Patents

Literature

72results about How to "Solve broken" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

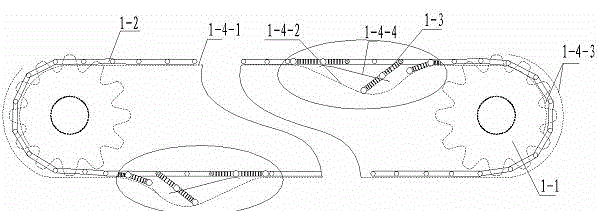

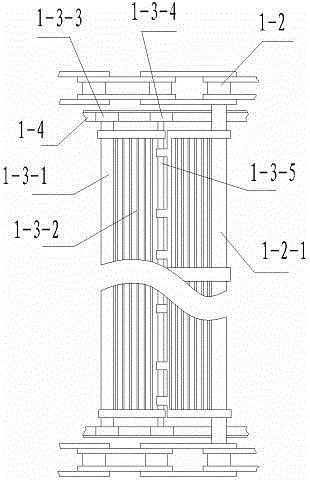

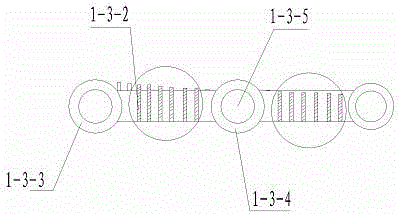

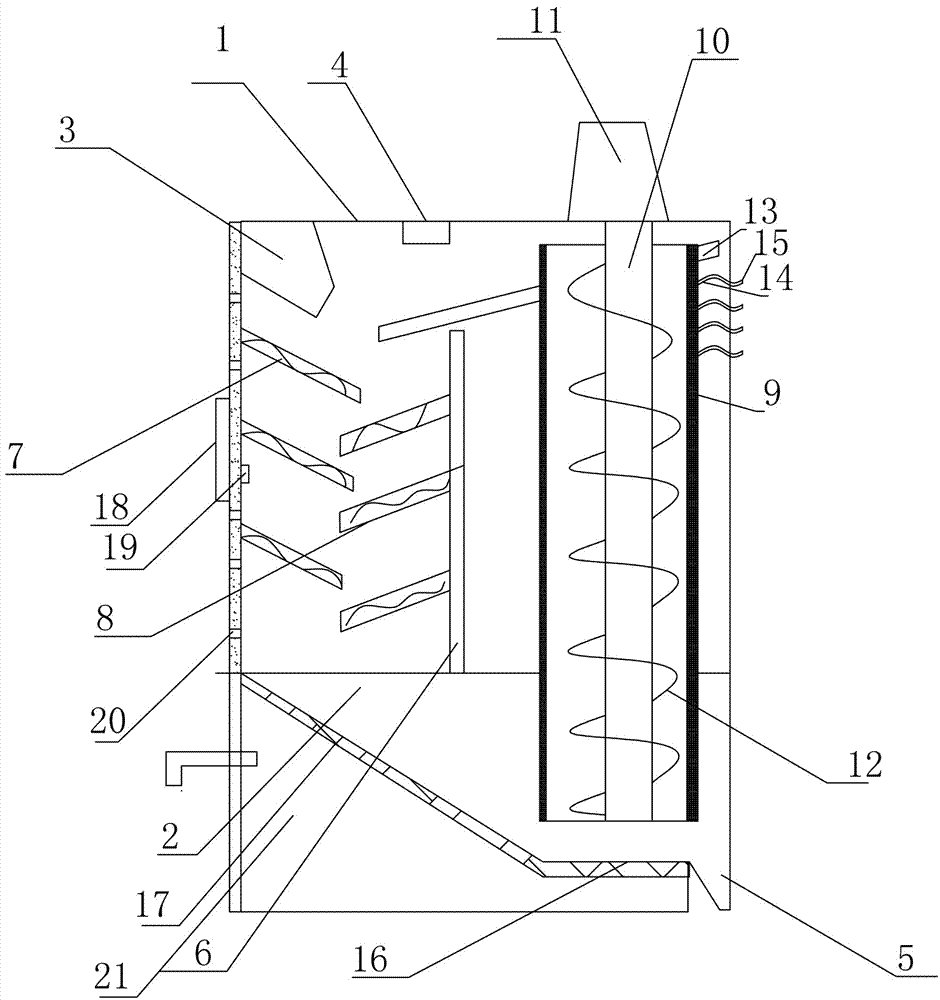

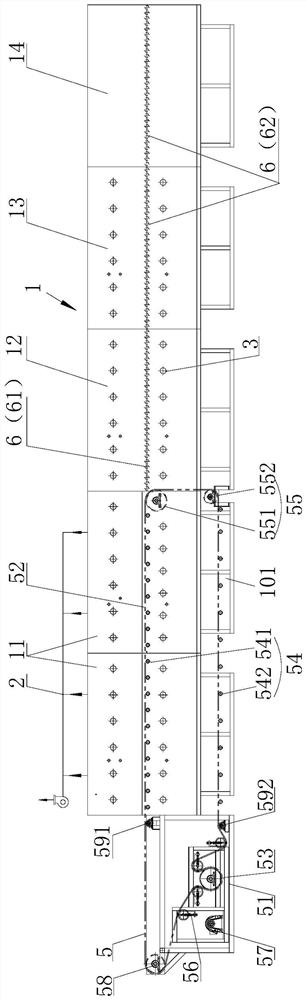

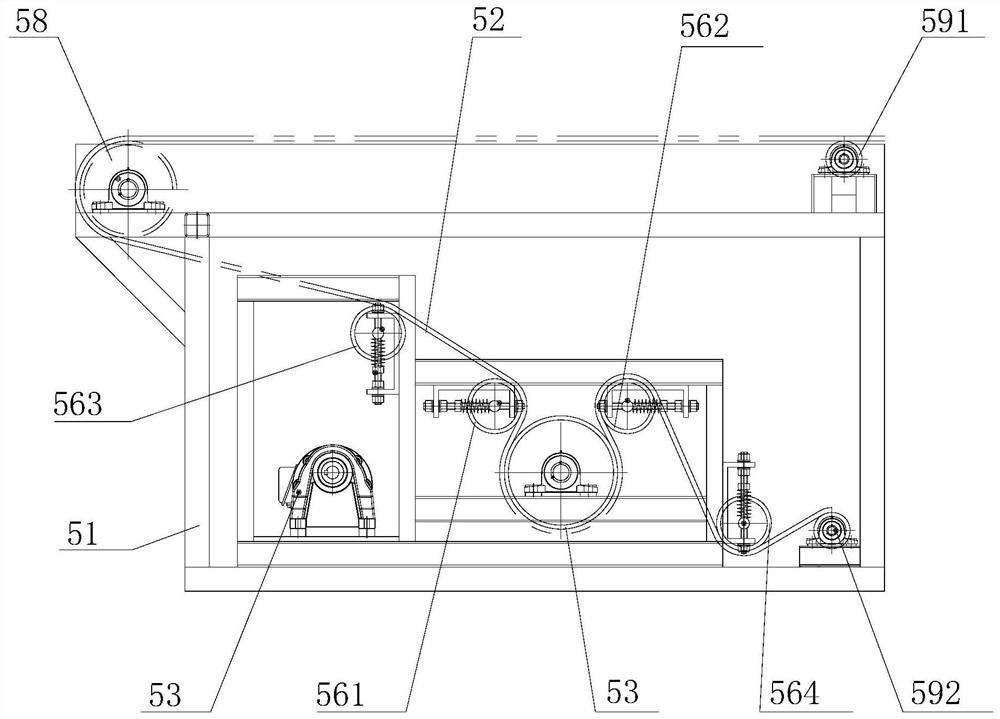

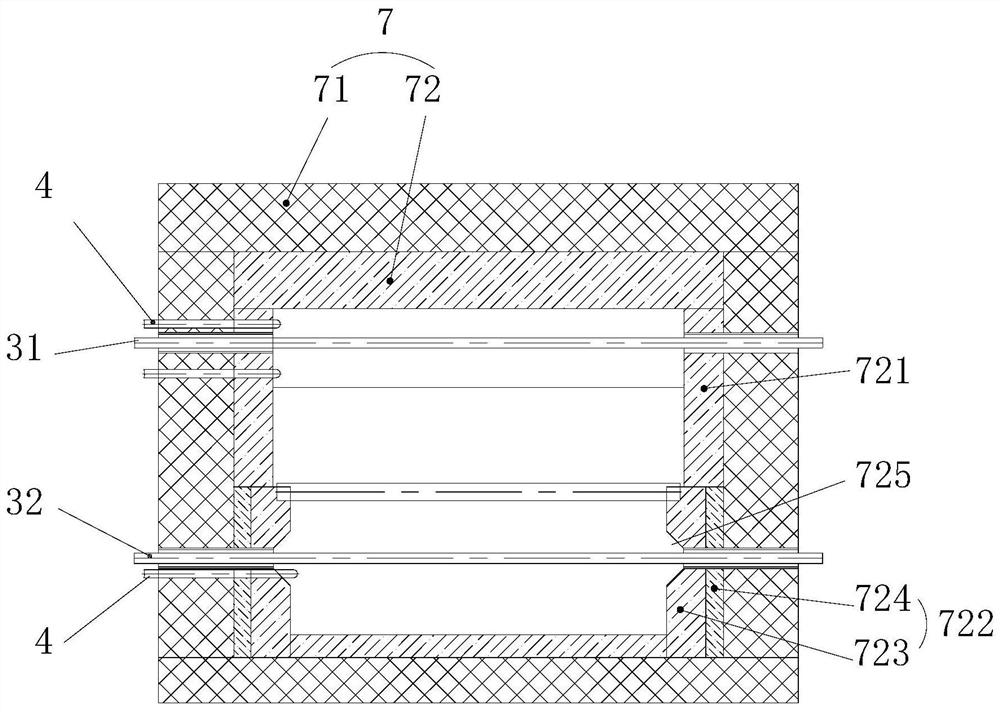

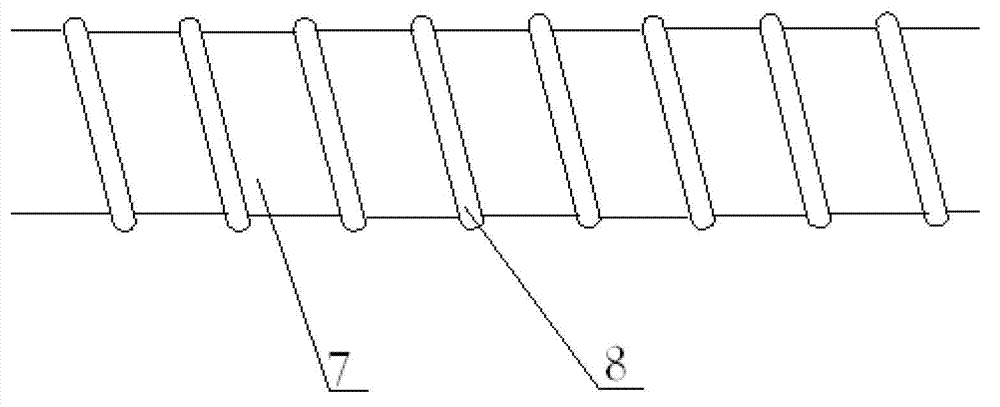

Chain plate conveying coal ball heat conduction oil dryer

ActiveCN104154728AUse diameter reductionImprove utilization efficiencyDrying machines with progressive movementsDrying solid materialsChain structureHeating effect

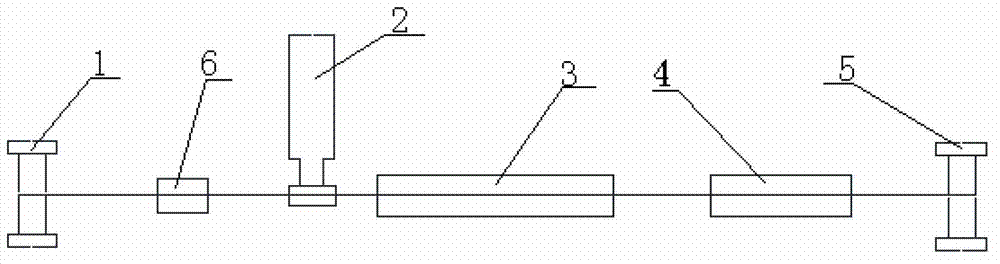

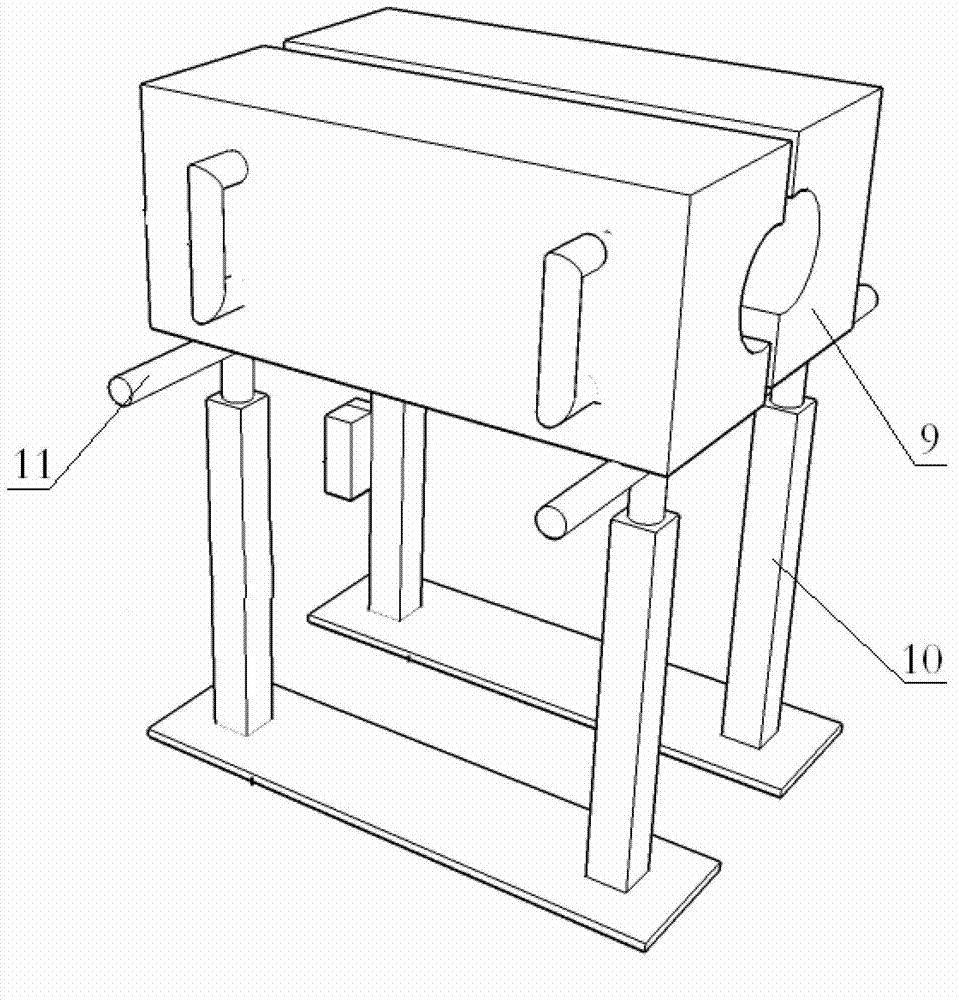

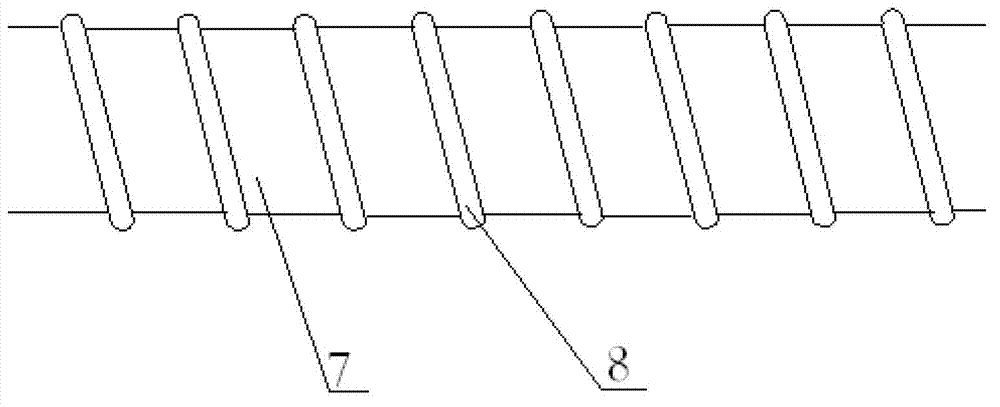

A chain plate conveying coal ball heat conduction oil dryer belongs to the field of drying equipment. The chain plate conveying coal ball heat conduction oil dryer comprises a heat insulation outer shell, a chain plate conveying mechanism, a feeding conveying belt, a discharging opening, a heating device and a waste heat using device. The chain plate conveying mechanism comprises a double-driving chain structure, a matched chain wheel, a bearing chain plate and a guiding sliding track. The bearing chain plate is a hollow-out structure formed by a frame and a grid bar and is located on a chain shaft in a hinge mode. The guiding sliding track is divided into an upper sliding track part and a lower sliding track part which have the same structure sequence. Each part is divided into a horizontal section, a V-shaped blanking section and an arc groove-shaped turning section which are connected in sequence. A falling zone corresponds to a lowering edge section of each V-shaped blanking section of the guiding sliding part. The heating device is connecting heat conduction oil furnace heat conduction calandrias which are distributed above and below a conveying interface formed by the bearing chain plate. An improved double-chain strip plate type conveyor is used, a high-efficiency heat conduction oil furnace is used as a heat source, a controllable heat conduction oil pipe composite layer distribution structure is used for improving the heating effect, and the effects of small space size, energy saving and environment protection are achieved.

Owner:HEBEI GOLD BANGZI BOILER

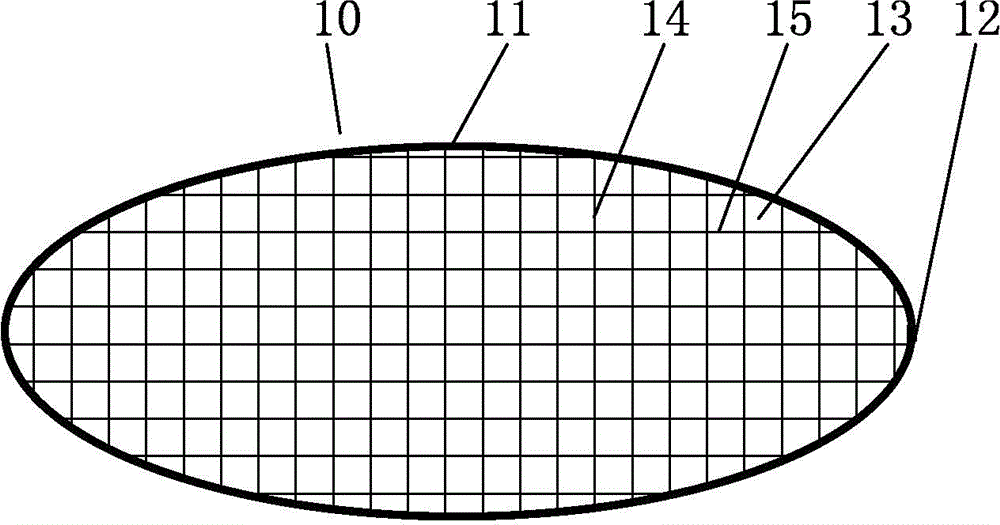

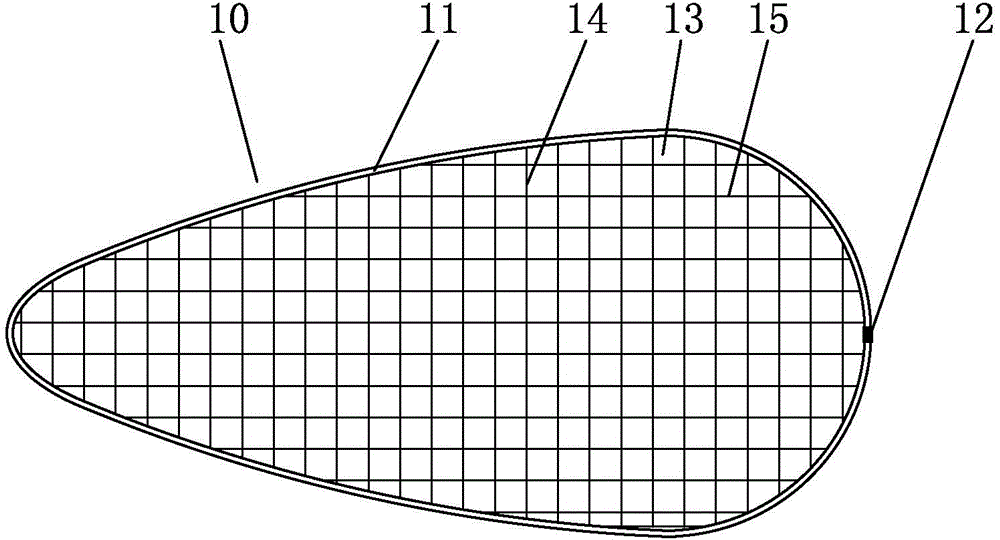

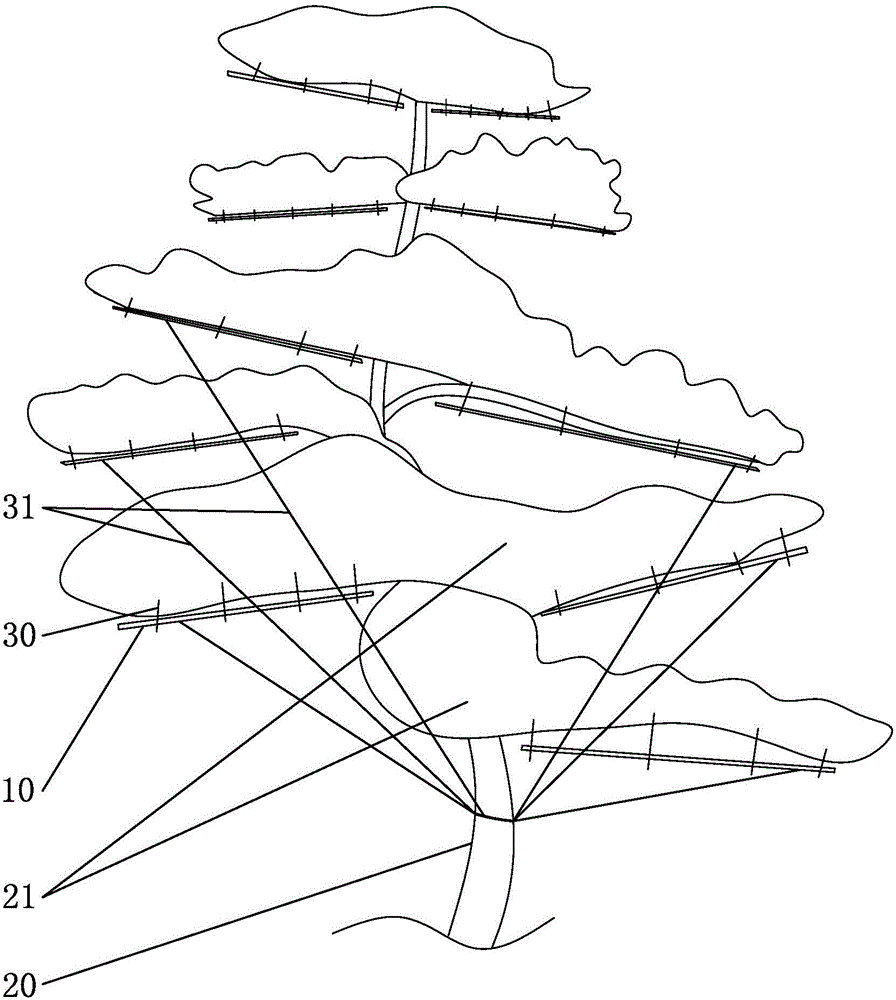

Shape positioning device and shape positioning method for potted plants/landscape trees

ActiveCN104396595ARapid positioningEasy to operateCultivating equipmentsHorticulture methodsMain branchEngineering

The invention relates to a shape positioning device and shape positioning method for potted plants / landscape trees, belonging to the technical field of shaping of potted plants. The shape positioning device is such structured that one or two contour rods are connected and bent to prepare a closed shape contour edge; a branch positioning net formed through knitting of warp and weft is arranged in the shape contour edge; and corresponding places of the periphery of the branch positioning net and the shape contour edge are fixedly connected via welding, bonding or binding with binding ropes so as to form a shape rack. The shape positioning method comprises the following steps: designing the shape of a potted plant or landscape tree; connecting the shape racks to the lower sides of to-be-shaped branches; and successively binding the to-be-shaped branches onto each shape rack according to the designed shapes of main branches and lateral branches of the to-be-shaped branches and locally adjusting the positioned locations of the main branches and the lateral branches of a part of the to-be-shaped branches. The invention has the following advantages: positioning of the branches of potted plants / landscape trees can be quickly carried out; operation is simple; no damage is posed to the branches; good artistic appearance is obtained; production cost is low; and the shape positioning device and shape positioning method are applicable to shape positioning of potted plants / landscape trees.

