Paying-off and taking-up device with counting function

A pay-off device and pay-off reel technology, which is applied in the directions of transportation and packaging, thin material handling, and delivery of filamentous materials, etc., can solve the problems of difficult estimation of length, twisting force, bending, etc. Effects of loss and rate increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present application is not limited by the following examples, and specific implementation manners can be determined according to the technical solutions of the present application and actual conditions.

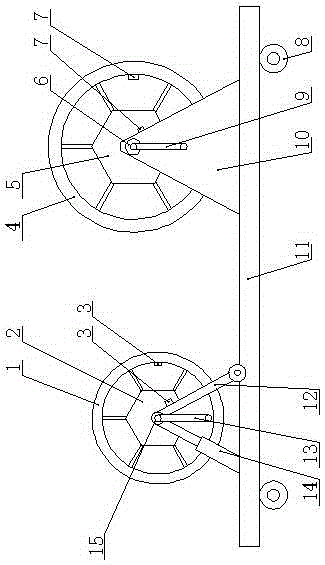

[0010] Example: such as figure 1 As shown, the countable pay-off and reel device includes a reel device and a pay-off device fixed on the base 11, and the pay-off device includes a pay-off core 2 for pay-off, and the pay-off core 2. Can rotate with pay-off shaft 15, and described pay-off shaft 15 axles are connected on the top of pay-off rack, and rocking handle 13 is arranged outside pay-off shaft 15. The coiling device includes a coiling core 5 for coiling, the coiling coil 5 can rotate with the coiling shaft 6, and the coiling shaft 6 is connected to the upper part of the coiling frame 10, outside the coiling shaft 6 Rocking handle 9 is provided.

[0011] The pay-off frame includes a telescopic telescopic rod 14 and a swing rod 12, the upper and lower parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com