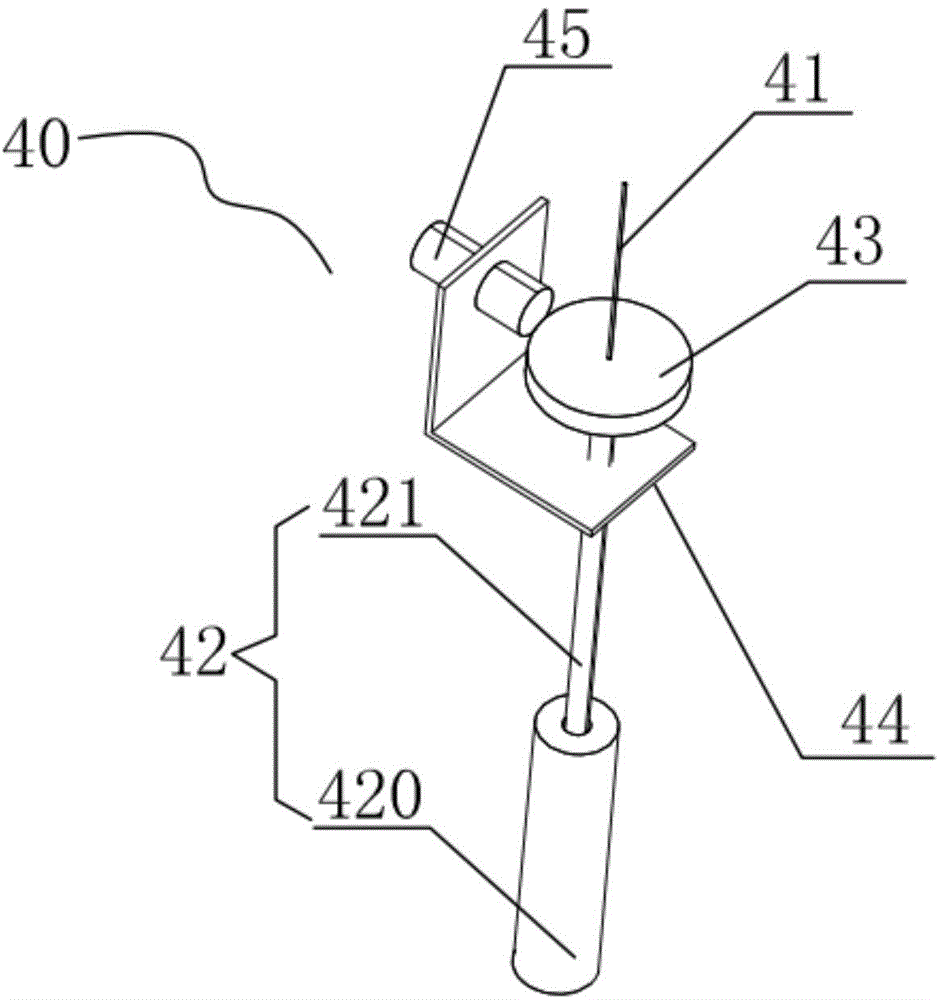

[0021] Such as figure 1 and figure 2 As shown, the microhole detection device 40 includes a stylus 41, a stylus protection mechanism 42, a detection force providing module 43, a movable bracket 44, and a sensing module 45. The stylus protection mechanism 42 includes a movable nested fixed mechanism 420 and sliding mechanism 421, the probe 41 passes through the sliding mechanism 421 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com