Super-high molecular weight polyethylene reinforced pipe and preparation method and production equipment thereof

A technology of ultra-high molecular weight and production equipment, applied in the direction of mechanical equipment, pipes/pipe joints/fittings, pipes, etc., can solve the problems of complex manufacturing process and large equipment investment, so as to reduce wall thickness, reduce production loss, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The proportion of ingredients for UHMWPE reinforced pipe in terms of parts by mass is:

[0035] UHMWPE 100

[0036] Talc 3

[0037] Graphite 0.5

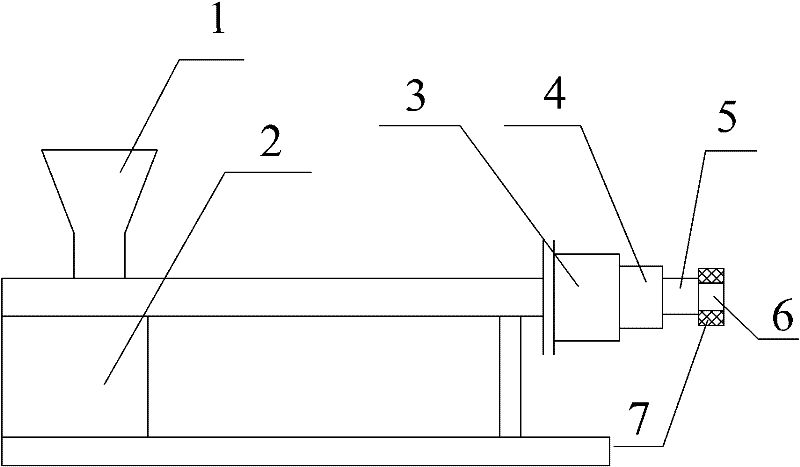

[0038] Add the ingredients prepared in the above proportions Figure 1 In the UHMWPE reinforced pipe extrusion equipment shown, the raw material enters the screw of the extruder 2 through the hopper 1 for transportation, compression and plasticization, and the material flow with a certain viscoelasticity passes through the extruder outlet. The filter plate enters the shunt section 3, the compression section 4, the forming section 5, and the demolding section 6 of the forming mold in turn to complete the process of material flow collection, compression, shaping, and cooling. The extruder pressure is 400Kg / cm 2 .

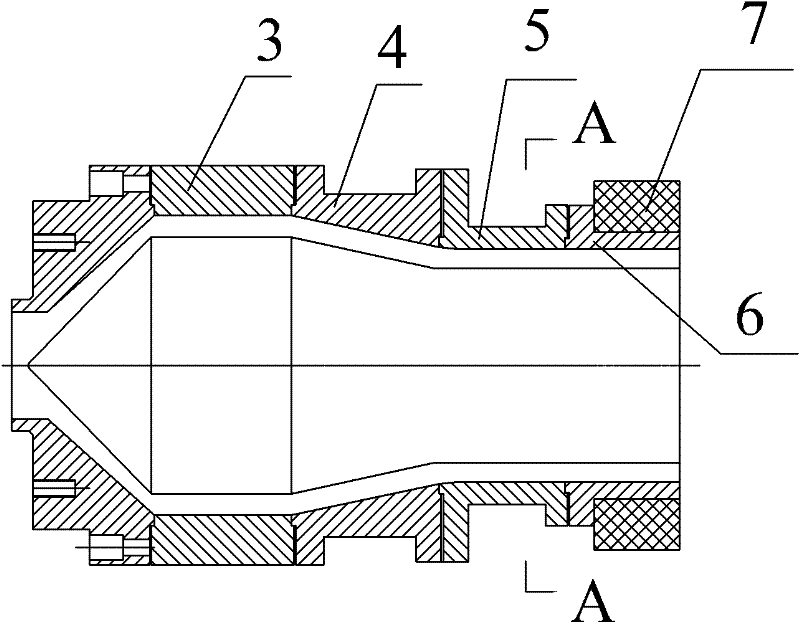

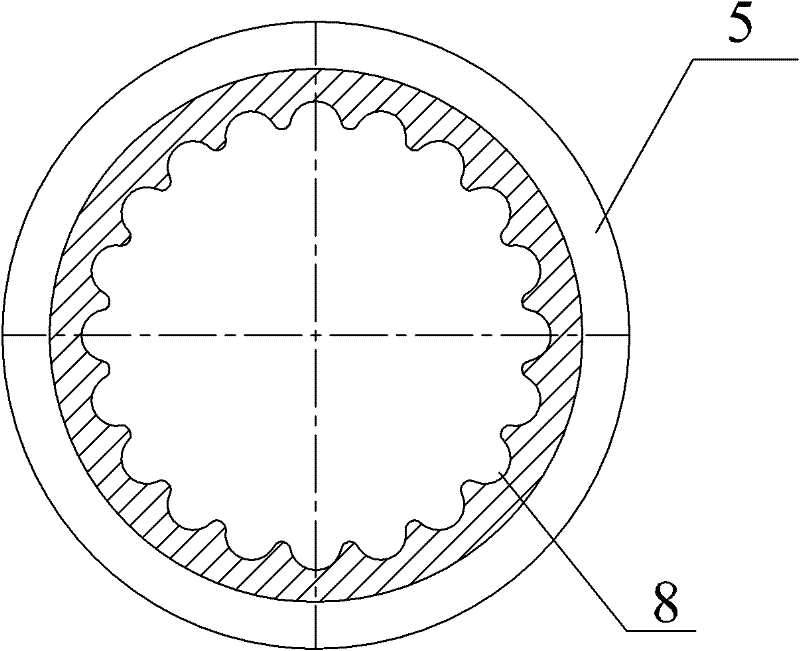

[0039] In the production equipment, the forming section 5 of the forming die and the die part of the demolding section 6 are provided with a longitudinal full communication groove 8 , and the demolding section 6...

Embodiment 2

[0045] The proportion of ingredients for UHMWPE reinforced pipe in terms of parts by mass is:

[0046] UHMWPE 100

[0047] Talc 6

[0048] Graphite 1.0

[0049] Add the ingredients prepared in the above proportions Figure 1 In the UHMWPE reinforced pipe extrusion equipment shown, the raw material enters the screw of the extruder 2 through the hopper 1 for transportation, compression and plasticization, and the material flow with a certain viscoelasticity passes through the extruder outlet. The filter plate enters the shunt section 3, the compression section 4, the forming section 5, and the demolding section 6 of the forming mold in turn to complete the process of material flow collection, compression, shaping, and cooling. The extruder pressure is 500Kg / cm 2 .

[0050] The molding section 5 of the molding die in the production equipment and the die part of the demolding section 6 are provided with a longitudinal full communication groove 8, and the demolding section 6 i...

Embodiment 3

[0056] The proportion of ingredients for UHMWPE reinforced pipe in terms of parts by mass is:

[0057] UHMWPE 100

[0058] Talc 4

[0059] Flame Retardant Antistatic Material 20

[0060] Add the ingredients prepared in the above proportions Figure 1In the UHMWPE reinforced pipe extrusion equipment shown, the raw material enters the screw of the extruder 2 through the hopper 1 for transportation, compression and plasticization, and the material flow with a certain viscoelasticity passes through the extruder outlet. The filter plate enters the shunt section 3, the compression section 4, the forming section 5, and the demolding section 6 of the forming mold in turn to complete the process of material flow collection, compression, shaping, and cooling. The extruder pressure is 400Kg / cm 2 .

[0061] In the production equipment, the forming section 5 of the forming die and the die part of the demolding section 6 are provided with a longitudinal full communication groove 8 , an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com