Silicon wafer carrier welding strength testing machine

A silicon wafer flower basket and welding strength technology, applied in strength characteristics, measuring devices, instruments, etc., can solve the problems of scratching hands, production losses, scratching hands, etc., to ensure personal safety, reduce production losses, and operate convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

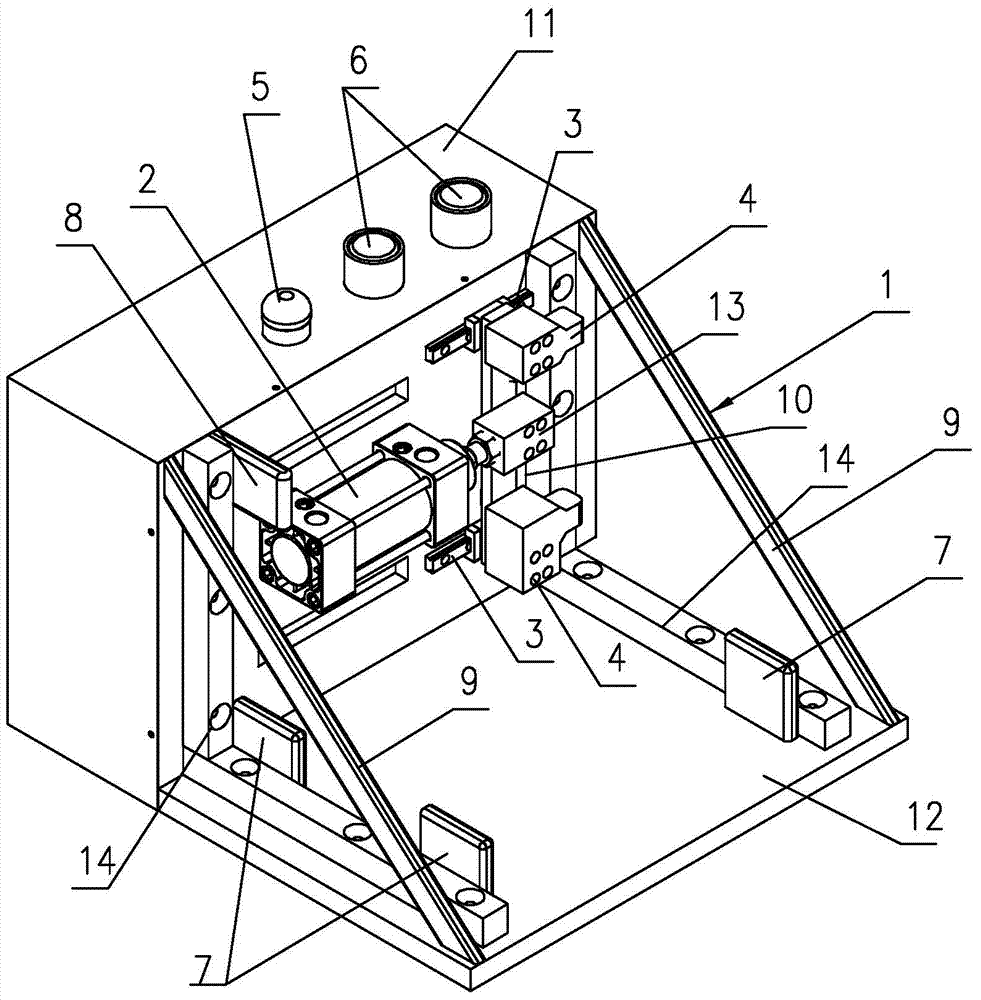

[0021] Such as figure 1 Shown is a silicon wafer flower basket welding strength testing machine of the present invention. It includes a frame 1, a cylinder 2 mounted on the frame 1, a guide rail 3, a top block 4 that is connected to the cylinder 2 in transmission, and an electric control device. The block 4 is made of PP material. The frame 1 has a test card position for placing the silicon wafer flower basket. The cylinder 2, the guide rail 3 and the top block 4 are located on one side of the test card position. The guide rail 3 extends horizontally, and the top block 4 Driven by the air cylinder 2, it can move laterally along the guide rail 3 to push the silicon wafer basket in the test position to detect the welding strength of the silicon wafer basket.

[0022] In this embodiment, the rack 1 is mainly composed of a control box 11 and a horizontal mounting plate 12 connected to the bottom of the front of the control box 11. The electric control device is located in the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com