Starting system of extra-large power DC amplitude-voltage motor

A motor starting and super-high power technology, which is applied to the starter of a single DC motor, the motor generator/starter, the deceleration device of an AC motor, etc., can solve the problems of large starting current, large power consumption, and long time, and achieve Small start-up current, reduced start-up energy consumption, and short start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

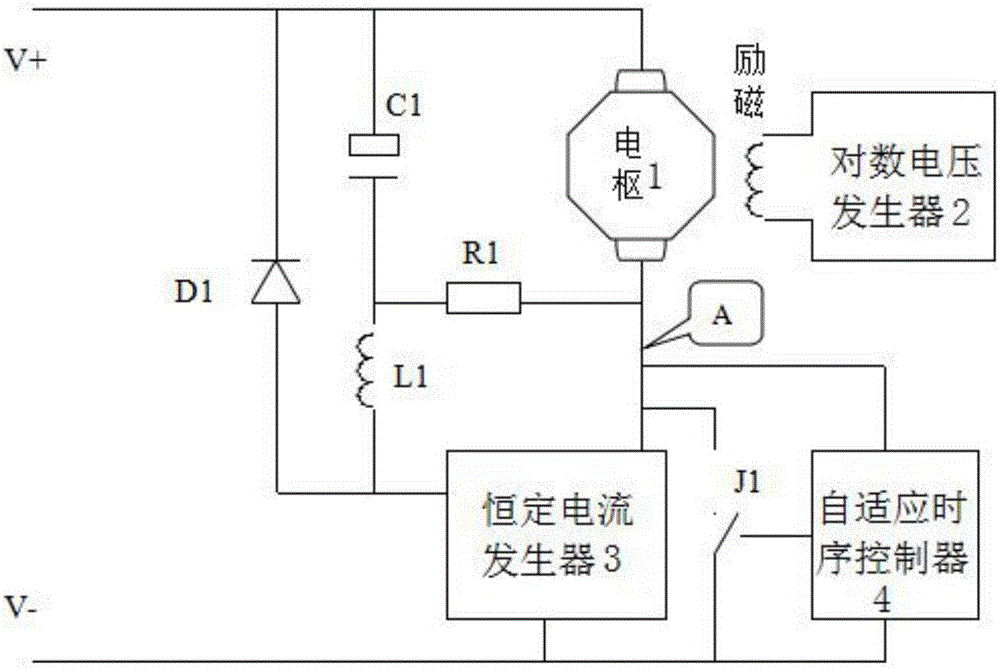

[0015] A starting system for a super-high-power DC amplitude voltage motor, such as figure 1 As shown, it includes armature 1, logarithmic voltage generator 2, constant current generator 3, adaptive timing controller 4, diode D1, capacitor C1, resistor R1, inductor L1, and relay J1;

[0016] The anode of the power supply is respectively connected to the cathode of diode D1, one end of capacitor C1 and one end of armature 1, wherein the anode of diode D1 is connected to one end of device 2, the other end of capacitor C1 is respectively connected to inductor L1 and one end of resistor R1, and the other end of inductor L1 One end is connected to the anode of the diode D1, the other end of the armature 1 is respectively connected to the other end of the resistor R1, one end of the relay J1, the adaptive timing controller 4, and the constant current generator 3, and the other end of the relay J1 is connected to the adaptive timing control The relay 4 is connected, and the third ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com