Method for preventing spiral shielding cable from integrally breaking

A shielded cable, helical technology, applied in the field of cable sheath processing equipment, can solve problems such as cable breakage and loss, and achieve the effect of improving extrusion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A preferred embodiment of the present invention will be briefly described below in conjunction with the accompanying drawings.

[0021] like Figures 1 to 4 Shown:

[0022] A method of preventing the overall breakage of a helical shielded cable,

[0023] The conductor core discharged from the pay-off rack 1 is heated before passing through the extruder 2;

[0024] Extruder 2 extrudes the cable sheath by extruding or semi-extruding tube extrusion technology;

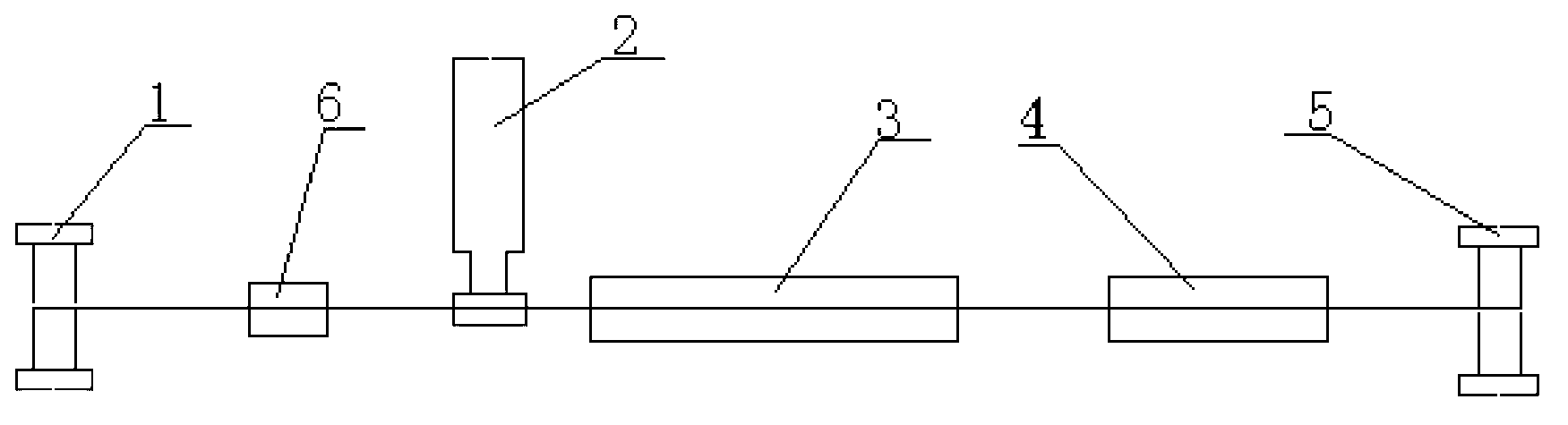

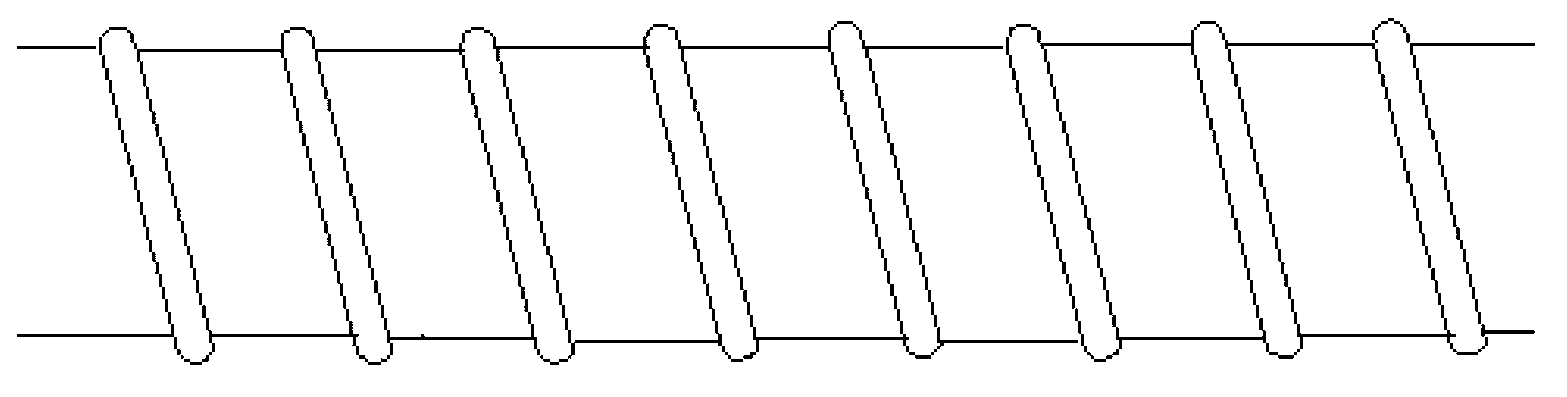

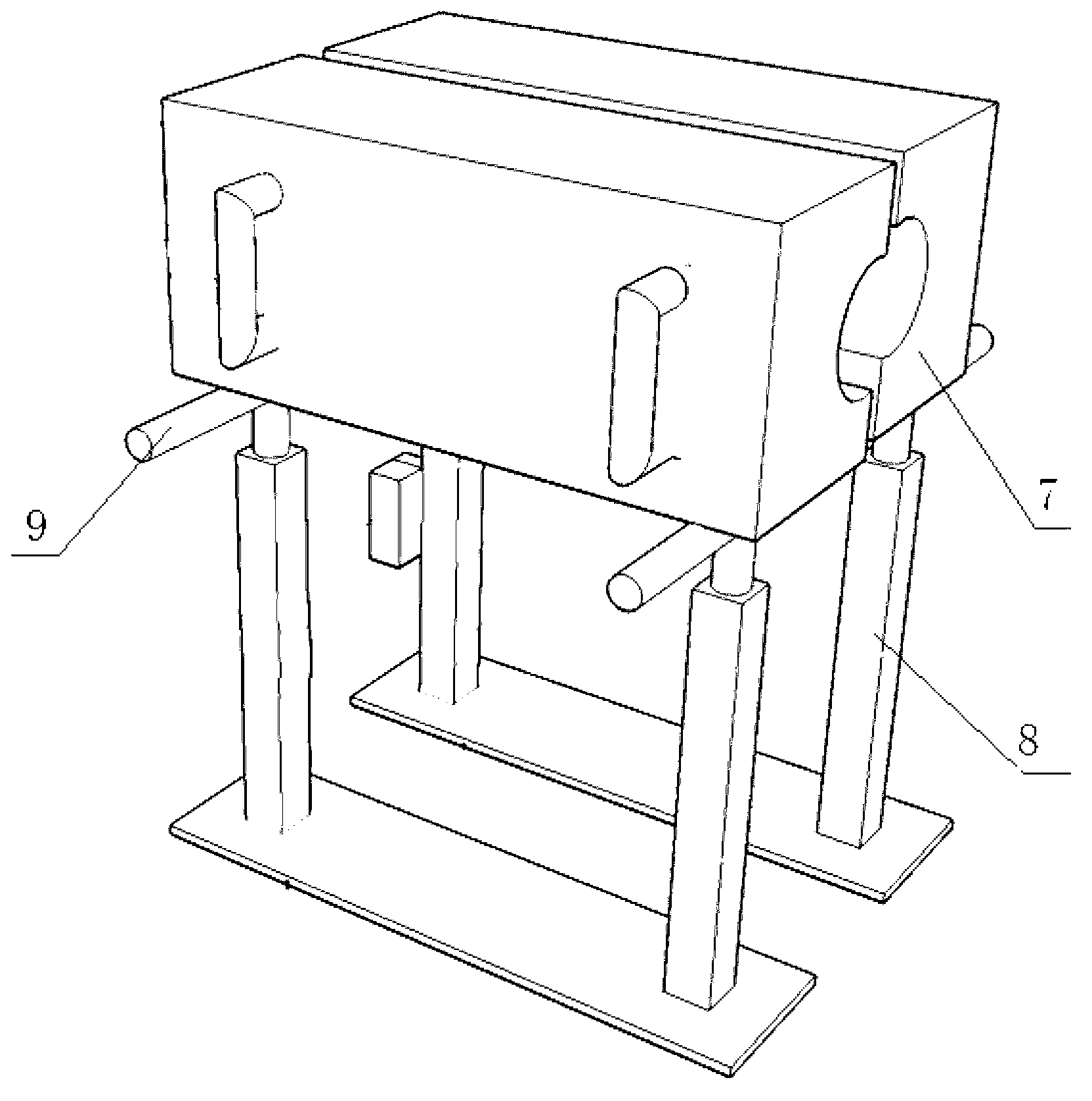

[0025] The equipment used for processing the spiral shielded cable sheath according to the above method includes a pay-off rack 1, an incoming wire heating device 6, an extruder 2, a cooling water tank 3, a tractor 4 and a wire take-up rack 5 arranged in series, The extruder 2 includes a frame, an extrusion screw in the frame, and an extrusion die at the head part. The extrusion screw of the extruder 2 is distributed with threads with equal distances and different depths, and the pitch is 150°. mm;

[0026] Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com