Owner:浙江百花园林集团有限公司

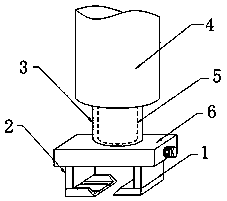

Rotatable simple industrial mechanical hand

InactiveCN107696057ARealize the function of anti-fallAvoid crash situationsGripping headsBall screwEngineering

The invention provides a rotatable simple industrial mechanical hand which comprises a ball screw, a moving clamping plate, a supporting block, an auxiliary bearing table, a guiding groove, a guide-incavity, a transparent protection sleeve, a guide wheel and an annular sliding groove. The ball screw is assembled to the middle position of the interior of the groove. The moving clamping plate is installed on the lower end face of a nut seat. The supporting block is fixed to the lower end face of the moving clamping plate. The auxiliary bearing table is installed on the lower end face of a fixedclamping plate. The guiding groove is formed in the lower end face of the interior of the guide-in cavity. The guide-in cavity is formed in the middle position of the auxiliary bearing table. By means of the design, the anti-falling function of goods clamping is achieved, the transparent protection sleeve is arranged on the annular side face of a rotating shaft in a sleeving manner, the guide wheel is installed on the upper end face of the transparent protection sleeve, and the annular sliding groove is formed in the lower end of a mechanical arm. By means of the design, the protection function of the rotating shaft is achieved, the service life of the rotating shaft is prolonged, and the rotatable simple industrial mechanical hand is reasonable in structure, good in protection performance, long in service life, good in stability and high in reliability.

Owner:董杰

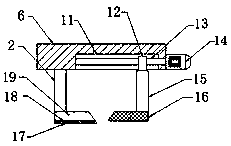

Clamping device for abnormal-shape glass bottle

The invention relates to the technical field of machining of glass bottles and in particular to a clamping device for an abnormal-shape glass bottle. The clamping device comprises a hoisting mechanism and further comprises a first air pump and a plurality of second air pumps; the hoisting mechanism is fixedly connected with a hollow positioning rod; the positioning rod is communicated with the first air pump; a limiting plate is horizontally arranged on the positioning rod; the positioning rod penetrates through the limiting plate and is fixedly connected with the limiting plate; the second air pumps are connected with air inflation pipes; the air inflation pipes penetrate through the limiting plate and are fixedly connected with the limiting plate; airbags made of rubber are connected with parts, which are located below the limiting plate, on the air inflation pipes; the airbags are fixedly connected onto a side wall of the positioning rod; and the lower end of the positioning rod is located below the airbags. By adopting the clamping device for the abnormal-shape glass bottle, provided by the invention, the problems that an existing mechanical arm only can be applied to glass bottles with specific types and the abnormal-shape glass bottles are easily crashed can be solved.

Owner:CHONGQING RONGCHENG GLASS PROD CO LTD

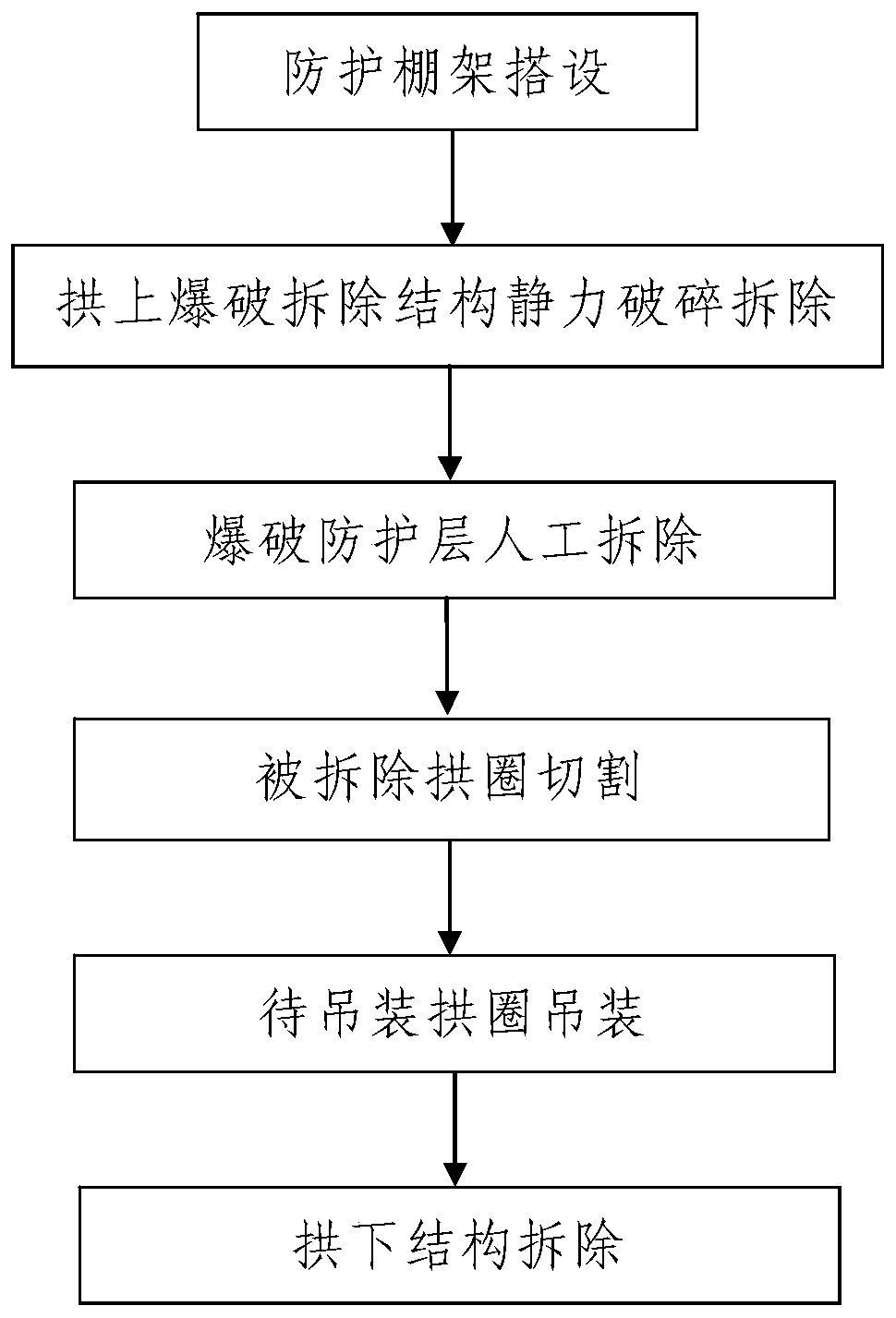

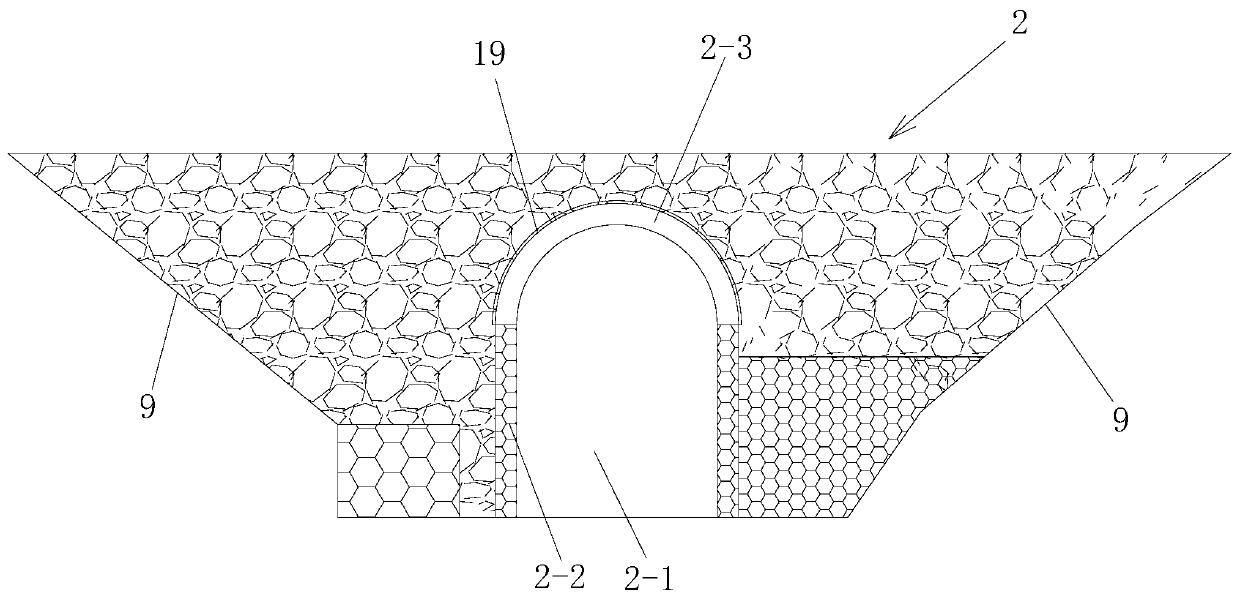

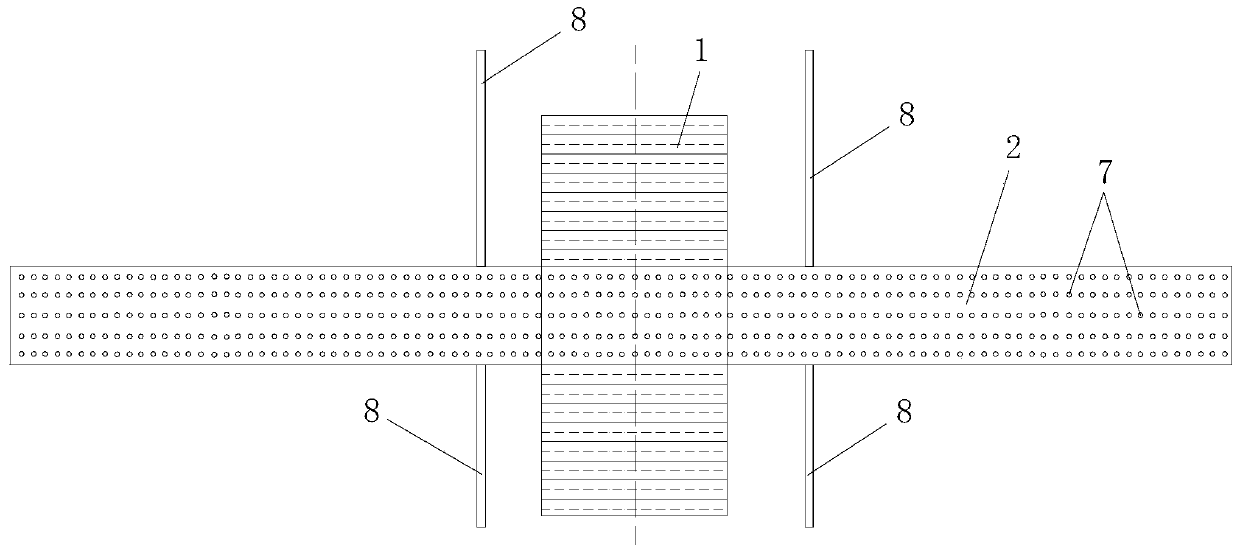

Demolition construction method for overpass existing line arch bridge

ActiveCN110904867AThe method steps are simpleReasonable designBuilding repairsBridge strengtheningArchitectural engineeringStructural engineering

The invention discloses a demolition construction method for an overpass existing line arch bridge. The demolition construction method comprises the steps: 1, erecting a protective shed frame; 2, carrying out static crushing demolition on the arch blasting demolition structure; 3, manually removing the blasting protection layer; 4, cutting the removed arch ring; 5, hoisting the arch ring to be hoisted; and 6, dismantling the under-arch structure. The method is simple, reasonable in design, easy and convenient to construct and good in using effect; the protection shed frames fixed to the frontside and the rear side of the removed arch bridge are adopted for effective protection, meanwhile, the structure on the arch of the removed arch bridge is removed in the mode that static crushing andmanual chiseling are combined, it is guaranteed that a plain concrete arch ring cannot be damaged in the static crushing process, and an existing spanned railway line cannot be disturbed. After the arch ring is exposed, the removed arch ring is cut and decomposed through a rope saw and then hoisted and removed, then the under-arch structures on the left side and the right side are rapidly removed,the construction period can be effectively shortened, the arch bridge removing efficiency is improved, and the removing process is safe and reliable.

Owner:THE FOURTH ENG CO LTD OF CHINA RAILWAYNO 20 BUREAU GRP

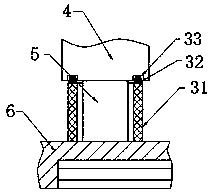

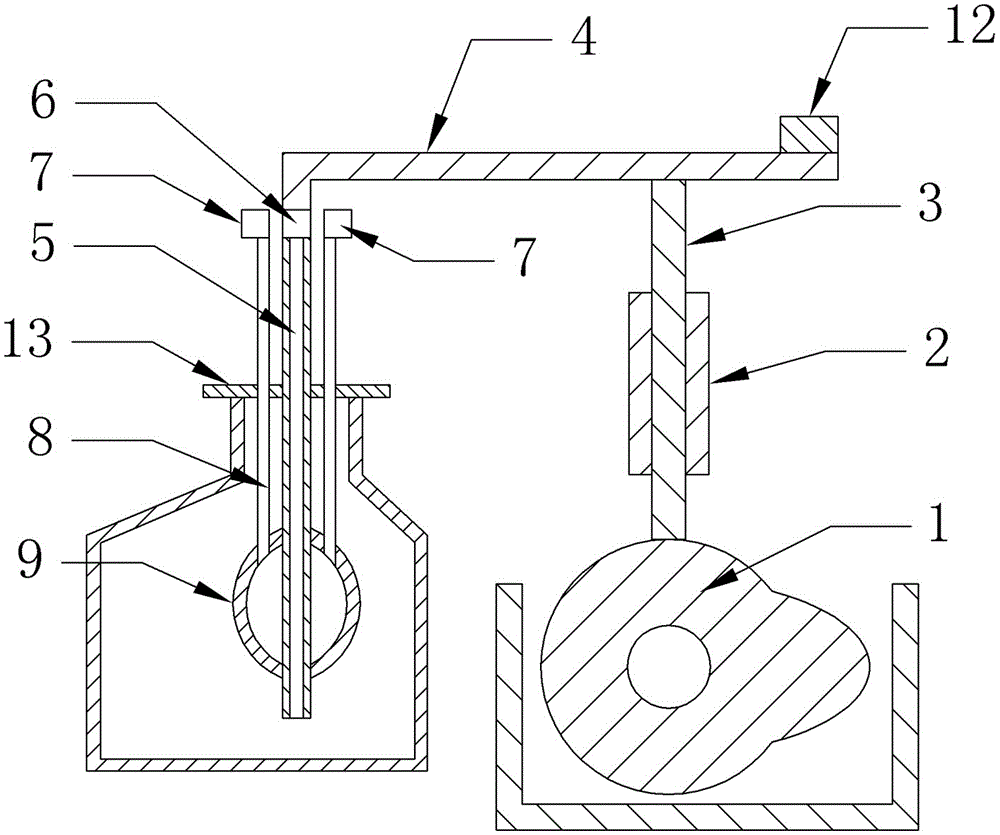

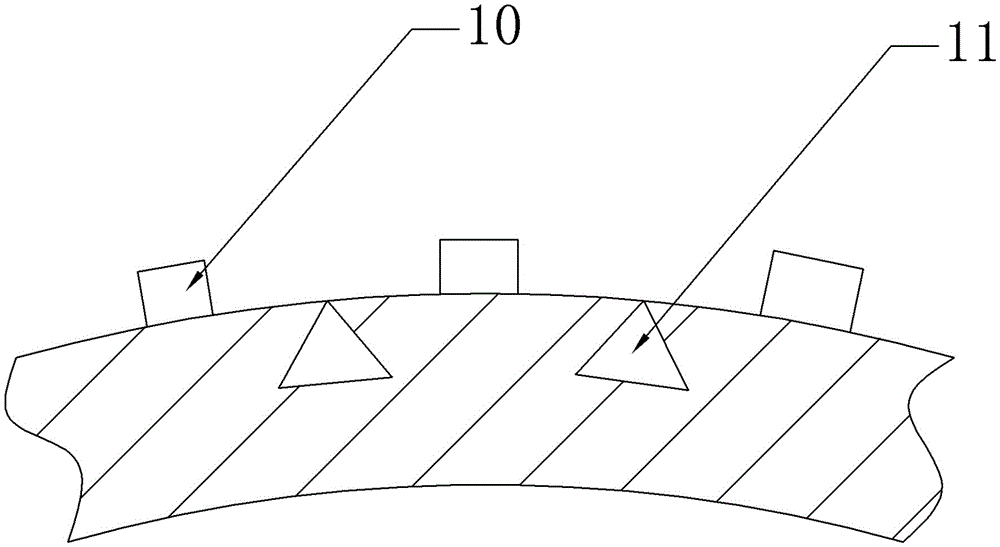

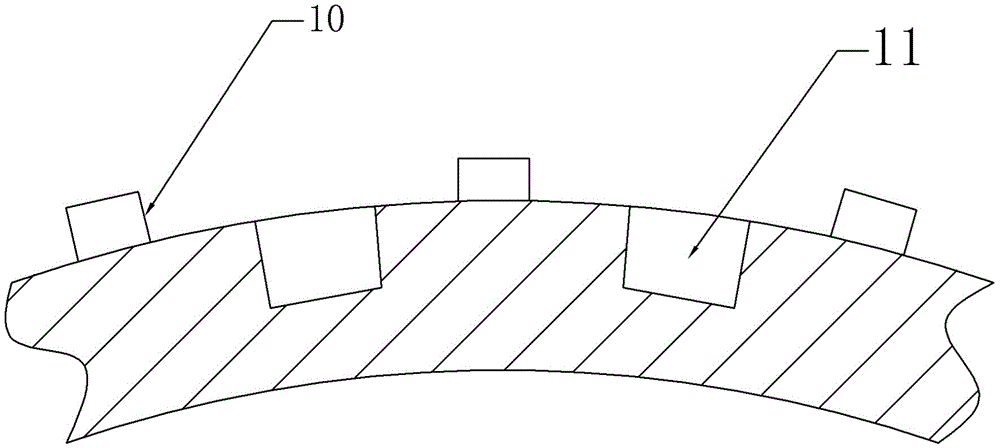

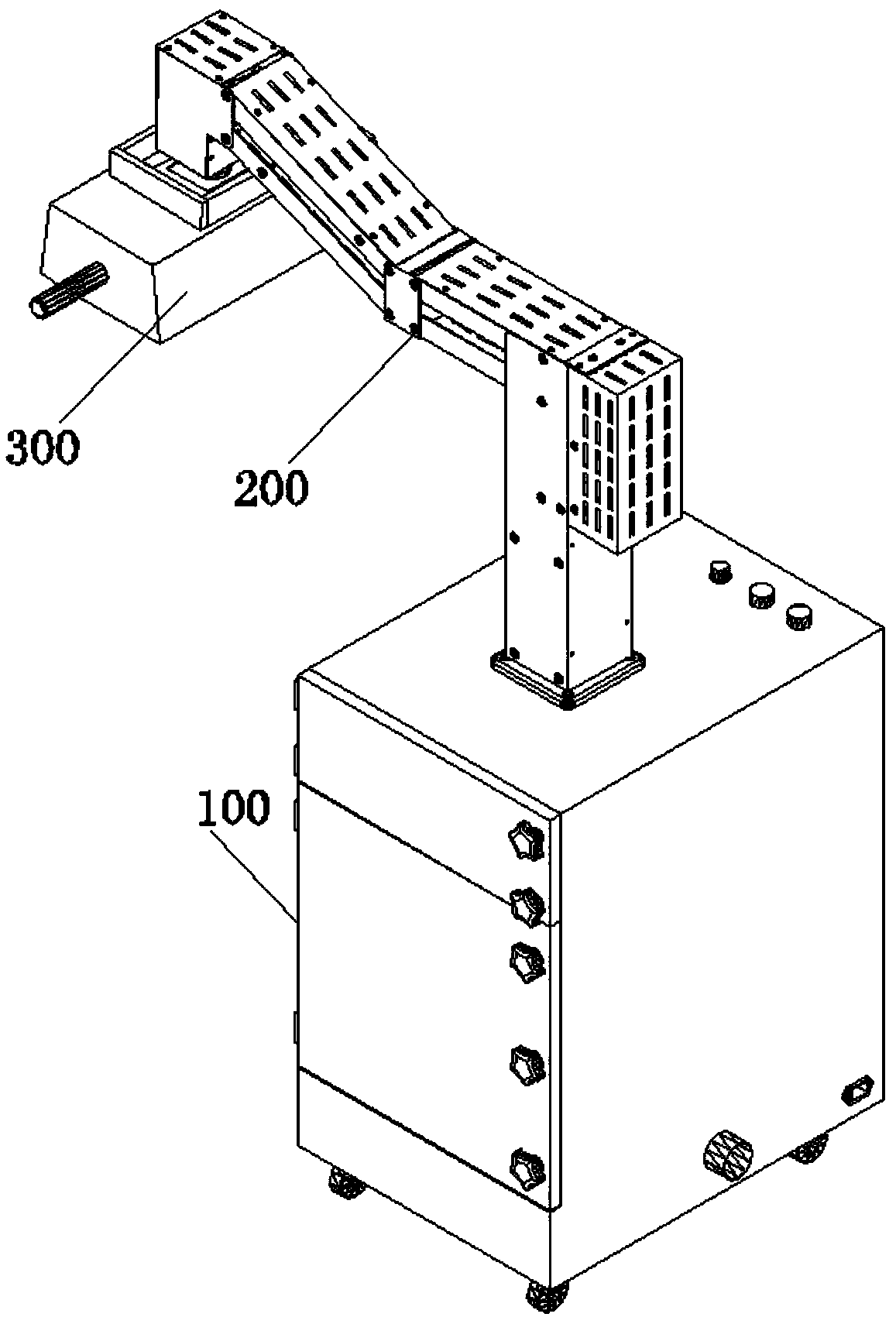

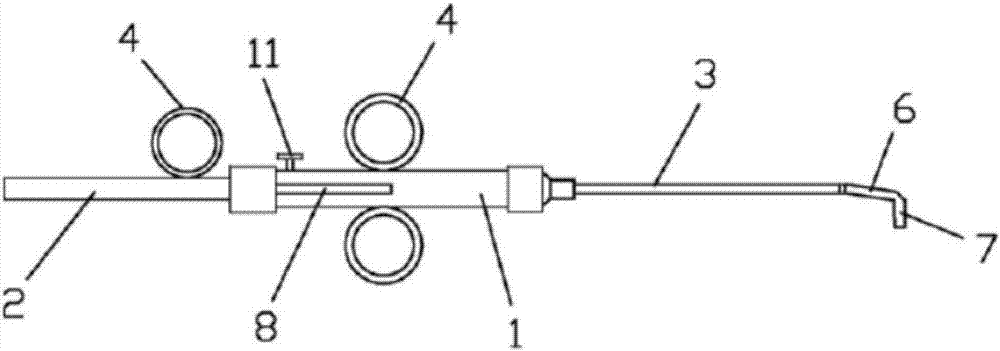

Moxibustion machine

InactiveCN108670813AFilter evenlyReduce the impactDevices for heating/cooling reflex pointsGas treatmentEngineeringCantilever

The inVention discloses a moxibustion machine. The moxibustion machine comprises a main machine assembly for purifying moxibustion smoke, a cantileVer assembly for connection and a moxibustion box assembly for burning moxa, wherein the main machine assembly, the cantileVer assembly and the moxibustion box assembly are sequentially connected; the bottom of a smoke feeding tube is fixedly installedon the top face of a machine box, a filtering assembly is installed in an inserting grooVe of the machine box, and a main machine head is slidingly connected with a manual cantileVer part through a right connecting coVer; the manual cantileVer part is slidingly connected with an automatic cantileVer part through a left connecting coVer, and the automatic cantileVer part is slidingly connected witha main support; a smoke discharging tube penetrates through the cantileVer assembly; the moxibustion box assembly comprises a connecting assembly and a moxibustion box, and the connecting assembly isfixedly arranged on the top face of the moxibustion box. By means of the moxibustion machine, the moxibustion smoke can be purified, the enVironmental comfortable degree of the moxibustion process isimproVed, the whole structure is reasonable, moxa sticks are rapidly and conVeniently replaced, and the burning process and the moxibustion process are safe and reliable.

