Bending and shearing mechanism

A technology of shearing mechanism and bending shaft, applied in the direction of household appliances, knives, applications, etc., can solve the problems of blade interference, the inability of knife molds to be produced, and the inability to do other shapes of shearing, etc., to achieve flexible and accurate control and expansion. The effect of using the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

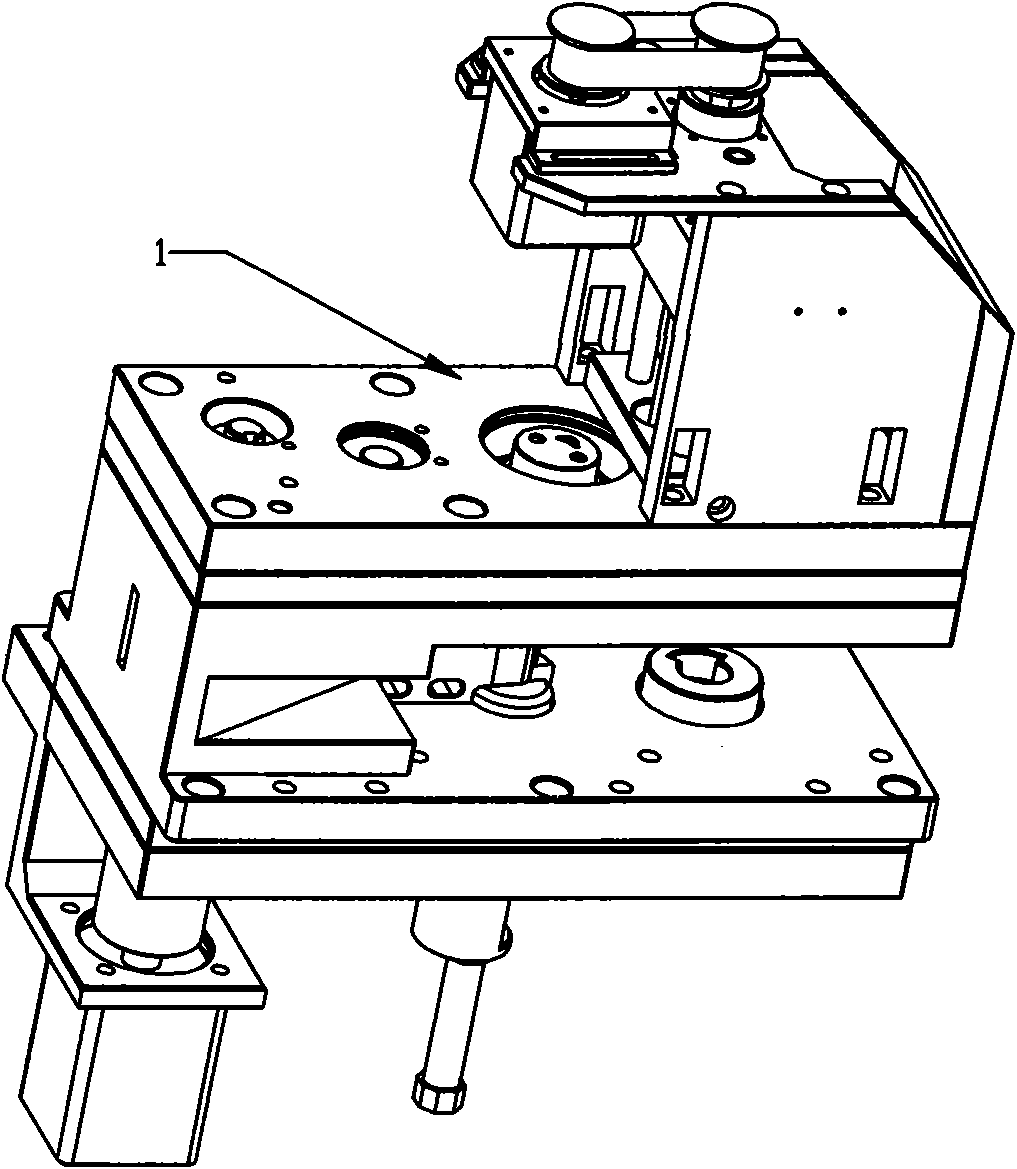

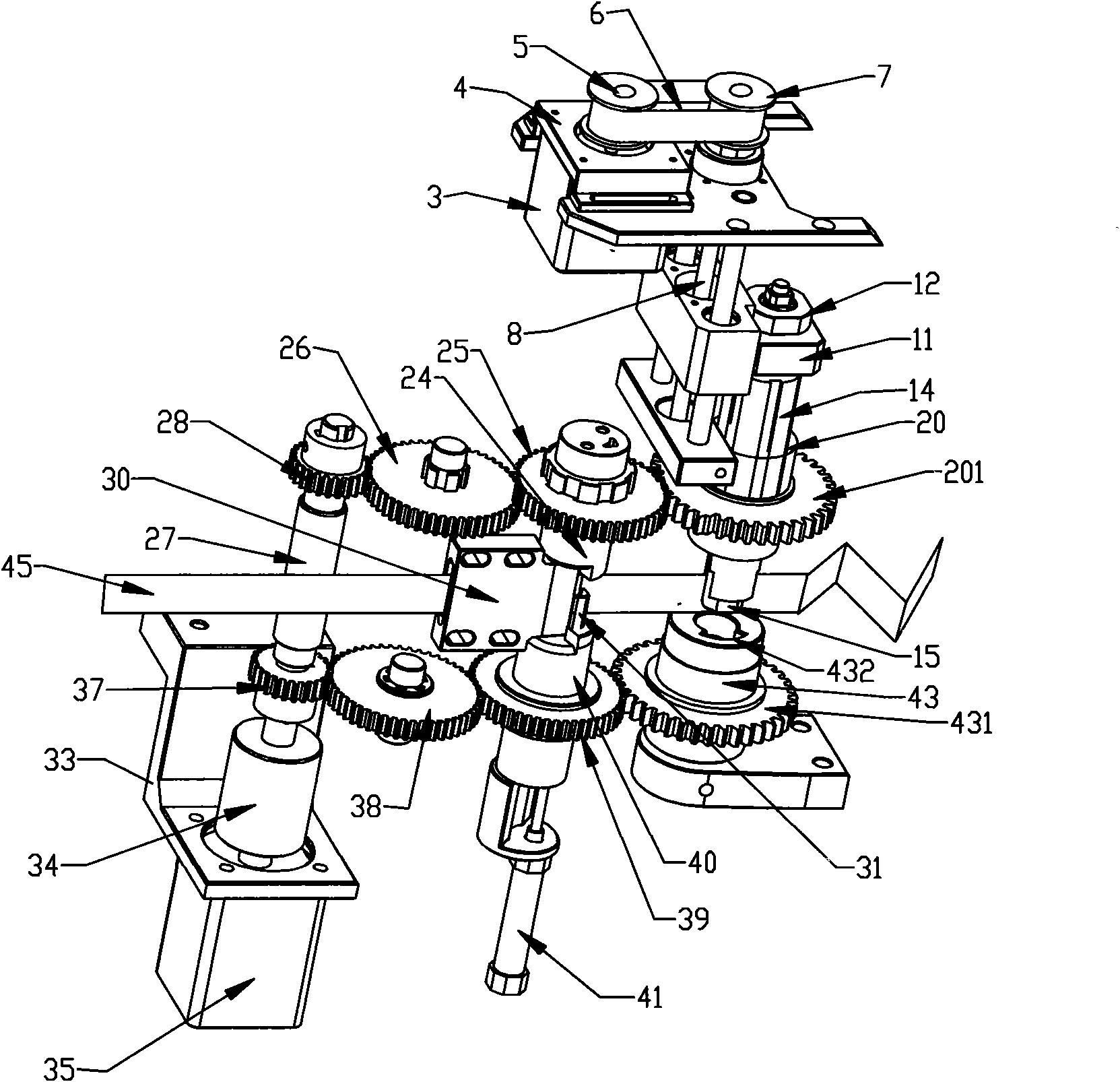

