Portable hydraulic pipe bending machine

A pipe bender, a portable technology, applied in the field of portable hydraulic pipe benders, can solve problems such as tube bundle bending that cannot be solved, and achieve the effect of solving tube bundle bending problems, large bending moment, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

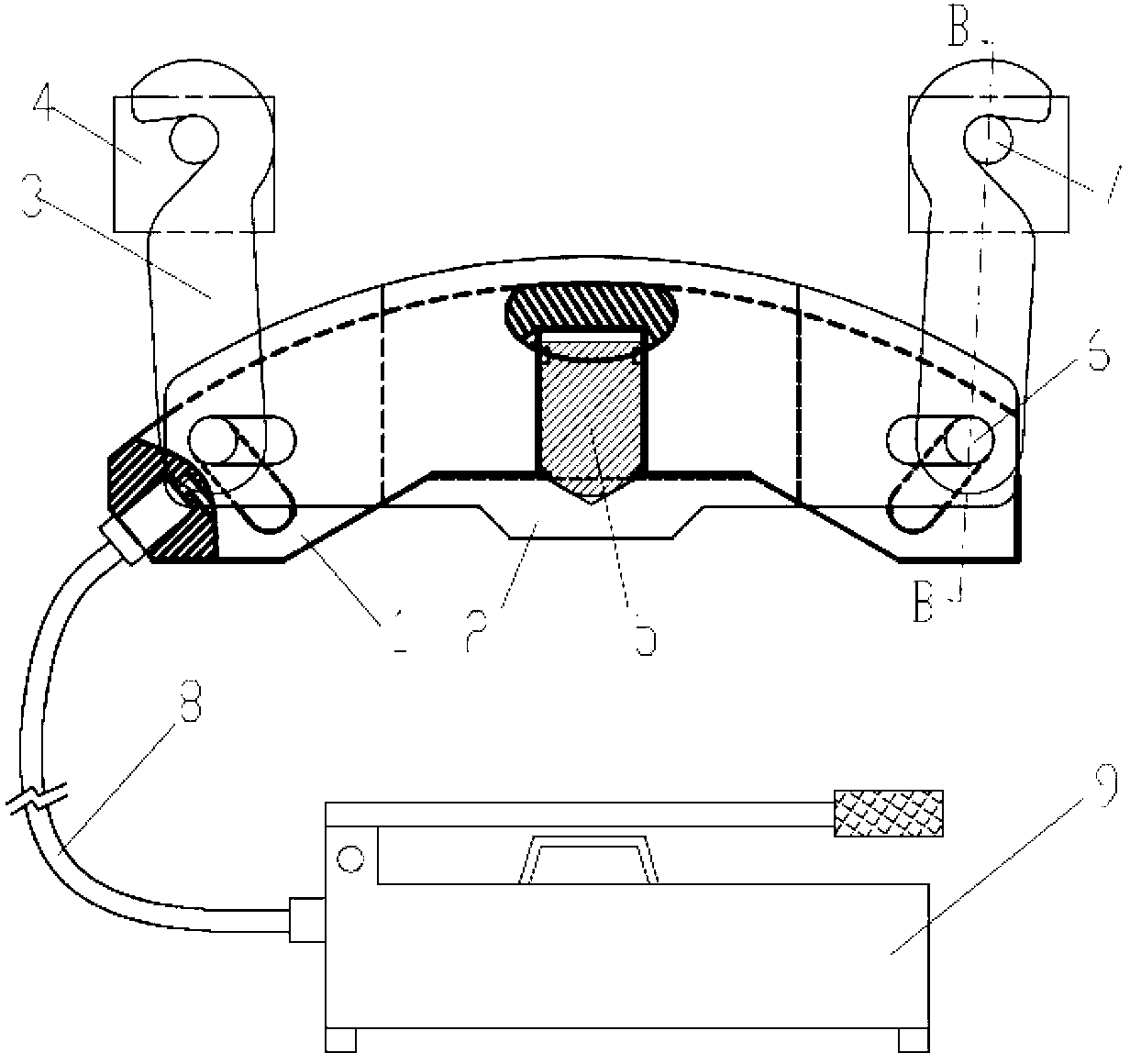

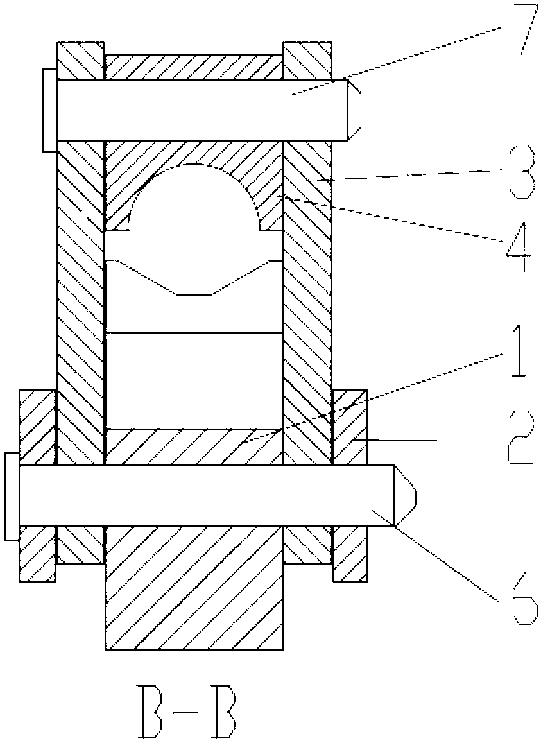

[0018] Such as figure 1 , figure 2 As shown, the portable hydraulic pipe bender of this embodiment is mainly divided into the following parts:

[0019] Membrane (1), moving beam (2), tie rod (3), briquetting block (4), piston (5), pin shaft (6), small pin (7), high-pressure hose (8), manual hydraulic pump (9).

[0020] The connection relationship of each part is as follows: the tire membrane (1) is hinged with the tie rod (3) and the moving beam (2) through the pin shaft (6); ) is hinged; the piston (5) is located in the oil cylinder inside the membrane (1).

[0021] The characteristics of each part are as follows:

[0022] The membrane (1) is a C-shaped plane symmetrical struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com