Owner:深圳市久喜电子有限公司

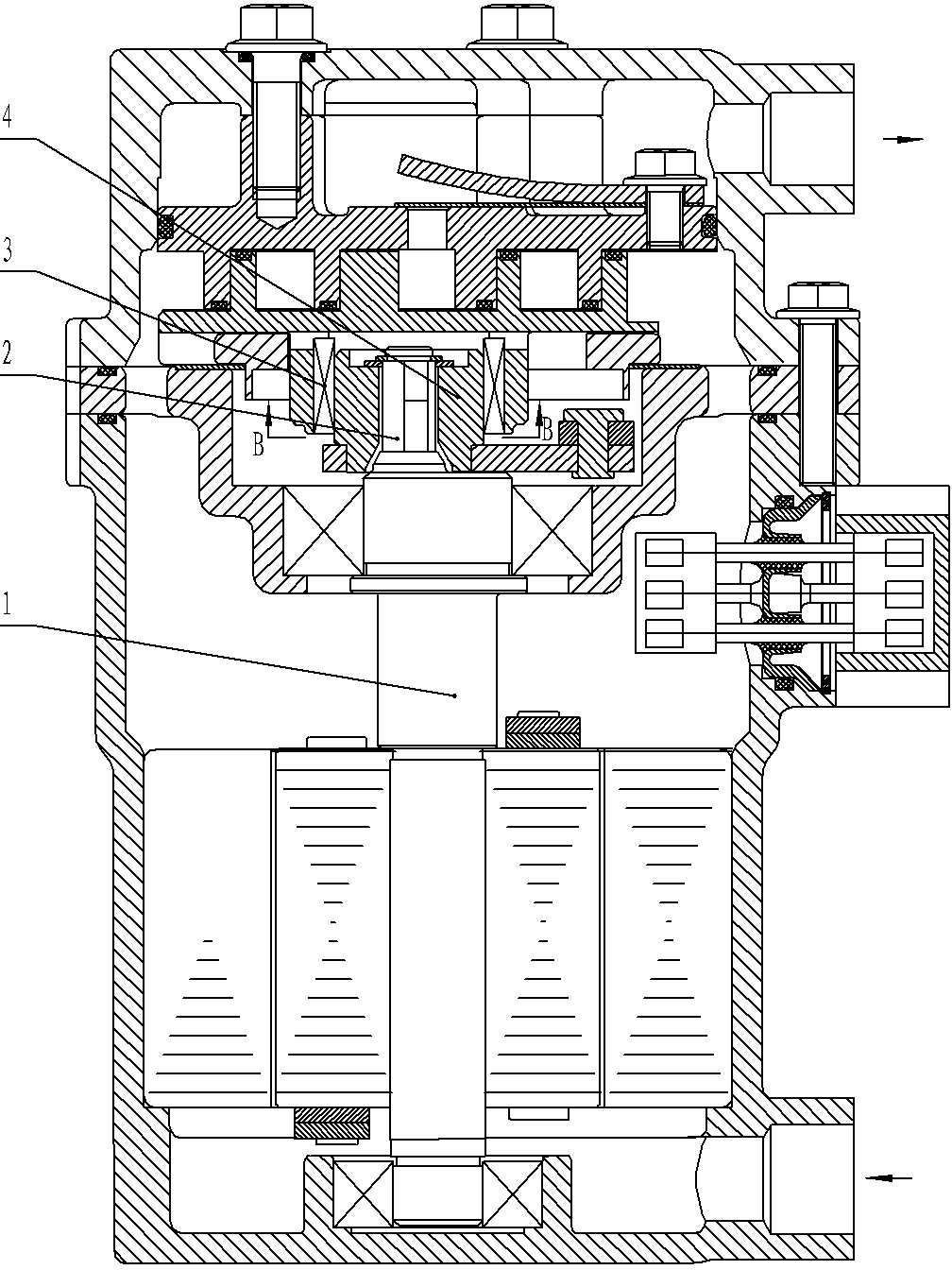

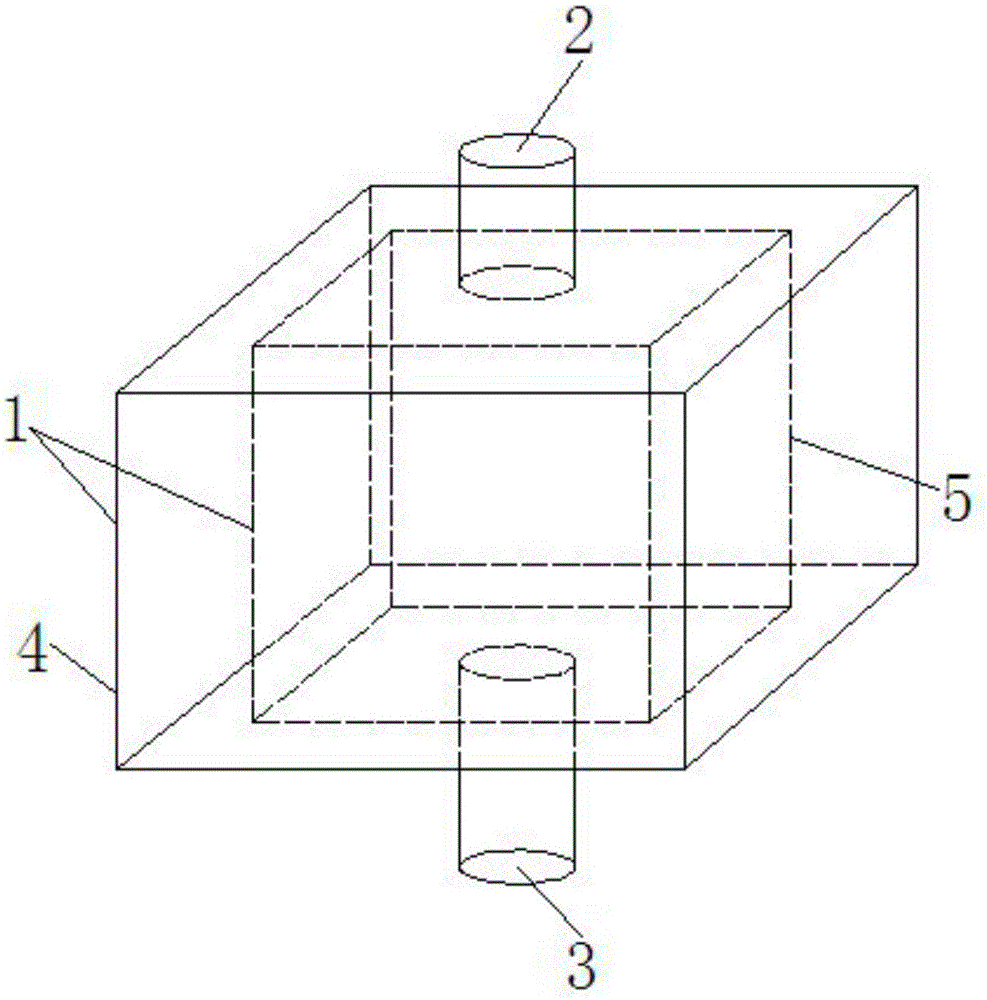

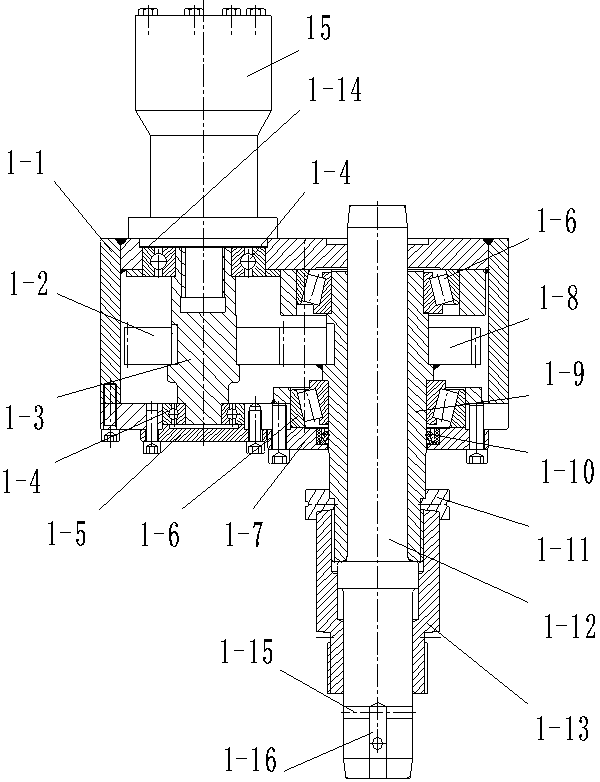

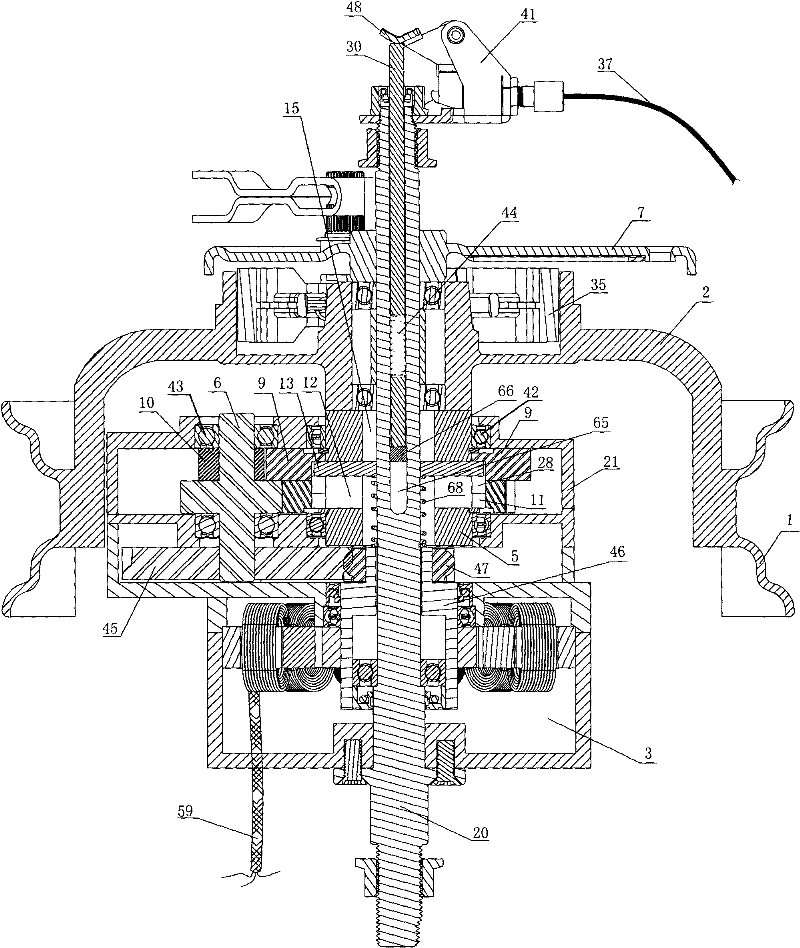

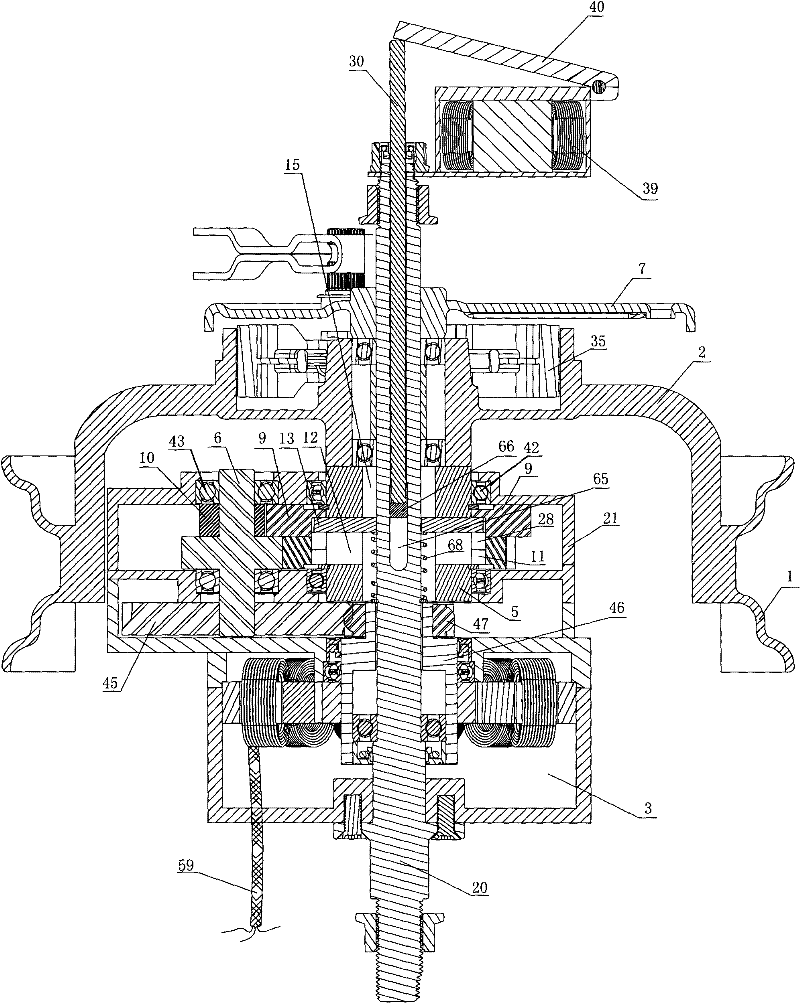

Scroll compressor

InactiveCN103089619AEasy to assembleSolve brokenRotary piston pumpsRotary piston liquid enginesNeedle roller bearingJoint component

The invention discloses a scroll compressor, relating to the technical field of fluid machinery. The scroll compressor comprises a driving shaft, a joint component installed on the driving shaft, and a needle roller bearing, wherein a crank of the driving shaft is connected with the needle roller bearing through a shaft sleeve of the joint component. The invention is characterized in that the wall of the shaft sleeve hole of the joint component at least has one bearing driving plane; and in the shaft sleeve hole, one section of the crank adjacent to the outer end is provided with a crank driving plane bonded with the shaft sleeve driving plane, and the other section of the crank is provided with a plane which has a 0.3-0.5mm clearance with the shaft sleeve driving plane. Compared with the prior art, the invention can solve the problems of low working reliability, difficulty in assembly, and insufficient operation stability in the existing scroll compressor.

Owner:LIUZHOU YIZHOU AUTOMOBILE AIR CONDITIONER

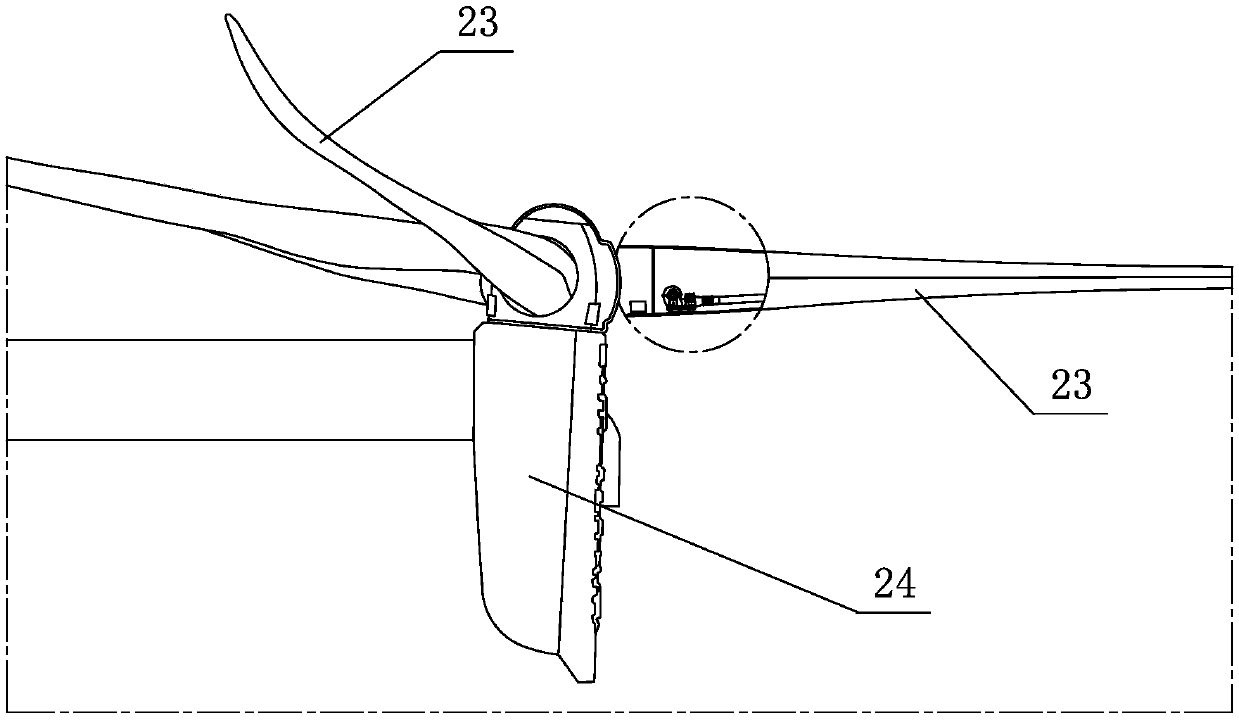

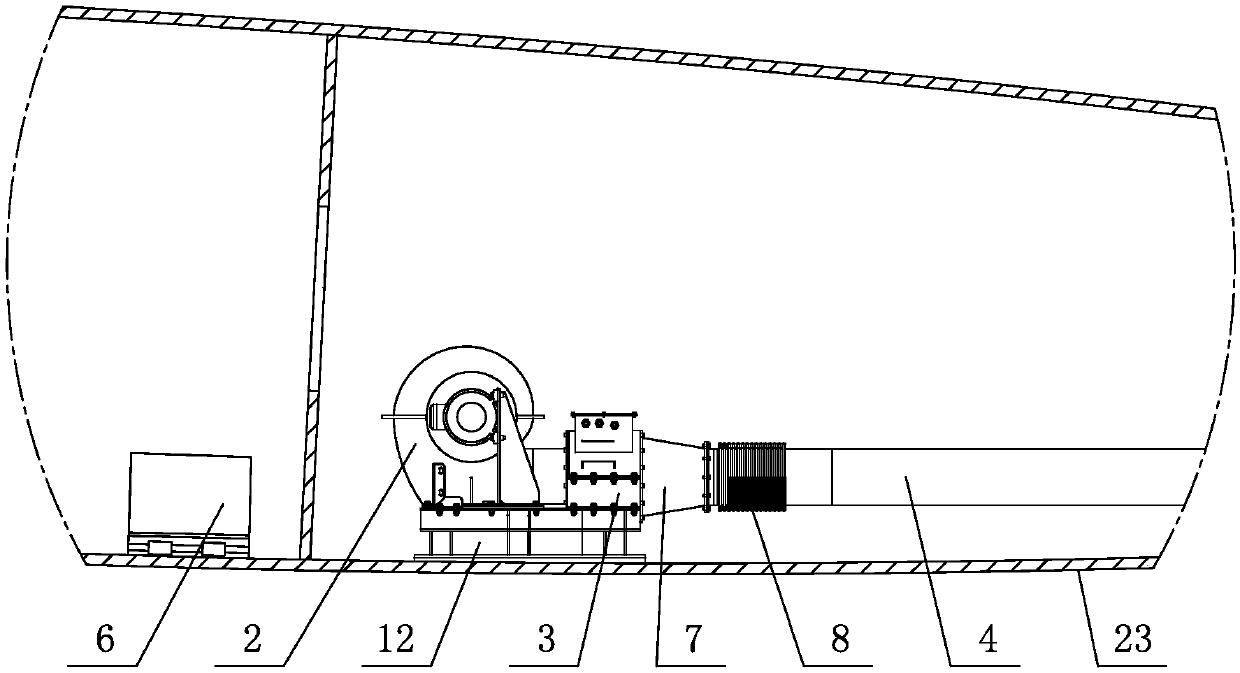

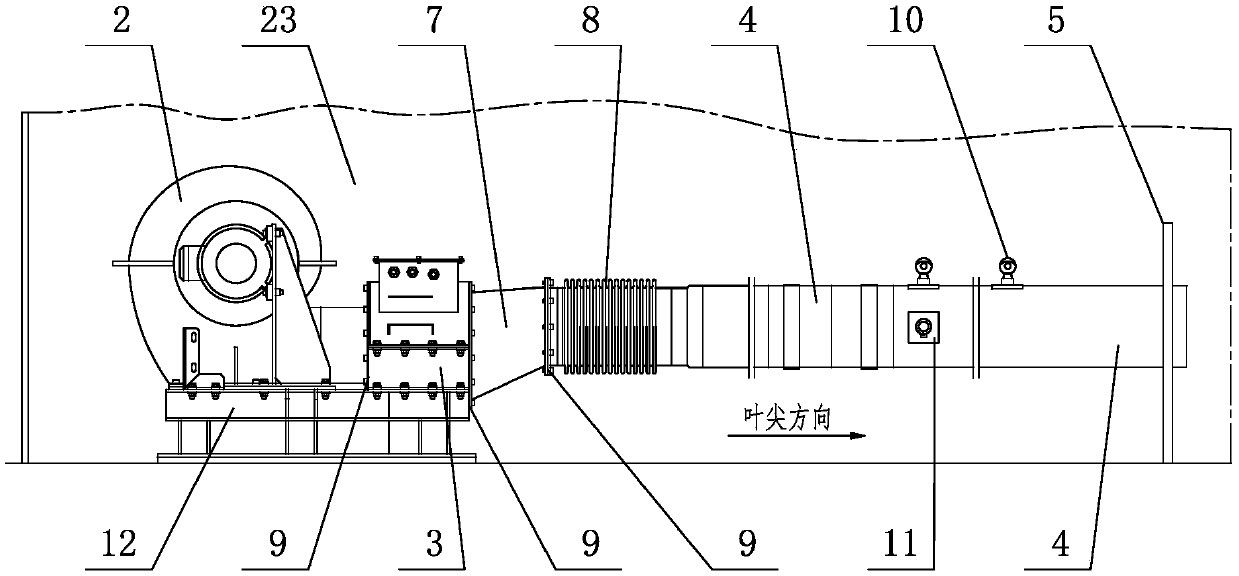

Hot blast type wind power generating set blade deicing device

ActiveCN109611290AEffective deicingSolve crackingMachines/enginesWind motor monitoringElectricityEngineering

The invention discloses a hot blast type wind power generating set blade deicing device. The hot blast type wind power generating set blade deicing device comprises a heating device and a ventilationpipeline. The heating device and the ventilation pipeline are arranged in a blade front edge cavity. The heating device comprises an air blower and a heater. An output end of the heater is connected with an air pipe. An air outlet end of the air pipe penetrates through a wind shield arranged in a blade inner cavity. The blade inner cavity is partitioned into a heating area and a non-heating area by the wind shield. The deicing device further comprises a control cabinet arranged at the root of the blade inner cavity. The heating device is connected with the control cabinet. By means of the hotblast type wind power generating set blade deicing device, blades of a wind power generating set can be effectively deiced, and the running safety and electricity generating capacity of the wind powergenerating set are improved. The hot blast type wind power generating set blade deicing device has a very high practical value.