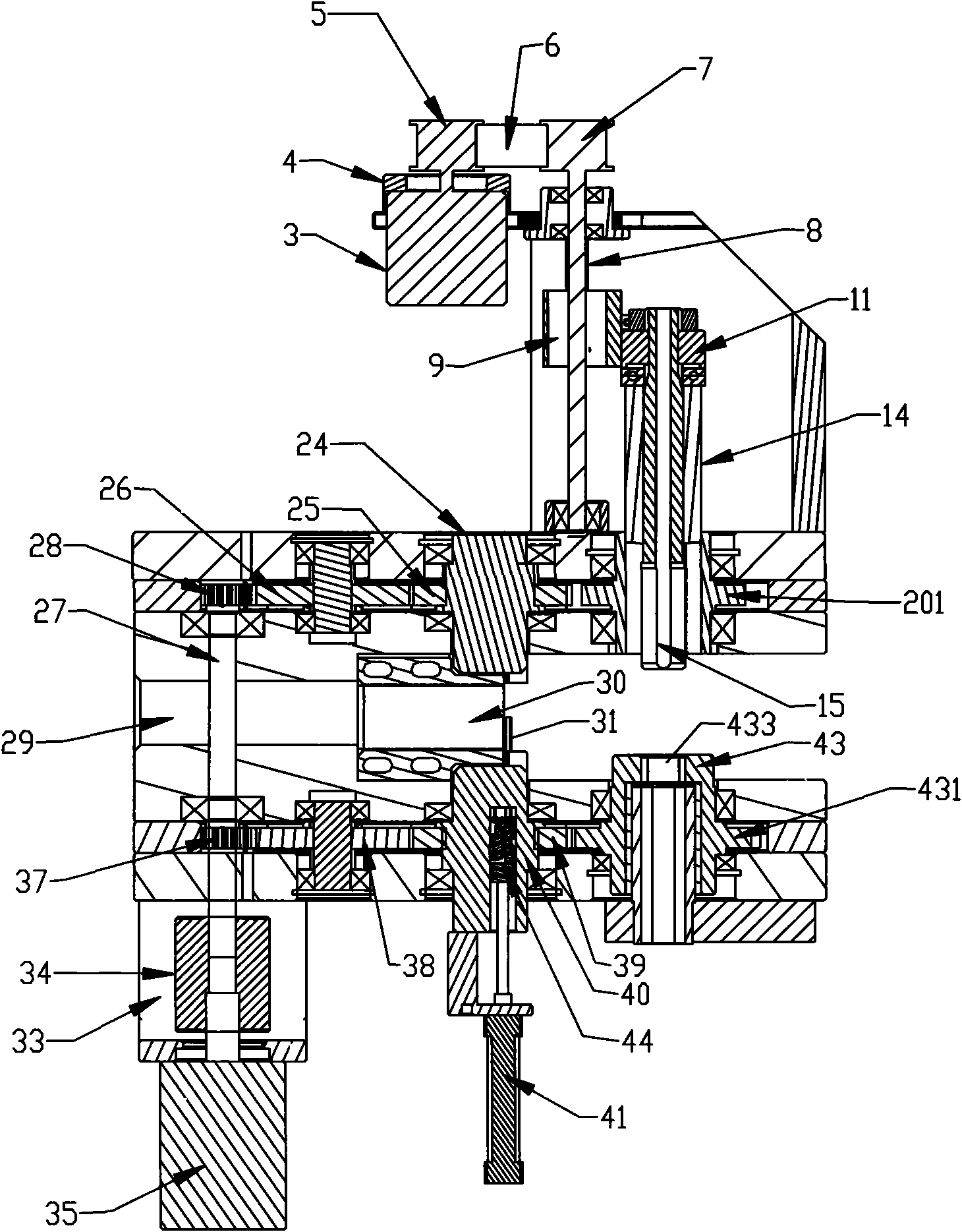

[0026] Such as figure 1 , figure 2 , image 3 As shown, the bending and shearing mechanism includes a machine body 1 on which a bending part and a shearing part are arranged.

[0027] The bending part includes a servo motor 35, a gear transmission mechanism, a bending shaft, a bending inner mold 30, a bending outer mold 31, and a bending outer mold lifting mechanism. The gear transmission mechanism includes a main drive shaft 27, upper and lower main shaft gears 28 and 37 , the upper and lower transmission gears 26 and 38, the upper bending shaft gear 25, the lower bending shaft gear 39, the bending shaft includes the upper bending shaft 24, the lower bending shaft 40, the servo motor 35 is installed on the body 1, and the servo motor is fixed On the seat 33, the upper and lower main shaft gears 28 and 37 are driven by coupling 34 to the main drive shaft 27, and the upper and lower main shaft gears 28 and 37 drive the upper bending shaft gear 25 and the lower bending shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com