Owner:ZHEJIANG WINDEY

Ejection mechanism for injection molding mold

The invention discloses an ejection mechanism for an injection molding mold, wherein the ejection mechanism comprises a sleeve pedestal installed on a male mold ejection plate and a sleeve body arranged on the sleeve pedestal, an axle hole used for mounting a pin shaft is arranged in the sleeve body, the sleeve body is a double-joint sleeve body, the double-joint sleeve body comprises a movable sleeve body connected with the pedestal and an ejection sleeve body, a conical connecting body with a gradually decreasing outside diameter is arranged at the crossing site of the ejection sleeve body and the movable sleeve body, the movable sleeve body is arranged in a male template, the outside diameter of the ejection sleeve body is smaller than that of the movable sleeve body, and the inside diameter of the ejection sleeve body is equal to that of the movable sleeve body. The double-joint sleeve body with outside diameter difference is utilized in the invention, so that the sleeve end face is used for ejecting the formed product during the ejection process, the double-joint sleeve body applies a uniform ejection force on the formed product to guarantee the demolding, reduce the breakage of the formed product and generate no ejection mark on the outline of the formed product, and the ejection mechanism is simple and reasonable in structure, high in stability and is capable of avoiding such demolding failures of the formed product as breakage, scratch, etc.

Owner:SHENGYANG PRECISION MOLD KUSN

High-barrier type packaging bag with aluminum plated film

InactiveCN106347829ASolve brokenEasy loading and unloadingSynthetic resin layered productsBagsEngineeringUltimate tensile strength

The invention relates to a high-barrier type packaging bag with an aluminum plated film. The high-barrier type packaging bag comprises a packaging bag body, wherein a feed port is formed in the middle of the upper part of the packaging bag body, a discharge port is formed in the middle of the lower part of the packaging bag body, the packaging bag body is formed by a woven fabric outer bag and a composite type inner bag, the composite type inner bag is formed by a PET outer film layer, a first bonding layer, a first connection film layer, a second connection film layer, a second bonding layer, a PET inner film layer, the aluminum plated layer and a PE film layer, the aluminum plated layer is plated on one side of the PET inner film layer, and enhanced type slings are arranged at the four corners of the upper part of the packaging bag body. According to the high-barrier type packaging bag with the aluminum plated film, the whole impact resistance and the toughness are good, the sealing performance and the barrier property are high, the service life is long, and the sling strength is high.

Owner:宜兴威尼特包装袋有限公司

Novel processing method for green tea capable of being stored and having abundant inclusions

InactiveCN107006625ASolve brokenSolve the problem of tea leaves having a charcoal tastePre-extraction tea treatmentCooking & bakingGreen tea

The invention relates to the field of tea processing and particularly relates to a novel processing method for green tea capable of being stored and having abundant inclusions. The method comprises the procedures of fresh leaf picking, fresh leaf tedding, fresh leaf cleaning, fresh leaf drying, slight rocking, steam fixation, secondary fixation and dehydration, primary rolling, first drying, re-rolling, low-temperature permanent baking and drying, cake pressing, drying in a drying room. The obtained green tea is long in storage time and abundant in inclusions.

Owner:萧氏茶业集团有限公司

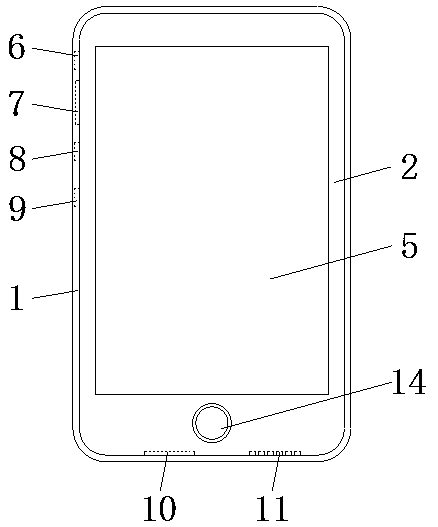

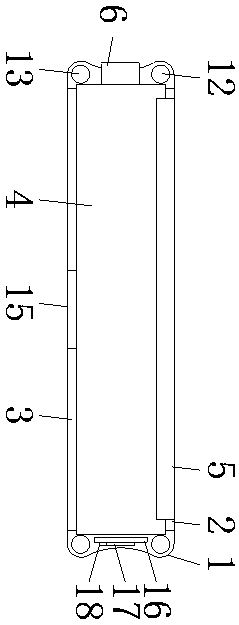

Anti-collision cell phone frame

The invention discloses an anti-collision cell phone frame comprising a groove frame. The front surface of the groove frame is fixedly provided with a front panel, and the back surface of the groove frame is fixedly provided with a back panel, and in addition, a cell phone body is fixedly connected between the front panel and the back panel, and the surface of the front panel is provided with a touch control screen in an embedded way. The left side of the groove frame is fixedly connected with a mute button, and a side button is fixedly connected with the left side of the groove frame and thebottom part of the mute button. A volume plus button is fixedly connected with the left side of the groove frame and the bottom part of the side button, and a volume minus button is fixedly connectedwith the left side of the groove frame and the bottom part of the volume plus button. A charging interface is fixedly connected with the bottom part of the groove frame, and a loudspeaker through holeis disposed in the bottom part of the groove frame and in the right side of the charging interface. The groove frame, the front panel, the back panel, a first damping gasket ring, and a second damping gasket ring are cooperated with each other, and problems of conventional cell phones such as poor anti-collision effect and inability of preventing damages on the cell phones are solved.

Owner:天津天衍星控城网科技股份有限公司

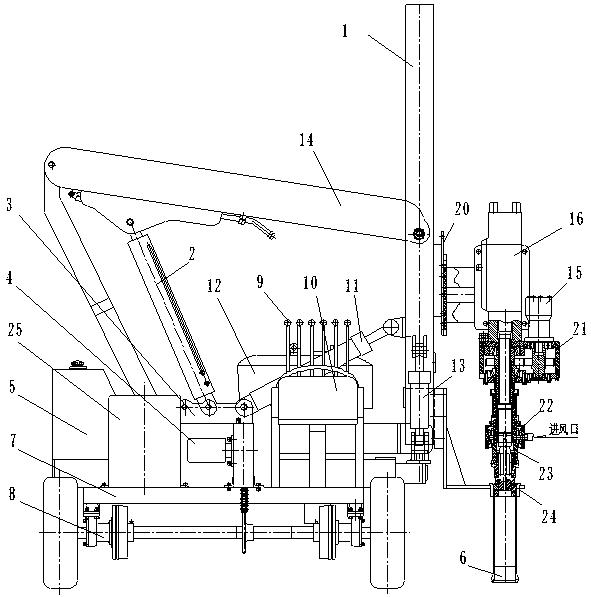

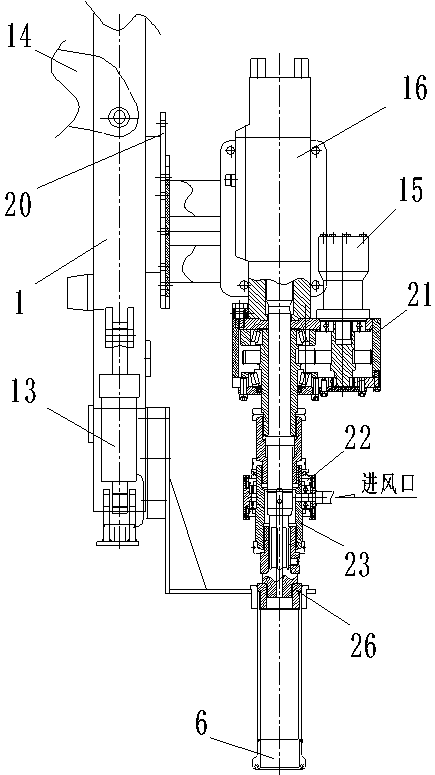

Drill pipe device of hydraulic pile driver

PendingCN107676035AExtended service lifeEasy to replaceDrill bitsDrilling rodsPile driverRotational joint

The invention discloses a drill pipe device of a hydraulic pile driver, and belongs to the field of drill pipe devices of pile drivers. A drill rod connecting sleeve of the drill pipe device is connected to one end of a main shaft of the hydraulic pile driver, the other end of the drill rod connecting sleeve is connected with a drill pipe connecting sleeve, and a rotating connector assembling assembly is installed on the drill pipe connecting sleeve; the drill pipe device comprises the drill rod connecting sleeve, the drill pipe connecting sleeve, a drill pipe upper sleeve, supporting sleeves,a drill pipe, a lower spline sleeve, a drill bit and a drill rod assembly; the lower end of the drill pipe connecting sleeve is connected to the drill pipe upper sleeve, the drill pipe and the lowerspline sleeve in sequence; the centers of the drill pipe connecting sleeve, the drill pipe upper sleeve, the drill pipe and the lower spline sleeve are axial through holes, the drill rod assembly is arranged in the through holes, the drill bit is connected to the lower spline sleeve, and the supporting sleeves are connected into the drill pipe. The drill pipe device has the advantages that the service life of the drill pipe is prolonged, impact force is large, detachment and replacement are convenient, the use cost is lowered, and the working efficiency is improved.

Owner:侯丽娜

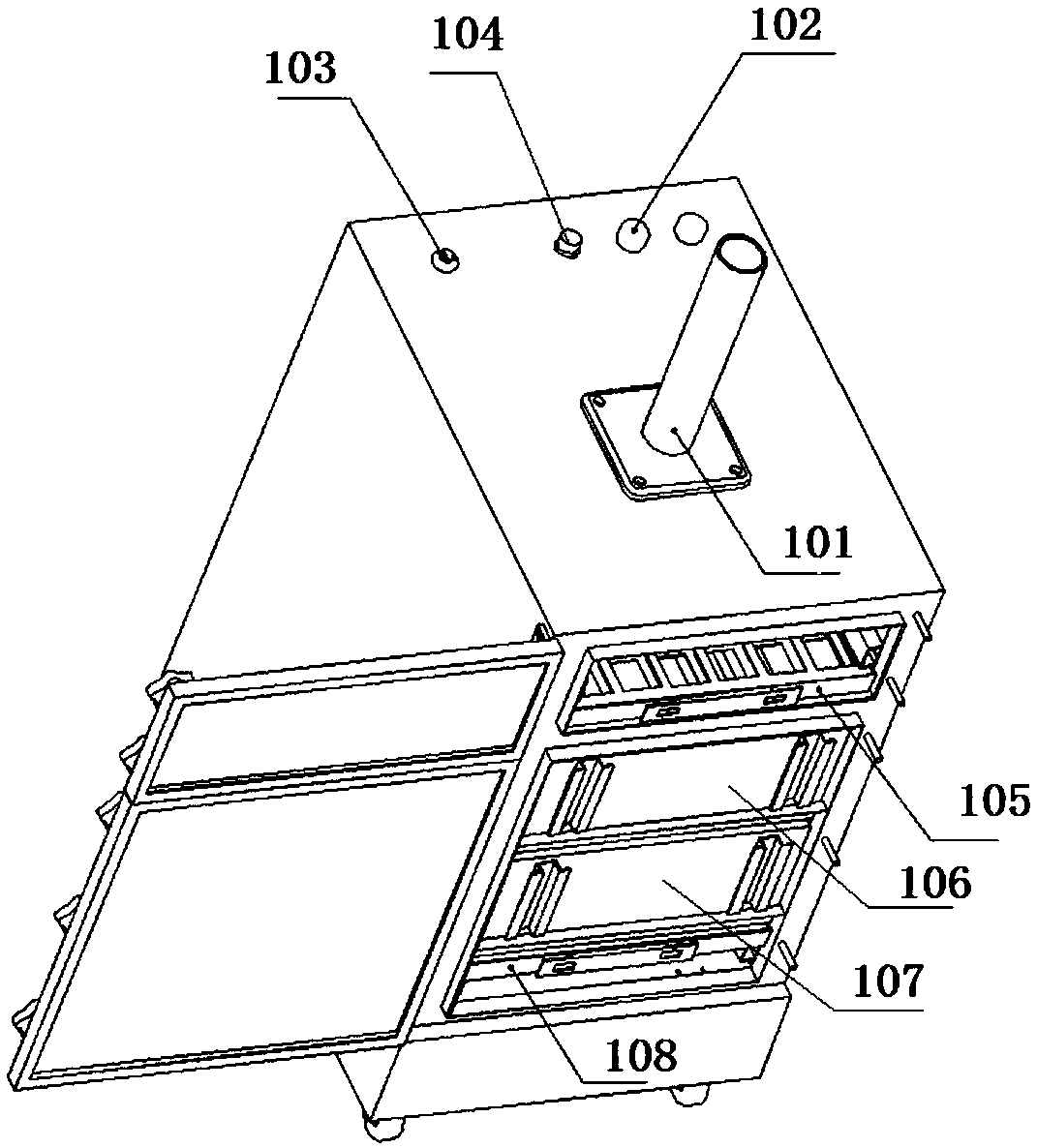

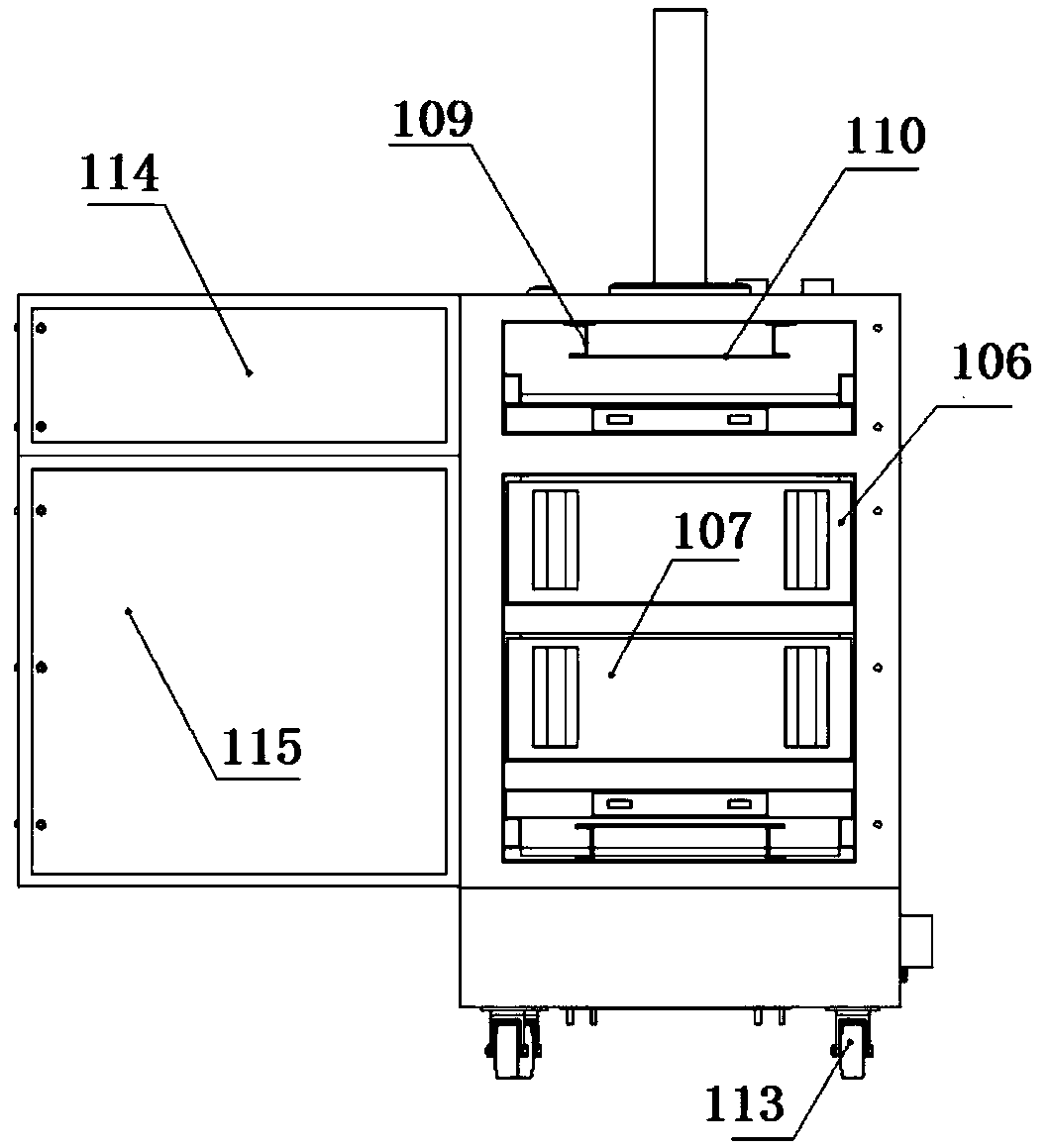

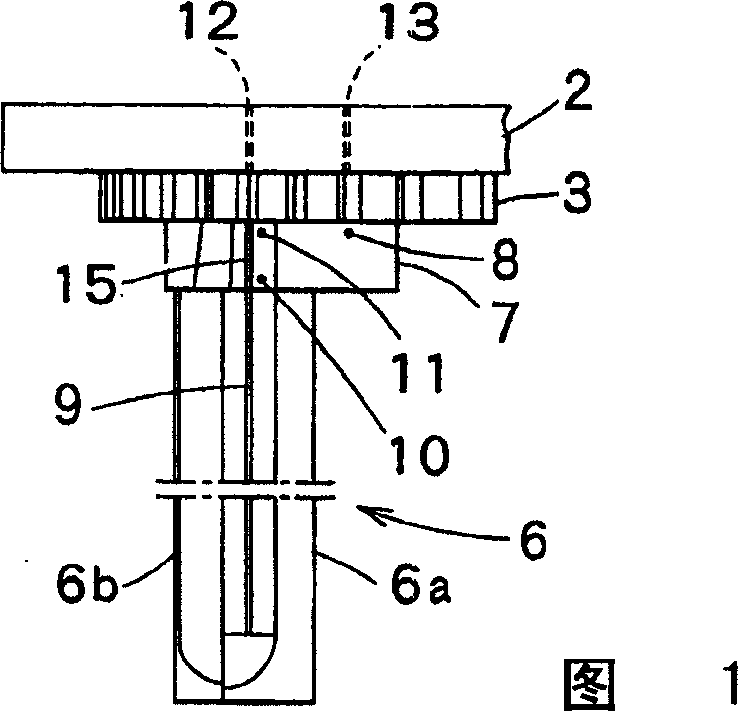

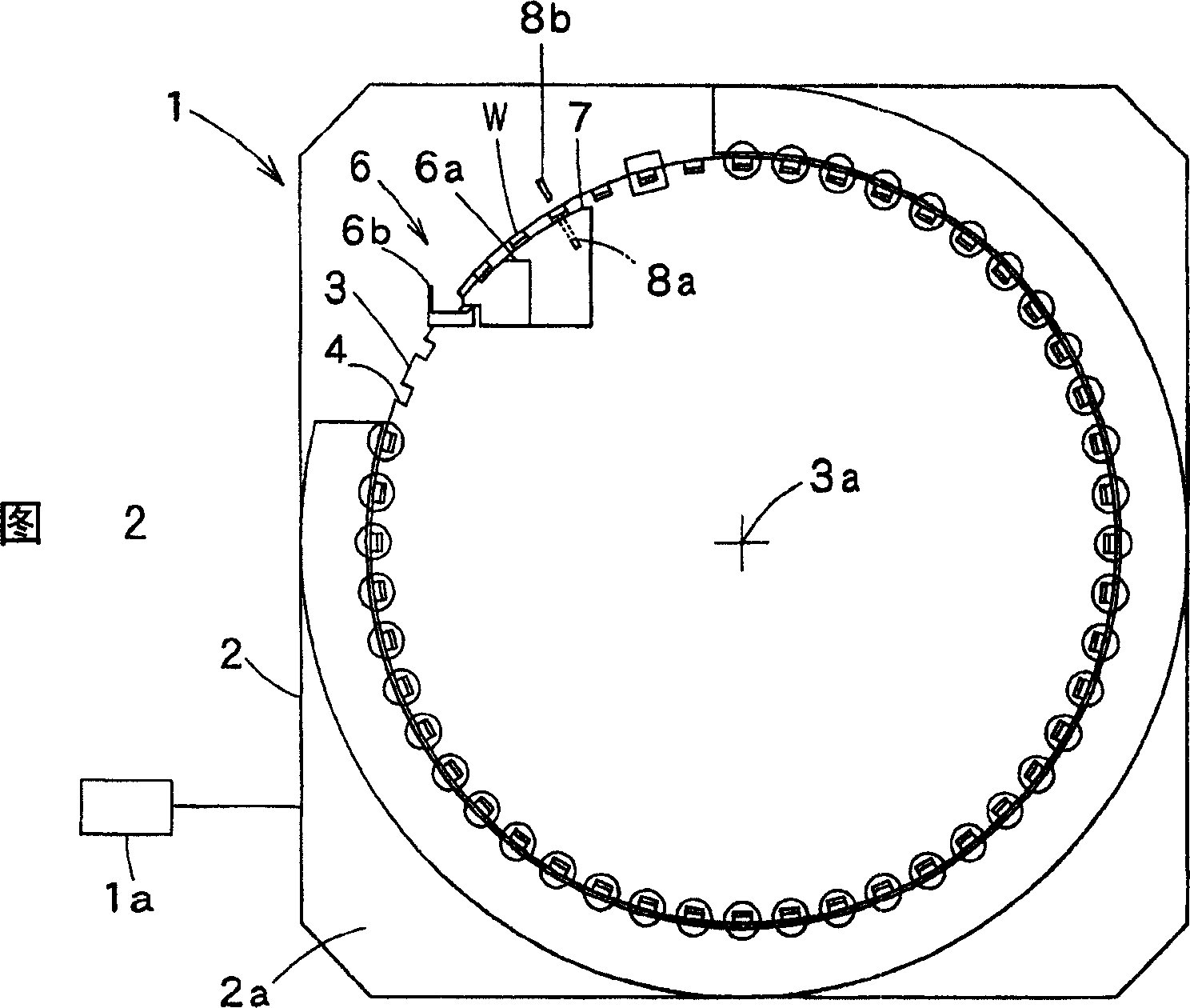

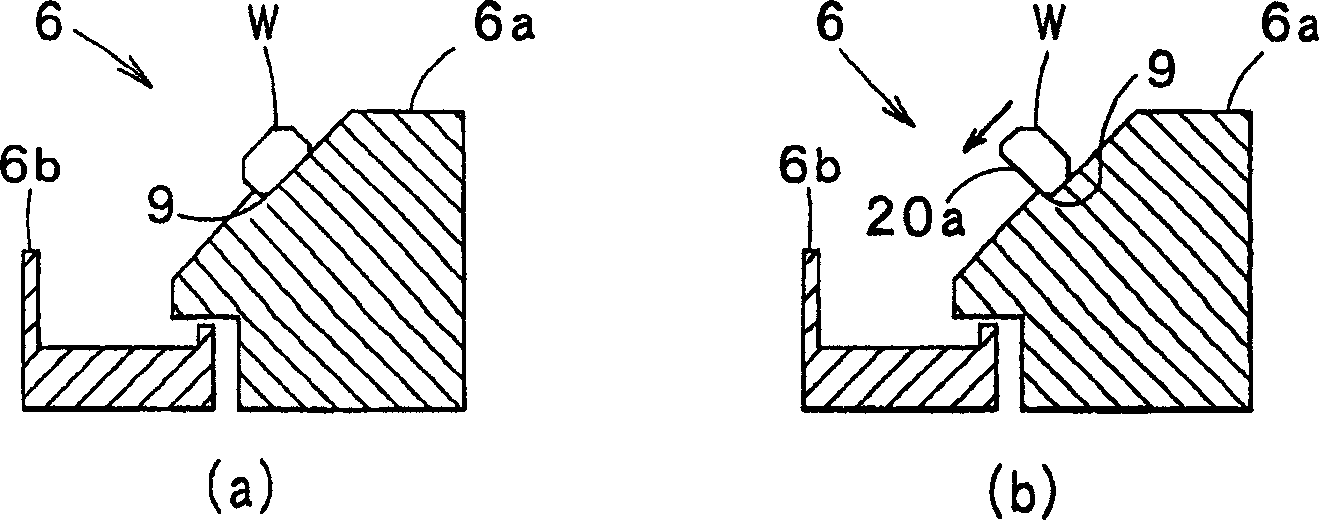

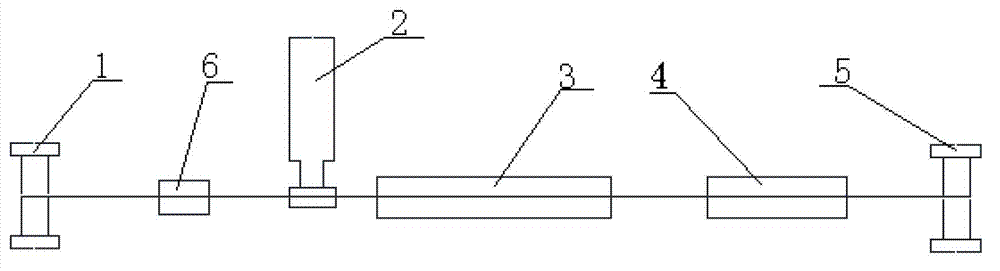

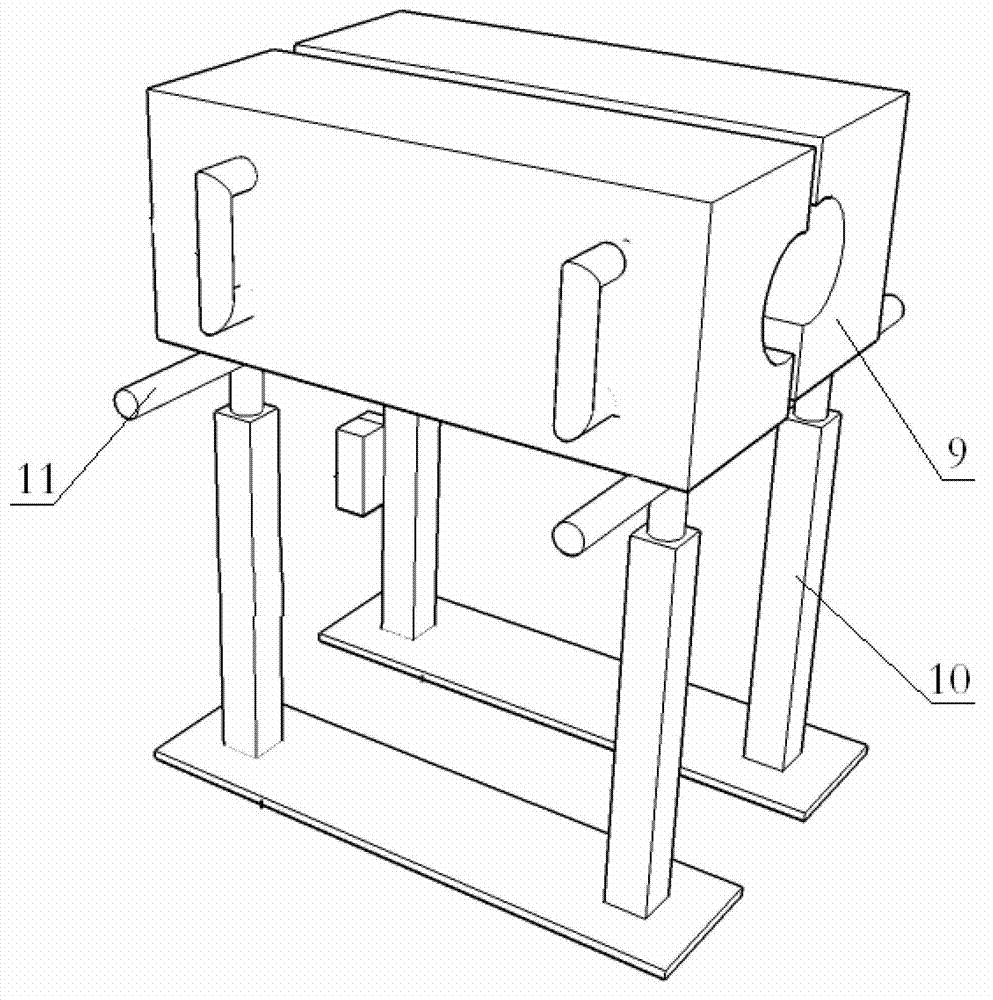

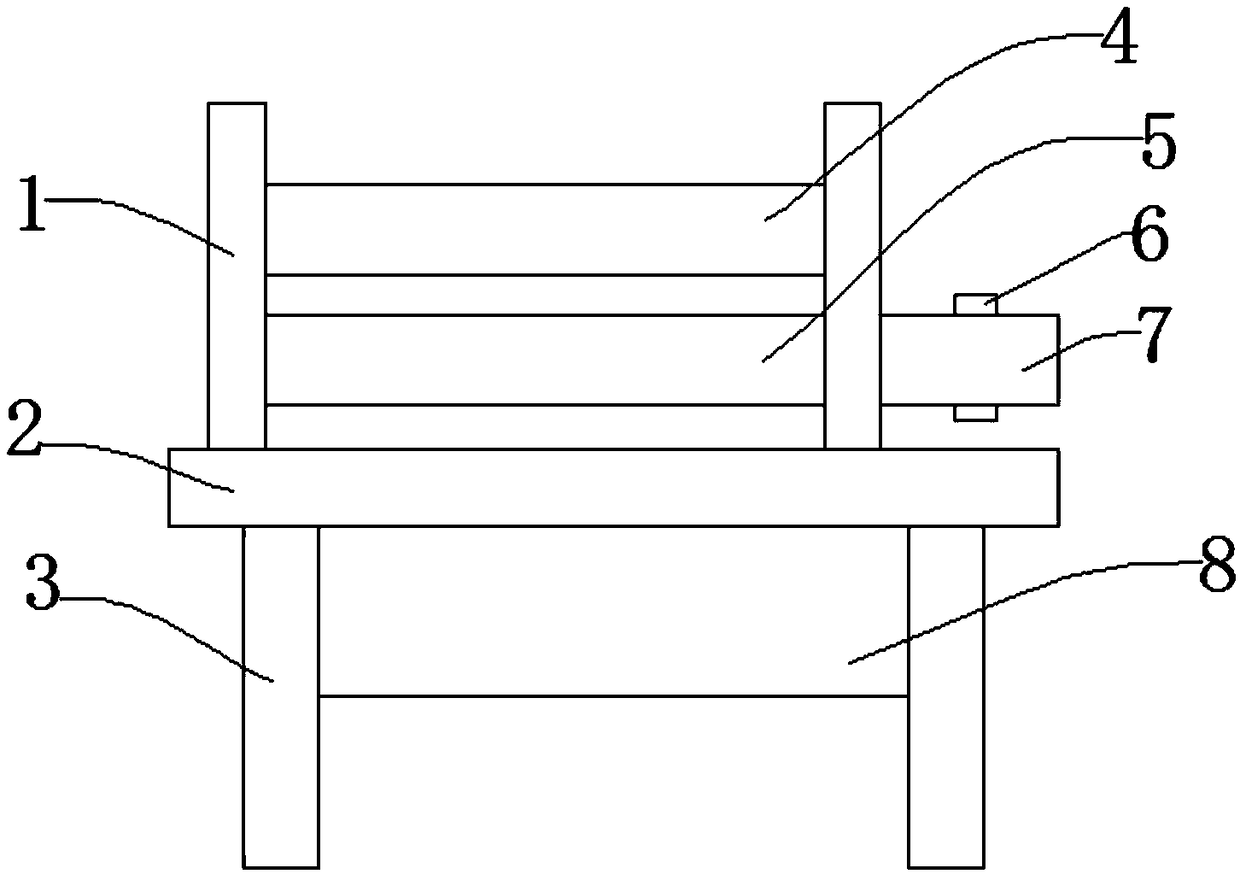

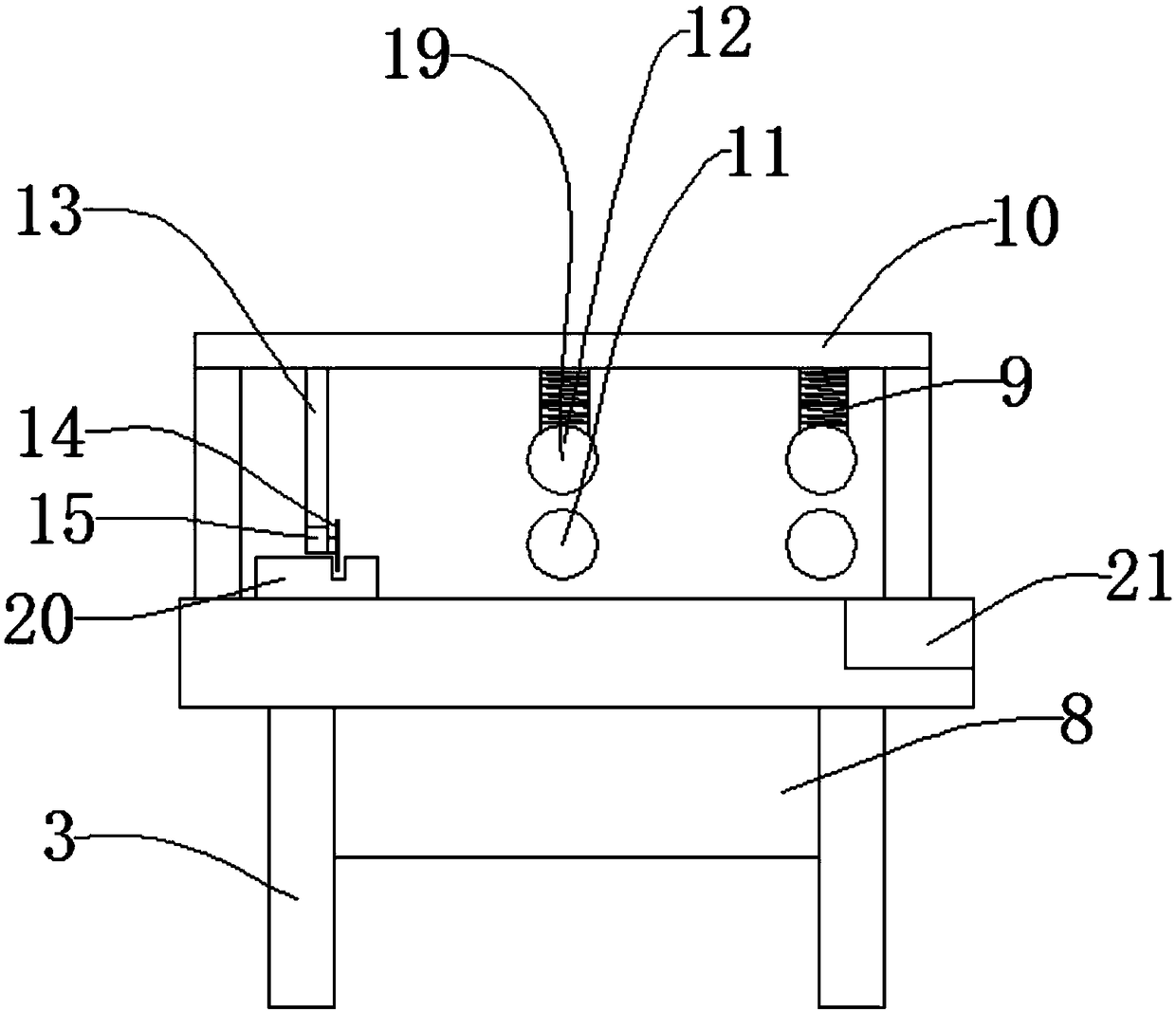

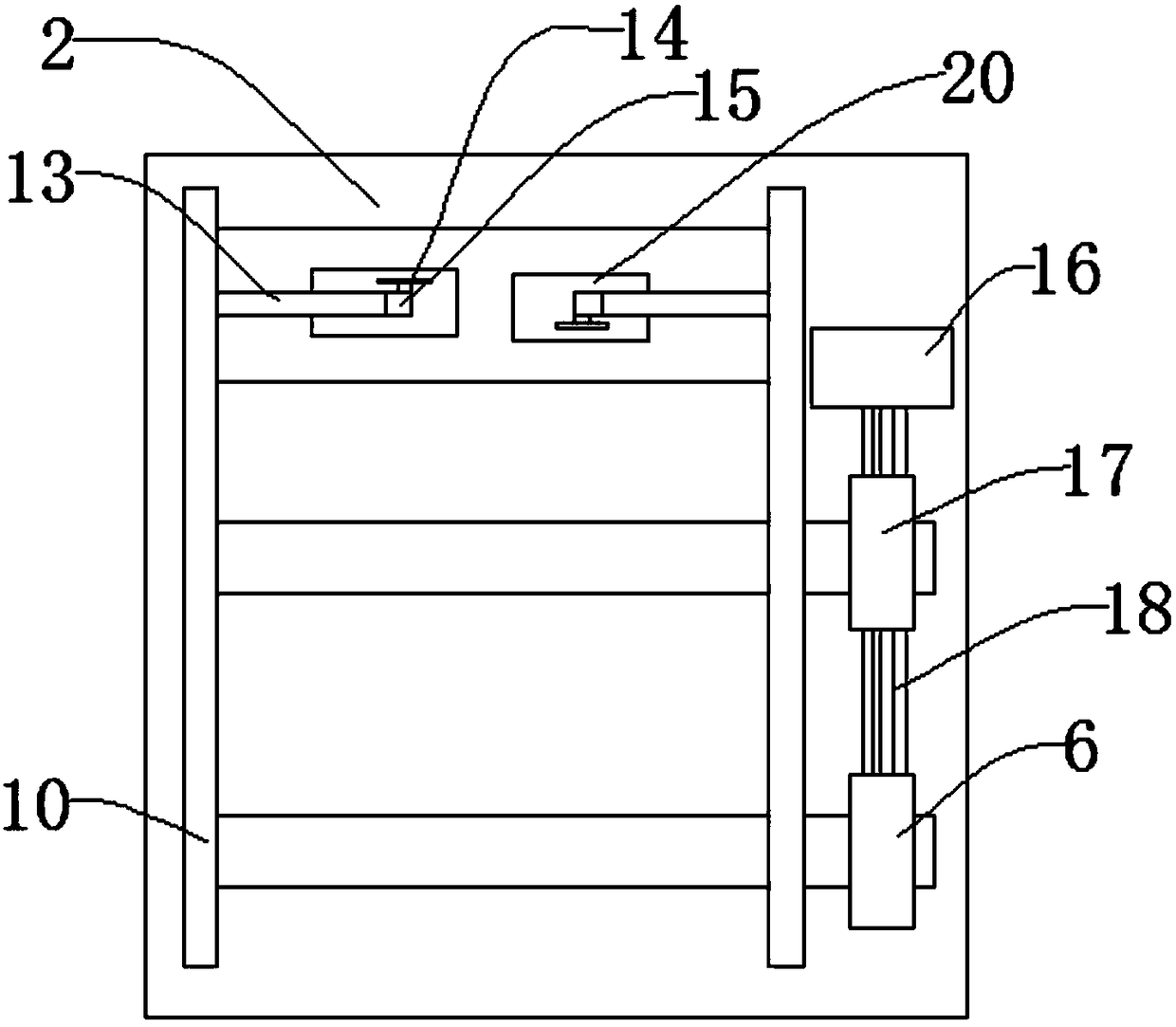

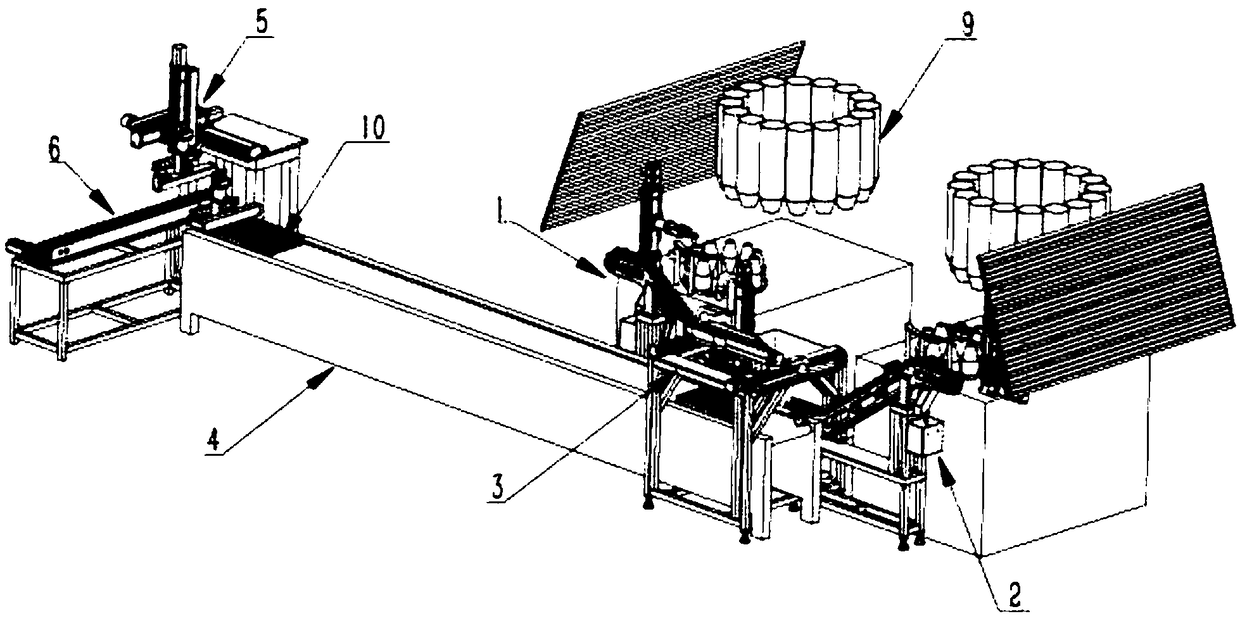

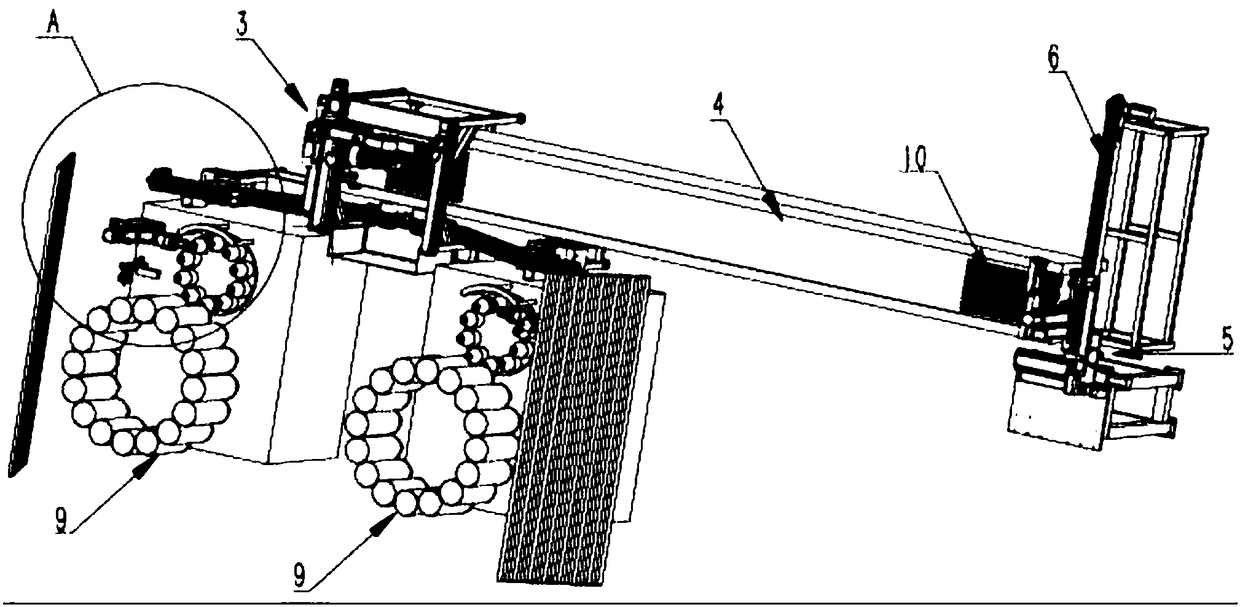

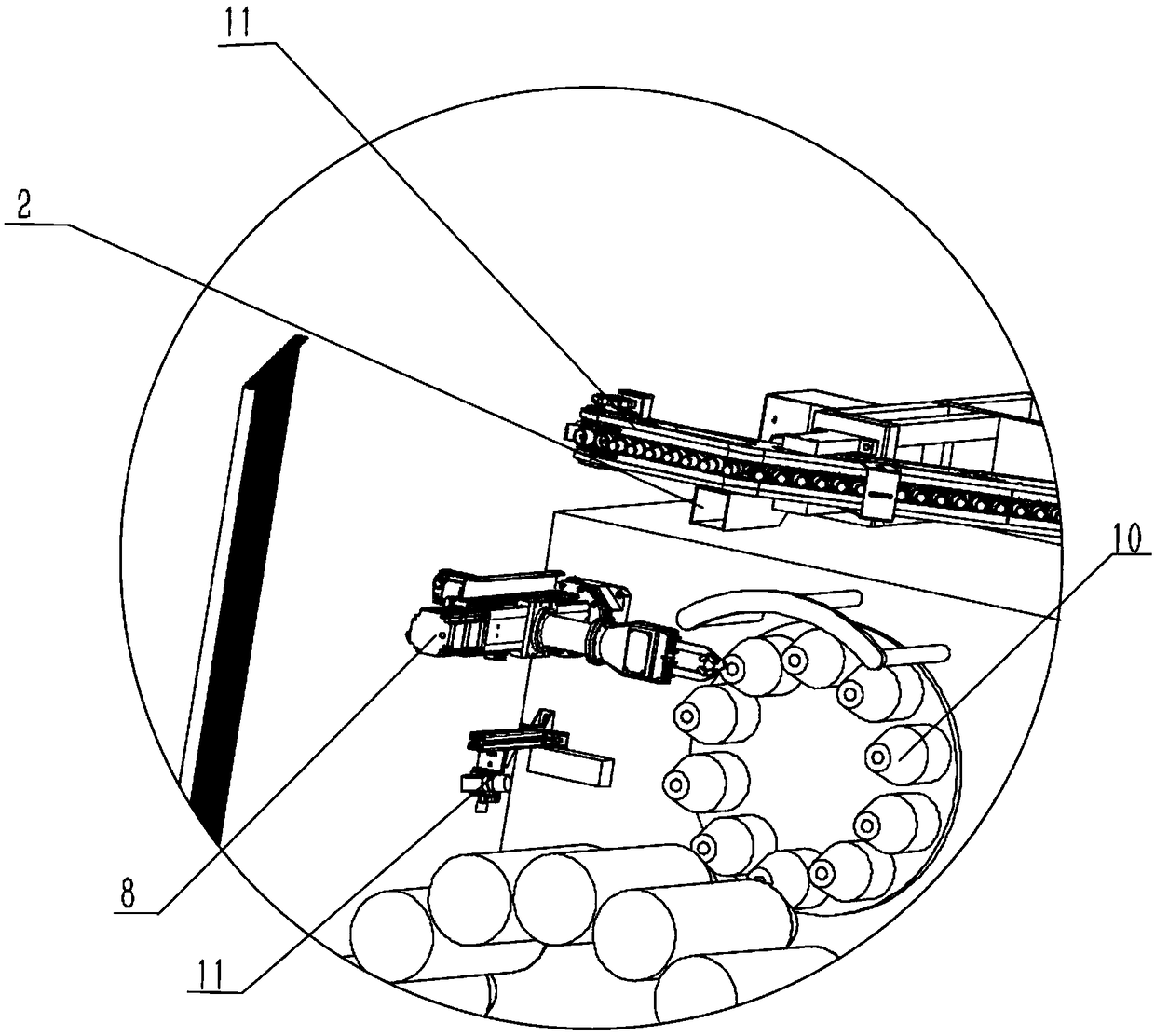

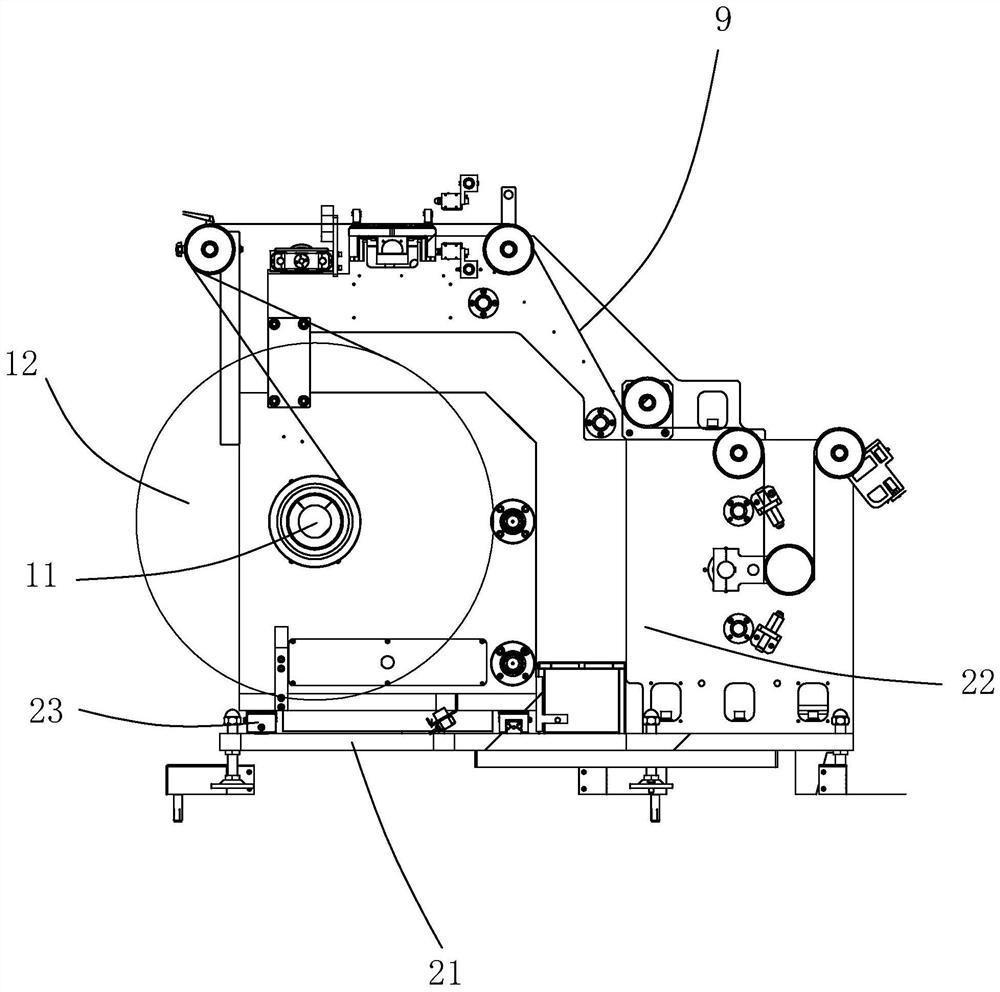

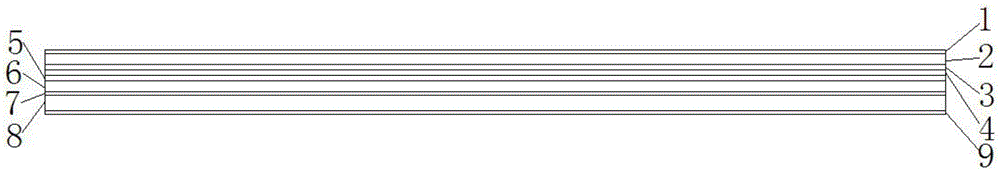

Work piece transport system

ActiveCN1715156ASolve brokenTroubleshoot loading issuesAutomatic workpiece supply/removalMeasurement/indication equipmentsTransport systemDelivery system

To provide a work conveying system capable of reliably charging works one by one in a work storage part of a conveying table without stuffing of the works. The work conveying system comprises a vertically arranged table base 2, a conveying table 3 which is rotatably arranged on the table base 2, and a linear feeder 6 arranged orthogonal to the conveying table 3. A separation chute 7 to separate works w fed from the linear feeder 6 one by one is provided between the linear feeder 6 and the conveying table 3. Each work w has a rectangular section, and a feeder 6a of the linear feeder 6 has a first V-shaped groove 9 having a long side 9a and a short side 9b. When a long side 20a of the work w reaches the short side 9b of the first V-shaped groove 9, the work w is dropped from the feeder 6a.

Owner:TOKYO WELD CO LTD

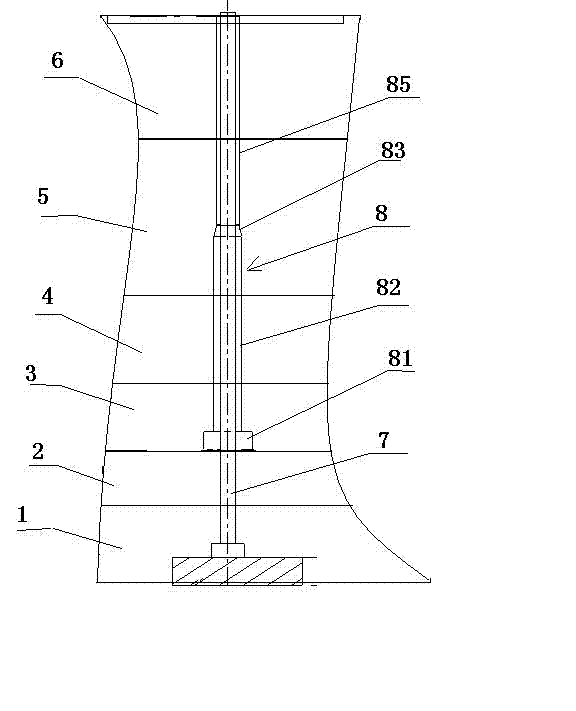

Continuous sintering furnace for ceramic fiber material

ActiveCN111637743AReduce intensityIncrease moisture contentCharge composition/stateCharge treatment typeFiberExhaust pipe

The invention discloses a continuous sintering furnace for a ceramic fiber material. The continuous sintering furnace comprises a furnace body assembly, a transfer system and an exhaust duct; the furnace body assembly is divided into a heating zone furnace body, a rapid heating zone furnace body, a constant temperature zone furnace body and a cooling zone furnace body in sequence along the transfer direction; a heating element and a temperature measuring element are respectively arranged in the heating zone furnace body, the rapid heating zone furnace body and the constant temperature zone furnace body; the exhaust duct is arranged at the top of the heating zone furnace body; the transfer system comprises a mesh belt transfer part and a roller transfer part; and the mesh belt transfer partis used for transferring the heating area furnace body, and the roller transfer part is used for transferring the rapid heating zone furnace body, the constant temperature zone furnace body and the cooling zone furnace body. The continuous sintering furnace for the ceramic fiber material provided by the invention has the advantages of being capable of effectively solving the problem of winding and breaking of fiber filaments, and effectively guaranteeing the consistency and uniformity of products.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP +1

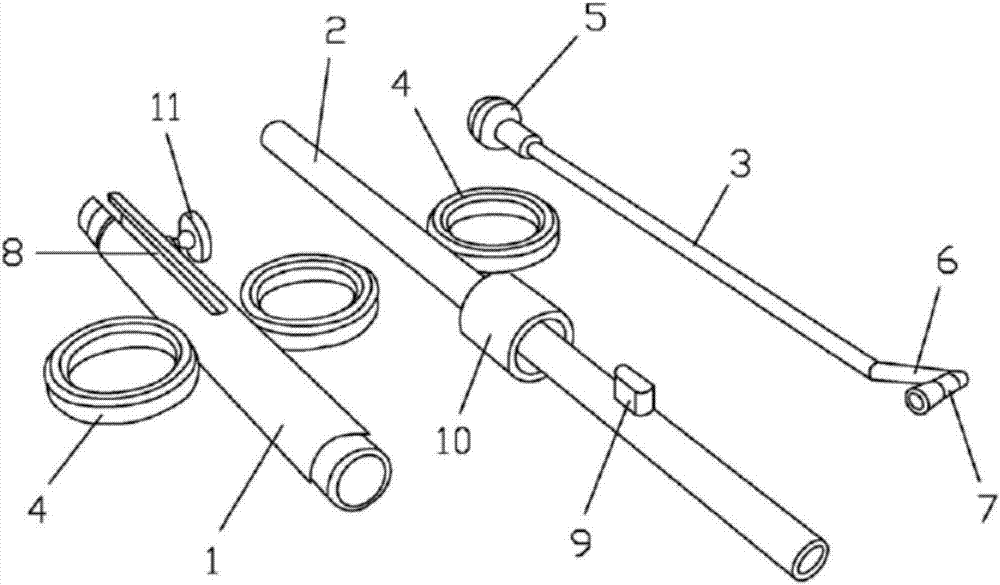

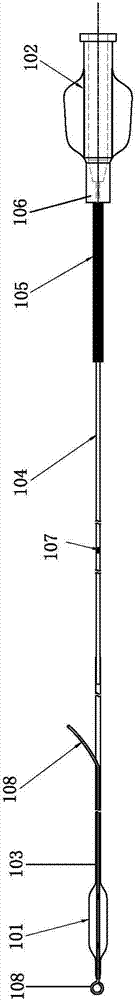

Medicine carrying device for treating salpingostenochoria

ActiveCN107242936AStandardization of surgeryReturn to normal ventilationEar treatmentClimate change adaptationEustachian tubeBalloon dilation

The invention discloses a medicine carrying device for treating salpingostenochoria. The medicine carrying device comprises a first balloon body, a catheter body and a handle. The catheter body comprises a far-end tube body, a middle wavy tube and a near-end tube body. The first balloon body wraps one end of the far-end tube body. The left end of the middle wavy tube is fixedly connected with the far-end tube body, and the right end of the middle wavy tube is fixedly connected with the near-end tube body. The near-end tube body is connected with the handle. A fixing part special for being matched with a built-in apparatus is arranged at the joint of the handle and the near-end tube body. A medicine coating is arranged on the surface of the first balloon body. The medicine carrying device can be used in cooperation with the medical special built-in apparatus, and operation is more standard; lumen is expanded after balloon dilatation, normal aeration of middle ears is restored, drainage is smooth, eustachian tube mucous membrane swelling is relieved, and meanwhile the regeneration and physiological function restoration of mucous membrane cilium are promoted; the problem that a balloon expanding catheter is prone to being broken in a catheter of a special built-in apparatus is solved.

Owner:BIOVAS (WUHAN) MEDICAL TECH CO LTD

Spiral shield cable sheath extrusion device

InactiveCN103029281ASolve brokenSolve appearance quality problems such as inconsistent diametersCable/conductor manufactureShielded cableEngineering

The invention aims to provide a spiral shield cable sheath extrusion device. The spiral shield cable sheath extrusion device comprises a pay-off rack, an extrusion machine, a cooling water channel, a traction machine and a take-up rack which are arranged sequentially in a serial manner, wherein the extrusion machine comprises a machine frame, an extrusion screw rod in the machine frame and an extrusion die at the machine head part; a wire inlet heating device is arranged between the pay-off rack and the extrusion machine; the extrusion screw rod comprises a screw rod body and screw threads; and the screw threads with different depths are distributed on the screw rod body equidistantly. The spiral shield cable sheath extrusion device has the benefits that the extrusion efficiency is greatly improved; the extrusion amount reaches 200 percent; the extrusion amount is increased, so large back pressure is generated when sheath materials are extruded to a sizing die mouth by the extrusion machine, the sheath materials are filled in a shield spiral groove outside the cable, the bending degree of the cable is supported and the problem that the cable is broken is solved.

Owner:TIANJIN DAILY PROSPERITY SCI & TECH GROUP

Electrode antioxidant coating

The invention discloses an electrode antioxidant coating, and the antioxidant coating comprises the following components: boron carbide, aluminium dihydrogen phosphate, metal powder, and conductive carbon black; The manufacturing method comprises the following steps: proportionally weighing boron carbide, aluminium dihydrogen phosphate, copper powder or nickle powder, and conductive carbon black into a vessel, stirring for one hour at normal temperature, allowing the mixture to stand for 30 min, and brushing the mixture on a surface of a graphite electrode repeatedly by a hairbrush. The coating brushed on the surface of the graphite electrode has protective effect, can decrease the oxidation consumption of the electrode side surface by above 50% during application, can greatly decrease the consumption of the graphite electrode per ton of zinc or steel, and can solve the problem of electrode fracture caused by the oxidation consumption of the electrode side surface.

Owner:孙振光

A peeling device for cable processing

InactiveCN109193479ASolve easy wear and tearImprove practicalityApparatus for removing/armouring cablesEngineeringDrive wheel

The invention discloses a peeling device for cable processing, Including bottom plate, First spring, Control Panel, a control panel is arranged at the front of the bottom plate, a low part of that bottom plate is provided with a control box, a support leg is arranged around that control box, a support plate is arranged on that upper part of the bottom plate, a support bar is arranged at that top of the support plate, a low part of that support rod is provided with a first spr, an upper hob is arranged at the lower part of the first spring, a low hob is arranged at the lower part of the upper hob, a connecting shaft is arranged at one side of the lower hob, a second driven wheel is arranged on the connecting shaft, a belt is arranged on the second driven wheel, and a second spring is arranged at one side of the first spring. The invention has the advantages that: 1, the hob is used for peeling instead of the traditional blade, and the problem of easy wear and break of the blade is solved; 2, a spring is arrange, that peeling of the cable with different thicknesses is realized, and the practicability of the device is increase.

Owner:马爱华

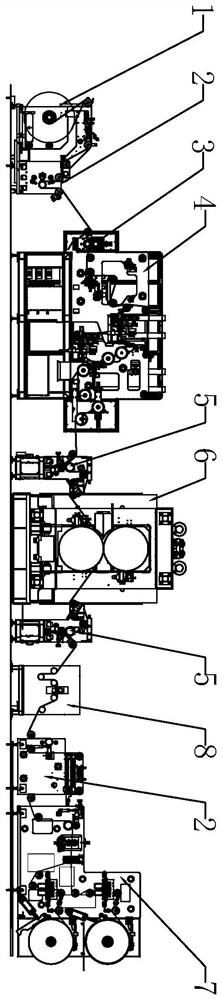

Drug bottle transfer method and transfer system

ActiveCN109332198AImprove circulation efficiencyImprove production efficiencySortingBiochemical engineeringTransfer system

The invention discloses a drug bottle transfer method and transfer system. The transfer method comprises the following steps that (1), drug bottles are vertically arranged on a second conveying device; and (2), at the downstream of the second conveying device, a third manipulator grasps the dug bottles rotates the drug bottles, and adjusts the distance between the drug bottles, the drug bottles can be conveyed to a detecting line by moving the third manipulator. The drug bottle transfer method and transfer system can avoid the process of a freshly fired bottle dropping directly from a bottle firing machine into a lower bottle collection device, and can solve the problem of medium boron glass bottle braking. A second robot has the functions of bottle grasping, bottle rotating and bottle distance changing, and therefore the drug bottles on the second conveying device can be vertically and tightly arranged, and therefore the transfer amount of the second conveying device is improved, anddug bottle transfer efficiency between the second conveying device and a bottle detecting machine is further improved. Drug bottle production efficiency and production qualification rate can be greatly improved.

Owner:重庆环视高科技有限公司

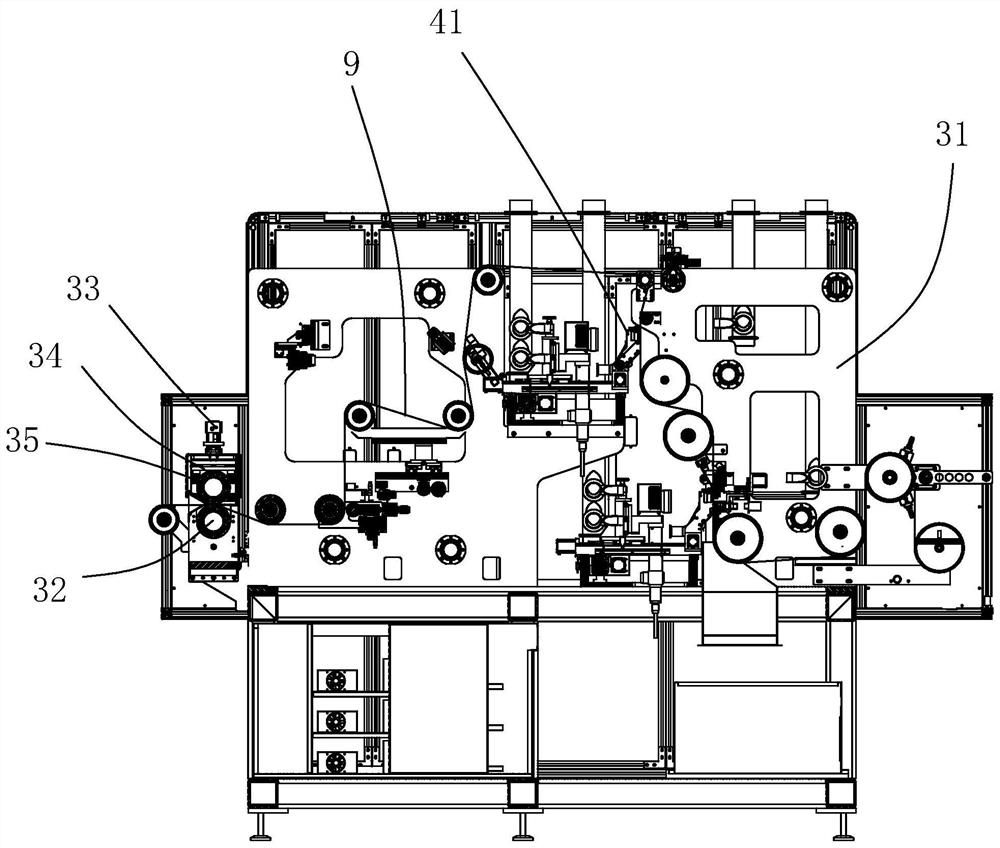

Tension control method and laser cutting and rolling integrated machine for pole pieces

PendingCN113602878AImprove qualityReduce manufacturing costArticle deliveryWebs handlingControl systemControl engineering

The invention discloses a tension control method and a laser cutting and rolling integrated machine for pole pieces. The laser cutting and rolling integrated machine comprises an unwinding device, two deviation rectifying devices, a traction device, a laser die cutting device, a swing roller device, a winding device, a winding device and a control system, wherein one deviation rectifying device is arranged at the feeding position of the integrated machine, and the other deviation rectifying device is arranged at the discharging position of the integrated machine; the traction device is used for clamping pole pieces; the laser die cutting device is used for die cutting of the pole pieces; the swing roller device is used for adjusting the tension of the pole pieces; and the rolling device is used for rolling the pole pieces. The laser cutting and rolling integrated machine has the effect that the tension is stabilized, so as to improve the production stability.

Owner:广东海中新能源设备股份有限公司

Electric shifting wheel hub with sliding stopper

InactiveCN102442154ASolve the deformationSolve brokenHubsElectric propulsion mountingGear wheelEngineering

The invention belongs to the technical field of wheels, and discloses an electric shifting wheel hub with a sliding stopper, which is used for solving the problem of easiness in breaking a support shaft and influence on the driving safety due to reduction in the strength of the support shaft caused by the formation of a power wire hole on an original support shaft and the problem of failure in effectively dissipating heat of a motor wrapped inside a hub ring. The electric shifting wheel hub with the sliding stopper comprises a hub ring, an end face, a support shaft hole, a support shaft and a motor, wherein an adjusting rod is connected with the stopper; the stopper arranged in a shaft hole of a hollow output shaft can be moved by rotating a stepper motor shaft; during movement, the stopper can be clamped in an inner groove and connected with a driven gear and can rotate together with the hollow output shaft; the hollow output shaft and an input shaft are arranged in a transmission case; the support shaft is inserted into the shaft hole of the hollow output shaft; the input shaft is in transmission connection with the motor shaft; the hollow output shaft is in transmission connection with the hub ring; the hollow output shaft is provided with a stopper moving groove and at least two rotatable driven gears; a driving gear is correspondingly fixed on the input shaft; an inner groove is formed on the shaft hole wall of the driven gear; the support shaft is provided with the stopper; and the stopper can be clamped into the inner groove.

Owner:蔡旭阳

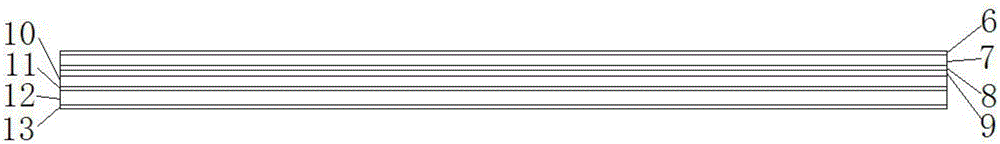

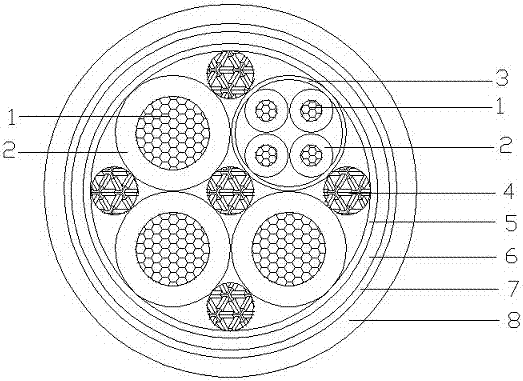

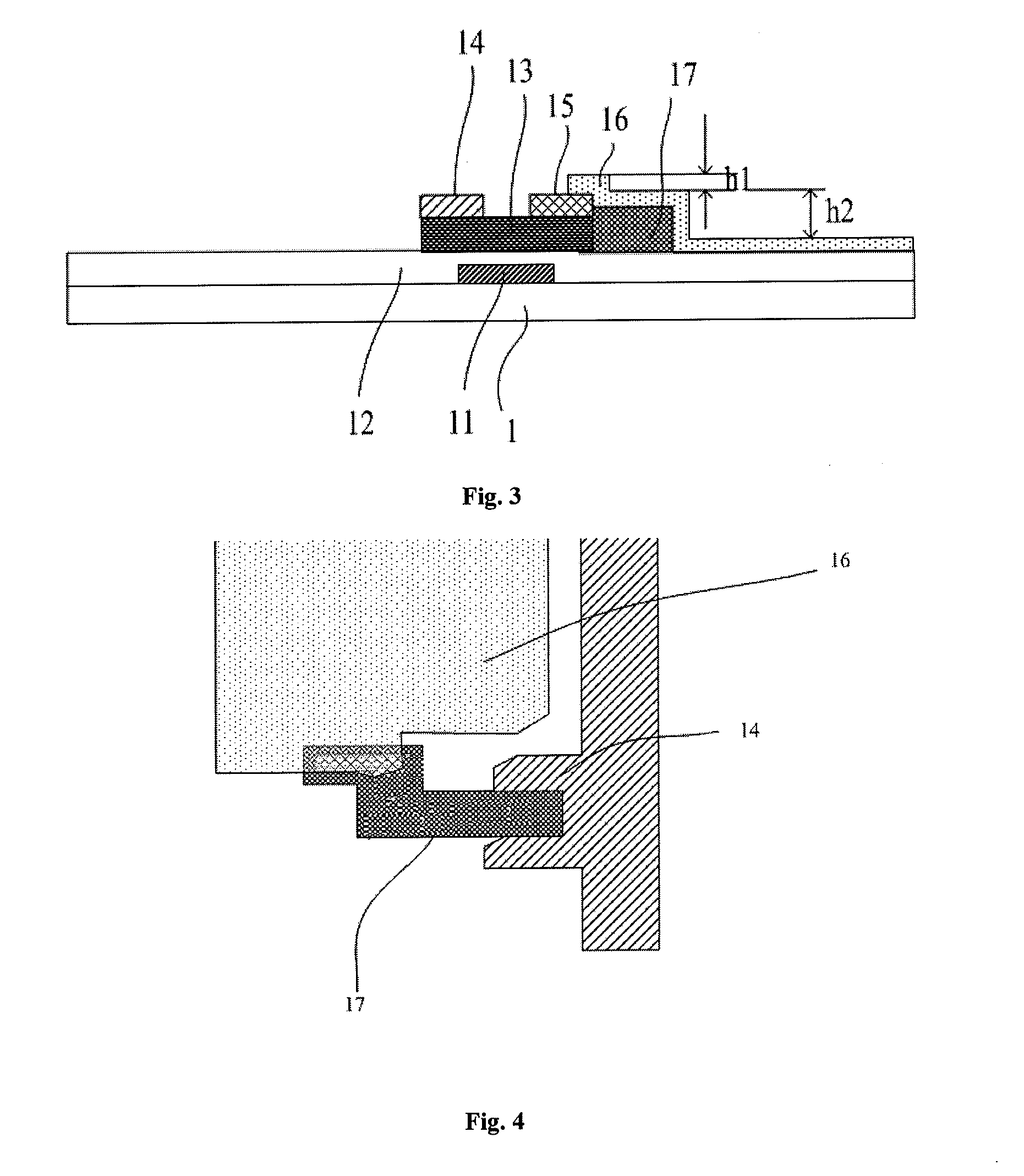

High-flexibility anti-torsion composite cable for robot

PendingCN107507667AImprove bending resistanceGood flexibilityConductive materialPower cables with screens/conductive layersFlexural torsionalManufacturing technology

The invention discloses a high-flexibility anti-torsion composite cable for a robot. A control wire group, a plurality of power wire cores and a cotton silk filling rope are twisted to form a cable core, and the cable core is sequentially wrapped by a first shielding protection layer, a shielding layer, a second shielding protection layer and an external sheath from the inside to the outside. The power wire cores respectively consist of a conductor and an insulating layer wrapping the conductor. The control wire group is formed by the twisting of four control wire cores, and the control wire cores respectively consist of a conductor and an insulating layer wrapping the conductor. The cotton silk filling rope is formed by the twisting of the cotton silks. The cable is enabled to be flexible and elastic and to be resistant to bending and torsion through the development of a new material, a cable structure and the optimization design of the manufacturing technology. The cable can be widely used in the high-frequency and high-speed work environments of an industrial robot, can be widely used in occasions of frequent bending and moving, is high in resistant to wear and oil, and is long in service life. The number of bending and torsion times can reach 20,000,000.

Owner:SHANGHAI QIFAN CABLE CO LTD

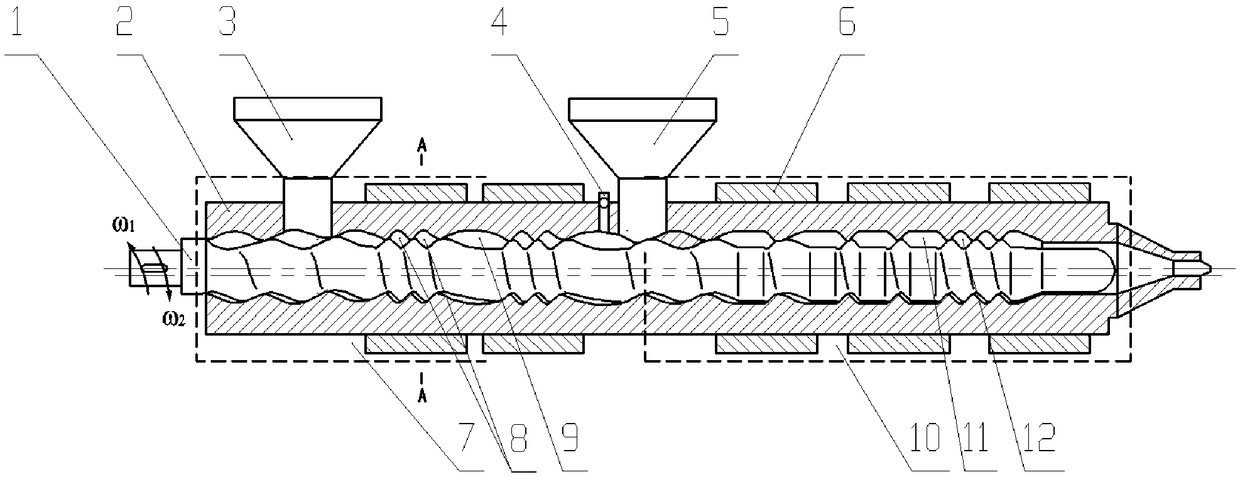

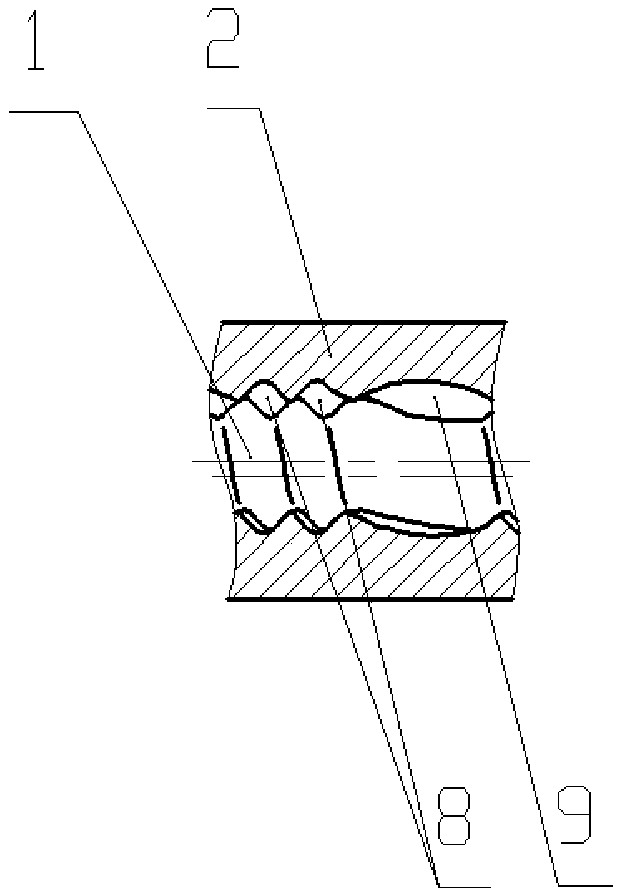

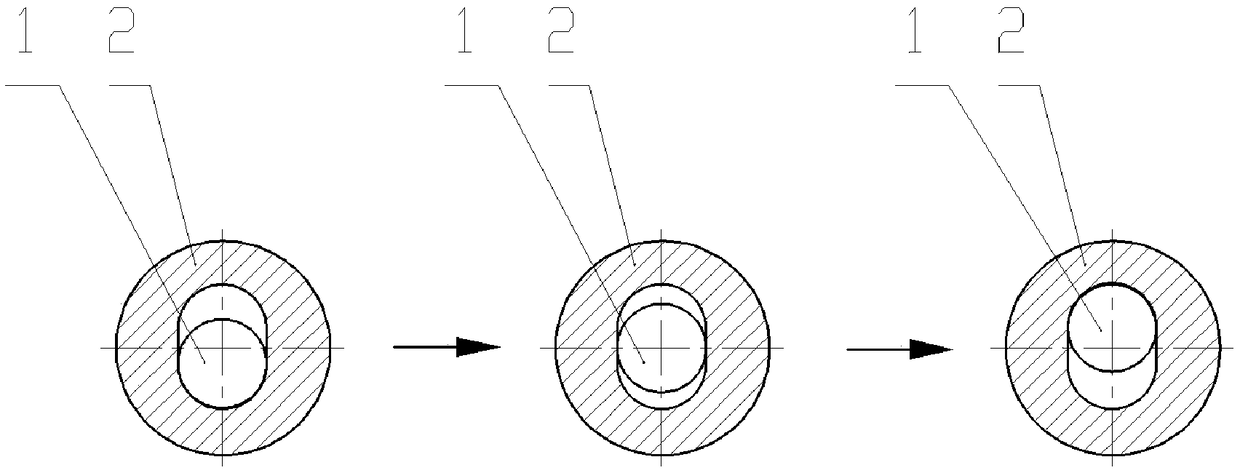

Volume fluctuation-based biomass continuous flash explosion and in situ alloying method and device

The invention discloses a volume fluctuation-based biomass continuous flash explosion and in situ alloying method and device. According to the method, water on a biomass surface is converted into subcritical water under the high pressure generated by volume compression and the effect of external heating; the subcritical water permeates into the biomass; when the volume is suddenly released, the pressure drops sharply, and the subcritical water vaporizes and swells so as to generate an acting force to the outside, so that once flash explosion can be finished; multiple flash explosions can be realized through a plurality of volume fluctuation periods. Flash explosion products and plastics continue to complete in situ continuous alloying under the effects of extrusion and stretching of the volume fluctuation and the effect of external heating, so as to acquire a biomass composite. The device is an eccentric runner device which is equipped with a flash explosion part and an alloying part successively arranged along a conveying direction, wherein the volume compression and releasing of an accommodating chamber between an eccentric runner and a stator have a periodic fluctuating change.According to the method, the problem of fiber breaking under a strong shearing effect of a screw rod can be solved, the dispersing performance of the biomass is improved, the device structure is simplified and the process operation is reduced. The invention belongs to the technical field of composite material processing.

Owner:SOUTH CHINA UNIV OF TECH +1

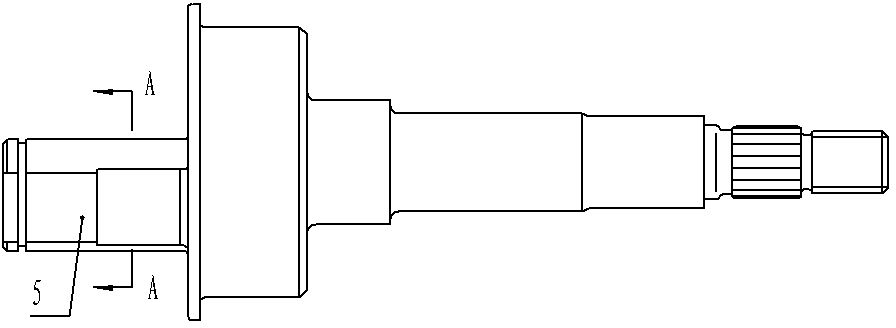

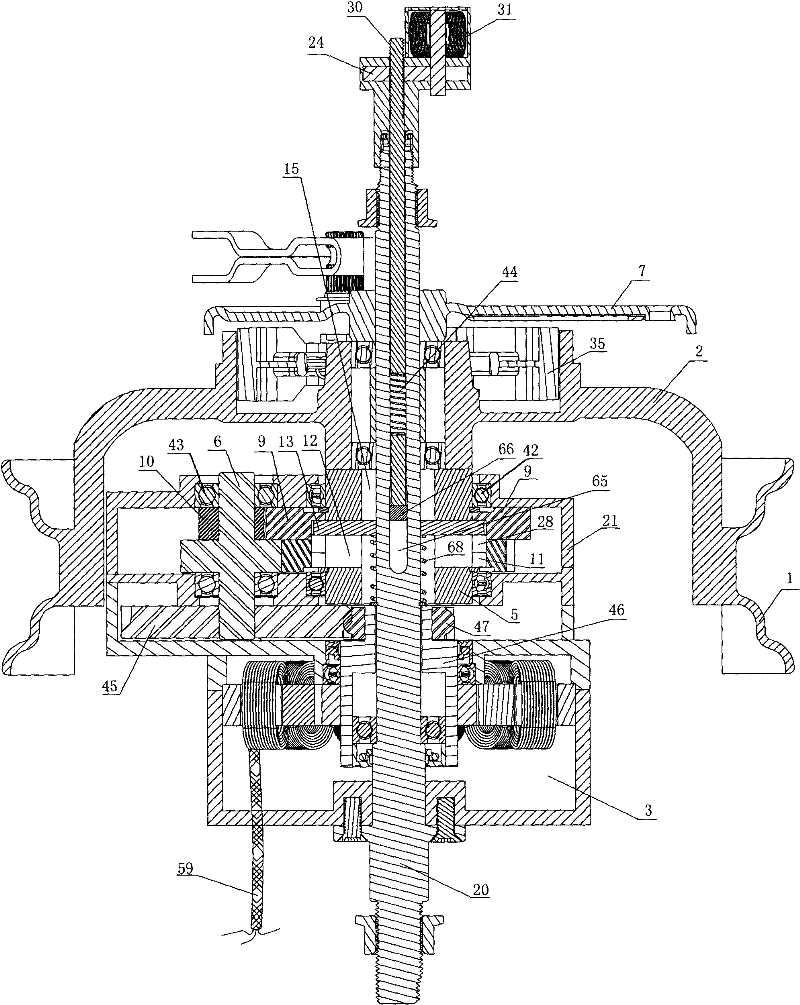

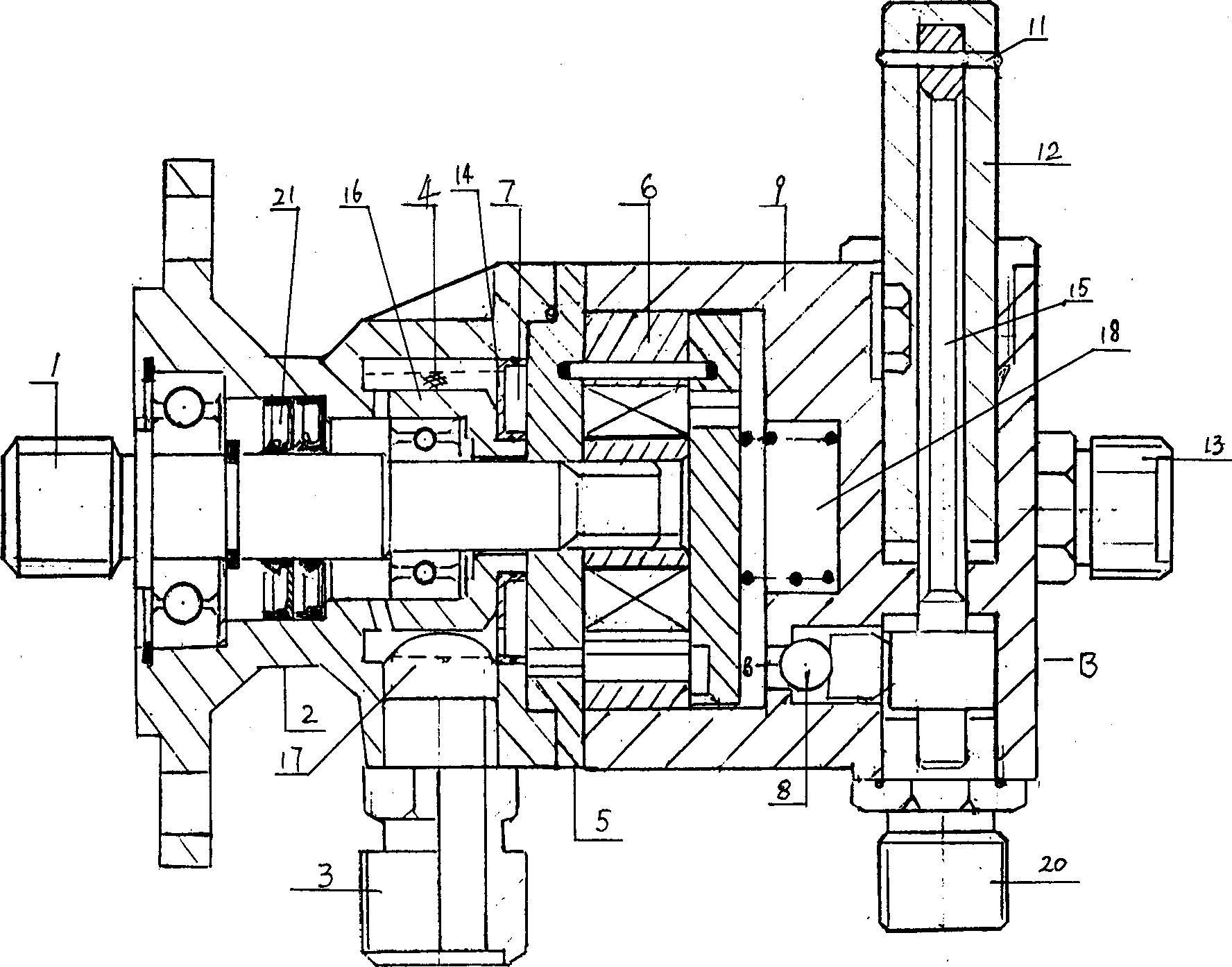

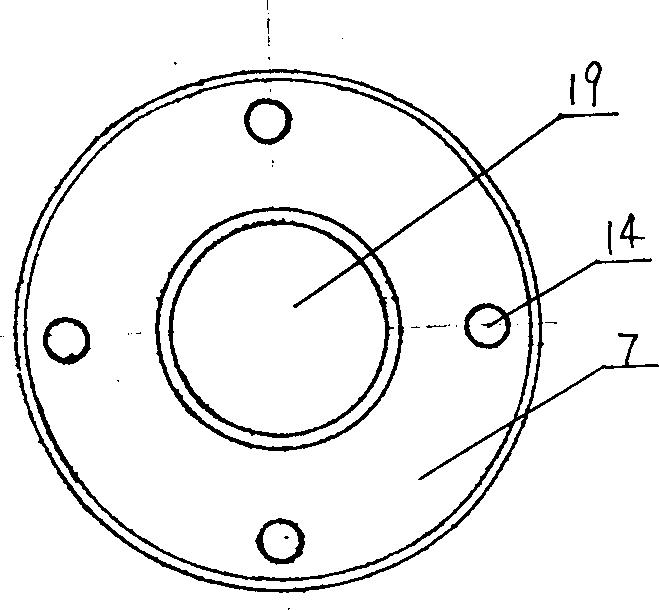

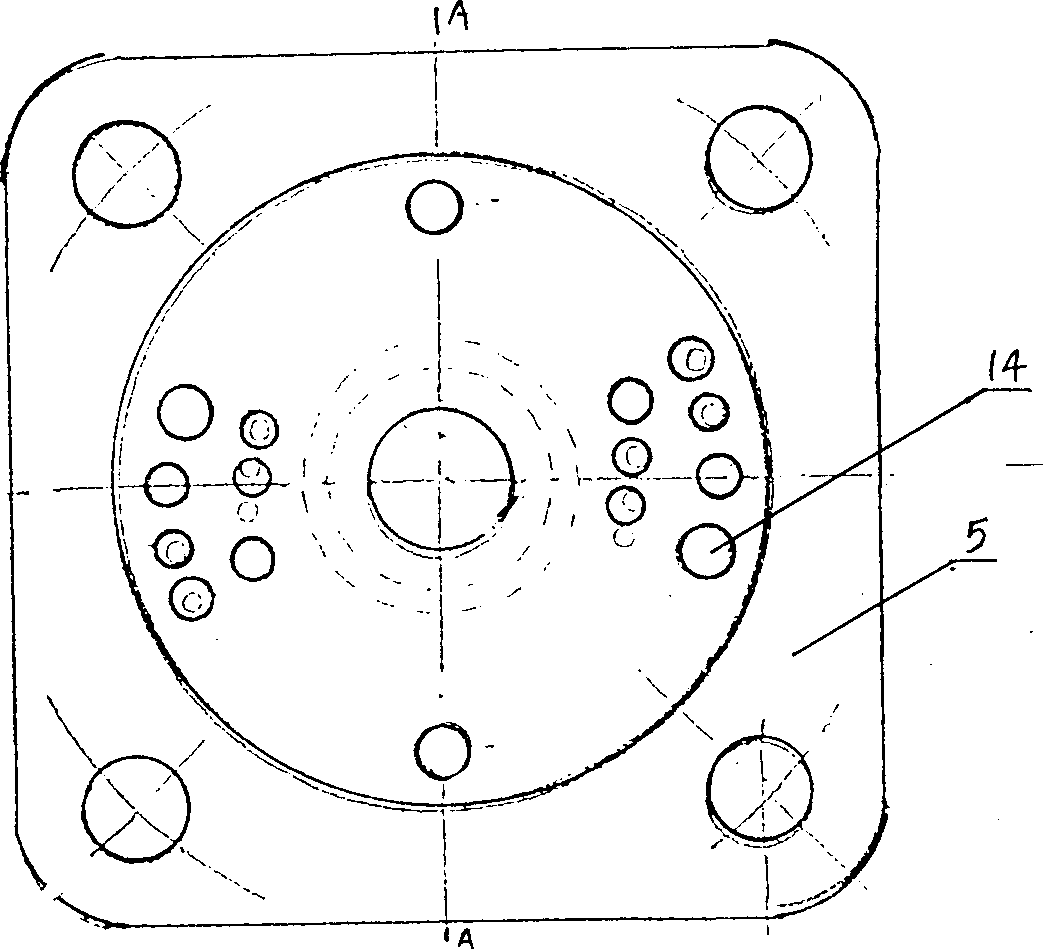

Boosting pump for steering car

Owner:王良仁

Spiral shield cable sheath extrusion device and anti-broken method

InactiveCN103029282ATroubleshooting a Broken CableSolve brokenCable/conductor manufactureEngineeringElectrical conductor

The invention aims to provide a spiral shield cable sheath extrusion device and an anti-broken method. According to the method, a conductor wire core released by a pay-off rack is heated before passing through an extrusion machine; and the extrusion machine extrudes a cable sheath by an extrusion or semi-extrusion pipe extrusion technology. The spiral shield cable sheath extrusion device comprises the pay-off rack, the extrusion machine, a cooling water channel, a traction machine and a take-up rack which are arranged sequentially in a serial manner, wherein the extrusion machine comprises a machine frame, an extrusion screw rod in the machine frame and an extrusion die at the machine head part; and a wire inlet heating device is arranged between the pay-off rack and the extrusion machine. The invention has the benefits that the conductor wire core released by the pay-off rack is heated before passing through the extrusion machine, so that sheath materials are filled in a shield spiral groove outside the cable, the bending degree of the cable is supported, and the problem that the cable is broken is solved fundamentally.

Owner:TIANJIN DAILY PROSPERITY SCI & TECH GROUP

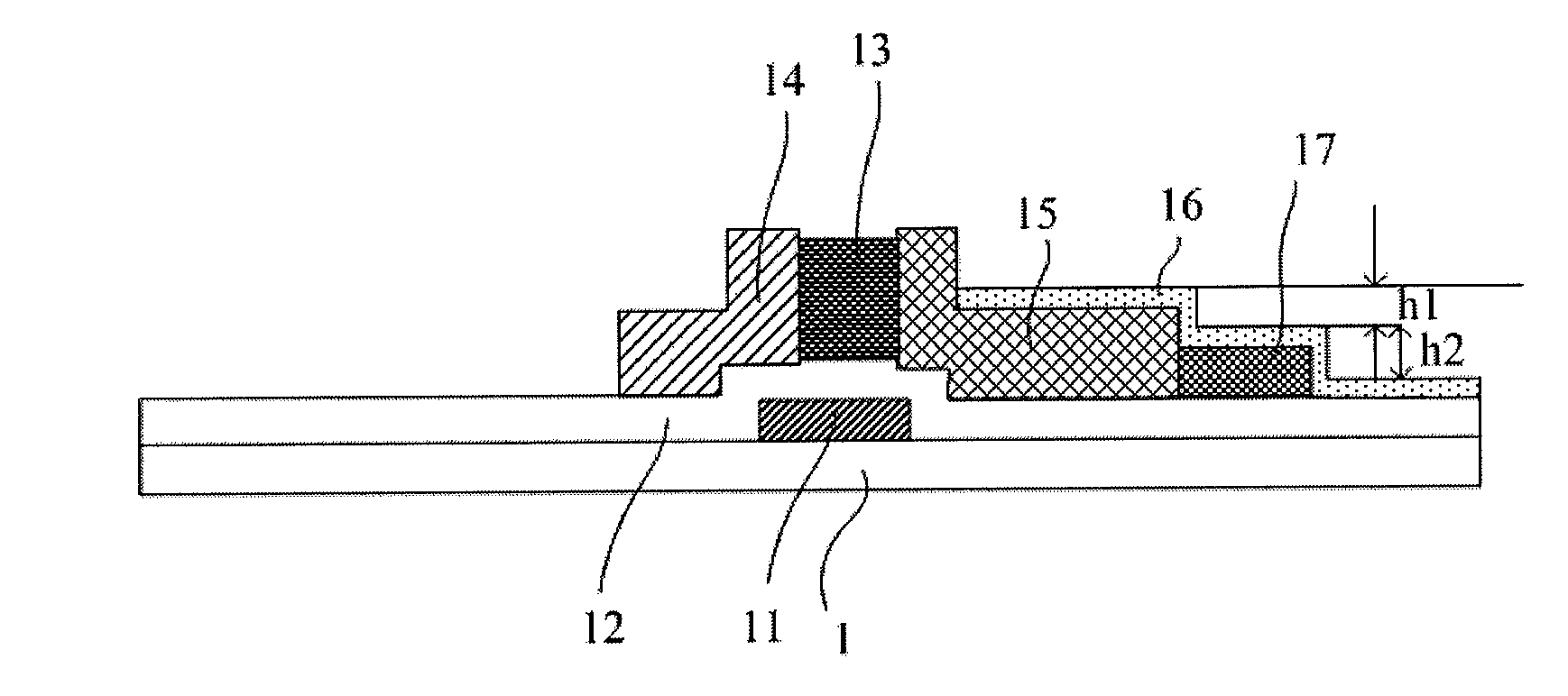

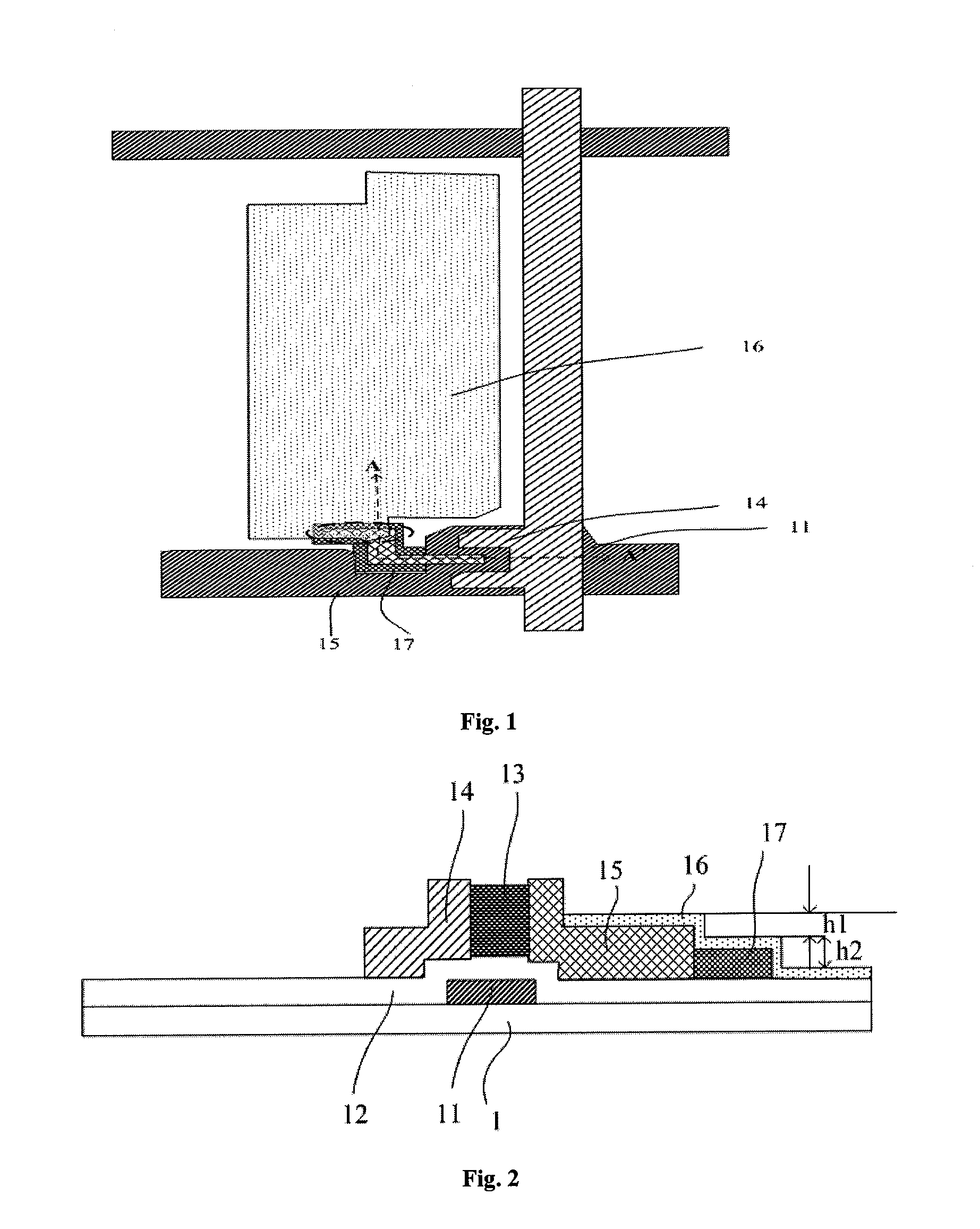

Array substrate, manufacturing method thereof and display device

ActiveUS20150372024A1Reducing local deformation degreeSolve brokenTransistorSolid-state devicesInsulation layerDisplay device

The invention discloses an array substrate, a manufacturing method thereof and a display device. The array substrate includes a gate, an active layer, a source and a drain on a substrate, and a pixel electrode located above the drain and lapped with the drain, and a part of the pixel electrode lapped with the drain is a lapping part of the pixel electrode; the array substrate further includes a first insulation layer located below the pixel electrode and in contact with the drain, the first insulation layer extends along the edge of the lapping part towards a direction away from the lapping part, part of the drain to be in contact with the lapping part is exposed from the first insulation layer, and the plane where the upper surface of the first insulation layer is located is lower than the plane where the upper surface of the drain is located.

Owner:BOE TECH GRP CO LTD +1

Uvioresistant impact resistant composite type flexible freight bag film

InactiveCN106346906AImproves UV resistanceEasy to useSynthetic resin layered productsSacksEngineeringUltraviolet absorption

The invention relates to an uvioresistant impact resistant composite type flexible freight bag film, wherein the uvioresistant impact resistant composite type flexible freight bag film comprises a PET outer film layer, a first adhesion layer, a first connection film layer, an ultraviolet absorption layer, a second connection film layer, a second adhesion layer, a PET inner film layer, an aluminum coating layer and a PE film layer which are sequentially connected, the aluminum coating layer is coated on one side of the PET inner film layer, and the thickness ratio of the PET outer film layer to the first adhesion layer to the first connection film layer to the ultraviolet absorption layer to the second connection film layer to the second adhesion layer to the PET inner film layer to the aluminum coating layer to the PE film layer is 1:(4-6):(0.8-1.8):(0.8-1.8):(0.8-1.8):(4-6):(0.8-1.2):(7-8):(0.5-1.5). The uvioresistant impact resistant composite type flexible freight bag film is good in impact resistance property, high in seal and barrier properties and good in toughness, and resists ultraviolet.

Owner:宜兴威尼特包装袋有限公司

Method for preventing spiral shielding cable from integrally breaking

InactiveCN103021584ASolve brokenSolve appearance quality problems such as inconsistent diametersCable/conductor manufactureElectrical conductorEngineering

The invention provides a method for preventing a spiral shielding cable from integrally breaking. A conductor wire cable paid off by a pay-off rack is heated before passing through an extruder, and the extruder extrudes a cable sheath by extrusion or semi-extrusion tube extrusion technology. The method has the advantages that extrusion efficiency is greatly improved, extrusion capacity reaches 200%, high back pressure can be generated when sheath materials are extruded to a plug die orifice by the extruder owing to improvement of the extrusion capacity, a spiral shielding groove outside the cable is filled with the sheath materials, the bent cable is supported, and the problem of breaking of the cable is solved.

Owner:TIANJIN DAILY PROSPERITY SCI & TECH GROUP

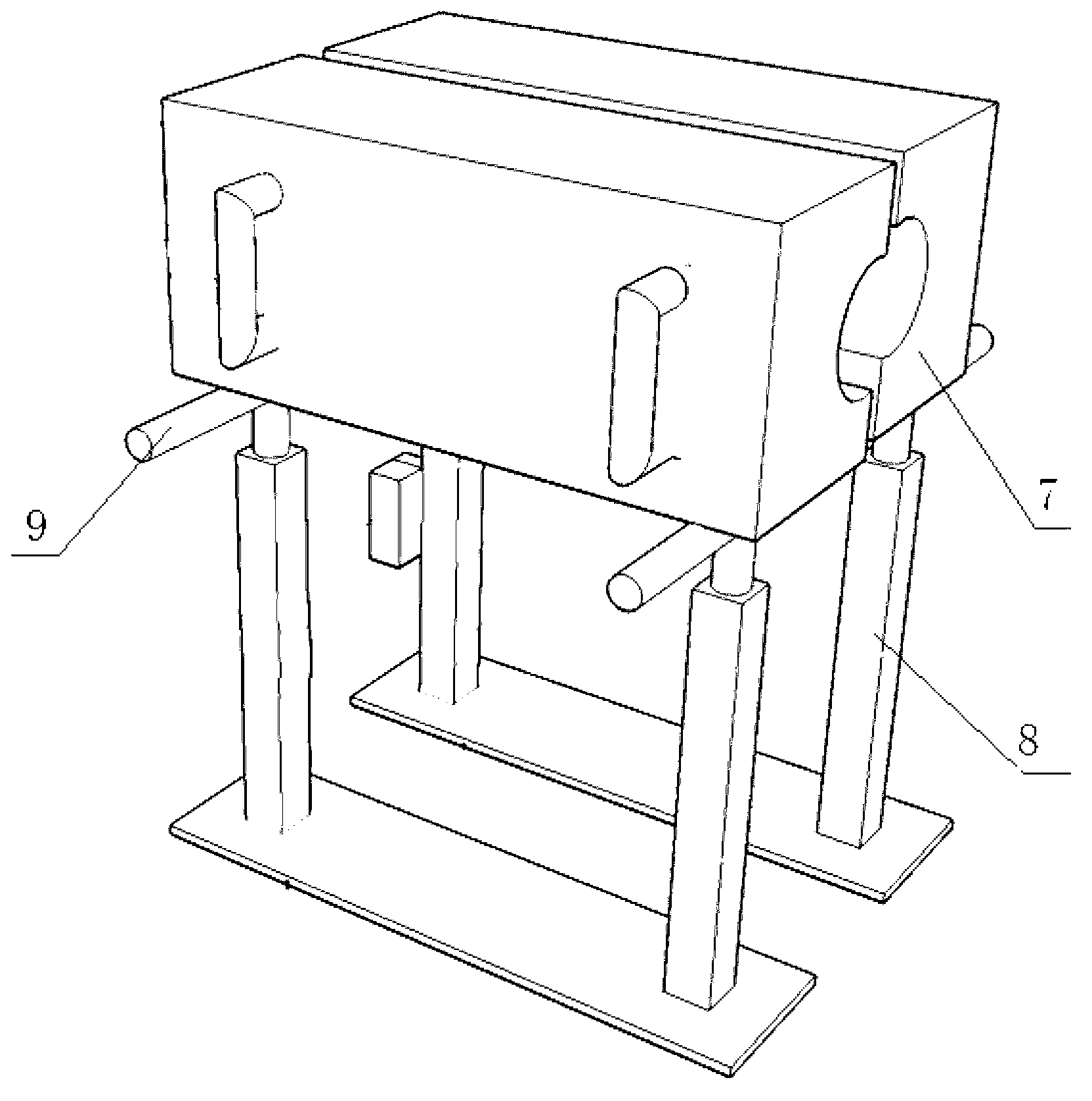

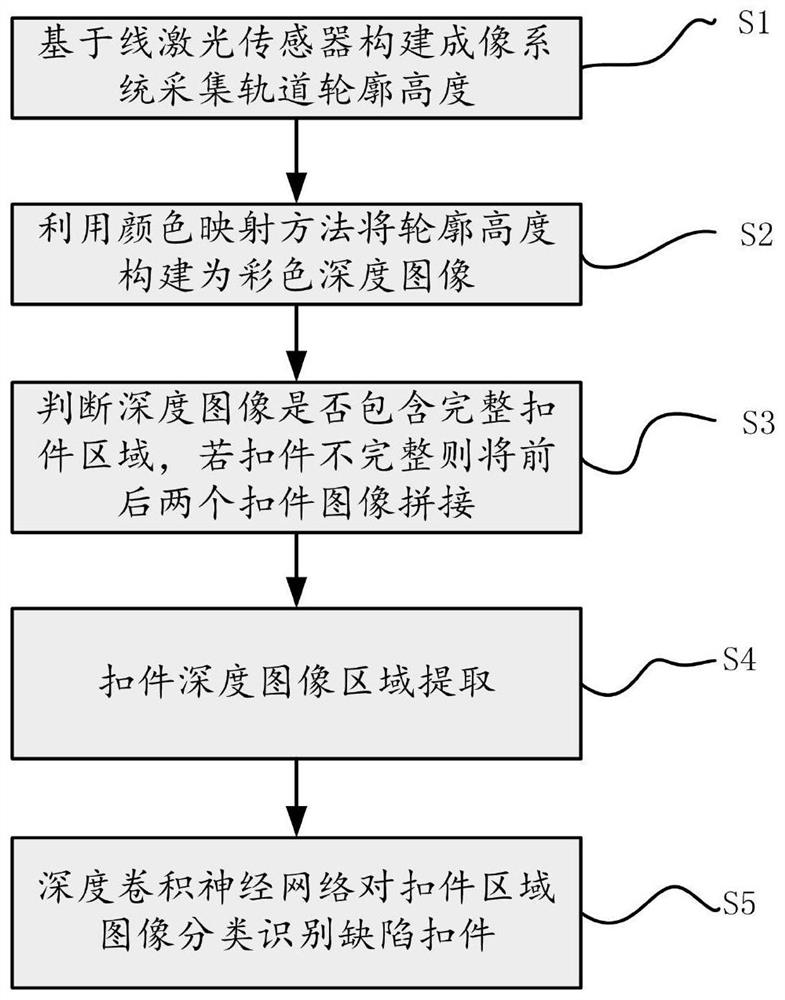

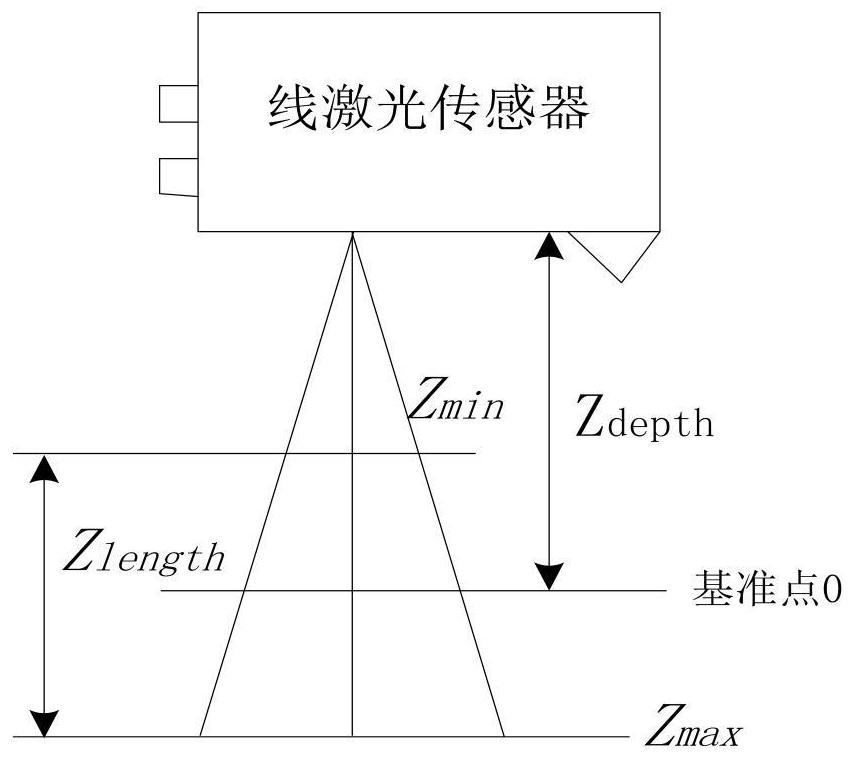

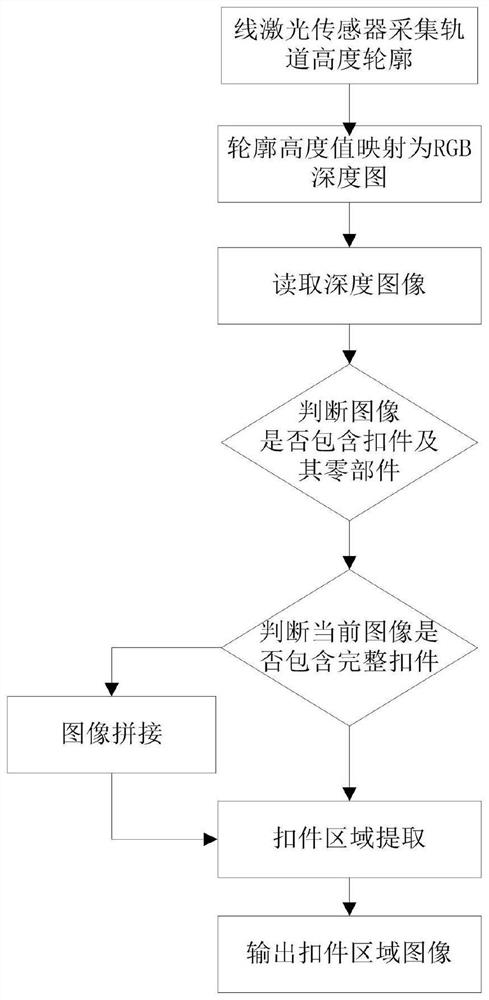

Track elastic strip fastener defect recognition method, device and computer equipment

ActiveCN113781537AReduce data volumeThe detection process is fastImage enhancementImage analysisMachine visionColor mapping

The invention discloses a track elastic strip fastener defect recognition method and device and computer equipment, and belongs to the technical field of machine vision detection. The recognition method comprises the following steps: constructing an imaging system based on a line laser sensor to collect a track contour height; using a color mapping method to construct the contour height into a color depth image; judging whether the depth image contains a complete fastener area or not, and if the fastener area is incomplete, splicing the front fastener image and the rear fastener image; extracting a depth image region of the fastener; and the deep convolutional neural network classifies the fastener region image to identify the defect fastener. According to the method, the height contour value of the track is collected and constructed into the depth image, and the fastener defect is recognized according to the difference of the depth image, so that the problem of simultaneously detecting the defects of loss, dislocation, fracture and looseness of the fastener is solved. Meanwhile, the defect detection rate of the fastener is improved.

Owner:NANCHANG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com